Comparative Study of the SEM Evaluation, EDX Assessment, Morphometric Analysis, and Cyclic Fatigue Resistance of Three Novel Brands of NiTi Alloy Endodontic Files

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Design

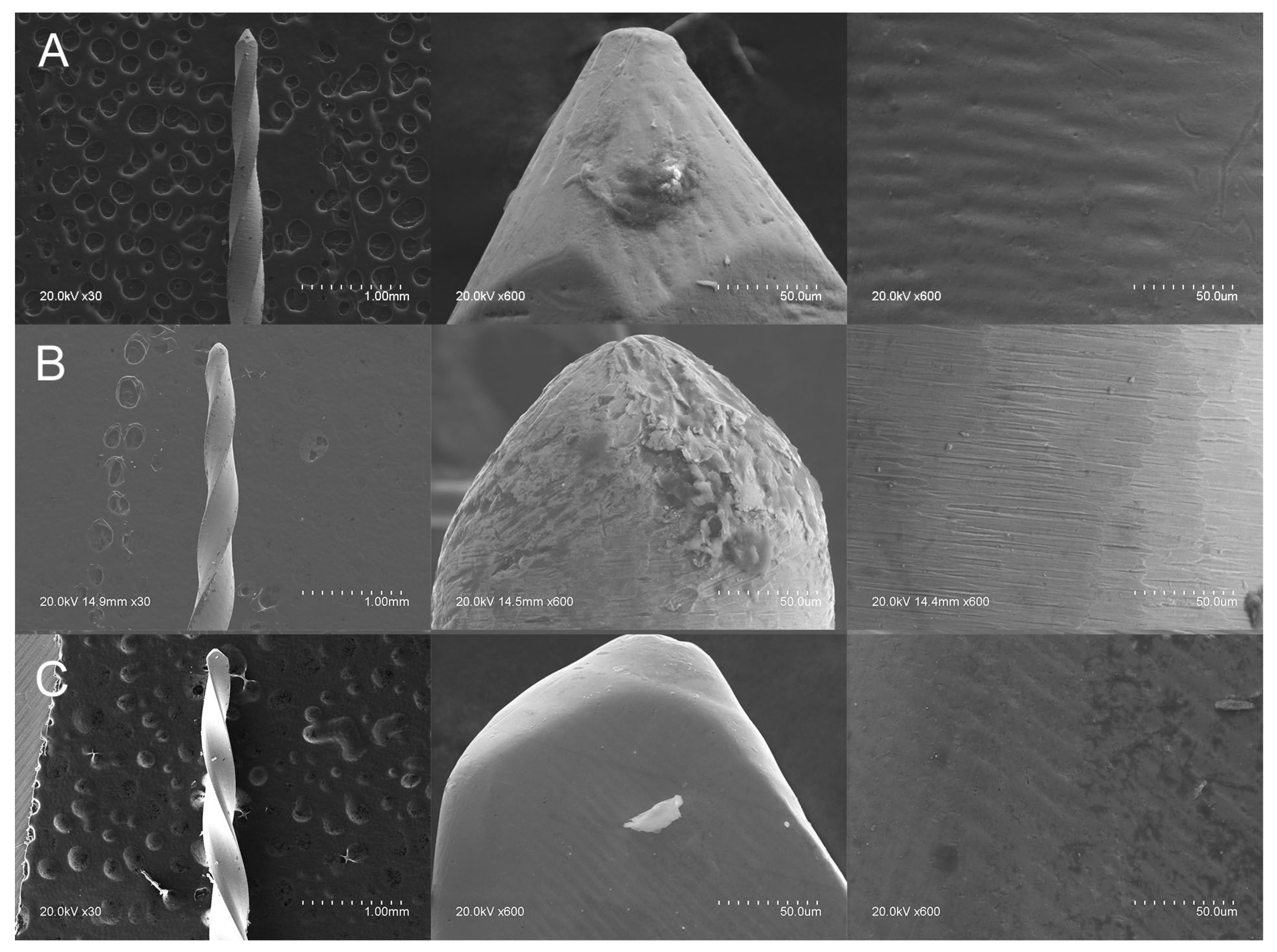

2.2. Scanning Electron Microscopy Analysis

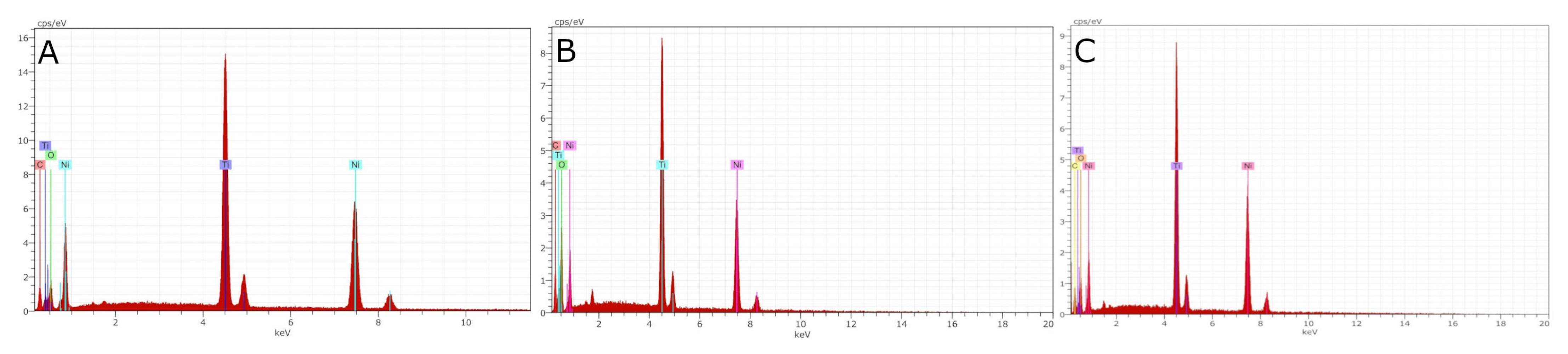

2.3. Energy-Dispersive X-ray Spectroscopy Analysis

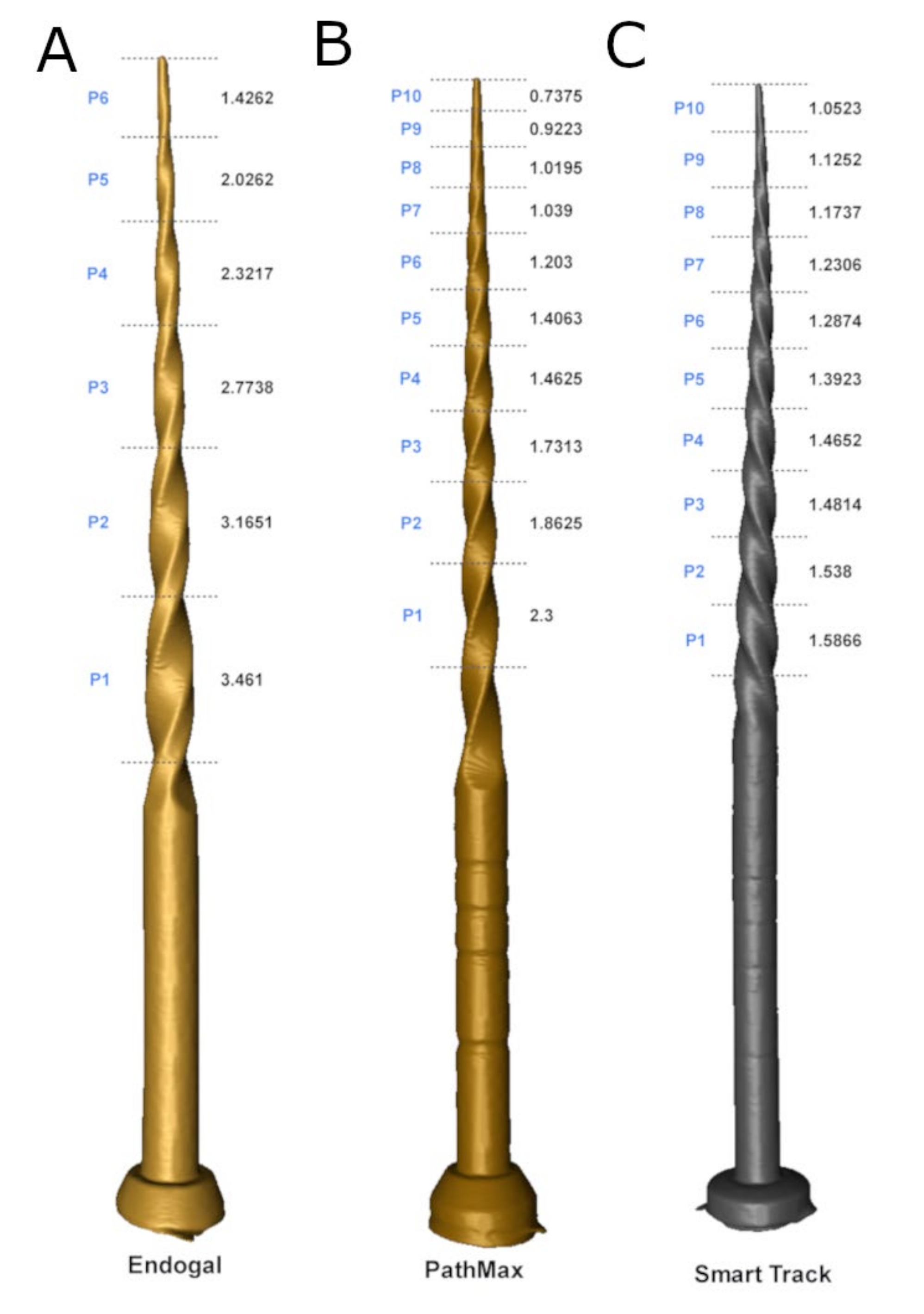

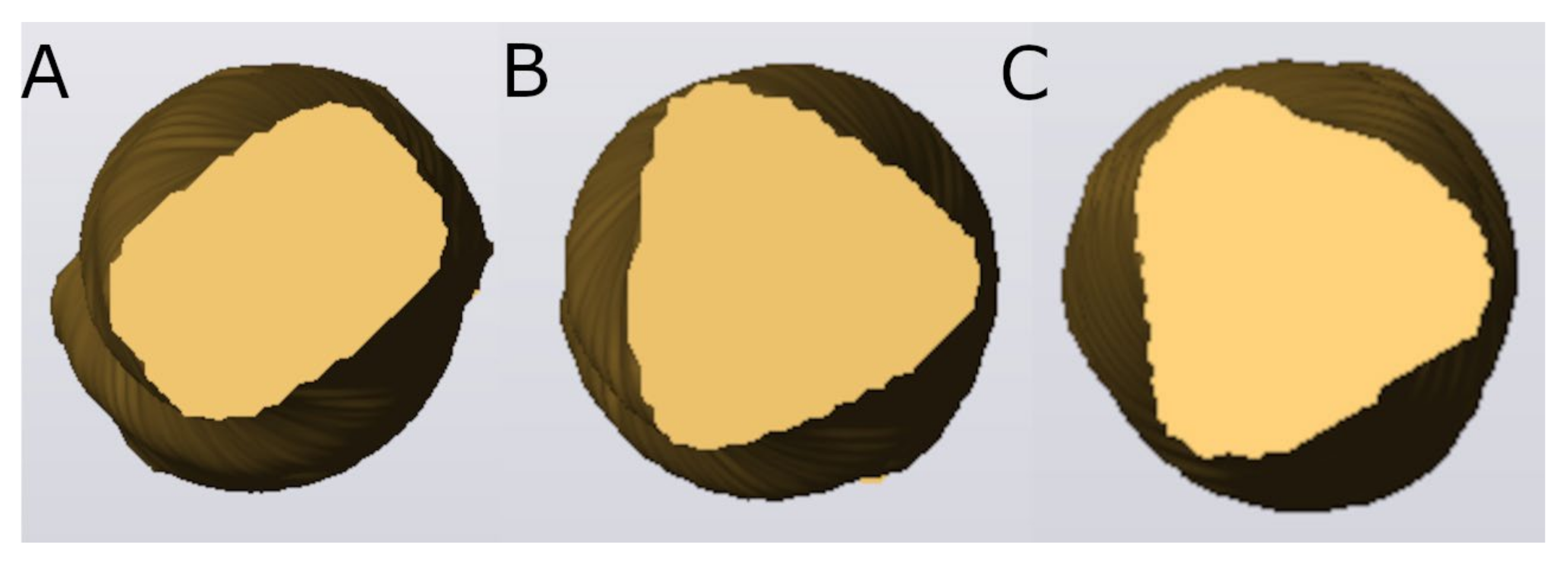

2.4. Micro-Computed Tomography Scan and Morphometric Analyses

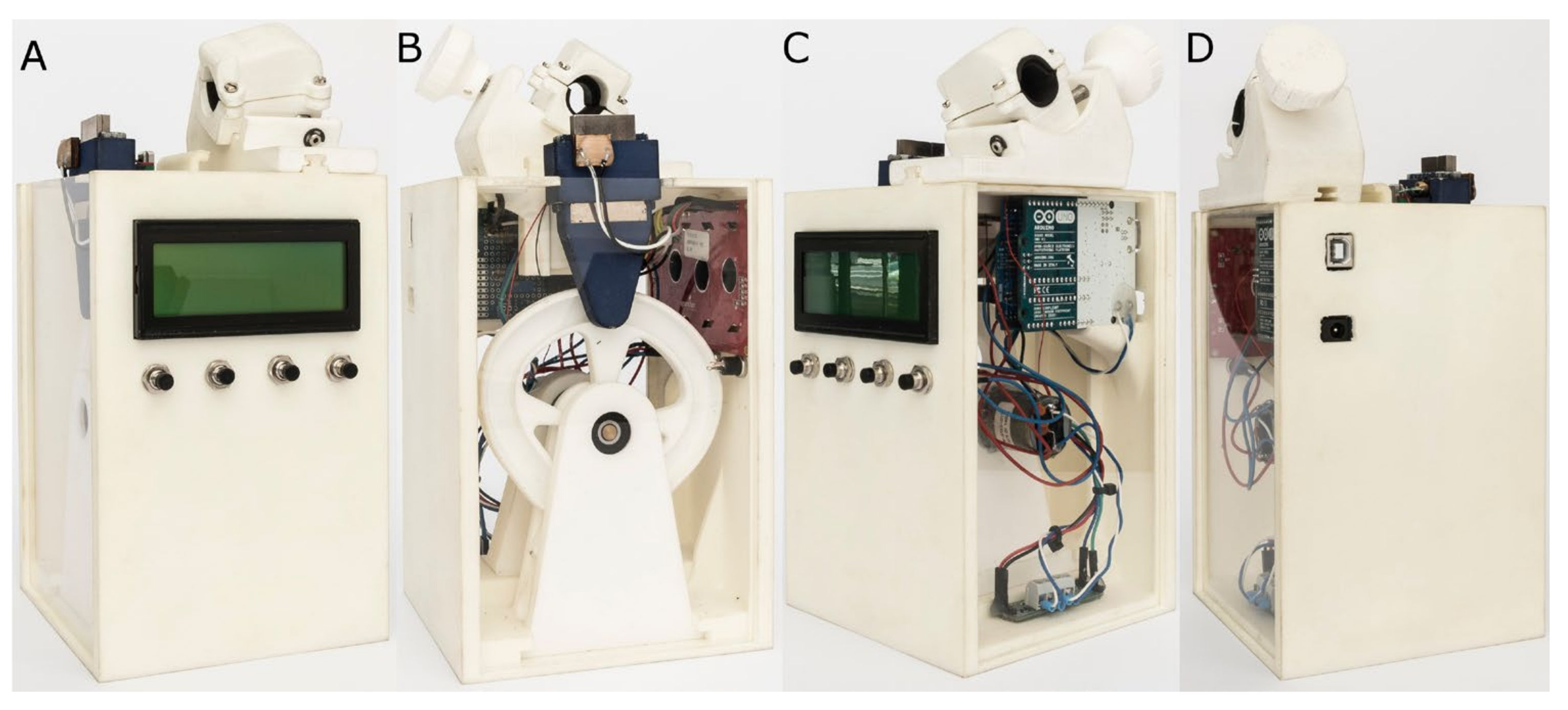

2.5. Experimental Cyclic Fatigue Model

2.6. Statistical Tests

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Walia, H.M.; Brantley, W.A.; Gerstein, H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J. Endod. 1988, 14, 346–351. [Google Scholar] [CrossRef]

- Esposito, P.T.; Cunningham, C.J. A comparison of canal preparation with nickel-titanium and stainless steel instruments. J. Endod. 1995, 21, 173–176. [Google Scholar] [CrossRef]

- Bergmans, L.; van Cleynenbreugel, J.; Wevers, M.; Lambrechts, P. Mechanical root canal preparation with NiTi rotary instruments: Rationale, performance and safety. Status report for the American Journal of Dentistry. Am. J. Dent. 2001, 14, 324–333. [Google Scholar] [PubMed]

- Parashos, P.; Gordon, I.; Messer, H.H. Factors influencing defects of rotary nickel-titanium endodontic instruments after clinical use. J. Endod. 2004, 30, 722–725. [Google Scholar] [CrossRef] [PubMed]

- Spili, P.; Parashos, P.; Messer, H.H. The impact of instrument fracture on outcome of endodontic treatment. J. Endod. 2005, 31, 845–850. [Google Scholar] [CrossRef] [PubMed]

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.; Messer, H.H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef] [Green Version]

- Peters, O.A.; Barbakow, F. Dynamic torque and apical forces of ProFile.04 rotary instruments during preparation of curved canals. Int. Endod. J. 2002, 35, 379–389. [Google Scholar] [CrossRef]

- Kuhn, G.; Tavernier, B.; Jordan, L. Influence of structure on nickel-titanium endodontic instruments failure. J. Endod. 2001, 27, 516–520. [Google Scholar] [CrossRef]

- Carpegna, G.; Alovisi, M.; Salvatore Paolino, D.; Marchetti, A.; Gibello, U.; Scotti, N.; Pasqualini, D.; Scattina, A.; Chiandussi, G.; Berutti, E. Evaluation of Pressure Distribution against Root Canal Walls of NiTi Rotary Instruments by Finite Element Analysis. Appl. Sci. 2020, 10, 2981. [Google Scholar] [CrossRef]

- Alovisi, M.; Pasqualini, D.; Scotti, N.; ·Carpegna, G.; Comba, A.; Bernardi, M.; Tutino, F.; Dioguardi, M.; Berutti, E. Micro-CT evaluation of rotary and reciprocating glide path and shaping systems outcomes in maxillary molar curved canals. Odontology 2022, 110, 54–61. [Google Scholar] [CrossRef]

- Pruett, J.P.; Clement, D.J.; Carnes, D.L., Jr. Cyclic fatigue testing of nickel-titanium endodontic instruments. J. Endod. 1997, 23, 77–85. [Google Scholar] [CrossRef]

- Parashos, P.; Messer, H.H. Rotary NiTi instrument fracture and its consequences. J. Endod. 2006, 32, 1031–1043. [Google Scholar] [CrossRef] [PubMed]

- Topçuoğlu, H.S.; Topçuoğlu, G. Cyclic fatigue resistance of reciproc blue and reciproc files in an s-shaped canal. J. Endod. 2017, 43, 1679–1682. [Google Scholar] [CrossRef]

- Siqueira, J.F., Jr.; Rôças, I.N. Polymerase chain reaction–based analysis of microorganisms associated with failed endodontic treatment. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2014, 97, 85–94. [Google Scholar] [CrossRef]

- Heydari, A.; Rahmani, M.; Heydari, M. Removal of a Broken Instrument from a Tooth with Apical Periodontitis Using a Novel Approach. Iran. Endod. J. 2016, 11, 237–240. [Google Scholar] [CrossRef] [PubMed]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef] [Green Version]

- Faus-Llácer, V.; Kharrat, N.H.; Ruiz-Sánchez, C.; Faus-Matoses, I.; Zubizarreta-Macho, Á.; Faus-Matoses, V. The effect of taper and apical diameter on the cyclic fatigue resistance of rotary endodontic files using an experimental electronic device. Appl. Sci. 2021, 11, 863. [Google Scholar] [CrossRef]

- Turpin, Y.L.; Chagneau, F.; Vulcain, J.M. Impact of two theoretical cross-sections on torsional and bending stresses of nickel-titanium root canal instrument models. J. Endod. 2000, 26, 414–417. [Google Scholar] [CrossRef]

- Sekar, V.; Kumar, R.; Nandini, S.; Ballal, S.; Velmurugan, N. Assessment of the role of cross section on fatigue resistance of rotary files when used in reciprocation. Eur. J. Dent. 2016, 10, 541–545. [Google Scholar] [CrossRef] [Green Version]

- Alovisi, M.; Pasqualini, D.; Carpegna, G.; Comba, A.; Moccia, E.; Multari, S.; Dioguardi, M.; Scotti, N.; Berutti, E. The influence of brushing movement on geometrical shaping outcomes: A micro-ct study. Appl. Sci. 2020, 10, 4805. [Google Scholar] [CrossRef]

- Nóvoa, X.R.; Martin-Biedma, B.; Varela-Patiño, P.; Collazo, A.; Macías-Luaces, A.; Cantatore, G.; Pérez, M.C.; Magán-Muñoz, F. The corrosion of nickel-titanium rotary endodontic instruments in sodium hypochlorite. Int. Endod. J. 2007, 40, 36–44. [Google Scholar] [CrossRef] [PubMed]

- Cavalleri, G.; Cantatore, G.; Costa, A.; Grillenzoni, M.; Comin Chiaramonti, L.; Gerosa, R. The corrosive effects of sodium hypochlorite on nickel-titanium endodontic instruments: Assessment by digital scanning microscope. Minerva Stomatol. 2009, 58, 225–231. [Google Scholar] [PubMed]

- Martins, J.N.R.; Nogueira Leal Silva, E.J.; Marques, D.; Ginjeira, A.; Braz Fernandes, F.M.; De Deus, G.; Versiani, M.A. Influence of kinematics on the cyclic fatigue resistance of replicalike and original brand rotary instruments. J. Endod. 2020, 46, 1136–1143. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods. 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Zubizarreta-Macho, A.; Mena Álvarez, J.; Albadalejo Martínez, A.; Segura-Egea, J.J.; Caviedes Brucheli, J.; Agustín-Panadero, R.; López Píriz, R.; Alonso-Ezpeleta, O. Influence of the pecking motion on the cyclic fatigue resistance of endodontic rotary files. J. Clin. Med. 2020, 9, 45. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schneider, S.W. A comparison of canal preparations in straight and curved root canals. Oral Surg. Oral Med. Oral Pathol. 1971, 32, 271–275. [Google Scholar] [CrossRef]

- Seracchiani, M.; Miccoli, G.; Di Nardo, D.; Zanza, A.; Cantore, M.; Gambarini, G.; Testarelli, L. Effect of flexural stress on torsional resistance of NiTi instruments. J. Endod. 2020, 47, 472–476. [Google Scholar] [CrossRef]

- Versluis, A.; Kim, H.C.; Lee, W.; Kim, B.M.; Lee, C.J. Flexural stiffness and stresses in nickel-titanium rotary files for various pitch and cross-sectional geometries. J. Endod. 2012, 38, 1399–1403. [Google Scholar] [CrossRef]

- Al Raeesi, D.; Kwak, S.W.; Ha, J.H.; Sulaiman, S.; El Abed, R.; Kim, H.C. Mechanical properties of glide path preparation instruments with different pitch lengths. J. Endod. 2018, 44, 864–868. [Google Scholar] [CrossRef]

- He, R.; Ni, J. Design improvement and failure reduction of endodontic files through finite element analysis: Application to V-Taper file designs. J Endod. 2010, 36, 1552–1557. [Google Scholar] [CrossRef]

- Faus-Llacer, V.; Hamoud-Kharrat, N.; Marhuenda Ramos, M.T.; Faus-Matoses, I.; Zubizarreta-Macho, A.; Ruiz-Sánchez, C.; Faus-Matoses, V. Efficacy of a novel influence of the geometrical cross-section design on the dynamic cyclic fatigue resistance of niti endodontic rotary files. An In Vitro Study. J. Clin. Med. 2021, 10, 4713. [Google Scholar] [CrossRef]

- Freire, L.G.; Gavini, G.; Cunha, R.S.; Santos, M. Assessing apical transportation in curved canals: Comparison between cross-sections and micro-computed tomography. Braz. Oral Res. 2012, 26, 222–227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ounsi, H.F.; Salameh, Z.; Al-Shalan, T.; Ferrari, M.; Grandini, S.; Pashley, D.H.; Tay, F.R. Effect of clinical use on the cyclic fatigue resistance of ProTaper nickel-titanium rotary instruments. J. Endod. 2007, 33, 737–741. [Google Scholar] [CrossRef] [PubMed]

- Grande, N.M.; Plotino, G.; Pecci, R.; Bedini, R.; Malagnino, V.A.; Somma, F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel-titanium rotary systems. Int. Endod. J. 2006, 39, 755–763. [Google Scholar] [CrossRef] [PubMed]

- Azimi, S.; Delvari, P.; Hajarian, H.C.; Saghiri, M.A.; Karamifar, K.; Lotfi, M. Cyclic fatigue resistance and fractographic analysis of race and protaper rotary niti instruments. Iran. Endod. J. 2011, 6, 80–86. [Google Scholar] [PubMed]

- Haikel, Y.; Serfaty, R.; Bateman, G.; Senger, B.; Allemann, C. Dynamic and cyclic fatigue of engine-driven rotary nickel-titanium endodontic instruments. J. Endod. 1999, 25, 434–440. [Google Scholar] [CrossRef]

- ISO 3630–3631; Dentistry—Root Canal Instruments—Part 1: General Requirements and Test Methods. ISO: Geneva, Switzerland, 2008.

- Peters, O.; Scott, R.; Arias, A.; Lim, E.; Paque, F.; Almassi, S.; Hejlawy, S. Evaluation of dental students´skills acquisition in endodontics using a 3D printed tooth model. Eur. Endod. J. 2021, 6, 290–294. [Google Scholar]

- Whipple, S.J.; Kirkpatrick, T.C.; Rutledge, R.E. Cyclic fatigue resistance of two variable-taper rotary file systems: ProTaper universal and V-Taper. J. Endod. 2009, 35, 555–558. [Google Scholar] [CrossRef]

- Gambarini, G. Cyclic fatigue of nickel-titanium rotary instruments after clinical use with low- and high-torque endodontic motors. J. Endod. 2001, 27, 772–774. [Google Scholar] [CrossRef]

| Study Group | Speed | Torque/Direction | Movement |

|---|---|---|---|

| EDG | 250 rpm | 4 N/cm | Continuous rotational |

| PMP | 250 rpm | 4 N/cm | Continuous rotational |

| ST | 350 rpm | 170° CCW/50° CW | Reciprocant |

| Spectrum | C | O | Ti | Ni |

|---|---|---|---|---|

| EDG 15 kV (1–3) | 27.66 | 24.05 | 25.98 | 22.31 |

| PMP 15 kV (1–3) | 28.79 | 39.78 | 17.32 | 14.10 |

| ST 15 kV (1–3) | 29.57 | 27.57 | 22.69 | 20.18 |

| EDG 20 kV (1–3) | 45.60 | 25.41 | 16.13 | 12.86 |

| PMP 20 kV (1–3) | 30.74 | 38.79 | 16.44 | 14.03 |

| ST 20 kV (1–3) | 30.64 | 24.79 | 22.45 | 22.11 |

| Study Group | P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | P9 |

|---|---|---|---|---|---|---|---|---|---|

| EDG | 26.7 | 23.3 | 21.9 | 18.3 | 15.1 | 13.6 | |||

| PMP | 25.5 | 25.4 | 26 | 24.9 | 25.7 | 26.3 | 26 | 26.6 | 25.2 |

| ST | 35.8 | 33.7 | 32.7 | 31.2 | 28 | 25.5 | 22.3 | 20.2 | 17.1 |

| n | Mean | SD | Minimum | Maximum | |

|---|---|---|---|---|---|

| EDG | 10 | 420.78 a | 5.83 | 413.00 | 431.10 |

| PMP | 10 | 463.97 b | 7.55 | 455.90 | 477.50 |

| ST | 10 | 675.95 c | 8.07 | 664.70 | 689.60 |

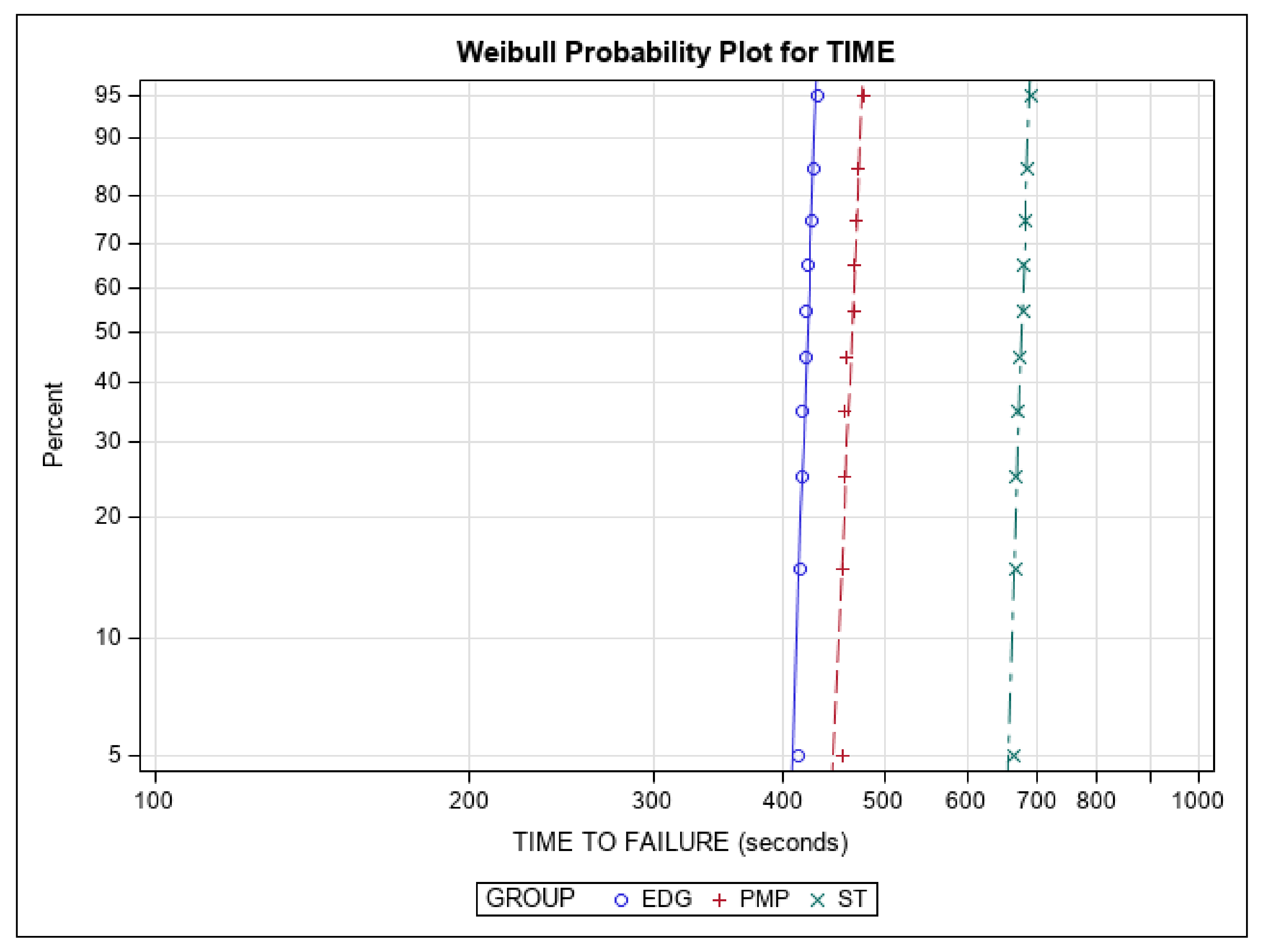

| Weibull Shape (β) | Weibull Scale (η) | |||||||

|---|---|---|---|---|---|---|---|---|

| Study Group | Estimate | Std. Error | Lower | Upper | Estimate | Std. Error | Lower | Upper |

| EDG | 76.9 | 18.0 | 48.5 | 121.9 | 423.5 | 1.8 | 419.9 | 427.2 |

| PMP | 65.6 | 15.4 | 41.4 | 104.1 | 467.6 | 2.3 | 462.9 | 472.3 |

| ST | 91.1 | 21.6 | 57.2 | 145.2 | 679.8 | 2.5 | 674.9 | 684.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faus-Matoses, V.; Pérez García, R.; Faus-Llácer, V.; Faus-Matoses, I.; Alonso Ezpeleta, Ó.; Albaladejo Martínez, A.; Zubizarreta-Macho, Á. Comparative Study of the SEM Evaluation, EDX Assessment, Morphometric Analysis, and Cyclic Fatigue Resistance of Three Novel Brands of NiTi Alloy Endodontic Files. Int. J. Environ. Res. Public Health 2022, 19, 4414. https://doi.org/10.3390/ijerph19074414

Faus-Matoses V, Pérez García R, Faus-Llácer V, Faus-Matoses I, Alonso Ezpeleta Ó, Albaladejo Martínez A, Zubizarreta-Macho Á. Comparative Study of the SEM Evaluation, EDX Assessment, Morphometric Analysis, and Cyclic Fatigue Resistance of Three Novel Brands of NiTi Alloy Endodontic Files. International Journal of Environmental Research and Public Health. 2022; 19(7):4414. https://doi.org/10.3390/ijerph19074414

Chicago/Turabian StyleFaus-Matoses, Vicente, Raúl Pérez García, Vicente Faus-Llácer, Ignacio Faus-Matoses, Óscar Alonso Ezpeleta, Alberto Albaladejo Martínez, and Álvaro Zubizarreta-Macho. 2022. "Comparative Study of the SEM Evaluation, EDX Assessment, Morphometric Analysis, and Cyclic Fatigue Resistance of Three Novel Brands of NiTi Alloy Endodontic Files" International Journal of Environmental Research and Public Health 19, no. 7: 4414. https://doi.org/10.3390/ijerph19074414

APA StyleFaus-Matoses, V., Pérez García, R., Faus-Llácer, V., Faus-Matoses, I., Alonso Ezpeleta, Ó., Albaladejo Martínez, A., & Zubizarreta-Macho, Á. (2022). Comparative Study of the SEM Evaluation, EDX Assessment, Morphometric Analysis, and Cyclic Fatigue Resistance of Three Novel Brands of NiTi Alloy Endodontic Files. International Journal of Environmental Research and Public Health, 19(7), 4414. https://doi.org/10.3390/ijerph19074414