Biomethane Production from Anaerobic Co-Digestion of Selected Organic Fraction of Municipal Solid Waste (OFMSW) with Sewage Sludge: Effect of the Inoculum to Substrate Ratio (ISR) and Mixture Composition on Process Performances

Abstract

:1. Introduction

2. Materials and Methods

2.1. Organic Waste, Sewage Sludge and Inoculum

2.2. Biochemical Methane Potential Assays

2.3. Co-Digestion Mixtures

2.4. Calculation

2.5. Assessment of Synergistic Effects

2.6. Analytical Methods

3. Results and Discussion

3.1. Reduction of VS

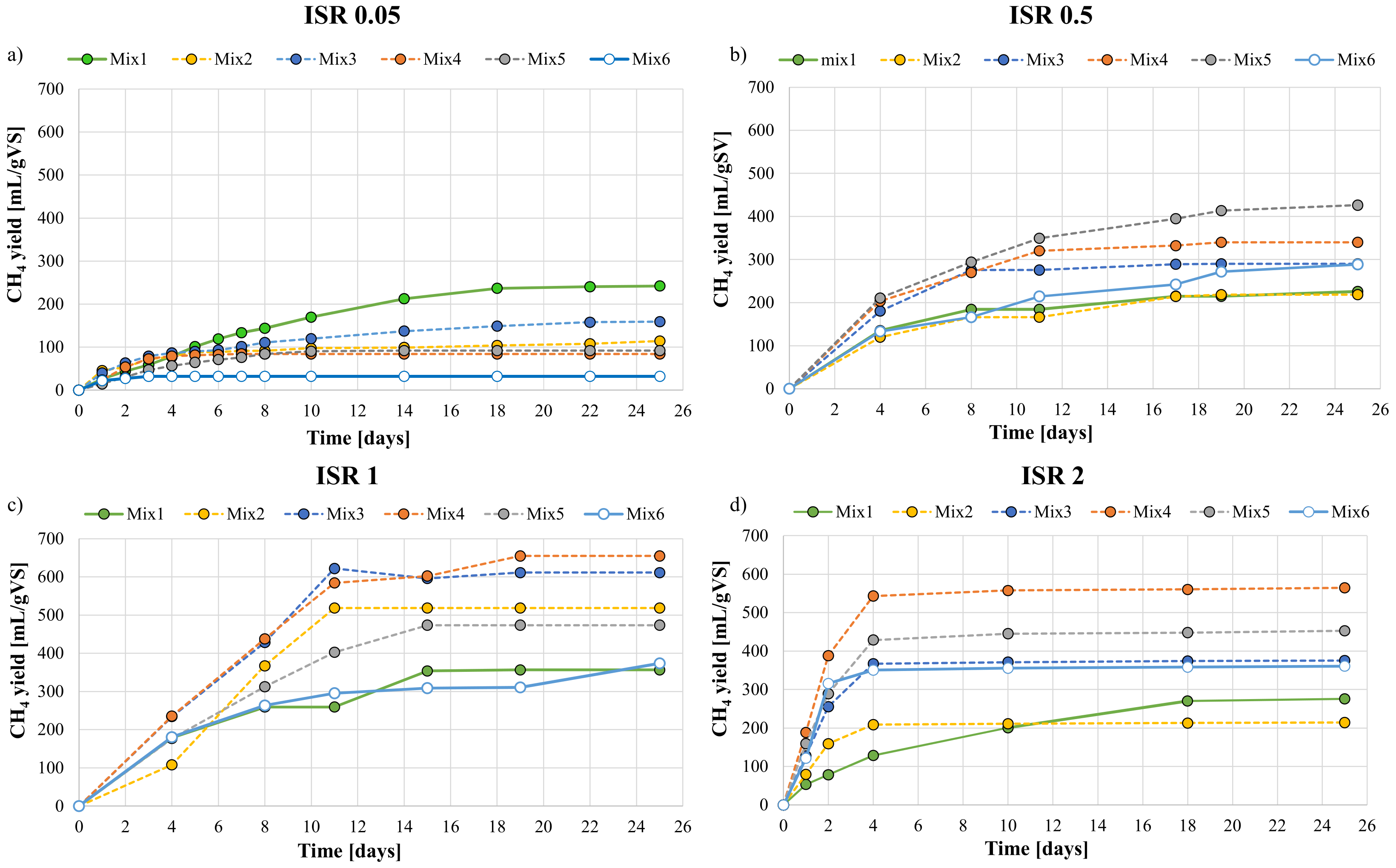

3.2. Methane Production Yield

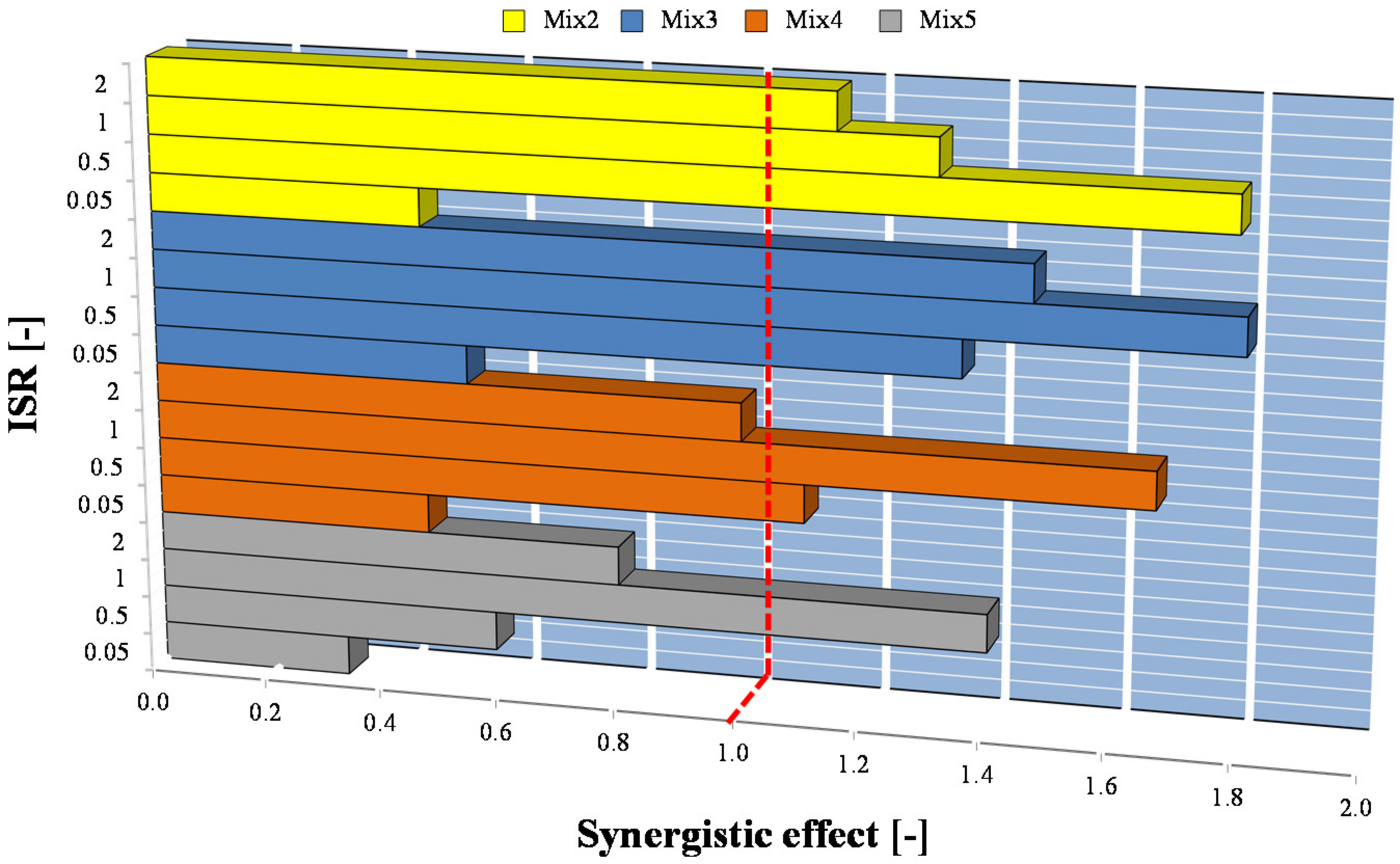

3.3. Evaluation of Synergistic Effects

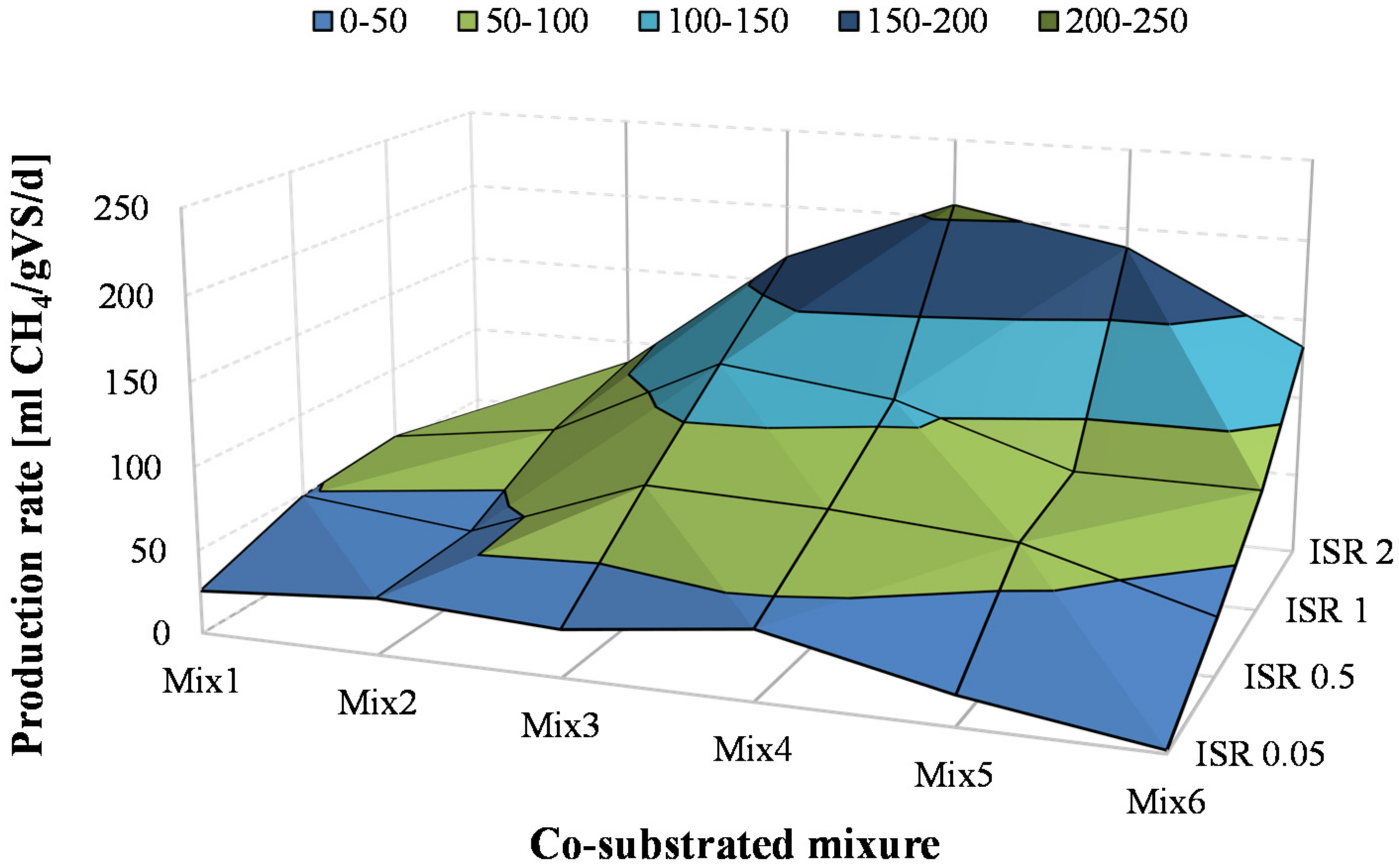

3.4. Kinetics of Methane Production

3.5. General Remarks and Considerations for Continuous Mode Operation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tyagi, V.K.; Fdez-Güelfo, L.A.; Zhou, Y.; Álvarez-Gallego, C.J.; Garcia, L.I.R.; Ng, W.J. Anaerobic co-digestion of organic fraction of municipal solid waste (OFMSW): Progress and challenges. Renew. Sustain. Energy Rev. 2018, 93, 380–399. [Google Scholar] [CrossRef]

- Zamri, M.F.M.A.; Hasmady, S.; Akhiar, A.; Ideris, F.; Shamsuddin, A.H.; Mofijur, M.; Fattah, I.M.R.; Mahlia, T.M.I. A comprehensive review on anaerobic digestion of organic fraction of municipal solid waste. Renew. Sustain. Energy Rev. 2021, 137, 110637. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S.M. Solid waste issue: Sources, composition, disposal, recycling, and valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Alibardi, L.; Cossu, R. Composition variability of the organic fraction of municipal solid waste and effects on hydrogen and methane production potentials. Waste Manag. 2015, 36, 147–155. [Google Scholar] [CrossRef] [PubMed]

- De Clercq, D.; Wen, Z.; Gottfried, O.; Schmidt, F.; Fei, F. A review of global strategies promoting the conversion of food waste to bioenergy via anaerobic digestion. Renew. Sustain. Energy Rev. 2017, 79, 204–221. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Guo, W.Q.; Yang, S.S.; Xiang, W.S.; Wang, X.J.; Ren, N.Q. Minimization of excess sludge production by in-situ activated sludge treatment processes - A comprehensive review. Biotechnol. Adv. 2013, 31, 1386–1396. [Google Scholar] [CrossRef] [PubMed]

- Di Capua, F.; Spasiano, D.; Giordano, A.; Adani, F.; Fratino, U.; Pirozzi, F.; Esposito, G. High-solid anaerobic digestion of sewage sludge: Challenges and opportunities. Appl. Energy 2020, 278, 115608. [Google Scholar] [CrossRef]

- Aichinger, P.; Wadhawan, T.; Kuprian, M.; Higgins, M.; Ebner, C.; Fimml, C.; Murthy, S.; Wett, B. Synergistic co-digestion of solid-organic-waste and municipal-sewage-sludge: 1 plus 1 equals more than 2 in terms of biogas production and solids reduction. Water Res. 2015, 87, 416–423. [Google Scholar] [CrossRef]

- Nielfa, A.; Cano, R.; Fdz-Polanco, M. Theoretical methane production generated by the co-digestion of organic fraction municipal solid waste and biological sludge. Biotechnol. Rep. 2015, 5, 14–21. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.W.; Nam, J.Y.; Shin, H.S. A comparison study on the high-rate co-digestion of sewage sludge and food waste using a temperature-phased anaerobic sequencing batch reactor system. Bioresour. Technol. 2011, 102, 7272–7279. [Google Scholar] [CrossRef] [PubMed]

- la Cour Jansen, J.; Gruvberger, C.; Hanner, N.; Aspegren, H.; Avärd, Å. Digestion of sludge and organic waste in the sustainability concept for Malmö, Sweden. Water Sci. Technol. 2004, 49, 163–169. [Google Scholar] [CrossRef]

- Björn, A.; Shakeri Yekta, S.; Ziels, R.M.; Gustafsson, K.; Svensson, B.H.; Karlsson, A. Feasibility of OFMSW co-digestion with sewage sludge for increasing biogas production at wastewater treatment plants. Euro-Mediterr. J. Environ. Integr. 2017, 2, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Raposo, F.; Fernández-Cegrí, V.; De la Rubia, M.A.; Borja, R.; Béline, F.; Cavinato, C.; Demirer, G.; Fernández, B.; Fernández-Polanco, M.; Frigon, J.C.; et al. Biochemical methane potential (BMP) of solid organic substrates: Evaluation of anaerobic biodegradability using data from an international interlaboratory study. J. Chem. Technol. Biotechnol. 2011, 86, 1088–1098. [Google Scholar] [CrossRef]

- Ma, X.; Jiang, T.; Chang, J.; Tang, Q.; Luo, T.; Cui, Z. Effect of Substrate to Inoculum Ratio on Biogas Production and Microbial Community During Hemi-Solid-State Batch Anaerobic Co-digestion of Rape Straw and Dairy Manure. Appl. Biochem. Biotechnol. 2019, 189, 884–902. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Shi, J.; Lv, W.; Yu, Z.; Li, Y. Comparison of different liquid anaerobic digestion effluents as inocula and nitrogen sources for solid-state batch anaerobic digestion of corn stover. Waste Manag. 2013, 33, 26–32. [Google Scholar] [CrossRef]

- Motte, J.C.; Escudié, R.; Bernet, N.; Delgenes, J.P.; Steyer, J.P.; Dumas, C. Dynamic effect of total solid content, low substrate/inoculum ratio and particle size on solid-state anaerobic digestion. Bioresour. Technol. 2013, 144, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Slimane, K.; Fathya, S.; Assia, K.; Hamza, M. Influence of inoculums/substrate ratios (ISRs) on the mesophilic anaerobic digestion of slaughterhouse waste in batch mode: Process stability and biogas production. Energy Procedia 2014, 50, 57–63. [Google Scholar] [CrossRef] [Green Version]

- Sri Bala Kameswari, K.; Kalyanaraman, C.; Porselvam, S.; Thanasekaran, K. Optimization of inoculum to substrate ratio for bio-energy generation in co-digestion of tannery solid wastes. Clean Technol. Environ. Policy 2012, 14, 241–250. [Google Scholar] [CrossRef]

- Zhang, L.; Ouyang, W.; Lia, A. Essential Role of Trace Elements in Continuous Anaerobic Digestion of Food Waste. Procedia Environ. Sci. 2012, 16, 102–111. [Google Scholar] [CrossRef] [Green Version]

- Sosnowski, P.; Klepacz-Smolka, A.; Kaczorek, K.; Ledakowicz, S. Kinetic investigations of methane co-fermentation of sewage sludge and organic fraction of municipal solid wastes. Bioresour. Technol. 2008, 99, 5731–5737. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2012; ISBN 978-0875532356. [Google Scholar]

- Lowry, O.H.; Rosebrough, N.J.; Farr, L.; Randall, R. Protein measurement with the folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef]

- DuBois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric method for determination of sugars and related substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Bligh, E.G.; Dyer, W.J. A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef]

- Achinas, S.; Li, Y.; Achinas, V.; Euverink, G.J.W. Biogas potential from the anaerobic digestion of potato peels: Process performance and kinetics evaluation. Energies 2019, 12, 2311. [Google Scholar] [CrossRef] [Green Version]

- Latifi, P.; Karrabi, M.; Danesh, S. Anaerobic co-digestion of poultry slaughterhouse wastes with sewage sludge in batch-mode bioreactors (effect of inoculum-substrate ratio and total solids). Renew. Sustain. Energy Rev. 2019, 107, 288–296. [Google Scholar] [CrossRef]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; De Wilde, V.; et al. Towards a standardization of biomethane potential tests. Water Sci. Technol. 2016, 74, 2515–2522. [Google Scholar] [CrossRef] [PubMed]

- Franke-Whittle, I.H.; Walter, A.; Ebner, C.; Insam, H. Investigation into the effect of high concentrations of volatile fatty acids in anaerobic digestion on methanogenic communities. Waste Manag. 2014, 34, 2080–2089. [Google Scholar] [CrossRef] [Green Version]

- Cabbai, V.; Ballico, M.; Aneggi, E.; Goi, D. BMP tests of source selected OFMSW to evaluate anaerobic codigestion with sewage sludge. Waste Manag. 2013, 33, 1626–1632. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Banks, C.J. Impact of different particle size distributions on anaerobic digestion of the organic fraction of municipal solid waste. Waste Manag. 2013, 33, 297–307. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zeng, S.; Yuan, X.; Shi, X.; Qiu, Y. Effect of inoculum/substrate ratio on methane yield and orthophosphate release from anaerobic digestion of Microcystis spp. J. Hazard. Mater. 2010, 178, 89–93. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zeng, G.; Zhang, G.; Li, Y.; Zhang, B.; Fan, M. Anaerobic co-digestion of biosolids and organic fraction of municipal solid waste by sequencing batch process. Fuel Process. Technol. 2008, 89, 485–489. [Google Scholar] [CrossRef]

- Esposito, G.; Frunzo, L.; Giordano, A.; Liotta, F.; Panico, A.; Pirozzi, F. Anaerobic co-digestion of organic wastes. Rev. Environ. Sci. Biotechnol. 2012, 11, 325–341. [Google Scholar] [CrossRef]

- Filer, J.; Ding, H.H.; Chang, S. Biochemical Methane Potential (BMP) Assay Method for Anaerobic Digestion Research. Water 2019, 11, 921. [Google Scholar] [CrossRef] [Green Version]

| Mixure ID | OFMSW/SS | Percentage TS | Moisture | VS | TN | TP | COD | PN | CS | LS |

|---|---|---|---|---|---|---|---|---|---|---|

| – | %dw | %TS | % | %TVS | mgN/gTS | mgP/gTS | mgO2/gTS | %TS | %TS | %TS |

| ISR = 0.05 | ||||||||||

| Mix 1 | 0–100 | 2.82 | 97.2 | 72% | 6.3 | 1.98 | 963.57 | 75.29 | 22.40 | 0.21 |

| Mix 2 | 20–80 | 3.30 | 96.7 | 80% | 10.9 | 1.85 | 1184.55 | 57.73 | 32.34 | 6.51 |

| Mix 3 | 40–60 | 4.88 | 95.1 | 82% | 12.4 | 1.90 | 1256.62 | 51.83 | 35.39 | 9.08 |

| Mix 4 | 60–40 | 5.07 | 94.9 | 87% | 15.3 | 1.87 | 1389.61 | 41.36 | 41.53 | 13.64 |

| Mix 5 | 80–20 | 5.04 | 95.0 | 91% | 18.2 | 1.83 | 1530.44 | 29.63 | 47.91 | 18.83 |

| Mix 6 | 100–0 | 5.81 | 94.2 | 95% | 20.8 | 1.96 | 1644.32 | 17.67 | 55.06 | 23.51 |

| ISR = 0.5 | ||||||||||

| Mix 1 | 0–100 | 1.51 | 98.5 | 74% | 6.4 | 4.33 | 944.94 | 63.41 | 33.21 | 0.78 |

| Mix 2 | 20–80 | 1.60 | 98.4 | 76% | 7.8 | 4.46 | 1005.77 | 59.62 | 36.13 | 1.61 |

| Mix 3 | 40–60 | 1.72 | 98.3 | 77% | 9.3 | 4.60 | 1071.97 | 54.92 | 39.12 | 3.36 |

| Mix 4 | 60–40 | 1.86 | 98.1 | 79% | 10.9 | 4.79 | 1144.22 | 49.66 | 42.43 | 5.29 |

| Mix 5 | 80–20 | 2.05 | 98.0 | 81% | 12.8 | 4.97 | 1223.82 | 43.84 | 46.18 | 7.34 |

| Mix 6 | 100–0 | 2.31 | 97.7 | 84% | 14.8 | 5.17 | 1311.62 | 37.47 | 50.23 | 9.73 |

| ISR = 1 | ||||||||||

| Mix 1 | 0–100 | 1.34 | 98.7 | 72% | 6.4 | 5.67 | 917.85 | 59.44 | 37.51 | 0.51 |

| Mix 2 | 20–80 | 1.39 | 98.6 | 74% | 7.4 | 5.81 | 961.80 | 56.53 | 39.53 | 1.57 |

| Mix 3 | 40–60 | 1.44 | 98.6 | 75% | 8.5 | 5.94 | 1008.67 | 53.41 | 41.54 | 2.63 |

| Mix 4 | 60–40 | 1.50 | 98.5 | 76% | 9.7 | 6.13 | 1058.02 | 50.33 | 43.88 | 3.71 |

| Mix 5 | 80–20 | 1.57 | 98.4 | 77% | 10.9 | 6.30 | 1111.29 | 46.41 | 46.23 | 5.06 |

| Mix 6 | 100–0 | 1.66 | 98.3 | 79% | 12.2 | 6.50 | 1167.01 | 42.67 | 48.71 | 6.21 |

| ISR = 2 | ||||||||||

| Mix 1 | 0–100 | 1.51 | 98.5 | 70% | 5.2 | 5.58 | 719.89 | 55.96 | 40.66 | 0.73 |

| Mix 2 | 20–80 | 1.54 | 98.5 | 71% | 5.7 | 5.67 | 738.02 | 54.01 | 41.92 | 1.32 |

| Mix 3 | 40–60 | 1.58 | 98.4 | 71% | 6.2 | 5.75 | 758.10 | 52.11 | 43.22 | 1.94 |

| Mix 4 | 60–40 | 1.61 | 98.4 | 72% | 6.8 | 5.81 | 780.17 | 50.16 | 44.43 | 2.66 |

| Mix 5 | 80–20 | 1.65 | 98.3 | 72% | 7.3 | 5.90 | 801.54 | 48.06 | 45.98 | 3.31 |

| Mix 6 | 100–0 | 1.69 | 98.3 | 73% | 7.9 | 6.01 | 822.52 | 45.83 | 47.44 | 4.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corsino, S.F.; Torregrossa, M.; Viviani, G. Biomethane Production from Anaerobic Co-Digestion of Selected Organic Fraction of Municipal Solid Waste (OFMSW) with Sewage Sludge: Effect of the Inoculum to Substrate Ratio (ISR) and Mixture Composition on Process Performances. Int. J. Environ. Res. Public Health 2021, 18, 13048. https://doi.org/10.3390/ijerph182413048

Corsino SF, Torregrossa M, Viviani G. Biomethane Production from Anaerobic Co-Digestion of Selected Organic Fraction of Municipal Solid Waste (OFMSW) with Sewage Sludge: Effect of the Inoculum to Substrate Ratio (ISR) and Mixture Composition on Process Performances. International Journal of Environmental Research and Public Health. 2021; 18(24):13048. https://doi.org/10.3390/ijerph182413048

Chicago/Turabian StyleCorsino, Santo Fabio, Michele Torregrossa, and Gaspare Viviani. 2021. "Biomethane Production from Anaerobic Co-Digestion of Selected Organic Fraction of Municipal Solid Waste (OFMSW) with Sewage Sludge: Effect of the Inoculum to Substrate Ratio (ISR) and Mixture Composition on Process Performances" International Journal of Environmental Research and Public Health 18, no. 24: 13048. https://doi.org/10.3390/ijerph182413048

APA StyleCorsino, S. F., Torregrossa, M., & Viviani, G. (2021). Biomethane Production from Anaerobic Co-Digestion of Selected Organic Fraction of Municipal Solid Waste (OFMSW) with Sewage Sludge: Effect of the Inoculum to Substrate Ratio (ISR) and Mixture Composition on Process Performances. International Journal of Environmental Research and Public Health, 18(24), 13048. https://doi.org/10.3390/ijerph182413048