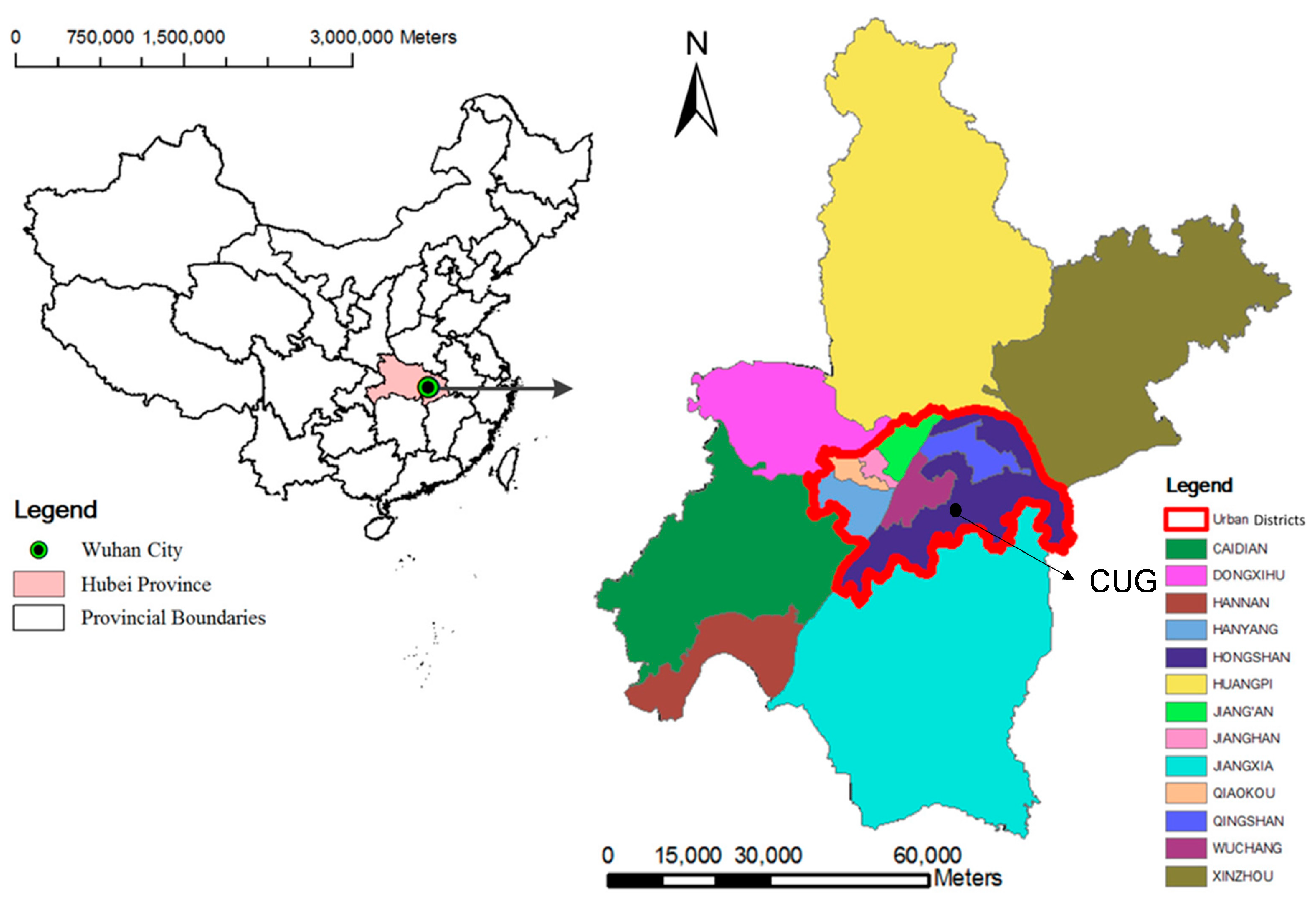

Effects of Municipal Solid Waste on Planting Properties and Scouring Resistance of Vegetation Concrete (Wuhan, China)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Mixture Proportions

2.1.1. Soil

2.1.2. Compound Portland Cement

2.1.3. Admixtures

- (1)

- Organic fertilizer made of kitchen waste (KW)

- (2)

- Silica fume

- (3)

- Fly ash

- (4)

- Wheat straw

- (5)

- Fallen leaves

2.1.4. Plants Seeds

2.2. Specimen Preparation and Test Procedure

2.2.1. Mix Proportion

2.2.2. Planting Tests

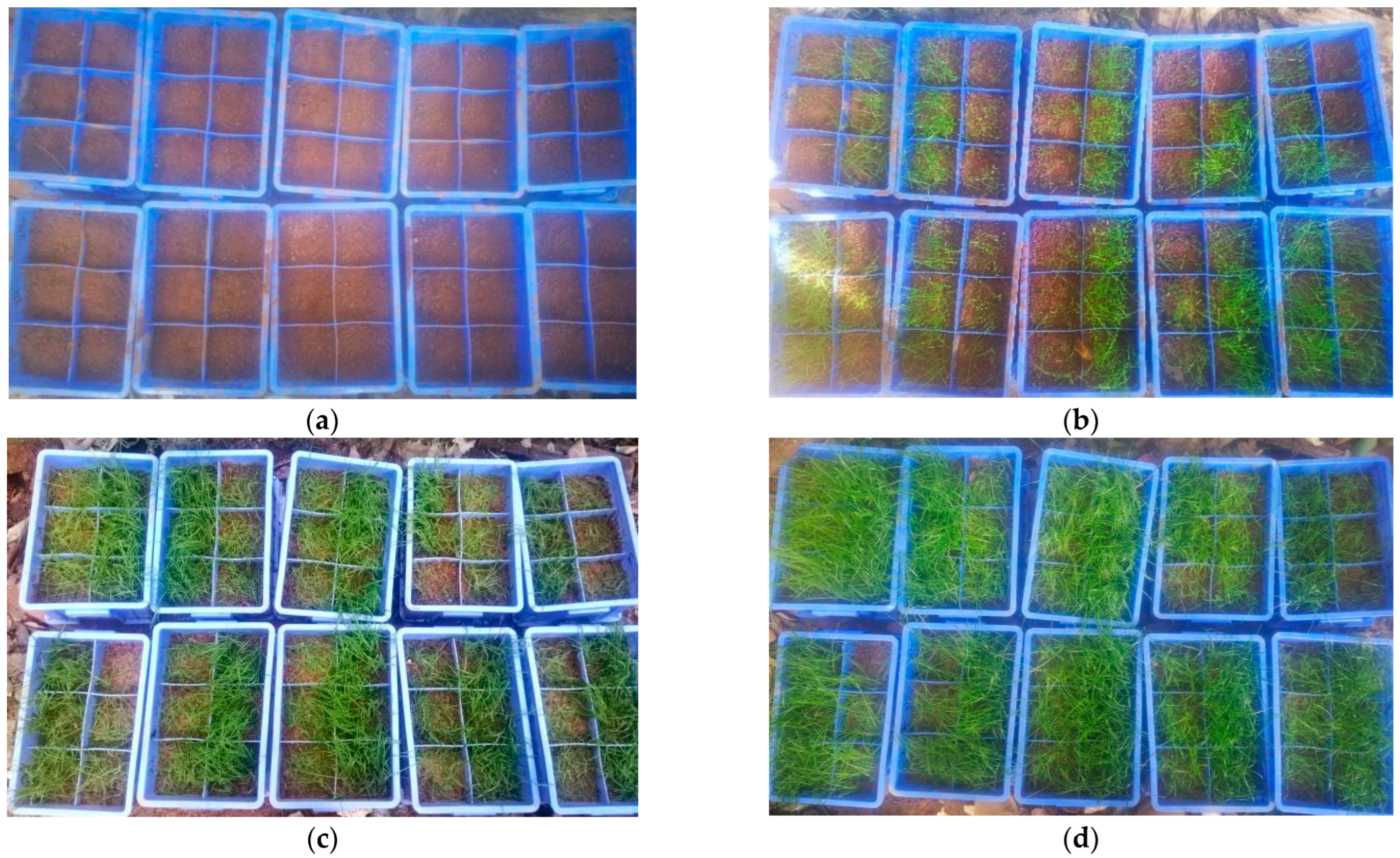

2.2.3. Scouring Tests

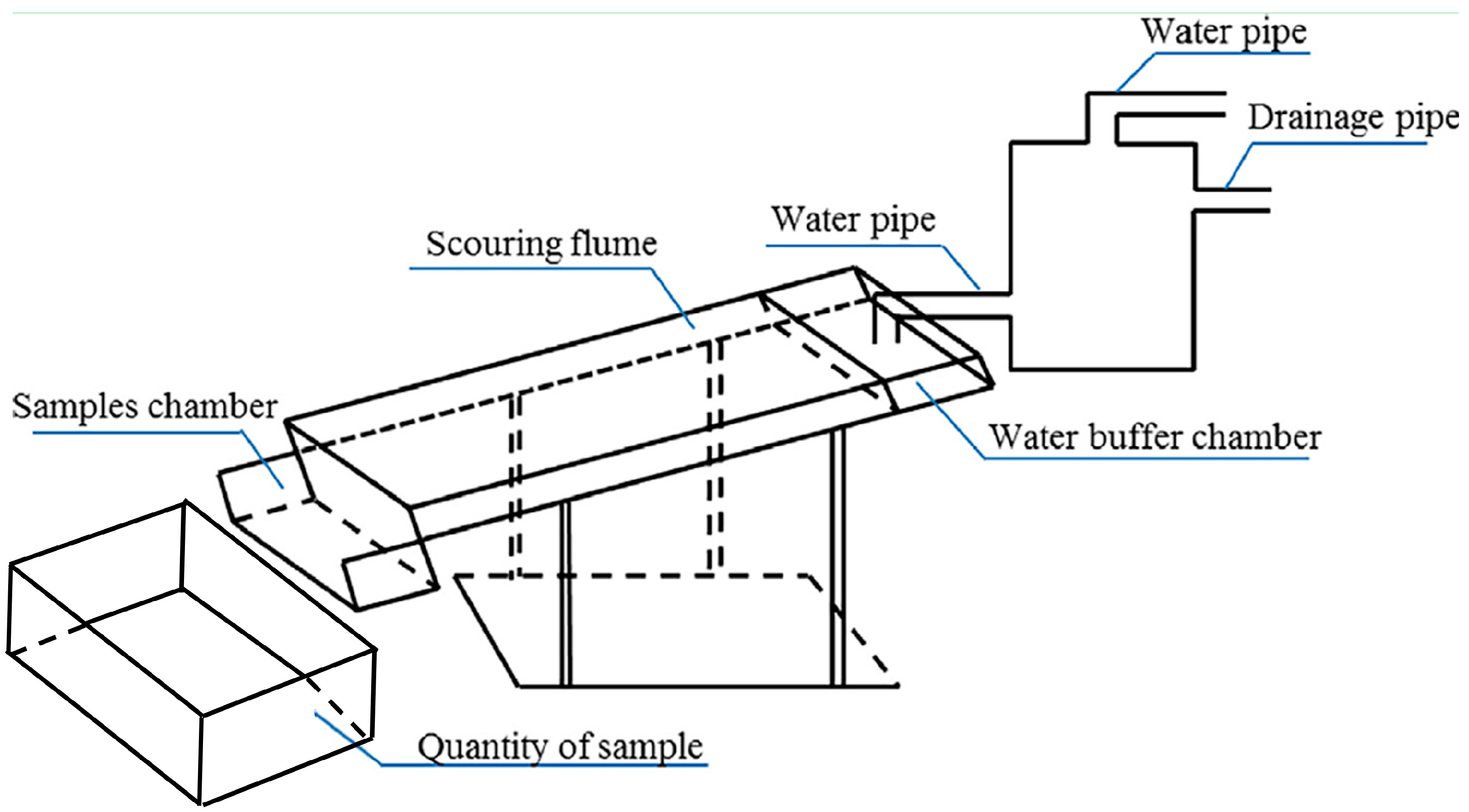

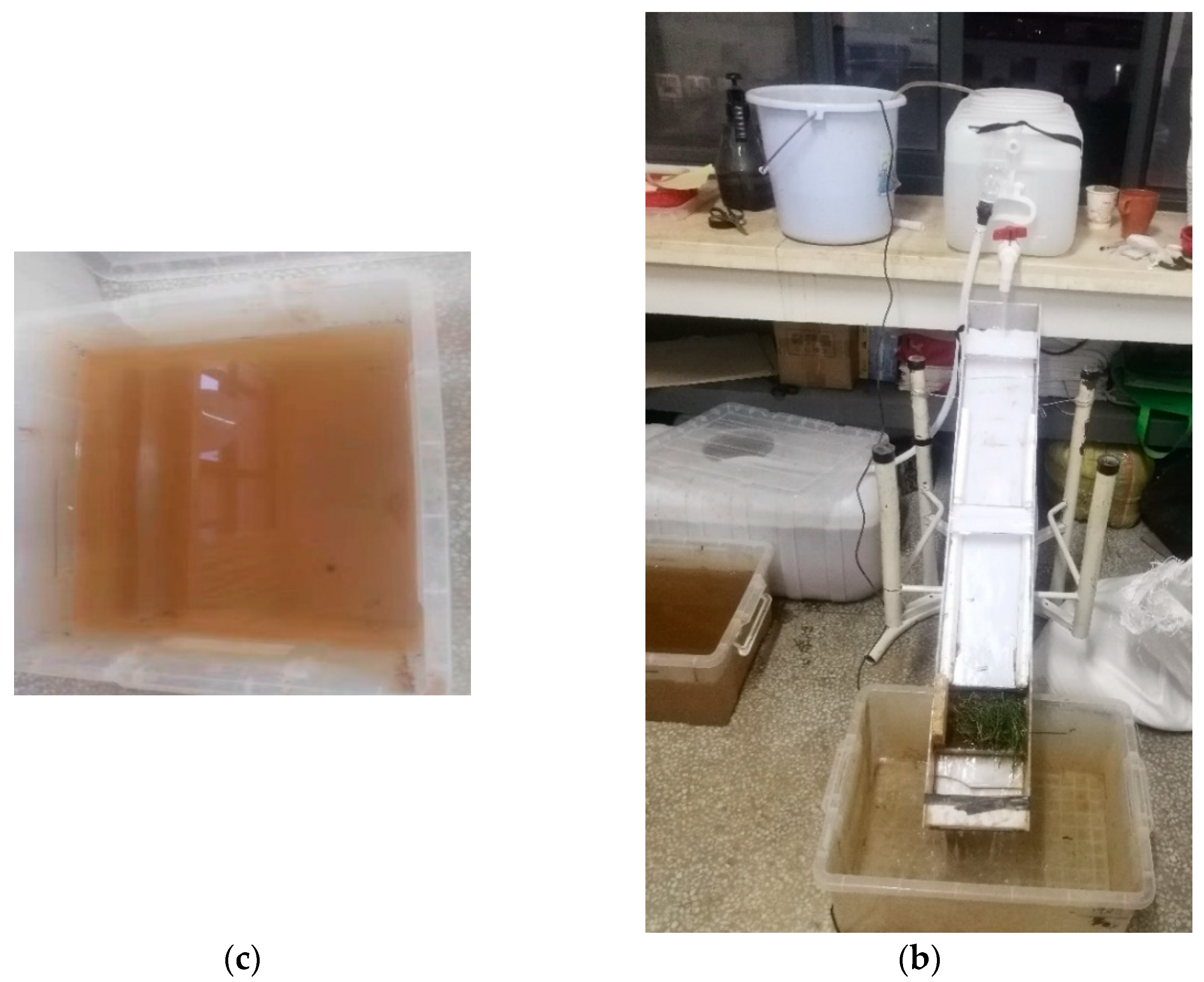

3. Test Results and Discussion

3.1. Effect of MSW on Planting Properties

3.1.1. Basic Properties

3.1.2. Effect of Cement Content on Seed Germination and Plant Height

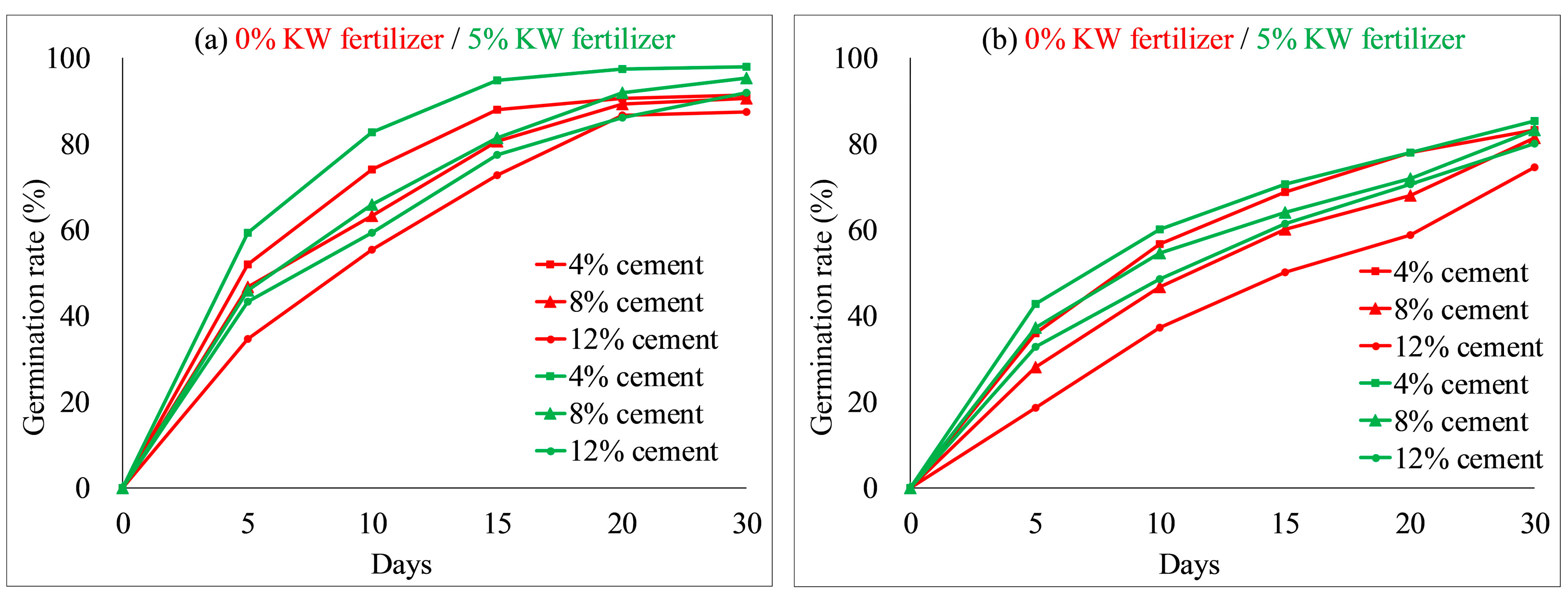

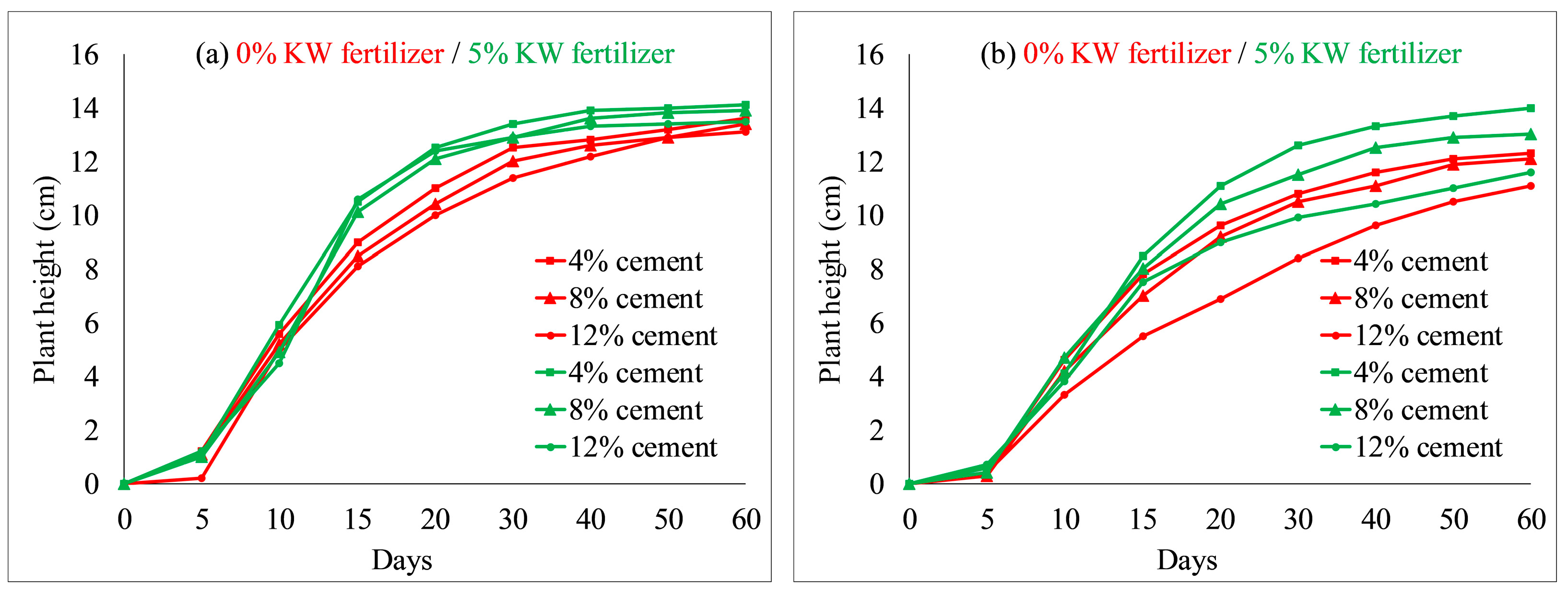

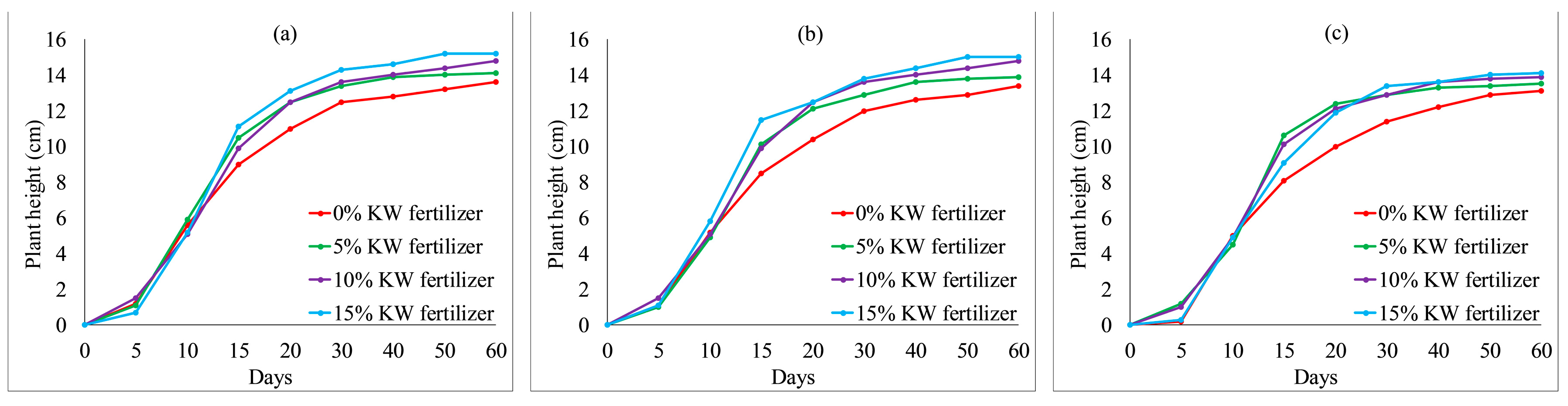

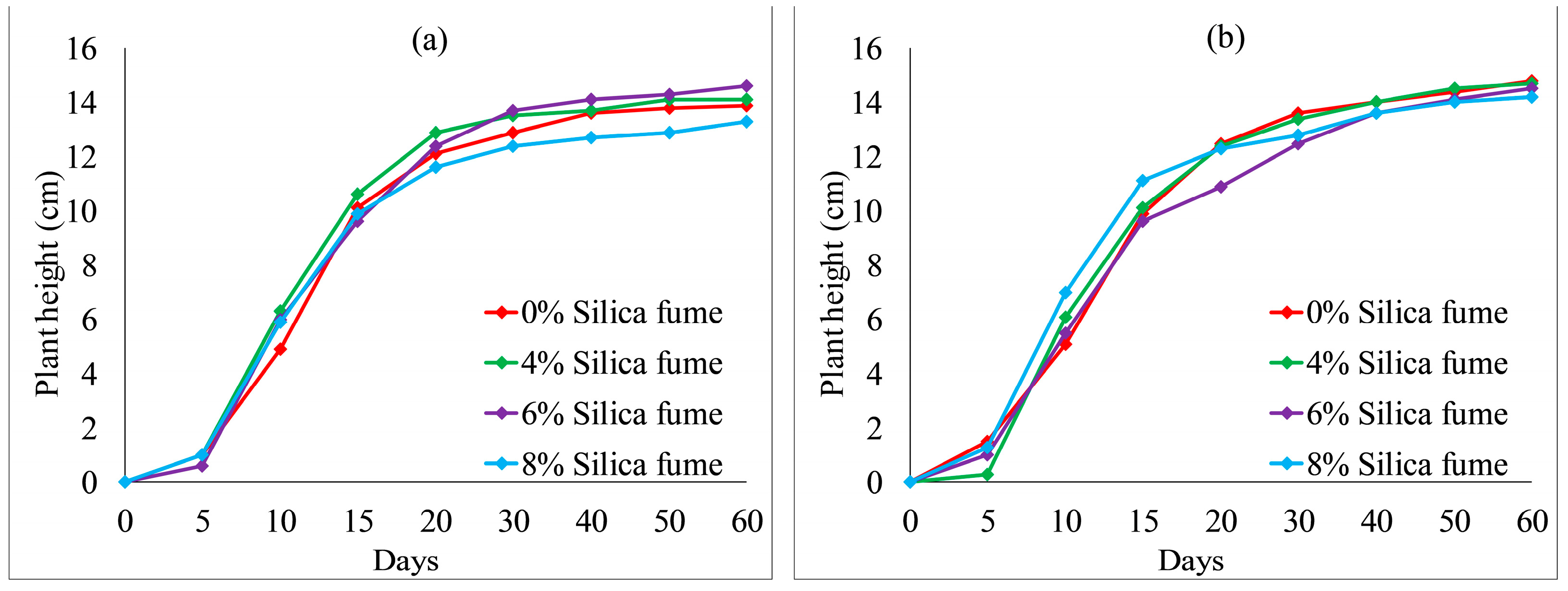

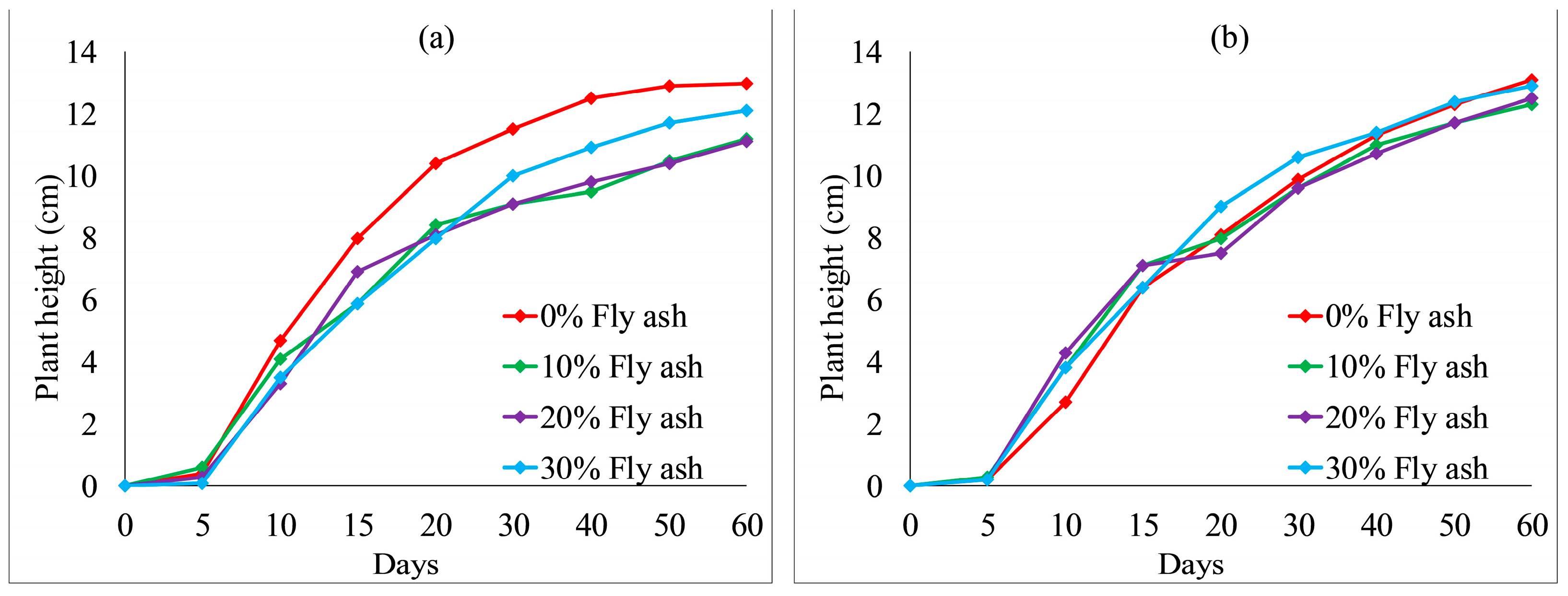

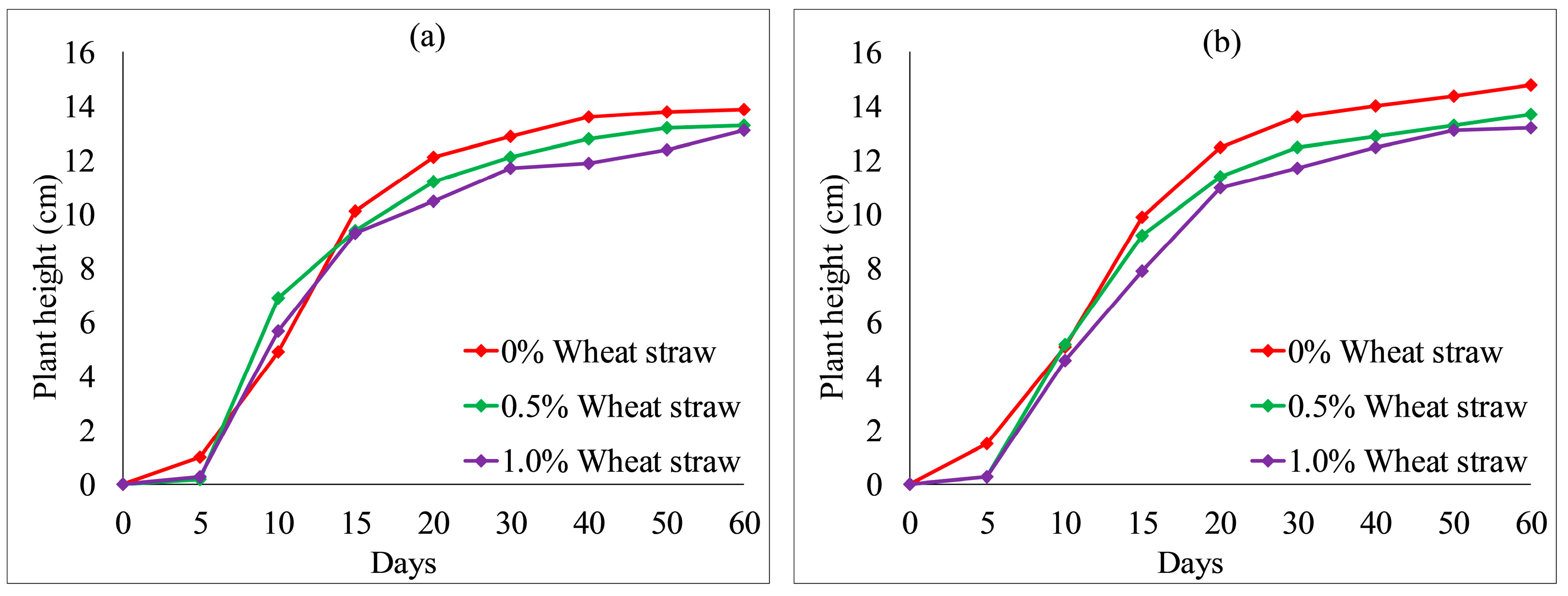

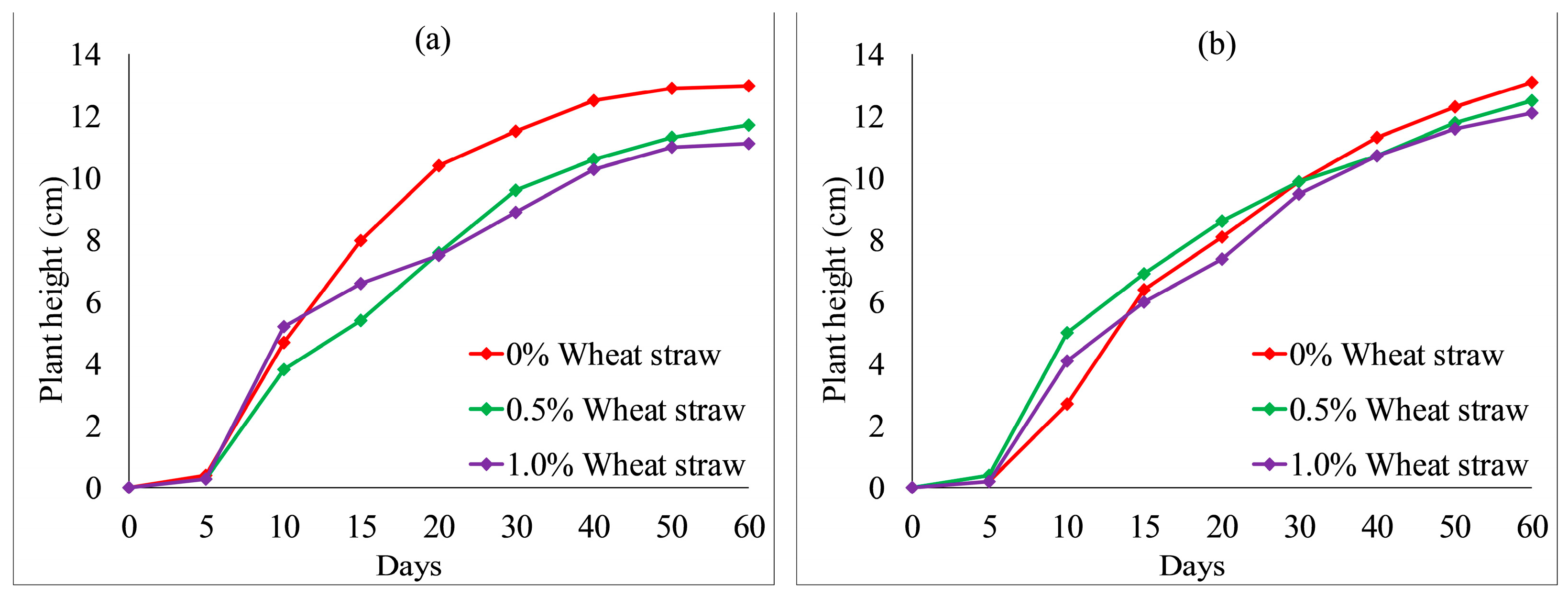

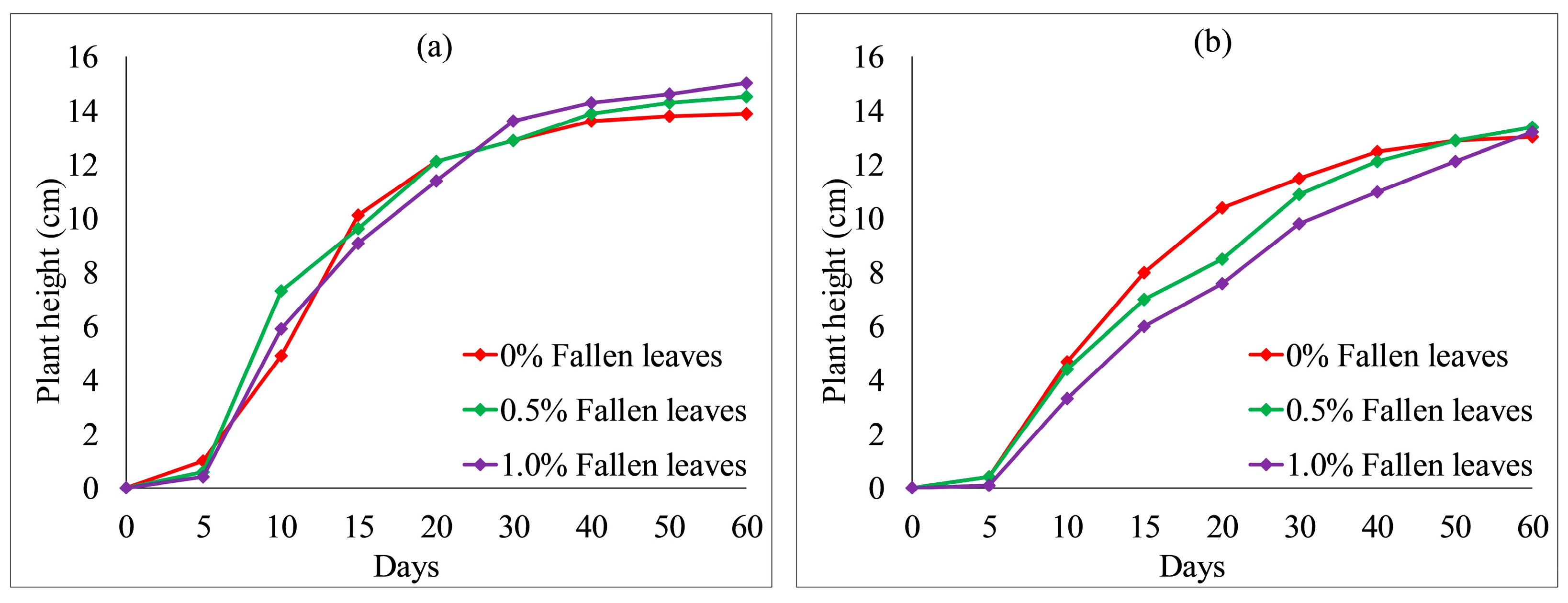

3.1.3. Effect of MSW on Grass Heights

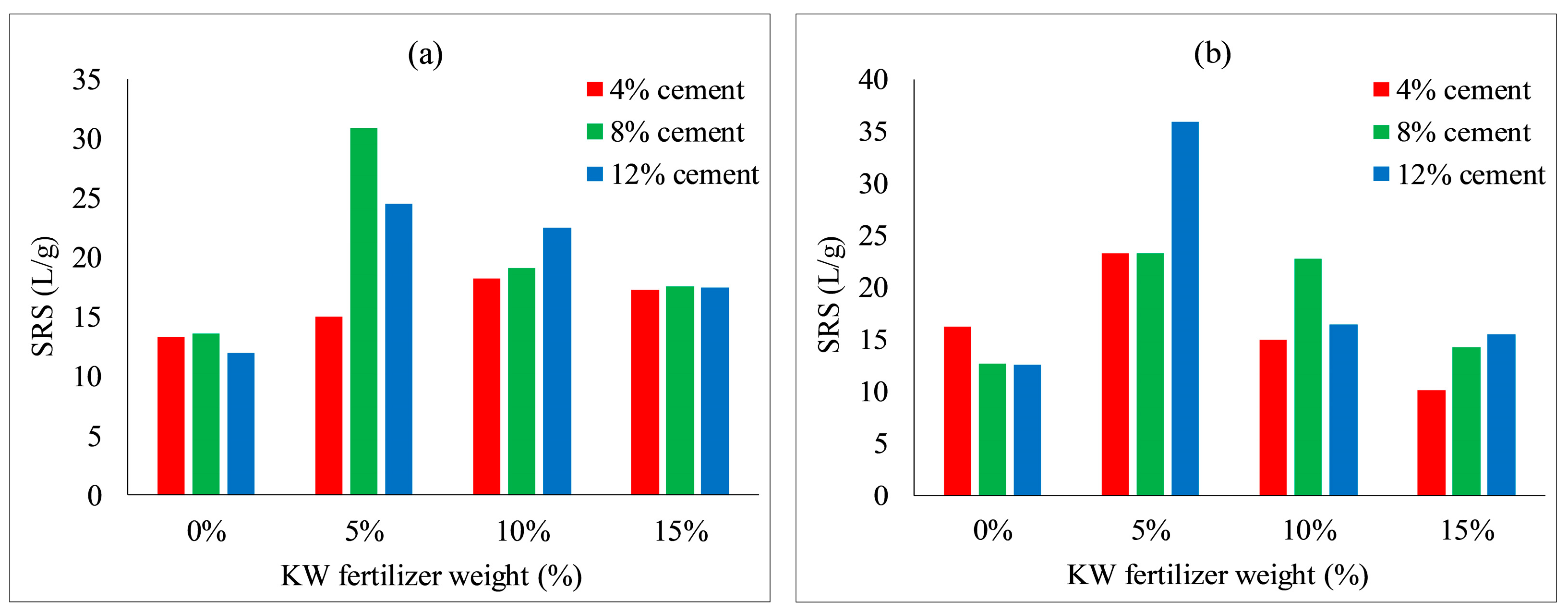

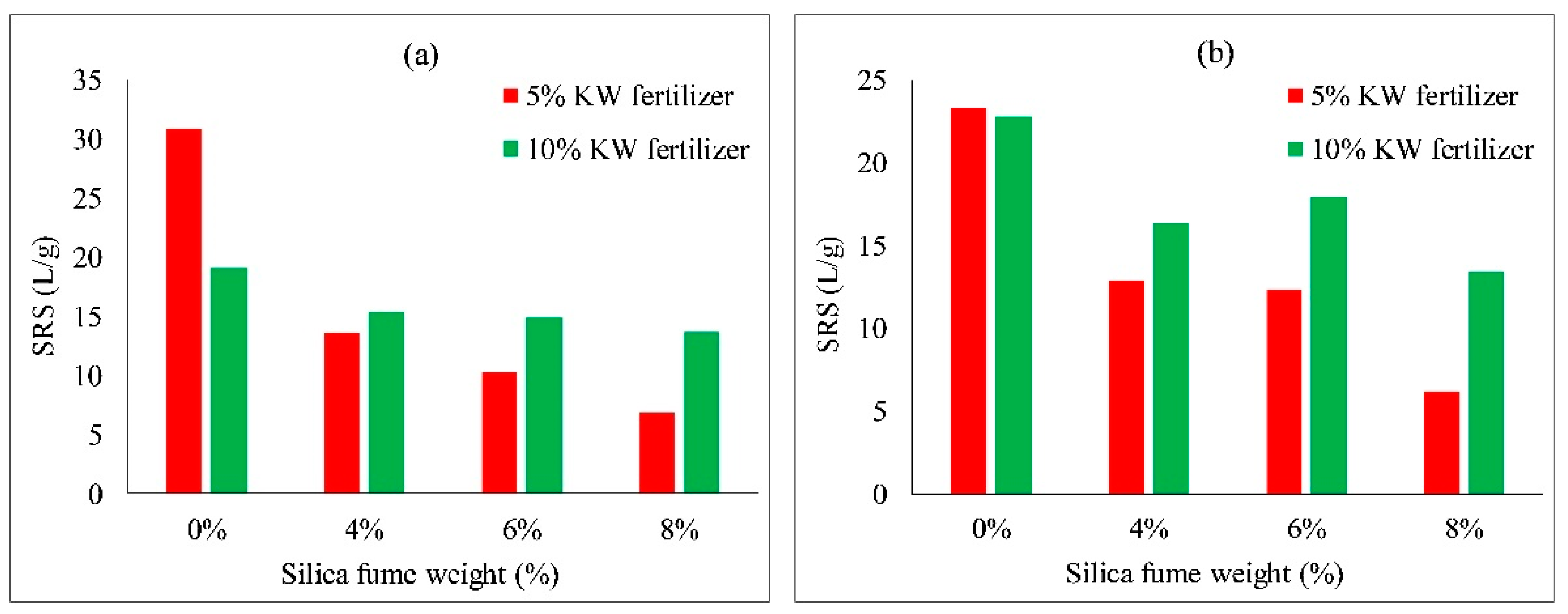

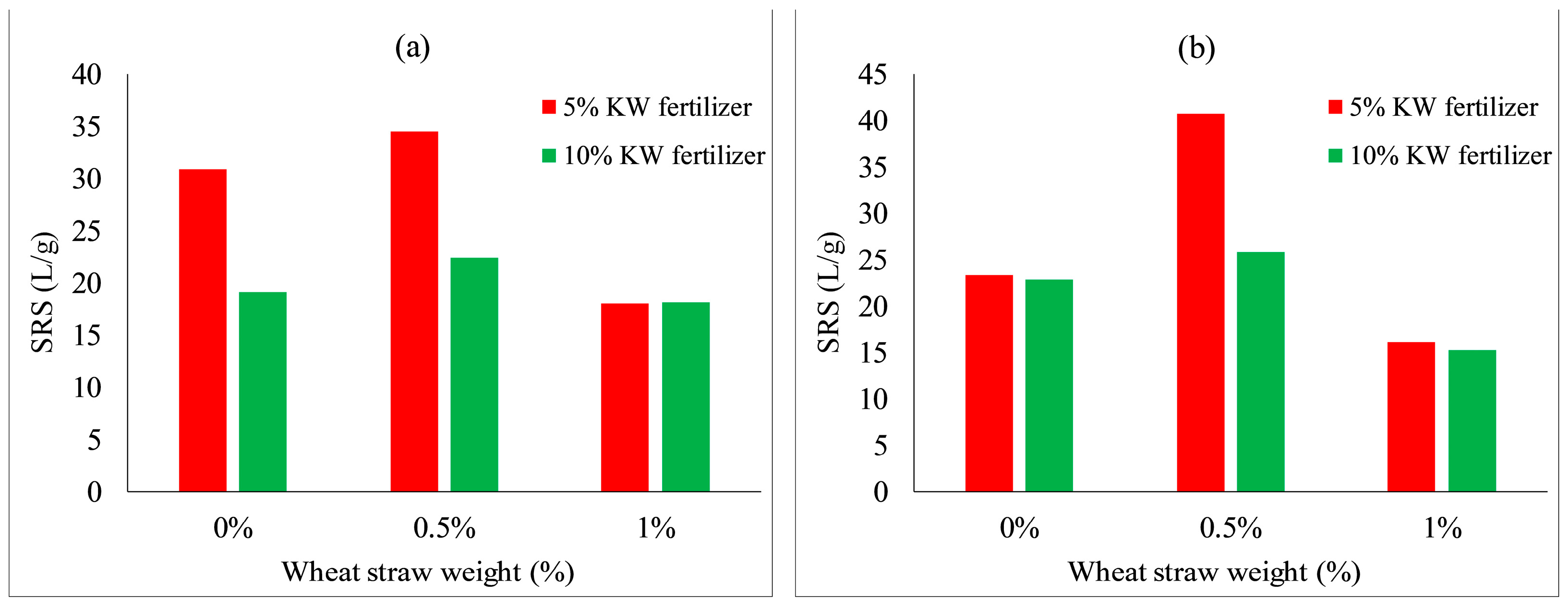

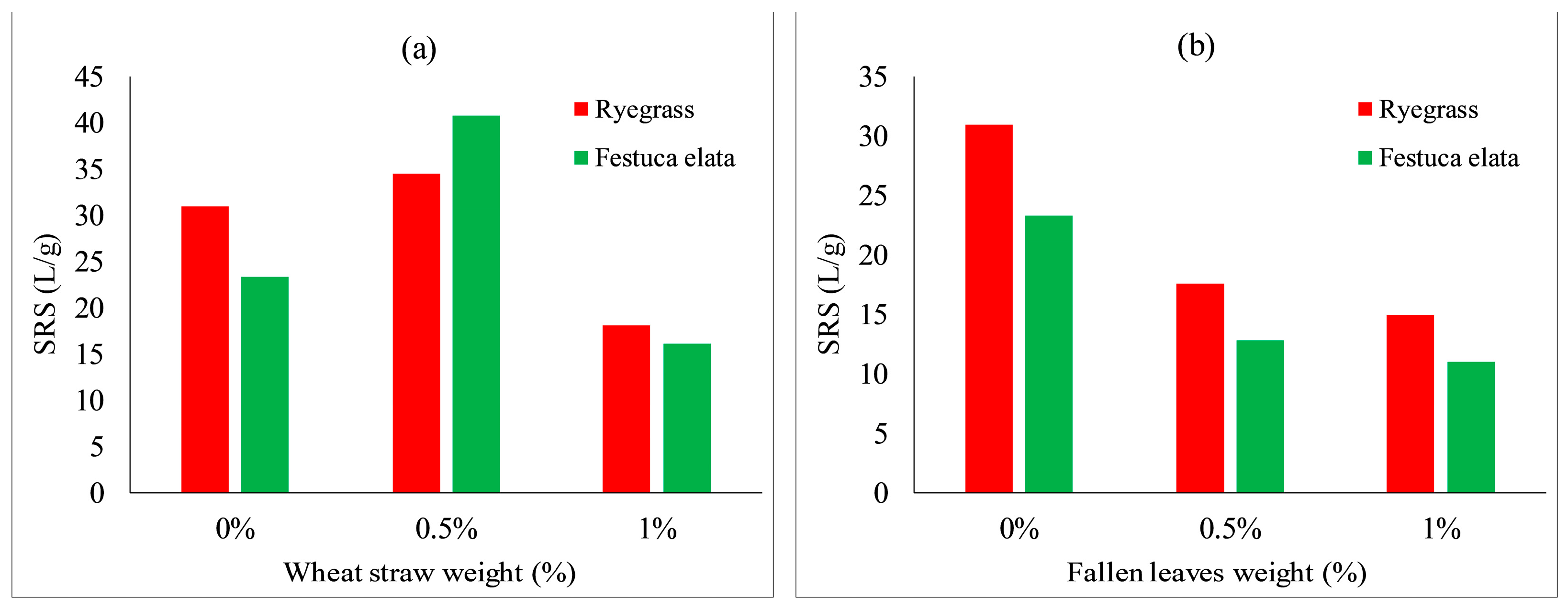

3.2. Scouring Resistance of Soil (SRS)

4. Conclusions

- (1)

- The designed mixtures were suitable for growing the two tested species. Most mixes had high germination rates in the first 15 days and low germination rates in the last 15 days.

- (2)

- The germination rates and plant heights of both species decreased with an increase in concrete content; the scouring resistances of Ryegrass and Festuca elata peaked with concrete contents of 8% and 12%, respectively.

- (3)

- Ryegrass preferred high KW fertilizer content for a remarkable plant height, whereas the optimum ratio of KW fertilizer content with respect to the scouring resistance of both species was 5%.

- (4)

- Moderate silica fume content (e.g., <4%) had a positive effect on the plant heights of both species, whereas silica fume content had an inverse effect on the scouring resistance of both species.

- (5)

- The addition of fly ash and wheat straw content had an inhibitory effect on plant height, but the scouring resistance of both species increased slightly when wheat straw content was increased to 0.5% and achieved the highest scouring resistances.

- (6)

- A small amount of fallen leaves added to VC can promote the growth of Ryegrass somewhat and slightly for Festuca elata; however, fallen leaves content had an inverse effect on the scouring resistance of both species.

- (7)

- Considering the scouring resistances, the optimal mix proportion of MSW-modified VC were recommended as No. 25 with 5% KW fertilizer, 8% cement and 0.5% wheat straw in this study.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.S.; Xu, W.N.; Xia, Z.Y.; Yang, Q. Research on the Evaluation of the Soil Quality in the Evolution of Ecological Slope-Protected Base Material. Appl. Mech. Mater. 2012, 193, 274–278. [Google Scholar] [CrossRef]

- Duan, L.; Huang, M.; Zhang, L. Differences in hydrological responses for different vegetation types on a steep slope on the Loess Plateau, China. J. Hydrol. 2016, 537, 356–366. [Google Scholar] [CrossRef]

- Li, L.; Zhang, H.; Zhou, X.; Chen, M.; Lu, L.; Cheng, X. Effects of super absorbent polymer on scouring resistance and water retention performance of soil for growing plants in ecological concrete. Ecol. Eng. 2019, 138, 237–247. [Google Scholar] [CrossRef]

- Li, X.; Poon, C.S.; Sun, H.; Lo, I.; Kirk, D.W. Heavy metal speciation and leaching behaviors in cement based solidified/stabilized waste materials. J. Hazard. Mater. 2001, 82, 215–230. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, B.; Guo, H.; Xiao, H.; Wei, T. The effect of super absorbent polymers on soil and water conservation on the terraces of the loess plateau. Ecol. Eng. 2017, 102, 270–279. [Google Scholar] [CrossRef]

- Rajasekaran, G. Sulphate attack and ettringite formation in the lime and cement stabilized marine clays. Ocean. Eng. 2005, 32, 1133–1159. [Google Scholar] [CrossRef]

- Tang, W.; Mohseni, E.; Wang, Z. Development of vegetation concrete technology for slope protection and greening. Constr. Build. Mater. 2018, 179, 605–613. [Google Scholar] [CrossRef]

- Zhao, M.; Jia, Y.; Yuan, L.; Qiu, J.; Xie, C. Experimental study on the vegetation characteristics of biochar-modified vegetation concrete. Constr. Build. Mater. 2019, 206, 321–328. [Google Scholar] [CrossRef]

- Chen, F.; Xu, Y.; Wang, C.; Mao, J. Effects of concrete content on seed germination and seedling establishment in vegetation concrete matrix in slope restoration. Ecol. Eng. 2013, 58, 99–104. [Google Scholar] [CrossRef]

- Yan, X.B.; Lu, L.C.; Gong, C.C.; De Wang, S. Preparation and Properties of Sulphoaluminate Cementitious Materials with Low Alkalinity. Appl. Mech. Mater. 2012, 174–177, 1164–1167. [Google Scholar] [CrossRef]

- Martin, L.H.; Winnefeld, F.; Müller, C.J.; Lothenbach, B. Contribution of limestone to the hydration of calcium sulfoaluminate cement. Cem. Concr. Compos. 2015, 62, 204–211. [Google Scholar] [CrossRef]

- Yuan, D.H.; Guo, X.J.; Xiong, Y.; Cui, J.; Yin, X.A.; Li, Y.Z. Pollutant-removal performance and variability of DOM quantity and composition with traditional ecological concrete (TEC) and improved multi-aggregate eco-concrete (IMAEC) revetment treatments. Ecol. Eng. 2017, 105, 141–149. [Google Scholar] [CrossRef]

- Gong, C.; Zhou, X.; Dai, W.; Liu, Y.; Lu, L.; Cheng, X. Effects of carbamide on fluidity and setting time of sulphoaluminate cement and properties of planting concrete from sulphoaluminate cement. Constr. Build. Mater. 2018, 182, 290–297. [Google Scholar] [CrossRef]

- Chang, I.; Jeon, M.; Cho, G.C. Application of microbial biopolymers as an alternative construction binder for earth buildings in underdeveloped countries. Int. J. Polym. Sci. 2015, 2015, 326745. [Google Scholar] [CrossRef] [Green Version]

- Chang, I.; Im, J.; Chung, M.K.; Cho, G.C. Bovine casein as a new soil strengthening binder from diary wastes. Constr. Build. Mater. 2018, 160, 1–9. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, R.; Li, Y.C.; Liu, H.; Zhan, T.L. A degradation model for high kitchen waste content municipal solid waste. Waste Manag. 2016, 58, 376–385. [Google Scholar] [CrossRef]

- Chand Malav, L.; Yadav, K.K.; Gupta, N.; Kumar, S.; Sharma, G.K.; Krishnan, S.; Rezania, S.; Kamyab, H.; Pham, Q.B.; Yadav, S.; et al. A review on municipal solid waste as a renewable source for waste-to-energy project in India, Current practices, challenges, and future opportunities. J. Clean. Prod. 2020, 277, 123227. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P. What A Waste, A Global Review of Solid Waste Management; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Li, M.; Li, F.; Zhou, J.; Yuan, Q.; Hu, N. Fallen leaves are superior to tree pruning as bulking agents in aerobic composting disposing kitchen waste. Bioresour. Technol. 2021, 346, 126374. [Google Scholar] [CrossRef]

- Yu, D.; Yu, Y.; Tang, J.; Li, X.; Ke, C.; Yao, Z. Application fields of kitchen waste biochar and its prospects as catalytic material, A review. Sci. Total Environ. 2022, 810, 152171. [Google Scholar] [CrossRef]

- Singh, M.K.; Sharma, J.S.; Fleming, I.R. Shear strength testing of intact and recompacted samples of municipal solid waste. Can. Geotech. J. 2009, 46, 1133–1145. [Google Scholar] [CrossRef]

- Pulat, H.F.; Yukselen-Aksoy, Y. Factors affecting the shear strength behavior of municipal solid wastes. Waste Manag. 2017, 69, 215–224. [Google Scholar] [CrossRef]

- Cho, Y.M.; Ko, J.H.; Chi, L.; Townsend, T.G. Food waste impact on municipal solid waste angle of internal friction. Waste Manag. 2011, 31, 26–32. [Google Scholar] [CrossRef]

- Yuan, P.; Kavazanjian Jr, E.; Chen, W.; Seo, B. Compositional effects on the dynamic properties of municipal solid waste. Waste Manag. 2011, 31, 2380–2390. [Google Scholar] [CrossRef] [PubMed]

- Zekkos, D.; Bray, J.D.; Riemer, M.F. Drained response of municipal solid waste in large-scale triaxial shear testing. Waste Manag. 2012, 32, 1873–1885. [Google Scholar] [CrossRef] [PubMed]

- Zekkos, D.; Fei, X. Constant load and constant volume response of municipal solid waste in simple shear. Waste Manag. 2017, 63, 380–392. [Google Scholar] [CrossRef]

- Xu, Y. Unconfined Compressive Strength of Municipal Solid Waste Incineration Bottom Ashes. Geotech. Geol. Eng. 2019, 37, 1373–1382. [Google Scholar] [CrossRef]

- Ren, J.; Hu, L.; Dong, Z.; Tang, L.; Xing, F.; Liu, J. Effect of silica fume on the mechanical property and hydration characteristic of alkali-activated municipal solid waste incinerator (MSWI) fly ash. J. Clean. Prod. 2021, 295, 126317. [Google Scholar] [CrossRef]

- Liu, Q.; Su, L.J.; Xiao, H.; Xu, W.N.; Yan, W.M.; Xia, Z.Y. Preparation of shale ceramsite vegetative porous concrete and its performance as a planting medium. Eur. J. Environ. Civil. Eng. 2021, 25, 2111–2126. [Google Scholar] [CrossRef]

- Cheng, J.F.; Luo, X.Y.; Shen, Z.Y.; Guo, X.Q. Study on Vegetation Concrete Technology for Slope Protection and Greening Engineering. Pol. J. Environ. Stud. 2020, 29, 4017–4028. [Google Scholar] [CrossRef]

- Hu, H.; Zhou, M.T.; Hu, X.D. Development of Composite Antifreeze to Ecological Slope Protection Substrate. Adv. Mater. Res. 2014, 827, 355–359. [Google Scholar] [CrossRef]

- Bao, X.; Liao, W.; Dong, Z.; Wang, S.; Tang, W. Development of Vegetation-Pervious Concrete in Grid Beam System for Soil Slope Protection. Materials 2017, 10, 96. [Google Scholar] [CrossRef]

- Kim, H.H.; Park, C.G. Plant Growth and Water Purification of Porous Vegetation Concrete Formed of Blast Furnace Slag, Natural Jute Fiber and Styrene Butadiene Latex. Sustainability 2016, 8, 386. [Google Scholar] [CrossRef]

- Faiz, H.; Serina, N.; Rahman, M. A state-of-the-art review on the advancement of sustainable vegetation concrete in slope stability. Constr. Build. Mater. 2022, 326, 126502. [Google Scholar] [CrossRef]

- Wang, D.L.; Zhao, Q.X.; Yang, C.; Chi, Y.A.; Qi, W.Y.; Teng, Z.C. Study on frost resistance and vegetation performance of seashell waste pervious concrete in cold area. Constr. Build. Mater. 2020, 265, 120758. [Google Scholar] [CrossRef]

- Martirena, F.; Monzó, J. Vegetable ashes as Supplementary Cementitious Materials. Cem. Concr. Res. 2018, 114, 57–64. [Google Scholar] [CrossRef]

- Shu, T.; Tong, L.; Guo, H.; Li, X.; Bai, B.; Chen, Y.; Nie, X. Research Status of Generation and Management of Garden Waste in China, A case of Shanghai. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 766, p. 012074. [Google Scholar]

- Zhou, Z.C.; Gan, Z.T.; Shangguan, Z.P.; Dong, Z.B. Effects of grazing on soil physical properties and soil erodibility in semiarid grassland of the Northern Loess Plateau (China). Catena 2010, 82, 87–91. [Google Scholar] [CrossRef]

- Baeten, L.; Jacquemyn, H.; Van-Calster, H.; Van-Beek, E.; Devlaeminck, R.; Verheyen, K.; Hermy, M. Low recruitment across life stages partly accounts for the slow colonization of forest herbs. J. Ecol. 2009, 97, 109–117. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Chena, F. Effects of concrete content in vegetation concrete matrix on seed germination and seeding establishment of cynodon dactylon. Procedia Eng. 2012, 28, 105–109. [Google Scholar] [CrossRef] [Green Version]

| Relative Density | Plastic Limit (%) | Liquid Limit (%) | MDD (g/cm³) | OMC (%) |

|---|---|---|---|---|

| 2.5 | 17.6 | 32.3 | 1.73 | 15.6 |

| Specimen No. | Material (% Weight) | |||||

|---|---|---|---|---|---|---|

| Kitchen Waste | Cement | Silica Fume | Fly Ash | Wheat Straw | Fallen Leaves | |

| 1 | 0.0 | 4.0 | ||||

| 2 | 0.0 | 8.0 | ||||

| 3 | 0.0 | 12.0 | ||||

| 4 | 5.0 | 4.0 | ||||

| 5 | 5.0 | 8.0 | ||||

| 6 | 5.0 | 12.0 | ||||

| 7 | 10.0 | 4.0 | ||||

| 8 | 10.0 | 8.0 | ||||

| 9 | 10.0 | 12.0 | ||||

| 10 | 15.0 | 4.0 | ||||

| 11 | 15.0 | 8.0 | ||||

| 12 | 15.0 | 12.0 | ||||

| 13 | 5.0 | 8.0 | 4.0 | |||

| 14 | 10.0 | 8.0 | 4.0 | |||

| 15 | 5.0 | 8.0 | 6.0 | |||

| 16 | 10.0 | 8.0 | 6.0 | |||

| 17 | 5.0 | 8.0 | 8.0 | |||

| 18 | 10.0 | 8.0 | 8.0 | |||

| 19 | 5.0 | 8.0 | 10.0 | |||

| 20 | 10.0 | 8.0 | 10.0 | |||

| 21 | 5.0 | 8.0 | 20.0 | |||

| 22 | 10.0 | 8.0 | 20.0 | |||

| 23 | 5.0 | 8.0 | 30.0 | |||

| 24 | 10.0 | 8.0 | 30.0 | |||

| 25 | 5.0 | 8.0 | 0.5 | |||

| 26 | 10.0 | 8.0 | 0.5 | |||

| 27 | 5.0 | 8.0 | 1.0 | |||

| 28 | 10.0 | 8.0 | 1.0 | |||

| 29 | 5.0 | 8.0 | 0.5 | |||

| 30 | 10.0 | 8.0 | 1.0 | |||

| No. | Number of Ryegrass Seed Germinations (N1) | Number of Festuca elata Seed Germinations (N2) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 5 Days | 10 Days | 15 Days | 20 Days | 30 Days | 5 Days | 10 Days | 15 Days | 20 Days | 30 Days | |

| 1 | 78 | 111 | 132 | 136 | 137 | 54 | 85 | 103 | 117 | 125 |

| 2 | 70 | 95 | 121 | 134 | 136 | 42 | 70 | 90 | 102 | 122 |

| 3 | 52 | 83 | 109 | 130 | 131 | 28 | 56 | 75 | 88 | 112 |

| 4 | 89 | 124 | 142 | 146 | 147 | 64 | 90 | 106 | 117 | 128 |

| 5 | 69 | 99 | 122 | 138 | 143 | 56 | 82 | 96 | 108 | 125 |

| 6 | 65 | 89 | 116 | 129 | 138 | 49 | 73 | 92 | 106 | 120 |

| 7 | 76 | 116 | 131 | 142 | 144 | 51 | 79 | 98 | 111 | 126 |

| 8 | 60 | 91 | 115 | 131 | 140 | 43 | 76 | 99 | 109 | 127 |

| 9 | 65 | 92 | 114 | 126 | 137 | 22 | 64 | 89 | 102 | 123 |

| 10 | 70 | 117 | 125 | 128 | 134 | 42 | 67 | 87 | 95 | 112 |

| 11 | 66 | 105 | 119 | 124 | 131 | 36 | 60 | 85 | 94 | 111 |

| 12 | 65 | 95 | 111 | 123 | 130 | 23 | 47 | 69 | 90 | 107 |

| 13 | 67 | 97 | 120 | 134 | 141 | 49 | 69 | 93 | 102 | 124 |

| 14 | 55 | 90 | 115 | 130 | 138 | 42 | 70 | 93 | 102 | 122 |

| 15 | 63 | 89 | 112 | 132 | 136 | 41 | 62 | 87 | 100 | 123 |

| 16 | 58 | 88 | 115 | 134 | 136 | 42 | 66 | 84 | 103 | 118 |

| 17 | 55 | 87 | 118 | 130 | 133 | 35 | 59 | 83 | 95 | 116 |

| 18 | 48 | 86 | 108 | 123 | 134 | 34 | 62 | 81 | 95 | 117 |

| 19 | 61 | 93 | 118 | 136 | 140 | 53 | 71 | 89 | 103 | 119 |

| 20 | 44 | 74 | 103 | 126 | 137 | 40 | 66 | 86 | 105 | 120 |

| 21 | 43 | 80 | 107 | 128 | 137 | 48 | 67 | 83 | 97 | 115 |

| 22 | 39 | 69 | 95 | 118 | 137 | 35 | 63 | 82 | 98 | 117 |

| 23 | 28 | 67 | 102 | 120 | 130 | 46 | 63 | 78 | 91 | 113 |

| 24 | 40 | 65 | 92 | 113 | 133 | 37 | 62 | 81 | 94 | 114 |

| 25 | 59 | 103 | 128 | 140 | 144 | 45 | 75 | 96 | 106 | 128 |

| 26 | 73 | 99 | 127 | 134 | 141 | 59 | 77 | 93 | 112 | 130 |

| 27 | 59 | 102 | 130 | 135 | 138 | 53 | 81 | 100 | 120 | 132 |

| 28 | 65 | 101 | 128 | 140 | 142 | 54 | 85 | 100 | 110 | 130 |

| 29 | 53 | 92 | 116 | 129 | 142 | 51 | 81 | 99 | 115 | 131 |

| 30 | 54 | 99 | 117 | 127 | 138 | 60 | 93 | 109 | 123 | 132 |

| No. | Average Grass Heights of Ryegrass at Age (cm) | |||||||

|---|---|---|---|---|---|---|---|---|

| 5 Days | 10 Days | 15 Days | 20 Days | 30 Days | 40 Days | 50 Days | 60 Days | |

| 1 | 1.2 | 5.6 | 9.0 | 11.0 | 12.5 | 12.8 | 13.2 | 13.6 |

| 2 | 1.1 | 5.2 | 8.5 | 10.4 | 12.0 | 12.6 | 12.9 | 13.4 |

| 3 | 0.2 | 5.0 | 8.1 | 10.0 | 11.4 | 12.2 | 12.9 | 13.1 |

| 4 | 1.1 | 5.9 | 10.5 | 12.5 | 13.4 | 13.9 | 14.0 | 14.1 |

| 5 | 1.0 | 4.9 | 10.1 | 12.1 | 12.9 | 13.6 | 13.8 | 13.9 |

| 6 | 1.2 | 4.5 | 10.6 | 12.4 | 12.9 | 13.3 | 13.4 | 13.5 |

| 7 | 1.5 | 5.1 | 9.9 | 12.5 | 13.6 | 14.0 | 14.4 | 14.8 |

| 8 | 1.5 | 5.1 | 9.9 | 12.5 | 13.6 | 14.0 | 14.4 | 14.8 |

| 9 | 1.0 | 4.9 | 10.1 | 12.1 | 12.9 | 13.6 | 13.8 | 13.9 |

| 10 | 0.7 | 5.2 | 11.1 | 13.1 | 14.3 | 14.6 | 15.2 | 15.2 |

| 11 | 1.1 | 5.8 | 11.5 | 12.5 | 13.8 | 14.4 | 15.0 | 15.0 |

| 12 | 0.3 | 4.9 | 9.1 | 11.9 | 13.4 | 13.6 | 14.0 | 14.1 |

| 13 | 1.0 | 6.3 | 10.6 | 12.9 | 13.5 | 13.7 | 14.1 | 14.1 |

| 14 | 0.3 | 6.1 | 10.1 | 12.4 | 13.4 | 14.0 | 14.5 | 14.7 |

| 15 | 0.6 | 6.0 | 9.6 | 12.4 | 13.7 | 14.1 | 14.3 | 14.6 |

| 16 | 1.0 | 5.5 | 9.6 | 10.9 | 12.5 | 13.6 | 14.1 | 14.5 |

| 17 | 1.0 | 5.9 | 9.9 | 11.6 | 12.4 | 12.7 | 12.9 | 13.3 |

| 18 | 1.3 | 7.0 | 11.1 | 12.3 | 12.8 | 13.6 | 14.0 | 14.2 |

| 19 | 0.7 | 6.2 | 9.6 | 11.0 | 11.9 | 12.1 | 12.5 | 12.5 |

| 20 | 0.2 | 5.0 | 10.0 | 11.7 | 12.0 | 12.4 | 13.0 | 13.6 |

| 21 | 0.4 | 6.4 | 10.0 | 11.5 | 12.0 | 12.2 | 12.5 | 12.7 |

| 22 | 0.5 | 6.8 | 9.9 | 11.5 | 12.1 | 12.4 | 12.8 | 13.0 |

| 23 | 0.0 | 4.8 | 10.5 | 11.7 | 12.5 | 13.0 | 13.6 | 13.5 |

| 24 | 0.4 | 5.2 | 9.0 | 11.3 | 12.3 | 12.6 | 13.5 | 13.8 |

| 25 | 0.2 | 6.9 | 9.4 | 11.2 | 12.1 | 12.8 | 13.2 | 13.3 |

| 26 | 0.3 | 5.2 | 9.2 | 11.4 | 12.5 | 12.9 | 13.3 | 13.7 |

| 27 | 0.3 | 5.7 | 9.3 | 10.5 | 11.7 | 11.9 | 12.4 | 13.1 |

| 28 | 0.3 | 4.6 | 7.9 | 11.0 | 11.7 | 12.5 | 13.1 | 13.2 |

| 29 | 0.6 | 7.3 | 9.6 | 12.1 | 12.9 | 13.9 | 14.3 | 14.5 |

| 30 | 0.4 | 5.9 | 9.1 | 11.4 | 13.6 | 14.3 | 14.6 | 15.0 |

| No. | Average Grass Heights of Festuca elata at Age (cm) | |||||||

|---|---|---|---|---|---|---|---|---|

| 5 Days | 10 Days | 15 Days | 20 Days | 30 Days | 40 Days | 50 Days | 60 Days | |

| 1 | 0.4 | 4.6 | 7.8 | 9.6 | 10.8 | 11.6 | 12.1 | 12.3 |

| 2 | 0.3 | 4.2 | 7.0 | 9.2 | 10.5 | 11.1 | 11.9 | 12.1 |

| 3 | 0.4 | 3.3 | 5.5 | 6.9 | 8.4 | 9.6 | 10.5 | 11.1 |

| 4 | 0.6 | 4.1 | 8.5 | 11.1 | 12.6 | 13.3 | 13.7 | 14.0 |

| 5 | 0.4 | 4.7 | 8.0 | 10.4 | 11.5 | 12.5 | 12.9 | 13.0 |

| 6 | 0.7 | 3.8 | 7.5 | 9.0 | 9.9 | 10.4 | 11.0 | 11.6 |

| 7 | 0.5 | 3.6 | 6.9 | 9.9 | 11.9 | 13.2 | 13.9 | 14.1 |

| 8 | 0.2 | 2.7 | 6.4 | 8.1 | 9.9 | 11.3 | 12.3 | 13.1 |

| 9 | 0.2 | 4.0 | 6.1 | 7.4 | 9.0 | 9.9 | 11.2 | 12.0 |

| 10 | 0.4 | 3.6 | 8.1 | 10.6 | 12.5 | 13.7 | 14.3 | 14.7 |

| 11 | 0.5 | 4.2 | 7.6 | 9.9 | 11.9 | 12.5 | 13.0 | 13.1 |

| 12 | 0.2 | 3.0 | 6.6 | 8.7 | 9.7 | 10.9 | 11.4 | 12.2 |

| 13 | 0.2 | 4.1 | 6.4 | 9.1 | 11.3 | 12.7 | 13.4 | 14.3 |

| 14 | 0.4 | 4.8 | 7.9 | 10.0 | 11.8 | 13.9 | 15.2 | 16.4 |

| 15 | 1.1 | 3.7 | 8.0 | 9.6 | 11.8 | 12.9 | 13.6 | 14.5 |

| 16 | 0.4 | 3.4 | 5.9 | 8.5 | 10.7 | 11.8 | 13.0 | 15.0 |

| 17 | 0.2 | 3.8 | 6.6 | 9.1 | 10.0 | 10.6 | 11.3 | 11.7 |

| 18 | 0.1 | 3.3 | 6.9 | 8.5 | 9.9 | 11.0 | 11.8 | 12.8 |

| 19 | 0.6 | 4.1 | 5.9 | 8.4 | 9.1 | 9.5 | 10.5 | 11.2 |

| 20 | 0.3 | 3.8 | 7.1 | 8.0 | 9.6 | 11.0 | 11.7 | 12.3 |

| 21 | 0.3 | 3.3 | 6.9 | 8.1 | 9.1 | 9.8 | 10.4 | 11.1 |

| 22 | 0.2 | 4.3 | 7.1 | 7.5 | 9.6 | 10.7 | 11.7 | 12.5 |

| 23 | 0.1 | 3.5 | 5.9 | 8.0 | 10.0 | 10.9 | 11.7 | 12.1 |

| 24 | 0.2 | 3.8 | 6.4 | 9.0 | 10.6 | 11.4 | 12.4 | 12.9 |

| 25 | 0.3 | 3.8 | 5.4 | 7.6 | 9.6 | 10.6 | 11.3 | 11.7 |

| 26 | 0.4 | 5.0 | 6.9 | 8.6 | 9.9 | 10.7 | 11.8 | 12.5 |

| 27 | 0.3 | 5.2 | 6.6 | 7.5 | 8.9 | 10.3 | 11.0 | 11.1 |

| 28 | 0.2 | 4.1 | 6.0 | 7.4 | 9.5 | 10.7 | 11.6 | 12.1 |

| 29 | 0.4 | 4.4 | 7.0 | 8.5 | 10.9 | 12.1 | 12.9 | 13.4 |

| 30 | 0.1 | 3.3 | 6.0 | 7.6 | 9.8 | 11.0 | 12.1 | 13.2 |

| No. | Ryegrass (L/g) | Festuca elata (L/g) |

|---|---|---|

| 1 | 13.3 | 16.2 |

| 2 | 13.6 | 12.6 |

| 3 | 12.0 | 12.5 |

| 4 | 15.0 | 23.3 |

| 5 | 30.9 | 23.3 |

| 6 | 24.5 | 35.9 |

| 7 | 18.2 | 15.0 |

| 8 | 19.1 | 22.8 |

| 9 | 22.5 | 16.4 |

| 10 | 17.3 | 10.1 |

| 11 | 17.6 | 14.2 |

| 12 | 17.5 | 15.5 |

| 13 | 13.6 | 12.9 |

| 14 | 15.4 | 16.3 |

| 15 | 10.3 | 12.3 |

| 16 | 14.9 | 17.9 |

| 17 | 6.8 | 6.2 |

| 18 | 13.7 | 13.4 |

| 19 | 19.3 | 16.3 |

| 20 | 19.1 | 20.1 |

| 21 | 28.3 | 21.5 |

| 22 | 19.5 | 22.1 |

| 23 | 11.4 | 10.9 |

| 24 | 10.6 | 8.9 |

| 25 | 34.5 | 40.8 |

| 26 | 22.4 | 25.8 |

| 27 | 18.0 | 16.1 |

| 28 | 18.1 | 15.2 |

| 29 | 17.6 | 12.8 |

| 30 | 14.9 | 11.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, L.; Wang, X.; Guo, W.; Zhang, Y. Effects of Municipal Solid Waste on Planting Properties and Scouring Resistance of Vegetation Concrete (Wuhan, China). Int. J. Environ. Res. Public Health 2022, 19, 8143. https://doi.org/10.3390/ijerph19138143

Kong L, Wang X, Guo W, Zhang Y. Effects of Municipal Solid Waste on Planting Properties and Scouring Resistance of Vegetation Concrete (Wuhan, China). International Journal of Environmental Research and Public Health. 2022; 19(13):8143. https://doi.org/10.3390/ijerph19138143

Chicago/Turabian StyleKong, Liulin, Xiaomei Wang, Wencheng Guo, and Yongcheng Zhang. 2022. "Effects of Municipal Solid Waste on Planting Properties and Scouring Resistance of Vegetation Concrete (Wuhan, China)" International Journal of Environmental Research and Public Health 19, no. 13: 8143. https://doi.org/10.3390/ijerph19138143

APA StyleKong, L., Wang, X., Guo, W., & Zhang, Y. (2022). Effects of Municipal Solid Waste on Planting Properties and Scouring Resistance of Vegetation Concrete (Wuhan, China). International Journal of Environmental Research and Public Health, 19(13), 8143. https://doi.org/10.3390/ijerph19138143