Screening of Factors for Assessing the Environmental and Economic Efficiency of Investment Projects in the Energy Sector

Abstract

:1. Introduction

- high capital intensity and long-term investment;

- regulated nature of operational and capital activities;

- limited external investment;

- organizational and technical complexity;

- high demand for qualified personnel.

2. Materials and Methods

2.1. Formation of a List of Factors for the Appraisal of Environmental and Economic Project Efficiency That Considers the Specifics of the Energy Industry

- Resource intensity of energy production;

- Environmental payments;

- Management of the energy facility;

- Environmental costs and cost of energy production;

- The environmental impact of the energy facility (atmospheric air; water resources; soil and land resources; and production-related waste generation).

2.2. Double Screening of Selected Factors to Determine the Minimum Sufficient Set of Key Factors for the Appraisal of Environmental and Economic Project Efficiency

- two experts holding major management positions in the industry;

- two research experts, working in universities or for the Academy of Sciences;

- one expert working at an energy company in scientific cooperation with universities.

2.3. Approbation of the Proposed System of Environmental Indicators in the Example of a Regional Energy Project for the Eco-Modernization of an Energy Facility

3. Results

3.1. Key Factors for Environmental and Economic Evaluation of Energy Investment Projects

- specific fuel consumption for energy production per unit of produced energy capacity;

- specific water consumption for energy production per unit of produced energy capacity;

- specific volume of toxic substance emissions per unit of produced energy capacity;

- specific volume of greenhouse gas emissions per unit of produced energy capacity;

- specific volume of discharges of pollutants per unit of produced energy capacity;

- specific volume of residual waste per unit of produced energy capacity;

- specific wastewater discharges per unit of produced energy capacity.

3.2. Case-Study

- specific fuel consumption for energy production per unit of produced energy capacity;

- specific water consumption for energy production per unit of produced energy capacity;

- specific volume of toxic substance emissions per unit of produced energy capacity;

- specific volume of greenhouse gas emissions per unit of produced energy capacity;

- specific volume of residual waste per unit of produced energy capacity.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Group of Factors | Name of the Factor | Factor Code | Number of the Expert | The Sum of Ranks | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Absolute Value | % | |||

| Resource intensity of energy production | Type of fuel used (natural gas, coal, fuel oil) | X1 | 1 | 1.5 | 8.5 | 6.5 | 3 | 1 | 1 | 1 | 1 | 1 | 25.5 | 0.26% |

| Fuel consumption for energy production per year | X2 | 33 | 34 | 37.5 | 33.5 | 28.5 | 35 | 2 | 28 | 10 | 10 | 251.5 | 2.54% | |

| Specific fuel consumption for energy production per unit of produced energy capacity | X3 | 2 | 6 | 8.5 | 17.5 | 3 | 4 | 3 | 3 | 2 | 2 | 51 | 0.52% | |

| Water consumption for production needs per year | X4 | 34 | 39.5 | 37.5 | 33.5 | 28.5 | 36 | 42 | 29 | 28 | 30 | 338 | 3.41% | |

| Specific water consumption for energy production per unit of produced energy capacity | X5 | 3 | 16 | 8.5 | 26.5 | 17.5 | 17 | 41 | 18 | 24 | 20 | 191.5 | 1.93% | |

| Land occupation for the implementation of the investment project | X6 | 35 | 39.5 | 29 | 38.5 | 37.5 | 37 | 4 | 44 | 30 | 33 | 327.5 | 3.31% | |

| Land occupation per unit of produced energy capacity | X7 | 21.5 | 26.5 | 29 | 33.5 | 28.5 | 28 | 5 | 35 | 29 | 32 | 268 | 2.71% | |

| Environmental payments | The amount of annual environmental payments (fee for emissions, fee for discharges, fee for waste disposal) | X8 | 37 | 42.5 | 40.5 | 43.5 | 44 | 38 | 44 | 33 | 39 | 36 | 397.5 | 4.02% |

| The amount of environmental payments (fee for emissions, fee for discharges, fee for waste disposal) per unit of produced energy capacity | X9 | 36 | 34 | 40.5 | 43.5 | 37.5 | 20 | 43 | 34 | 34 | 35 | 357.5 | 3.61% | |

| Management of the energy facility | The share of “green” investments in the total amount of project investments | X10 | 4 | 16 | 8.5 | 6.5 | 17.5 | 23 | 11 | 23 | 16 | 7 | 132.5 | 1.34% |

| Availability of own energy raw materials for energy production in the region of project implementation | X11 | 43 | 42.5 | 29 | 33.5 | 41.5 | 24 | 10 | 22 | 42 | 34 | 321.5 | 3.25% | |

| Availability of the necessary transport infrastructure | X12 | 44 | 26.5 | 19 | 17.5 | 17.5 | 25 | 32 | 24 | 17 | 13 | 235.5 | 2.38% | |

| Environmental costs and cost of energy production | The share of “green” investments in the total amount of project investments | X13 | 5 | 6 | 8.5 | 6.5 | 3 | 2 | 9 | 2 | 43 | 31 | 116 | 1.17% |

| Availability of own energy raw materials for energy production in the region of project implementation | X14 | 6 | 16 | 43.5 | 41.5 | 41.5 | 26 | 7 | 32 | 38 | 43 | 294.5 | 2.97% | |

| Availability of the necessary transport infrastructure | X15 | 42 | 16 | 43.5 | 41.5 | 41.5 | 27 | 8 | 27 | 44 | 44 | 334.5 | 3.38% | |

| Cost of energy production | X16 | 7 | 16 | 29 | 33.5 | 17.5 | 3 | 6 | 4 | 33 | 21 | 170 | 1.72% | |

| The environmental impact of the energy facility (atmospheric air) | Volume of greenhouse gas emissions per year | X17 | 21.5 | 44 | 29 | 26.5 | 28.5 | 34 | 18 | 30 | 7 | 23 | 261.5 | 2.64% |

| Specific volume of greenhouse gas emissions per unit of produced energy capacity | X18 | 8 | 16 | 8.5 | 17.5 | 9.5 | 7 | 17 | 6 | 3 | 3 | 95.5 | 0.96% | |

| Composition and structure of toxic substance emissions | X19 | 23 | 6 | 40.5 | 17.5 | 9.5 | 5 | 13 | 5 | 6 | 5 | 130.5 | 1.32% | |

| Volume of toxic substance emissions per year | X20 | 24 | 34 | 29 | 26.5 | 28.5 | 29 | 16 | 25 | 8 | 22 | 242 | 2.44% | |

| Specific volume of toxic substance emissions per unit of produced energy capacity | X21 | 9 | 6 | 8.5 | 6.5 | 9.5 | 8 | 15 | 7 | 4 | 4 | 77.5 | 0.78% | |

| Toxicity of emission components | X22 | 10 | 1.5 | 29 | 6.5 | 9.5 | 6 | 14 | 36 | 5 | 6 | 123.5 | 1.25% | |

| Volume of oxygen consumption during fuel combustion per year | X23 | 25 | 39.5 | 29 | 26.5 | 28.5 | 39 | 20 | 26 | 26 | 24 | 283.5 | 2.86% | |

| Specific oxygen consumption during fuel combustion per unit of produced energy capacity | X24 | 11 | 16 | 8.5 | 17.5 | 9.5 | 9 | 19 | 8 | 23 | 9 | 130.5 | 1.32% | |

| Thermal pollution of the atmosphere | X25 | 38 | 26.5 | 19 | 38.5 | 28.5 | 40 | 21 | 37 | 37 | 37 | 322.5 | 3.26% | |

| Compliance of emission purification technologies with the best available techniques | X26 | 31 | 6 | 8.5 | 6.5 | 3 | 19 | 12 | 14 | 9 | 8 | 117 | 1.18% | |

| The environmental impact of the energy facility (water resources) | Volume of wastewater discharges per year | X27 | 26 | 34 | 29 | 26.5 | 37.5 | 41 | 39 | 38 | 36 | 29 | 336 | 3.39% |

| Specific wastewater discharges per unit of produced energy capacity | X28 | 12 | 26.5 | 8.5 | 6.5 | 28.5 | 18 | 34 | 17 | 21 | 16 | 188 | 1.90% | |

| Composition and structure of discharges of pollutants into water bodies | X29 | 27 | 16 | 29 | 17.5 | 17.5 | 10 | 35 | 13 | 22 | 28 | 215 | 2.17% | |

| Specific volume of discharges of pollutants per unit of produced energy capacity | X30 | 13 | 16 | 8.5 | 6.5 | 9.5 | 11 | 38 | 12 | 19 | 15 | 148.5 | 1.50% | |

| Toxicity of discharge components | X31 | 14 | 16 | 29 | 6.5 | 9.5 | 12 | 36 | 9 | 20 | 17 | 169 | 1.71% | |

| Thermal pollution of the water bodies | X32 | 40 | 34 | 40.5 | 38.5 | 28.5 | 21 | 40 | 21 | 40 | 38 | 341.5 | 3.45% | |

| Compliance of waste treatment technologies with the best available techniques | X33 | 32 | 6 | 8.5 | 6.5 | 3 | 22 | 33 | 19 | 18 | 18 | 166 | 1.68% | |

| The environmental impact of the energy facility (soil and land resources, production-related waste generation) | The degree of change in the natural landscape of territories during the construction of an energy facility | X34 | 39 | 34 | 19 | 26.5 | 37.5 | 30 | 22 | 31 | 35 | 42 | 316 | 3.19% |

| Volume of soil and land resource pollution | X35 | 28 | 34 | 29 | 38.5 | 28.5 | 42 | 24 | 20 | 27 | 27 | 298 | 3.01% | |

| Specific soil and land resource pollution per unit of produced energy capacity | X36 | 15 | 16 | 8.5 | 17.5 | 28.5 | 13 | 23 | 16 | 14 | 14 | 165.5 | 1.67% | |

| Thermal pollution of the soil | X37 | 41 | 16 | 19 | 26.5 | 17.5 | 43 | 37 | 41 | 41 | 39 | 321 | 3.24% | |

| Production-related waste generation per year | X38 | 29 | 39.5 | 19 | 33.5 | 41.5 | 44 | 26 | 15 | 25 | 25 | 297.5 | 3.01% | |

| Specific production-related waste generation per unit of produced energy capacity | X39 | 16 | 26.5 | 8.5 | 17.5 | 17.5 | 31 | 25 | 42 | 11 | 11 | 206 | 2.08% | |

| Land occupation for storage of production-related waste | X40 | 30 | 26.5 | 29 | 26.5 | 28.5 | 14 | 30 | 43 | 13 | 26 | 266.5 | 2.69% | |

| Hazard class of production-related waste | X41 | 17 | 6 | 29 | 6.5 | 9.5 | 15 | 27 | 10 | 12 | 19 | 151 | 1.53% | |

| Specific volume of residual waste per unit of produced energy capacity | X42 | 18 | 16 | 8.5 | 6.5 | 17.5 | 16 | 28 | 11 | 15 | 12 | 148.5 | 1.50% | |

| The volume of waste used as secondary resources in own production per unit of produced energy capacity | X43 | 19 | 26.5 | 29 | 17.5 | 28.5 | 32 | 29 | 39 | 32 | 40 | 292.5 | 2.95% | |

| The volume of production-related waste sent for useful use to other enterprises per unit of produced energy capacity | X44 | 20 | 26.5 | 8.5 | 17.5 | 28.5 | 33 | 31 | 40 | 31 | 41 | 277 | 2.80% | |

| The sum of ranks | - | 990 | 990 | 990 | 990 | 990 | 990 | 990 | 990 | 990 | 990 | 9900 | 100.00% | |

References

- Chirambo, D. Towards the achievement of SDG 7 in sub-Saharan Africa: Creating synergies between Power Africa, Sustainable Energy for All and climate finance in-order to achieve universal energy access before 2030. Renew. Sustain. Energ Rev. 2018, 94, 600–608. [Google Scholar] [CrossRef]

- Kulczycka, J.; Smol, M. Application LCA for eco-efficiency assessment of investment projects. Acta Innov. 2015, 16, 29–38. [Google Scholar]

- Hennicke, P.; Borbonus, S.; Woerlen, C. The GEF’s interventions in the climate change focal area: The contribution to strategies for climate change mitigation and sustainable development. Energ. Sustain. Develop. 2007, 11, 13–25. [Google Scholar] [CrossRef]

- Ranjbari, M.; Saidani, M.; Shams Esfandabadi, Z.; Peng, W.; Lam, S.S.; Ashbashlo, M.; Quatraro, F.; Tabatabaei, M. Two decades of research on waste management in the circular economy: Insights from bibliometric, text mining, and content analyses. J. Clean. Prod. 2021, 314, 128009. [Google Scholar] [CrossRef]

- Rada, E.C.; Cioca, L.I.; Ionescu, G. Energy recovery from Municipal Solid Waste in EU: Proposals to assess the management performance under a circular economy perspective. MATEC Web Conf. 2017, 121, 05006. [Google Scholar] [CrossRef]

- Karaeva, A.; Magaril, E.; Al-Kayiem, H.; Torretta, V.; Rada, E.C. Approaches to the assessment of ecological and economic efficiency of investment projects: Brief review and recommendations for improvements. WIT Trans. Ecol. Environ. 2021, 253, 515–525. [Google Scholar] [CrossRef]

- Lehni, M.; Schmidheiny, S.; Stigson, B. Eco-Efficiency: Creating More Value with Less Impact; World Business Council for Sustainable Development: Geneva, Switzerland, 2000. [Google Scholar]

- Jin, X.; Liu, Q.; Long, H. Impact of cost–benefit analysis on financial benefit evaluation of investment projects under back propagation neural network. J. Comput. Appl. Math. 2021, 384, 113–172. [Google Scholar] [CrossRef]

- Karaeva, A.; Magaril, E.; Rada, E.C. Improving approaches to efficiency assessment of investment projects in the energy sector. WIT Trans. Ecol. Environ. 2020, 246, 113–123. [Google Scholar]

- ESCAP, Eco-Efficiency Indicators: Measuring Resource-Use Efficiency and the Impact of Economic Activities on the Environment. Available online: www.sustainabledevelopment.un.org/content/documents/785eco.pdf (accessed on 25 July 2022).

- Karaeva, A.; Magaril, E.; Torretta, V.; Ragazzi, M.; Rada, E.C. Green energy development in an industrial region: A case-study of Sverdlovsk region. Energy Rep. 2021, 7, 137–148. [Google Scholar] [CrossRef]

- Total Energy Consumption. Enerdata. Available online: https://yearbook.enerdata.net/total-energy/world-consumption-statistics.html (accessed on 25 July 2022).

- Global Energy Consumption Only Going Up. The World Counts. Available online: https://www.theworldcounts.com/challenges/climate-change/energy/global-energy-consumption (accessed on 25 July 2022).

- Al-Shetwi, A.Q. Sustainable development of renewable energy integrated power sector: Trends, environmental impacts, and recent challenges. Sci. Total Environ. 2022, 822, 153645. [Google Scholar] [CrossRef]

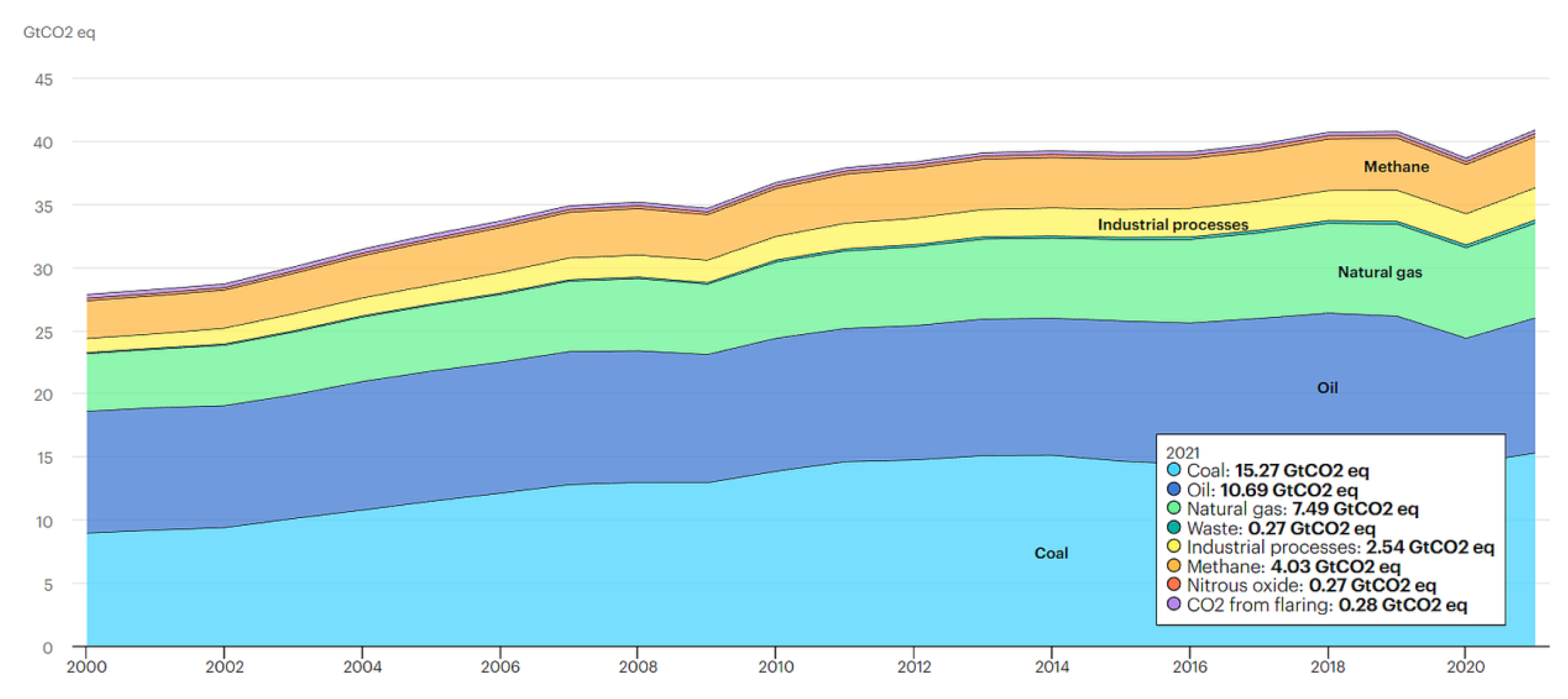

- IEA, Energy Related Greenhouse Gas Emissions, 2000–2021, IEA, Paris. Available online: https://www.iea.org/data-and-statistics/charts/energy-related-greenhouse-gas-emissions-2000-2021 (accessed on 25 July 2022).

- Sources of Greenhouse Gas Emissions. EPA. Available online: https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions (accessed on 26 July 2022).

- Importance of Methane. EPA. Available online: https://www.epa.gov/gmi/importance-methane (accessed on 26 July 2022).

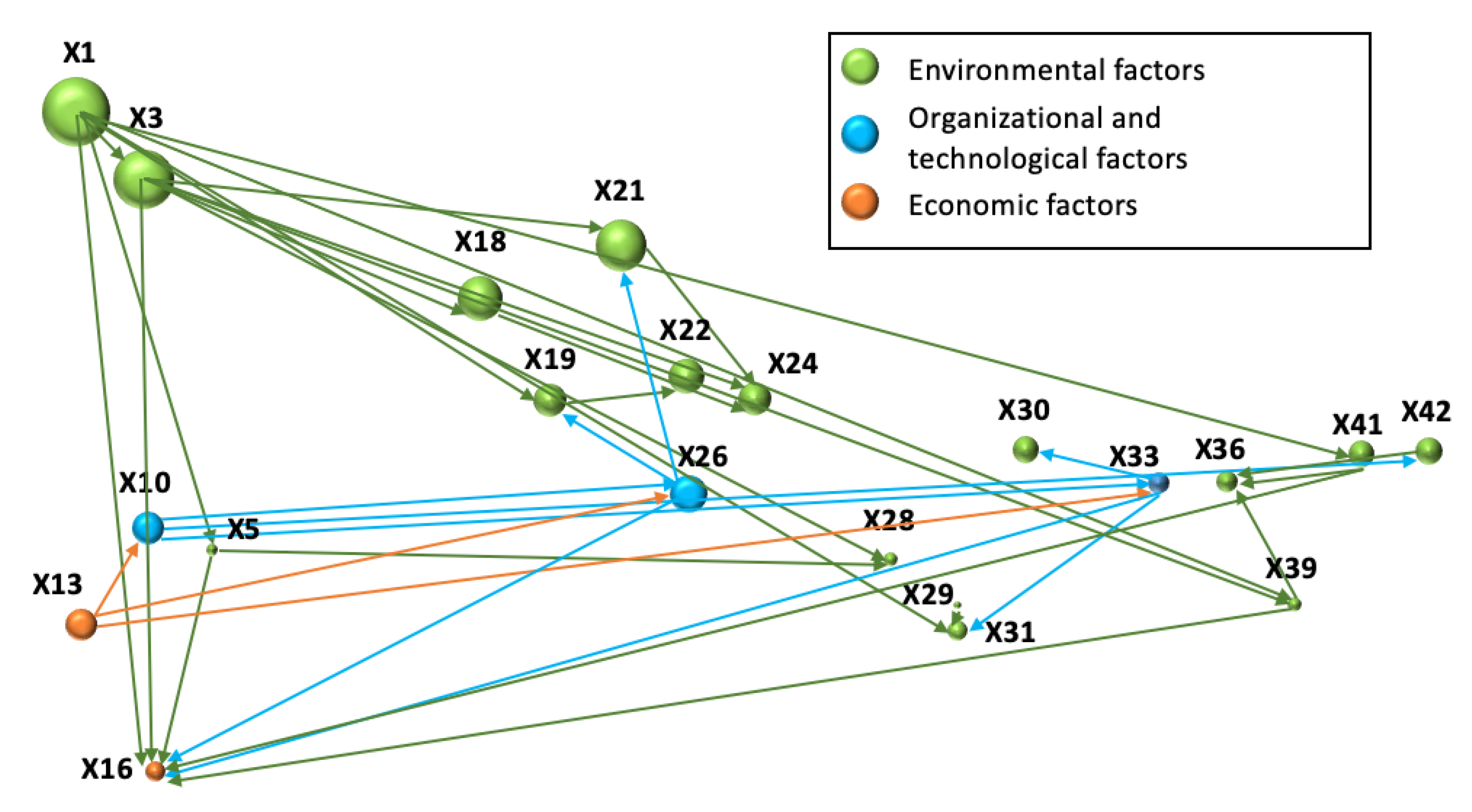

- Xu, Y.; Yang, K.; Zhao, G. The influencing factors and hierarchical relationships of offshore wind power industry in China. Environ. Sci. Pollut. Res. 2021, 28, 52329–52344. [Google Scholar] [CrossRef] [PubMed]

- Abdul Wahhab, H.A.; Al-Kayiem, H.H. Environmental Risk Mitigation by Biodiesel Blending from Eichhornia crassipes: Performance and Emission Assessment. Sustainability 2021, 13, 8274. [Google Scholar] [CrossRef]

- Gao, J.; Men, H.; Guo, F.; Liang, P.; Fan, Y. A multi-criteria decision-making framework for the location of photovoltaic power coupling hydrogen storage projects. J. Energy Storage 2021, 44, 103469. [Google Scholar] [CrossRef]

- Tao, U.; Wu, Y.; Wu, M.; Luo, X.; He, F.; Gao, R.; Zhang, L. Multi-criteria decision making for comprehensive benefits assessment of photovoltaic poverty alleviation project under sustainability perspective: A case study in Yunnan, China. J. Clean. Prod. 2022, 346, 131175. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Laclau, B.; Garnesson, T.; Yang, X.; Tukker, A. Energy-carbon-investment payback analysis of prefabricated envelope-cladding system for building energy renovation: Cases in Spain, the Netherlands, and Sweden. Renew. Sustain. Energy Rev. 2021, 145, 111077. [Google Scholar] [CrossRef]

- Chiang, C.; Young, C.-H. An engineering project for a flood detention pond surface-type floating photovoltaic power generation system with an installed capacity of 32,600.88 kWp. Energy Rep. 2022, 8, 2219–2232. [Google Scholar] [CrossRef]

- Kiselev, A.; Magaril, E. Financial tools for biogas project implementation at wastewater treatment plants: A case study of the Russian Federation. WIT Trans. Ecol. Environ. 2022, 255, 63–77. [Google Scholar] [CrossRef]

- Rocha, D.H.D.; Siqueira, D.S.; Silva, R.J. Effects of coal compositions on the environment and economic feasibility of coal generation technologies. Sustain. Energy Technol. Assess. 2021, 47, 101500. [Google Scholar] [CrossRef]

- Riansyah, S.; Chalid, D.A. Consideration factors in domestic investment for renewable energy development in Indonesia. E3S Web Conf. 2020, 202, 08002. [Google Scholar] [CrossRef]

- Szafranko, E. Assessment of the economic efficiency of energy-saving projects, methodology based on simple and compound methods. Energy Sci. Eng. 2022, 10, 423–438. [Google Scholar] [CrossRef]

- Gajdzik, B.; Sroka, W. Resource Intensity vs. Investment in Production Installations—The Case of the Steel Industry in Poland. Energies 2021, 14, 443. [Google Scholar] [CrossRef]

- Yingjian, L.; Abakr, A.Y.; Qi, Q.; Xinkui, U.; Jiping, Z. Energy efficiency assessment of fixed asset investment projects—A case study of a Shenzhen combined-cycle power plant. Renew. Sustain. Energy Rev. 2016, 59, 1195–1208. [Google Scholar] [CrossRef]

- Shah, W.U.H.; Hao, G.; Yan, H.; Yasmeen, R.; Padda, I.U.H.; Ullah, A. The impact of trade, financial development and government integrity on energy efficiency: An analysis from G7-Countries. Energy 2022, 255, 124507. [Google Scholar] [CrossRef]

- Yao, X.; Shah, W.U.H.; Yasmeen, R.; Zhang, Y.; Kamal, M.A.; Khan, A. The impact of trade on energy efficiency in the global value chain: A simultaneous equation approach. Sci. Total Environ. 2021, 765, 142759. [Google Scholar] [CrossRef] [PubMed]

- Nie, P.-Y.; Chen, Z.-R.; Wang, W.; Chen, X.-L. Innovation analysis under trading energy efficiency. Energy 2019, 186, 115866. [Google Scholar] [CrossRef]

- Becchetti, L.; Cordella, M.; Morone, P. Measuring investments progress in ecological transition: The Green Investment Financial Tool (GIFT) approach. J. Clean. Prod. 2022, 357, 131915. [Google Scholar] [CrossRef]

- Treshcheva, M.; Anikina, I.; Sergeev, V.; Skulkin, S.; Treshchev, D. Selection of Heat Pump Capacity Used at Thermal Power Plants under Electricity Market Operating Conditions. Energies 2021, 14, 226. [Google Scholar] [CrossRef]

- Muthuraman, M. Reduction in power plant specific water consumption. Int. Power Plant OM Conf. 2016, 1, 1–8. [Google Scholar] [CrossRef]

- Zurano-Cervelló, P.; Pozo, C.; Mateo-Sanz, J.M.; Jiménez, L.; Guillén-Gosálbez, G. Sustainability efficiency assessment of the electricity mix of the 28 EU member countries combining data envelopment analysis and optimized projections. Energy Policy 2019, 134, 110921. [Google Scholar] [CrossRef]

- Iosifov, V.V.; Ratner, S.V. Environmental management systems and environmental performance: The case of Russian energy sector. J. Environ. Manag. Tour. 2018, 9, 1377–1388. [Google Scholar] [CrossRef]

- Maia, R.; Ottoni, M.; Barros, J.; Aurélio, M.D.S. Assessment of the waste management reporting in the electricity sector. Clean. Responsib. Consum. 2021, 3, 100031. [Google Scholar] [CrossRef]

- Odeh, N.A.; Cockerill, T.T. Life cycle GHG assessment of fossil fuel power plants with carbon capture and storage. Energy Policy 2008, 36, 367–380. [Google Scholar] [CrossRef]

- Cormos, A.-M.; Dragan, S.; Cormos, C.-C. Integration of membrane technology for decarbonization of gasification power plants: A techno-economic and environmental investigation. Appl. Therm. Eng. 2022, 205, 118078. [Google Scholar] [CrossRef]

- Maysyuk, E.P.; Ivanova, I.Y. Environmental assessment of different fuel types for energy production in the Arctic regions of the Russian Far East. Arct. Ecol. Econ. 2020, 1, 26–36. [Google Scholar] [CrossRef]

- Toxic Wastewater from Coal Plants. Available online: https://environmentalintegrity.org/wp-content/uploads/Toxic-Wastewater-from-Coal-Plants-2016.08.11-1.pdf (accessed on 18 July 2022).

- Demir, C.; Yetis, U.; Unlu, K. Identification of waste management strategies and waste generation factors for thermal power plant sector wastes in Turkey. Waste Manag. Res. 2018, 37, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Chi-Squared Distribution. Available online: https://en.wikibooks.org/wiki/Engineering_Tables/Chi-Squared_Distibution (accessed on 13 July 2022).

- The Procedure for Recalculation of Indicators into Tons of Oil Equivalent. Available online: https://cogeneration.ru/recount/ (accessed on 15 July 2022). (In Russian).

- Nihalani, S.A.; Mishra, Y.D. Water Consumption Management for Thermal Power Plant. In Environmental Processes and Management; Singh, R., Shukla, P., Singh, P., Eds.; Springer: Cham, Switzerland, 2020; Volume 91, pp. 135–153. [Google Scholar] [CrossRef]

- Cost of Coal and Natural Gas for Electricity Generation in the United States from 1980 to 2021. Statista. Available online: https://www.statista.com/statistics/189180/natural-gas-vis-a-vis-coal-prices/ (accessed on 18 July 2022).

- Jin, Y.; Behrens, P.; Tukker, A.; Scherer, L. Water use of electricity technologies: A global meta-analysis. Renew. Sustain. Energy Rev. 2019, 115, 109391. [Google Scholar] [CrossRef]

- Federal Law N 7-FZ of 10.01.2002 (ed. of 12/30/2021) “On Environmental Protection”. Available online: www.consultant.ru/document/cons_doc_LAW_34823/ (accessed on 20 July 2022).

- Adami, L.; Schiavon, M.; Rada, E.C. Potential environmental benefits of direct electric heating powered by waste-to-energy processes as a replacement of solid-fuel combustion in semi-rural and remote areas. Sci. Total Environ. 2020, 740, 140078. [Google Scholar] [CrossRef]

- Shvetsova, O.A.; Lee, J.H. Minimizing the environmental impact of industrial production: Evidence from south Korean waste treatment investment projects. Appl. Sci. 2020, 10, 3489. [Google Scholar] [CrossRef]

- Ragazzi, M.; Ferrari, K.; Adami, L.; Schiavon, M.; Rada, E.C. Potentials of the waste-to-energy sector for an unconventional district heating system. Int. J. Energy Prod. Manag. 2019, 4, 115–123. [Google Scholar] [CrossRef]

- Kulczycka, J.; Smol, M. Environmentally friendly pathways for the evaluation of investment projects using life cycle assessment (LCA) and life cycle cost analysis (LCCA). Clean Technol. Environ. Pol. 2016, 18, 829–842. [Google Scholar] [CrossRef]

- Government Support for Business Research and Innovation in a World in Crisis. OECD iLibrary. Available online: https://www.oecd-ilibrary.org/sites/7a7891a5-en/index.html?itemId=/content/component/7a7891a5-en (accessed on 18 July 2022).

- Li, S.; Yu, Y.; Jahanger, A.; Usman, M.; Ning, Y. The Impact of Green Investment, Technological Innovation, and Globalization on CO2 Emissions: Evidence from MINT Countries. Front. Environ. Sci. 2022, 10, 868704. [Google Scholar] [CrossRef]

- Best Available Techniques (BAT) for Preventing and Controlling Industrial Pollution. OECD. Available online: https://www.oecd.org/chemicalsafety/risk-management/policies-on-best-available-techniques-or-similar-concepts-around-the-world.pdf (accessed on 18 July 2022).

- Temporary Methodology for Determining the Prevented Environmental Damage. Available online: http://www.consultant.ru/law/podborki/vremennaya_metodika_opredeleniya_predotvraschennogo_jekologicheskogo_uscherba/ (accessed on 18 July 2022).

- Tsai, W.H.; Lee, H.L.; Yang, C.H.; Huang, C.C. Input-output analysis for sustainability by using DEA method: A comparison study between European and Asian countries. Sustainability 2016, 8, 1230. [Google Scholar] [CrossRef]

- Arman, H.; Jamshidi, A.; Hadi-Vencheh, A. Eco-innovation analysis: A data envelopment analysis methodology. Environ. Technol. Innov. 2021, 23, 101770. [Google Scholar] [CrossRef]

- Halkos, G.E.; Polemis, M.L. The impact of economic growth on environmental efficiency of the electricity sector: A hybrid window DEA methodology for the USA. J. Environ. Manag. 2018, 211, 334–346. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. DEA environmental assessment in a time horizon: Malmquist index on fuel mix, electricity and CO2 of industrial nations. Energy Econ. 2013, 40, 370–382. [Google Scholar] [CrossRef]

- Bi, G.B.; Song, W.; Zhou, P.; Liang, L. Does environmental regulation affect energy efficiency in China’s thermal power generationα empirical evidence from a slacks-based DEA model. Energy Policy 2014, 66, 537–546. [Google Scholar] [CrossRef]

- Tenente, M.; Henriques, C.; da Silva, P.P. Eco-efficiency assessment of the electricity sector: Evidence from 28 European union countries. Econ. Anal. Policy 2020, 66, 293–314. [Google Scholar] [CrossRef]

| Factor Code | Name of the Factor | Reference |

|---|---|---|

| 1. Resource intensity of energy production | ||

| X1 | Type of fuel used (natural gas, coal, fuel oil) | [9,34] |

| X2 | Fuel consumption for energy production per year | [34] |

| X3 | Specific fuel consumption for energy production per unit of produced energy capacity | [9] |

| X4 | Water consumption for production needs per year | [35] |

| X5 | Specific water consumption for energy production per unit of produced energy capacity | [35] |

| X6 | Land occupation for the implementation of the investment project | [36] |

| X7 | Land occupation per unit of produced energy capacity | [9,36] |

| 2. Environmental payments | ||

| X8 | The amount of annual environmental payments (fee for emissions, fee for discharges, fee for waste disposal) | proposed by experts |

| X9 | The amount of environmental payments (fee for emissions, fee for discharges, fee for waste disposal) per unit of produced energy capacity | proposed by experts |

| 3. Management of the energy facility | ||

| X10 | Availability of an environmental management system at the energy facility | [37] |

| X11 | Compliance of the energy facility management system with international standards | proposed by authors |

| X12 | Availability of a waste management system at the energy facility | [38] |

| 4. Environmental costs and cost of energy production | ||

| X13 | The share of “green” investments in the total amount of project investments | proposed by authors |

| X14 | Availability of own energy raw materials for energy production in the region of the project implementation | proposed by experts |

| X15 | Availability of the necessary transport infrastructure | proposed by experts |

| X16 | Cost of energy production | [25] |

| 5. The environmental impact of the energy facility | ||

| Atmospheric air | ||

| X17 | Volume of greenhouse gas emissions per year | [39] |

| X18 | Specific volume of greenhouse gas emissions per unit of produced energy capacity | proposed by authors |

| X19 | Composition and structure of toxic substance emissions | [40] |

| X20 | Volume of toxic substance emissions per year | [41] |

| X21 | Specific volume of toxic substance emissions per unit of produced energy capacity | proposed by authors |

| X22 | Toxicity of emission components | [41] |

| X23 | Volume of oxygen consumption during fuel combustion per year | proposed by authors |

| X24 | Specific oxygen consumption during fuel combustion per unit of produced energy capacity | proposed by authors |

| X25 | Thermal pollution of the atmosphere | proposed by authors |

| X26 | Compliance of emission purification technologies with the best available techniques | proposed by authors |

| Water resources | ||

| X27 | Volume of wastewater discharges per year | [42] |

| X28 | Specific wastewater discharges per unit of produced energy capacity | proposed by authors |

| X29 | Composition and structure of discharges of pollutants into water bodies | [42] |

| X30 | Specific volume of discharges of pollutants per unit of produced energy capacity | proposed by authors |

| X31 | Toxicity of discharge components | [42] |

| X32 | Thermal pollution of the water bodies | proposed by authors |

| X33 | Compliance of waste treatment technologies with the best available techniques | proposed by authors |

| Soil and land resources, production-related waste generation | ||

| X34 | The degree of change in the natural landscape of territories during the construction of an energy facility | [36] |

| X35 | Volume of soil and land resource pollution | [36] |

| X36 | Specific soil and land resource pollution per unit of produced energy capacity | [36] |

| X37 | Thermal pollution of the soil | proposed by authors |

| X38 | Production-related waste generation per year | [43] |

| X39 | Specific production waste generation per unit of produced energy capacity | [9] |

| X40 | Land occupation for storage of production-related waste | proposed by experts |

| X41 | Hazard class of production-related waste | [43] |

| X42 | Specific volume of residual waste per unit of produced energy capacity | [9] |

| X43 | The volume of waste used as secondary resources in own production per unit of produced energy capacity | proposed by authors |

| X44 | The volume of production-related waste sent for useful use to other enterprises per unit of produced energy capacity | proposed by authors |

| Indicator | Before Project Implementation | After Project Implementation |

|---|---|---|

| Energy production, kWh | 178,550 | 191,700 |

| Total fuel consumption *, tons/tons of fuel equivalent including: | 539,220/387,520 | 224,500/323,520 |

| Natural gas, m3/tons/tons of oil equivalent | 121,900/97,500/140,670 | 275,000/220,000/317,350 |

| Fuel oil, tons/tons of oil equivalent | 3700/5070 | 4500/6170 |

| Coal, tons/tons of oil equivalent | 438,000/241,780 | 0 |

| Water consumption, m3 | 175,280 | 154,920 |

| Residual production waste, tons | 319,300 | 169,200 |

| Total emissions of harmful substances, tons including | 0.89 | 0.75 |

| SO2, tons | 0.39 | 0.02 |

| NOx, tons | 0.17 | 0.15 |

| CO, tons | 0.14 | 0.49 |

| PM, tons | 0.19 | 0.09 |

| CO2 emissions, tons | 933,668 | 535,769 |

| Name of the Factor | Factor Code | The Sum of Ranks | |

|---|---|---|---|

| Absolute Value | % | ||

| Type of fuel used (natural gas, coal, fuel oil) | X1 | 25.5 | 0.26 |

| Specific fuel consumption for energy production per unit of produced energy capacity | X3 | 51 | 0.52 |

| Specific volume of toxic substance emissions per unit of produced energy capacity | X21 | 77.5 | 0.78 |

| Specific volume of greenhouse gas emissions per unit of produced energy capacity | X18 | 95.5 | 0.96 |

| Share of “green” investments in the total amount of project investments | X13 | 116 | 1.17 |

| Compliance of emission purification technologies with the best available techniques | X26 | 117 | 1.18 |

| Toxicity of emission components | X22 | 123.5 | 1.25 |

| Composition and structure of toxic substance emissions | X19 | 130.5 | 1.32 |

| Specific oxygen consumption during fuel combustion per unit of produced energy capacity | X24 | 130.5 | 1.32 |

| Availability of an environmental management system at the energy facility | X10 | 132.5 | 1.34 |

| Specific volume of discharges of pollutants per unit of produced energy capacity | X30 | 148.5 | 1.50 |

| Specific volume of residual waste per unit of produced energy capacity | X42 | 148.5 | 1.50 |

| Hazard class of production-related waste | X41 | 151 | 1.53 |

| Specific soil and land resource pollution per unit of produced energy capacity | X36 | 165.5 | 1.67 |

| Compliance of waste treatment technologies with the best available techniques | X33 | 166 | 1.68 |

| Toxicity of discharge components | X31 | 169 | 1.71 |

| Cost of energy production | X16 | 170 | 1.72 |

| Specific wastewater discharges per unit of produced energy capacity | X28 | 188 | 1.90 |

| Specific water consumption for energy production per unit of produced energy capacity | X5 | 191.5 | 1.93 |

| Specific production-related waste generation per unit of produced energy capacity | X39 | 206 | 2.08 |

| Composition and structure of discharges of pollutants into water bodies | X29 | 215 | 2.17 |

| Name of Substance | ki * | Before Project Implementation | After Project Implementation | ||

|---|---|---|---|---|---|

| tons | Reduced Mass, tons | tons | Reduced Mass, tons | ||

| SO2 | 20.00 | 0.39 | 7.80 | 0.02 | 0.40 |

| NOx | 16.50 | 0.17 | 2.81 | 0.15 | 2.48 |

| CO | 0.40 | 0.14 | 0.06 | 0.49 | 0.20 |

| PM | 2.70 | 0.19 | 0.51 | 0.09 | 0.24 |

| Total | - | 0.89 | 11.17 | 0.75 | 3.31 |

| Indicator | Before Project Implementation | After Project Implementation |

|---|---|---|

| Specific fuel consumption for energy production per unit of produced energy capacity | 2.17 | 1.69 |

| Specific volume of toxic substance emissions per unit of produced energy capacity (considering the relative toxicity of the emission components, Table 4) | 0.06 | 0.02 |

| Specific volume of greenhouse gas emissions per unit of produced energy capacity | 5.23 | 2.79 |

| Specific water consumption for energy production per unit of produced energy capacity | 0.98 | 0.81 |

| Specific volume of residual waste per unit of produced energy capacity | 1.79 | 0.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karaeva, A.P.; Magaril, E.R.; Kiselev, A.V.; Cioca, L.-I. Screening of Factors for Assessing the Environmental and Economic Efficiency of Investment Projects in the Energy Sector. Int. J. Environ. Res. Public Health 2022, 19, 11716. https://doi.org/10.3390/ijerph191811716

Karaeva AP, Magaril ER, Kiselev AV, Cioca L-I. Screening of Factors for Assessing the Environmental and Economic Efficiency of Investment Projects in the Energy Sector. International Journal of Environmental Research and Public Health. 2022; 19(18):11716. https://doi.org/10.3390/ijerph191811716

Chicago/Turabian StyleKaraeva, Anzhelika Pirmamedovna, Elena Romenovna Magaril, Andrey Vladimirovich Kiselev, and Lucian-Ionel Cioca. 2022. "Screening of Factors for Assessing the Environmental and Economic Efficiency of Investment Projects in the Energy Sector" International Journal of Environmental Research and Public Health 19, no. 18: 11716. https://doi.org/10.3390/ijerph191811716

APA StyleKaraeva, A. P., Magaril, E. R., Kiselev, A. V., & Cioca, L.-I. (2022). Screening of Factors for Assessing the Environmental and Economic Efficiency of Investment Projects in the Energy Sector. International Journal of Environmental Research and Public Health, 19(18), 11716. https://doi.org/10.3390/ijerph191811716