Multi-Index Geophysical Monitoring and Early Warning for Rockburst in Coalmine: A Case Study

Abstract

1. Introduction

2. Prediction of Impact Hazard in Mining Site

2.1. Mine Overview

2.2. Statistics of Rockburst Accidents

2.3. Monitoring Equipment and Layout

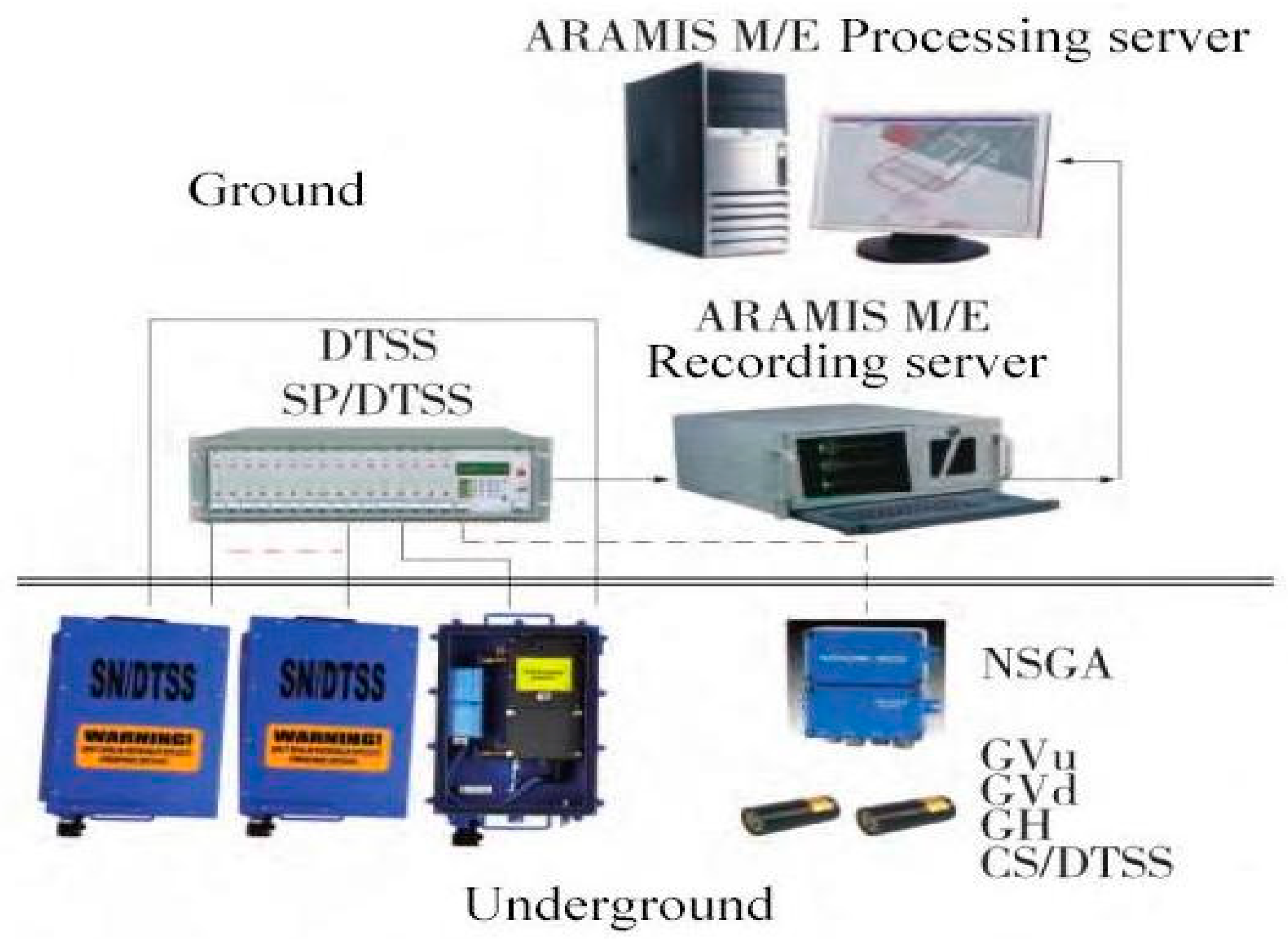

2.3.1. Microseismic Monitoring System

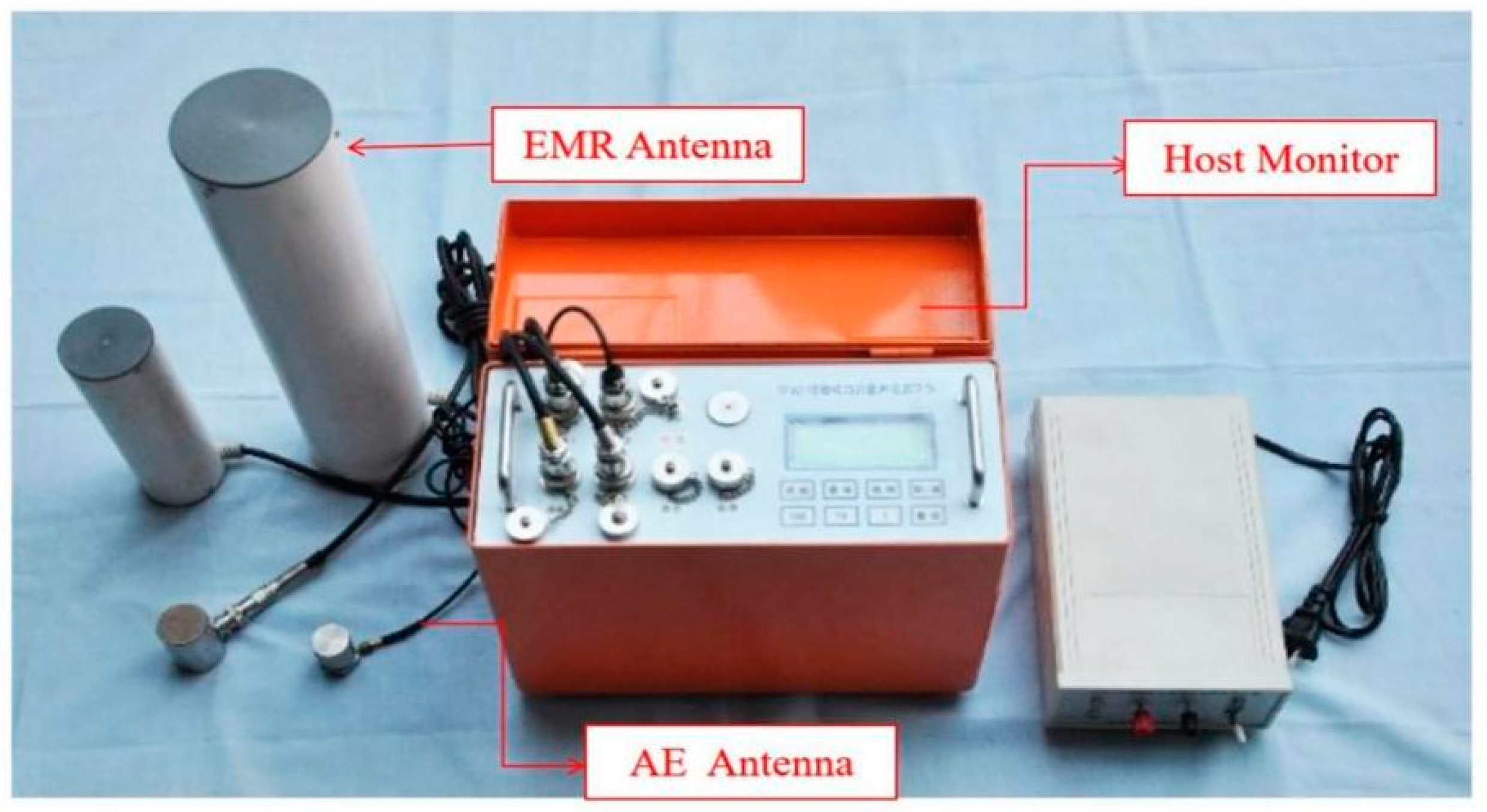

2.3.2. Acoustic Emission and Electromagnetic Radiation Monitoring System

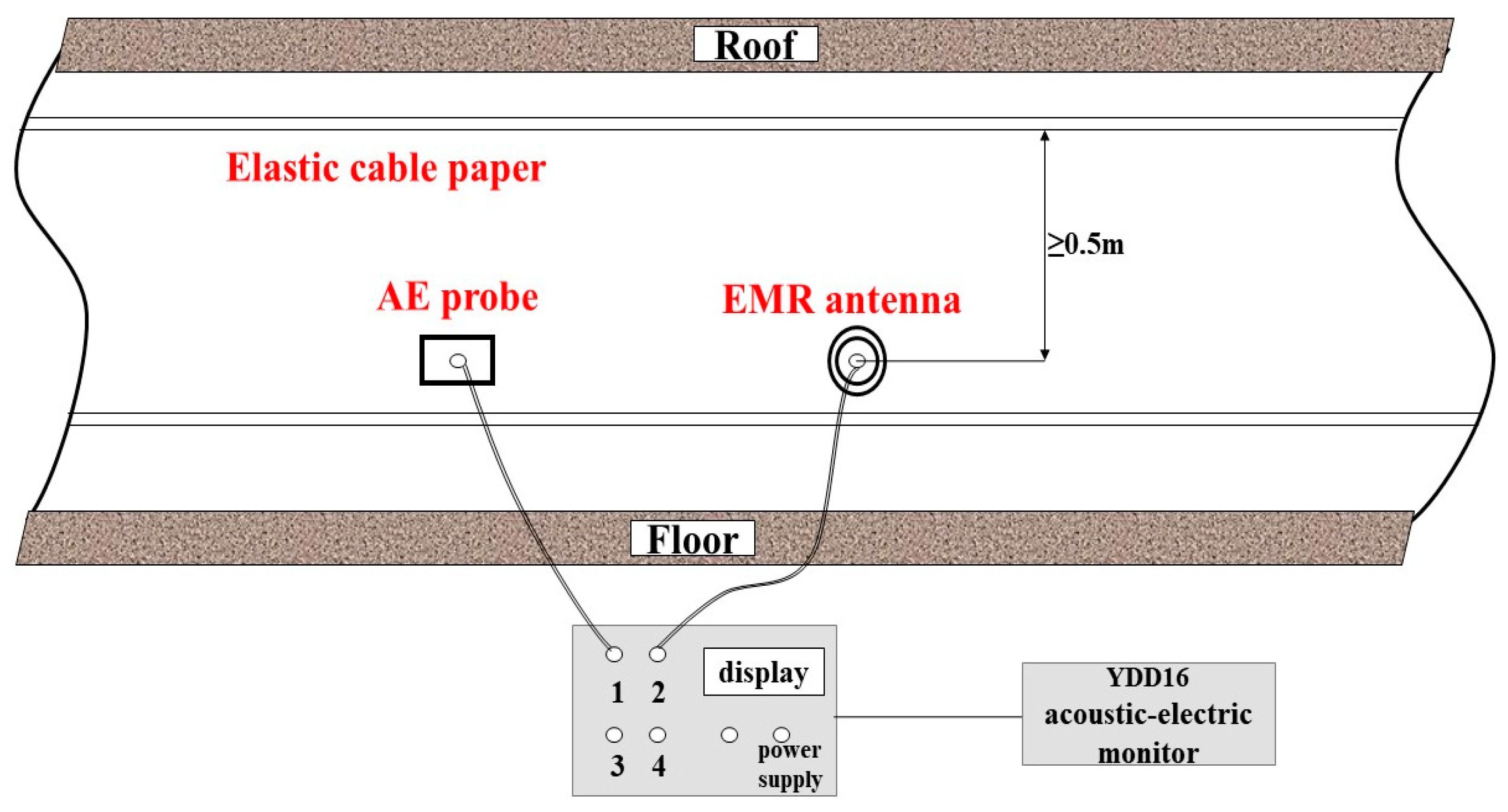

2.3.3. Layout of Acoustic-Electromagnetic Monitoring Points

2.4. Monitoring Results and Precursor Laws

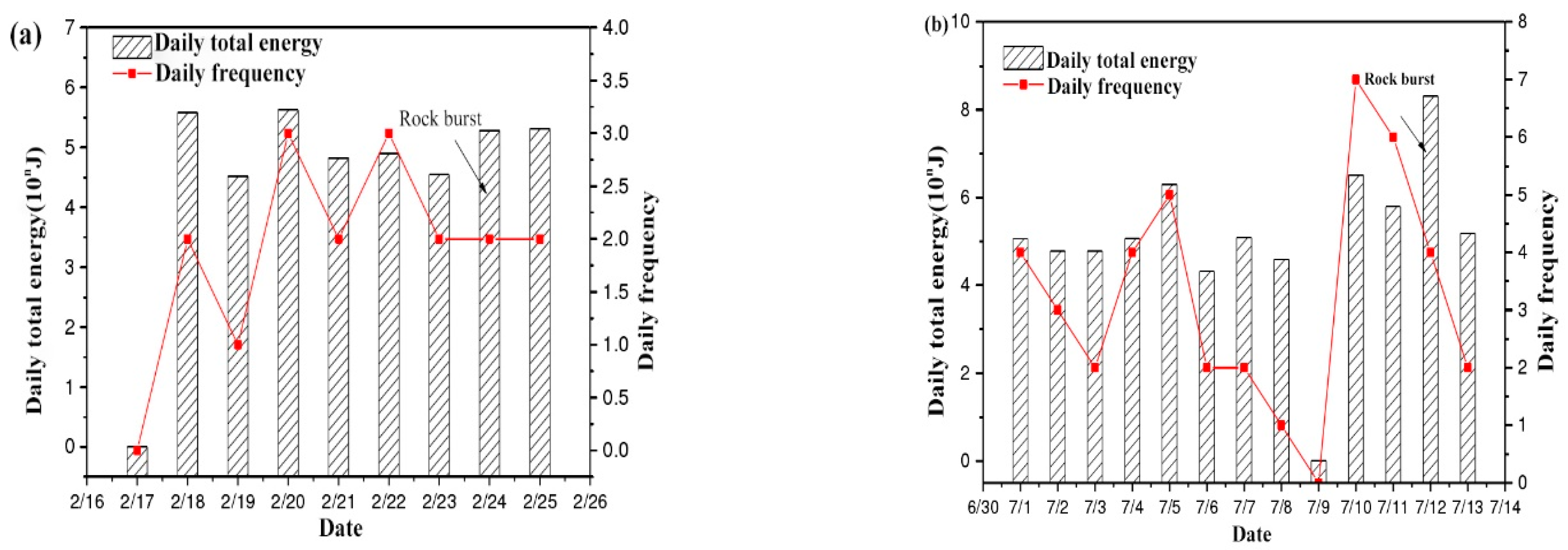

2.4.1. Microseismic Monitoring Results

- (1)

- 24 February 2014 rockburst event 73005# working face

- (2)

- 12 July 2014 rockburst event 83003# working face

2.4.2. Acoustic-Electromagnetic Monitoring Results

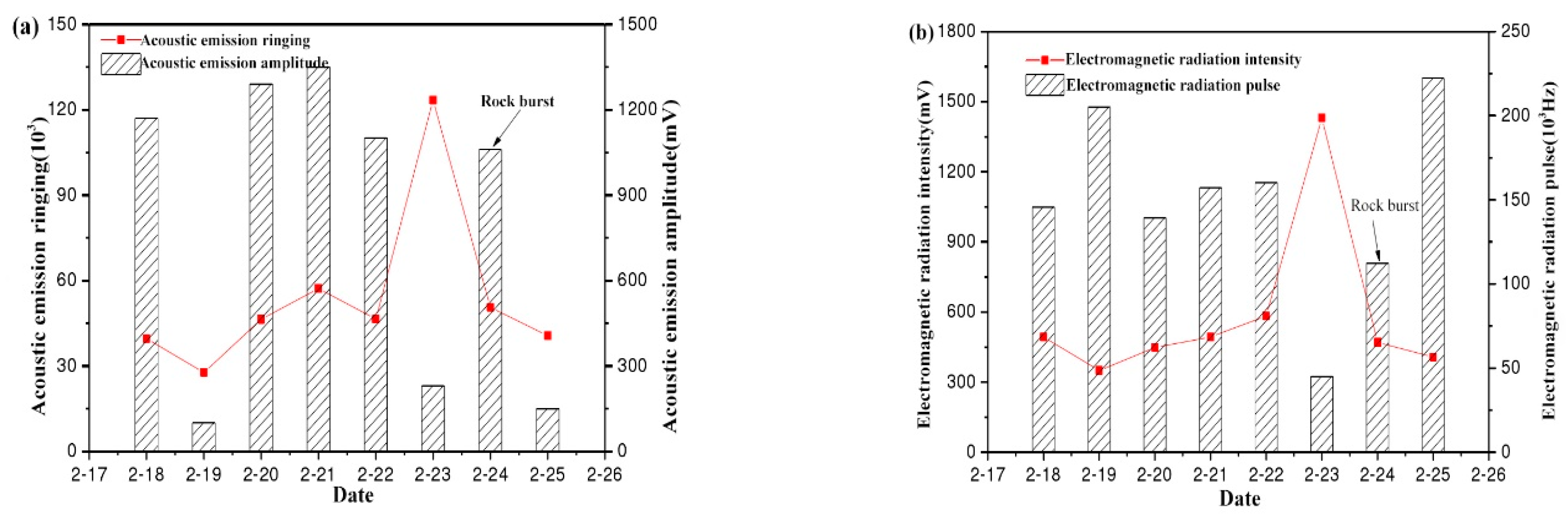

- (1)

- 24 February, 2014 rockburst event-73005# working face

- (2)

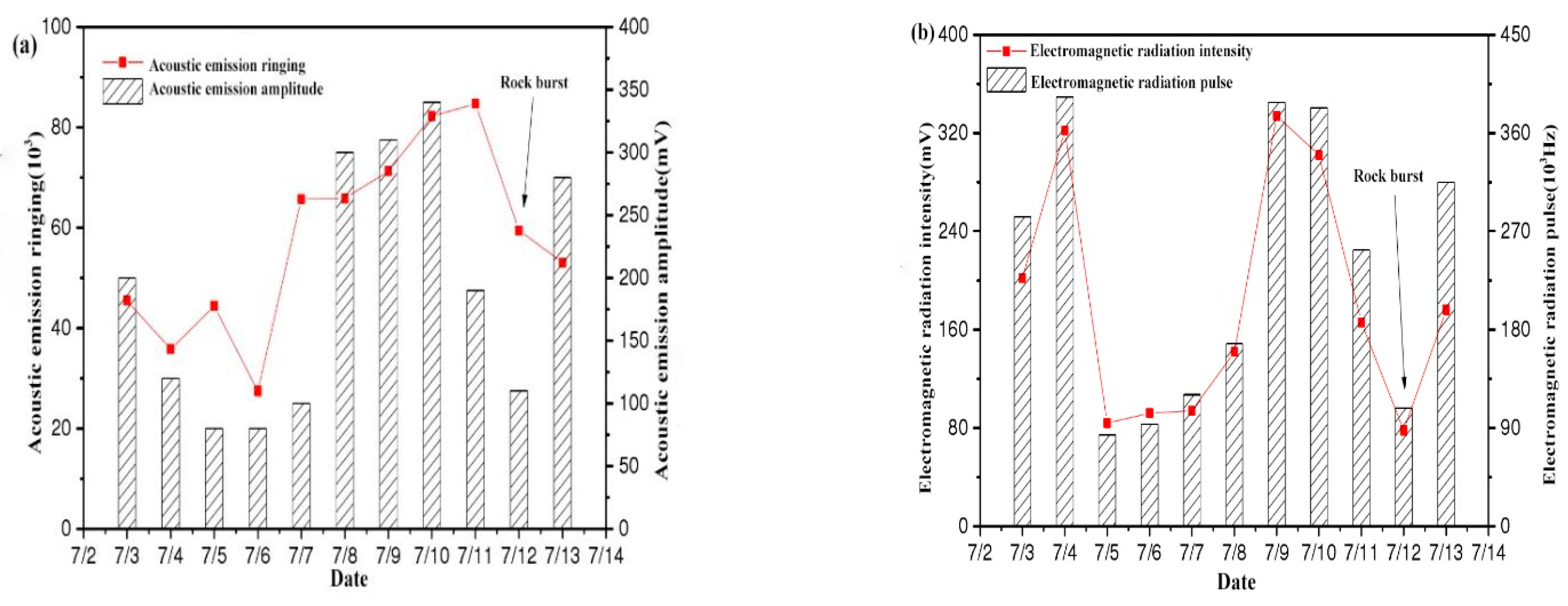

- 12 July 2014 rockburst event 83003# working face

2.4.3. Precursor Laws

- (1)

- The changing trend of microseismic energy and frequency in Laohutai Coal Mine has a good consistency, which can reflect the failure strength and frequency of coal rock. The frequency generally increases with the increase of total energy and decreases with the decrease of total energy, showing a positive correlation. The microseismic signal has obvious fluctuation before the rockburst event, and there is a very low value within five days before the impact. The common feature is that there is an upward stage, and the rockburst occurs during the upward process. Therefore, if the microseismic signal value shows a continuous upward or upward trend in the process of change, and there is a very low value in the process of change, it indicates that the possibility of impact events is greater, to which special attention should be paid.

- (2)

- Summarizing the acoustic-electromagnetic response laws of rockburst events, it can be seen that the overall change trend of electromagnetic radiation and acoustic emission signals in the Laohutai Coal Mine before rockburst events can be divided into two basic forms: rising type and inverted V-shaped. The rising type shows the rising trend of the acoustic-electromagnetic signal exceeding four consecutive days, while the inverted V-shaped shows that the acoustic-electromagnetic signal rises to the peak state and the rockburst occurs in the descending process, which is closely related to the heterogeneous structure of coal. In contrast, the acoustic emission signal changes more diverse, and the electromagnetic radiation signal is mainly represented by an inverted V-shaped.

3. The Method and Application of Acoustic-Electromagnetic Early Warning for Rockbursts

3.1. Theoretical Basis

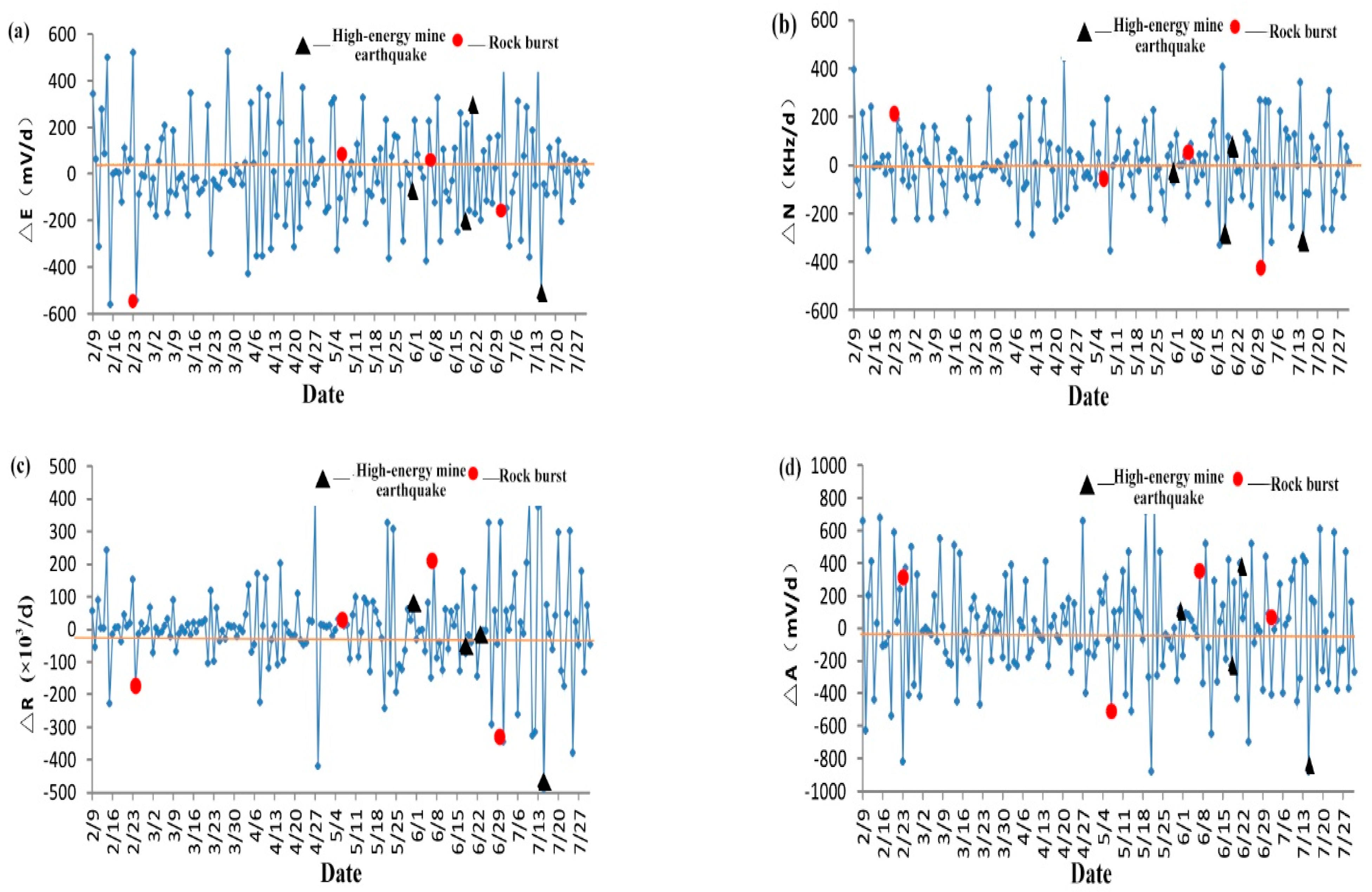

3.2. Hazard Discrimination Index

3.3. Hazard Warning Guidelines

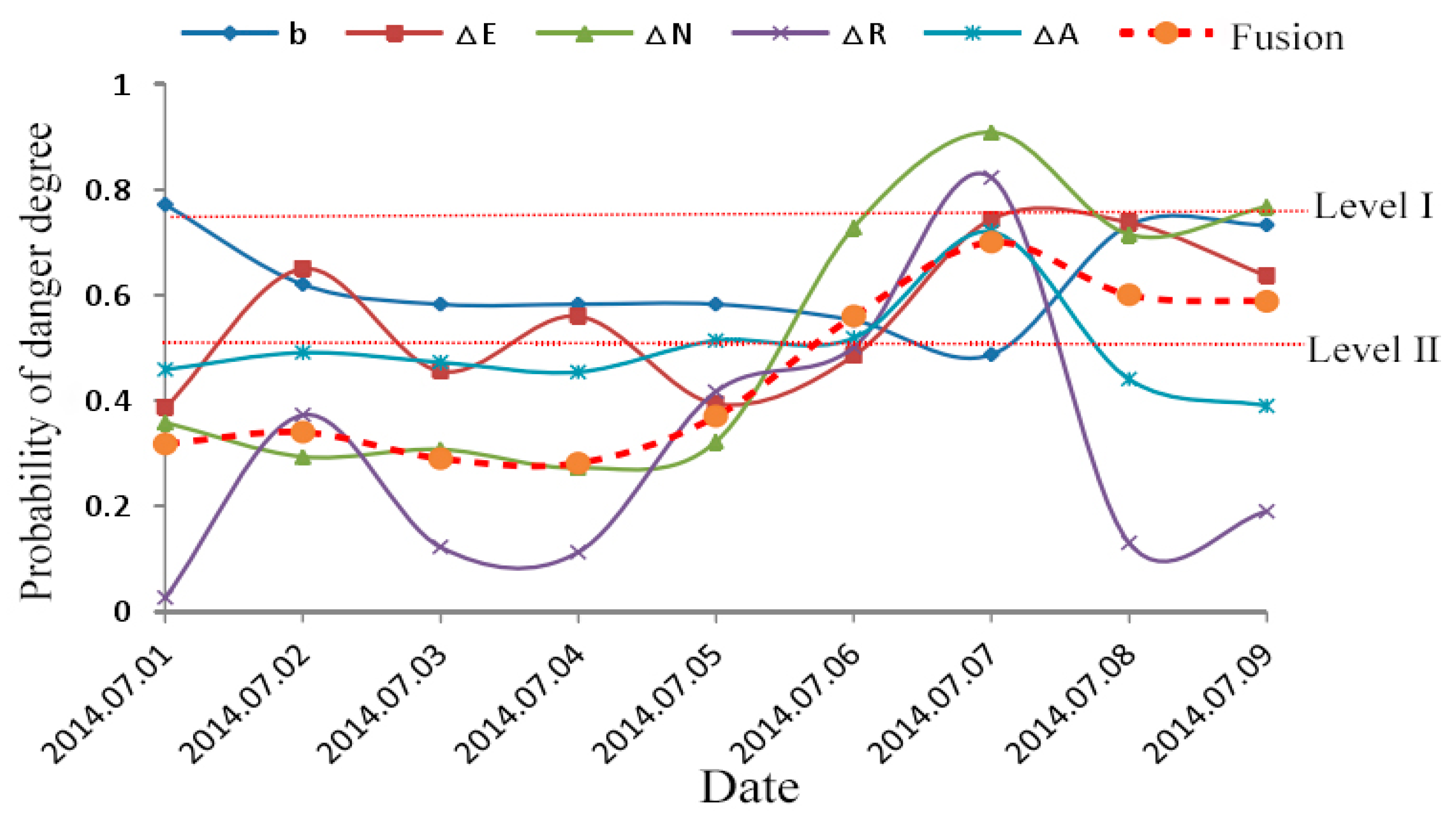

3.4. Early Warning Practice

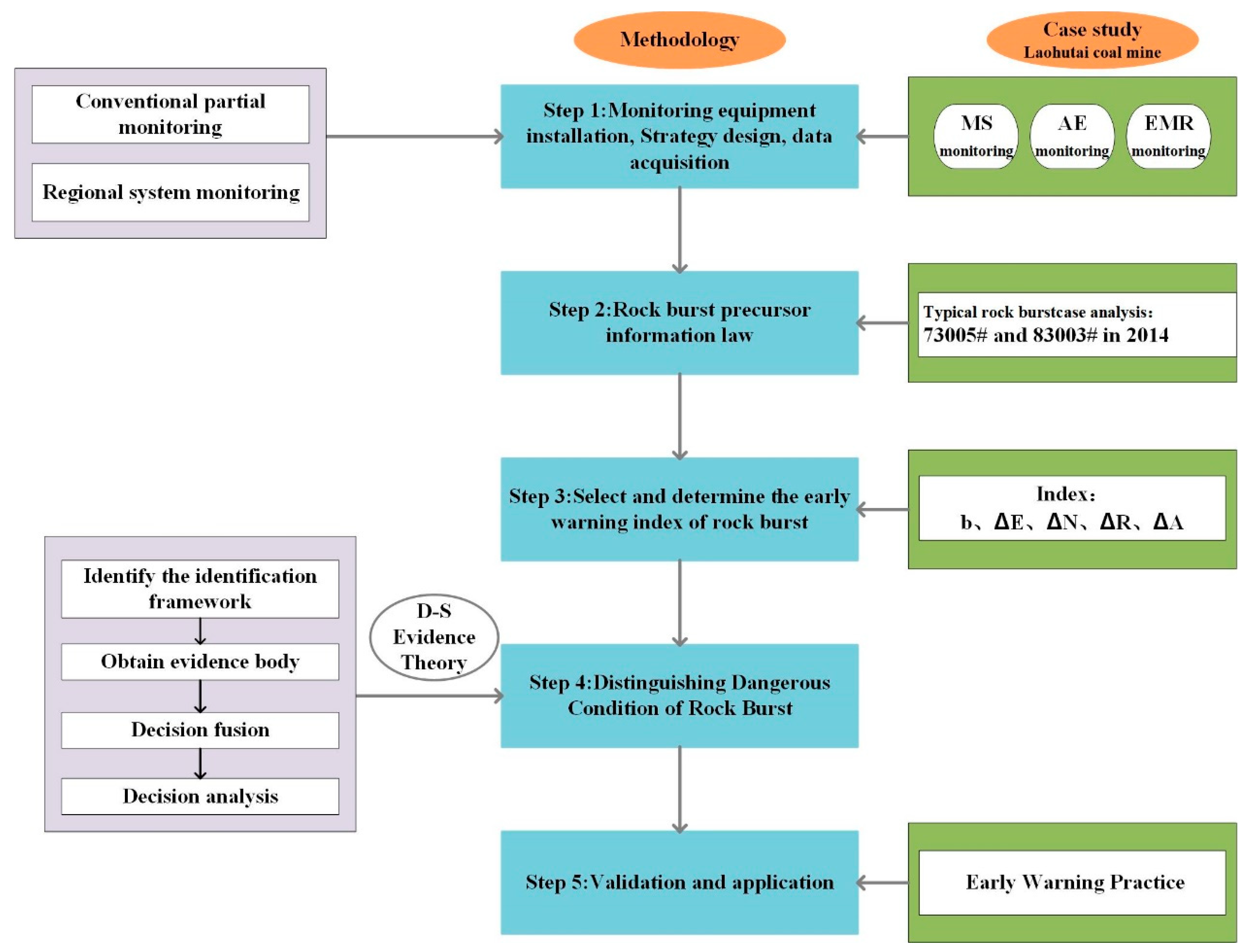

4. Joint Early Warning Method

- (1)

- Installation of monitoring equipment, design, and data collection. According to the geological conditions of Fushun Laohutai Coal Mine, monitoring equipment is installed and a monitoring scheme is designed before mining. Ensure that all monitoring data of MS, EMR, and AE can be completely recorded during the mining process.

- (2)

- Rockburst precursor information. According to the monitoring and test data of microseismic, electromagnetic radiation, and acoustic emission collected and measured, the response characteristics of each rockburst disaster are analyzed.

- (3)

- Select and determine the early warning index of rockburst. Determine the appropriate microseismic and acoustic indicators, analyze their time series changes, and summarize their respective thresholds.

- (4)

- Identify the risk of rockburst. Based on the D-S evidence theory, the multi-parameter monitoring indicators are combined to determine the identification framework, obtain the evidence body, carry out decision fusion and decision analysis, and establish a multi-parameter monitoring and early warning model for rockbursts.

- (5)

- Application and verification. Combined with engineering practice, the effectiveness of the multi-index fusion early warning technology is verified.

5. Conclusions

- The precursory laws of microseismic and acoustic signals of rockburst in the Laohutai Coal Mine have been analyzed. It is found that the correlation between energy and frequency parameters of microseismic signals in the Laohutai Coal Mine is good. The overall change trend of electromagnetic radiation and acoustic emission signals before rockburst events is divided into two basic forms: rising type and inverted V-type, and the signals have obvious fluctuation before rockburst. It is feasible to use acoustic emission-electromagnetic radiation-microseismic monitoring technology for comprehensive early warning of coalmine rockbursts.

- According to the seismic G–R relationship and the wave theory, the microseismic b value and the acoustic–electric time fluctuation gradient are determined as the main research indicators of rockburst monitoring and early warning, and the respective thresholds are obtained as the critical reference value for judging the risk degree of rockbursts. According to the D-S evidence theory, the above five indicators are used as evidence bodies for decision fusion and decision analysis, and a comprehensive early warning technology for multi-index information fusion of rockburst in Laohutai Coal Mine is established.

- The method is verified in the 63007# working face. The field application shows that the method can accurately identify and warn of the potential risk of rockburst in the working face and ensure the safe and efficient production of the working face, which has important guiding significance for the prevention and control of rockburst in coalmines in China.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dou, L.-M.; Chen, T.-J.; Gong, S.-Y.; Hu, H.; Zhang, S.-B. Rockburst hazard determination by using computed tomography technology in deep workface. Saf. Sci. 2012, 50, 736–740. [Google Scholar] [CrossRef]

- He, M.-C.; Nie, W.; Zhao, Z.-Y.; Guo, W. Experimental investigation of bedding plane orientation on the rockburst behavior of sandstone. Rock Mech. Rock Eng. 2012, 45, 311–326. [Google Scholar] [CrossRef]

- Jiang, Y.-D.; Zhao, Y.-X. State of the art: Investigation on the mechanism, forecast, and control of coal bumps in China. Chin. J. Rock Mech. Eng. 2015, 34, 2188–2204. (In Chinese) [Google Scholar]

- Ma, T.-H.; Tang, C.-A.; Tang, S.-B.; Liang, K.; Yu, Q.; Kong, D.-Q.; Xu, Z. Rockburst mechanism and prediction based on microseismic monitoring. Int. J. Rock Mech. Min. Sci. 2018, 110, 177–188. [Google Scholar] [CrossRef]

- Jiang, F.-X. Application of microseismic monitoring in fracture monitoring of mine rock formations. Chin. J. Geo. Eng. 2002, 24, 147–149. (In Chinese) [Google Scholar]

- Lu, C.-P.; Dou, L.-M.; Wang, Y.-F. Microseismic effect of hard roof induced impact of coal body. Chin. J. Geo. 2010, 53, 450–456. (In Chinese) [Google Scholar]

- Li, B.-L.; Li, N.; Wang, E.-Y.; Li, X.-L.; Niu, Y.; Zhang, X. Characteristics of coal mining microseismic and blasting signals at Qianqiu coal mine. Shock Vib. 2017, 76, 722. [Google Scholar] [CrossRef]

- He, X.-Q.; Chen, W.-X.; Nie, B.-S. Electromagnetic emission theory and its application to dynamic phenomena in coal-rock. Int. J. Rock Mech. Min. Sci. 2011, 48, 1352–1358. [Google Scholar] [CrossRef]

- Dou, L.-M.; He, X.-Q.; Wang, E.-Y. Electromagnetic emission technique of monitoring coal bump and its application. J. China Coal Soc. 2004, 29, 396–399. [Google Scholar]

- Wang, H.; Wang, E.-Y.; Li, Z.-H.; Wang, X.-R.; Li, D.-X.; Ali, M.; Zhang, Q.-M. Varying characteristics of electromagnetic radiation from coal failure during hydraulic flushing in coal seam. Arab. J. Geosci. 2020, 13, 644. [Google Scholar] [CrossRef]

- Liu, X.-F.; Zhang, Z.-B.; Wang, E.-Y.; Wang, X.-R.; Yang, B.; Wang, H. Characteristics of electromagnetic radiation signal of coal and rock under uniaxial compression and its field application. J. Earth Syst. Sci. 2020, 129, 34. [Google Scholar] [CrossRef]

- Qi, Q.-X.; Li, S.-B.; Wang, S.-K. Application of AE technique in monitoring ground pressure. J. Chin. Coal Soc. 1994, 19, 221–232. [Google Scholar]

- He, H.; Dou, L.-M.; Gong, S.-Y.; Zhou, P.; Xue, Z.-J.; He, J. Study of acoustic emission monitoring technology for rockburst. Rock Soil Mech. 2011, 32, 1262–1268. [Google Scholar]

- Feng, X.-J.; Ding, Z.; Ju, Y.-Q.; Zhang, Q.-M.; Ali, M. “Double Peak” of Dynamic Strengths and Acoustic Emission Responses of Coal Masses under Dynamic Loading. Nat. Resour. Res. 2022, 31, 1705–1720. [Google Scholar] [CrossRef]

- Ding, Z.; Feng, X.-J.; Wang, E.-Y.; Wei, Q.-L.; Zhao, X.; Hu, Q.-J. Acoustic emission response and evolution of precracked coal in the meta-instability stage under graded loading. Eng. Geol. 2023, 312, 106930. [Google Scholar] [CrossRef]

- Wang, S.-R.; Li, C.-Y.; Yan, W.-F.; Zou, Z.-S.; Chen, W.-X. Multiple indicators prediction method of rock burst based on microseismic monitoring technology. Arab. J. Geo. Sci. 2017, 10, 132. [Google Scholar] [CrossRef]

- Li, X.-L.; Li, Z.-H.; Wang, E.-Y.; Feng, J.-J.; Chen, L.; Li, N.; Zou, Q.-L. Microseismic Signal Spectra, Energy Characteristics, and Fractal Features Prior to Rock Burst: A Case Study from the Qianqiu Coal Mine, China. J. Earthq. Eng. 2017, 21, 891–911. [Google Scholar] [CrossRef]

- Li, X.-L.; Wang, E.-Y.; Li, Z.-H.; Liu, Z.-T.; Song, D.-Z.; Qiu, L.-M. Rock burst monitoring by integrated microseismic and electromagnetic radiation methods. Rock Mech. Rock Eng. 2016, 49, 4393–4406. [Google Scholar] [CrossRef]

- Feng, G.-L.; Feng, X.-T.; Chen, B.-R.; Xiao, Y.-X.; Yu, Y. A Microseismic Method for Dynamic Warning of Rockburst Development Processes in Tunnels. Rock Mech. Rock Eng. 2015, 48, 2061–2076. [Google Scholar] [CrossRef]

- He, J.; Dou, L.-M.; Gong, S.-Y.; Li, J.; Ma, Z.-Q. Rock burst assessment and prediction by dynamic and static stress analysis based on micro-seismic monitoring. Int. J. Rock Mech. Min. Sci. 2017, 93, 46–53. [Google Scholar] [CrossRef]

- Li, J.-G.; Liu, H. Application Conditions on Acoustic Emission (AE) Technique Monitoring Coal and Rock Dynamic Disasters in Mines. Adv. Mater. Res. 2012, 413, 235–240. [Google Scholar] [CrossRef]

- Wen, Z.-J.; Wang, X.; Chen, L.-J.; Lin, G.; Zhang, H.-L.; Santulli, C. Size effect on acoustic emission characteristics of coal-rock damage evolution. Adv. Mater. Sci. Eng. 2017, 2017, 3472485. [Google Scholar] [CrossRef]

- Gong, Y.; Song, Z.; He, M.; Gong, W.; Rem, F. Precursory waves and eigenfrequencies identified from acoustic emission data based on Singular Spectrum Analysis and laboratory rock-burst experiments. Int. J. Rock Mech. Min. Sci. 2017, 91, 155–169. [Google Scholar] [CrossRef]

- Song, D.-Z.; Wang, E.-Y.; Li, Z.-H.; Qiu, L.-M.; Xu, Z.-Y. EMR: An effective method for monitoring and warning of rock burst hazard. Geomech. Eng. 2017, 12, 53–69. [Google Scholar] [CrossRef]

- Mutke, G.; Dubiński, J.; Lurka, A. New Criteria to Assess Seismic and Rock Burst Hazard in Coal Mines/Nowe Kryteria Dla Oceny Zagrożenia Sejsmicznego I Tąpaniami W Kopalniach Węgla Kamiennego. Arch. Min. Sci. 2015, 60, 743–760. [Google Scholar] [CrossRef]

- Jiang, F.-X.; Miao, X.-H.; Wang, C.-W.; Song, J.-H.; Deng, J.-M.; Men, F. Predicting research and practice of tectonic controlled coal burst by microseismic monitoring. J. Chin. Coal Soc. 2010, 35, 900–903. (In Chinese) [Google Scholar]

- Xia, Y.-X.; Kang, L.-J.; Qi, Q.-X.; Mao, D.-B.; Ren, Y.; Lan, H.; Pan, J.-F. Five indexes of microseismic and their application in rock burst forecastion. J. Chin. Coal Soc. 2010, 35, 900–903. (In Chinese) [Google Scholar]

- Pan, Y.-S.; Zhao, Y.-F.; Li, G.-Z. Charge-Induced Technique of Rockburst Prediction and its Application. Chin. J. Rock Mech. Eng. 2012, 31, 3988–3993. (In Chinese) [Google Scholar]

- Wang, E.-Y.; He, X.-Q.; Li, Z.-H. Coal and Rock Electromagnetic Radiation Technology and Its Application; Science Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Jiang, F.-X.; Qu, X.-C.; Yu, Z.-X.; Wang, C.-W. Real-Time Monitoring and Measuring Early Warning Technology and Development of Mine Pressure Bumping. Coal Sci. Tech. 2011, 39, 59–64. (In Chinese) [Google Scholar]

- Lu, C.-P.; Dou, L.-M.; Cao, A.-Y.; Wu, X.-R.; Li, Z.-H. Research on Microseismic Activity Rules in Deep High-Stress Concentration District. Chin. J. Rock Mech. Eng. 2008, 27, 2302–2308. (In Chinese) [Google Scholar]

- Wang, Y.-J.; Qi, Q.-X.; Mao, D.-B.; Wei, D. Impact hazard prediction based on ground sound monitoring technology. Saf. Coal Min. 2010, 4, 52–54. (In Chinese) [Google Scholar]

- Li, G.-J. Comprehensive Prevention and Control Technology of Rock Burst in Fushun Mining Area. Saf. Coal Min. 2020, 51, 144–151. (In Chinese) [Google Scholar]

- Tanaka, K.; Sugeno, M. Stability analysis and design of fuzzy control systems. Fuzzy Sets Syst. 1992, 45, 135–156. [Google Scholar] [CrossRef]

- Jafarizadeh, S.; Jamalipour, A. Fastest distributed consensus problem on the fusion of two star sensor networks. IEEE Sens. J. 2010, 11, 2494–2506. [Google Scholar] [CrossRef]

- Dempster, A.-P. Upper and Lower probabilities induced by a multivalued mapping. Ann. Math. Stat. 1967, 38, 325–339. [Google Scholar] [CrossRef]

- Shafer, G. A Mathematical Theory of Evidence; Princeton University Press: Princeton, NJ, USA, 1976. [Google Scholar]

- Makridakis, S.; Andersen, A.; Carbone, R.; Filder, R.; Hibon, M.; Lewandoski, R.; Newton, J.; Paraenand, E.; Winker, P. The accuracy of extrapolation (time series) methods: Results of a forecasting competition. J. Forecast. 1982, 1, 111–153. [Google Scholar] [CrossRef]

- Sharda, R.; Patil, R. Neural Networks as Forecasting Experts: An Em Pirieal Test. In Proceedings of the International Joint Conference on Neural Networks, San Diego, CA, USA, 17–21 June 1990; pp. 491–494. [Google Scholar]

| Hazard Level | Level Ⅰ | Level II | Level III | Level IV |

|---|---|---|---|---|

| Judgement standard | [0.75,1] | [0.5,0.75) | [0.25,0.5) | [0,0.25) |

| Hazard Level | Representative Meaning | Specific Instructions |

|---|---|---|

| Level Ⅰ | Dangerous | Regional and local prevention and control measures are taken and checked, and monitoring and forecasting are carried out at the same time. Excavation can only be carried out when the safety level is reached. |

| Level II | More dangerous | The prevention and control measures should be strengthened during excavation, and monitoring and forecasting are carried out at the same time. Excavation can only be carried out when the safety level is reached. |

| Level III | Safer | Strengthening the monitoring and forecasting of coal and rock dynamic disasters during mining |

| Level IV | Safe | Excavation work can proceed normally. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, S.; Wang, E.; Zhang, Z.; Wang, Y.; Yang, S. Multi-Index Geophysical Monitoring and Early Warning for Rockburst in Coalmine: A Case Study. Int. J. Environ. Res. Public Health 2023, 20, 392. https://doi.org/10.3390/ijerph20010392

Liu X, Zhang S, Wang E, Zhang Z, Wang Y, Yang S. Multi-Index Geophysical Monitoring and Early Warning for Rockburst in Coalmine: A Case Study. International Journal of Environmental Research and Public Health. 2023; 20(1):392. https://doi.org/10.3390/ijerph20010392

Chicago/Turabian StyleLiu, Xiaofei, Siqing Zhang, Enyuan Wang, Zhibo Zhang, Yong Wang, and Shengli Yang. 2023. "Multi-Index Geophysical Monitoring and Early Warning for Rockburst in Coalmine: A Case Study" International Journal of Environmental Research and Public Health 20, no. 1: 392. https://doi.org/10.3390/ijerph20010392

APA StyleLiu, X., Zhang, S., Wang, E., Zhang, Z., Wang, Y., & Yang, S. (2023). Multi-Index Geophysical Monitoring and Early Warning for Rockburst in Coalmine: A Case Study. International Journal of Environmental Research and Public Health, 20(1), 392. https://doi.org/10.3390/ijerph20010392