Types and Characteristics of Fatal Accidents Caused by Multiple Processes in a Workplace: Based on Actual Cases in South Korea

Abstract

:1. Introduction

2. Determination Procedure and Actual Cases of Fatal Accidents Caused by Multiple Processes in the Workplace

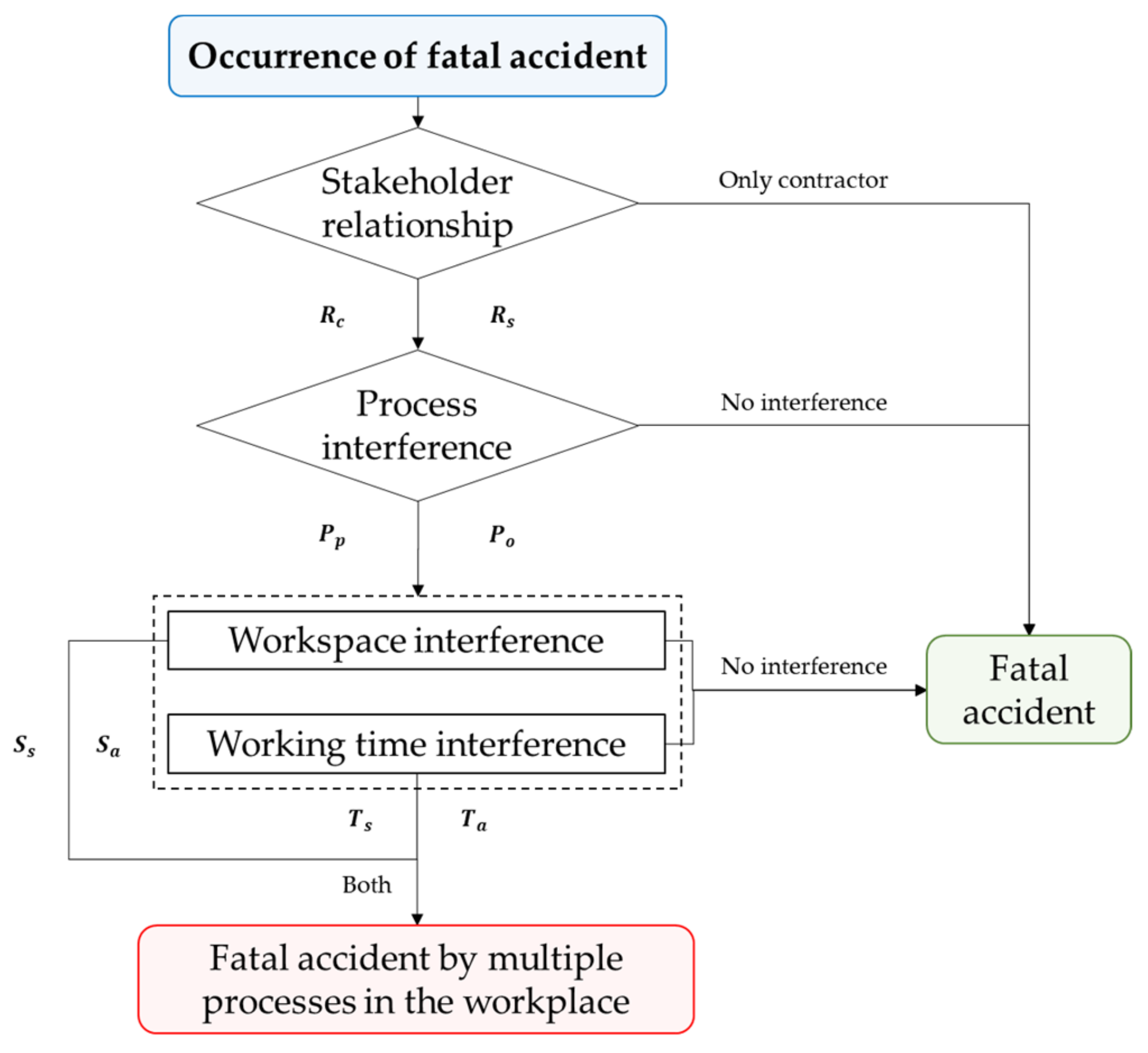

2.1. Procedures and Decision Criteria to Determine Fatal Accidents Caused by Multiple Processes in the Workplace

2.2. Analysis of Representative Cases of Industries According to the Developed Determination Procedure

2.2.1. Construction Industry

2.2.2. Manufacturing

2.2.3. Service and Other Industries

3. Classification of Accidental Types and Their Characteristics Based on Statistical Analysis of Actual Fatal Accidents Caused by Multiple Processes in the Workplace

3.1. Statistical Analysis of Fatal Accidents Caused by Multiple Processes in the Workplace

3.2. Classification of Accidental Types Caused by Multiple Processes in the Workplace

4. Conclusions

- Based on the criteria and procedures to classify multiple processes in the workplace, 4641 cases of occupational accidents and deaths in Korea over the past 5 years were analyzed and quantified using statistical data. According to the statistical data, 426 (average 9.2%) of the occupational accidents that occurred over the past 5 years were considered fatal accidents caused by multiple processes in the workplace. Moreover, from 2017 (66 persons, 6.8%) to 2020 (126 persons, 14.3%), the graph exhibited a tendency to increase every year. Among all the industries, the distribution of deaths caused by multiple processes in the workplace was found to be more than 87% in the construction (average 58.9%) and manufacturing (average 28.6%) industries. In addition, it was 4.2% (on average) in the service industry and 8.3% (on average) in other industries. In addition, it was 4.2% (on average) in the service industry and 8.3% (on average) in other industries.

- The accident types were reviewed based on statistical data and fatal accident investigation opinions. Accidents caused by the “Caught in equipment or machinery” and “Collision” types occurred at a high rate every year, and fatalities were the highest. On the other hand, accidents where the cause was listed as “Struck by the object”, “Fire or explosion”, and “Crushed” occurred less frequently; however, a large number of fatalities occurred in each case. Most accidents with regard to “Fall” were caused by an external impact or object interference from the work platform. “Collapse” is less likely to cause accidents with regard to the execution of multiple processes in the workplace, and it has been investigated whether those accidents occurred due to non-compliance with the process sequence and insufficient safety control and preparation with regard to the work assigned by a contractor.

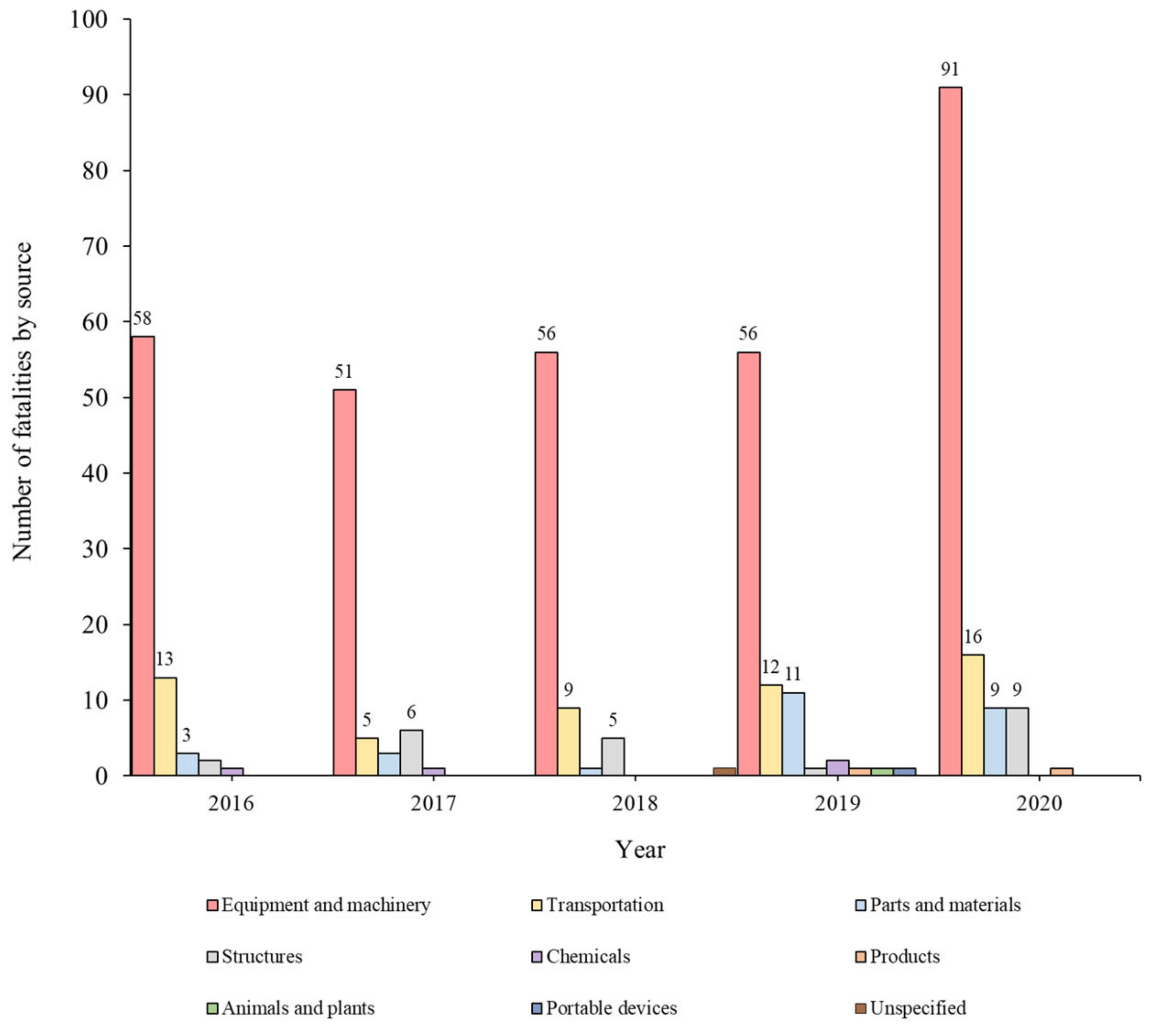

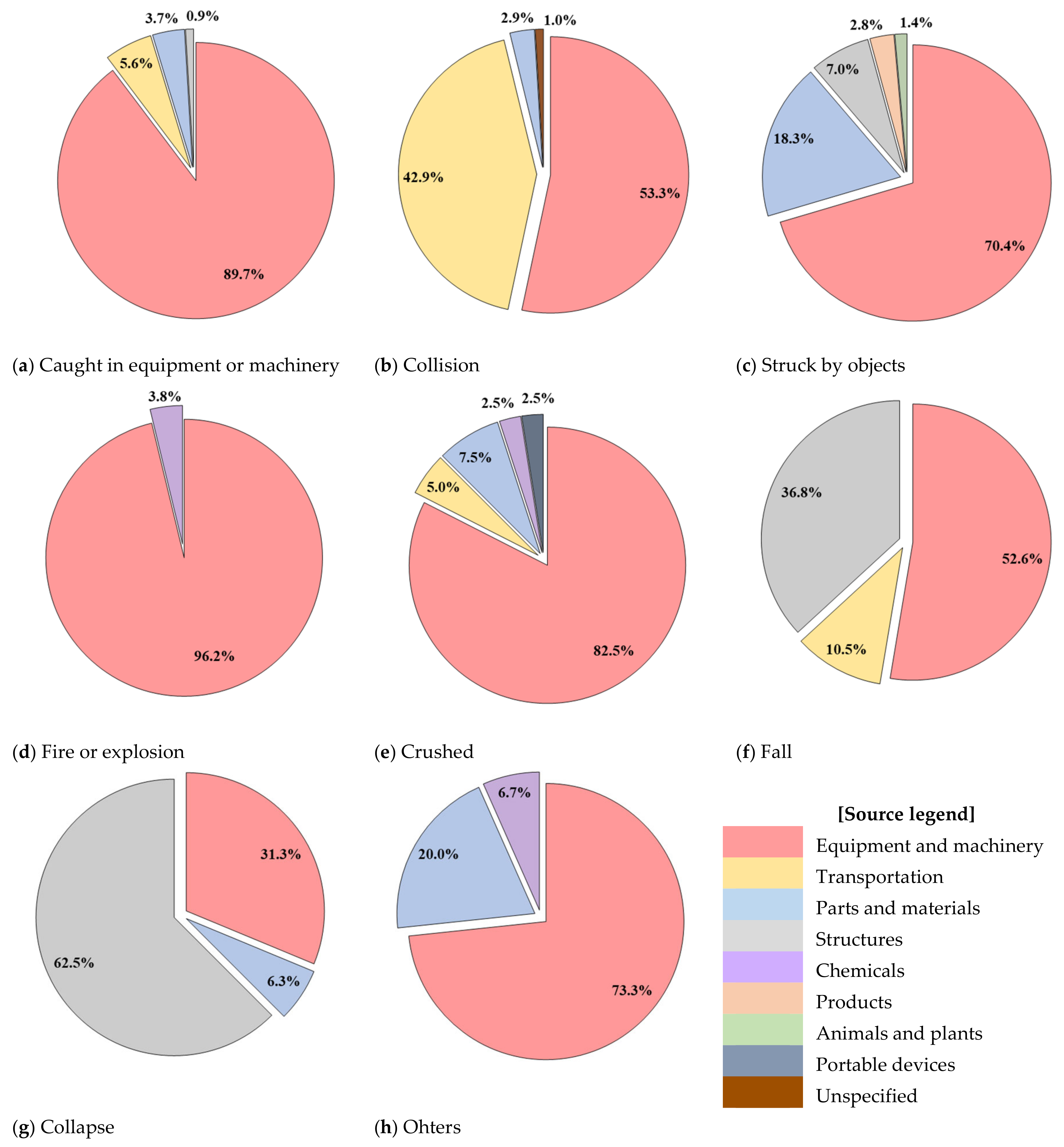

- Sources were analyzed as they had a direct relationship with causes of accidents owing to the execution of multiple processes in the workplace. Among the sources of accidents caused by multiple processes in the workplace, the highest fatalities were caused by “equipment and machinery”. Moreover, this was confirmed in the relationship with the accident type, and most accidents are related to interference with the operation of equipment and machines near workers. With regard to the source based on “Transportation”, accidents related to “Collision” were maximum in numbers, and with regard to source based on “Parts and materials”, accidents related to “Struck by objects” were maximum in numbers. “Structure” was the main source of “Collapse”, and the remaining causes exhibited a low frequency of occurrences.

- The following eight accident types were derived based on actual cases of fatal accidents caused by multiple processes in the workplace: “Caught in equipment or machinery”; “Collision”; “Struck by objects”; “Fire or explosion”; “Crushed”; “Fall”; “Collapse”; and others. This category is based on fatal accident investigation opinions, and work-related fatalities provide statistical data and actual cases. Therefore, the source and occurrence investigated in the actual case were analyzed in detail, and the risks and characteristics of the accident types that can cause death owing to the execution of multiple processes in the workplace were explained based on the interference of work and process, space, and time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Labour Organization. ILOSTAT Statistics Resources. 2021. Available online: https://ilostat.ilo.org/ (accessed on 1 September 2021).

- Hämäläinen, P.; Leena Saarela, K.; Takala, J. Global trend according to estimated number of occupational accidents and fatal work-related diseases at region and country level. J. Saf. Res. 2009, 40, 125–139. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J. A Study on the Establishment of Mid & Long Term Strategies for Prevention of Occupational Accident Plan. In Occupational Safety and Health Research Institute Report; Occupational Safety and Health Research Institute: Ulsan, Korea, 2019. [Google Scholar]

- Japan Ministry of Health, Labour and Welfare. Database Service such as Ministry of Health, Labor and Welfare Laws. 2021. Available online: https://www.mhlw.go.jp/hourei/ (accessed on 2 September 2021).

- Cho, J.W.; Hong, S.H. Analysis of Safety Management System and Implications for Japanese Construction Sites; Institute of Comparative Legal Studies, Kangwon National University: Chuncheon-si, Korea, 2016. [Google Scholar]

- Roh, S.H. Subcontracting Legal Regulation to Relate to Outsourcing of Industrial Accident Danger: Mainly on the Examination of Japanese Legislation; Research Report; Institute of Comparative Legal Studies, Kangwon National University: Chuncheon-si, Korea, 2016; Volume 48, pp. 67–97. [Google Scholar]

- Germany Federal Ministry of Justice. Act on the Implementation of Measures of Occupational Safety and Health to Encourage Improvements in the Safety and Health Protection of Workers at Work (Arbeitsschutzgesetz, ArbSchG). 2021. Available online: https://www.gesetze-im-internet.de/arbschg/ (accessed on 2 September 2021).

- Germany Deutsche Gesetzliche Unfallversicherung. Rules, Regulations and Informations: DGUV Regulation 2. 2021. Available online: https://www.dguv.de/en/prevention/rules_regulations/index.jsp (accessed on 3 September 2021).

- Kim, K.S. In House Subcontracting and Occupational Safety and Health Governancel: Focusing on the Implications of the German Legal System; Research Report; Institute of Comparative Legal Studies, Kangwon National University: Chuncheon-si, Korea, 2016; Volume 48, pp. 31–66. [Google Scholar]

- United Kingdom Department of Work and Pensions. The Construction (Design and Management) Regulations, CDMR. 2015. Available online: https://www.hse.gov.uk/construction/cdm/2015/index.htm (accessed on 4 September 2021).

- Korea Ministry of Employment and Labor. e-Employment and Labor Indicators Statistics Resources. 2020. Available online: http://eboard.moel.go.kr/indicator/detail?menu_idx=47 (accessed on 5 September 2021).

- Korea Ministry of Employment and Labor. “Five-Year Occupational Accident Prevention Plan” Policy Resources. 2020. Available online: http://www.moel.go.kr/policy/policydata/view.do?bbs_seq=20200700536 (accessed on 10 September 2021).

- Bong, J.K.; Lee, H.D.; Kim, S.; Mha, H.-S.; Yim, D.-K.; Won, J.-H. Probabilistic characteristics of moment capacity and rotational stiffness of wedge joints used in support systems reflecting reused members. Appl. Sci. 2019, 9, 4056. [Google Scholar] [CrossRef] [Green Version]

- Do Lee, H.; Won, J.H.; Jang, N.G.; Mha, H.S.; Jeong, S.C.; Kim, S. Experimental study on load carrying capacity enhancement of system supports considering full installation of bracing members. Int. J. Steel Struct. 2020, 20, 2051–2067. [Google Scholar] [CrossRef]

- Kim, H.S.; Lim, J.H.; Lee, J.H.; Kang, Y.J.; Kim, S. Experimental Investigations on Ultimate Behavior of Fabricated Mobile Scaffolds. Metals 2021, 11, 851. [Google Scholar] [CrossRef]

- Kim, H.S.; Lim, J.H.; Won, J.-H.; Kwon, J.-H.; Kim, S. Suggestion of Safety Certification Standards and Performance Evaluation Methods for Fabricated Mobile Scaffold in South Korea. Int. J. Environ. Res. Public Health 2022, 19, 133. [Google Scholar] [CrossRef] [PubMed]

- Jo, B.W.; Lee, Y.S.; Kim, J.H.; Khan, R. Trend Analysis of Construction Industrial Accidents in Korea from 2011 to 2015. Sustainability 2017, 9, 1297. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.Y.; Min, S.; Won, D.; Kang, Y.J.; Kim, S. Suggestion of an Improved Evaluation Method of Construction Companies’ Industrial Accident Prevention Activities in South Korea. Int. J. Environ. Res. Public Health 2021, 18, 8442. [Google Scholar] [CrossRef] [PubMed]

- Korea Occupational Safety and Health Agency. “Evaluation of Construction Company Industrial Accident Prevention Activities” Policy Resources. 2020. Available online: https://www.kosha.or.kr/kosha/business/preventiveactivity.do (accessed on 11 September 2021).

- Korea Occupational Safety and Health Agency. “Hazard and Risk Prevention Plan Review” Policy Resources. 2020. Available online: https://www.kosha.or.kr/kosha/business/confirmation.do (accessed on 11 September 2021).

- Korea Occupational Safety and Health Agency. “KOSHA-MS” Policy Resources. 2020. Available online: https://www.kosha.or.kr/kosha/business/managementsystem_a.do (accessed on 11 September 2021).

- The Chosunilbo. “Bus Terminal Fire Kills Seven (Goyang City, Gyeonggi Province, South Korea)” National Article. 2014. Available online: http://english.chosun.com/site/data/html_dir/2014/05/27/2014052701508.html (accessed on 11 September 2021).

- Won, J.H.; Park, H.K.; Jo, J.J.; Mun, J.K. A study on assigning client’s duty and responsibility for safety and health management in construction. 2015. In Occupational Safety and Health Research Institute Report; Occupational Safety and Health Research Institute: Ulsan, Korea, 2015. [Google Scholar]

- Oh, T.K.; Kwon, Y.J.; Oh, B.H.; Gwon, Y.I.; Yoon, H.K. Suggestions for Safety Coordinator’s Roles at Each Construction Stage (client, designer, supervisor, and contractor) to Improve Safety and Health Activities in South Korea. Saf. Sci. 2021, 133, 104994. [Google Scholar]

- Korea Ministry of Employment and Labor. Occupational Safety and Health Act, Article 68 Safety and Health Coordinators. 2020. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=219125&chrClsCd=010203&urlMode=engLsInfoR&viewCls=engLsInfoR#0000 (accessed on 15 September 2021).

- The Chosunilbo. “Police Search and Seizure Heavy Industry Company after Crane Accident (Geoje City, Gyeongsangnam Province, South Korea)” Law Article. 2017. Available online: https://www.chosun.com/site/data/html_dir/2017/05/04/2017050401472.html (accessed on 15 September 2021).

- Korea Ministry of Employment and Labor. Occupational Safety and Health Act, Article 64 Measures for Preventing Industrial Accidents in Contracting. 2021. Available online: https://www.law.go.kr/LSW/lsInfoP.do?efYd=20211119&lsiSeq=232227#0000 (accessed on 15 September 2021).

- Michael, B.; Arthur, S. Application of the Loughborough Construction Accident Causation model: A framework for organizational learning. Constr. Manag. Econ. 2013, 31, 580–595. [Google Scholar]

- Winge, S.; Alberchtsen, E.; Mostue, B.A. Causal factors and connections in construction accidents. Saf. Sci. 2019, 112, 130–141. [Google Scholar] [CrossRef]

- Bellamy, L.J.; Ale, B.J.M.; Geyer, T.A.W.; Goossens, L.H.J.; Hale, A.R.; Oh, J.; Mud, M.; Bloemhof, A.; Papazoglou, I.A.; Whiston, J.Y. Storybuilder—A tool for the analysis of accident reports. Reliab. Eng. Syst. Saf. 2007, 92, 735–744. [Google Scholar] [CrossRef]

- Ale, B.J.M.; Bellamy, L.J.; Baksteen, H.; Damen, M.; Goossens, L.H.J.; Hale, A.R.; Mud, M.; Oh, J.; Papazoglou, I.A.; Whiston, J.Y. Accidents in the construction industry in the Netherlands: An analysis of accident reports using Storybuilder. Reliab. Eng. Syst. Saf. 2008, 93, 1523–1533. [Google Scholar] [CrossRef]

| Article 64: Measures for Preventing Industrial Accidents in Contracting |

|---|

| Paragraph 1: A contractor shall consider the following measures when employees work under him or her: (Nos. 1–6 omitted) No. 7: In the work of a contractor/subcontractor in the same workplace, the work period and content of the contract, e.g., safety and health measures must be confirmed. No. 8: In addition to No. 7, if there is a risk, based on the presidential decree, of catching fire or explosion owing to the implementation of multiple processes in the workplace, the work period and content of the contract must be adjusted. |

| Step | Classification | Decision Criteria | Notation |

|---|---|---|---|

| A | Stakeholder relationship | ■ Accidents occurred involving a contractor and a subcontractor | |

| ■ Accidents occurred involving subcontractors | |||

| B | Process interference | ■ Accidents caused by other processes | |

| ■ Accidents caused by two or more operations within a process | |||

| C | Workspace interference | ■ Accidents occurring in the same workplace | |

| ■ Accidents occurring in adjacent workplaces | |||

| Working time interference | ■ Accidents occurring at the same working time | ||

| ■ Accidents caused by the previous process affecting continuous working time |

| Case 1 | Accident summary | During the urethane foam work on the first basement floor of the logistics center construction site, sparks occurred during welding and cutting of pipes on the first floor, resulting in a fire (36 dead, 12 injured). | |||

| Decision process | Step | Notation | Analysis | ||

| A | Subcontractors | ||||

| B | Plumbing work and insulation work | ||||

| C | Workspace | Continuous piping work after not finishing the urethane foam work in the adjacent space | |||

| Working time | |||||

| Cause of disaster | Fire caused by sparks | ||||

| Accident type | Fire or explosion | ||||

| Source | Equipment and machinery | ||||

| Classification | Multiple processes in the workplace | ||||

| Case 2 | Accident summary | The victim was on a table lift to install a temporary wall inside the factory by welding. At the same time, the girder of the overhead fixed crane, which was transporting materials from an adjacent place, collided with the victim, causing a fall accident. (1 dead) | |||

| Decision process | Step | Notation | Analysis | ||

| A | A contractor and a subcontractor | ||||

| B | Welding work and transport work | ||||

| C | Workspace | Temporary structure installation work and transport work carried out at the same time in an adjacent place | |||

| Working time | |||||

| Cause of disaster | Collision while moving equipment | ||||

| Accident type | Collision | ||||

| Source | Equipment and machinery | ||||

| Classification | Multiple processes in the workplace | ||||

| Case 3 | Accident summary | While lifting the workbench (portable climbing system) installed for curtain wall work on the outer wall of a skyscraper of height >200 m, the fixing bracket fell, and the entire structure fell to the floor. At the same time, workers who were pouring concrete from below collided with the structure. (4 dead) | |||

| Decision process | Step | Notation | Analysis | ||

| A | A contractor and a subcontractor | ||||

| B | Curtain wall installation work and concrete pouring work | ||||

| C | Workspace | Upper exterior wall work and lower pour work at the same time in adjacent places | |||

| Working time | |||||

| Cause of disaster | Struck by a falling object | ||||

| Accident type | Struck by objects | ||||

| Source | Structures | ||||

| Classification | Multiple processes in the workplace | ||||

| Case 1 | Accident summary | In the shipyard an accident occurred, in which the jib and wire rope of the auxiliary crane fell due to collision caused by the interference of the turning radius during the lifting operation of the main and auxiliary cranes. At the same time, an accident occurred, in which workers working on the lower main deck collided with a falling object. (6 dead, 25 injured). | |||

| Decision process | Step | Notation | Analysis | ||

| A | A contractor and a subcontractor | ||||

| B | Lifting cranes work and working on decks | ||||

| C | Workspace | A secondary accident occurred while working at the same time on the lower part during the crane lifting operation | |||

| Working time | |||||

| Cause of disaster | Struck by a falling object | ||||

| Accident type | Struck by objects | ||||

| Source | Parts and materials | ||||

| Classification | Multiple processes in the workplace | ||||

| Case 2 | Accident summary | A subcontractor worker got caught between the machine and floor while cleaning the floor of an automatic lift that transports food in a contractor’s factory. (1 dead) | |||

| Decision process | Step | Notation | Analysis | ||

| A | A contractor and a subcontractor | ||||

| B | Production equipment operation and cleaning | ||||

| C | Workspace | Automated lift operation (power on) and cleaning at the same time | |||

| Working time | |||||

| Cause of disaster | Caught between rotating machines (both rotating in the opposite direction) | ||||

| Accident type | Caught in equipment or machinery | ||||

| Source | Equipment and machinery | ||||

| Classification | Multiple processes in the workplace | ||||

| Case 3 | Accident summary | A worker entered the pipe that was being welded to produce a gas carrier in the shipyard. The worker suffocated to death owing to lack of oxygen caused by argon gas while connecting the compressor pipe. (1 dead) | |||

| Decision process | Step | Notation | Analysis | ||

| A | Subcontractors | ||||

| B | Plumbing work and welding work | ||||

| C | Workspace | Upper exterior wall work and lower pour work at the same time in adjacent places | |||

| Working time | |||||

| Cause of disaster | Depletion of oxygen | ||||

| Accident type | Others (Suffocations) | ||||

| Source | Chemicals | ||||

| Classification | Multiple processes in the workplace | ||||

| Case 1 | Accident summary | Subcontractor workers were hit by a running train while making repairs related to the power supply to the line. (3 deaths) | |||

| Decision process | Step | Notation | Analysis | ||

| A | A contractor and a subcontractor | ||||

| B | Train operation and maintenance work | ||||

| C | Workspace | Perform maintenance at the same time on active train tracks | |||

| Working time | |||||

| Cause of disaster | Collision with the transport medium | ||||

| Accident type | Collision | ||||

| Source | Transportation | ||||

| Classification | Multiple processes in the workplace | ||||

| Case 2 | Accident summary | While moving the blasted rock from the quarry to the excavator, the rock broke off and hit a worker, who was dismantling the fence under the slope. (1 dead) | |||

| Decision process | Notation | Notation | Analysis | ||

| A contractor and a subcontractor | |||||

| Production equipment operation and cleaning | |||||

| Workspace | Automated lift operation (power on) and cleaning at the same time | ||||

| Working time | |||||

| Cause of disaster | Struck by a falling object | ||||

| Accident type | Struck by objects | ||||

| Source | Parts and materials | ||||

| Classification | Multiple processes in the workplace | ||||

| Case 3 | Accident summary | The victim was installing structural H-beams in the cargo hold of a ship for logistics transport. At the same time, an accident occurred when a forklift that was carrying out the unloading work collided with the H-beam, and the victim was crushed. (1 dead) | |||

| Decision process | Step | Notation | Analysis | ||

| A | Subcontractors | ||||

| B | Temporary installation work and shipping work | ||||

| C | Workspace | Shipment work is carried out at the same time in the same space as the temporary installation work | |||

| Working time | |||||

| Cause of disaster | Crushed by an overturned object | ||||

| Accident type | Crushed | ||||

| Source | Parts and materials | ||||

| Classification | Multiple processes in the workplace | ||||

| Year | 2016 | 2017 | 2018 | 2019 | 2020 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Classification | Fatalities (Persons) | Ratio | Fatalities (Persons) | Ratio | Fatalities (Persons) | Ratio | Fatalities (Persons) | Ratio | Fatalities (Persons) | Ratio |

| Construction | 50 | 64.9% | 39 | 59.1% | 39 | 54.2% | 41 | 48.2% | 86 | 68.3% |

| Manufacturing | 18 | 23.4% | 22 | 33.3% | 23 | 31.9% | 30 | 35.3% | 24 | 19.0% |

| Service | 2 | 2.6% | 2 | 3.0% | 6 | 8.3% | 4 | 4.7% | 3 | 2.4% |

| Others | 7 | 9.1% | 3 | 4.6% | 4 | 5.6% | 10 | 11.8% | 13 | 10.3% |

| Total | 77 | 66 | 72 | 85 | 126 | |||||

| Year | 2016 | 2017 | 2018 | 2019 | 2020 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Classification | Fatalities (Persons) | Ratio | Fatalities (Persons) | Ratio | Fatalities (Persons) | Ratio | Fatalities (Persons) | Ratio | Fatalities (Persons) | Ratio |

| Caught in equipment or machinery | 20 | 26.0% | 17 | 25.8% | 19 | 26.4% | 22 | 25.9% | 29 | 23.0% |

| Collision | 24 | 31.1% | 15 | 22.8% | 20 | 27.8% | 23 | 27.0% | 23 | 18.2% |

| Struck by the object | 11 | 14.3% | 15 | 22.8% | 10 | 13.9% | 18 | 21.2% | 17 | 13.5% |

| Fire or explosion | 9 | 11.7% | 3 | 4.5% | 2 | 2.8% | 3 | 3.5% | 36 | 28.6% |

| Crushed | 4 | 5.2% | 8 | 12.1% | 7 | 9.7% | 12 | 14.1% | 9 | 7.1% |

| Fall | 4 | 5.2% | 3 | 4.5% | 7 | 9.7% | 1 | 1.2% | 4 | 3.2% |

| Collapse | 2 | 2.6% | 3 | 4.5% | 2 | 2.8% | 2 | 2.4% | 7 | 5.6% |

| Others | 3 | 3.9% | 2 | 3.0% | 5 | 6.9% | 4 | 4.7% | 1 | 0.8% |

| Total | 77 | 66 | 72 | 85 | 126 | |||||

| Accident Type | Caught in Equipment or Machinery | Collision | Struck by the Object | Fire or Explosion | Crushed | Fall | Collapse | Etc. | |

|---|---|---|---|---|---|---|---|---|---|

| Sources | |||||||||

| Equipment and machinery | Fatalities and ratio | 96 (89.7%) | 56 (53.3%) | 50 (70.4%) | 51 (96.2%) | 33 (82.5%) | 10 (52.6%) | 5 (31.3%) | 11 (73.3%) |

| Construction | 31 | 31 | 33 | 46 | 20 | 9 | 5 | 2 | |

| Manufacturing | 50 | 15 | 12 | 5 | 9 | 1 | 9 | ||

| Service | 6 | 3 | 3 | 2 | |||||

| Etc. | 9 | 7 | 2 | 2 | |||||

| Transportation | Fatalities and ratio | 6 (5.6%) | 45 (42.9%) | 2 (5.0%) | 2 (10.5%) | ||||

| Construction | 2 | 29 | 1 | ||||||

| Manufacturing | 1 | 5 | |||||||

| Service | 3 | ||||||||

| Etc. | 3 | 8 | 1 | 2 | |||||

| Parts and materials | Fatalities and ratio | 4 (3.7%) | 3 (2.9%) | 13 (18.3%) | 3 (7.5%) | 1 (6.3%) | 3 (20.0%) | ||

| Construction | 2 | 1 | 11 | 1 | 1 | ||||

| Manufacturing | 2 | 1 | 1 | 3 | 2 | ||||

| Etc. | 1 | 1 | |||||||

| Structures | Fatalities and ratio | 1 (0.9%) | 5 (7.0%) | 7 (36.8%) | 10 (62.5%) | ||||

| Construction | 5 | 7 | 10 | ||||||

| Manufacturing | 1 | ||||||||

| Chemicals | Fatalities and ratio | 2 (3.8%) | 1 (2.5%) | 1 (6.7%) | |||||

| Construction | 2 | 1 | 1 | ||||||

| Products | Fatalities and ratio | 2 (2.8%) | |||||||

| Construction | 2 | ||||||||

| Animals and plants | Fatalities and ratio | 1 (1.4%) | |||||||

| Etc. | 1 | ||||||||

| Portable devices | Fatalities and ratio | 1 (2.5%) | |||||||

| Construction | 1 | ||||||||

| Unspecified | Fatalities and ratio | 1 (1.0%) | |||||||

| Construction | 1 |

| Risks and Characteristics | Risk of Fatal Accidents Caused by Multiple Processes in the Workplace Based the Industry Type | Interference Characteristics | ||

|---|---|---|---|---|

| Accident Type | Space | Time | ||

| Caught in equipment or machinery | When working with operating (powered on) equipment or machinery, there is a risk of interference with other operations performed in the same workplace at the same time | Same workplace | Work at the same time | |

| Collision | Risk arises when other operations are simultaneously interfered within the working radius or movement range of the equipment, machinery, or means of transport used during the process | Same workplace | Work at the same time | |

| Struck by the object | When equipment, machinery, parts, or materials that have been displaced during work are fly-in or fall into another workspace where they are implemented at the same time | Upper and lower workplace or adjacent workplace | Work at the same time | |

| Fire or explosion | Risk of interference when welding and cutting using operating equipment or machines at the same time in a workplace that uses inflammable substances or combustible gas | Same workplace | Work at the same time | |

| Crushed | Risk of interference if equipment, machinery, parts, materials, or vehicles fall over during work or at the same time invade the work area being carried out in the workplace | Same workplace | Work at the same time | |

| Fall | When equipment, machinery, parts, materials, or structures used for other processes interfere with the working space of the worker and cause a fall | Same workplace | Work at the same time or successive temporal relationships | |

| Collapse | When a region or part, material, or structure collapses and spills out and at the same time invades the workplace | Same workplace | Work at the same time | |

| Others | When performing other work in a space where there is lack of oxygen or that is filled with toxic gases that may cause suffocation or poisoning | Same workplace | Work at the same time or successive temporal relationships | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.-Y.; Min, S.; Kim, W.-S.; Won, J.-H.; Kang, Y.-J.; Kim, S. Types and Characteristics of Fatal Accidents Caused by Multiple Processes in a Workplace: Based on Actual Cases in South Korea. Int. J. Environ. Res. Public Health 2022, 19, 2047. https://doi.org/10.3390/ijerph19042047

Kang S-Y, Min S, Kim W-S, Won J-H, Kang Y-J, Kim S. Types and Characteristics of Fatal Accidents Caused by Multiple Processes in a Workplace: Based on Actual Cases in South Korea. International Journal of Environmental Research and Public Health. 2022; 19(4):2047. https://doi.org/10.3390/ijerph19042047

Chicago/Turabian StyleKang, Sung-Yong, Seongi Min, Won-Seok Kim, Jeong-Hun Won, Young-Jong Kang, and Seungjun Kim. 2022. "Types and Characteristics of Fatal Accidents Caused by Multiple Processes in a Workplace: Based on Actual Cases in South Korea" International Journal of Environmental Research and Public Health 19, no. 4: 2047. https://doi.org/10.3390/ijerph19042047

APA StyleKang, S.-Y., Min, S., Kim, W.-S., Won, J.-H., Kang, Y.-J., & Kim, S. (2022). Types and Characteristics of Fatal Accidents Caused by Multiple Processes in a Workplace: Based on Actual Cases in South Korea. International Journal of Environmental Research and Public Health, 19(4), 2047. https://doi.org/10.3390/ijerph19042047