Impact of Recycler Information Sharing on Supply Chain Performance of Construction and Demolition Waste Resource Utilization

Abstract

:1. Introduction

2. Literature Review

2.1. CDW Management from the Perspective of Supply Chain Operation

2.1.1. Closed-Loop Supply Chain Aspects

2.1.2. Reverse Supply Chain Aspects

2.2. DRSC

2.3. Information Sharing

Aspects of the Impact of Information Sharing on Supply Chain Performance

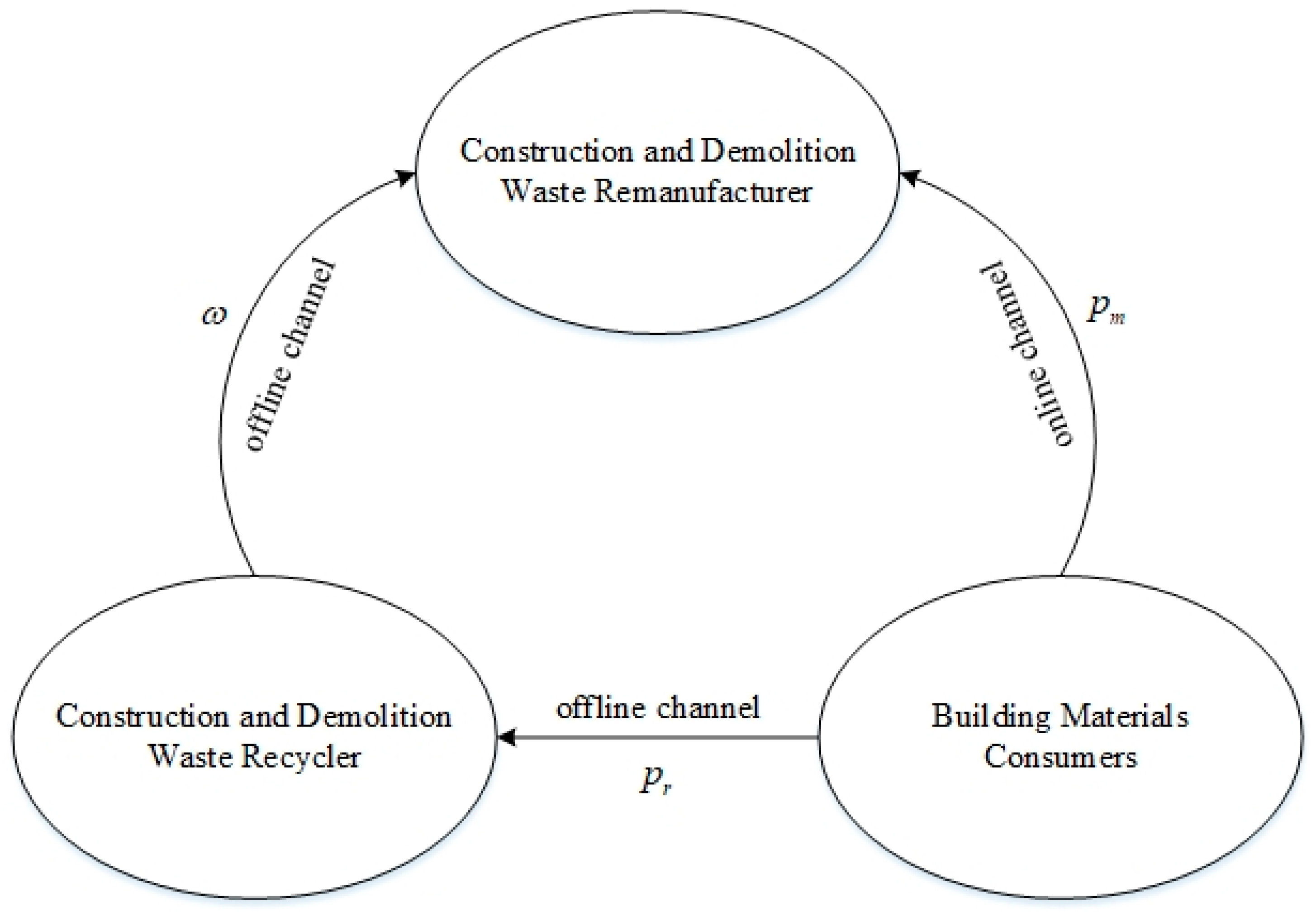

3. Problem Description and Associated Assumptions

3.1. Model Assumptions

- (1)

- (2)

- It is assumed that the common knowledge of the remanufacturer and recycler include the potential market demand . In addition to the recycler’s market demand forecast information is their private information, the recycler has the right to decide whether to share this information with the remanufacturer. The rest of the information is also common knowledge for the remanufacturer and recycler [42,43].

- (3)

- This paper mainly examines the recycling pricing of recyclers and remanufacturers in the CDW resource utilization supply chain and does not consider the sales pricing of the remanufactured products. Therefore, separate from the CDW recycling prices , and as decision variables, it is assumed that the market sales price of CDW remanufactured products is a constant .

- (4)

- The CDW that is recovered by the remanufacturer through offline channels is fully provided by the recycler and all of the CDW that is recovered through any means can be used for remanufacturing [44,45]. There is no difference in quality between the remanufactured products that are produced by the remanufacturer using CDW and new products that are produced from the raw materials [42,46]; that is, the CDW that is recycled through dual channels does not affect the quality of offline new product construction materials. However, these remanufactured products are superior to new products in terms of their environmental and economic performance [47].

- (5)

- In the offline recycling channel, the recycler can recycle CDW through their well-established recycling network; in the online recycling channel, the remanufacturer can contact consumers in order for them to recycle their CDW through the Internet. Obviously, in the production and operation processes, neither the recycler nor the remanufacturer has a fixed cost input. Therefore, this study does not consider the fixed costs of the recycler and the remanufacturer.

3.2. Information Structure

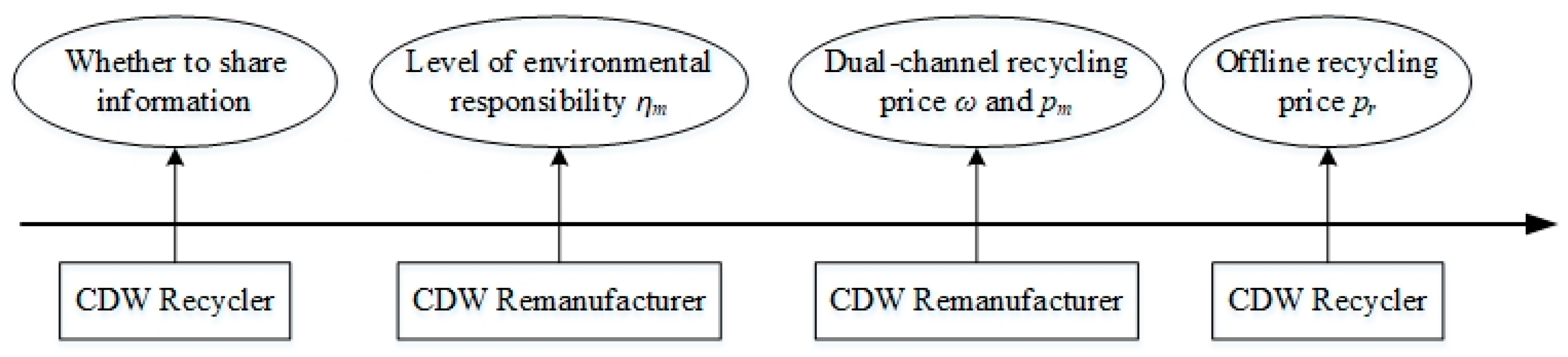

3.3. Game Order

4. Model Building and Solving

4.1. Recycler Information Is Not Shared

4.2. Recycler Information Sharing

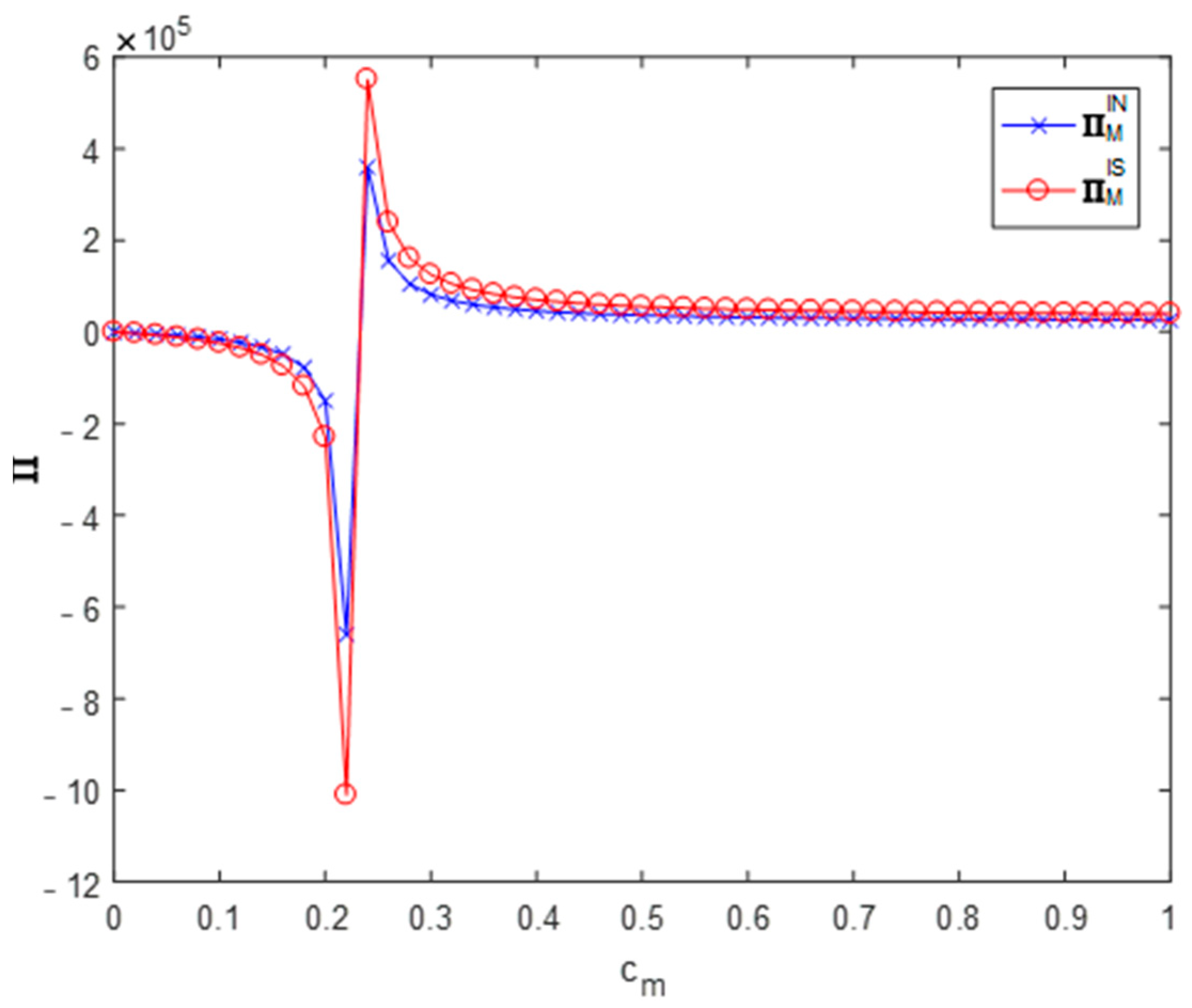

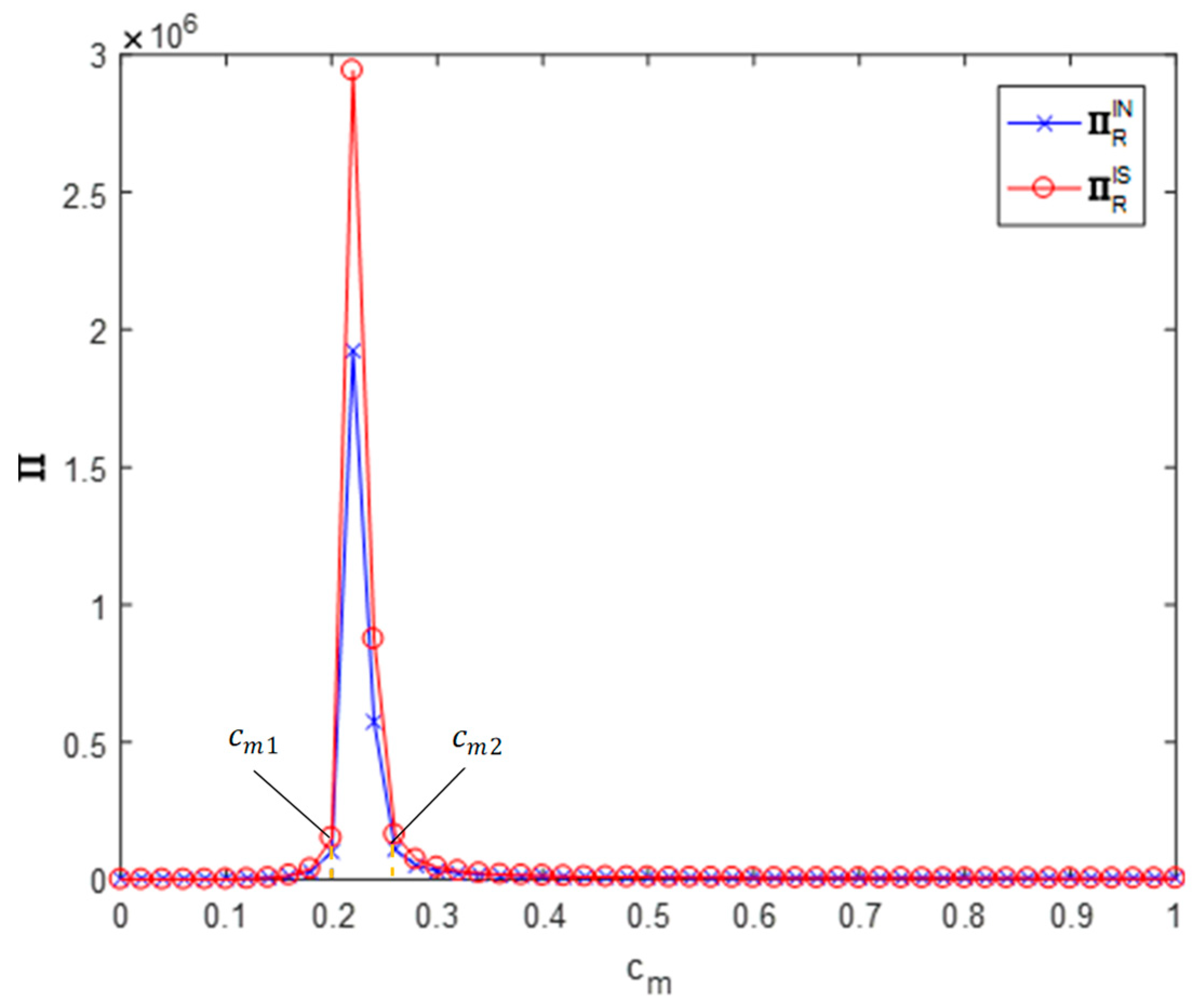

5. Model Analysis

- (1)

- When , information sharing will increase the profit of the recycler;

- (2)

- When , the impact of information sharing on the profit of the recycler is not significant.

- (1)

- When , information sharing will reduce the profit of the supply chain; when , information sharing will increase the profit of the supply chain; when , information sharing will increase the profit of the supply chain slightly but not significantly.

- (2)

- When , information sharing will increase the profit of the supply chain.

- (3)

- When , information sharing will increase the profit of the supply chain; when , information sharing will reduce the profit of the supply chain.

- (1)

- ;

- (2)

- and.

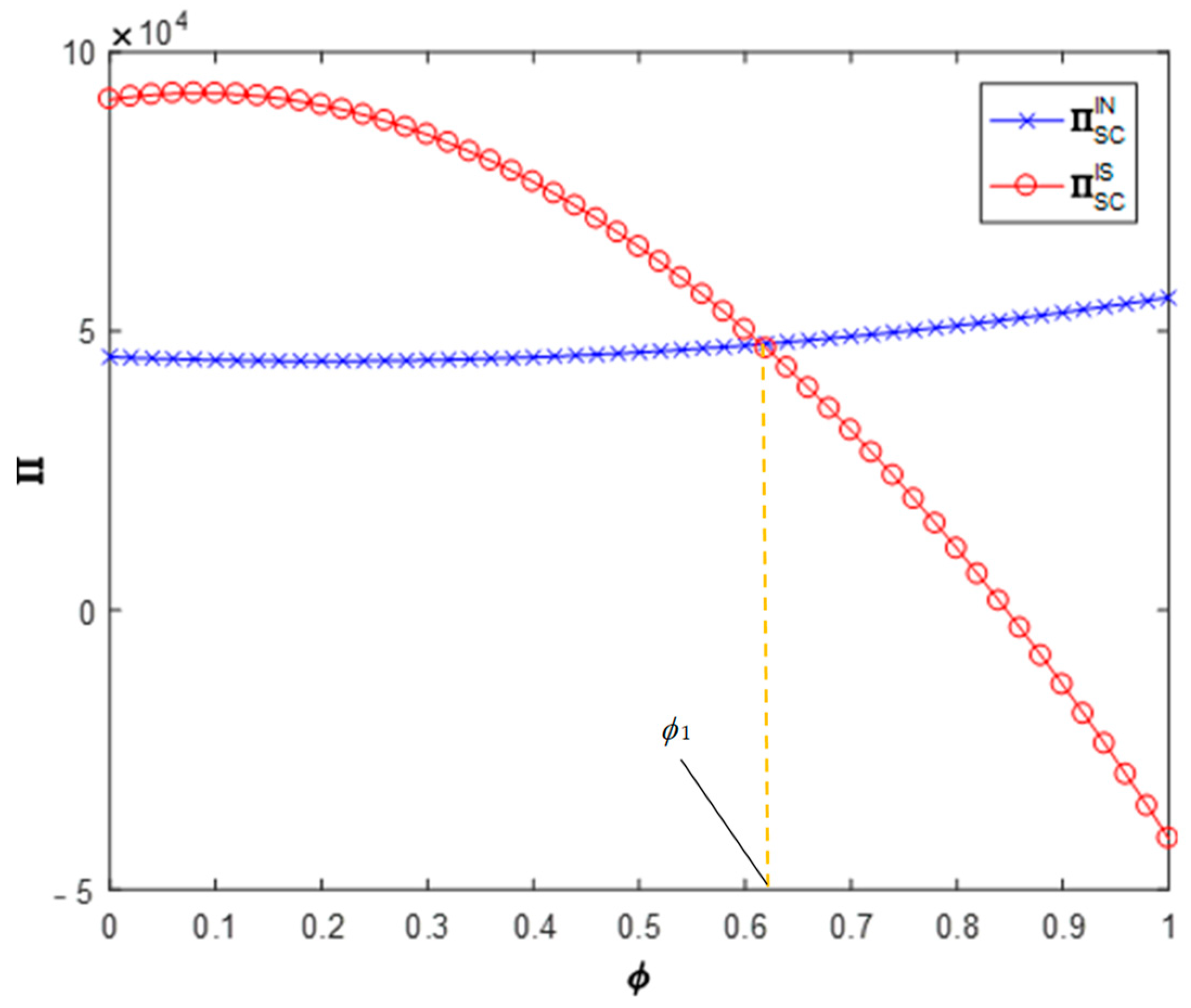

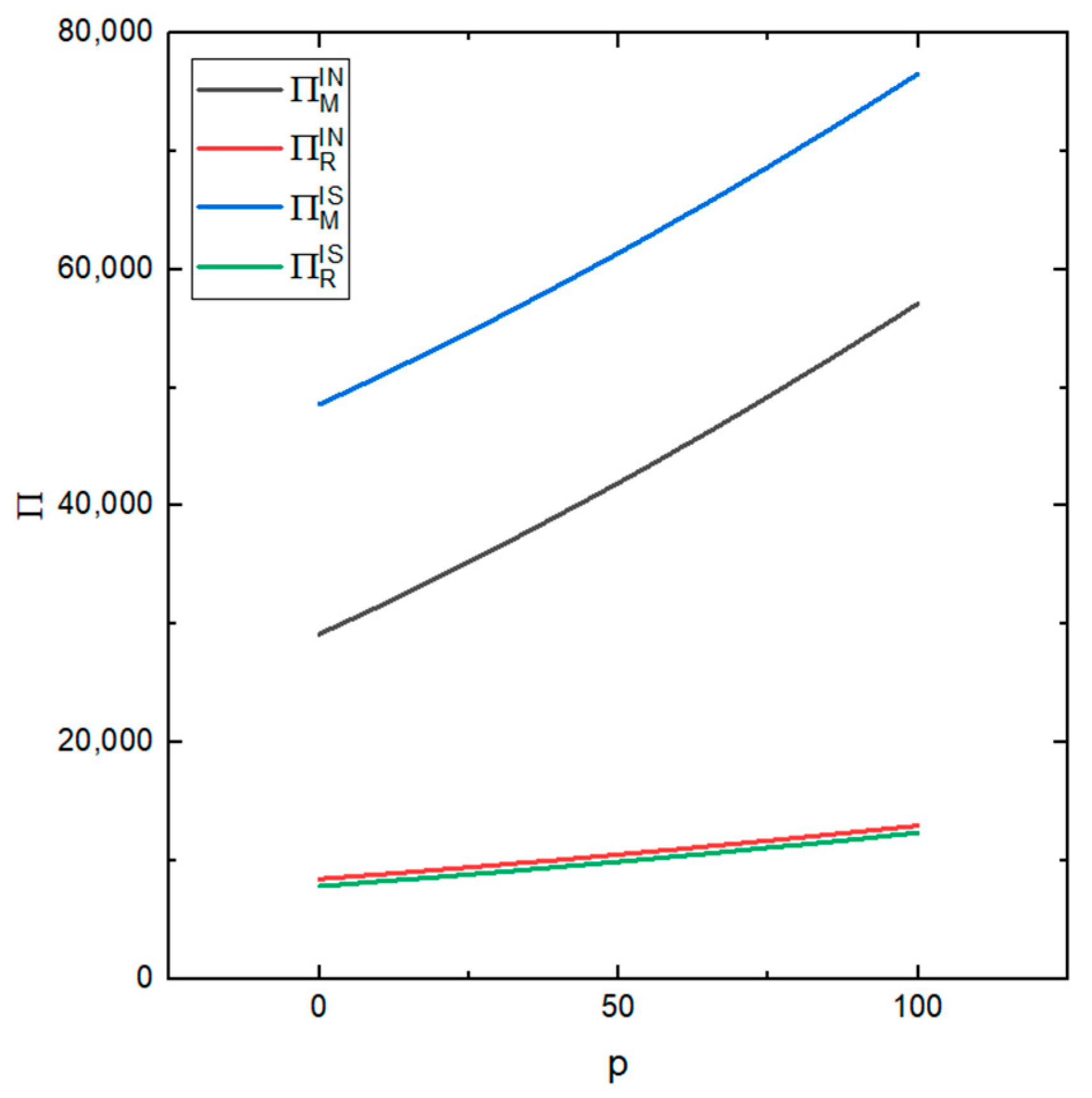

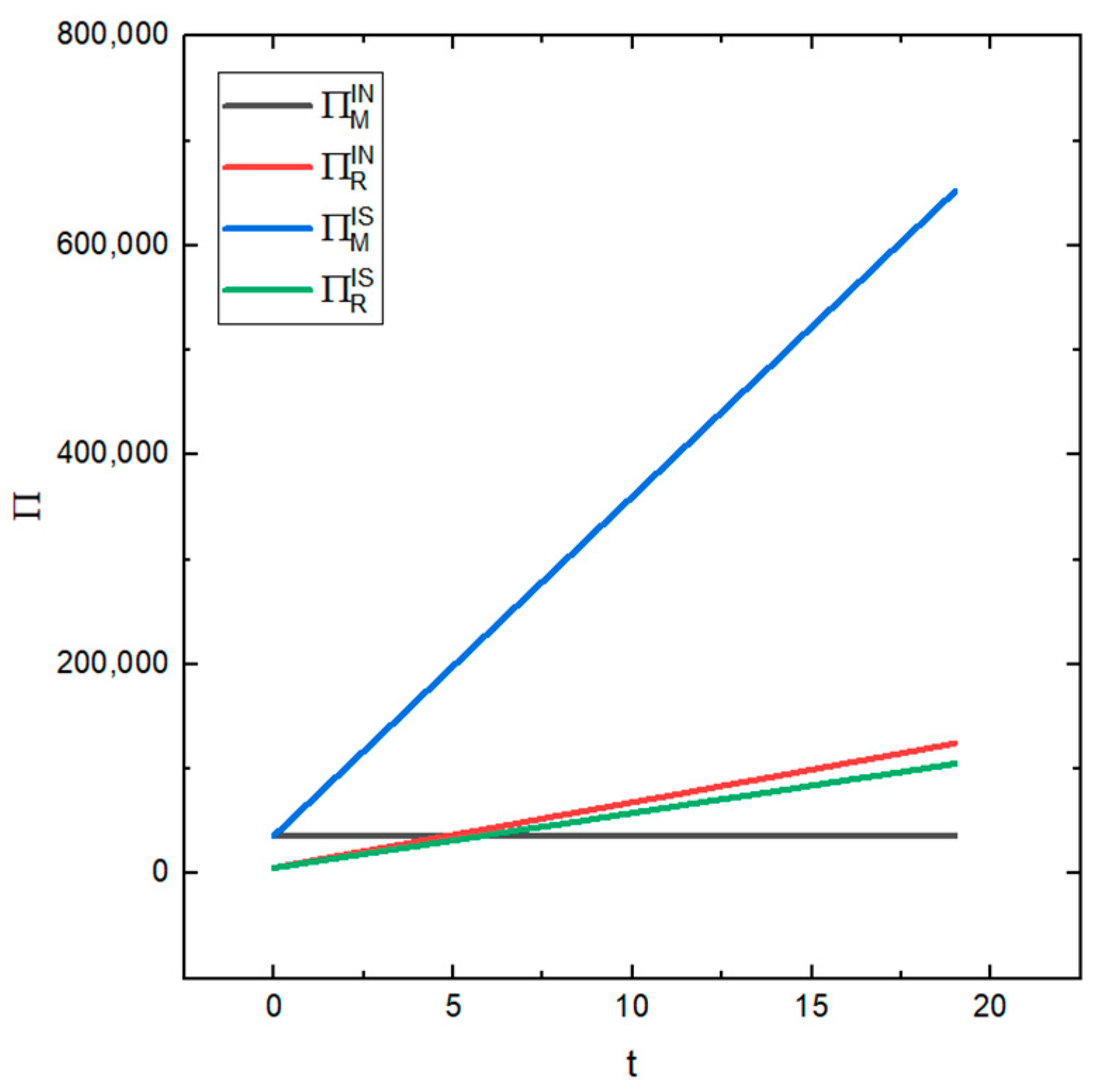

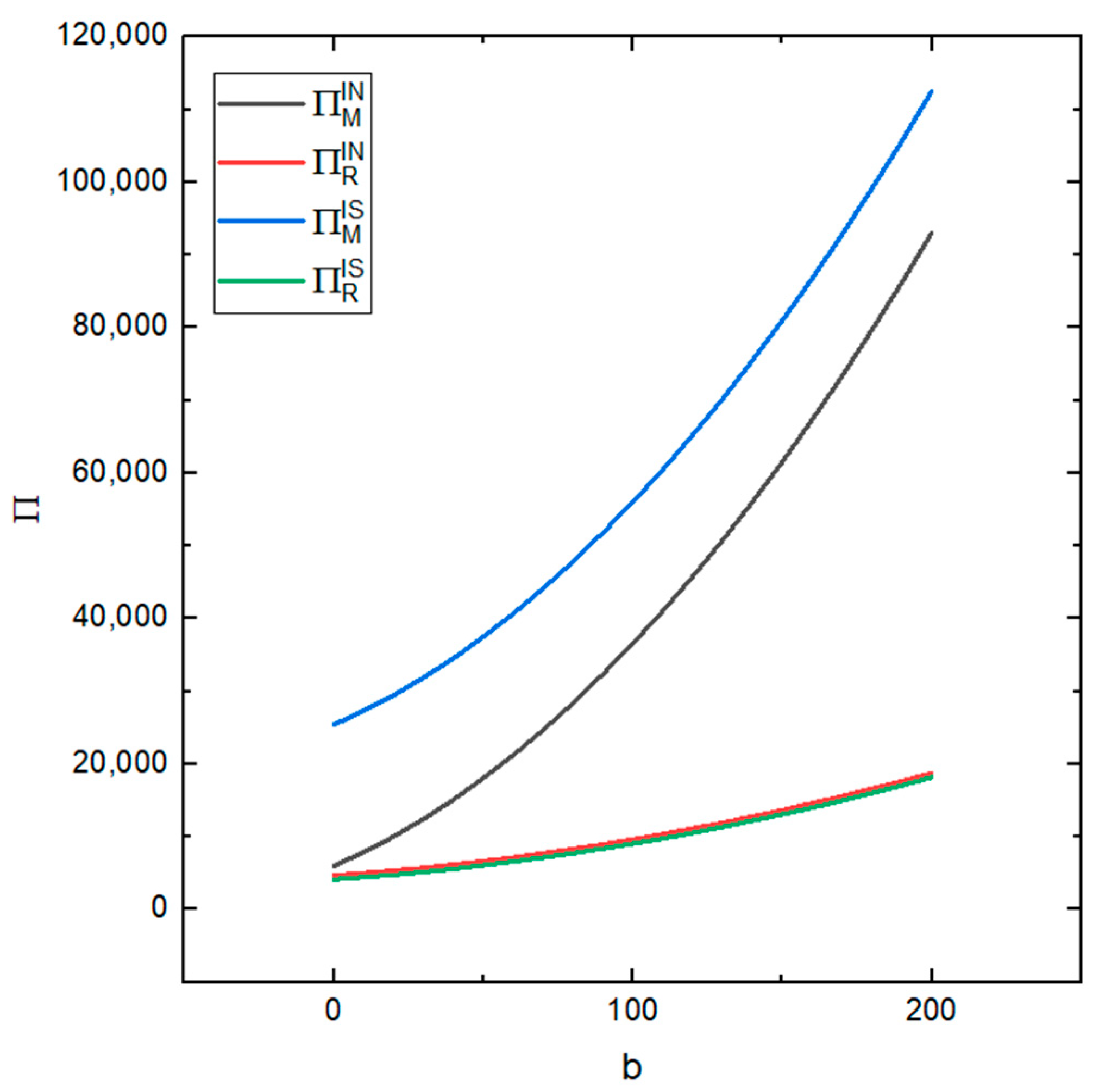

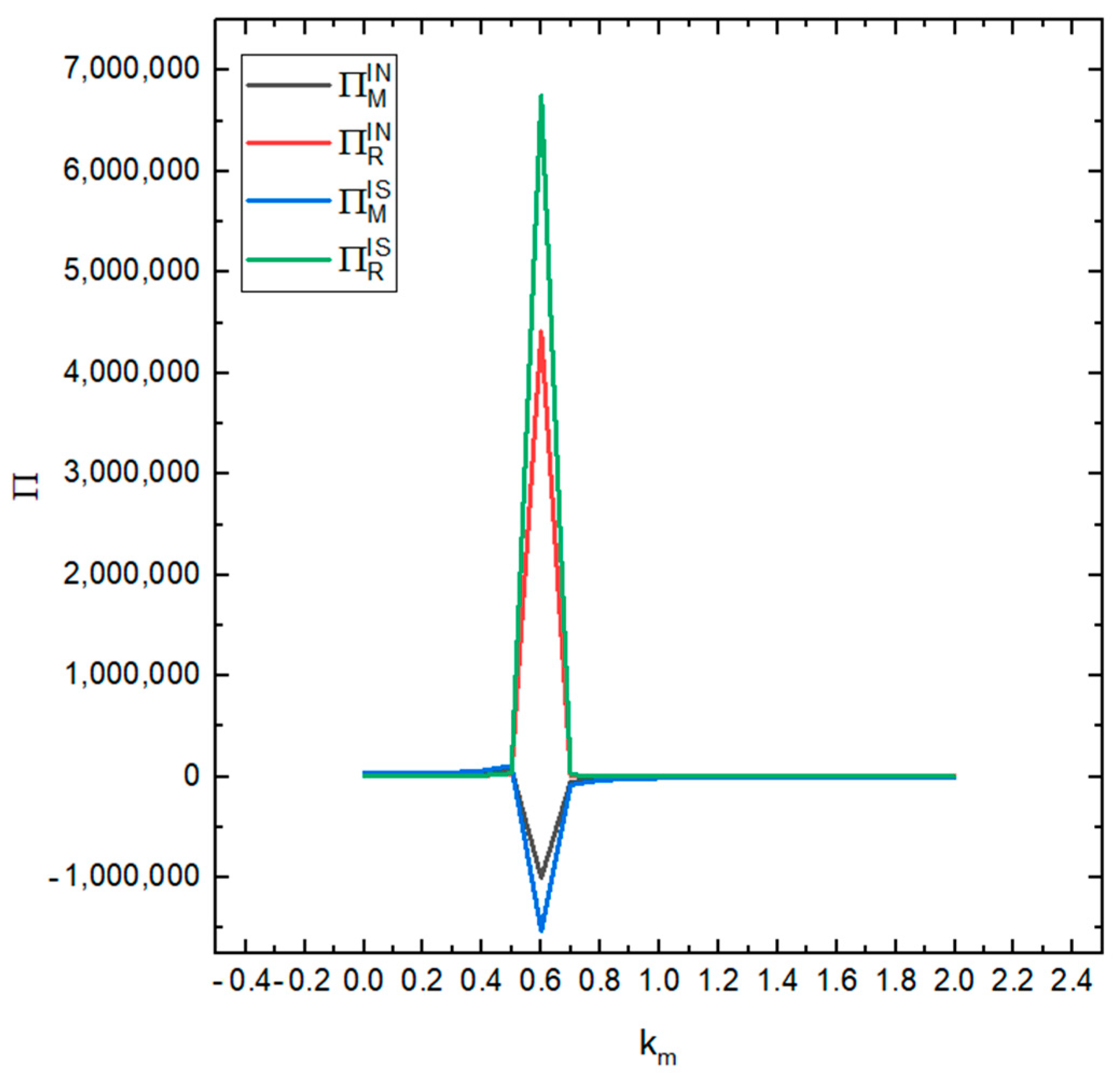

6. Numerical Simulation

6.1. Numerical Analysis

6.2. Sensitivity Analysis

7. Conclusions and Implications

7.1. Conclusions

7.2. Implications

- (1)

- For remanufacturers, there is always a benefit from the sharing of information in the CDW resource utilization supply chain. Therefore, remanufacturers should strive to obtain demand forecast information from recyclers. When the cost of obtaining the information is less than the increase in income, that is, when the marginal income is greater than zero, a certain fee can be paid to the recycler in order to obtain their demand forecast information and improve the remanufacturer’s own profit. Alternatively, the remanufacturer can assume the appropriate environmental responsibility investment efficiency to achieve a win–win situation with the recycler, prompting the recycler to share their demand forecast information.

- (2)

- For recyclers, when information is shared, the level of the environmental responsibility of the remanufacturer can be affected by controlling the degree of their optimism or pessimism within their market demand forecast information, thereby affecting the efficiency of the remanufacturer’s environmental responsibility investment, so as to increase their own profits.

- (3)

- For the government, in order to promote the efficient and sustainable development of the CDW resource utilization industry, relevant policies should be introduced in order to stimulate the overall profit of the supply chain. Specifically, corresponding policies should be introduced that require the remanufacturer’s environmental responsibility input, so as to avoid the remanufacturer’s environmental responsibility input cost coefficient being too low. In order to achieve an effective level of macro-control, the government must also encourage the remanufacturer to use online channels to recycle CDW and adopt policies such as raising the taxes on offline CDW recycling channels in order to avoid offline recycling channels occupying too much market share.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Su, Y.; Si, H.; Chen, J. Managerial areas of construction and demolition waste: A scientometric review. Int. J. Environ. Res. Public Health 2018, 15, 2350. [Google Scholar]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar]

- Yuan, H.; Shen, L.; Wang, J. Major obstacles to improving the performance of waste management in China’s construction industry. Facilities 2011, 29, 224–242. [Google Scholar]

- Peng, C.L.; Scorpio, D.E.; Kibert, C.J. Strategies for successful construction and demolition waste recycling operations. Constr. Manag. Econ. 1997, 15, 49–58. [Google Scholar]

- Cao, M.; Zhang, Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. J. Oper. Manag. 2011, 29, 163–180. [Google Scholar]

- Xiao, X.W.; Feng, D.K.; Tian, W. State and suggestion on construction waste recycling in China. Constr. Technol 2015, 44, 6–8. (In Chinese) [Google Scholar]

- Li, D.; Peng, Y.; Guo, C.; Tan, R. Pricing strategy of construction and demolition waste considering retailer fairness concerns under a governmental regulation environment. Int. J. Environ. Res. Public Health 2019, 16, 3896. [Google Scholar]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Durability performance of concrete with recycled aggregates from construction and demolition waste plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar]

- Hafez, H.; Kurda, R.; Kurda, R.; Al-Hadad, B.; Mustafa, R.; Ali, B. A critical review on the influence of fine recycled aggregates on technical performance, environmental impact and cost of concrete. Appl. Sci. 2020, 10, 1018. [Google Scholar]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [PubMed]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar]

- Tsay, A.A.; Agrawal, N. Channel conflict and coordination in the e-commerce age. Prod. Oper. Manag. 2004, 13, 93–110. [Google Scholar]

- Chan, H.K.; Chan, F.T. Effect of information sharing in supply chains with flexibility. Int. J. Prod. Res. 2009, 47, 213–232. [Google Scholar]

- Khan, M.; Hussain, M.; Saber, H.M. Information sharing in a sustainable supply chain. Int. J. Prod. Econ. 2016, 181, 208–214. [Google Scholar]

- Baihaqi, I.; Sohal, A.S. The impact of information sharing in supply chains on organisational performance: An empirical study. Prod. Plan. Control 2013, 24, 743–758. [Google Scholar]

- Zhou, H.; Benton, W.C., Jr. Supply chain practice and information sharing. J. Oper. Manag. 2007, 25, 1348–1365. [Google Scholar]

- Xu, H.; Liu, Z.Z.; Zhang, S.H. A strategic analysis of dual-channel supply chain design with price and delivery lead time considerations. Int. J. Prod. Econ. 2012, 139, 654–663. [Google Scholar]

- Cattani, K.; Gilland, W.; Heese, H.S.; Swaminathan, J. Boiling frogs: Pricing strategies for a manufacturer adding a direct channel that competes with the traditional channel. Prod. Oper. Manag. 2006, 15, 40–56. [Google Scholar]

- Su, P.; Peng, Y.; Hu, Q.; Tan, R. Incentive mechanism and subsidy design for construction and demolition waste recycling under information asymmetry with reciprocal behaviors. Int. J. Environ. Res. Public Health 2020, 17, 4346. [Google Scholar]

- Hu, Q.; Su, P.; Xiong, F. Dynamic game strategies for construction and demolition waste recycling with learning and reference effects. Environ. Impact Assess. Rev. 2021, 89, 106592. [Google Scholar]

- Su, Y.; Chen, J.; Si, H.; Wu, G.; Zhang, R.; Lei, W. Decision-making interaction among stakeholders regarding construction and demolition waste recycling under different power structures. Waste Manag. 2021, 131, 491–502. [Google Scholar] [PubMed]

- Giri, B.C.; Chakraborty, A.; Maiti, T. Pricing and return product collection decisions in a closed-loop supply chain with dual-channel in both forward and reverse logistics. J. Manuf. Syst. 2017, 42, 104–123. [Google Scholar]

- Liu, L.; Wang, Z.; Xu, L.; Hong, X.; Govindan, K. Collection effort and reverse channel choices in a closed-loop supply chain. J. Clean. Prod. 2017, 144, 492–500. [Google Scholar]

- Feng, L.; Govindan, K.; Li, C. Strategic planning: Design and coordination for dual-recycling channel reverse supply chain considering consumer behavior. Eur. J. Oper. Res. 2017, 260, 601–612. [Google Scholar]

- Chen, J.; Wu, D.; Li, P. Research on the pricing model of the dual-channel reverse supply chain considering logistics costs and consumers’ awareness of sustainability based on regional differences. Sustainability 2018, 10, 2229. [Google Scholar]

- Wu, D.; Chen, J.; Li, P.; Zhang, R. Contract coordination of dual channel reverse supply chain considering service level. J. Clean. Prod. 2020, 260, 121071. [Google Scholar]

- Jin, L.; Zheng, B.; Huang, S. Pricing and coordination in a reverse supply chain with online and offline recycling channels: A power perspective. J. Clean. Prod. 2021, 298, 126786. [Google Scholar]

- Li, P.; Wu, D. A Multi-Echelon Network Design in a Dual-Channel Reverse Supply Chain Considering Consumer Preference. Int. J. Environ. Res. Public Health 2021, 18, 4760. [Google Scholar] [PubMed]

- Lee, H.L.; So, K.C.; Tang, C.S. The value of information sharing in a two-level supply chain. Manag. Sci. 2000, 46, 626–643. [Google Scholar]

- Cheng, T.C.E.; Wu, Y.N. The impact of information sharing in a two-level supply chain with multiple retailers. J. Oper. Res. Soc. 2005, 56, 1159–1165. [Google Scholar]

- Wang, T.Y.; Wang, Z.Q.; He, P. Impact of information sharing modes on the dual-channel closed loop supply chains under different power structures. Asia-Pac. J. Oper. Res. 2021, 38, 2050051. [Google Scholar]

- Li, L. Information sharing in a supply chain with horizontal competition. Manag. Sci. 2002, 48, 1196–1212. [Google Scholar]

- Huang, Y.; Zheng, B.; Wang, Z. The value of information sharing in a dual-channel closed-loop supply chain. RAIRO-Oper. Res. 2021, 55, 2001–2022. [Google Scholar]

- Guan, Z.; Zhang, X.; Zhou, M.; Dan, Y. Demand information sharing in competing supply chains with manufacturer-provided service. Int. J. Prod. Econ. 2020, 220, 107450. [Google Scholar]

- Long, H.; Liu, H.; Li, X.; Chen, L. An evolutionary game theory study for construction and demolition waste recycling considering green development performance under the Chinese government’s reward–penalty mechanism. Int. J. Environ. Res. Public Health 2020, 17, 6303. [Google Scholar]

- Li, X.; Huang, R.; Dai, J.; Li, J.; Shen, Q. Research on the evolutionary game of construction and demolition waste (CDW) recycling units’ green behavior, considering remanufacturing capability. Int. J. Environ. Res. Public Health 2021, 18, 9268. [Google Scholar]

- Giri, B.C.; Dey, S.K. Game theoretic analysis of a closed-loop supply chain with backup supplier under dual channel recycling. Comput. Ind. Eng. 2019, 129, 179–191. [Google Scholar]

- Xie, J.; Zhang, W.; Liang, L.; Xia, Y.; Yin, J.; Yang, G. The revenue and cost sharing contract of pricing and servicing policies in a dual-channel closed-loop supply chain. J. Clean. Prod. 2018, 191, 361–383. [Google Scholar]

- Savaskan, R.C.; Bhattacharya, S.; Van Wassenhove, L.N. Closed-loop supply chain models with product remanufacturing. Manag. Sci. 2004, 50, 239–252. [Google Scholar]

- Huang, Y.; Wang, Z. Values of information sharing: A comparison of supplier-remanufacturing and manufacturer-remanufacturing scenarios. Transp. Res. Part. E Logist. Transp. Rev. 2017, 106, 20–44. [Google Scholar]

- Ma, J.; Wang, H. Complexity analysis of dynamic noncooperative game models for closed-loop supply chain with product recovery. Appl. Math. Model. 2014, 38, 5562–5572. [Google Scholar]

- Wan, N.; Hong, D. The impacts of subsidy policies and transfer pricing policies on the closed-loop supply chain with dual collection channels. J. Clean. Prod. 2019, 224, 881–891. [Google Scholar]

- Ferrer, G.; Swaminathan, J.M. Managing new and differentiated remanufactured products. Eur. J. Oper. Res. 2010, 203, 370–379. [Google Scholar]

- Crucho, J.; Picado-Santos, L.; Neves, J. Cement-Treated Pavement Layers Incorporating Construction and Demolition Waste and Coconut Fibres: A Review. J. Pavement Eng. 2021, 1–20. [Google Scholar] [CrossRef]

- Yue, X.; Liu, J. Demand forecast sharing in a dual-channel supply chain. Eur. J. Oper. Res. 2006, 174, 646–667. [Google Scholar]

- Gao, J.; Han, H.; Hou, L.; Wang, H. Pricing and effort decisions in a closed-loop supply chain under different channel power structures. J. Clean. Prod. 2016, 112, 2043–2057. [Google Scholar]

- Huang, M.; Yi, P.; Shi, T. Triple recycling channel strategies for remanufacturing of construction machinery in a retailer-dominated closed-loop supply chain. Sustainability 2017, 9, 2167. [Google Scholar]

- Esmaeili, M.; Aryanezhad, M.B.; Zeephongsekul, P. A game theory approach in seller–buyer supply chain. Eur. J. Oper. Res. 2009, 195, 442–448. [Google Scholar]

- He, L.; Chen, Y.; Li, J. A three-level framework for balancing the tradeoffs among the energy, water, and air-emission implications within the life-cycle shale gas supply chains. Resour. Conserv. Recycl. 2018, 133, 206–228. [Google Scholar]

- Ranjan, A.; Jha, J.K. Pricing and coordination strategies of a dual-channel supply chain considering green quality and sales effort. J. Clean. Prod. 2019, 218, 409–424. [Google Scholar]

- Lu, C.J.; Yang, C.T.; Yen, H.F. Stackelberg game approach for sustainable production-inventory model with collaborative investment in technology for reducing carbon emissions. J. Clean. Prod. 2020, 270, 121963. [Google Scholar]

| Research Topics | Dimensions | Sosurce Papers |

|---|---|---|

| CDW management from a supply chain operational perspective | Behavioral decision-making in closed-loop supply chains of CDW | [7] |

| Recycling incentives in closed-loop supply chains of CDW under asymmetric information | [22] | |

| Recycling dynamic game strategy in the reverse supply chain of CDW | [23] | |

| Charging decisions in the reverse supply chain of CDW under different rights structures | [24] | |

| DRSC | Closed-loop supply chain for recycling activities through e-tail and third-party channels | [25] |

| Pricing and reverse channel selection decision problems in closed-loop supply chains | [26] | |

| Reverse supply chain including online recycling channels | [27] | |

| Supply chain model with coexistence of online and offline recycling channels | [28] | |

| Contract design, pricing strategy and network design | [29,30,31] | |

| Information sharing | The impact of information sharing on supply chain performance | [32,33,34] |

| The decisions of information holders in the supply chain on information sharing behavior | [35,36,37] |

| Parameter | Definition |

|---|---|

| CDW market potential recycling demand. ≥ 0 | |

| Online CDW recycling demand. ≥ 0 | |

| Recycling demand for offline CDW. ≥ 0 | |

| Market share of offline recycling channels. | |

| Consumers’ green development concept. | |

| Cross-recycling price influence coefficient and , wherein the larger the , the more intense the competition between channels | |

| Consumer environmental protection sensitivity coefficient, which represents the sensitivity of consumers to the level of environmental responsibility of the remanufacturer. | |

| Environmental responsibility investment cost coefficient, which represents the efficiency of the remanufacturer’s environmental responsibility investment. | |

| Market price of remanufactured CDW products. > 0 | |

| Information payment fee. > 0 | |

| The profit of under the model. , , represent Remanufacturer, recycler and supply chain, respectively; , represent recycler information not sharing and information sharing, respectively. | |

| Recycling prices for CDW recovered by remanufacturer from recycler in offline recycling channels (Decision variables). | |

| Recycling prices for CDW recovered by recycler from consumers in offline recycling channels (Decision variables). | |

| Recycling prices for CDW recovered directly from consumers by remanufacturer in online recycling channels (Decision variables). | |

| Remanufacturer’s level of environmental responsibility (Decision variables). |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, H.; Li, X.; Zhu, X.; Huang, Y.; Liu, Z.; Liu, Y.; Liu, J.; Li, X.; Li, Y.; Li, C. Impact of Recycler Information Sharing on Supply Chain Performance of Construction and Demolition Waste Resource Utilization. Int. J. Environ. Res. Public Health 2022, 19, 3878. https://doi.org/10.3390/ijerph19073878

Zheng H, Li X, Zhu X, Huang Y, Liu Z, Liu Y, Liu J, Li X, Li Y, Li C. Impact of Recycler Information Sharing on Supply Chain Performance of Construction and Demolition Waste Resource Utilization. International Journal of Environmental Research and Public Health. 2022; 19(7):3878. https://doi.org/10.3390/ijerph19073878

Chicago/Turabian StyleZheng, Haoxuan, Xingwei Li, Xiaowen Zhu, Yicheng Huang, Zhili Liu, Yuxin Liu, Jiaxin Liu, Xiangye Li, Yuejia Li, and Chunhui Li. 2022. "Impact of Recycler Information Sharing on Supply Chain Performance of Construction and Demolition Waste Resource Utilization" International Journal of Environmental Research and Public Health 19, no. 7: 3878. https://doi.org/10.3390/ijerph19073878

APA StyleZheng, H., Li, X., Zhu, X., Huang, Y., Liu, Z., Liu, Y., Liu, J., Li, X., Li, Y., & Li, C. (2022). Impact of Recycler Information Sharing on Supply Chain Performance of Construction and Demolition Waste Resource Utilization. International Journal of Environmental Research and Public Health, 19(7), 3878. https://doi.org/10.3390/ijerph19073878