Energy and Environmental Assessment of Steam Management Optimization in an Ethylene Plant

Abstract

1. Introduction

1.1. Overview and Literature Survey

1.2. Contribution of This Study

- Whether and how are energy savings achievable by internal SC energy management optimization affected by the possibility of steam import/export to/from an SC?

- What does the resulting balance of the main air pollutants look like, and to what extent can the feasibility of energy costs saving measures be affected by the increasing carbon tax?

2. Materials and Methods

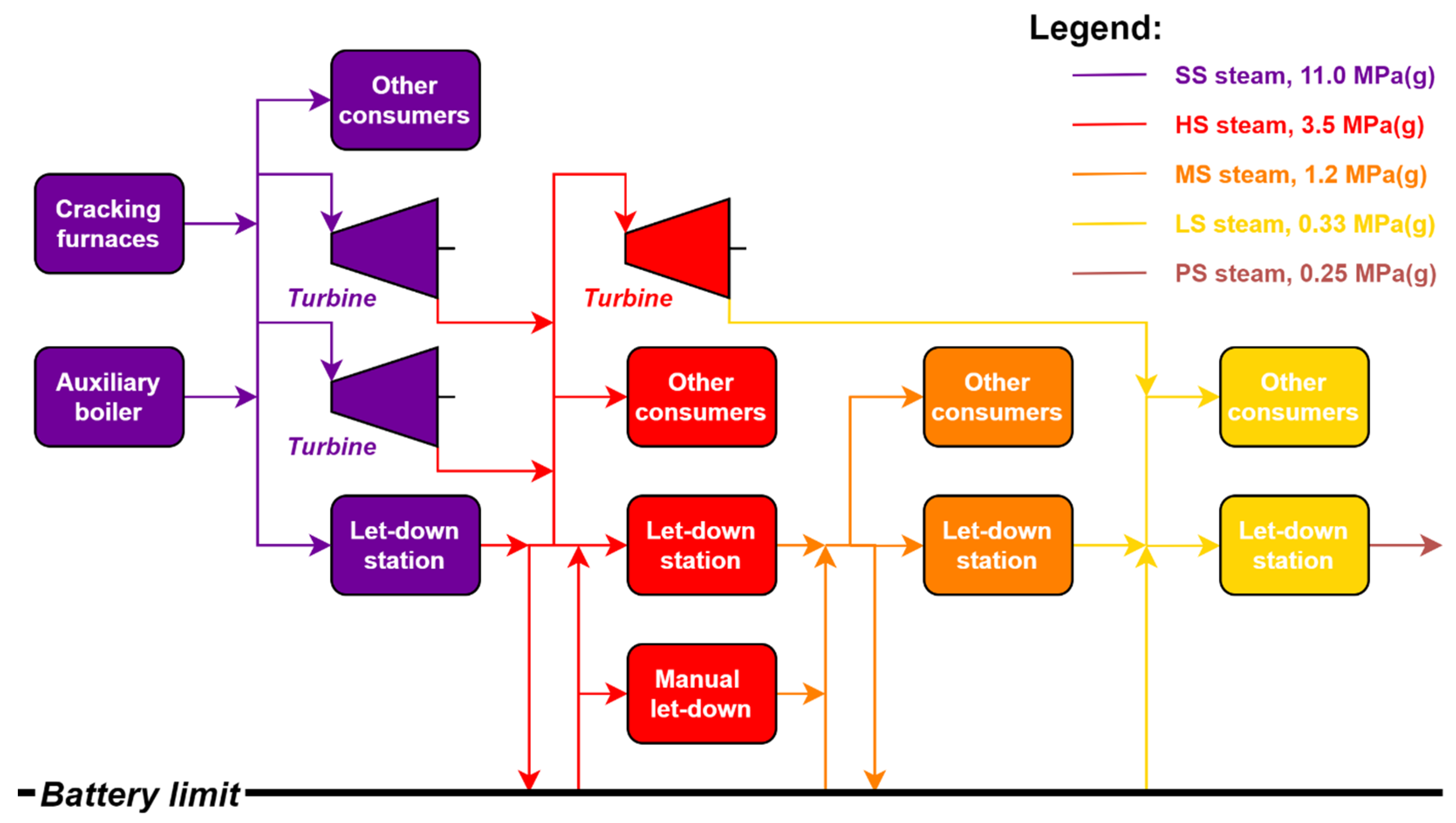

2.1. Steam Cracker Steam System

- SS (superhigh pressure) steam: 11.0 MPa (g), 520 °C;

- HS steam: (high pressure) 3.5 MPa (g), 350 °C;

- MS steam: (intermediate pressure) 1.2 MPa (g), 250 °C;

- LS steam: (low pressure) 0.4 MPa (g), 170 °C;

- PS steam: (very low pressure) 0.25 MPa (g), 138 °C;

- DS steam: (dilution steam) 0.7 MPa, 190 °C.

- Direct fuel (natural gas) savings are expected due to more efficient co-generative HS steam production by extraction from steam drives instead of SS to HS steam throttling, translated into a reduced condensing load of the steam drives. Thus, an improvement in the energy efficiency of SC and the whole refinery is expected. In addition, fewer GHG emissions will be produced.

- HS and LS steam import will be enabled due to less steam being produced internally. Imported steam is usually produced from cheaper fuel (mixed petroleum residue, MPR, which is usually in excess). Additional extraction electricity generation will be possible thanks to the increased steam supply from the CHP unit. These effects contribute to better economic results. On the other hand, there is a negative environmental effect of MPR fuel utilization, as its combustion produces more greenhouse gases (GHGs) than that of natural gas.

2.2. Combined Heat and Power Unit

2.3. Energy and Environmental Assessment

2.3.1. Steam Cracker

- Rerouting 4 t/h of SS steam from the let-down station to the steam turbine and letting it expand to the HS pressure level reduces steam flow to the turbine condenser by 1 t/h;

- Heat rejection in the steam turbine condenser is reduced by 2.268 GJ/h per 1 t/h of steam flow to the condenser, considering the enthalpy of the discharge steam to the condenser of 2.438 GJ/t and that of the steam condensate leaving the condenser of 0.168 GJ/t.

- SS steam enthalpy leaving the SC steam boiler is 3.435 GJ/t and the difference between this value and that of steam condensate enthalpy leaving the turbine condenser has to be supplied by the fuel combusted in the boiler;

- Thermal efficiency of the boiler resulting from certified measurements is 94.1%, based on the lower heating value of the combusted fuel (natural gas, NG);

- The lower heating value of NG is 49 GJ/t and its emission factor is 2.75 tCO2/tNG.

2.3.2. Combined Heat and Power Plant

- Specific MPR consumption is 0.09 t per ton of exported steam;

- The lower heating value of MPR is 40.3 GJ/t and its emission factor is 3.2 tCO2/tMPR;

- The average steam enthalpy imported to the SC from the CHP is 2.9 GJ/t;

- Marginal backpressure electricity production in the CHP amounts to 150 kWh per ton of exported steam.

3. Results and Discussion

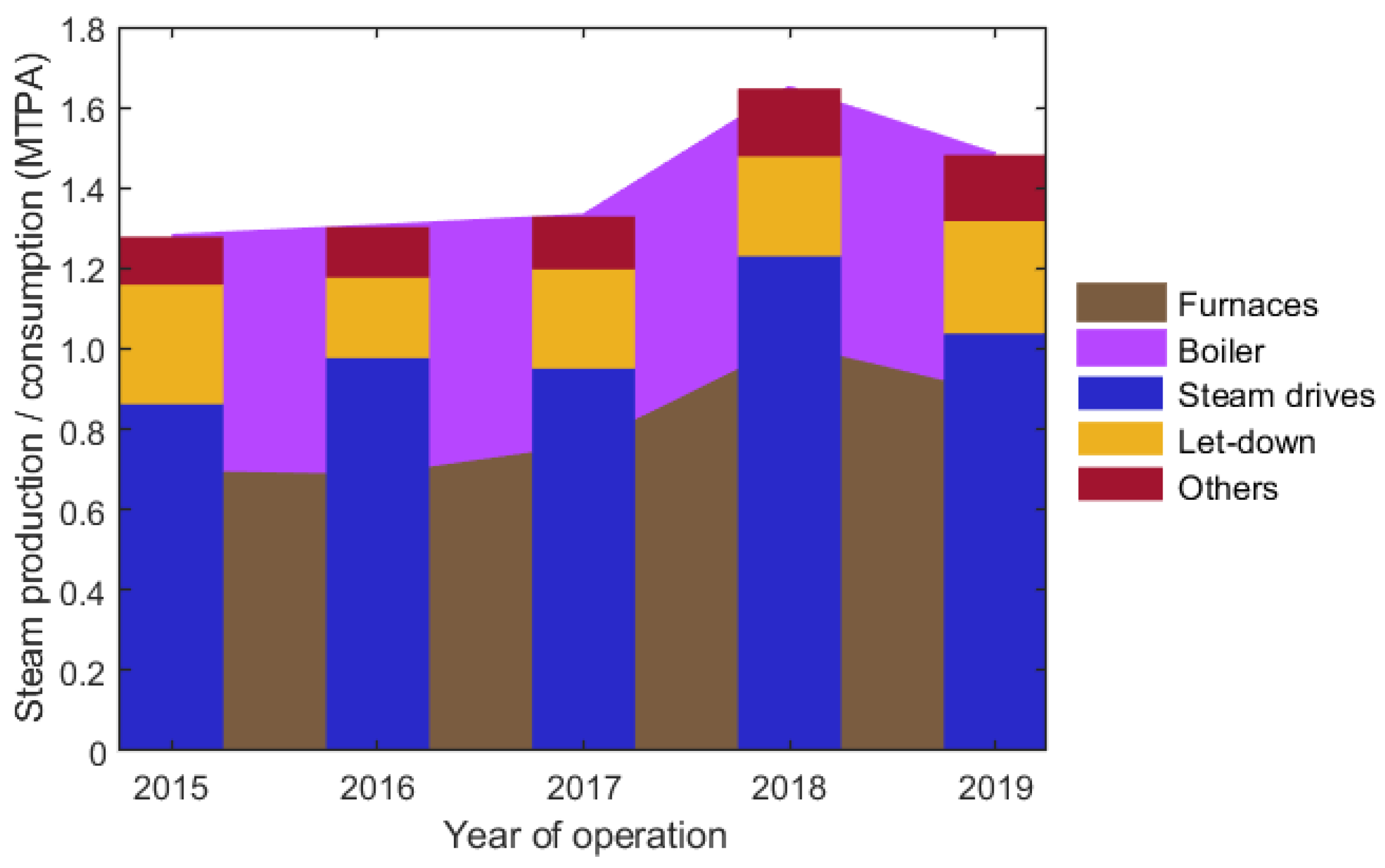

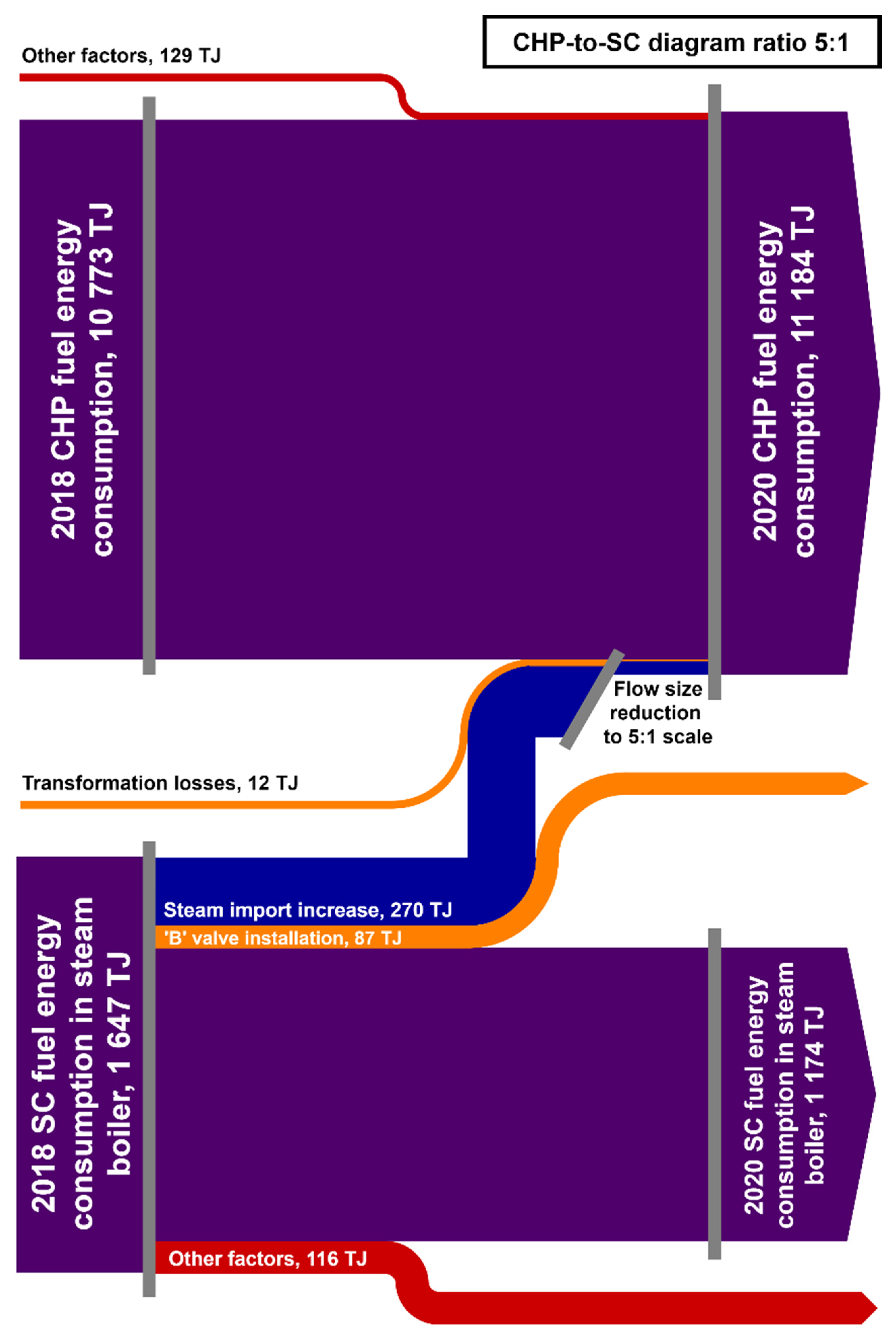

3.1. Energy Consumption

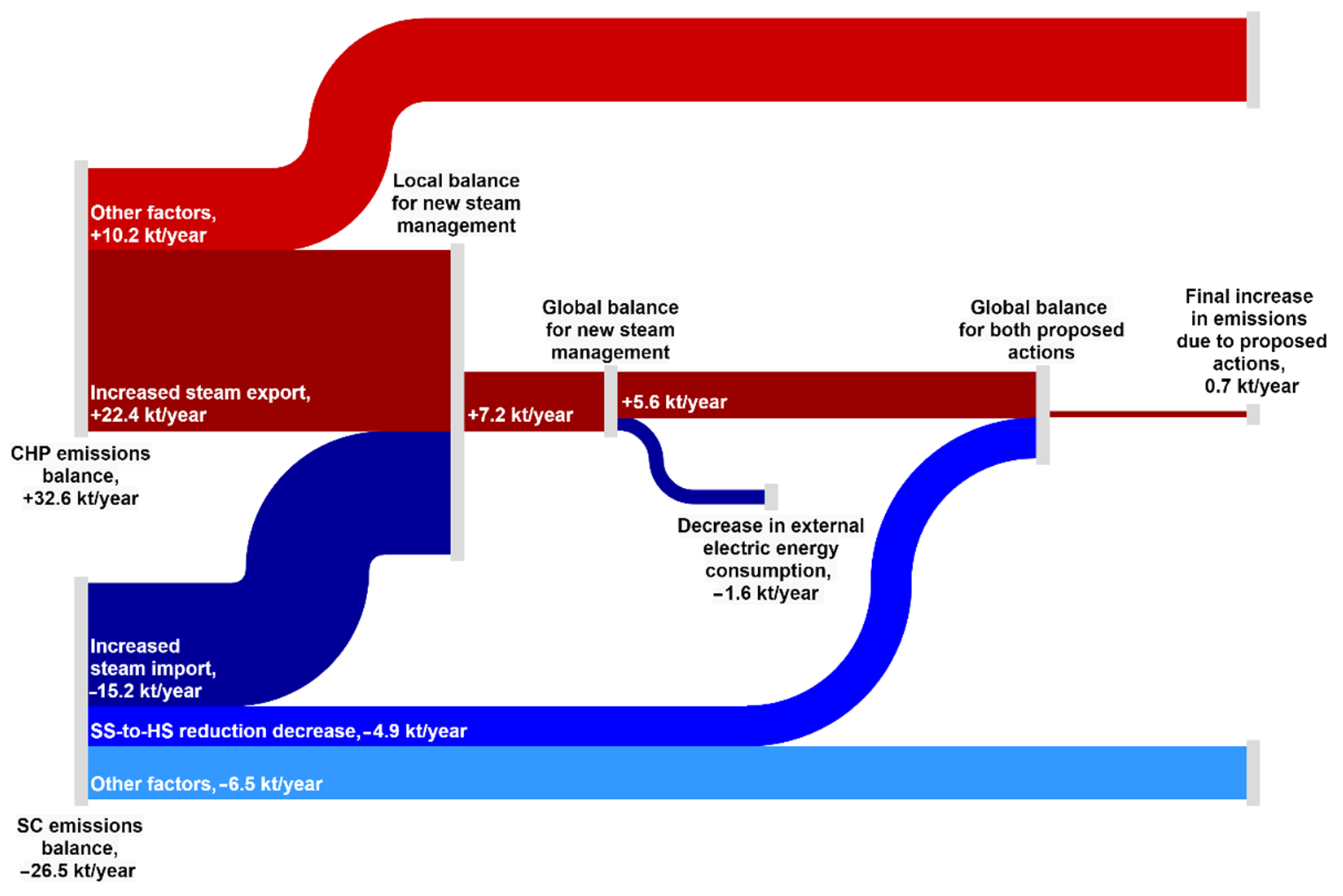

3.2. GHG Emissions

3.3. Economic Considerations

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- Gharaie, M.; Panjeshahi, M.H.; Kim, J.-K.; Jobson, M.; Smith, R. Retrofit strategy for the site-wide mitigation of CO2 emissions in the process industries. Chem. Eng. Res. Des. 2015, 94, 213–241. [Google Scholar] [CrossRef]

- Rehfeldt, M.; Worrell, E.; Eichhammer, W.; Fleiter, T. A review of the emission reduction potential of fuel switch towards biomass and electricity in European basic materials industry until 2030. Renew. Sustain. Energy Rev. 2020, 120, 109672. [Google Scholar] [CrossRef]

- Borozan, D. Decomposing the changes in European final energy consumption. Energy Strategy Rev. 2018, 22, 26–36. [Google Scholar] [CrossRef]

- Gerres, T.; Ávila, J.P.C.; Llamas, P.L.; San Román, T.G. A review of cross-sector decarbonisation potentials in the European energy intensive industry. J. Clean. Prod. 2019, 210, 585–601. [Google Scholar] [CrossRef]

- Bungener, S.L.; Van Eetvelde, G.; Maréchal, F. Optimal Operations and Resilient Investments in Steam Networks. Front. Energy Res. 2016, 4, 1. [Google Scholar] [CrossRef][Green Version]

- Liu, R.; He, F.; Chen, L. Can Energy Management Systems Improve the Performance of Industrial Enterprises? Pol. J. Environ. Stud. 2021, 30, 5133–5147. [Google Scholar] [CrossRef]

- Kubule, A.; Ločmelis, K.; Blumberga, D. Analysis of the results of national energy audit program in Latvia. Energy 2020, 202, 117679. [Google Scholar] [CrossRef]

- de Magalhães, R.F.; Danilevicz, Â.d.M.F.; Palazzo, J. Managing trade-offs in complex scenarios: A decision-making tool for sustainability projects. J. Clean. Prod. 2019, 212, 447–460. [Google Scholar] [CrossRef]

- Maciková, L.; Smorada, M.; Dorčák, P.; Beug, B.; Markovič, P. Financial Aspects of Sustainability: An Evidence from Slovak Companies. Sustainability 2018, 10, 2274. [Google Scholar] [CrossRef]

- Drobyazko, S.; Skrypnyk, M.; Radionova, N.; Hryhorevska, O.; Matiukha, M. Enterprise energy supply system design management based on renewable energy sources. Glob. J. Environ. Sci. Manag. 2021, 7, 369–382. [Google Scholar] [CrossRef]

- Kar, Y. Catalytic cracking of pyrolytic oil by using bentonite clay for green liquid hydrocarbon fuels production. Biomass Bioenergy 2018, 119, 473–479. [Google Scholar] [CrossRef]

- Ciesielska-Maciągowska, D.; Klimczak, D.; Skrzek-Lubasińska, M. Central and Eastern European CO2 Market—Challenges of Emissions Trading for Energy Companies. Energies 2021, 14, 1051. [Google Scholar] [CrossRef]

- Jiang, C.; Yue, Y. Sensitivity Analysis of Key Factors Influencing Carbon Prices under the EU ETS. Pol. J. Environ. Stud. 2021, 30, 3645–3658. [Google Scholar] [CrossRef]

- Locmelis, K.; Blumberga, D.; Blumberga, A.; Kubule, A. Benchmarking of Industrial Energy Efficiency. Outcomes of an Energy Audit Policy Program. Energies 2020, 13, 2210. [Google Scholar] [CrossRef]

- Malega, P.; Majerník, M.; Rudy, V.; Daneshjo, N. Innovation Support and Eco-Innovations in the Slovak Republic in the Intentions of Sustainable Development. Pol. J. Environ. Stud. 2021, 30, 3753–3768. [Google Scholar] [CrossRef]

- Glavič, P.; Pintarič, Z.N.; Bogataj, M. Process Design and Sustainable Development—A European Perspective. Processes 2021, 9, 148. [Google Scholar] [CrossRef]

- Locmelis, K.; Blumberga, D.; Bariss, U. Energy efficiency in large industrial plants. Legislative aspects. Energy Procedia 2018, 147, 202–206. [Google Scholar] [CrossRef]

- Rehfeldt, M.; Globisch, J.; Fleiter, T. Fuel choice in industrial steam generation: Empirical evidence reveals technology preferences. Energy Strategy Rev. 2019, 26, 100407. [Google Scholar] [CrossRef]

- Martins, F.; Felgueiras, C.; Smitkova, M.; Caetano, N. Analysis of Fossil Fuel Energy Consumption and Environmental Impacts in European Countries. Energies 2019, 12, 964. [Google Scholar] [CrossRef]

- Wang, R.Q.; Jiang, L.; Wang, Y.D.; Roskilly, A.P. Energy saving technologies and mass-thermal network optimization for decarbonized iron and steel industry: A review. J. Clean. Prod. 2020, 274, 122997. [Google Scholar] [CrossRef]

- Peng, Z.; Fu, C.; Zhu, K.; Zhang, Q.; Ni, D.; Yang, S. An improved LP model for energy optimization of the integrated iron and steel plant with a cogeneration system in China. J. Syst. Sci. Syst. Eng. 2016, 25, 515–534. [Google Scholar] [CrossRef]

- Griffin, P.W.; Hammond, G.P.; Norman, J.B. Industrial decarbonisation of the pulp and paper sector: A UK perspective. Appl. Therm. Eng. 2018, 134, 152–162. [Google Scholar] [CrossRef]

- Gambini, M.; Vellini, M.; Stilo, T.; Manno, M.; Bellocchi, S. High-Efficiency Cogeneration Systems: The Case of the Paper Industry in Italy. Energies 2019, 12, 335. [Google Scholar] [CrossRef]

- Vooradi, R.; Anne, S.B.; Tula, A.K.; Eden, M.R.; Gani, R. Energy and CO2 management for chemical and related industries: Issues, opportunities and challenges. BMC Chem. Eng. 2019, 1, 7. [Google Scholar] [CrossRef]

- Ahmadi, G.; Toghraie, D.; Akbari, O. Energy, exergy and environmental (3E) analysis of the existing CHP system in a petrochemical plant. Renew. Sustain. Energy Rev. 2019, 99, 234–242. [Google Scholar] [CrossRef]

- Morandin, M.; Hackl, R.; Harvey, S. Economic feasibility of district heating delivery from industrial excess heat: A case study of a Swedish petrochemical cluster. Energy 2014, 65, 209–220. [Google Scholar] [CrossRef]

- Hanus, K.; Variny, M.; Illés, P. Assessment and Prediction of Complex Industrial Steam Network Operation by Combined Thermo-Hydrodynamic Modeling. Processes 2020, 8, 622. [Google Scholar] [CrossRef]

- Berghout, N.; Meerman, H.; van den Broek, M.; Faaij, A. Assessing deployment pathways for greenhouse gas emissions reductions in an industrial plant—A case study for a complex oil refinery. Appl. Energy 2019, 236, 354–378. [Google Scholar] [CrossRef]

- Bütün, H.; Kantor, I.; Maréchal, F. Incorporating Location Aspects in Process Integration Methodology. Energies 2019, 12, 3338. [Google Scholar] [CrossRef]

- Chen, C.-L.; Lin, C.-Y. A flexible structural and operational design of steam systems. Appl. Therm. Eng. 2011, 31, 2084–2093. [Google Scholar] [CrossRef]

- Del Nogal, F.L.; Kim, J.K.; Perry, S.; Smith, R. Synthesis of Mechanical Driver and Power Generation Configurations, Part 1: Optimization Framework. AIChE J. 2010, 56, 2356–2376. [Google Scholar] [CrossRef]

- Zhao, L.; Zhong, W.; Du, W. Data-Driven Robust Optimization for Steam Systems in Ethylene Plants under Uncertainty. Processes 2019, 7, 744. [Google Scholar] [CrossRef]

- Svensson, E.; Morandin, M.; Harvey, S.; Papadokonstantakis, S. Studying the Role of System Aggregation in Energy Targeting: A Case Study of a Swedish Oil Refinery. Energies 2020, 13, 958. [Google Scholar] [CrossRef]

- Hassiba, R.J.; Linke, P. On the simultaneous integration of heat and carbon dioxide in industrial parks. Appl. Therm. Eng. 2017, 127, 81–94. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, S.; Wang, K.; Liu, L.; Zhang, R. Co-benefits analysis of energy cascade utilization in an industrial park in China. Environ. Sci. Pollut. Res. 2019, 26, 16181–16194. [Google Scholar] [CrossRef]

- Zhu, Q.; Luo, X.; Zhang, B.; Chen, Y.; Mo, S. Mathematical modeling, validation, and operation optimization of an industrial complex steam turbine network-methodology and application. Energy 2016, 97, 191–213. [Google Scholar] [CrossRef]

- Variny, M.; Jediná, D.; Kizek, J.; Illés, P.; Lukáč, L.; Janošovský, J.; Lesný, M. An Investigation of the Techno-Economic and Environmental Aspects of Process Heat Source Change in a Refinery. Processes 2019, 7, 776. [Google Scholar] [CrossRef]

- Marton, S.; Svensson, E.; Subiaco, R.; Bengtsson, F.; Harvey, S. A Steam Utility Network Model for the Evaluation of Heat Integration Retrofits—A Case Study of an Oil Refinery. J. Sustain. Dev. Energy Water Environ. Syst. 2017, 5, 560–578. [Google Scholar] [CrossRef][Green Version]

- Nguyen, T.Q.; Slawnwhite, J.D.; Boulama, K.G. Power generation from residual industrial heat. Energy Convers. Manag. 2010, 51, 2220–2229. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, L.; Du, W.; Qian, F. Modeling and Optimization of the Steam Turbine Network of an Ethylene Plant. Chin. J. Chem. Eng. 2013, 21, 520–528. [Google Scholar] [CrossRef]

- Verhees, P.; Amghizar, I.; Goemare, J.; Akhras, A.R.; Marin, G.B.; Van Geem, K.M.; Heynderickx, G.J. 1D Model for Coupled Simulation of Steam Cracker Convection Section with Improved Evaporation Model. Chem. Ing. Tech. 2016, 88, 1650–1664. [Google Scholar] [CrossRef]

- Hackl, R.; Harvey, S. Applying exergy and total site analysis for targeting refrigeration shaft power in industrial clusters. Energy 2013, 55, 5–14. [Google Scholar] [CrossRef]

- Zhao, L.; Ning, C.; You, F. Operational optimization of industrial steam systems under uncertainty using data- Driven adaptive robust optimization. AIChE J. 2019, 65, e16500. [Google Scholar] [CrossRef]

- Li, Z.; Du, W.; Zhao, L.; Qian, F. Modeling and Optimization of a Steam System in a Chemical Plant Containing Multiple Direct Drive Steam Turbines. Ind. Eng. Chem. Res. 2014, 53, 11021–11032. [Google Scholar] [CrossRef]

- Zhao, H.; Ierapetritou, M.G.; Shah, N.K.; Rong, G. Integrated model of refining and petrochemical plant for enterprise-wide optimization. Comput. Chem. Eng. 2017, 97, 194–207. [Google Scholar] [CrossRef]

- Ketabchi, E.; Mechleri, E.; Arellano-Garcia, H. Increasing operational efficiency through the integration of an oil refinery and an ethylene production plant. Chem. Eng. Res. Des. 2019, 152, 85–94. [Google Scholar] [CrossRef]

- Mrzljak, V.; Poljak, I.; Mrakovčić, T. Energy and exergy analysis of the turbo-generators and steam turbine for the main feed water pump drive on LNG carrier. Energy Convers. Manag. 2017, 140, 307–323. [Google Scholar] [CrossRef]

- Weickgenannt, A.; Kantor, I.; Maréchal, F.; Schiffmann, J. On the Application of Small-Scale Turbines in Industrial Steam Networks. Energies 2021, 14, 3149. [Google Scholar] [CrossRef]

- Ren, X.-Y.; Jia, X.-X.; Varbanov, P.S.; Klemeš, J.J.; Liu, Z.-Y. Targeting the cogeneration potential for Total Site utility systems. J. Clean. Prod. 2018, 170, 625–635. [Google Scholar] [CrossRef]

- Murugan, S.; Horák, B. Tri and polygeneration systems—A review. Renew. Sustain. Energy Rev. 2016, 60, 1032–1051. [Google Scholar] [CrossRef]

- Ng, K.S.; Hernandez, E.M. A systematic framework for energetic, environmental and economic (3E) assessment and design of polygeneration systems. Chem. Eng. Res. Des. 2016, 106, 1–25. [Google Scholar] [CrossRef]

- Dai, M.; Yang, F.; Zhang, Z.; Liu, G.; Feng, X. Energetic, economic and environmental (3E) multi-objective optimization of the back-end separation of ethylene plant based on adaptive surrogate model. J. Clean. Prod. 2021, 310, 127426. [Google Scholar] [CrossRef]

- Nabavi, S.R.; Rangaiah, G.P.; Niaei, A.; Salari, D. Multiobjective Optimization of an Industrial LPG Thermal Cracker using a First Principles Model. Ind. Eng. Chem. Res. 2009, 48, 9523–9533. [Google Scholar] [CrossRef]

- Deng, C.; Zhou, Y.; Jiang, W.; Feng, X. Optimal design of inter-plant hydrogen network with purification reuse/recycle. Int. J. Hydrogen Energy 2017, 42, 19984–20002. [Google Scholar] [CrossRef]

- Kamrava, S.; Gabriel, K.J.; El-Halwagi, M.M.; Eljack, F.T. Managing abnormal operation through process integration and cogeneration systems. Clean Technol. Environ. Policy 2014, 17, 119–128. [Google Scholar] [CrossRef]

- Gong, S.; Shao, C.; Zhu, L. An energy efficiency integration optimization scheme for ethylene production with respect to multiple working conditions. Energy 2019, 182, 280–295. [Google Scholar] [CrossRef]

- Shen, F.; Wang, X.; Huang, L.; Ye, Z.; Qian, F. Modeling and Optimization of a Large-Scale Ethylene Plant Energy System with Energy Structure Analysis and Management. Ind. Eng. Chem. Res. 2019, 58, 1686–1700. [Google Scholar] [CrossRef]

- Geng, Z.; Zhang, Y.; Li, C.; Han, Y.; Cui, Y.; Yu, B. Energy optimization and prediction modeling of petrochemical industries: An improved convolutional neural network based on cross-feature. Energy 2020, 194, 116851. [Google Scholar] [CrossRef]

- Shen, F.; Wang, M.; Huang, L.; Qian, F. Exergy analysis and multi-objective optimisation for energy system: A case study of a separation process in ethylene manufacturing. J. Ind. Eng. Chem. 2021, 93, 394–406. [Google Scholar] [CrossRef]

- Wang, J.; He, Y.-L.; Zhu, Q.-X. Energy and Production Efficiency Optimization of an Ethylene Plant Considering Process Operation and Structure. Ind. Eng. Chem. Res. 2020, 59, 1202–1217. [Google Scholar] [CrossRef]

- Chen, K.; Liu, S.; Han, Y.; Zhang, Y.; Geng, Z.; Liu, L.; Peng, T.; Ding, Y. Energy efficiency assessment and resource optimization using novel DEA model: Evidence from complex chemical processes. Energy Effic. 2020, 13, 1427–1439. [Google Scholar] [CrossRef]

- Sanaye, S.; Khakpaay, N.; Chitsaz, A. Thermo-economic and environmental multi-objective optimization of a novel arranged biomass-fueled gas engine and backpressure steam turbine combined system for pulp and paper mills. Sustain. Energy Technol. Assess. 2020, 40, 100778. [Google Scholar] [CrossRef]

- Ziółkowski, P.; Kowalczyk, T.; Lemański, M.; Badur, J. On energy, exergy, and environmental aspects of a combined gas-steam cycle for heat and power generation undergoing a process of retrofitting by steam injection. Energy Convers. Manag. 2019, 192, 374–384. [Google Scholar] [CrossRef]

- Pintarič, Z.N.; Varbanov, P.S.; Klemeš, J.J.; Kravanja, Z. Multi-objective multi-period synthesis of energy efficient processes under variable environmental taxes. Energy 2019, 189, 116182. [Google Scholar] [CrossRef]

- Ahmadi, G.; Toghraie, D.; Akbari, O.A. Technical and environmental analysis of repowering the existing CHP system in a petrochemical plant: A case study. Energy 2018, 159, 937–949. [Google Scholar] [CrossRef]

- Rimar, M.; Kulikova, O.; Kulikov, A.; Fedak, M. Energy Treatment of Solid Municipal Waste in Combination with Biomass by Decentralized Method with the Respect to the Negative Effects on the Environment. Sustainability 2021, 13, 4405. [Google Scholar] [CrossRef]

- Bamufleh, H.S.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Multi-objective optimization of process cogeneration systems with economic, environmental, and social tradeoffs. Clean Technol. Environ. Policy 2012, 15, 185–197. [Google Scholar] [CrossRef]

- Alhajji, M.; Demirel, Y. Energy and environmental sustainability assessment of a crude oil refinery by thermodynamic analysis. Int. J. Energy Res. 2015, 39, 1925–1941. [Google Scholar] [CrossRef]

- Carmo-Calado, L.; Hermoso-Orzáez, M.J.; Mota-Panizio, R.; Guilherme-Garcia, B.; Brito, P. Co-Combustion of Waste Tires and Plastic-Rubber Wastes with Biomass Technical and Environmental Analysis. Sustainability 2020, 12, 1036. [Google Scholar] [CrossRef]

- Constantin, D.E.; Bocaneala, C.; Voiculescu, M.; Rosu, A.; Merlaud, A.; Van Roozendael, M.; Georgescu, P.L. Evolution of SO2 and NOx Emissions from Several Large Combustion Plants in Europe during 2005–2015. Int. J. Environ. Res. Public Health 2020, 17, 3630. [Google Scholar] [CrossRef]

- Variny, M.; Blahušiak, M.; Mierka, O.; Godó, Š.; Margetíny, T. Energy saving measures from their cradle to full adoption with verified, monitored, and targeted performance: A look back at energy audit at Catalytic Naphtha Reforming Unit (CCR). Energy Effic. 2019, 12, 1771–1793. [Google Scholar] [CrossRef]

- Medica-Viola, V.; Šegota, S.B.; Mrzljak, V.; Štifanić, D. Comparison of conventional and heat balance based energy analyses of steam turbine. Pomorstvo 2020, 34, 74–85. [Google Scholar] [CrossRef]

- Mac Kinnon, M.A.; Brouwer, J.; Samuelsen, S. The role of natural gas and its infrastructure in mitigating greenhouse gas emissions, improving regional air quality, and renewable resource integration. Prog. Energy Combust. Sci. 2018, 64, 62–92. [Google Scholar] [CrossRef]

- Mach, V. EDISON Rekonstrukce a Modernizace Teplárny v Areálu SLOVNAFT, a.s. Available online: http://old.allforpower.cz/UserFiles/files/2011/mach.pdf (accessed on 28 June 2021). (In Slovak).

- SLOVNAFT, a.s. Sustainable Development Commitment—Environment. Available online: https://slovnaft.sk/sk/o-nas/trvalo-udrzatelny-rozvoj/zivotne-prostredie/ (accessed on 12 October 2021). (In Slovak).

- SLOVNAFT, a.s. Recently Realized Investment and Modernization Actions. Available online: https://slovnaft.sk/sk/o-nas/informacie-o-investiciach/modernizacia-etylenovej-jednotky-a-vystavba-ldpe-4/ (accessed on 12 October 2021). (In Slovak).

- MOL Group Strategy 2030. Available online: https://molgroup.info/en/strategy-2030 (accessed on 28 September 2021).

- Rehfeldt, M.; Fleiter, T.; Worrell, E. Inter-fuel substitution in European industry: A random utility approach on industrial heat demand. J. Clean. Prod. 2018, 187, 98–110. [Google Scholar] [CrossRef]

- Ditaranto, M.; Anantharaman, R.; Weydahl, T. Performance and NOx Emissions of Refinery Fired Heaters Retrofitted to Hydrogen Combustion. Energy Procedia 2013, 37, 7214–7220. [Google Scholar] [CrossRef]

- Glushkov, D.; Kuznetsov, G.; Paushkina, K. Switching Coal-Fired Thermal Power Plant to Composite Fuel for Recovering Industrial and Municipal Waste: Combustion Characteristics, Emissions, and Economic Effect. Energies 2020, 13, 259. [Google Scholar] [CrossRef]

- Jou, C.-J.G.; Wu, C.-R.; Lee, C.-L. Reduction of energy cost and CO2 emission for the furnace using energy recovered from waste tail-gas. Energy 2010, 35, 1232–1236. [Google Scholar] [CrossRef]

- Seckinger, N.; Radgen, P. Dynamic Prospective Average and Marginal GHG Emission Factors—Scenario-Based Method for the German Power System until 2050. Energies 2021, 14, 2527. [Google Scholar] [CrossRef]

- Smith, C.N.; Hittinger, E. Using marginal emission factors to improve estimates of emission benefits from appliance efficiency upgrades. Energy Effic. 2019, 12, 585–600. [Google Scholar] [CrossRef]

- Variny, M.; Jediná, D.; Rimár, M.; Kizek, J.; Kšiňanová, M. Cutting Oxygen Production-Related Greenhouse Gas Emissions by Improved Compression Heat Management in a Cryogenic Air Separation Unit. Int. J. Environ. Res. Public Health 2021, 18, 10370. [Google Scholar] [CrossRef]

- Hamels, S. CO2 Intensities and Primary Energy Factors in the Future European Electricity System. Energies 2021, 14, 2165. [Google Scholar] [CrossRef]

- Campbell, P.E.; McMullan, J.T.; Williams, B.C. Concept for a competitive coal fired integrated gasification combined cycle power plant. Fuel 2000, 79, 1031–1040. [Google Scholar] [CrossRef]

- Strachan, N.; Farrell, A. Emissions from distributed vs. centralized generation: The importance of system performance. Energy Policy 2006, 34, 2677–2689. [Google Scholar] [CrossRef]

- Luo, X.; Hu, J.; Zhao, J.; Zhang, B.; Chen, Y.; Mo, S. Multi-objective optimization for the design and synthesis of utility systems with emission abatement technology concerns. Appl. Energy 2014, 136, 1110–1131. [Google Scholar] [CrossRef]

- Comodi, G.; Renzi, M.; Rossi, M. Energy efficiency improvement in oil refineries through flare gas recovery technique to meet the emission trading targets. Energy 2016, 109, 1–12. [Google Scholar] [CrossRef]

- García, N.; Fernández-Torres, M.J.; Caballero, J.A. Simultaneous environmental and economic process synthesis of isobutane alkylation. J. Clean. Prod. 2014, 81, 270–280. [Google Scholar] [CrossRef]

- Ifaei, P.; Safder, U.; Yoo, C. Multi-scale smart management of integrated energy systems, Part 1: Energy, economic, environmental, exergy, risk (4ER) and water-exergy nexus analyses. Energy Convers. Manag. 2019, 197, 111851. [Google Scholar] [CrossRef]

- Safder, U.; Ifaei, P.; Yoo, C. Multi-scale smart management of integrated energy systems, Part 2: Weighted multi-objective optimization, multi-criteria decision making, and multi-scale management (3M) methodology. Energy Convers. Manag. 2019, 198, 111830. [Google Scholar] [CrossRef]

- Hadidi, L.A.; AlDosary, A.S.; Al-Matar, A.K.; Mudallah, O.A. An optimization model to improve gas emission mitigation in oil refineries. J. Clean. Prod. 2016, 118, 29–36. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Fang, L.; Jin, Z.; Zhang, Y.; Yu, X.; Ma, X.; Deng, N.; Wu, Z. Energy, exergy, economic, and environmental analysis of an integrated system of high-temperature heat pump and gas separation unit. Energy Convers. Manag. 2019, 198, 111911. [Google Scholar] [CrossRef]

| Year | Specific Ethylene Production (% of Design Capacity) | SS Steam Consumption (t/% of Specific Ethylene Production) |

|---|---|---|

| 2015 | 68 | 18,795 |

| 2016 | 73 | 17,849 |

| 2017 | 88 | 15,102 |

| 2018 | 100 | 16,460 |

| 2019 | 85 | 17,429 |

| Time Period | Specific Ethylene Production (% of Quarterly Design Capacity) | SS Steam Let-Down to HS (t) | Let-Down Valve ‘A’ Opening (%) |

|---|---|---|---|

| 2018 X to XII | 94 | 55,264 | 15.10 |

| 2019 I to III | 93 | 63,990 | 13.68 |

| 2019 IV to VI | 106 | 78,924 | 14.19 |

| 2019 VII to IX | 110 | 75,037 | 13.78 |

| Quarterly average | 68,304 |

| Fuel Energy Consumed in 2018 | 1647 TJ | |

|---|---|---|

| Pollutant | Emissions in 2018 (t) | Emission Factor (kg/TJ) |

| SOx | 0.13 | 0.08 |

| NOx | 94.84 | 57.58 |

| CO | 1.787 | 1.09 |

| Fuel Energy Consumed in 2018 | 10,773 TJ | |

|---|---|---|

| Pollutant | Emissions in 2018 (t) 1 | Emission Factor (kg/TJ) |

| SOx | 705.55 | 65.50 |

| NOx | 1165.03 | 108.14 |

| CO | 10.28 | 0.95 |

| Pollutant | CO2 | SOx | NOx | CO |

|---|---|---|---|---|

| Emission factor (kg/MWh) | 136 | 0.392 | 0.107 | 0.061 |

| Time Period | Specific Ethylene Production (% of Quarterly Design Capacity) | SS Steam Let-Down to HS (t) 1 | SS to HS Steam Let-Down Valves Opening (%) | NG Consumption Decrease * (GJ) | NG Consumption Decrease * (t) | |

|---|---|---|---|---|---|---|

| Valve ‘A’ | Valve ‘B’ | |||||

| 2020 I to III | 108 | 47,326 | 1.58 | 69.51 | 8808 | 179.8 |

| 2020 IV to VI | 106 | 15,136 | 0.01 | 46.31 | 28,198 | 575.5 |

| 2020 VII to IX | 103 | 14,490 | 0.00 | 49.56 | 28,587 | 583.4 |

| 2020 X to XII | 99 | 26,255 | 0.68 | 52.01 | 21,500 | 438.8 |

| 2020 total | 87,094 | 1777.5 | ||||

| Pollutant | CO | NOx | SOx |

|---|---|---|---|

| Effect of decreased SS to HS steam reduction, total (t) 1 | −0.10 | −5.02 | −0.01 |

| Effect of increased steam export to the SC, total (t), out of which | −0.02 | 14.95 | 18.45 |

| Change in GHG emissions from the SC steam boiler (t) | −0.29 | −15.54 | −0.02 |

| Change in GHG emissions from the CHP steam boilers (t) | 0.27 | 30.49 | 18.47 |

| Change in GHG emissions outside the refinery due to the increased steam export to the SC (t) | −0.71 | −1.25 | −4.57 |

| Global change in GHG emissions due to the increased steam export to the SC (t) | −0.73 | 13.70 | 13.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Variny, M.; Hanus, K.; Blahušiak, M.; Furda, P.; Illés, P.; Janošovský, J. Energy and Environmental Assessment of Steam Management Optimization in an Ethylene Plant. Int. J. Environ. Res. Public Health 2021, 18, 12267. https://doi.org/10.3390/ijerph182212267

Variny M, Hanus K, Blahušiak M, Furda P, Illés P, Janošovský J. Energy and Environmental Assessment of Steam Management Optimization in an Ethylene Plant. International Journal of Environmental Research and Public Health. 2021; 18(22):12267. https://doi.org/10.3390/ijerph182212267

Chicago/Turabian StyleVariny, Miroslav, Kristián Hanus, Marek Blahušiak, Patrik Furda, Peter Illés, and Ján Janošovský. 2021. "Energy and Environmental Assessment of Steam Management Optimization in an Ethylene Plant" International Journal of Environmental Research and Public Health 18, no. 22: 12267. https://doi.org/10.3390/ijerph182212267

APA StyleVariny, M., Hanus, K., Blahušiak, M., Furda, P., Illés, P., & Janošovský, J. (2021). Energy and Environmental Assessment of Steam Management Optimization in an Ethylene Plant. International Journal of Environmental Research and Public Health, 18(22), 12267. https://doi.org/10.3390/ijerph182212267