Numerical Investigation of Safety Strategy for Gas Disaster Prevention in Successive Panels Using Upper Protective Layer Mining: A Case Study

Abstract

:1. Introduction

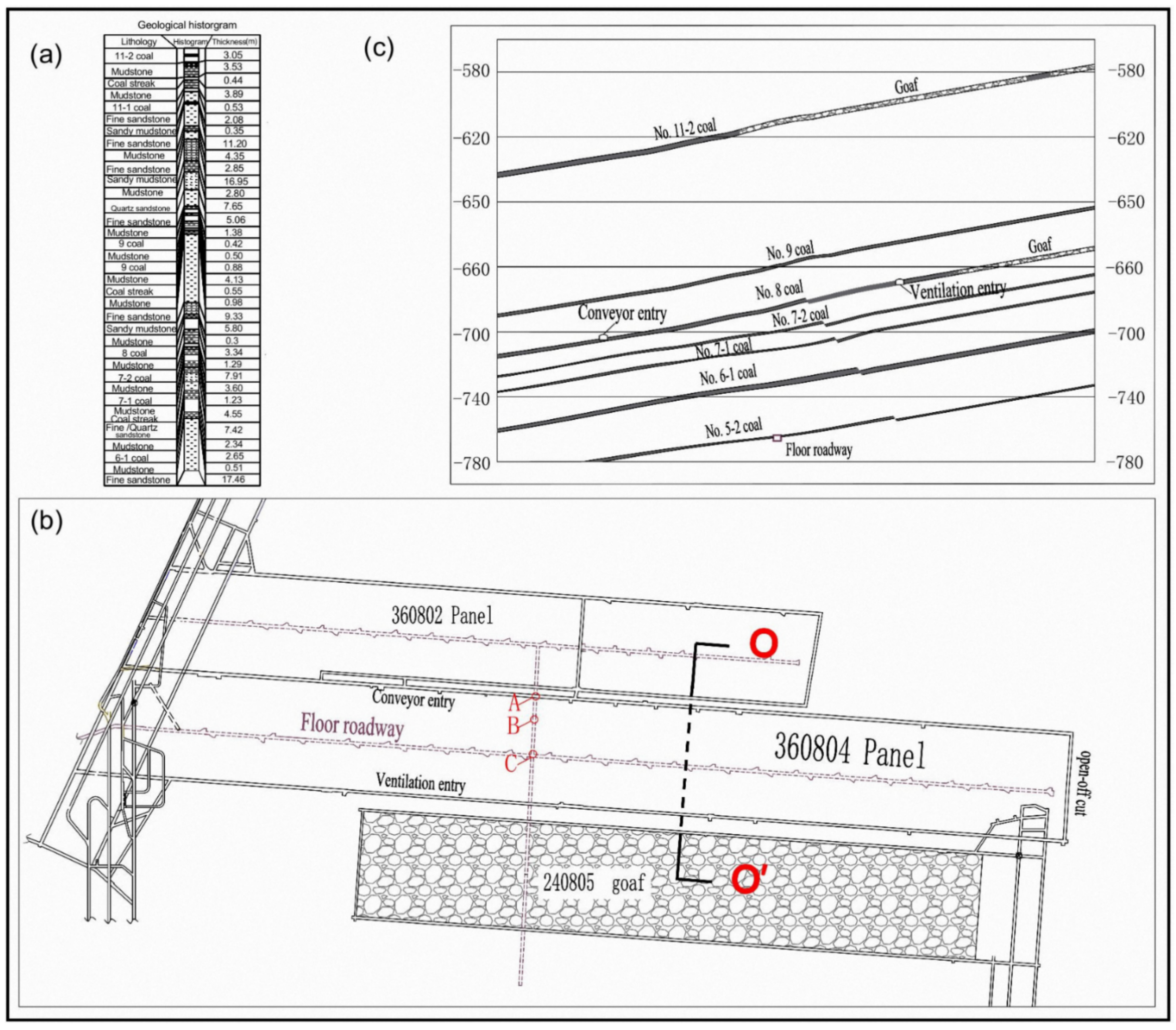

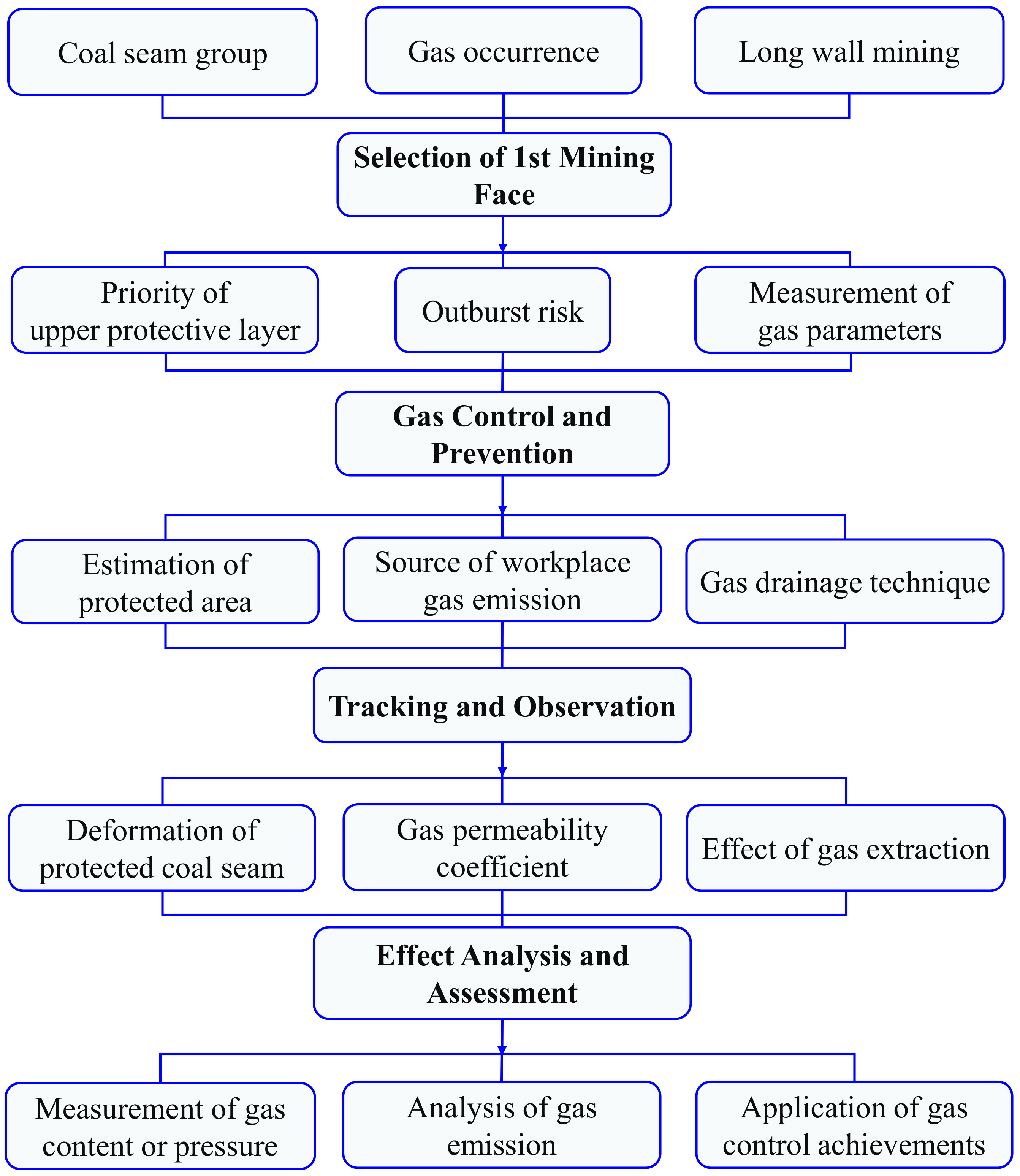

2. Investigation Scheme and Details

2.1. Selection of First Mining Face

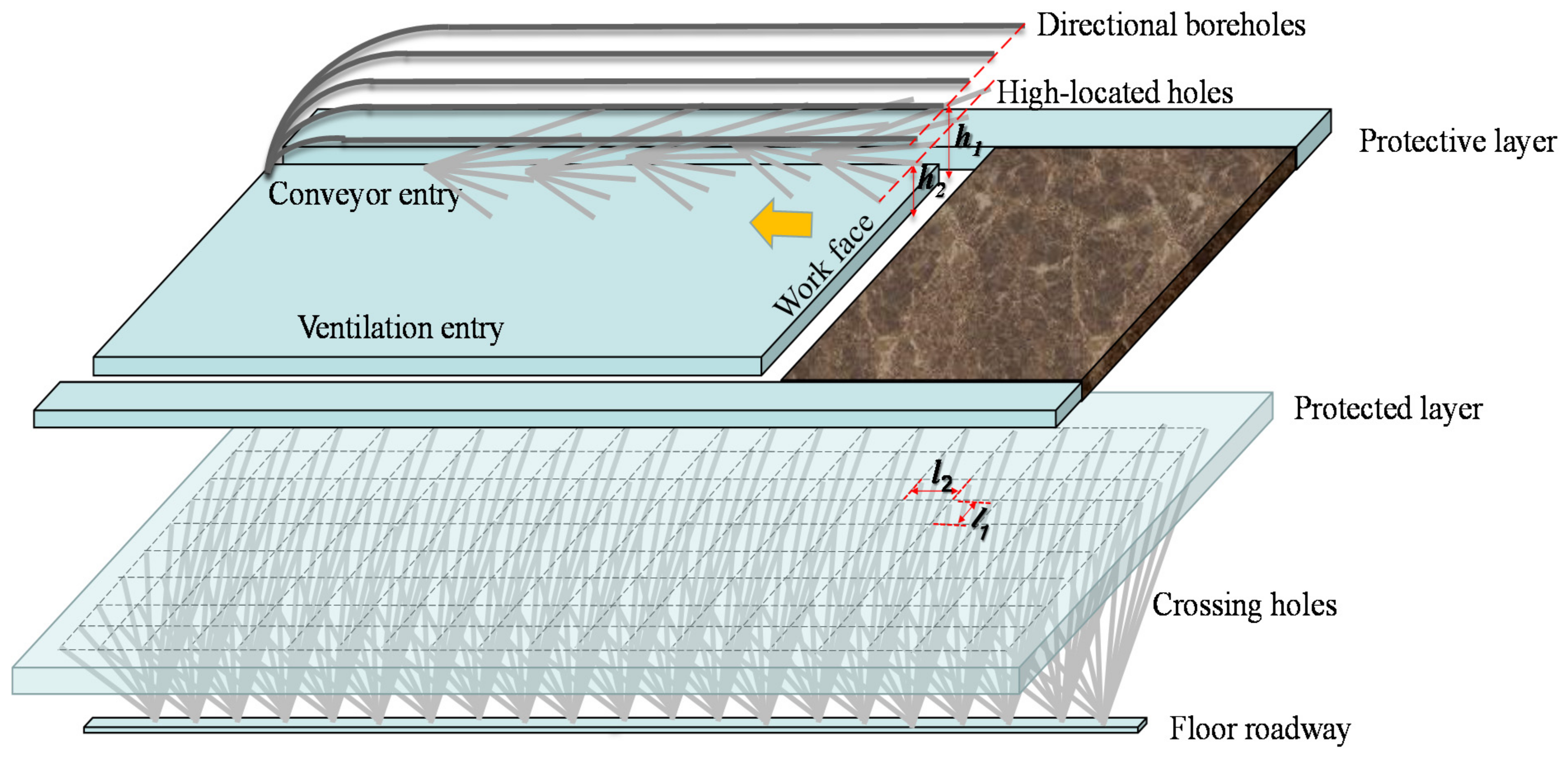

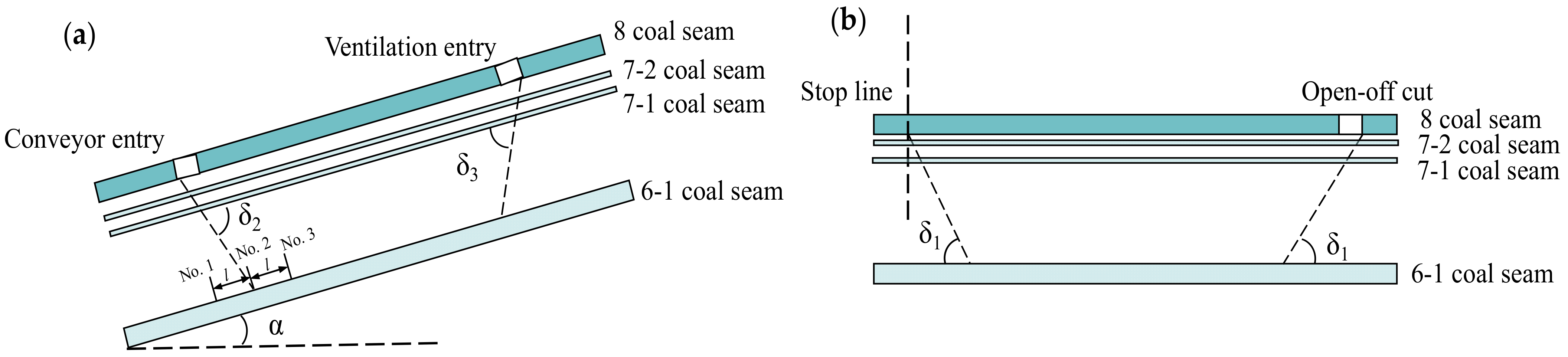

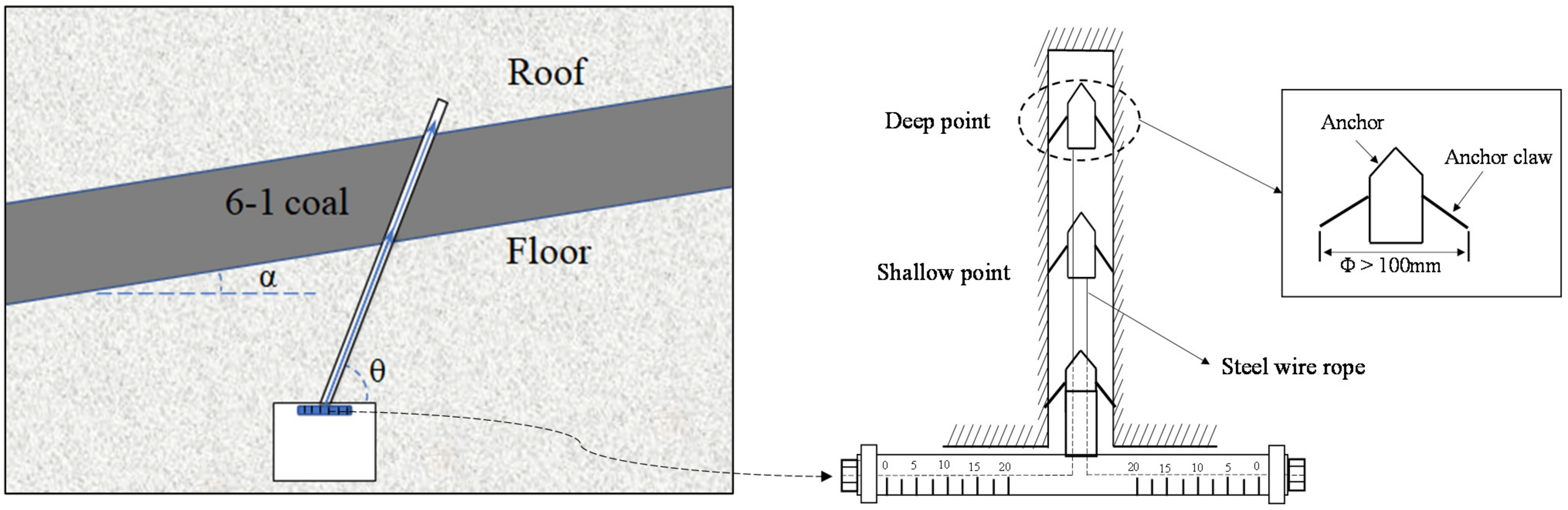

2.2. Gas Disaster Control and Prevention

2.3. Tracking and Observations

2.3.1. Observation of Coal Deformation

2.3.2. Permeability Coefficient Test

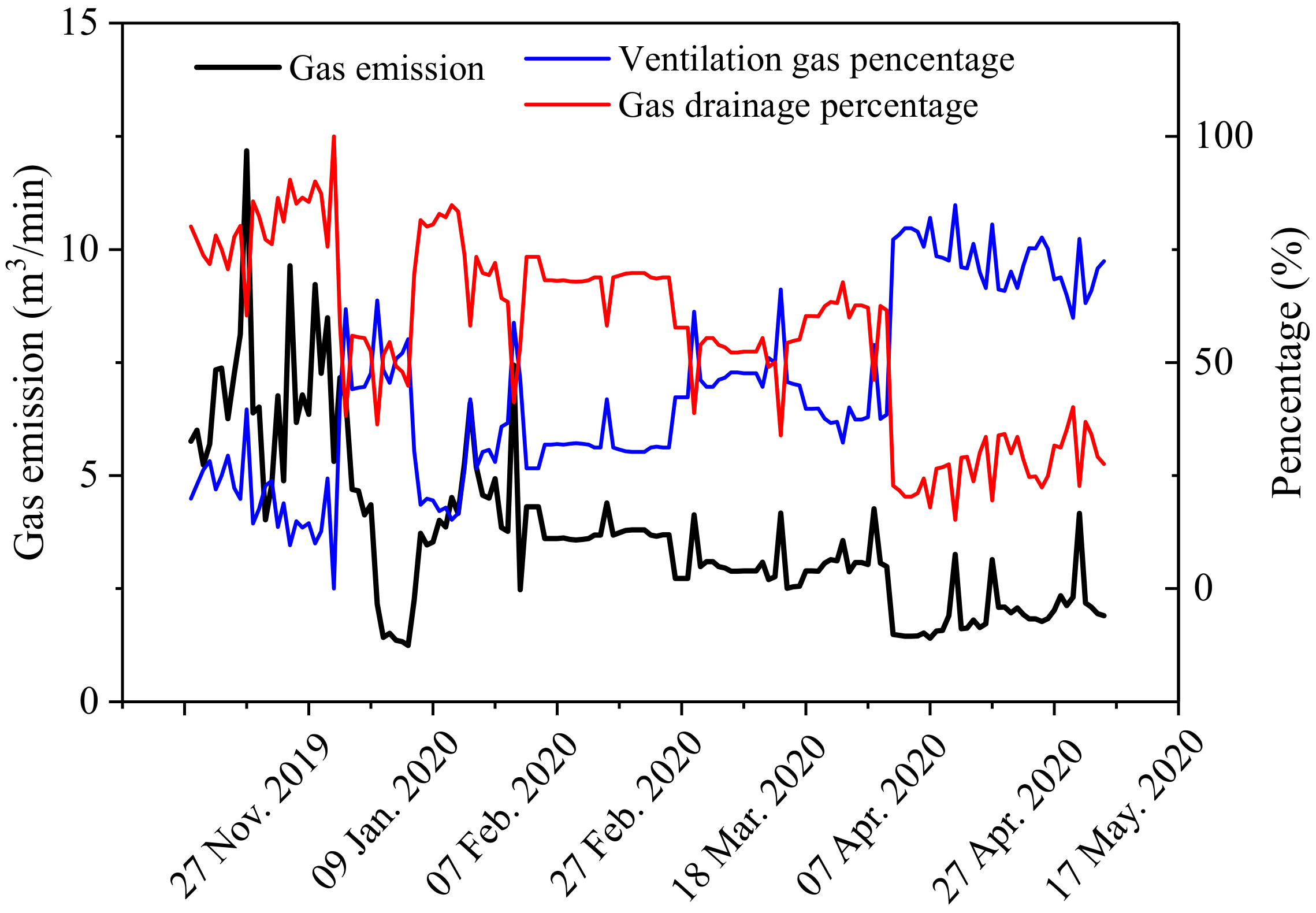

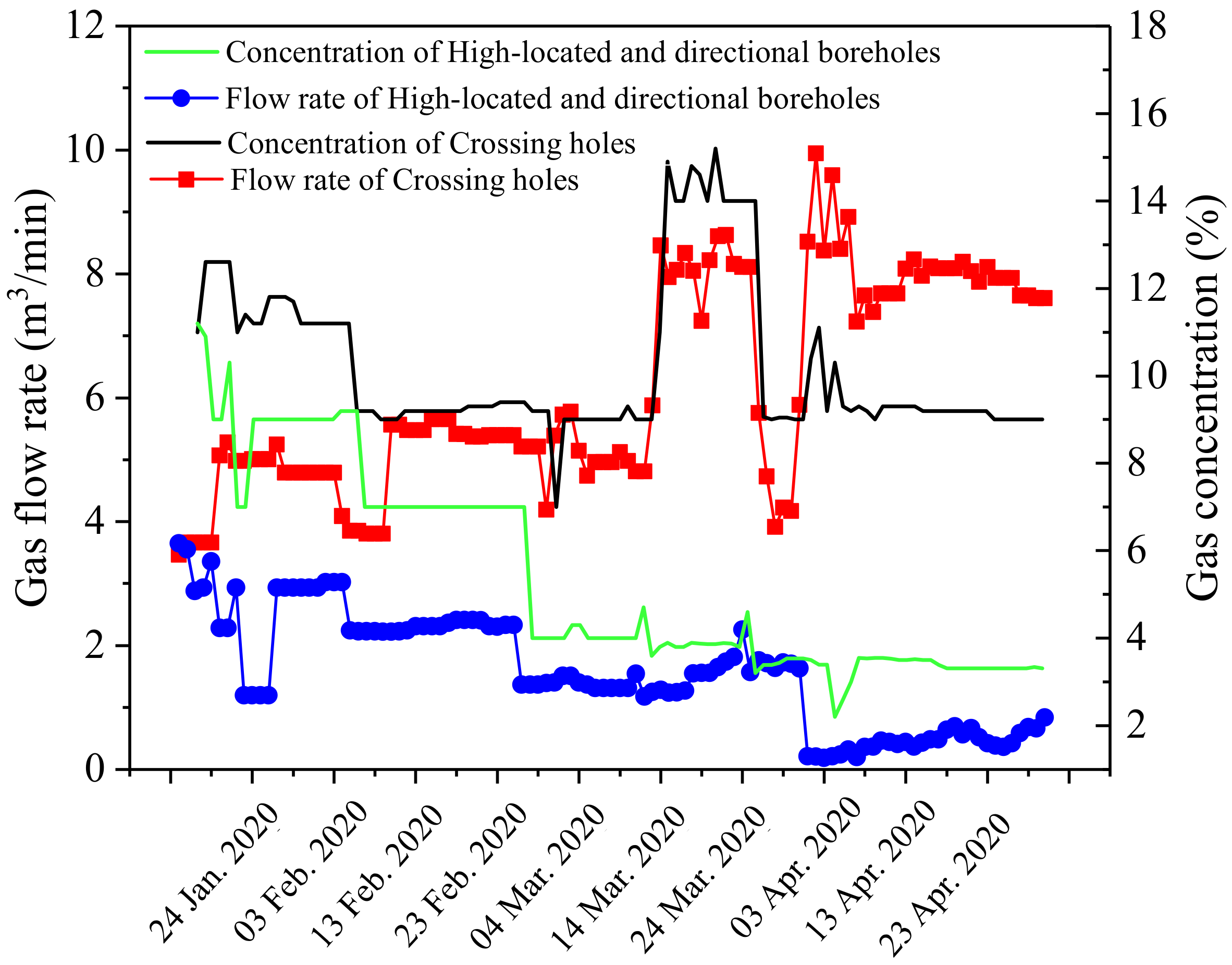

2.3.3. Observation of Gas Emission and Extraction

2.4. Effect Analysis and Assessment

3. Numerical Modeling

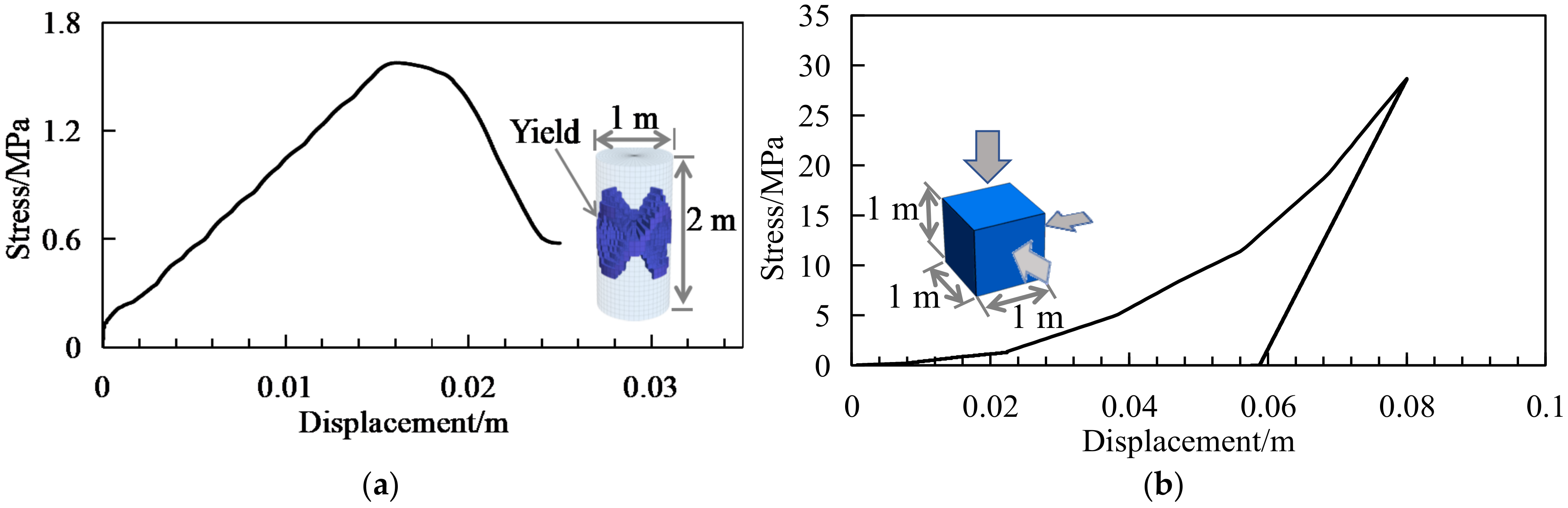

3.1. A Stability Assessment Model for Coal and Rock

3.1.1. Strain-Softening Mohr–Coulomb Model

3.1.2. Double-Yield Model

3.1.3. Permeability Evolution Equation

3.2. Global Model and Simulation Plans

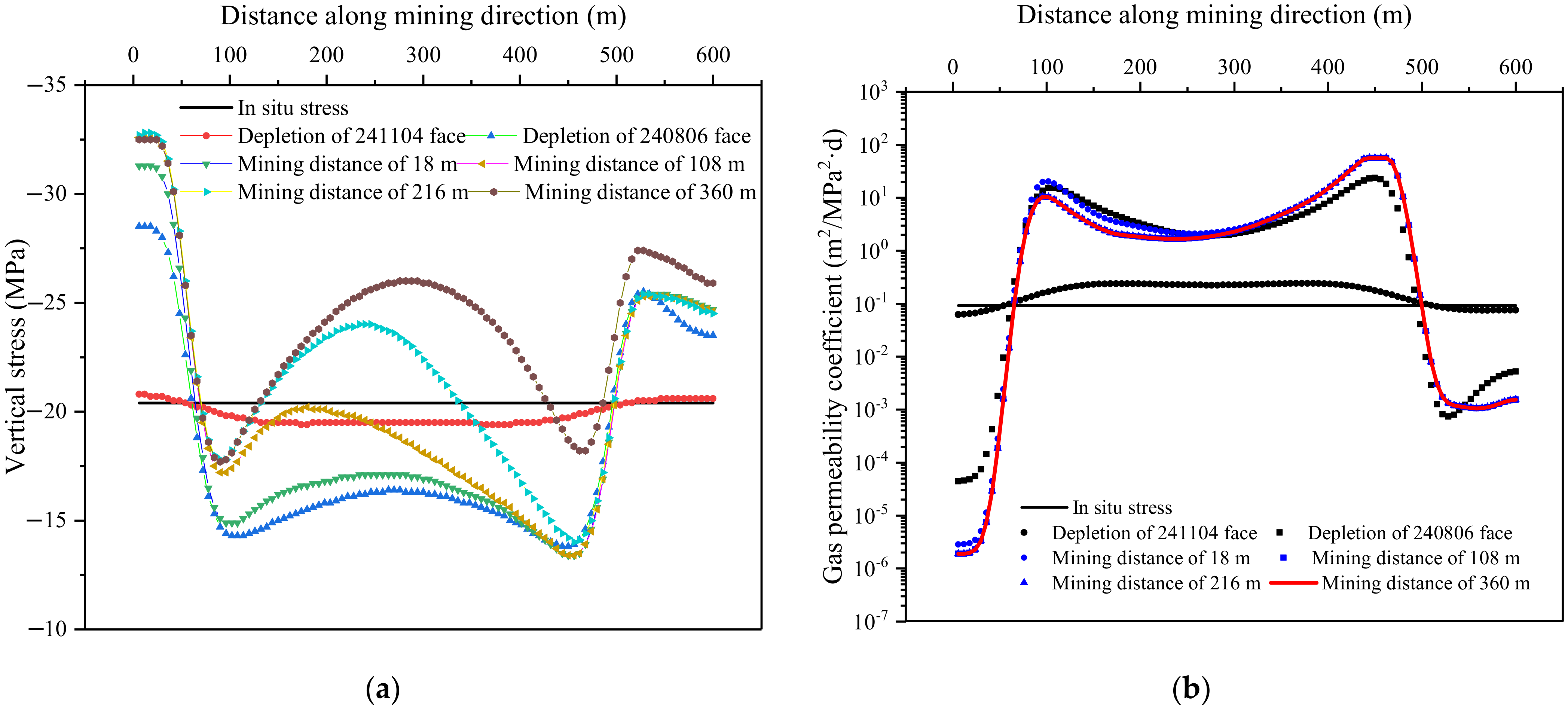

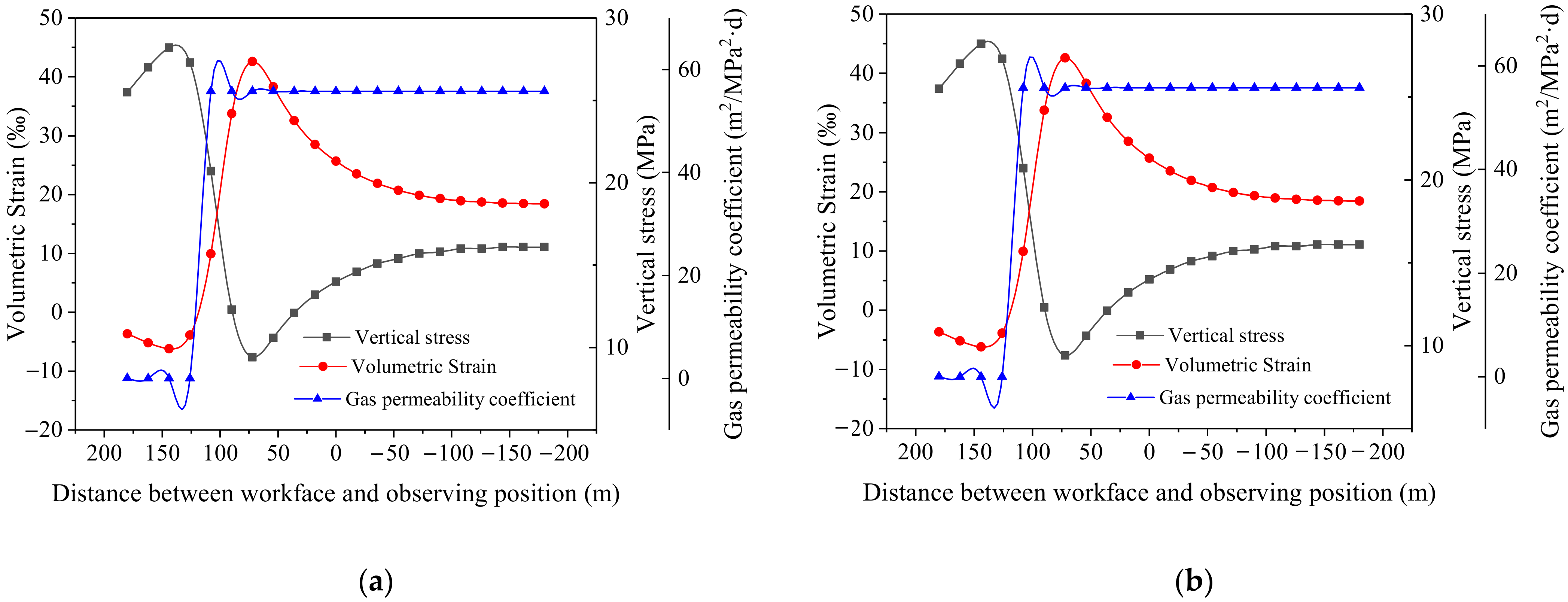

3.3. Distribution of Stress and Gas Permeability Coefficient in No. 6-1 Coal

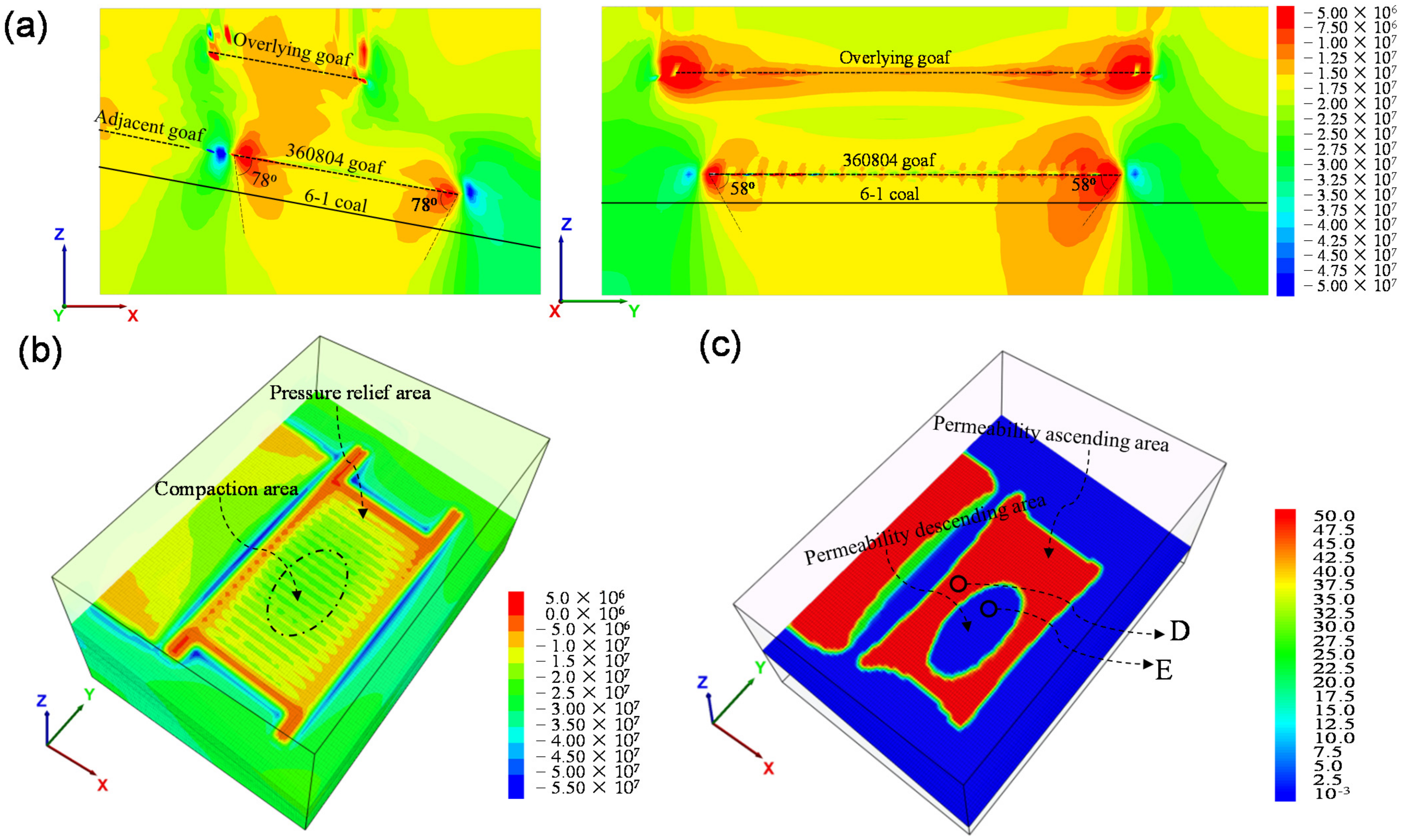

3.4. Evolution of Mining Disturbance for No. 6-1 Coal

4. Field Application and Analysis

5. Discussion

6. Conclusions

- (1)

- The regularity of permeability within the protected layer was verified spatially by means of coal deformation and stress evolution. The maximum compressional and expansional deformation of the 6-1 coal were 18‰ and 28‰, respectively. The gas-permeability coefficient of the 6-1 coal underwent a decrease, an increase and finally stabilized. The high-permeability-coefficient area presented an “O-shape” distribution in the coal seam, and the maximum value was 55.8 m2/(MPa2·d).

- (2)

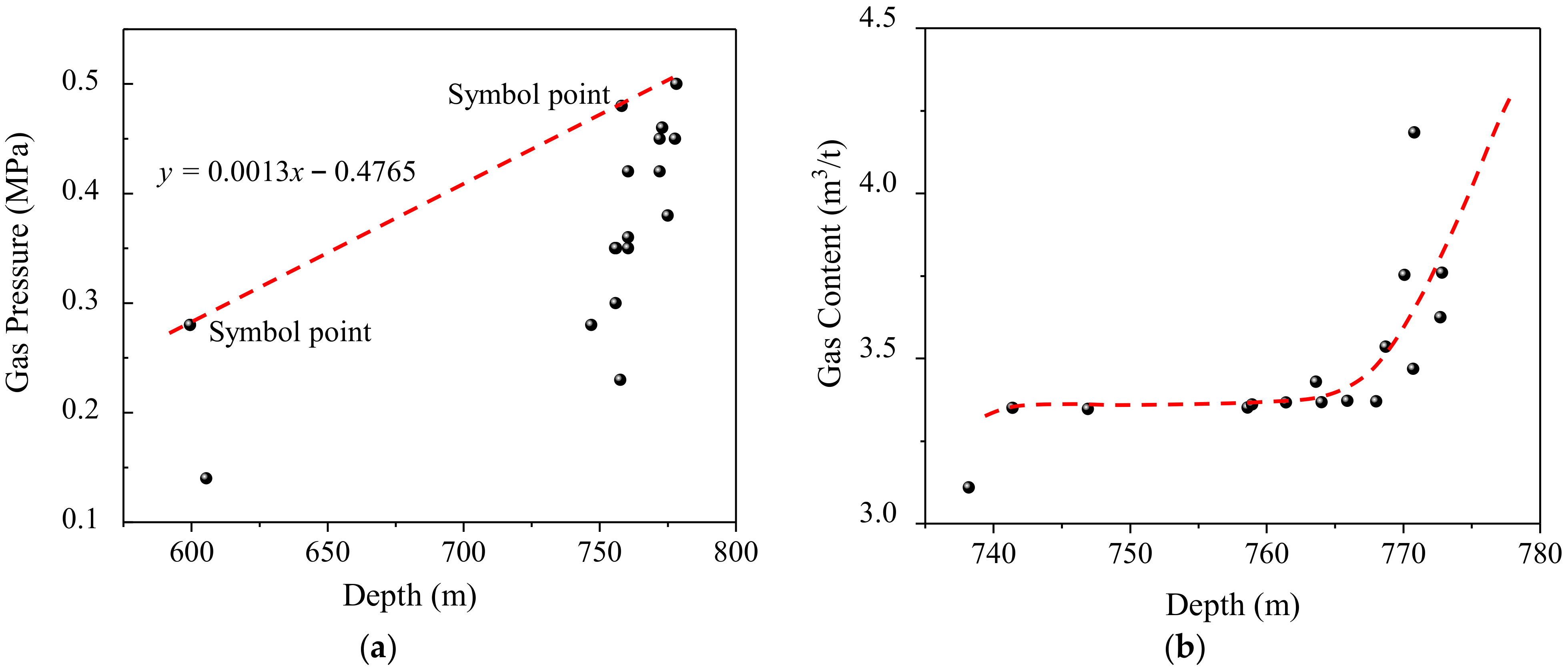

- Applying gas disaster control and prevention treatments to the 360804 mining face produced significant protective effects on the underlying No. 6-1 coal seam. The residual gas content and pressure in the area, determined by the dip-pressure-relief angle of 78° and the strike-pressure-relief angle of 58°, were reduced to far less than the threshold values. The treatments, utilizing the mining effect and adopting the pre-drainage technology of crossing holes, played a very effective role in reducing the gas emission in the mining face and eliminating the outburst risk of 6-1 coal.

- (3)

- The procedures, methods and results of the investigation are instructive for subsequent applications in other work faces with similar geological conditions. Reasonable prediction of gas occurrence can further improve the guiding role of the investigation results. All of this adds up to a safety strategy that is beneficial to the planning of gas control in successive panels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- BP Amoco. BP Energy Outlook 2020. 2020. Available online: https://www.bp.com/en/global/corporate/news-and-insights/press-releases/bp-energy-outlook-2020.html (accessed on 4 April 2020).

- Wang, L.; Liu, S.; Cheng, Y.; Yin, G.; Zhang, D.; Guo, P. Reservoir reconstruction technologies for coalbed methane recovery in deep and multiple seams. Int. J. Min. Sci. Technol. 2017, 27, 277–284. [Google Scholar] [CrossRef]

- Kang, H.P. Spatial scale analysis on coal mining and strata control technologies. J. Min. Strat. Control Eng. 2020, 2, 023538. [Google Scholar]

- Qin, Z.; Yuan, L.; Guo, H.; Qu, Q. Investigation of longwall goaf gas flows and borehole drainage performance by CFD simulation. Int. J. Coal Geol. 2015, 150, 51–63. [Google Scholar] [CrossRef]

- Flores, R.M. Coalbed methane: From hazard to resource. Int. J. Coal Geol. 1998, 35, 3–26. [Google Scholar] [CrossRef]

- Karacan, C.O.; Ruiz, F.A.; Cote, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Yin, G.; Li, M.; Wang, J.G.; Xu, J.; Li, W. Mechanical behavior and permeability evolution of gas infiltrated coals during protective layer mining. Int. J. Rock Mech. Min. 2015, 80, 292–301. [Google Scholar] [CrossRef]

- Fernandez-Diaz, J.J.; Gonzalez-Nicieza, C.; Alvarez-Fernandez, M.I.; Lopez-Gayarre, F. Analysis of gas-dynamic phenomenon in underground coal mines in the central basin of Asturias (Spain). Eng. Fail. Anal. 2013, 34, 464–477. [Google Scholar] [CrossRef]

- Durucan, S.; Daltaban, T.; Shi, J.; Foley, L. Permeability characterisation for modelling methane flow in coal seams. In Proceedings of the 1993 International Coalbed Methane Symposium, Tuscaloosa, AL, USA, 17–21 May 1993. [Google Scholar]

- Si, G.; Shi, J.-Q.; Durucan, S.; Korre, A.; Lazar, J.; Jamnikar, S.; Zavšek, S. Monitoring and modelling of gas dynamics in multi-level longwall top coal caving of ultra-thick coal seams, Part II: Numerical modelling. Int. J. Coal Geol. 2015, 144–145, 58–70. [Google Scholar] [CrossRef]

- Connell, L.D. Coupled flow and geomechanical processes during gas production from coal seams. Int. J. Coal Geol. 2009, 79, 18–28. [Google Scholar] [CrossRef]

- Liu, H.H.; Rutqvist, J. A New Coal-Permeability Model: Internal Swelling Stress and Fracture-Matrix Interaction. Transp. Porous. Med. 2010, 82, 157–171. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.D.; Cheng, Y.P.; Ren, T.X.; Zhou, H.X.; Liu, Q.Q. Permeability distribution characteristics of protected coal seams during unloading of the coal body. Int. J. Rock. Mech. Min. 2014, 71, 105–116. [Google Scholar] [CrossRef]

- Zhou, S.N.; Lin, B.Q. The Theory of Gas Flow and Storage in Coal Seams, 1st ed.; China Coal Industry Publishing House: Beijing, China, 1999; pp. 153–156. [Google Scholar]

- National Mine Safety Administration. MTT 1173-2019 Measuring Method for Gas Permeability Coefficient of Coal Seam—Radial Flow Method; China Coal Industry Publishing House: Beijing, China, 2019. [Google Scholar]

- China State Administration of Work Safety. Detailed Rules for Prevention and Control of Coal and Gas Outburst; Coal Industry Press: Beijing, China, 2019; Volume 41, pp. 122–129. [Google Scholar]

- Guo, H.; Yuan, L.; Shen, B.T.; Qu, Q.D.; Xue, J.H. Mining-induced strata stress changes, fractures and gas flow dynamics in multi-seam longwall mining. Int. J. Rock Mech. Min. 2012, 54, 129–139. [Google Scholar] [CrossRef]

- Xu, C.; Cheng, Y.; Ren, T.; Wang, L.; Kong, S.; Lu, S. Gas ejection accident analysis in bed splitting under igneous sills and the associated control technologies: A case study in the Yangliu mine, Huaibei coalfield, China. Nat. Hazards 2013, 71, 109–134. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Z.; Chen, D.; Liu, Q.; Chu, P.; Shu, L.; Ullah, B.; Wen, Z. Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 2020, 129, 104800. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, L.; Zhou, H.; Kong, S. Reservoir Reconstruction Technology for Coalbed Methane Development in Deep Coal Seam Groups. Int. J. Min. Sci. Technol. 2015, 27, 277–284. [Google Scholar]

- Yuan, L. Control of coal and gas outbursts in Huainan mines in China: A review. J. Rock Mech. Geotechnol. 2016, 8, 559–567. [Google Scholar] [CrossRef] [Green Version]

- Norbert, S. Estimating gas and rock outburst risk on the basis of knowledge and experience—The expert system based on fuzzy logic. Arch. Min. Sci. 2014, 59, 41–52. [Google Scholar]

- Díaz Aguado, M.B.; González Nicieza, C. Control and prevention of gas outbursts in coal mines, Riosa-Olloniego coalfield, Spain. Int. J. Coal. Geol. 2007, 69, 253–266. [Google Scholar] [CrossRef]

- Lama, R.D.; Bodziony, J. Management of outburst in underground coal mines. Int. J. Coal. Geol. 1998, 35, 83–115. [Google Scholar] [CrossRef]

- Harvey, C.R.; Singh, R.N. A review of fatal outburst incidents in the Bulli Seam. In Proceedings of the Coal 1998: Coal Operators’ Conference, Wollongong, Australia, 18–20 February 1988. [Google Scholar]

- Yan, F.; Lin, B.; Zhu, C.; Shen, C.; Zou, Q.; Guo, C.; Liu, T. A novel ECBM extraction technology based on the integration of hydraulic slotting and hydraulic fracturing. J. Nat. Gas Sci. Eng. 2015, 22, 571–579. [Google Scholar] [CrossRef]

- Lin, B.Q.; Yan, F.Z.; Zhu, C.J.; Zhou, Y.; Zou, Q.L.; Guo, C.; Liu, T. Cross-borehole hydraulic slotting technique for preventing and controlling coal and gas outbursts during coal roadway excavation. J. Nat. Gas Sci. Eng. 2015, 26, 518–525. [Google Scholar] [CrossRef]

- Zhang, R.; Cheng, Y.; Zhou, H.; Yuan, L.; Li, W.; Liu, Q.; Jin, K.; Tu, Q. New insights into the permeability-increasing area of overlying coal seams disturbed by the mining of coal. J. Nat. Gas Sci. Eng. 2018, 49, 352–364. [Google Scholar] [CrossRef]

- China State Administration of Work Safety. AQ1018-2006 The Predicted Method of Mine Gas Emission Rate; Coal Industry Press: Beijing, China, 2006; pp. 154–155. [Google Scholar]

- Black, D.J.; Aziz, N.I. Gas drainage improvement in underground coal mines. In Proceedings of the 1st ASIA Pacific Coalbed Methane Symposium, Brisbane, Australia, 22–24 September 2008. [Google Scholar]

- Lunarzewski, L.W. Gas Drainage Practices. In Proceedings of the 2001 Coal Operators’ Conference, Wollongong, Australia, 15 February 2001. [Google Scholar]

- Wang, S.L.; Hao, S.P.; Chen, Y.; Bai, J.B.; Wang, X.Y.; Xu, Y. Numerical investigation of coal pillar failure under simultaneous static and dynamic loading. Int. J. Rock. Mech. Min. 2016, 84, 59–68. [Google Scholar] [CrossRef]

- Esterhuizen, E.; Mark, C.; Engineer, P.; Engineer, M.; Murphy, M. Numerical Model Calibration for Simulating Coal Pillars, Gob and Overburden Response. In Proceedings of the 29th International Conference on Ground Control in Mining, Morgantown, WV, USA, 27–29 July 2010. [Google Scholar]

- Sherizadeh, T.; Kulatilake, P.H.S.W. Assessment of roof stability in a room and pillar coal mine in the U.S. using three-dimensional distinct element method. Tunn. Undergr. Space Technol. 2016, 59, 24–37. [Google Scholar] [CrossRef] [Green Version]

- Yavuz, H. An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int. J. Rock. Mech. Min. 2004, 41, 193–205. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, P.; Chen, L.; Hao, Z.; Sainoki, A.; Mitri, H.S.; Wang, Q. Numerical Approach for Goaf-Side Entry Layout and Yield Pillar Design in Fractured Ground Conditions. Rock. Mech. Rock. Eng. 2017, 50, 3049–3071. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Elsworth, D.; Qu, H.; Chen, D. Interactions of multiple processes during CBM extraction: A critical review. Int. J. Coal Geol. 2011, 87, 175–189. [Google Scholar] [CrossRef]

- Ma, Y.K.; He, X.Q.; Li, Z.H. A unified model with solid-fluid transition for coal and gas outburst and FEMLIP modeling. Tunn. Undergr. Space Technol. 2020, 99, 103349. [Google Scholar]

- Xue, S.; Wang, Y.C.; Xie, J.; Wang, G. A coupled approach to simulate initiation of outbursts of coal and gas—Model development. Int. J. Coal. Geol. 2011, 86, 222–230. [Google Scholar] [CrossRef]

- Zhang, R.; Ju, Y.J.; Peng, H.; Jiang, C.L. Analysis on Ground Stress Measurement and Application in Xinji No11 Mine. Coal Sci. Technol. 2010, 38, 15–21. [Google Scholar] [CrossRef]

- Mohammad, N.; Reddish, D.J.; Stace, L.R. The relation between in situ and laboratory rock properties used in numerical modelling. Int. J. Rock. Mech. Min. 1997, 34, 289–297. [Google Scholar] [CrossRef]

- Balusu, R.; Belle, B.; Tanguturi, K. Development of Goaf Gas Drainage and Inertisation Strategies in 1.0-km- and 3.0-km-Long Panels. Min. Metall. Explor. 2019, 36, 1127–1136. [Google Scholar] [CrossRef]

- Lolon, S.A.; Brune, J.F.; Bogin, G.E.; Juganda, A. Study of Methane Outgassing and Mitigation in Longwall Coal Mines. Min. Metall. Explor. 2020, 37, 1437–1449. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.P.; Wang, L.; Guo, P.K.; Li, W. Safety line method for the prediction of deep coal-seam gas pressure and its application in coal mines. Saf. Sci. 2012, 50, 523–529. [Google Scholar] [CrossRef]

- Burra, A.; Esterle, J. Gas distribution and geology: A Hunter Valley example. In Proceedings of the 38th Symposium on the Advances in the Study of the Sydney Basin, Hunter Valley, Australia, 10–11 May 2012. [Google Scholar]

| Coal Seam | Thickness, m | Gas Pressure, MPa | Gas Content, m3/t | Coal Hardiness Coefficient | Initial Velocity of Diffusion of Coal Gas |

|---|---|---|---|---|---|

| No. 6-1 | 2.65 | 0.48 | 4.23 | 0.37 | 9 |

| No. 7 | 2.52 | 0.3 | 2.45 | 0.37 | 6 |

| No. 8 | 3.34 | 0.4 | 3.51 | 0.27 | 7 |

| No. 9 | 1.3 | 0.4 | 3.28 | 0.37 | 6 |

| Parameters | Value |

|---|---|

| Rock emission coefficient, | 1.3 |

| Coal drop coefficient, | 1.08 |

| Preparatory workings discharge coefficient, | 0.86 |

| Mining height, , m | 3 |

| Original gas content of No. 8 coal, , m3/t | 3.51 |

| Residual gas content of No. 8 coal, , m3/t | 0.63 |

| Original gas content of No. 6-1 coal, , m3/t | 4.23 |

| Residual gas content of No. 6-1 coal, , m3/t | 0.74 |

| Seam thickness, m, m | 3 |

| Emission ratio of no. 6-1 coal, | 0.25 |

| Original gas content of No. 7 coal, , m3/t | 2.45 |

| Residual gas content of no. 7 coal, , m3/t | 0.55 |

| Emission ratio of No. 7 coal, | 0.5 |

| Original gas content of No. 9 coal, , m3/t | 3.28 |

| Residual gas content of No. 9 coal, , m3/t | 0.62 |

| Emission ratio of No. 9 coal, | 0.9 |

| Lithology | Density, kg/m3 | Bulk Modulus, GPa | Shear Modulus, GPa | Cohesion, MPa | Friction, ° |

|---|---|---|---|---|---|

| Quartz sandstone | 2530 | 13.67 | 9.41 | 6.22 | 34.1 |

| Fine sandstone | 2550 | 8.05 | 24.79 | 6.3 | 36 |

| Mudstone | 2100 | 0.24 | 0.16 | 2.3 | 32 |

| Sandy mudstone | 2600 | 13.67 | 9.41 | 6.12 | 30 |

| Coal | 1400 | 0.23 | 1.91 | 0.3 | 32 |

| Goaf material | 1000 | 0.45 | 0.60 | 0 | 40 |

| Volume Strain/% | Friction/° | Cohesion/MPa |

|---|---|---|

| 0 | 35 | 0.4 |

| 0.03 | 20 | 0.2 |

| 0.1 | 10 | 0.01 |

| Volume Strain, % | Cap Pressure, MPa | Volume Strain, % | Cap Pressure, MPa |

|---|---|---|---|

| 0 | 0.01 | 0.12 | 8.5 |

| 0.02 | 0.2 | 0.14 | 11.5 |

| 0.04 | 0.8 | 0.16 | 19 |

| 0.06 | 1.3 | 0.18 | 34 |

| 0.1 | 5.5 | 0.2 | 50 |

| No. | Site | Gas Content, m3/t | Gas Pressure, MPa |

|---|---|---|---|

| 1 | 360604 floor auxiliary roadway (in Figure 1 site A) | 1.97 | 0.1 |

| 2 | 360604 floor auxiliary roadway (in Figure 1 site A) | -- | 0.1 |

| 3 | 360604 floor auxiliary roadway (in Figure 1 site A) | 2.01 | 0.1 |

| 4 | 360604 floor roadway (in Figure 1 site C) | 2.01 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Shu, L.; Li, H.; Cui, C.; Zhou, Y.; Li, Y. Numerical Investigation of Safety Strategy for Gas Disaster Prevention in Successive Panels Using Upper Protective Layer Mining: A Case Study. Int. J. Environ. Res. Public Health 2022, 19, 4408. https://doi.org/10.3390/ijerph19074408

Ma Y, Shu L, Li H, Cui C, Zhou Y, Li Y. Numerical Investigation of Safety Strategy for Gas Disaster Prevention in Successive Panels Using Upper Protective Layer Mining: A Case Study. International Journal of Environmental Research and Public Health. 2022; 19(7):4408. https://doi.org/10.3390/ijerph19074408

Chicago/Turabian StyleMa, Yankun, Longyong Shu, Hongyan Li, Cong Cui, Yang Zhou, and Yang Li. 2022. "Numerical Investigation of Safety Strategy for Gas Disaster Prevention in Successive Panels Using Upper Protective Layer Mining: A Case Study" International Journal of Environmental Research and Public Health 19, no. 7: 4408. https://doi.org/10.3390/ijerph19074408

APA StyleMa, Y., Shu, L., Li, H., Cui, C., Zhou, Y., & Li, Y. (2022). Numerical Investigation of Safety Strategy for Gas Disaster Prevention in Successive Panels Using Upper Protective Layer Mining: A Case Study. International Journal of Environmental Research and Public Health, 19(7), 4408. https://doi.org/10.3390/ijerph19074408