Conversion of Waste Cooking Oil to Rhamnolipid by a Newly Oleophylic Pseudomonas aeruginosa WO2

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sludge Samples and Culture Medium

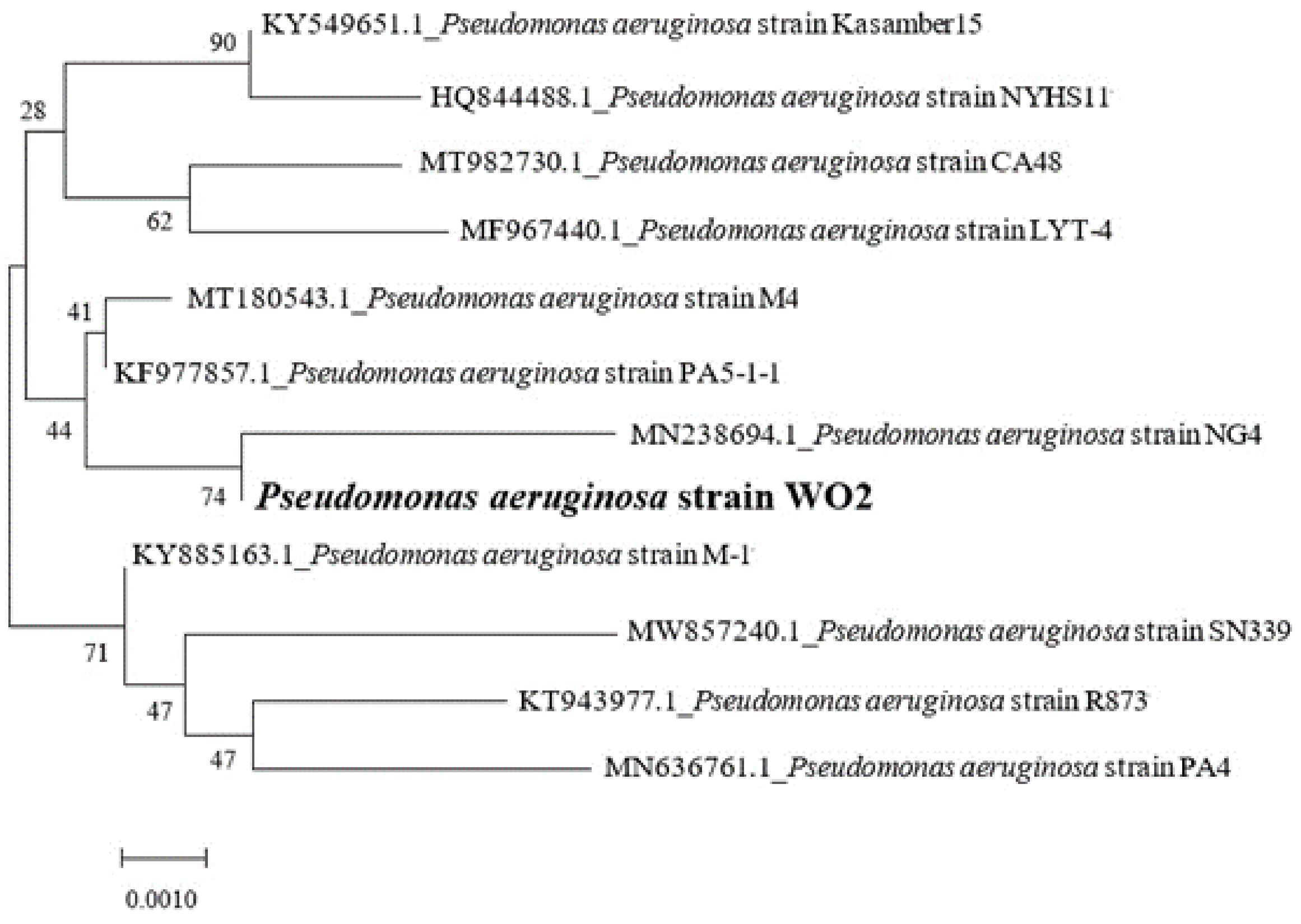

2.2. Isolation and Identification of WCO-Utilizing Strains

2.3. Optimization of WCO Consumption Conditions

2.4. WCO Tolerance Test

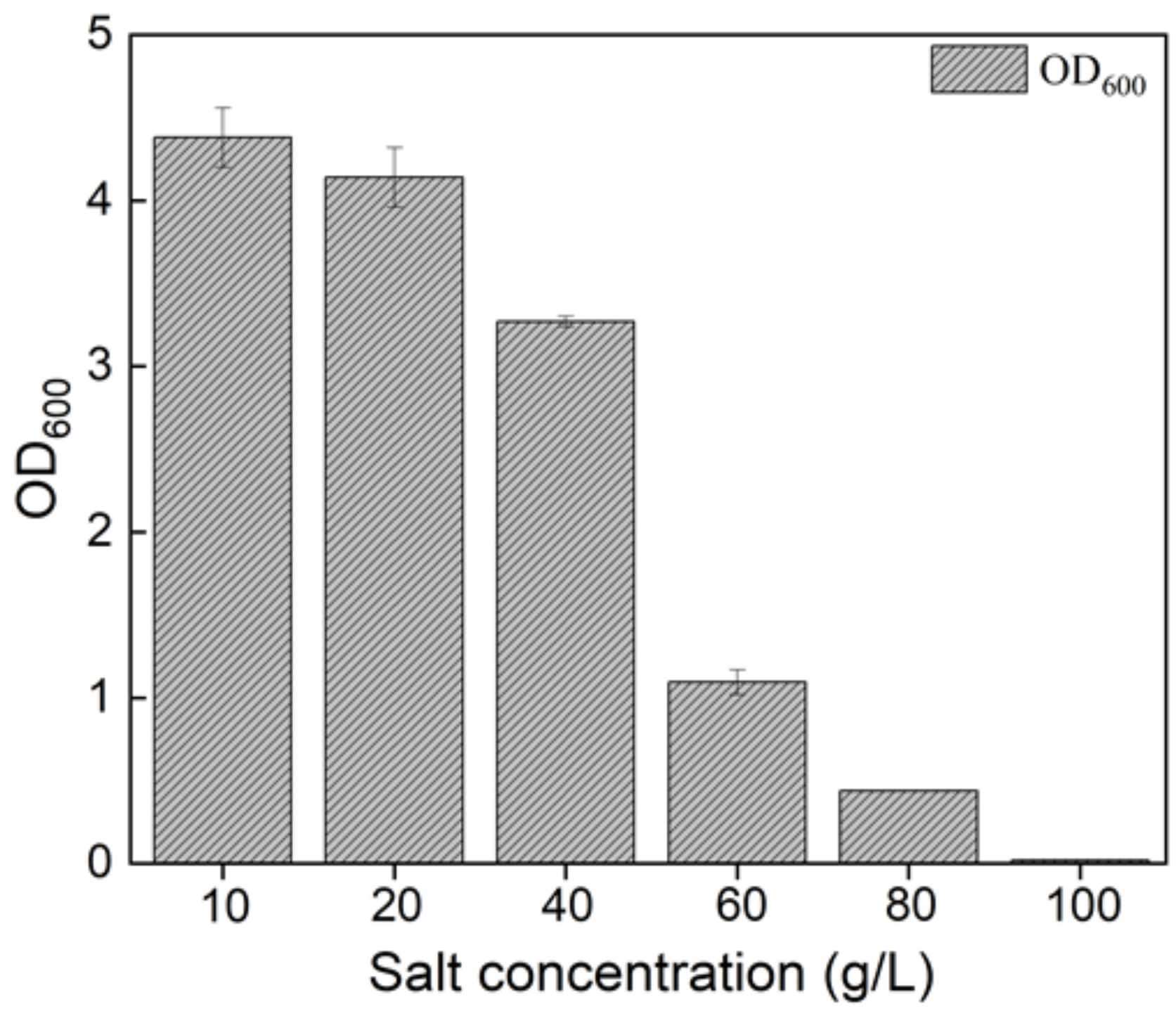

2.5. Salt Stress Test

2.6. Cell Density and Enzymatic Assay

2.7. WCO Consumption

mresidue oil: Amount of WCO remaining in the culture medium after microbial metabolism.

minitial oil: Amount of WCO initially added to the culture medium.

2.8. Rhamnolipid Production

3. Results and Discussion

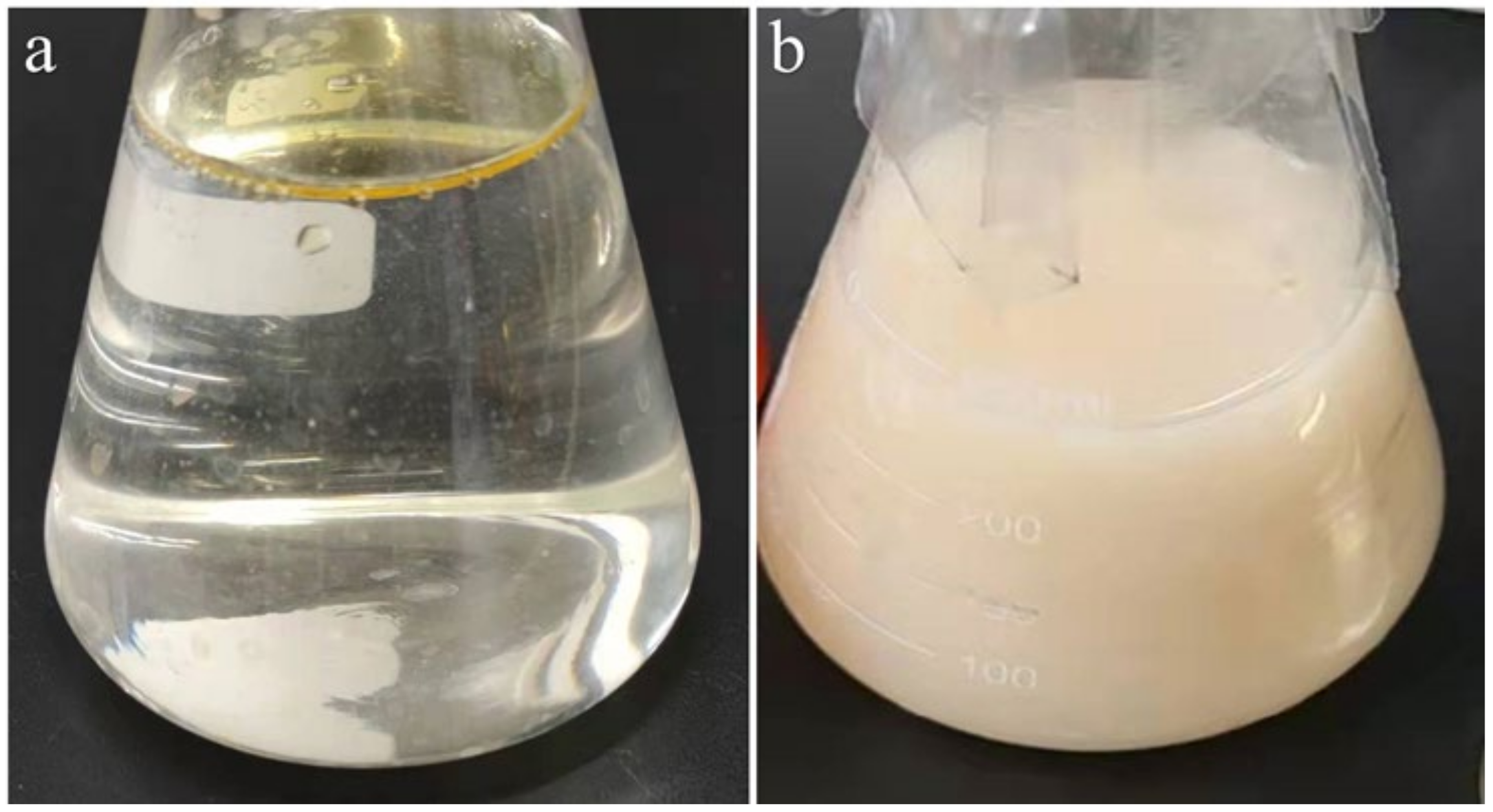

3.1. Isolation of WCO-Utilizing Strains

3.2. Optimization of WCO Utilization by Pseudomonas aeruginosa WO2

3.2.1. Temperature, Inoculum Ratio, and pH

3.2.2. Carbon and Nitrogen Sources

3.3. WCO Fermentation Kinetics

3.4. WCO Tolerance Test

3.5. Salt Stress Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karthikeyan, P.O.; Trably, E.; Mehariya, S.; Bernet, N.; Wong, J.W.C.; Carrere, H. Pretreatment of food waste for methane and hydrogen recovery: A review. Bioresour. Technol. 2018, 249, 1025–1039. [Google Scholar] [CrossRef] [Green Version]

- Masson, M.; Delarue, J.; Blumenthal, D. An observational study of refrigerator food storage by consumers in controlled conditions. Food Qual. Prefer. 2017, 56, 294–300. [Google Scholar] [CrossRef]

- Liu, N.; Jiang, J. Valorisation of food waste using salt to alleviate inhibition by animal fats and vegetable oils during anaerobic digestion. Biomass Bioenerg. 2020, 143, 105826. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, G.; Xue, L.; Zuo, J.; Chen, T.; Vuppaladadiyam, A.; Duan, H. Anaerobic digestion based waste-to-energy technologies can halve the climate impact of China’s fast-growing food waste by 2040. J. Clean. Prod. 2020, 277, 123490. [Google Scholar] [CrossRef]

- Zhu, K.; Zhang, L.; Mu, L.; Ma, J.; Li, C.; Li, A. Comprehensive investigation of soybean oil-derived LCFAs on anaerobic digestion of organic waste: Inhibitory effect and transformation. Biochem. Eng. J. 2019, 151, 107314. [Google Scholar] [CrossRef]

- Santana, J.C.C.; Miranda, A.C.; Souza, L.; Yamamura, C.L.K.; Coelho, D.d.F.; Tambourgi, E.B.; Berssaneti, F.T.; Ho, L.L. Clean Production of Biofuel from Waste Cooking Oil to Reduce Emissions, Fuel Cost, and Respiratory Disease Hospitalizations. Sustainability 2021, 13, 9185. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, C.; Zhang, L.; Chang, Y.; Hao, Y. Converting waste cooking oil to biodiesel in China: Environmental impacts and economic feasibility. Renew. Sustain. Energy Rev. 2021, 140, 110661. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Li, C.; Chen, X.; Peng, W.; Aghbashlo, M.; Lam, S.S.; Tabatabaei, M. Managing the hazardous waste cooking oil by conversion into bioenergy through the application of waste-derived green catalysts: A review. J. Hazard. Mater. 2022, 424, 127636. [Google Scholar] [CrossRef]

- Yu, N.; Xing, D.; Li, W.; Yang, Y.; Li, Z.; Li, Y.; Ren, N. Electricity and methane production from soybean edible oil refinery wastewater using microbial electrochemical systems. Int. J. Hydrog. Energy 2017, 42, 96–102. [Google Scholar] [CrossRef]

- Radelyuk, I.; Tussupova, K.; Klemeš, J.J.; Persson, K.M. Oil refinery and water pollution in the context of sustainable development: Developing and developed countries. J. Clean. Prod. 2021, 302, 126987. [Google Scholar] [CrossRef]

- Hong, Y.; Wu, Y.-R. Acidolysis as a biorefinery approach to producing advanced bioenergy from macroalgal biomass: A state-of-the-art review. Bioresour. Technol. 2020, 318, 124080. [Google Scholar] [CrossRef]

- Zhou, X.; Yan, H.; Sun, Z.; Feng, X.; Zhao, H.; Liu, Y.; Chen, X.; Yang, C. Opportunities for utilizing waste cooking oil in crude to petrochemical process: Novel process design, optimal strategy, techno-economic analysis and life cycle society-environment assessment. Energy 2021, 237, 121530. [Google Scholar] [CrossRef]

- Fan, F.; Alagumalai, A.; Mahian, O. Sustainable biodiesel production from waste cooking oil: ANN modeling and environmental factor assessment. Sustain. Energy Technol. Assess 2021, 46, 101265. [Google Scholar]

- Goh, B.H.H.; Chong, C.T.; Ge, Y.; Ong, H.C.; Ng, J.-H.; Tian, B.; Ashokkumar, V.; Lim, S.; Seljak, T.; Józsa, V. Progress in utilisation of waste cooking oil for sustainable biodiesel and biojet fuel production. Energy Convers. Manag. 2020, 223, 113296. [Google Scholar] [CrossRef]

- Zhang, H.; Ozturk, U.A.; Wang, Q.; Zhao, Z. Biodiesel produced by waste cooking oil: Review of recycling modes in China, the US and Japan. Renew. Sustain. Energ. Rev. 2014, 38, 677–685. [Google Scholar] [CrossRef]

- Sun, J.; Xiong, X.; Wang, M.; Du, H.; Li, J.; Zhou, D.; Zuo, J. Microalgae biodiesel production in China: A preliminary economic analysis. Renew. Sustain. Energ. Rev. 2019, 104, 296–306. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Adamu, A.; Zhu, Z. Economic evaluation and production process simulation of biodiesel production from waste cooking oil. Curr. Opin. Green. Sustain. 2021, 4, 100091. [Google Scholar] [CrossRef]

- Ke, X.; Hua, X.; Sun, J.C.; Zheng, R.C.; Zheng, Y.-G. Synergetic Degradation of waste oil by constructed bacterial consortium for rapid in-situ reduction of kitchen waste. J. Biosci. Bioeng. 2021, 131, 412–419. [Google Scholar] [CrossRef] [PubMed]

- Jahan, R.; Bodratti, A.M.; Tsianou, M.; Alexandridis, P. Biosurfactants, natural alternatives to synthetic surfactants: Physicochemical properties and applications. Adv. Colloid Interface Sci. 2020, 275, 102061. [Google Scholar] [CrossRef]

- Varjani, S.; Rakholiya, P.; Yong Ng, H.; Taherzadeh, M.J.; Hao Ngo, H.; Chang, J.-S.; Wong, J.W.C.; You, S.; Teixeira, J.A.; Bui, X.-T. Bio-based rhamnolipids production and recovery from waste streams: Status and perspectives. Bioresour. Technol. 2021, 319, 124213. [Google Scholar] [CrossRef]

- Dolman, B.M.; Wang, F.; Winterburn, J.B. Integrated production and separation of biosurfactants. Process Biochem. 2019, 83, 1–8. [Google Scholar] [CrossRef]

- Karlapudi, A.P.; Venkateswarulu, T.C.; Tammineedi, J.; Kanumuri, L.; Ravuru, B.K.; Dirisala, V.R.; Kodali, V.P. Role of biosurfactants in bioremediation of oil pollution-a review. Petroleum 2018, 4, 241–249. [Google Scholar] [CrossRef]

- Reis, R.S.; Pereira, A.G.; Neves, B.C.; Freire, D.M.G. Gene regulation of rhamnolipid production in Pseudomonas aeruginosa–A review. Bioresour. Technol. 2011, 102, 6377–6384. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Varjani, S.J.; Upasani, V.N. Critical review on biosurfactant analysis, purification and characterization using rhamnolipid as a model biosurfactant. Bioresour. Technol. 2017, 232, 389–397. [Google Scholar] [CrossRef]

- Varjani, S.J.; Upasani, V.N. Carbon spectrum utilization by an indigenous strain of Pseudomonas aeruginosa NCIM 5514: Production, characterization and surface active properties of biosurfactant. Bioresour. Technol. 2016, 221, 510–516. [Google Scholar] [CrossRef]

- Henkel, M.; Müller, M.M.; Kügler, J.H.; Lovaglio, R.B.; Contiero, J.; Syldatk, C.; Hausmann, R. Rhamnolipids as biosurfactants from renewable resources: Concepts for next-generation rhamnolipid production. Process Biochem. 2012, 47, 1207–1219. [Google Scholar] [CrossRef]

- Radzuan, M.N.; Banat, I.M.; Winterburn, J. Production and characterization of rhamnolipid using palm oil agricultural refinery waste. Bioresour. Technol. 2017, 225, 99–105. [Google Scholar] [CrossRef]

- Pathania, A.S.; Jana, A.K. Utilization of waste frying oil for rhamnolipid production by indigenous Pseudomonas aeruginosa: Improvement through co-substrate optimization. J. Environ. Chem. Eng. 2020, 8, 104304. [Google Scholar] [CrossRef]

- Zhang, L.; Pemberton, J.E.; Maier, R.M. Effect of fatty acid substrate chain length on Pseudomonas aeruginosa ATCC 9027 monorhamnolipid yield and congener distribution. Process Biochem. 2014, 49, 989–995. [Google Scholar] [CrossRef]

- Jin, H.; Li, H.; Yin, Z.; Zhu, Y.; Lu, A.; Zhao, D.; Li, C. Application of raman spectroscopy in the rapid detection of waste cooking oil. Food Chem. 2021, 362, 130191. [Google Scholar] [CrossRef]

- Lan, G.; Fan, Q.; Liu, Y.; Chen, C.; Li, G.; Liu, Y.; Yin, X. Rhamnolipid production from waste cooking oil using Pseudomonas SWP-4. Biochem. Eng. J. 2015, 101, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Zhao, F.; Zhang, J.; Shi, R.; Han, S.; Ma, F.; Zhang, Y. Production of biosurfactant by a Pseudomonas aeruginosa isolate and its applicability to in situ microbial enhanced oil recovery under anoxic conditions. RSC Adv. 2015, 5, 36044–36050. [Google Scholar] [CrossRef]

- Sathi Reddy, K.; Yahya Khan, M.; Archana, K.; Gopal Reddy, M.; Hameeda, B. Utilization of mango kernel oil for the rhamnolipid production by Pseudomonas aeruginosa DR1 towards its application as biocontrol agent. Bioresour. Technol. 2016, 221, 291–299. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-H.; Oh, Y.-R.; Hwang, J.; Kang, J.; Kim, H.; Jang, Y.-A.; Lee, S.-S.; Hwang, S.Y.; Park, J.; Eom, G.T. Valorization of waste-cooking oil into sophorolipids and application of their methyl hydroxyl branched fatty acid derivatives to produce engineering bioplastics. Waste Manage. 2021, 124, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Chen, Y.; Liu, X.; Li, D. Rhamnolipid production from waste cooking oil using newly isolated halotolerant Pseudomonas aeruginosa M4. J. Clean. Prod. 2021, 278, 123879. [Google Scholar] [CrossRef]

- Benincasa, M.; Contiero, J.; Manresa, M.A.; Moraes, I.O. Rhamnolipid production by Pseudomonas aeruginosa LBI growing on soapstock as the sole carbon source. J. Food Eng. 2002, 54, 283–288. [Google Scholar] [CrossRef]

- Baskaran, S.M.; Zakaria, M.R.; Mukhlis Ahmad Sabri, A.S.; Mohamed, M.S.; Wasoh, H.; Toshinari, M.; Hassan, M.A.; Banat, I.M. Valorization of biodiesel side stream waste glycerol for rhamnolipids production by Pseudomonas aeruginosa RS6. Environ. Pollut. 2021, 276, 116742. [Google Scholar] [CrossRef]

- Zhu, L.; Yang, X.; Xue, C.; Chen, Y.; Qu, L.; Lu, W. Enhanced rhamnolipids production by Pseudomonas aeruginosa based on a pH stage-controlled fed-batch fermentation process. Bioresour. Technol. 2012, 117, 208–213. [Google Scholar] [CrossRef]

- Xu, L.; Xu, X.; Xiong, H.; Chen, L.; Li, Y. Rapid detection of vegetable cooking oils adulterated with inedible used oil using fluorescence quenching method with aqueous CTAB-coated quantum dots. Sensor. Actuat. B-Chem. 2014, 203, 697–704. [Google Scholar] [CrossRef]

- Chen, C.; Sun, N.; Li, D.; Long, S.; Tang, X.; Xiao, G.; Wang, L. Optimization and characterization of biosurfactant production from kitchen waste oil using Pseudomonas aeruginosa. Environ. Sci. Pollut. Res. 2018, 25, 14934–14943. [Google Scholar] [CrossRef]

- Mostafa, N.A.; Tayeb, A.M.; Mohamed, O.A.; Farouq, R. Biodegradation of petroleum oil effluents and production of biosurfactants: Effect of initial oil concentration. J. Surfactants Deterg. 2019, 22, 385–394. [Google Scholar] [CrossRef]

- Moya Ramírez, I.; Altmajer Vaz, D.; Banat, I.M.; Marchant, R.; Jurado Alameda, E.; García Román, M. Hydrolysis of olive mill waste to enhance rhamnolipids and surfactin production. Bioresour. Technol. 2016, 205, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Zhou, H.; Qin, H.; Zheng, G.; Atakpa, E.O.; Lin, X.; Lin, Y.; Zhang, C. Rhamnolipids produced under aerobic/anaerobic conditions: Comparative analysis and their promising applications. Sci. Total Environ. 2021, 811, 152414. [Google Scholar] [CrossRef]

- Li, X.; Sadiq, S.; Zhang, W.; Chen, Y.; Xu, X.; Abbas, A.; Chen, S.; Zhang, R.; Xue, G.; Sobotka, D.; et al. Salinity enhances high optically active L-lactate production from co-fermentation of food waste and waste activated sludge: Unveiling the response of microbial community shift and functional profiling. Bioresour. Technol. 2021, 319, 124124. [Google Scholar] [CrossRef] [PubMed]

- Jin, C.; Sun, S.; Yang, D.; Sheng, W.; Ma, Y.; He, W.; Li, G. Anaerobic digestion: An alternative resource treatment option for food waste in China. Sci. Total Environ. 2021, 779, 146397. [Google Scholar] [CrossRef]

| Strain Number | WO1 | WO2 | WO3 |

|---|---|---|---|

| Bacterial colony color | Vermilion | Chartreuse | Ivory white |

| WCO utilization rate (%) | 62.03 ± 3.29 | 86.50 ± 0.85 | 37.53 ± 3.71 |

| Lipase activity (U/mL) | 8.426 ± 0.350 | 8.155 ± 0.532 | 5.093 ± 1.344 |

| Organism | Carbon source | Rhamnolipid (g/L) | Rhamnolipid Yield (g/g) | References |

|---|---|---|---|---|

| Pseudomonas aeruginosa DR1 | Mango kernel oil (1%) | 1.80 | 0.18 | [33] |

| Pseudomonas aeruginosa M4 | Waste cooking oil (2.5%) | 1.12 | 0.045 | [35] |

| Pseudomonas aeruginosa strain B | Kitchen waste oil (2%) | 2.47 | 0.123 | [40] |

| Pseudomonas aeruginosa ATCC 9027 | Petroleum oil waste (2%) | 2.70 | 0.135 | [41] |

| Pseudomonas aeruginosa PAO1 | Olive mill waste (0.2%) | 0.30 | 0.15 | [42] |

| Pseudomonas aeruginosa WO2 | Waste cooking oil (1%) | 3.03 | 0.328 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.; Teng, Z.; Liu, J.; Li, T. Conversion of Waste Cooking Oil to Rhamnolipid by a Newly Oleophylic Pseudomonas aeruginosa WO2. Int. J. Environ. Res. Public Health 2022, 19, 1700. https://doi.org/10.3390/ijerph19031700

Shi S, Teng Z, Liu J, Li T. Conversion of Waste Cooking Oil to Rhamnolipid by a Newly Oleophylic Pseudomonas aeruginosa WO2. International Journal of Environmental Research and Public Health. 2022; 19(3):1700. https://doi.org/10.3390/ijerph19031700

Chicago/Turabian StyleShi, Shu, Zedong Teng, Jianwei Liu, and Tinggang Li. 2022. "Conversion of Waste Cooking Oil to Rhamnolipid by a Newly Oleophylic Pseudomonas aeruginosa WO2" International Journal of Environmental Research and Public Health 19, no. 3: 1700. https://doi.org/10.3390/ijerph19031700

APA StyleShi, S., Teng, Z., Liu, J., & Li, T. (2022). Conversion of Waste Cooking Oil to Rhamnolipid by a Newly Oleophylic Pseudomonas aeruginosa WO2. International Journal of Environmental Research and Public Health, 19(3), 1700. https://doi.org/10.3390/ijerph19031700