Mapping Interactions among Green Innovations Barriers in Manufacturing Industry Using Hybrid Methodology: Insights from a Developing Country

Abstract

:1. Introduction

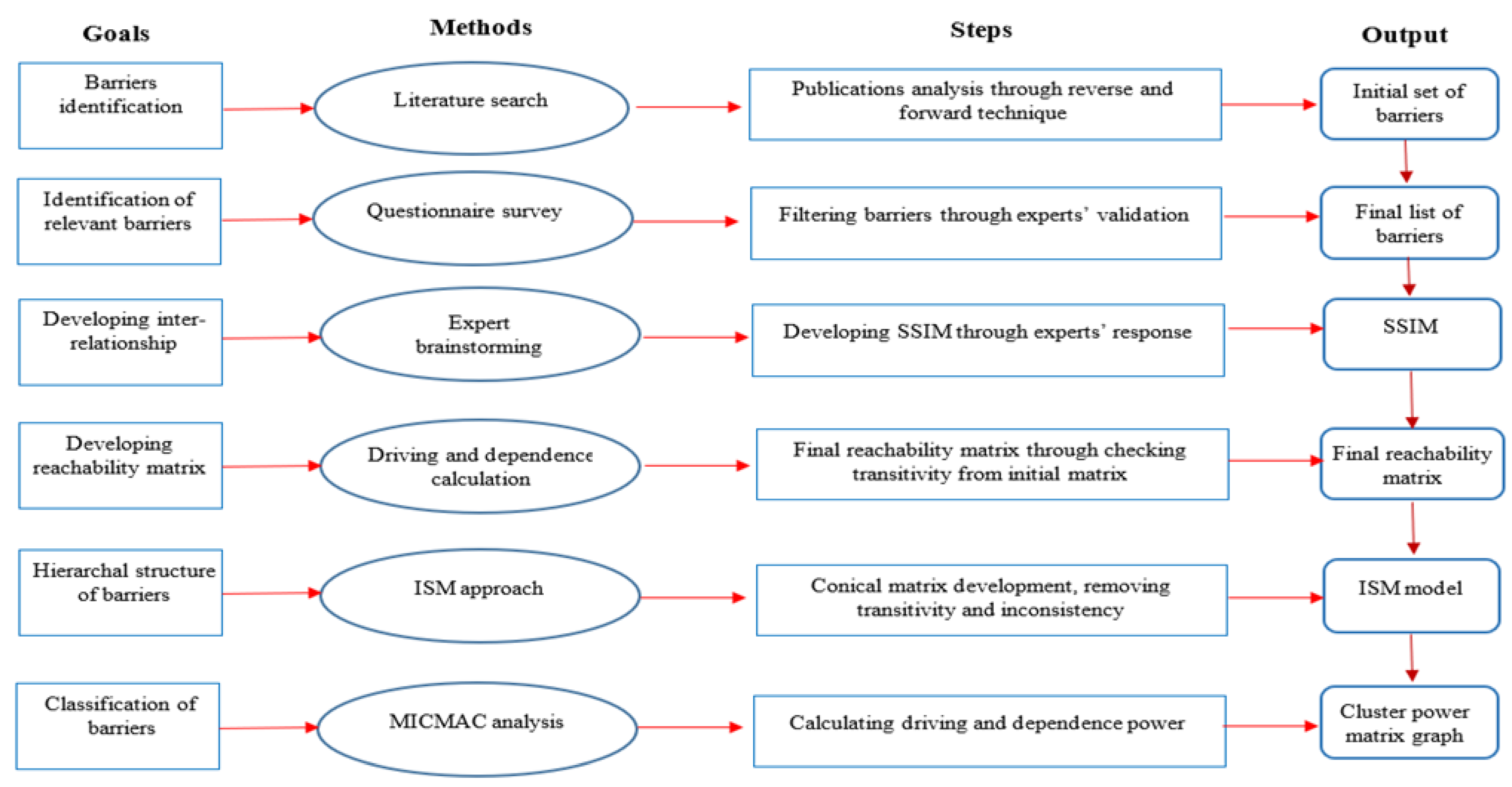

- Exploring green innovation barriers through comprehensive literature review;

- Developing a contextual relationship between different barriers to green innovation;

- Determining the driving and dependence power of barriers to green innovation.

2. Literature Review

2.1. Green Innovation in Current Era

2.2. Previous Studies Related to Green Innovation

2.3. Quest for Green Innovation and Pakistani Manufacturing Sector Perspective

2.4. Critical Review of Green Innovation Studies and Study Framework

- (a)

- Procedures pertaining to the current framework, such as selection of common barriers, the collection of relevant literature, and the applicability of the research techniques are all connected to this goal.

- (b)

- Every structural technique is supported by literature review, which has been approved by professionals. The barriers identified through extensive literature survey and then filtered with specific data.

- (c)

- This step entails finding the link between the identified barriers and developing hierarchical levels for the barriers to green innovation adoption. The ISM MICMAC technique is utilized for this purpose.

- (d)

- The outcomes of this research will help managers and specialists. This framework also aids managers in (a) picking suitable barriers to green innovation implementation, (b) recognizing barriers’ linkages, and (c) establishing hierarchical levels of green innovation implementation challenges.

2.5. Research Gap

3. Methodology

3.1. Identifying Initial Set of Barriers to Green Innovation (Literature Search—Step 1)

3.2. Identification of Relevant Barriers through Fuzzy Delphi Method (FDM) (Questionnaire Survey—Step 2)

3.3. Application of the Interpretive Structural Modeling (ISM) Method (Steps 3–5)

- Those factors affecting the process are listed. This research identifies the obstacles impeding the successful adoption of green innovation in manufacturing sectors are considered as factors.

- Contextual linkage between the investigated factors is formed.

- Pairwise relationships among factors are developed through the formulation of structural self-interaction matrix (SSIM).

- The reachability matrix is established to check the transitivity. The transitivity rule assumes that A has relationship with B and B has a relationship with C then, A has an obvious relationship with C.

- Final reachability is constructed through applying transitivity rule which is divided into different parts.

- A directed graph is drawn based on relationships for the final reachability matrix, and the transitive links are removed.

- The final digraph is changed into an ISM by converting element nodes with statements.

- To ensure valid results, the theoretical interpretive structural model is retested in case of inconsistency and adjustments must be made.

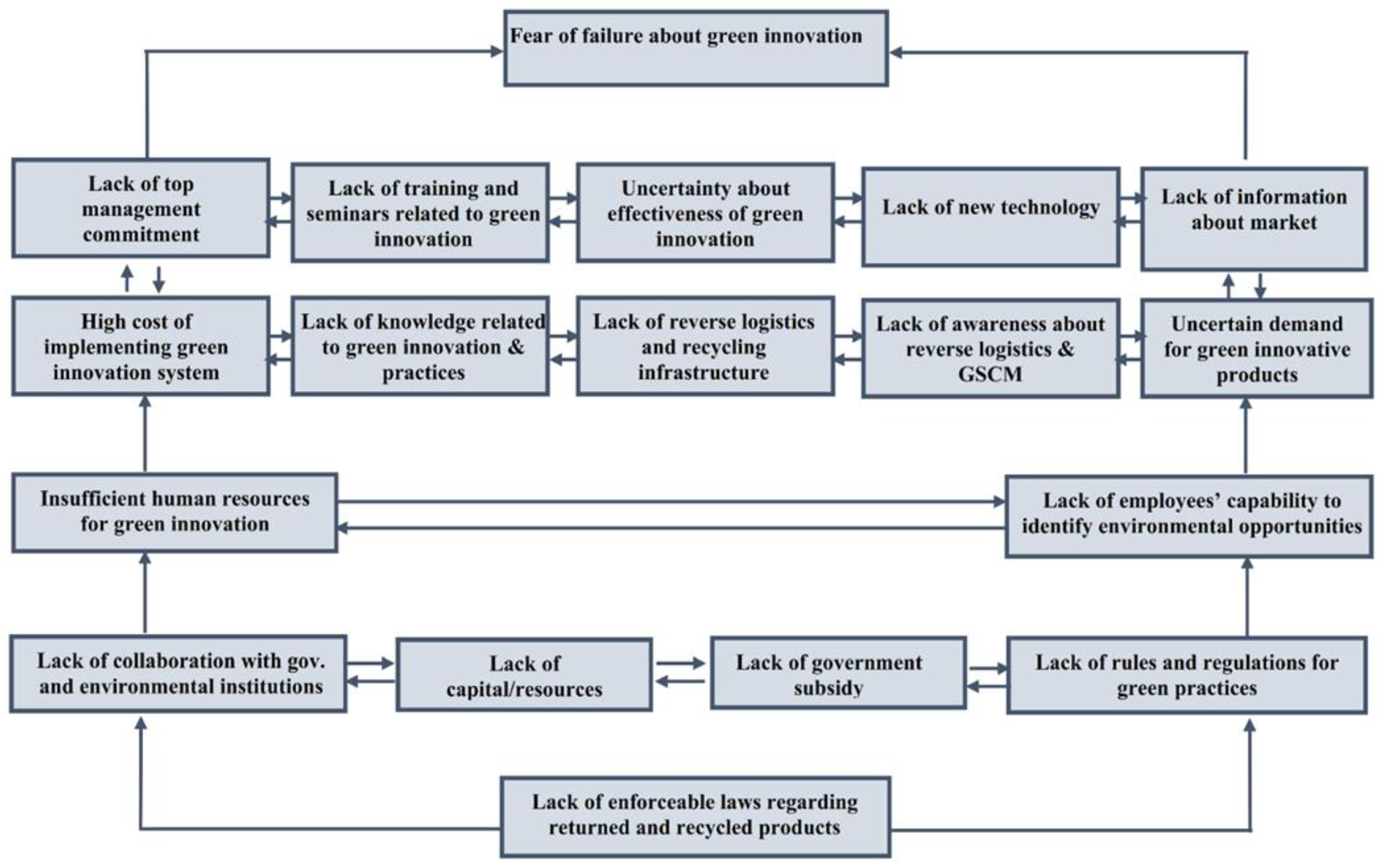

- Cell 1–2: The relationship between the Lack of top management commitment and lack of training and seminars related to green innovation. All the participants stated that: “due to lack of top management support firms cannot organize training and seminars related to green innovation. Top management plays key role in environmental training held in organizations”.

- Cell 1–3: The relationship between the lack of top management commitment and insufficient human resources for green innovation. The participants stated that non-seriousness of environmental leadership leads to lack of human personnel to adopt green practices. Top management plays key role for developing strategies and policies, hiring and training of related personnel. Similarly, same way the remaining barriers relationships are constructed using the symbols.

3.3.1. SSIM Construction

- V

- Barrier i will help to influence barrier j,

- A

- Barrier j will help to influence barriers i,

- X

- Barriers i and j influence each and others,

- O

- Barriers i and j are not related.

3.3.2. Reachability Matrix Formation (IRM)

- (1)

- For each cell (i,j) containing “V” we insert 1 and 0 for (j,i) cell.

- (2)

- For each cell (i,j) containing “A” we insert 0 and 1 for (j,i) cell.

- (3)

- For both cells (i,j) and (j,i) containing “X” we insert 1.

- (4)

- For both cells (i,j) and (j,i) containing “O” we insert 0.

3.3.3. Final Reachability Matrix

3.3.4. Level Partitions and ISM Model Formulation

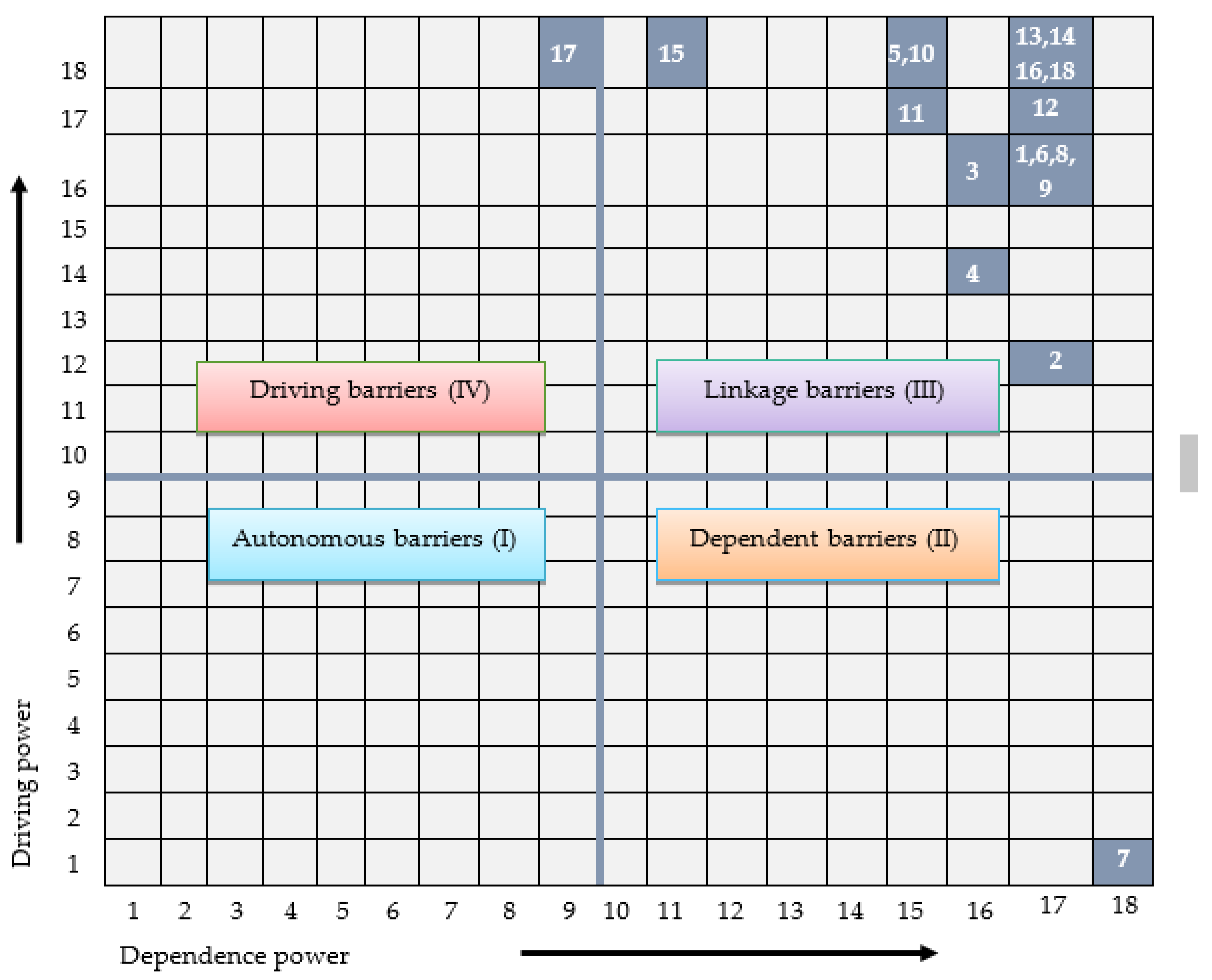

3.4. MICMAC Analysis

4. Results and Discussion

5. Policy Implications to Overcome Green Innovations Barriers

5.1. The Solution to the First Level Barrier

5.2. The Solution to Second Level Barriers

5.3. The Solution to Third Level Barriers

5.4. The Solution to Fourth Level Barriers

5.5. The Solution to Fifth Level Barriers

5.6. Comparison with Other Countries

6. Conclusions, Managerial Implications, and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Serial | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 1 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 18 | |

| 2 | 1, 2, 4, 6, 7, 8, 9, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 4, 6, 8, 9, 12, 13, 14, 16, 18 | |

| 3 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 11, 12, 13, 14, 15, 16, 18 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 11, 12, 13, 14, 15, 16, 18 | |

| 4 | 1, 2, 3, 4, 6, 7, 8, 9, 10, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 6, 8, 9, 10, 12, 13, 14, 16, 18 | |

| 5 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 6 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 18 | |

| 7 | 7 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 7 | 1st |

| 8 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | |

| 9 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | |

| 10 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 18 | 1, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 18 | |

| 12 | 1, 2, 3, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 14 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 3, 5, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 3, 5, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 16 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 17 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 5, 10, 12, 13, 14, 15, 16, 17, 18 | 5, 10, 12, 13, 14, 15, 16, 17, 18 | |

| 18 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 |

| Serial | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 1 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 2nd |

| 2 | 1, 2, 4, 6, 8, 9, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 4, 6, 8, 9, 12, 13, 14, 16, 18 | 2nd |

| 3 | 1, 2, 3, 4, 5, 6, 8, 9, 11, 12, 13, 14, 15, 16, 18 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 3, 4, 5, 6, 8, 9, 11, 12, 13, 14, 15, 16, 18 | |

| 4 | 1, 2, 3, 4, 6, 8, 9, 10, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 6, 8, 9, 10, 13, 14, 16, 18 | |

| 5 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 6 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 2nd |

| 8 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 2nd |

| 9 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 16, 18 | 2nd |

| 10 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 11 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 18 | 1, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 18 | |

| 12 | 1, 2, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 2nd |

| 13 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 2nd |

| 14 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 2nd |

| 15 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 3, 5, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 3, 5, 10, 11, 12, 13, 14, 15, 16, 17, 18 | |

| 16 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 2nd |

| 17 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 5, 10, 12, 13, 14, 15, 16, 17, 18 | 5, 10, 12, 13, 14, 15, 16, 17, 18 | |

| 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 | 2nd |

| Serial | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 3 | 3, 4, 5, 11, 15 | 3, 4, 5, 10, 11, 15, 17 | 3, 4, 5, 11, 15 | 3rd |

| 4 | 3, 4, 10 | 3, 4, 5, 10, 11, 15, 17 | 3, 4, 10 | 3rd |

| 5 | 3, 4, 5, 10, 11, 15, 17 | 3, 5, 10, 11, 15, 17 | 3, 5, 10, 11, 15, 17 | |

| 10 | 3, 4, 5, 10, 11, 15, 17 | 4, 5, 10, 11, 15, 17 | 4, 5, 10, 11, 15, 17 | |

| 11 | 3, 4, 5, 10, 11, 15 | 3, 5, 10, 11, 15, 17 | 3, 5, 10, 11, 15 | |

| 15 | 3, 4, 5, 10, 11, 15, 17 | 3, 5, 10, 11, 15, 17 | 3, 5, 10, 11, 15, 17 | |

| 17 | 3, 4, 5, 10, 11, 15, 17 | 5, 10, 15, 17 | 5, 10, 15, 17 |

| Serial | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 5 | 5, 10, 11, 15, 17 | 5, 10, 11, 15, 17 | 5, 10, 11, 15, 17 | 4th |

| 10 | 5, 10, 11, 15, 17 | 5, 10, 11, 15, 17 | 5, 10, 11, 15, 17 | 4th |

| 11 | 5, 10, 11, 15 | 5, 10, 11, 15, 17 | 5, 10, 11, 15 | 4th |

| 15 | 5, 10, 11, 15, 17 | 5, 10, 11, 15, 17 | 5, 10, 11, 15, 17 | 4th |

| 17 | 5, 10, 11, 15, 17 | 5, 10, 15, 17 | 5, 10, 15, 17 |

| Serial | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 17 | 17 | 17 | 17 | 5th |

References

- Du, L.; Zhang, Z.; Feng, T. Linking green customer and supplier integration with green innovation performance: The role of internal integration. Bus. Strateg. Environ. 2018, 27, 1583–1595. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; Noorul Haq, A. Pressure analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Res. 2014, 52, 188–202. [Google Scholar] [CrossRef] [Green Version]

- Pons, M.; Bikfalvi, A.; Llach, J.; Palcic, I. Exploring the impact of energy efficiency technologies on manufacturing firm performance. J. Clean. Prod. 2013, 52, 134–144. [Google Scholar] [CrossRef]

- Wakeford, J.J.; Gebreeyesus, M.; Ginbo, T.; Yimer, K.; Manzambi, O.; Okereke, C.; Black, M.; Mulugetta, Y. Innovation for green industrialisation: An empirical assessment of innovation in Ethiopia’s cement, leather and textile sectors. J. Clean. Prod. 2017, 166, 503–511. [Google Scholar] [CrossRef]

- De Vries, G.; Terwel, B.W.; Ellemers, N.; Daamen, D.D. Sustainability or profitability? How communicated motives for environmental policy affect public perceptions of corporate greenwashing. Corp. Soc. Resp. Environ. Manag. 2015, 22, 142–154. [Google Scholar] [CrossRef] [Green Version]

- Cai, W.-g.; Zhou, X.-l. On the drivers of eco-innovation: Empirical evidence from China. J. Clean. Prod. 2014, 79, 239–248. [Google Scholar] [CrossRef]

- Kemp, R. Eco-Innovation: Definition, measurement and open research issues. Econ. Politica 2010, 27, 397–420. [Google Scholar]

- Owusu, P.A.; Asumadu-Sarkodie, S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent. Eng. 2016, 3, 1167990. [Google Scholar] [CrossRef]

- Wettestad, J.; Jevnaker, T. Rescuing EU Emissions Trading: The Climate Policy Flagship; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Puppim de Oliveira, J.A.; Jabbour, C.J.C. Environmental management, climate change, CSR, and governance in clusters of small firms in developing countries: Toward an integrated analytical framework. Bus. Soc. 2017, 56, 130–151. [Google Scholar] [CrossRef]

- Cai, W.; Li, G. The drivers of eco-innovation and its impact on performance: Evidence from China. J. Clean. Prod. 2018, 176, 110–118. [Google Scholar] [CrossRef]

- Chiou, T.-Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transport. Res. E Log. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pontrandolfo, P. Being ‘green and competitive’: The impact of environmental actions and collaborations on firm performance. Bus. Strateg. Environ. 2015, 24, 413–430. [Google Scholar] [CrossRef]

- Porter, M.E.; VanderLinde, C. Toward a New Conception of the Environment Competitiveness Relationship. J. Econ. Perspect 1995, 9, 97r118. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D. Mainstreaming green product innovation: Why and how companies integrate environmental sustainability. J. Bus. Ethics 2010, 95, 471–486. [Google Scholar] [CrossRef]

- Triguero, A.; Moreno-Mondéjar, L.; Davia, M.A. Drivers of different types of eco-innovation in European SMEs. Ecol. Econ. 2013, 92, 25–33. [Google Scholar] [CrossRef]

- Abdullah, M.; Zailani, S.; Iranmanesh, M.; Jayaraman, K. Barriers to green innovation initiatives among manufacturers: The Malaysian case. Rev. Manag. Sci. 2016, 10, 683–709. [Google Scholar] [CrossRef]

- Woolthuis, R.K.; Lankhuizen, M.; Gilsing, V. A system failure framework for innovation policy design. Technovation 2005, 25, 609–619. [Google Scholar] [CrossRef]

- Chaminade, C.; Edquist, C. From theory to practice: The use of the systems of innovation approach in innovation policy. In Innovation, Science, and Institutional Change: A Research Handbook; Oxford University Press: Oxford, UK, 2006; pp. 141–163. [Google Scholar]

- D’Este, P.; Iammarino, S.; Savona, M.; von Tunzelmann, N. What Hampers Innovation? Evidence from the UK CIS4; University of Sussex: Brighton, UK, 2008; p. 168. [Google Scholar]

- Hens, L.; Cabello-Eras, J.J.; Sagastume-Gutiérez, A.; Garcia-Lorenzo, D.; Cogollos-Martinez, J.B.; Vandecasteele, C. University–industry interaction on cleaner production. The case of the Cleaner Production Center at the University of Cienfuegos in Cuba, a country in transition. J. Clean. Prod. 2017, 142, 63–68. [Google Scholar] [CrossRef]

- Luken, R. Industrial Policy and The Environment in Pakistan; UNIDO; NC/PAK/97/018, Vienna; UNEP (United Nations Environment Programme); UNDO Publications: Vienna, Austria, 2000. [Google Scholar]

- Ghisetti, C.; Mancinelli, S.; Mazzanti, M.; Zoli, M. Financial barriers and environmental innovations: Evidence from EU manufacturing firms. Clim. Policy 2017, 17, S131–S147. [Google Scholar] [CrossRef]

- Marin, G.; Marzucchi, A.; Zoboli, R. SMEs and barriers to Eco-innovation in the EU: Exploring different firm profiles. J. Evol. Econ. 2015, 25, 671–705. [Google Scholar] [CrossRef]

- Cecere, G.; Corrocher, N.; Mancusi, M.L. Financial constraints and public funding of eco-innovation: Empirical evidence from European SMEs. Small Bus. Econ. 2018, 54, 285–302. [Google Scholar] [CrossRef] [Green Version]

- Walker, H.; Di Sisto, L.; McBain, D. Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. J. Purch. Supply Manag. 2008, 14, 69–85. [Google Scholar] [CrossRef]

- Anser, M.K.; Zhang, Z.; Kanwal, L. Moderating effect of innovation on corporate social responsibility and firm performance in realm of sustainable development. Corp. Soc. Resp. Environ. Manag. 2018, 25, 799–806. [Google Scholar] [CrossRef]

- Panwar, R.; Nybakk, E.; Hansen, E.; Pinkse, J. The effect of small firms’ competitive strategies on their community and environmental engagement. J. Clean. Prod. 2016, 129, 578–585. [Google Scholar] [CrossRef]

- Li, D.; Zheng, M.; Cao, C.; Chen, X.; Ren, S.; Huang, M. The impact of legitimacy pressure and corporate profitability on green innovation: Evidence from China top 100. J. Clean. Prod. 2017, 141, 41–49. [Google Scholar] [CrossRef] [Green Version]

- Alam, M.M.; Murad, M.W.; Noman, A.H.M.; Ozturk, I. Relationships among carbon emissions, economic growth, energy consumption and population growth: Testing Environmental Kuznets Curve hypothesis for Brazil, China, India and Indonesia. Ecol. Indic. 2016, 70, 466–479. [Google Scholar] [CrossRef]

- Eckersley, R. Green Theory in International Relations Theories: Discipline and Diversity; Oxford University Press: New York, NY, USA, 2010; Volume 10, pp. 70200–70202. [Google Scholar]

- Abbas, J. Impact of total quality management on corporate green performance through the mediating role of corporate social responsibility. J. Clean. Prod. 2020, 242, 118458. [Google Scholar] [CrossRef]

- Ji, Q.; Zhang, D. How much does financial development contribute to renewable energy growth and upgrading of energy structure in China? Energy Policy 2019, 128, 114–124. [Google Scholar] [CrossRef]

- Raimi, L. Understanding theories of corporate social responsibility in the Ibero-American hospitality industry. Dev. Corp. Gov. Responsib. 2017, 11, 65–88. [Google Scholar]

- Galdeano-Gómez, E.; Aznar-Sánchez, J.A.; Pérez-Mesa, J.C. Sustainability dimensions related to agricultural-based development: The experience of 50 years of intensive farming in Almería (Spain). Int. J. Agric. Sustain. 2013, 11, 125–143. [Google Scholar] [CrossRef]

- Liao, W.; Wang, T. Promoting green and sustainability: A multi-objective optimization method for the job-shop scheduling problem. Sustainability 2018, 10, 4205. [Google Scholar] [CrossRef] [Green Version]

- Sanni, M. Drivers of eco-innovation in the manufacturing sector of Nigeria. Technol. Forecast. Soc. Chang. 2018, 131, 303–314. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. A framework to overcome barriers to green innovation in SMEs using BWM and Fuzzy TOPSIS. Sci. Total Environ. 2018, 633, 122–139. [Google Scholar] [CrossRef] [PubMed]

- Xia, D.; Zhang, M.; Yu, Q.; Tu, Y. Developing a framework to identify barriers of green technology adoption for enterprises. Resour. Conserv. Recycl. 2019, 143, 99–110. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Lai, S.-B.; Wen, C.-T. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Chen, Y.-S. The driver of green innovation and green image–green core competence. J. Bus. Ethics 2008, 81, 531–543. [Google Scholar] [CrossRef]

- Schiederig, T.; Tietze, F.; Herstatt, C. Green innovation in technology and innovation management—An exploratory literature review. RD Manag. 2012, 42, 180–192. [Google Scholar] [CrossRef]

- Huang, X.-X.; Hu, Z.-P.; Liu, C.-S.; Yu, D.-J.; Yu, L.-F. The relationships between regulatory and customer pressure, green organizational responses, and green innovation performance. J. Clean. Prod. 2016, 112, 3423–3433. [Google Scholar] [CrossRef]

- Eiadat, Y.; Kelly, A.; Roche, F.; Eyadat, H. Green and competitive? An empirical test of the mediating role of environmental innovation strategy. J. World Bus. 2008, 43, 131–145. [Google Scholar] [CrossRef]

- Zailani, S.; Iranmanesh, M.; Nikbin, D.; Jumadi, H.B. Determinants and environmental outcome of green technology innovation adoption in the transportation industry in Malaysia. Asian J. Technol. Innov. 2014, 22, 286–301. [Google Scholar] [CrossRef]

- Wong, S.K.S. Environmental requirements, knowledge sharing and green innovation: Empirical evidence from the electronics industry in China. Bus. Strateg. Environ. 2013, 22, 321–338. [Google Scholar] [CrossRef]

- Amara, N.; D’Este, P.; Landry, R.; Doloreux, D. Impacts of obstacles on innovation patterns in KIBS firms. J. Bus. Res. 2016, 69, 4065–4073. [Google Scholar] [CrossRef]

- Fu, X.; Guo, M.; Zhanwen, N. Applying the green Embedded lean production model in developing countries: A case study of china. Environ. Dev. 2017, 24, 22–35. [Google Scholar] [CrossRef]

- Van den Berg, A.; Masi, A.C.; Smucker, J.; Smith, M.R. Manufacturing change: A two-country, three-industry comparison. Acta Sociol. 2000, 43, 139–156. [Google Scholar] [CrossRef]

- Jun, M.; Cai, S.; Peterson, R. Obstacles to TQM implementation in Mexico’s maquiladora industry. Total Qual. Manag. Bus. 2004, 15, 59–72. [Google Scholar] [CrossRef]

- Hueske, A.-K.; Guenther, E. What hampers innovation? External stakeholders, the organization, groups and individuals: A systematic review of empirical barrier research. Manag. Rev. Q. 2015, 65, 113–148. [Google Scholar] [CrossRef]

- Oke, A. Barriers to innovation management in service companies. J. Chang. Manag. 2004, 4, 31–44. [Google Scholar] [CrossRef]

- Giunipero, L.C.; Hooker, R.E.; Denslow, D. Purchasing and supply management sustainability: Drivers and barriers. J. Purch. Supply Manag. 2012, 18, 258–269. [Google Scholar] [CrossRef]

- Tumpa, T.J.; Ali, S.M.; Rahman, M.H.; Paul, S.K.; Chowdhury, P.; Khan, S.A.R. Barriers to green supply chain management: An emerging economy context. J. Clean. Prod. 2019, 236, 117617. [Google Scholar] [CrossRef]

- Jayant, A.; Azhar, M. Analysis of the barriers for implementing green supply chain management (GSCM) practices: An interpretive structural modeling (ISM) approach. Procedia Eng. 2014, 97, 2157–2166. [Google Scholar] [CrossRef] [Green Version]

- Runhaar, H.; Tigchelaar, C.; Vermeulen, W.J. Environmental leaders: Making a difference. A typology of environmental leaders and recommendations for a differentiated policy approach. Bus. Strateg. Environ. 2008, 17, 160–178. [Google Scholar] [CrossRef] [Green Version]

- Gupta, H.; Barua, M.K. Evaluation of Manufacturing Organizations Ability to Overcome Internal Barriers to Green Innovations. In Strategic Decision Making for Sustainable Management of Industrial Networks; Springer: Berlin/Heidelberg, Germany, 2021; pp. 139–160. [Google Scholar]

- Musaad, O.; Sultan, A.; Zhuo, Z.; Musaad, O.; Otaibi, A.; Siyal, Z.A.; Hashmi, H.; Shah, S.A.A. A Fuzzy Multi-Criteria Analysis of Barriers and Policy Strategies for Small and Medium Enterprises to Adopt Green Innovation. Symmetry 2020, 12, 116. [Google Scholar] [CrossRef] [Green Version]

- Piyathanavong, V.; Garza-Reyes, J.A.; Kumar, V.; Maldonado-Guzmán, G.; Mangla, S.K. The adoption of operational environmental sustainability approaches in the Thai manufacturing sector. J. Clean. Prod. 2019, 220, 507–528. [Google Scholar] [CrossRef]

- da Silva, F.J.G.; Gouveia, R.M. Drivers and Barriers to Cleaner Production. In Cleaner Production; Springer: Cham, Switzerland, 2020; pp. 375–399. [Google Scholar]

- Zwick, T. Employee resistance against innovations. Int. J. Manpower 2002, 23, 542–552. [Google Scholar] [CrossRef]

- Ar, I.M. The impact of green product innovation on firm performance and competitive capability: The moderating role of managerial environmental concern. Procedia Soc. Behav. Sci. 2012, 62, 854–864. [Google Scholar] [CrossRef] [Green Version]

- Mangla, S.K.; Govindan, K.; Luthra, S. Prioritizing the barriers to achieve sustainable consumption and production trends in supply chains using fuzzy Analytical Hierarchy Process. J. Clean. Prod. 2017, 151, 509–525. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Zhang, Y.; Anees, M.; Golpîra, H.; Lahmar, A.; Qianli, D. Green supply chain management, economic growth and environment: A GMM based evidence. J. Clean. Prod. 2018, 185, 588–599. [Google Scholar] [CrossRef]

- Carter, C.R.; Dresner, M. Purchasing’s role in environmental management: Cross-functional development of grounded theory. J. Supply Chain Manag. 2001, 37, 12–27. [Google Scholar] [CrossRef]

- Ashford, N.A. Understanding Technological Responses of Industrial Firms to Environmental Problems: Implications for Government Policy (Chapter); Island Press: Washington, DC, USA, 1993. [Google Scholar]

- Collins, E.; Lawrence, S.; Pavlovich, K.; Ryan, C. Business networks and the uptake of sustainability practices: The case of New Zealand. J. Clean. Prod. 2007, 15, 729–740. [Google Scholar] [CrossRef]

- Hoffman, K.; Parejo, M.; Bessant, J.; Perren, L. Small firms, R&D, technology and innovation in the UK: A literature review. Technovation 1998, 18, 39–55. [Google Scholar]

- Van Hemel, C.; Cramer, J. Barriers and stimuli for ecodesign in SMEs. J. Clean. Prod. 2002, 10, 439–453. [Google Scholar] [CrossRef]

- Theyel, G. Management practices for environmental innovation and performance. Int. J. Oper. Prod. Manag. 2000, 20, 249–266. [Google Scholar] [CrossRef]

- Revell, A.; Rutherfoord, R. UK environmental policy and the small firm: Broadening the focus. Bus. Strategy Environ. 2003, 12, 26–35. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM approach for the barrier analysis in implementing green supply chain management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Wang, J. Discussion on the relationship between green technological innovation and system innovation. Energy Procedia 2011, 5, 2352–2357. [Google Scholar] [CrossRef] [Green Version]

- Pinget, A.; Bocquet, R.; Mothe, C. Barriers to environmental innovation in SMEs: Empirical evidence from French firms. M@n@gement 2015, 18, 132–155. [Google Scholar] [CrossRef] [Green Version]

- Balasubramanian, S. A hierarchiacal framework of barriers to green supply chain management in the construction sector. Eur. J. Sustain. Dev. 2012, 5. [Google Scholar] [CrossRef]

- Madrid-Guijarro, A.; Garcia, D.; Van Auken, H. Barriers to innovation among Spanish manufacturing SMEs. J. Small Bus. Manag. 2009, 47, 465–488. [Google Scholar] [CrossRef]

- AlKhidir, T.; Zailani, S. Going green in supply chain towards environmental sustainability. Glob. J. Environ. Res. 2009, 3, 246–251. [Google Scholar]

- Hojnik, J.; Ruzzier, M. Drivers of and barriers to eco-innovation: A case study. Int. J. Sustain. Econ. 2016, 8, 273–294. [Google Scholar] [CrossRef]

- Mudgal, R.K.; Shankar, R.; Talib, P.; Raj, T. Modelling the barriers of green supply chain practices: An Indian perspective. Int. J. Logist. Syst. Manag. 2010, 7, 81–107. [Google Scholar] [CrossRef]

- Silva, M.J.; Leitao, J.; Raposo, M. Barriers to innovation faced by manufacturing firms in Portugal: How to overcome it for fostering business excellence? Int. J. Bus. Excell. 2008, 1, 92–105. [Google Scholar] [CrossRef] [Green Version]

- Del Río, P.; Carrillo-Hermosilla, J.; Könnölä, T. Policy strategies to promote eco-innovation: An integrated framework. J. Ind. Ecol. 2010, 14, 541–557. [Google Scholar] [CrossRef]

- Oelze, N. Sustainable supply chain management implementation–enablers and barriers in the textile industry. Sustainability 2017, 9, 1435. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Sarkis, J.; Lai, K.-h. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Govindan, K.; Bouzon, M. From a literature review to a multi-perspective framework for reverse logistics barriers and drivers. J. Clean. Prod. 2018, 187, 318–337. [Google Scholar] [CrossRef]

- Marsillac, E.L. Environmental impacts on reverse logistics and green supply chains: Similarities and integration. Int. J. Logist. Syst. Manag. 2008, 4, 411–422. [Google Scholar] [CrossRef]

- Jindal, A.; Sangwan, K.S. Development of an interpretive structural model of barriers to reverse logistics implementation in Indian industry. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Cham, Switzerland, 2011; pp. 448–453. [Google Scholar]

- Mathiyazhagan, K.; Haq, A.N. Analysis of the influential pressures for green supply chain management adoption—an Indian perspective using interpretive structural modeling. Int. J. Adv. Manuf Tech. 2013, 68, 817–833. [Google Scholar] [CrossRef]

- Waqas, M.; Dong, Q.-l.; Ahmad, N.; Zhu, Y.; Nadeem, M. Critical barriers to implementation of reverse logistics in the manufacturing industry: A case study of a developing country. Sustainability 2018, 10, 4202. [Google Scholar] [CrossRef] [Green Version]

- Abdulrahman, M.D.; Gunasekaran, A.; Subramanian, N. Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int. J. Prod. Econ. 2014, 147, 460–471. [Google Scholar] [CrossRef]

- Dhull, S.; Narwal, M. Drivers and barriers in green supply chain management adaptation: A state-of-art review. Uncertain Supply Chain Manag. 2016, 4, 61–76. [Google Scholar] [CrossRef]

- Ahmed, W.; Ashraf, M.S.; Khan, S.A.; Kusi-Sarpong, S.; Arhin, F.K.; Kusi-Sarpong, H.; Najmi, A. Analyzing the impact of environmental collaboration among supply chain stakeholders on a firm’s sustainable performance. Oper. Manag. Res. 2020, 13, 1–18. [Google Scholar] [CrossRef]

- Khwaja, M.A. Environmental Challenges and Constraints to Policy Issues for Sustainable Industrial Development in Pakistan; Environment, Trade and Governance for Sustainable Development; SDPI: Islamabad, Pakistan, 2012. [Google Scholar]

- Sanchez-Triana, E.; Biller, D.; Nabi, I.; Ortolano, L.; Dezfuli, G.; Afzal, J.; Enriquez, S. Revitalizing Industrial Growth in Pakistan: Trade, Infrastructure, and Environmental Performance; The World Bank: Washington, DC, USA, 2014. [Google Scholar]

- Eckstein, D.; Hutfils, M.-L.; Winges, M. Global Climate Risk Index 2019: Who Suffers Most from Extreme Weather Events? Weather-Related Loss Events in 2017 and 1998 to 2017; Germanwatch Nord-Süd Initiative Ev. 2018. Available online: https://www.germanwatch.org/sites/default/files/Global%20Climate%20Risk%20Index%202019_2.pdf (accessed on 7 November 2019).

- Zubair, M.; Farid, M.; Danish, M.; Zafar, M.N. Evaluation of Air Pollution Sources in Selected Zone of Textile Industries in Pakistan. Environ. Eng. Manag. J. 2017, 16. [Google Scholar] [CrossRef]

- Wang, H.; Khan, M.A.S.; Anwar, F.; Shahzad, F.; Adu, D.; Murad, M. Green Innovation Practices and Its Impacts on Environmental and Organizational Performance. Front. Psychol. 2021, 11, 3316. [Google Scholar] [CrossRef] [PubMed]

- Hazarika, N.; Zhang, X. Factors that drive and sustain eco-innovation in the construction industry: The case of Hong Kong. J. Clean. Prod. 2019, 238, 117816. [Google Scholar] [CrossRef]

- Platts, K.W.; Gregory, M.J. Manufacturing audit in the process of strategy formulation. Int. J. Oper. Prod. Manag. 1990, 10, 9. [Google Scholar] [CrossRef]

- Govindan, K.; Muduli, K.; Devika, K.; Barve, A. Investigation of the influential strength of factors on adoption of green supply chain management practices: An Indian mining scenario. Resour. Conserv. Recycl. 2016, 107, 185–194. [Google Scholar] [CrossRef]

- Dresch, A.; Lacerda, D.P.; Antunes, J.A.V. Design science research. In Design Science Research; Springer: Cham, Switzerland, 2015; pp. 67–102. [Google Scholar]

- Wurlod, J.-D.; Noailly, J. The impact of green innovation on energy intensity: An empirical analysis for 14 industrial sectors in OECD countries. Energy Econ. 2018, 71, 47–61. [Google Scholar] [CrossRef] [Green Version]

- Pagell, M.; Yang, C.L.; Krumwiede, D.W.; Sheu, C. Does the competitive environment influence the efficacy of investments in environmental management? J. Supply Chain Manag. 2004, 40, 30–39. [Google Scholar] [CrossRef]

- Talib, F.; Rahman, Z.; Qureshi, M. Analysis of interaction among the barriers to total quality management implementation using interpretive structural modeling approach. Benchmarking 2011, 18, 563–587. [Google Scholar] [CrossRef]

- Kannan, G.; Pokharel, S.; Kumar, P.S. A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Resour. Conserv. Recycl. 2009, 54, 28–36. [Google Scholar] [CrossRef]

- Kumar, D.; Rahman, Z. Buyer supplier relationship and supply chain sustainability: Empirical study of Indian automobile industry. J. Clean. Prod. 2016, 131, 836–848. [Google Scholar] [CrossRef]

- Shen, L.; Govindan, K.; Shankar, M. Evaluation of barriers of corporate social responsibility using an analytical hierarchy process under a fuzzy environment—A textile case. Sustainability 2015, 7, 3493–3514. [Google Scholar] [CrossRef] [Green Version]

- Caniato, F.; Caridi, M.; Crippa, L.; Moretto, A. Environmental sustainability in fashion supply chains: An exploratory case based research. Int. J. Prod. Econ. 2012, 135, 659–670. [Google Scholar] [CrossRef]

- Azeem, S.; Naeem, M.A.; Waheed, A.; Thaheem, M.J. Examining barriers and measures to promote the adoption of green building practices in Pakistan. Smart Sustain. Built Environ. 2017, 6, 86–100. [Google Scholar] [CrossRef]

- Freel, M.S. Barriers to product innovation in small manufacturing firms. Int. Small Bus. J. 2000, 18, 60–80. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K.; Pandya, K.V. Barriers analysis for reverse logistics implementation in Indian electronics industry using fuzzy analytic hierarchy process. Proc. Soc. Behav. Sci. 2015, 189, 91–102. [Google Scholar] [CrossRef] [Green Version]

- Galia, F.; Legros, D. Complementarities between obstacles to innovation: Evidence from France. Res. Policy 2004, 33, 1185–1199. [Google Scholar] [CrossRef]

- Baldwin, J.; Lin, Z. Impediments to advanced technology adoption for Canadian manufacturers. Res. Policy 2002, 31, 1–18. [Google Scholar] [CrossRef]

- Pun, K.F. Determinants of environmentally responsible operations: A review. Int. J. Qual. Reliab. 2006, 23, 279–297. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, V.; Kumar, S.; Haleem, A. Barriers to implement green supply chain management in automobile industry using interpretive structural modeling technique—An Indian perspective. J. Ind. Eng. Manag. 2011, 4, 231–257. [Google Scholar] [CrossRef] [Green Version]

- Dashore, K.; Sohani, N. Green supply chain management: A hierarchical framework for barriers. J. Sustain. Dev. 2008, 5, 2011. [Google Scholar]

- Mani, V.; Gunasekaran, A.; Delgado, C. Enhancing supply chain performance through supplier social sustainability: An emerging economy perspective. Int. J. Prod. Econ. 2018, 195, 259–272. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Rahman, T.; Rahman, M.H.; Ali, S.M.; Paul, S.K. Drivers to sustainable manufacturing practices and circular economy: A perspective of leather industries in Bangladesh. J. Clean. Prod. 2018, 174, 1366–1380. [Google Scholar] [CrossRef]

- Lorek, S.; Fuchs, D. Strong sustainable consumption governance–precondition for a degrowth path? J. Clean. Prod. 2013, 38, 36–43. [Google Scholar] [CrossRef] [Green Version]

- Ortolano, L.; Sanchez-Triana, E.; Afzal, J.; Ali, C.L.; Rebellón, S.A. Cleaner production in Pakistan’s leather and textile sectors. J. Clean. Prod. 2014, 68, 121–129. [Google Scholar] [CrossRef] [Green Version]

- Campiglio, E. Beyond carbon pricing: The role of banking and monetary policy in financing the transition to a low-carbon economy. Ecol. Econ. 2016, 121, 220–230. [Google Scholar] [CrossRef] [Green Version]

- Veugelers, R. Which policy instruments to induce clean innovating? Res. Policy 2012, 41, 1770–1778. [Google Scholar] [CrossRef]

- Arent, D.J.; Wise, A.; Gelman, R. The status and prospects of renewable energy for combating global warming. Energy Econ. 2011, 33, 584–593. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J.; Dou, Y. Corporate sustainability development in China: Review and analysis. Ind. Manag. Data Syst. 2015, 5, 115–140. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. A grey DEMATEL-based approach for modeling enablers of green innovation in manufacturing organizations. Environ. Sci. Pollut. R 2018, 25, 9556–9578. [Google Scholar] [CrossRef] [PubMed]

- Messeni Petruzzelli, A.; Maria Dangelico, R.; Rotolo, D.; Albino, V. Organizational factors and technological features in the development of green innovations: Evidence from patent analysis. Innovation 2011, 13, 291–310. [Google Scholar] [CrossRef]

- Polzin, F.; von Flotow, P.; Klerkx, L. Addressing barriers to eco-innovation: Exploring the finance mobilisation functions of institutional innovation intermediaries. Technol. Forecast. Soc. 2016, 103, 34–46. [Google Scholar] [CrossRef]

- Waqas, M.; Qianli, D.; Ahmad, N.; Zhu, Y.; Nadeem, M. Modeling reverse logistics barriers in manufacturing industry of Pakistan: An ISM and MICMAC approach. J. Adv. Manuf. Syst. 2020, 19, 309–341. [Google Scholar] [CrossRef]

| S# | Impediment to Green Innovation | Descriptions | Sources |

|---|---|---|---|

| 1 | Lack of top management commitment | Lack of top management in green practices is considered a major impediment but the success of sustainable practices depends on top management commitment. | [38,61,62,63,64] |

| 2 | Lack of training and seminars related to green innovation | Lack of training and programs may slow the pace of green innovation as technical competencies play a vital role. | [58,63,65,66] |

| 3 | Insufficient human resources for green practices | Insufficient work force is a big challenge in the success of green practices. | [67,68] |

| 4 | Lack of employees’ capability to identify environmental opportunities | Untrained employees are unable to find the environmental opportunities. | [69,70] |

| 5 | Lack of collaboration with government and environmental institutions | Weak partnership between firm and government hinders the effective green process however, their collaboration is essential for green innovation adoption. | [17,38] |

| 6 | Uncertainty about the effectiveness of green innovation | Green innovation is risky in terms of uncertain returns perspectives. | [69,71,72,73] |

| 7 | Fear of failure about green innovation | This factor is critical to adopt green innovation. | [74] |

| 8 | Lack of new technology | The degree of technological information for understanding green innovation is high level but firm’s embraces low information face sustainability constraints. | [63,75,76] |

| 9 | Lack of information about the market | Green innovations requisite certain information to adopt eco practices successfully in the market. | [17,24,77] |

| 10 | Lack of capital/resources | Poor financial resources preclude organizations from implementing environmental plans. | [23,78] |

| 11 | Lack of government subsidy | Government incentives and subsidies play a key role to motivate green manufacturing. | [25,79] |

| 12 | The high cost of implementing green innovation system | High costs associated with manufacturing green products make it difficult to adopt green practices. | [79,80] |

| 13 | Lack of knowledge related to green innovation and practices | Lack of knowledge blocks the innovation process. | [63,65,69,72,81] |

| 14 | Lack of reverse logistics and recycling infrastructure | Green innovation requires sophisticated technology to absorb, reuse/recycle wastes during manufacturing. | [82] |

| 15 | Lack of rules and regulations for green practices | Unclear rules and regulations do not bind firms to follow environmental regulations. | [56,83,84] |

| 16 | Lack of awareness about reverse logistics and green SCM | Within companies there’s less conscious of recycling and disposing of products that affect the sustainability process. | [55,85,86,87,88,89] |

| 17 | Lack of enforceable laws regarding returned and recycled products | Organizations are often demotivated due to poor enforcement of environmental laws and hence, few firms take advantage of it. | [84,89,90] |

| 18 | Uncertain demand for green innovative products | Green product demand is uncertain due to high cost and uncertain returns, so firms hesitate to produce green products. | [17,81,91], |

| 19 | Attitude and perception * | Some organizations wrong perceptions about green innovation that it cannot help to improve their business. | [17] |

| 20 | Business practices * barriers | Business practices such as lean, sig sigma, and ISO and innovative technologies help organizations to be competitive and failing to adopt new initiatives restricts the business. | [17] |

| S.No | Position | Gender | Age | Years of Experience | Education Level |

|---|---|---|---|---|---|

| 1 | Environmental expert | Male | 65 | 15 | Ph.D. |

| 2 | Manufacturing specialist | Male | 60 | 15 | Ph.D. |

| 3 | R&D manager | Female | 64 | 11 | Ph.D. |

| 4 | Quality manager | Male | 58 | 14 | Master |

| 5 | Project manager | Male | 54 | 12 | Master |

| 6 | Technological specialist | Female | 62 | 10 | Ph.D. |

| No. | Variables | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Lack of top management commitment | V | V | O | V | A | V | X | X | X | A | A | V | V | A | V | O | O | |

| 2 | Lack of training and seminars related to green innovation | A | V | O | V | V | X | V | A | O | A | V | O | O | V | A | O | ||

| 3 | Insufficient human resources for green innovation | V | V | O | V | O | V | A | A | A | V | V | O | V | O | O | |||

| 4 | Lack of employees’ capability to identify environmental opportunities | A | V | V | X | V | A | O | V | A | A | O | A | O | V | ||||

| 5 | Lack of collaboration with government and environmental institutions | V | V | V | V | A | V | V | V | V | V | V | O | O | |||||

| 6 | Uncertainty about effectiveness of green innovation | V | O | A | A | A | O | A | A | O | A | O | A | ||||||

| 7 | Fear of failure about green innovation | A | A | O | O | A | A | O | O | O | O | O | |||||||

| 8 | Lack of new technology | X | A | A | V | A | V | O | O | O | O | ||||||||

| 9 | Lack of information about market | A | A | V | X | O | O | V | O | O | |||||||||

| 10 | Lack of capital/resources | O | X | V | V | O | V | O | A | ||||||||||

| 11 | Lack of government subsidy | V | O | V | A | V | O | O | |||||||||||

| 12 | High cost of implementing green innovation system | X | A | O | A | O | O | ||||||||||||

| 13 | Lack of knowledge related to green innovation and practices | V | A | X | A | O | |||||||||||||

| 14 | Lack of reverse logistics and recycling infrastructure | A | A | A | O | ||||||||||||||

| 15 | Lack of rules and regulations for green practices | V | V | O | |||||||||||||||

| 16 | Lack of awareness about reverse logistics and green SCM | A | V | ||||||||||||||||

| 17 | Lack of enforceable laws regarding returned and recycled products | O | |||||||||||||||||

| 18 | Uncertain demand for green innovative products |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 |

| 2 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 |

| 3 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 |

| 4 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 |

| 5 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 |

| 6 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 8 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 |

| 9 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 |

| 10 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 |

| 11 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 |

| 12 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 |

| 13 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 |

| 14 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 1 |

| 15 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 |

| 16 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 |

| 17 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 0 |

| 18 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | Driving Power |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 * | 1 | 1 * | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 1 | 0 | 1 | 0 | 1 * | 16 |

| 2 | 1 * | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 * | 1 | 1 * | 0 | 1 | 0 | 1 | 12 |

| 3 | 1 * | 1 | 1 | 1 | 1 | 1 * | 1 | 1 * | 1 | 0 | 1 * | 1 * | 1 | 1 | 1 * | 1 | 0 | 1 * | 16 |

| 4 | 1 * | 1 * | 1 * | 1 | 0 | 1 | 1 | 1 | 1 | 1 * | 0 | 1 | 1 * | 1 * | 0 | 1 * | 0 | 1 | 14 |

| 5 | 1 * | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 18 |

| 6 | 1 | 1 * | 1 * | 1 * | 1 * | 1 | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 0 | 1 * | 0 | 1 * | 16 |

| 7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 8 | 1 | 1 | 1 * | 1 | 1 * | 1 * | 1 | 1 | 1 | 1 * | 1 * | 1 | 1 * | 1 | 0 | 1 * | 0 | 1 * | 16 |

| 9 | 1 | 1 * | 1 * | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 1 | 1 * | 0 | 1 | 0 | 1 * | 16 |

| 10 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * | 1 | 1 | 1 | 1 * | 1 | 1 | 1 | 1 * | 1 | 1 * | 1 * | 18 |

| 11 | 1 | 1 * | 1 | 1 * | 1 * | 1 | 1 * | 1 | 1 | 1 * | 1 | 1 | 1 * | 1 | 1 * | 1 | 0 | 1 * | 17 |

| 12 | 1 | 1 | 1 | 0 | 1 * | 1 * | 1 | 1 * | 1 * | 1 | 1 * | 1 | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 17 |

| 13 | 1 * | 1 * | 1 * | 1 | 1 * | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 1 | 1 | 1 * | 1 | 1 * | 1 * | 18 |

| 14 | 1 * | 1 * | 1 * | 1 | 1 * | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 1 * | 1 | 1 * | 1 * | 1 * | 1 | 18 |

| 15 | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 1 * | 1 | 1 | 1 | 1 | 1 | 1 * | 18 |

| 16 | 1 * | 1 * | 1 * | 1 | 1 * | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 18 |

| 17 | 1 * | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 1 | 1 * | 1 | 1 | 1 * | 18 |

| 18 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 1 * | 1 * | 1 * | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 18 |

| Dep. power | 17 | 17 | 16 | 16 | 15 | 17 | 18 | 17 | 17 | 15 | 15 | 17 | 17 | 17 | 11 | 17 | 9 | 17 | 285 |

| 1 | Fear of failure about green innovation (B7) | Fifth |

| 2 | Uncertain demand for green innovative products (B18) | Fourth |

| Lack of awareness about reverse logistics and green SCM (B16) | ||

| Lack of reverse logistics and recycling infrastructure (B14) | ||

| Lack of knowledge related to green innovation and practices (B15) | ||

| The high cost of implementing green innovation system (B12) | ||

| Lack of information about the market (B9) | ||

| Lack of new technology (B8) | ||

| Uncertainty about the effectiveness of green innovation (B6) | ||

| Lack of training seminars and connected to green innovation (B2) | ||

| Lack of top management commitment (B1) | ||

| 3 | Insufficient human resources for green practices (B3) Lack of employees’ capability to identify environmental opportunities (B4) | Third |

| 4 | Lack of rules and regulations for green practices (B15) | Second |

| Lack of government subsidy(B11) | ||

| Lack of capital/resources (B10) | ||

| Lack of knowledge related to green innovation and practices (B5) | ||

| 5 | Lack of enforceable laws regarding returned and recycled products (B17) | First |

| Ranking | Pakistan | India | Saudi Arabia | Hong Kong |

|---|---|---|---|---|

| 1 | Lack of enforceable laws regarding returned and recycled products | Lack of financial support | Implementation of environmental policies | Additional cost due to green innovation |

| 2 | Lack of rules and regulations for green practices | Lack of technological capability | Lack of commitment | Possible delays due to green requirement |

| 3 | Lack of collaboration with government and environmental institutions | Lack of required infrastructure | Unwillingness to switch to green practices | Limited availability and reliability of green suppliers |

| 4 | Lack of capital/resources | Lack of skilled human resources | Lack of government policies to upgrade green technology | Limited knowledge on green technology and materials |

| 5 | Lack of government subsidy | Insufficient knowledge | Lack of R&D capacity | Unachievable specification requirements |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, S.; Ahmad, N.; Khan, F.U.; Badulescu, A.; Badulescu, D. Mapping Interactions among Green Innovations Barriers in Manufacturing Industry Using Hybrid Methodology: Insights from a Developing Country. Int. J. Environ. Res. Public Health 2021, 18, 7885. https://doi.org/10.3390/ijerph18157885

Ullah S, Ahmad N, Khan FU, Badulescu A, Badulescu D. Mapping Interactions among Green Innovations Barriers in Manufacturing Industry Using Hybrid Methodology: Insights from a Developing Country. International Journal of Environmental Research and Public Health. 2021; 18(15):7885. https://doi.org/10.3390/ijerph18157885

Chicago/Turabian StyleUllah, Sajid, Naveed Ahmad, Farman Ullah Khan, Alina Badulescu, and Daniel Badulescu. 2021. "Mapping Interactions among Green Innovations Barriers in Manufacturing Industry Using Hybrid Methodology: Insights from a Developing Country" International Journal of Environmental Research and Public Health 18, no. 15: 7885. https://doi.org/10.3390/ijerph18157885

APA StyleUllah, S., Ahmad, N., Khan, F. U., Badulescu, A., & Badulescu, D. (2021). Mapping Interactions among Green Innovations Barriers in Manufacturing Industry Using Hybrid Methodology: Insights from a Developing Country. International Journal of Environmental Research and Public Health, 18(15), 7885. https://doi.org/10.3390/ijerph18157885