Spatiotemporal Differences and Spatial Spillovers of China’s Green Manufacturing under Environmental Regulation

Abstract

:1. Introduction

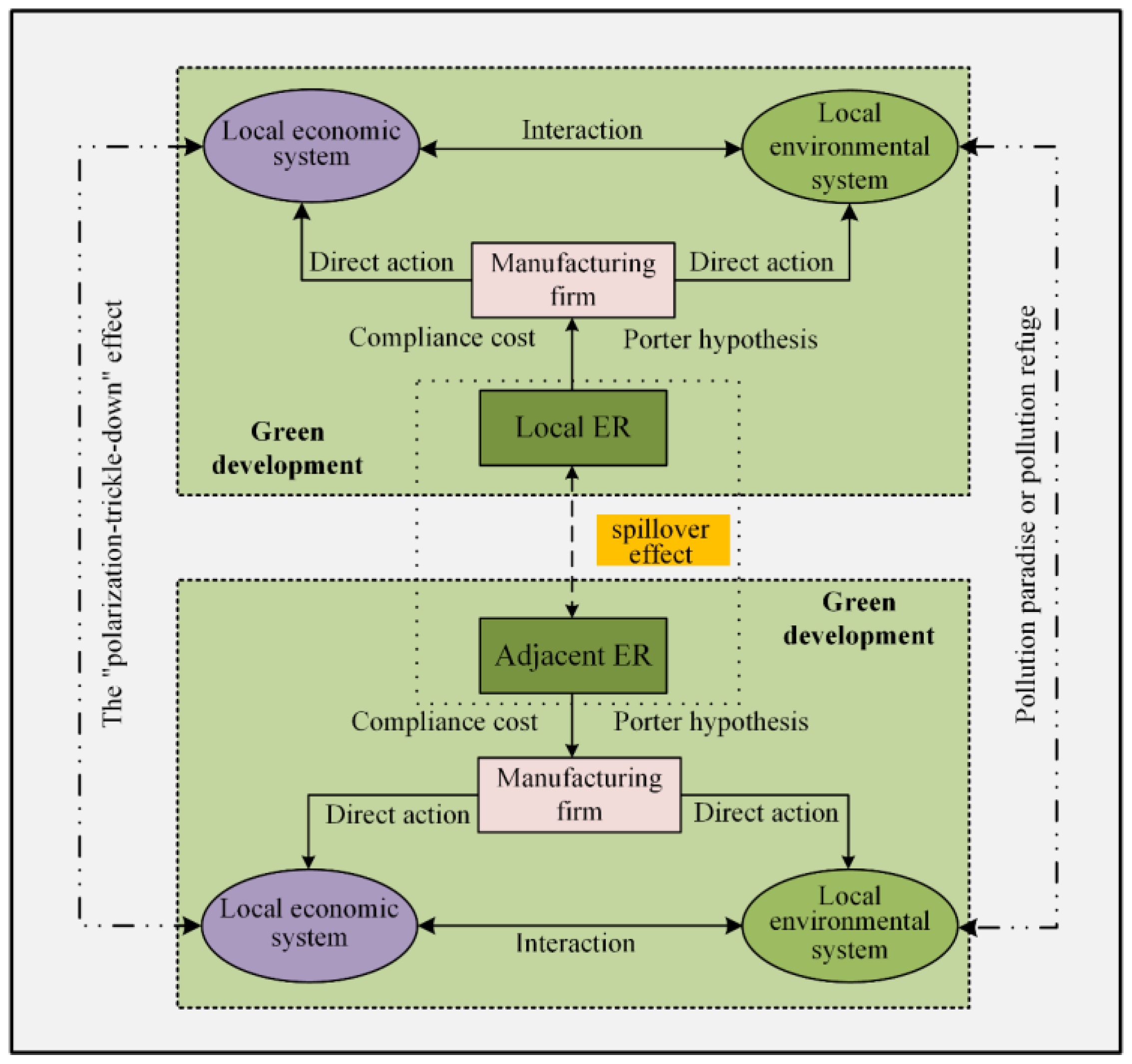

2. Theoretical Foundation

3. Methods and Data

3.1. Urban Green Manufacturing Efficiency

3.1.1. Indicator System Construction

3.1.2. Calculation Method

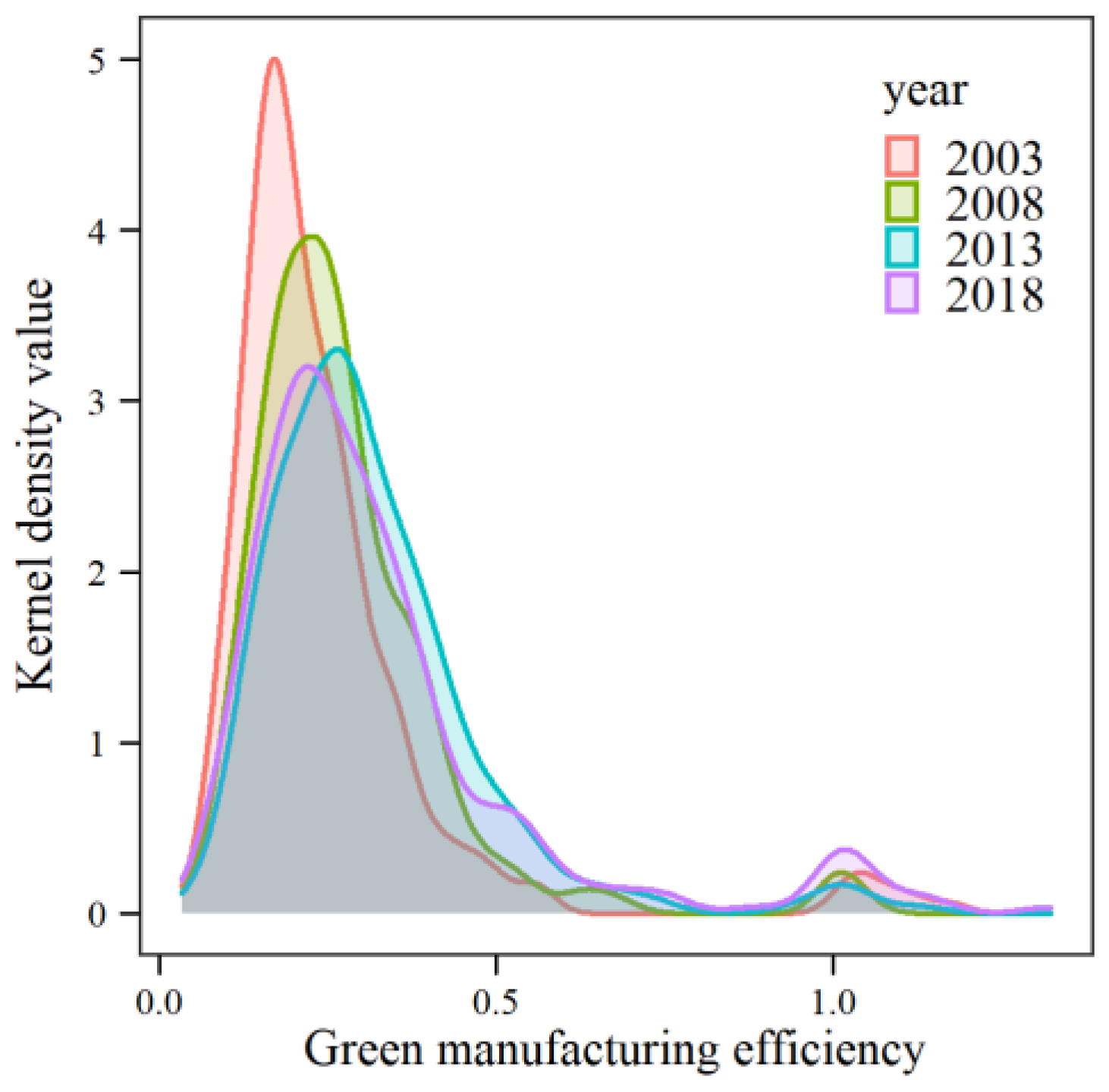

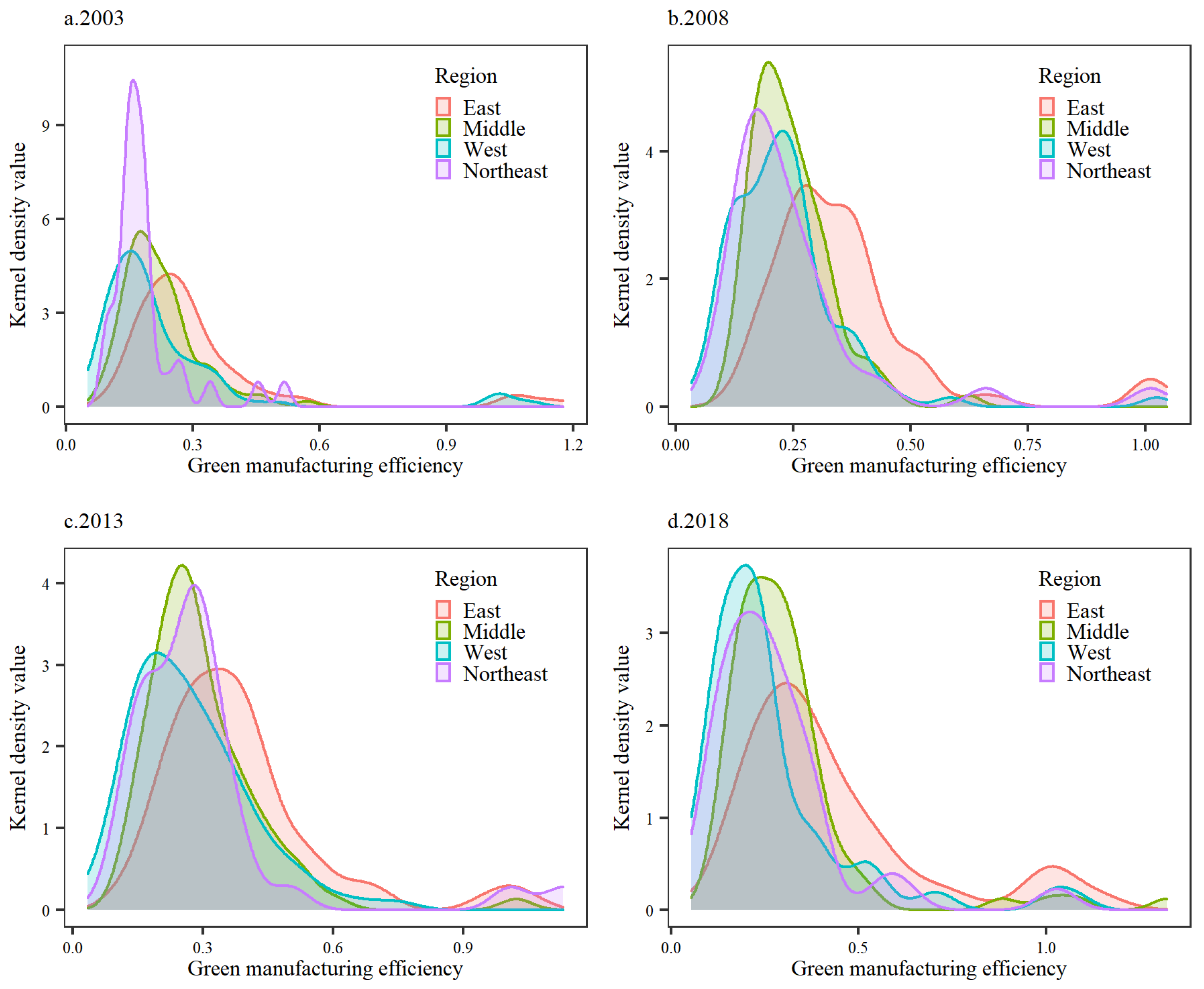

3.2. Kernel Density Estimation

3.3. Hot Spot Analysis

3.4. Space Panel Durbin Model

- (1)

- Geographic distance matrix (). The first law of geography in geography states that spatial influence presents as a characteristic of decay with spatial distance [48], so the inverse of the Euclidean distance between cities within the study sample was used to construct the weight matrix, and the formula is:

- (2)

- Economic distance matrix (). The close economic ties of spatial units with different economic development levels can reflect their actual economic spatial relationships through distance, so the economic distance matrix with the difference in GDP per capita among research units as the measurement index was constructed, and the formula is:where represent the per capita GDP of cities , respectively.

- (3)

- Economic-geographic distance nested matrix (). In fact, the economic development and closeness of linkage of spatial units is the result of the joint action of multiple factors, such as economic, cultural and institutional factors, and measuring the degree of spatial linkage simply by spatial distance or economic distance triggers certain errors. Therefore, the nested matrix of economic-geographical distance was used to measure the difference in regional unit spatial connections, and the formula is:where is the nested spatial weight of the economic-geographic distance between cities and ; is the constructed spatial weight matrix of geographic distance; is the average actual GDP of city λ from 2003 to 2018; and represents the sum of the actual GDP of all cities from 2003 to 2018.

4. Analysis of the Results

4.1. City Green Manufacturing Efficiency Measurement

4.1.1. Changes in Regional Characteristics

4.1.2. Spatial-Temporal Agglomeration and Differentiation

4.2. Empirical Study on Environmental Regulation Effect

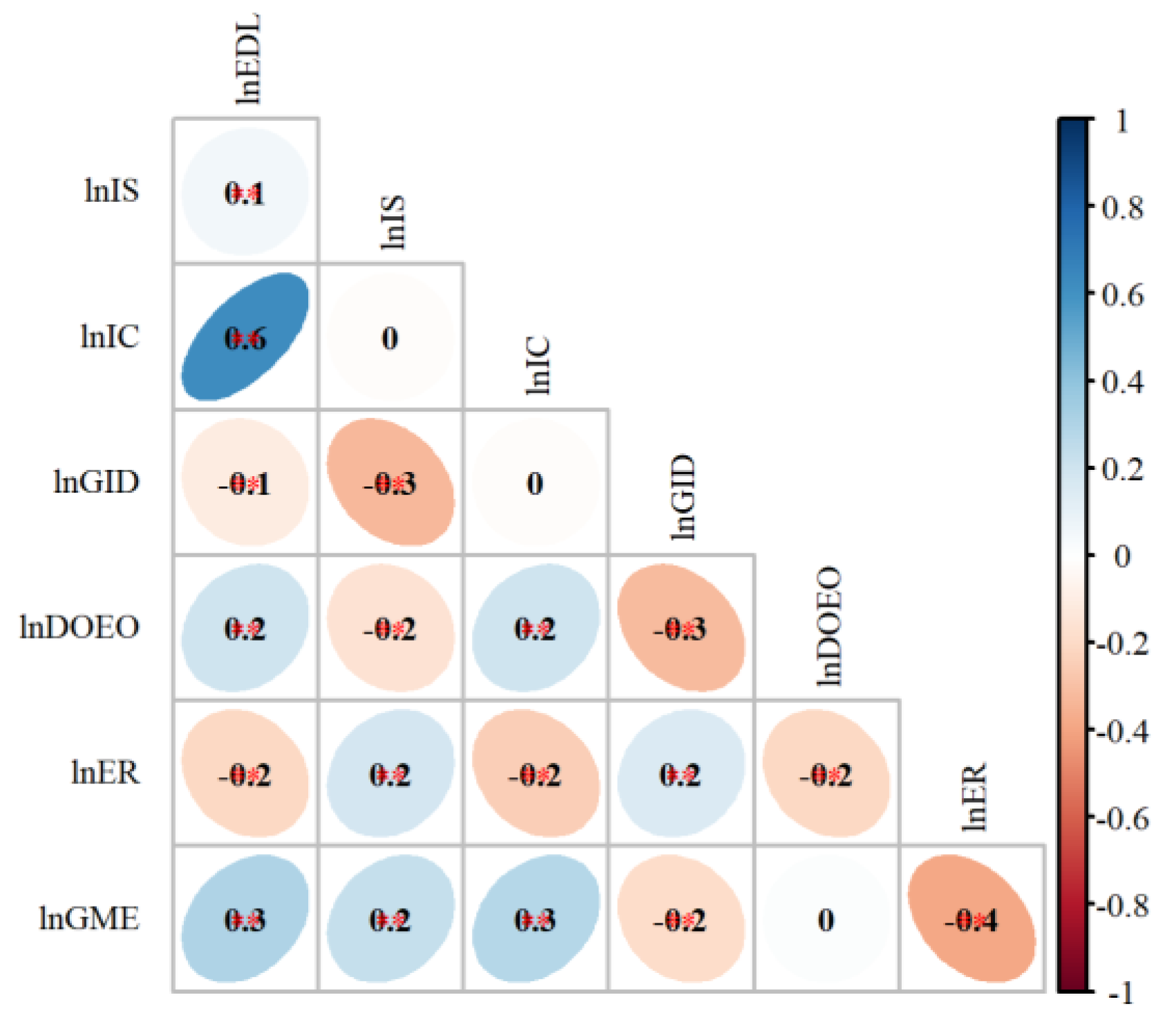

4.2.1. Variable Setting

- (1)

- Explained variable.

- (2)

- Core explanatory variable.

- (3)

- Control variables.

- Industrial Structure (IS). Due to the manufacturing industry belonging to secondary industry, the differentiated green development of industries has heterogeneity in economic output, environmental output and green efficiency [53]. To avoid multicollinearity among influencing factors, the ratio of the value added of secondary and tertiary industries, which reflects industrial upgrading, was applied to characterize the change in industrial structure.

- Economic development level (EDL). Taking the “Environmental Kuznets Curve” as the mainstream hypothesis, this paper expounded the relationship between economic growth and environmental development. So, economic growth was an important indicator that affected urban development, and economic development inevitably affects urban green manufacturing efficiency. Therefore, GDP per person was selected as the quantitative index [54].

- Innovation capability (IC). Digitalization and intelligence are the common trends of current manufacturing development, and innovation drive is an important push to achieve the improvement of manufacturing technology and management technology [34]. To measure the innovation capacity of cities in innovation activities, the proportion of local science and technology expenditure was considered as its proxy.

- Government Intervention Degree (GID). The inhibitory effect of “government failure” on urban green development has been confirmed by scholars, while some scholars believe that appropriate government intervention can effectively promote the urban innovation environment and infrastructure construction to provide basic guarantees for green all-factor improvement [55,56,57]. Fiscal expenditure is an important indicator of the degree of government intervention, so the share of fiscal expenditure was used as a token variable.

- Degree of external openness (DOEO). Foreign direct investment brings the externalities of a “pollution paradise” or “pollution halo”, which leads to a change in the green manufacturing efficiency of the city. Therefore, we chose the proportion of foreign-invested enterprises as the representation.

- (4)

- Variables set pre-test

4.2.2. Model Selection Test and Model Reconstruction

4.2.3. Environmental Regulation Parameter Estimation Analysis

4.3. Theoretical Framework Construction of Manufacturing Green Development from the Perspective of Environmental Regulation

5. Conclusions

5.1. Distribution of Cluster Centers

5.2. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zhou, Y.; Xiao, F.; Deng, W. Is smart city a slogan? Evidence from China. Asian Geogr. 2022, 39, 1–18. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and Smart Manufacturing: An Integrated Approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Li, L.Y. China Manufacturing Development Research Report 2019: 40 Years of Made in China and Smart Manufacturing; Science Press: Beijing, China, 2019. [Google Scholar]

- Ulucak, R. How do environmental technologies affect green growth? Evidence from BRICS economies. Sci. Total Environ. 2020, 712, 136504. [Google Scholar] [CrossRef]

- Yang, Q.Y.; Song, D.Y. How does environmental regulation break the resource curse: Theoretical and empirical study on China. Resour. Policy 2019, 64, 101480. [Google Scholar] [CrossRef]

- Khandelwal, A.K.; Schott, P.K.; Wei, S.J. Trade Liberalization and Embedded Institutional Reform: Evidence from Chinese Exporters. Am. Econ. Rev. 2013, 103, 2169–2195. [Google Scholar] [CrossRef]

- Young, A. The razor’s edge: Distortions and incremental reform in the People’s Republic of China. Q. J. Econ. 2000, 115, 1091–1135. [Google Scholar] [CrossRef]

- Young, A. The tyranny of numbers: Confronting the statistical realities of the East Asian growth experience. Q. J. Econ. 1995, 110, 641–680. [Google Scholar] [CrossRef]

- Brandt, L.; Biesebroeck, J.V.; Zhang, Y. Creative accounting or creative destruction? Firm-level productivity growth in Chinese manufacturing. J. Dev. Econ. 2012, 97, 339–351. [Google Scholar] [CrossRef]

- Brandt, L.; Biesebroeck, J.V.; Wang, L.H.; Zhang, Y.F. WTO accession and performance of Chinese manufacturing firms. Am. Econ. Rev. 2017, 107, 2784–2820. [Google Scholar] [CrossRef]

- Zhang, J. Capital formation, industrialization and economic growth: Understanding China’s economic reform. Econ. Syst. Res. 2002, 6, 3–13. (In Chinese) [Google Scholar]

- Shen, N. An empirical analysis on total factor productivity diversity in China’s manufacturing industry. China Soft Sci. 2006, 6, 101–110. (In Chinese) [Google Scholar] [CrossRef]

- Hong, L.; Shi, J.F. Energy efficiency analysis on Chinese industrial sectors: An improved Super-SBM model with undesirable outputs. J. Clean. Prod. 2014, 65, 97–107. [Google Scholar] [CrossRef]

- Goto, M.; Otsuka, A.; Sueyoshi, T. DEA (Data Envelopment Analysis) assessment of operational and environmental efficiencies on Japanese regional industries. Energy 2014, 66, 535–549. [Google Scholar] [CrossRef]

- Du, J.L.; Liu, Y.; Diao, W.X. Assessing Regional Differences in Green Innovation Efficiency of Industrial Enterprises in China. Int. J. Environ. Res. Public Health 2019, 16, 940. [Google Scholar] [CrossRef]

- Li, T.; Liang, L.; Han, D. Research on the Efficiency of Green Technology Innovation in China’s Provincial High-End Manufacturing Industry Based on the RAGA-PP-SFA Model. Math. Probl. Eng. 2018, 2018, 9463707. [Google Scholar] [CrossRef]

- Shi, X.; Lian, S. Green total factor productivity and its decomposition of Chinese manufacturing based on the MML index: 2003–2015. J. Clean. Prod. 2019, 222, 998–1008. [Google Scholar] [CrossRef]

- Xie, R.H.; Yuan, Y.J.; Huang, J.J. Different Types of Environmental Regulations and Heterogeneous Influence on “Green” Productivity: Evidence from China. Ecol. Econ. 2017, 132, 104–112. [Google Scholar] [CrossRef]

- Wu, H.; Hao, Y.; Ren, S. How do environmental regulation and environmental decentralization affect green total factor energy efficiency: Evidence from China. Energy Econ. 2020, 91, 104880. [Google Scholar] [CrossRef]

- Mani, M.; Wheeler, D. In Search of Pollution Havens? Dirty Industry in the World Economy, 1960–1995. J. Environ. Manag. 1998, 7, 215–247. [Google Scholar] [CrossRef]

- Antweiler, W.; Copeland, B.R.; Taylor, M.S. Is Free Trade Good for the Environment? Am. Econ. Rev. 1998, 91, 877–908. [Google Scholar] [CrossRef]

- Peng, X. Strategic interaction of environmental regulation and green productivity growth in China: Green innovation or pollution refuge? Sci. Total Environ. 2020, 732, 139200. [Google Scholar] [CrossRef] [PubMed]

- Ren, S.G.; Li, X.L.; Yuan, B.L.; Li, D.Y.; Chen, X.H. The effects of three types of environmental regulation on eco-efficiency: A cross-region analysis in China. J. Clean. Prod. 2018, 173, 245–255. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhong, S.H.; Shi, T.; Zhang, X.L. Environmental regulation and haze pollution: Neighbor-companion or neighbor-beggar? Energy Policy 2021, 151, 112183. [Google Scholar] [CrossRef]

- Porter, G. Global Environmental Politics; Westview Press: Boulder, CO, USA, 1991. [Google Scholar]

- Jean, O.L.; Ashoka, M. Innovation and the international diffusion of environmentally responsive technology. Res. Policy 1996, 25, 549–571. [Google Scholar] [CrossRef]

- Jaffe, A.B.; Stavins, R.N. Dynamic Incentives of Environmental Regulations: The Effects of Alternative Policy Instruments on Technology Diffusion. J. Environ. Econ. Manag. 1995, 29, S43–S63. [Google Scholar] [CrossRef]

- Beata, K.B. Does Relative Location Matter for Bilateral Trade Flows? An Extension of the Gravity Mode. J. Econ. Integr. 2001, 16, 379–398. [Google Scholar] [CrossRef]

- Tong, Y.; Liu, H.Y.; Ma, Y.; Liu, J.; Zhang, R. The impact of China’s tourism economy on urban green development and spatial spillover effect. Acta Geogr. Sin. 2021, 76, 2504–2521. (In Chinese) [Google Scholar] [CrossRef]

- Yan, C.; Di, D.; Li, G.; Wang, J. Environmental regulation and the supply efficiency of environmental public services: Evidence from environmental decentralization of 289 cities in China. Growth Change 2021, 53, 515–535. [Google Scholar] [CrossRef]

- Xiong, B.; Wang, R.M. Effect of Environmental Regulation on Industrial Solid Waste Pollution in China: From the Perspective of Formal Environmental Regulation and Informal Environmental Regulation. Int. J. Environ. Res. Public Health 2020, 17, 7798. [Google Scholar] [CrossRef]

- Chen, Q.; Mao, Y.; Morrison, A.M. Impacts of Environmental Regulations on Tourism Carbon Emissions. Int. J. Environ. Res. Public Health 2021, 18, 12850. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Wang, Y.X.; Zhao, L.; Zhao, L. Temporal and spatial evolution of total factor productivity in Chinese manufacturing industry and its influencing factors. Acta Geogr. Sin. 2021, 76, 3061–3075. (In Chinese) [Google Scholar] [CrossRef]

- Zhai, X.Q.; An, Y.F. Analyzing influencing factors of green transformation in China’s manufacturing industry under environmental regulation: A structural equation model. J. Clean. Prod. 2020, 251, 119760. [Google Scholar] [CrossRef]

- Cao, Y.R.; Liu, J.; Yu, Y.; Wei, G. Impact of environmental regulation on green growth in China’s manufacturing industry-based on the Malmquist-Luenberger index and the system GMM model. Environ. Sci. Pollut. Res. 2020, 27, 41928–41945. [Google Scholar] [CrossRef]

- Claudia, G.; Francesco, Q. Beyond inducement in climate change: Does environmental performance spur environmental technologies? A regional analysis of cross-sectoral differences. Ecol. Econ. 2013, 96, 99–113. [Google Scholar] [CrossRef]

- Porter, M.E.; Van der Linde, C. Toward a New Conception of the Environment-Competitiveness Relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Wang, F.Z.; Guo, X.C. The impact of environmental regulation intensity on green technology innovation in resource-based industries-an empirical test based on panel data from 2003 to 2011. Chin. J. Popul. Resour. Environ. 2015, S1, 143–146. (In Chinese) [Google Scholar]

- Candau, F.; Dienesch, E. Pollution Haven and Corruption Paradise. J. Environ. Econ. Manag. 2017, 85, 171–192. [Google Scholar] [CrossRef]

- Becker, R.A. Local environmental regulation and plant-level productivity. Ecol. Econ. 2011, 70, 2516–2522. [Google Scholar] [CrossRef]

- Stoever, J.; Weche, J.P. Environmental Regulation and Sustainable Competitiveness: Evaluating the Role of Firm-Level Green Investments in the Context of the Porter Hypothesis. Environ. Resour. Econ. 2018, 70, 429–455. [Google Scholar] [CrossRef]

- Song, M.L.; Wang, S.H.; Sun, J. Environmental regulations, staff quality, green technology, R&D efficiency, and profit in manufacturing. Technol. Forecast. Soc. Chang. 2018, 133, 1–14. [Google Scholar] [CrossRef]

- Ben Kheder, S.; Zugravu, N. Environmental regulation and French firms location abroad: An economic geography model in an international comparative study. Ecol. Econ. 2012, 77, 48–61. [Google Scholar] [CrossRef]

- Solarin, S.A.; Al-Mulali, U.; Musah, I.; Ozturk, I. Investigating the pollution haven hypothesis in Ghana: An empirical investigation. Energy 2017, 124, 706–719. [Google Scholar] [CrossRef]

- Brunnermeier, S.B.; Cohen, M.A. Determinants of Environmental Innovation in US Manufacturing Industries. J. Environ. Econ. Manag. 2003, 45, 278–293. [Google Scholar] [CrossRef]

- Young, A. Gold into base metals: Productivity growth in the People’s Republic of China during the reform period. J. Political Econ. 2003, 111, 1220–1260. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Tobler, W.R. A computer movie simulating urban growth in the Detroit region. Econ. Geogr. 1970, 46, 234–240. [Google Scholar] [CrossRef]

- Zhao, X.G.; Fan, L. Spatial distribution characteristics and convergence of China’s regional energy intensity: An industrial transfer perspective. J. Clean. Prod. 2019, 233, 903–917. [Google Scholar] [CrossRef]

- Baldassarre, B.; Schepers, M.; Bockenc, N.; Cuppenb, E.; Korevaarb, G.; Calabrettaa, G. Industrial Symbiosis: Towards a design process for eco-industrial clusters by integrating Circular Economy and Industrial Ecology perspectives. J. Clean. Prod. 2019, 216, 446–460. [Google Scholar] [CrossRef]

- Bezdek, R.H.; Wendling, R.M.; DiPerna, P. Environmental protection, the economy, and jobs: National and regional analyses. J. Environ. Econ. Manag. 2008, 86, 63–79. [Google Scholar] [CrossRef]

- Ye, Q.; Zeng, G.; Dai, S.; Wang, F.L. The impact of different environmental regulatory tools on China’s technological innovation of energy conservation and emission reduction-based on panel data of 285 prefecture-level cities. Chin. J. Popul. Resour. Environ. 2018, 28, 115–122. (In Chinese) [Google Scholar] [CrossRef]

- Liu, W.; Tong, J.; Yue, X.H. How Does Environmental Regulation Affect Industrial Transformation? A Study Based on the Methodology of Policy Simulation. Math. Probl. Eng. 2016, 2016, 2405624. [Google Scholar] [CrossRef]

- Blohmke, J.; Kemp, R.; Turkeli, S. Disentangling the causal structure behind environmental regulation. Technol. Forecast. Soc. Change 2016, 103, 174–190. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, J.H.; Dai, S. Regional eco-innovation in China: An analysis of eco-innovation levels and influencing factors. J. Clean. Prod. 2017, 153, 1–14. [Google Scholar] [CrossRef]

- Liu, X.H.; Buck, T. Innovation performance and channels for international technology spillovers: Evidence from Chinese high-tech industries. Res. Policy 2007, 36, 355–366. [Google Scholar] [CrossRef]

- Schuler, R.E. The long run limits to growth: Renewable resources, endogenous population, and technological change. J. Econ. Theory 1979, 21, 166–185. [Google Scholar] [CrossRef]

- Lian, Y.J.; Wang, W.D.; Ye, R.C. Monte Carlo simulation analysis of Hausman test statistics validity. Math. Stat. Manag. 2014, 5, 830–841. (In Chinese) [Google Scholar] [CrossRef]

- Li, H.; He, F.; Deng, G.J. How does Environmental Regulation Promote Technological Innovation and Green Development? New Evidence from China. Pol. J. Environ. Stud. 2020, 29, 689–702. [Google Scholar] [CrossRef]

- Lesage, J.P.; Pace, P.K. Introduce to Spatial Econometrics; Taylor & Francis: Boca Raton, FL, USA, 2009. [Google Scholar] [CrossRef]

- Meng, F.S.; Xu, Y.; Zhao, G. Environmental regulations, green innovation and intelligent upgrading of manufacturing enterprises: Evidence from China. Sci. Rep. 2020, 10, 14485. [Google Scholar] [CrossRef]

- Chatzistamoulou, N.; Diagourtas, G.; Kounetas, K. Do pollution abatement expenditures lead to higher productivity growth? Evidence from Greek manufacturing industries. Rev. Environ. Econ. Policy 2017, 19, 15–34. [Google Scholar] [CrossRef]

- Hu, W.Q.; Jin, T.; Liu, Y. Effects of environmental regulation on the upgrading of Chinese manufacturing industry. Environ. Sci. Pollut. Res. 2019, 26, 27087–27099. [Google Scholar] [CrossRef]

- Boschma, R.; Martin, V.; Minondo, A. Neighbour regions as the source of new industries. Pap. Reg. Sci. 2017, 96, 227–246. [Google Scholar] [CrossRef]

- Alpay, E.; Buccola, S.; Kerkvliet, J. Productivity growth and environmental regulation in Mexican and US food manufacturing. Am. J. Agric. Econ. 2002, 84, 887–901. [Google Scholar] [CrossRef]

| Variable | Obs | Mean | Std. Dev. | Min | Max |

|---|---|---|---|---|---|

| LnGME | 4544 | −1.4061 | 0.5150 | −3.7213 | 0.2797 |

| LnER | 4544 | 0.8346 | 0.6069 | −2.7949 | 4.3102 |

| LnIS | 4544 | 10.1645 | 0.8360 | 4.5951 | 13.0557 |

| LnEDL | 4544 | 11.8795 | 1.9130 | 1.6094 | 16.9217 |

| LnIC | 4544 | −0.2361 | 0.4443 | −2.3591 | 1.4713 |

| LnGID | 4544 | 14.0877 | 1.1087 | 10.4058 | 18.2405 |

| LnDOEO | 4544 | 9.4171 | 2.2215 | 0.0000 | 14.9413 |

| Variable | VIF | 1/VIF |

|---|---|---|

| LnER | 1.17 | 0.8541 |

| LnIS | 1.20 | 0.8305 |

| LnEDL | 1.69 | 0.5919 |

| LnIC | 1.71 | 0.5851 |

| LnGID | 1.19 | 0.8385 |

| Variables | ||||||

|---|---|---|---|---|---|---|

| Coefficient | p | Coefficient | p | Coefficient | p | |

| Moran’s I | 41.163 | 0 | 21.885 | 0 | 33.385 | 0 |

| LM-error | 992.849 | 0 | 474.483 | 0 | 1021.81 | 0 |

| LM-lag | 1552.48 | 0 | 432.727 | 0 | 561.028 | 0 |

| LR-lag | 12.44 | 0.0293 | 10.91 | 0.0533 | 19.88 | 0.0013 |

| LR-error | 12.5 | 0.0285 | 17.4 | 0.0038 | 20.59 | 0.001 |

| Hausman | −135.36 | / | 36.93 | 0 | −114.15 | / |

| Variables | |||

|---|---|---|---|

| LnER | −0.0448 *** | −0.0427 *** | −0.0415 *** |

| (−12.46) | (−12.15) | (−11.61) | |

| LnIS | 0.345 *** | 0.339 *** | 0.339 *** |

| (19.30) | (18.81) | (18.88) | |

| LnEDI | −0.0654 *** | −0.0601 *** | −0.0775 *** |

| (−4.13) | (−3.81) | (−4.89) | |

| LnIC | −0.00144 | −0.0062 | −0.00147 |

| (−0.19) | (−0.83) | (−0.20) | |

| LnGID | 0.0275 | 0.0574 ** | 0.0211 |

| (1.13) | (2.22) | (0.87) | |

| Wx * LnER | 0.0877 *** | 0.0078 | 0.0125 |

| (2.89) | (1.34) | (0.44) | |

| Wx * LnIS | 0.271 | 0.0685 ** | 0.269 * |

| (1.60) | (2.31) | (1.93) | |

| Wx * LnEDI | −0.00660 | −0.0392 | 0.186 |

| (−0.05) | (−1.53) | (1.49) | |

| Wx * LnIC | −0.0378 | −0.000917 | −0.0796 |

| (−0.89) | (−0.08) | (−1.61) | |

| Wx * LnGID | 0.147 | −0.0727 * | 0.129 |

| (0.75) | (−1.84) | (0.77) | |

| 0.318 *** | 0.112 *** | 0.0136 | |

| (3.07) | (5.75) | (0.12) | |

| R2 | 0.0199 | 0.0326 | 0.106 |

| N | 4544 | 4544 | 4544 |

| Decomposition Category | Variables | |||

|---|---|---|---|---|

| Direct effect | LnER | −0.0444 *** | −0.0425 *** | −0.0414 *** |

| (−12.07) | (−11.82) | (−11.28) | ||

| LnIS | 0.348 *** | 0.343 *** | 0.342 *** | |

| (20.38) | (20.02) | (19.80) | ||

| LnEDI | −0.0661 *** | −0.0619 *** | −0.0781 *** | |

| (−4.35) | (−4.10) | (−5.11) | ||

| LnIC | −0.00166 | −0.00636 | −0.00157 | |

| (−0.23) | (−0.90) | (−0.22) | ||

| LnGID | 0.0280 | 0.0557 ** | 0.0211 | |

| (1.17) | (2.21) | (0.88) | ||

| Indirect effect | LnER | 0.111 ** | 0.00370 | 0.0130 |

| (2.45) | (0.59) | (0.46) | ||

| LnIS | 0.556 ** | 0.115 *** | 0.274 ** | |

| (2.36) | (4.02) | (2.06) | ||

| LnIC | −0.0513 | −0.000606 | −0.0766 | |

| (−0.83) | (−0.05) | (−1.54) | ||

| LnEDI | −0.0371 | −0.0502 * | 0.193 | |

| (−0.18) | (−1.77) | (1.47) | ||

| LnGID | 0.243 | −0.0712 * | 0.146 | |

| (0.83) | (−1.68) | (0.83) | ||

| Total effect | LnER | 0.0664 | −0.0388 *** | −0.0284 |

| (1.48) | (−5.56) | (−1.01) | ||

| LnIS | 0.903*** | 0.459 *** | 0.615 *** | |

| (3.87) | (14.99) | (4.73) | ||

| LnEDI | −0.103 | −0.112 *** | 0.115 | |

| (−0.51) | (−3.65) | (0.88) | ||

| LnIC | −0.0530 | −0.00696 | −0.0782 * | |

| (−0.90) | (−0.63) | (−1.65) | ||

| LnGID | 0.271 | −0.0154 | 0.167 | |

| (0.95) | (−0.39) | (0.99) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, J.; Cao, W.; Fang, Y.; Liu, Y.; Wang, X.; Wei, H. Spatiotemporal Differences and Spatial Spillovers of China’s Green Manufacturing under Environmental Regulation. Int. J. Environ. Res. Public Health 2022, 19, 11970. https://doi.org/10.3390/ijerph191911970

Tao J, Cao W, Fang Y, Liu Y, Wang X, Wei H. Spatiotemporal Differences and Spatial Spillovers of China’s Green Manufacturing under Environmental Regulation. International Journal of Environmental Research and Public Health. 2022; 19(19):11970. https://doi.org/10.3390/ijerph191911970

Chicago/Turabian StyleTao, Jie, Weidong Cao, Yebing Fang, Yujie Liu, Xueyan Wang, and Haipeng Wei. 2022. "Spatiotemporal Differences and Spatial Spillovers of China’s Green Manufacturing under Environmental Regulation" International Journal of Environmental Research and Public Health 19, no. 19: 11970. https://doi.org/10.3390/ijerph191911970

APA StyleTao, J., Cao, W., Fang, Y., Liu, Y., Wang, X., & Wei, H. (2022). Spatiotemporal Differences and Spatial Spillovers of China’s Green Manufacturing under Environmental Regulation. International Journal of Environmental Research and Public Health, 19(19), 11970. https://doi.org/10.3390/ijerph191911970