Removal of Transition Metals from Contaminated Aquifers by PRB Technology: Performance Comparison among Reactive Materials

Abstract

1. Introduction

2. Materials

2.1. Vegetable Fiber

2.2. Zeolite Samples

2.3. Calcareous Limestone

2.4. Zero Valent Iron (ZVI)

3. Methods

3.1. Porosity Determination

3.2. Grain Size Analysis

3.3. Hydraulic Characterization Tests

3.4. Batch Tests

Batch Adsorption Kinetics

3.5. Metal Ions Column Adsorption Tests

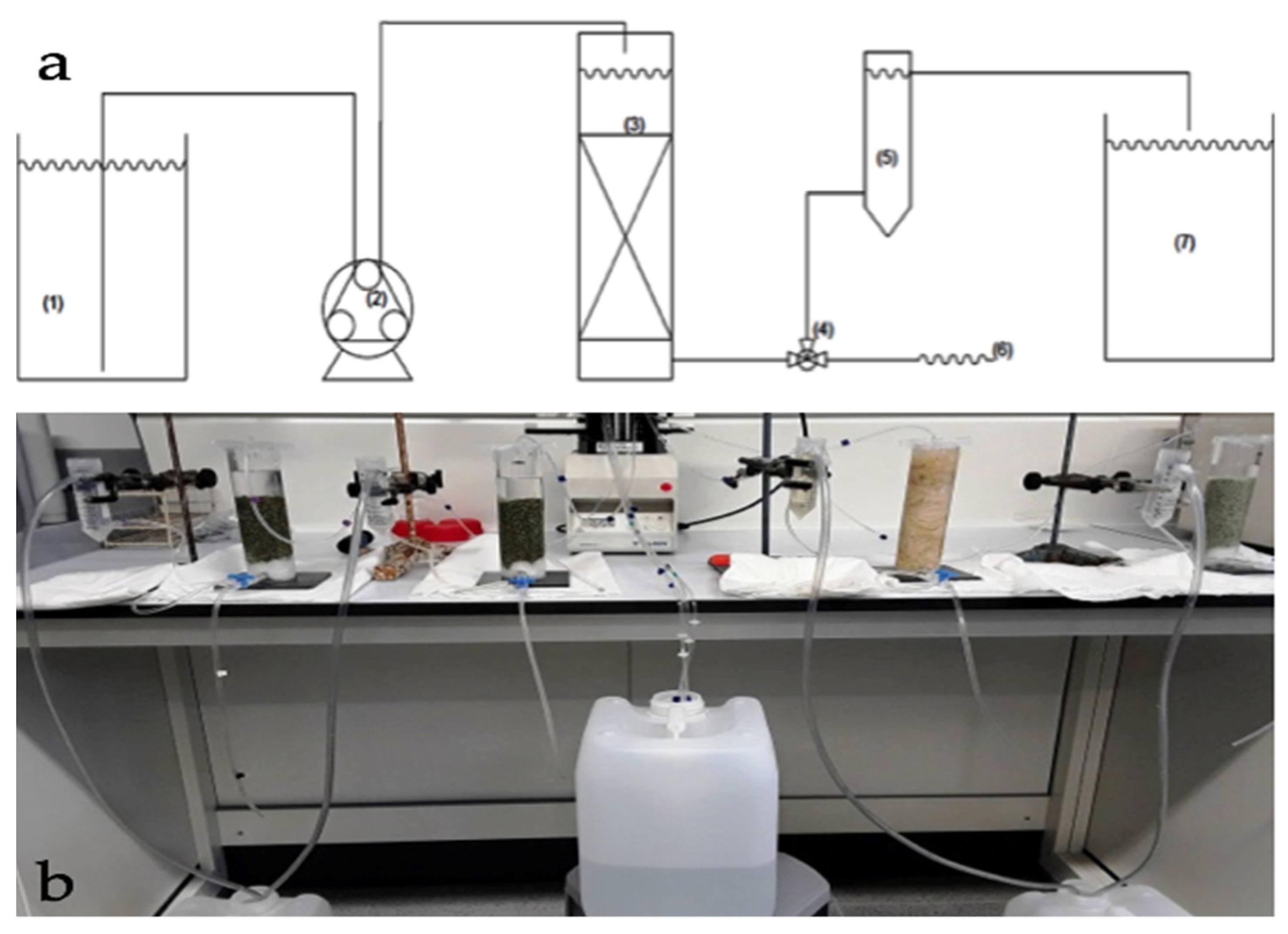

Experimental Device for Column Tests

3.6. Determination of the Permeable Reactive Barrier Thickness

3.7. Simulation of Mass Transport in Reactive Porous Media

4. Results and Discussion

4.1. Determination of Adsorption Isotherms

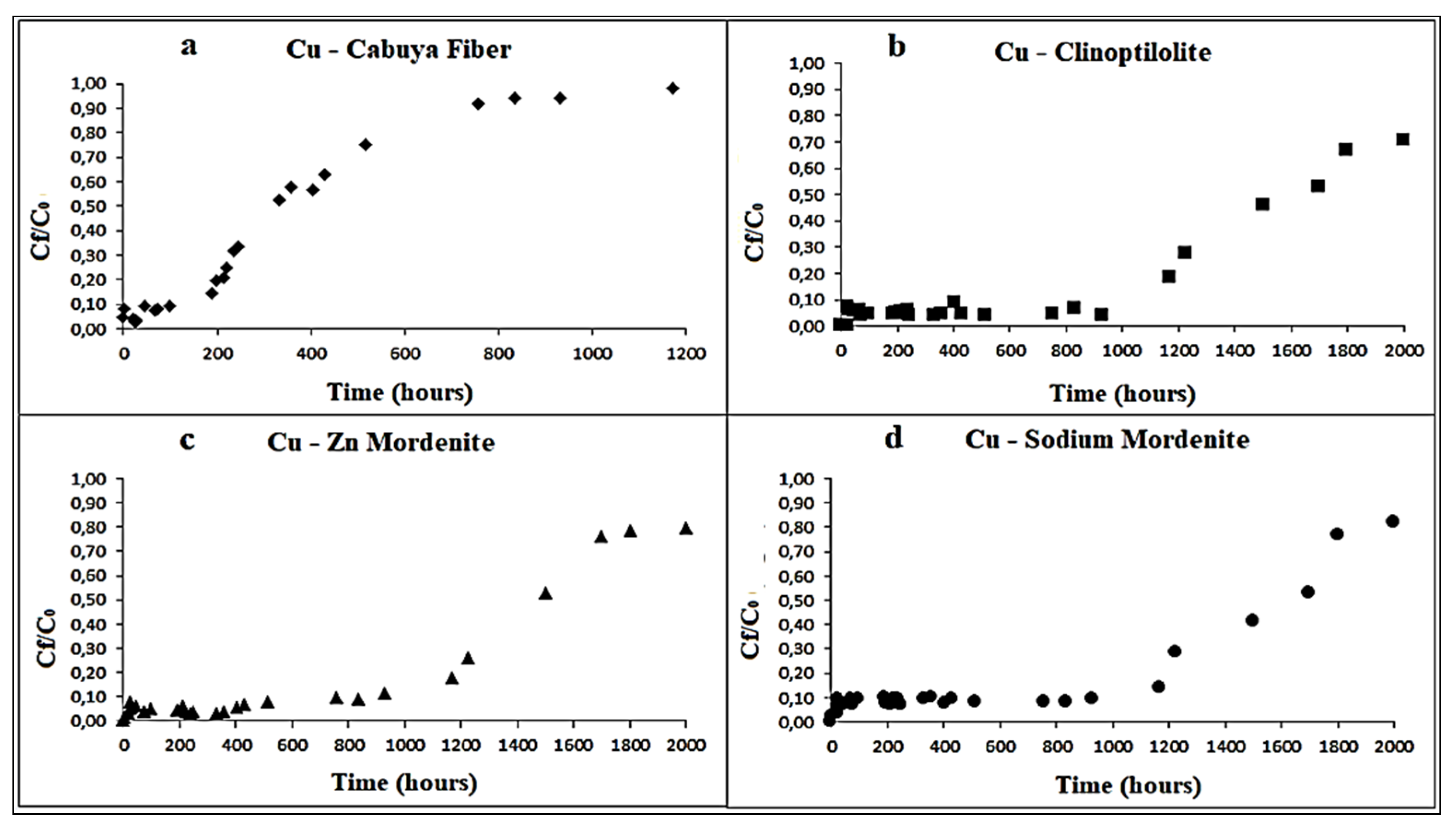

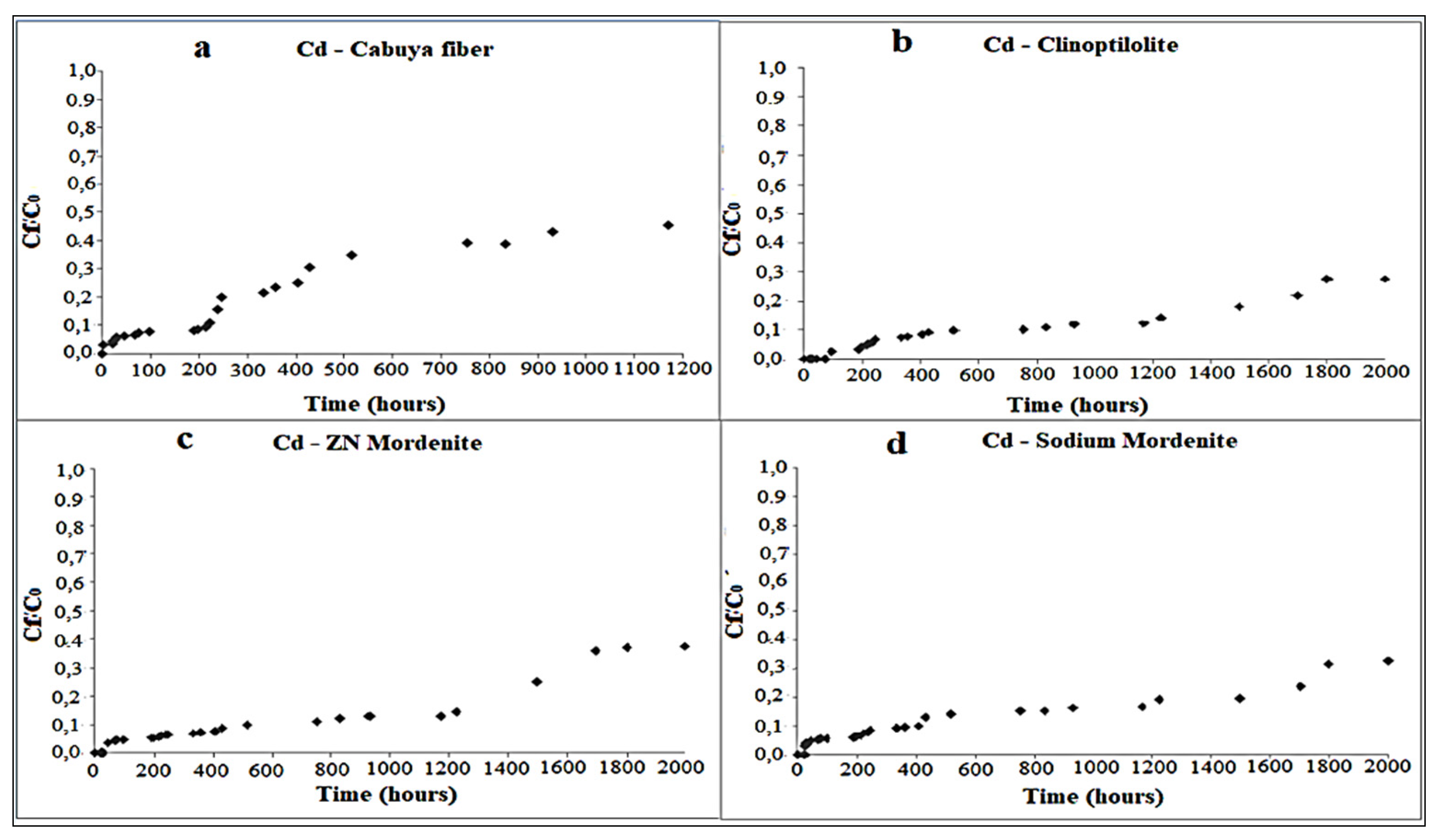

4.2. Metal Sorption Processes: Equilibrum and Kinetic Characterization with Columns Tests

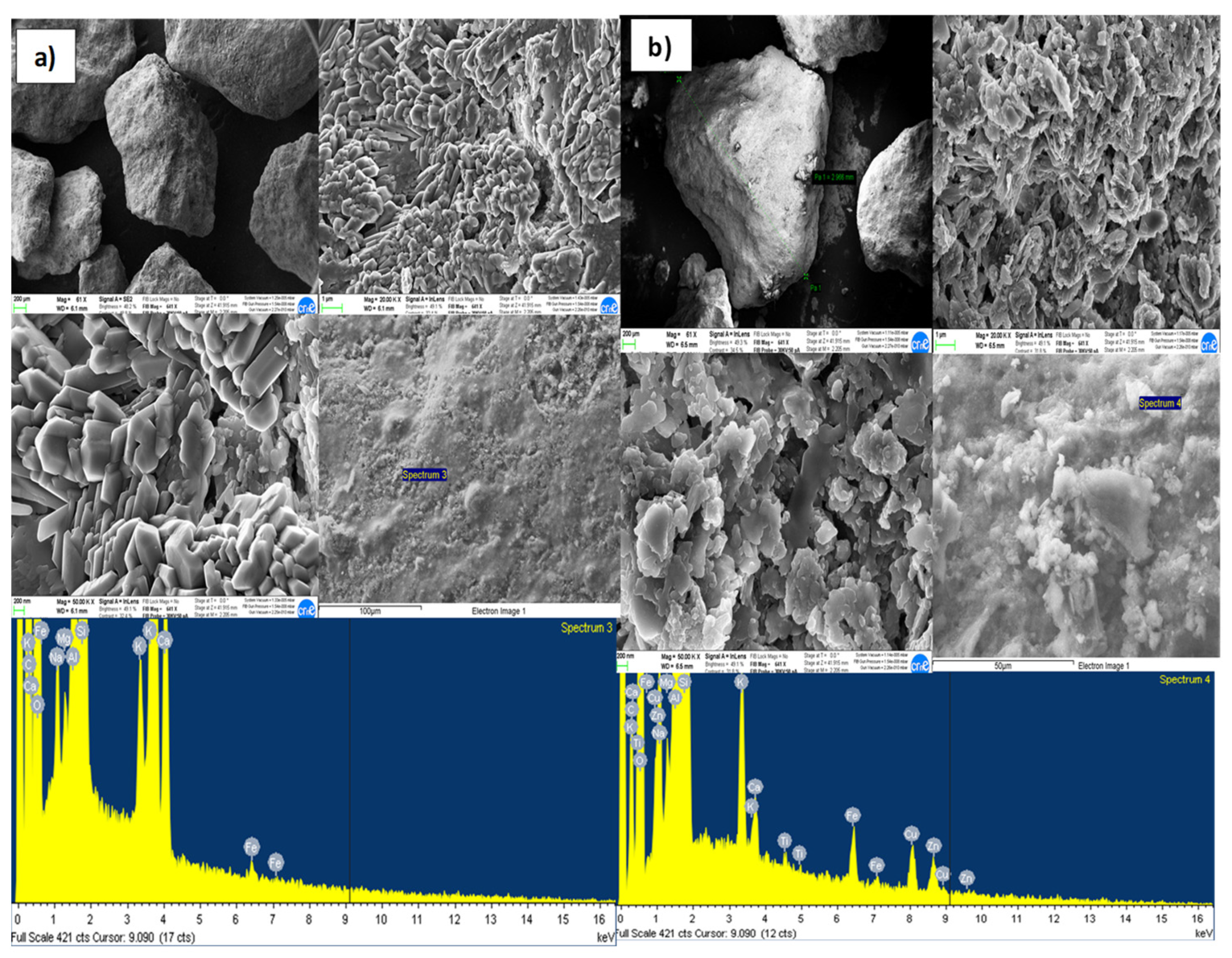

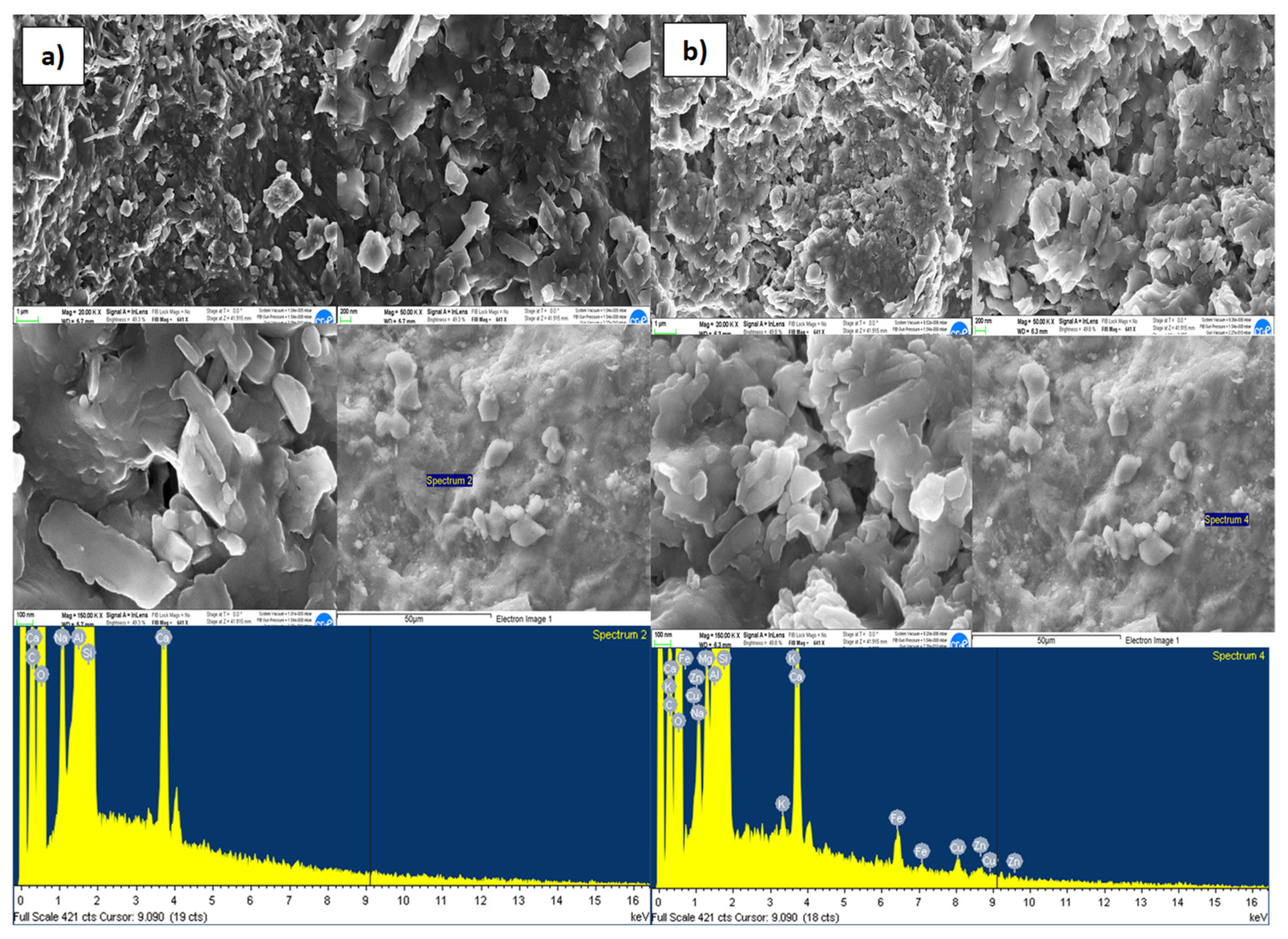

4.2.1. Characterization of the Metal Sorption Processes by FESEM and EDX Analysis

4.2.2. Estimation of PRB Thickness Using Tested Reactive Materials

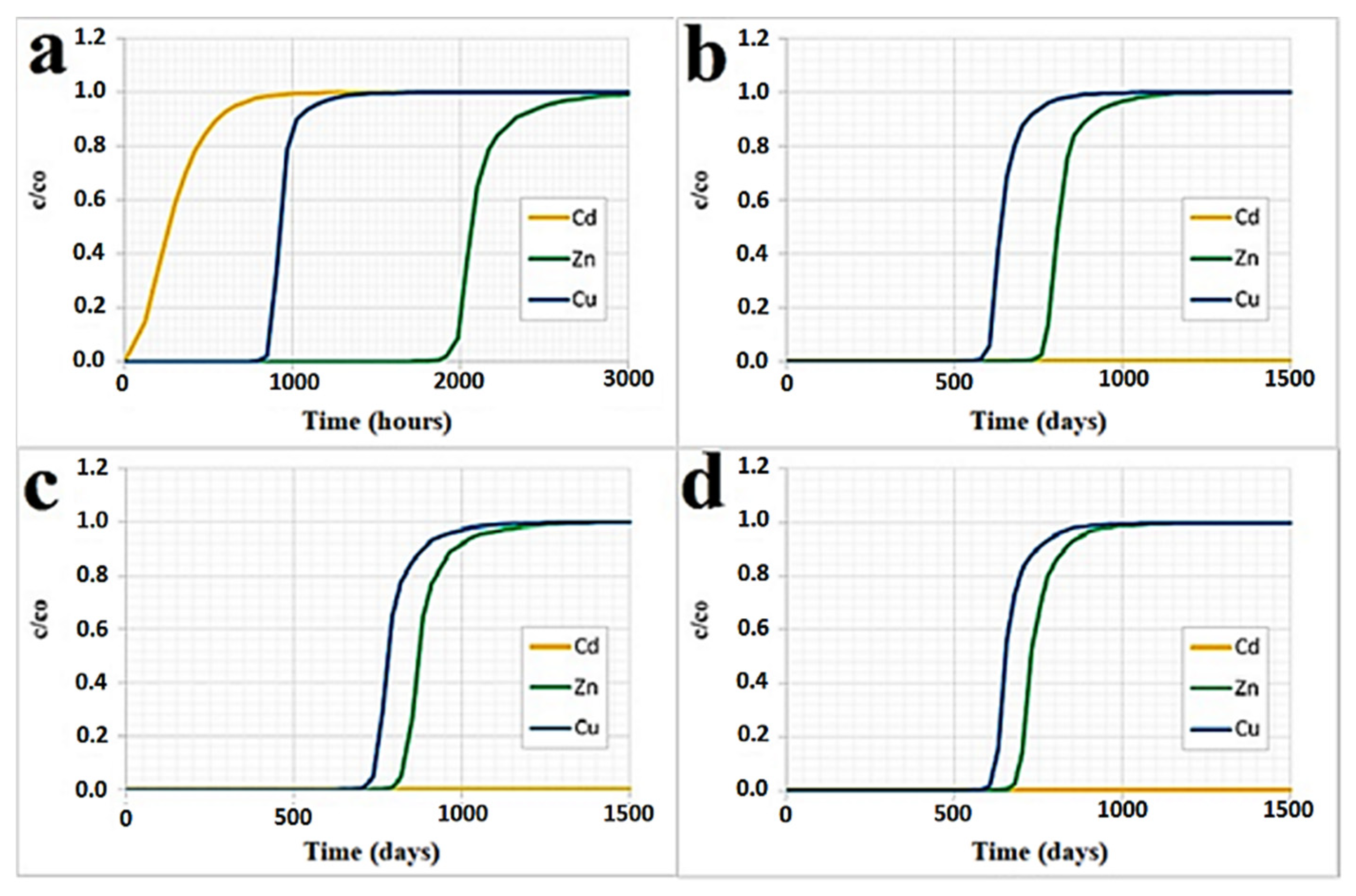

4.2.3. Simulation Results by RETRASO Code

5. Future Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UNESCO. Estrategia Regional para la Evaluación y Gestión de los Sistemas Acuíferos Transfronterizos en las Américas. In Phi-Lac; UNESCO: Paris, France, 2015. [Google Scholar]

- EPA. Permeable reactive barrier. Technologies for contaminant remediation. In Subsurface Protection and Remediation; Powell, R.M., Puls, R.W., Eds.; EPA: Washington, DC, USA, 1998. [Google Scholar]

- European Environment Agency (EEA). Groundwater Quality and Quantity in Europe; European Environment Agency (EEA): Copenhagen, Denmark, 1999. [Google Scholar]

- Stamatis, G.; Voudouris, K.; Karefilakis, F. Groundwater pollution by transition metals in historical mining area of Lavrio. Agwas 2001, 128, 61–83. [Google Scholar]

- National Research Council (NRC). Contaminants in the Subsurface: Source Zone Assessment and Remediation; The National Academies Press: Washington, DC, USA, 2005. [Google Scholar]

- Galitskayaa, I.V.; Rama Mohan, K.; Keshav Krishna, A.; Batraka, G.I.; Ereminaa, O.N.; Putilinaa, V.S.; Yuganova, T.I. Assessment of soil and groundwater contamination by transition metals and metalloids in Russian and Indian megacities. Procedia Earth Planet. Sci. 2017, 17, 674–677. [Google Scholar] [CrossRef]

- Thakur, A.; Vithanage, M.; Das, D.; Kumar, M. A review on design, material selection, mechanism, and modelling of permeable reactive barrier for community-scale groundwater treatmen. Environ. Technol. Innov. 2020, 19, 100917. [Google Scholar] [CrossRef]

- Gavaskar, A.; Gupta, N.; Sass, B.M.; Janosy, R.J.; O’Sullivan, D. Permeable Barriers for Groundwater Remediation: Design, Construction and Monitoring Battelle Press; OSTI.GOV: Washington, DC, USA, 1998.

- Di Molfetta, A.; Sethi, R. Metodologie di Bonifica di Siti Contaminate; Dipartimento Ambiente, Cambiamenti Globali e Sviluppo Sostenibile: Rome, Italy, 2001; Volume 1, pp. 16–24. [Google Scholar]

- Mulligan, C.N.; Yong, R.N.; Gibbs, B.F. Remediation technologies for metal-contaminated soils and groundwater: An evaluation. Eng. Geol. 2001, 60, 193–207. [Google Scholar] [CrossRef]

- Khan, F.I.; Husain, T.; Hejazi, R. An overview and analysis of site remediation technologies. J. Environ. Manag. 2004, 71, 95–122. [Google Scholar] [CrossRef] [PubMed]

- Hashim, M.A.; Soumyadeep, M.; Jaya, N. Remediation technologies for transition metal contaminated groundwater. J. Environ. Manag. 2011, 92, 2355–2388. [Google Scholar] [CrossRef]

- Vidic, R.D. Permeable Reactive Barriers: Case Study Review; Technology Evaluation Report TE01-01; GRTAC: Strasburg, France, 2001. [Google Scholar]

- Roehl, K.E.; Meggyes, T.; Simon, F.G.; Stewart, D.I. Long-Term Performance of Permeable Reactive Barriers; Gulf Publishing Company: Houston, TX, USA, 2005. [Google Scholar]

- Jun, D.; Yongsheng, Z.; Weihong, Z.; Mei, H. Laboratory study on sequenced permeable reactive barrier remediation for landfill leachate-contaminated groundwater. J. Hazard. Mater. 2009, 161, 224–230. [Google Scholar] [CrossRef]

- Obiri-Nyarko, F.; Grajales-Mesa, S.J.; Malina, G. An overview of permeable reactive barriers for in situ sustainable groundwater remediation. Chemosphere 2014, 111, 243–259. [Google Scholar] [CrossRef]

- Herbert, R.B.; Benner, S.G.; Blowes, D.W. Solid phase iron sulfur geochemistry of a reactive barrier for treatment of mine drainage. Appl. Geochem. 2000, 15, 1331–1343. [Google Scholar] [CrossRef]

- Di Molfetta, A.; Sethi, R. Criteri di Progettazione di Barriere Permeabili Reattive a Ferro Zero Valente; Dipartimento di Georisorse e Territorio, Politecnico di Torino: Turin, Italy, 2001. [Google Scholar]

- Korte, N.E. Zero-Valent Iron Permeable Reactive Barriers: A Review of Performance; IAEA: New York, NY, USA, 2001; p. 5056. [Google Scholar]

- USEPA. Long-Term Performance of Permeable Reactive Barriers Using Zero-Valent Iron: An Evaluation at Two Sites; Defense Technical Information Center: Fort Belvoir, VA, USA, 2002.

- Gavaskar, A.; Tatar, L.; Condit, W. Cost and Performance Report: Nanoscale Zero-Valent Iron Technologies for Source Remediation; Naval Facilities Engineering Service Center: Port Hueneme, CA, USA, 2005. [Google Scholar]

- Rangsivek, R.; Jekel, M.R. Removal of dissolved metals by zero-valent iron (ZVI): Kinetics, equilibria, processes and implications for stormwater runoff treatment. Water Res. 2005, 39, 4153–4163. [Google Scholar] [CrossRef]

- Bakir, A. Development of a Seaweed-Based Fixed-Bed Sorption Column for the Removal of Metals in a Waste Stream. Ph.D. Thesis, Waterford Institute of Technology, Waterford, Ireland, 2015. [Google Scholar]

- Böhm, J.; Debreczeni, A.; Gombkötő, I.; Simon, F.G.; Csővári, M. Laboratory tests using natural groundwater. In Long-Term Performance of Permeable Reactive Barriers; Roehl, K.E., Meggyes, T., Simon, F.G., Stewart, D.I., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 111–136. [Google Scholar]

- Brooks, R.M.; Bahadory, M.; Tovia, F.; Rostami, H. Removal of lead from contaminated water. Int. J. Soil Sediment Water 2010, 3, 14. [Google Scholar]

- Faisal, A.A.H.; Hmood, Z.A. Groundwater protection from cadmium contamination by zeolite permeable reactive barrier. DWT 2015, 53, 1377–1386. [Google Scholar] [CrossRef]

- Gappai, G.; De Gioannis, G.; Muntoni, A.; Spiga, D.; Zijlstra, J.J.P. Combined use of a transformed red mud reactive barrier and electrokinetics for remediation of Cr/As contaminated soil. Chemosphere 2012, 86, 400–408. [Google Scholar]

- Geranio, L.; Elzinga, E. Review of zero valent iron and apatite as reactive materials for permeable reactive barrier. In Term Paper; Citeseer: Princeton, NJ, USA, 2007. [Google Scholar]

- Gibert, O.; Assal, A.; Devlin, H.; Elliot, T.; Kalin, R.M. Performance of a field-scale biological permeable reactive barrier for in-situ remediation of nitrate-contaminated groundwater. Sci. Total Environ. 2019, 659, 211–220. [Google Scholar] [CrossRef] [PubMed]

- Golab, A.N.; Peterson, M.A.; Indraratna, B. Selection of potential reactive materials for a permeable reactive barrier for remediating acidic groundwater in acid sulphate soil terrains. Quart. J. Eng. Geol. Hydrogeol. 2006, 39, 209–223. [Google Scholar] [CrossRef]

- Han, Z.Y.; Lv, X.B.; Di, L. Experiment study on the remediation effects of copper polluted groundwater by PRB with the volcanic as reactive medium. In Proceedings of the 2018 7th International Conference on Energy and Environmental Protection (ICEEP 2018), Shenzhen, China, 14–15 July 2018; Atlantis Press: Paris, France, 2018. [Google Scholar]

- Hiller, K.A.; Foreman, K.H.; Weisman, D.; Bowen, J.L. Permeable reactive barriers designed to mitigate eutrophication alter bacterial community composition and aquifer redox conditions. Appl. Environ. Microbiol. 2015, 81, 7114–7124. [Google Scholar] [CrossRef] [PubMed]

- Indraratna, B.; Pathirage, P.; Rowe, K.; Banasiak, L. Coupled hydro-geochemical modelling of a permeable reactive barrier for treating acidic groundwater. Comput. Geotech. 2014, 55, 429–439. [Google Scholar] [CrossRef]

- Liu, C.; Chen, X.; Mack, E.E.; Wang, S.; Du, W.; Yin, Y.; Banwart, S.A.; Guo, H. Evaluating a novel permeable reactive bio-barrier to remediate PAH-contaminated groundwater. J. Hazard. Mater. 2019, 368, 444–451. [Google Scholar] [CrossRef]

- Liu, Y.; Mou, H.; Chen, L.; Mirza, Z.A.; Liu, L. Cr (VI)-contaminated groundwater remediation with simulated permeable reactive barrier (PRB) filled with natural pyrite as reactive material: Environmental factors and effectiveness. J. Hazard. Mater. 2015, 298, 83–90. [Google Scholar] [CrossRef] [PubMed]

- Park, J.B.; Lee, S.H.; Lee, J.W.; Lee, C.Y. Lab scale experiments for permeable reactive barriers against contaminated groundwater with ammonium and heavy metals using clinoptilolite (01-29B). J. Hazard. Mater. 2002, 95, 65–79. [Google Scholar] [CrossRef]

- Pathirage, P.U.; Indraratna, B.; Nghiem, L.D.; Banasiak, L.; Regmi, G. Armoring by Precipitates and the Associated Reduction in Hydraulic Conductivity of Recycled Concrete Aggregates Used in a Novel Prb for the Treatment of Acidic Groundwater; University of Wollongong: Wollongong, NSW, Australia, 2012; pp. 828–833. [Google Scholar]

- Reddy, K.R.; Xie, T.; Dastgheibi, S. Adsorption of mixtures of nutrients and heavy metals in simulated urban stormwater by different filter materials. J. Environ. Sci. Health Part A 2014, 49, 524–539. [Google Scholar] [CrossRef]

- Robertson, W.D.; Blowes, D.W.; Ptacek, C.J.; Cherry, J.A. Long-term performance of in situ reactive barriers for nitrate remediation. Groundwater 2000, 38, 689–695. [Google Scholar] [CrossRef]

- Sulaymon, A.H.; Faisal, A.A.H.; Khaliefa, Q.M. Dominant mechanisms for metal removal from acidic aqueous solutions by cement kiln dust. Mine Water Environ. 2017, 36, 209–216. [Google Scholar] [CrossRef]

- Sulaymon, A.H.; Faisal, A.A.H.; Khaliefa, Q.M. Simultaneous adsorption–precipitation characterization as mechanisms for metals removal from aqueous solutions by cement kiln dust (CKD). Desalination Water Treat. 2016, 57, 819–826. [Google Scholar] [CrossRef]

- Vinati, A.; Rene, E.R.; Pakshirajan, K.; Behera, S.K. Activated red mud as a permeable reactive barrier material for fluoride removal from groundwater: Parameter optimisation and physico-chemical characterization. Environ. Technol. 2019, 41, 3375–3386. [Google Scholar] [CrossRef]

- Wantanaphong, J.; Mooney, S.J.; Bailey, E.H. Natural and waste materials as metal sorbents in permeable reactive barriers (PRBs). Environ. Chem. Lett. 2005, 3, 19–23. [Google Scholar] [CrossRef]

- Waybrant, K.R.; Blowes, D.W.; Ptacek, C.J. Selection of reactive mixtures for use in permeable reactive walls for treatment of mine drainage. Environ. Sci. Technol. 1998, 32, 1972–1979. [Google Scholar] [CrossRef]

- Fallico, C.; Troisi, S.; Molinari, A.; Rivera, M.F. Characterization of broom fibers for PRB in the remediation of aquifers contaminated by transition metals. Biogeosciences 2010, 7, 2545–2556. [Google Scholar] [CrossRef]

- Mayacela Rojas, C.M.; Rivera Velásquez, M.F.; Tavolaro, A.; Molinari, A.; Fallico, C. Use of Vegetable Fibers for PRB to Remove Transition Metals from Contaminated Aquifers—Comparisons among Cabuya Fibers, Broom Fibers and ZVI. Int. J. Environ. Res. Public Health 2017, 14, 684. [Google Scholar] [CrossRef]

- Molinari, A.; Mayacela Rojas, C.M.; Beneduci, A.; Tavolaro, A.; Rivera Velasquez, M.F.; Fallico, C. Adsorption Performance Analysis of Alternative Reactive Media for Remediation of Aquifers Affected by Transition Metal Contamination. Int. J. Environ. Res. Public Health 2018, 15, 980. [Google Scholar] [CrossRef] [PubMed]

- Saaltink, M.W.; Batlle, F.; Ayora, C.; Carrera, J.; Olivella, S. RETRASO, a Code for Modeling Reactive Transport in Saturated and Unsaturated Porous Media; CSIC: Madrid, Spain, 2004; p. 2. [Google Scholar]

- Fallico, C. Reconsideration at Field Scale of the Relationship between Hydraulic Conductivity and Porosity: The Case of a Sandy Aquifer in South Italy. Sci. World J 2014, 2014, 15–23. [Google Scholar] [CrossRef]

- Jiménez-Cedillo, M.J.; Olguín, M.T.; Fall, C. Adsorption kinetic of arsenates as water pollutant on iron, manganese and iron–manganese-modified clinoptilolite-rich tuffs. J. Hazard. Mater. 2009, 163, 939–945. [Google Scholar] [CrossRef]

- Lambe, T.W. Soil Testing for Engineers; Wolters Kluwer: Alphen aan den Rijn, The Netherlands, 1951. [Google Scholar]

- Danielson, R.E.; Sutherland, P.L. Porosity. In Methods of Soil Analysis-Part 1. Physical and Mineralogical Methods; Soil Science Society of America; John Wiley & Sons: Hoboken, NJ, USA, 1986; Volume 9, pp. 443–461. [Google Scholar]

- Staub, M.; Galietti, B.; Oxarango, L.; Khire, M.V.; Gourc, J.P. Porosity and hydraulic conductivity of MSW using laboratory-scale tests. In Proceedings of the 3rd International Workshop “Hydro-Physico-Mechanics of Landfills, Braunschweig, Germany, 10–13 March 2009. [Google Scholar]

- Ahuja, L.R.; Naney, J.W.; Green, R.E.; Nielsen, D.R. Macroporosity to characterize spatial variability of hydraulic conductivity and effects of land management. Soil Sci. Soc. Am. J. 1984, 48, 699–702. [Google Scholar] [CrossRef]

- Ahuja, L.R.; Cassel, D.K.; Bruce, R.R.; Barnes, B.B. Evaluation of spatial distribution of hydraulic conductivity using effective porosity data. Soil Sci. 1989, 148, 404–411. [Google Scholar] [CrossRef]

- Sauty, J.P. Identification des paramètres du transfert hydrodispersif dans les aquifères par interprétation des expériences des traçage. Bureau de recherches geologiques et minieres. J. Hydrol. 1978, 39, 69–103. [Google Scholar] [CrossRef]

- Levenspiel, O. Ingeníeria de Las Reacciones Químicas; Reverté: Tarragona, Spain, 1985. [Google Scholar]

- Kaczala, F.; Marques, M.; Hogland, W. Lead and vanadium removal from a real industrial wastewater by gravitational settling/sedimentation and sorption onto Pinus sylvestris sawdust. Bioresour. Technol. 2009, 100, 235–243. [Google Scholar] [CrossRef] [PubMed]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef]

- Freundlich, H.M.F. Over the adsorption in solution. J. Phys. Chem. 1906, 57, 1100–1107. [Google Scholar]

- Legislative Decree 3 April 2006; n. 152. Norme in Materia Ambientale. Gazzetta Ufficiale n. 88 del 14 Aprile 2006—Supplemento Ordinario n. 96. Available online: http://www.camera.it/parlam/leggi/deleghe/06152dl.htm (accessed on 19 April 2017). (In Italian).

- Bear, J. Dynamics of Fluids in Porous Media; Courier Corporation: Chelmsford, MA, USA, 1972. [Google Scholar]

- De Pourcq, K.; Ayora, C.; García-Gutiérrez, M.; Missana, T.; Carrera, J. A clay permeable reactive barrier to remove Cs-137 from groundwater: Column experiments. J. Environ. Radioact. 2015, 149, 36–42. [Google Scholar] [CrossRef]

- Obiri-Nyarko, F.; Kwiatkowska, J.; Malina, G.; Kasela, C.; Wołowiec, C. Assessment of zeolite and compost-zeolite mixture as permeable reactive materials for the removal of lead from a model acidic groundwater. J. Contam. Hydrol. 2019. [Google Scholar] [CrossRef]

- Obiri-Nyarko, F.; Kwiatkowska, J.; Malina, G.; Kasela, C. Geochemical modelling for predicting the long-term performance of zeolite-PRB to treat lead contaminated groundwater. J. Contam. Hydrol. 2015, 177, 76–84. [Google Scholar] [CrossRef] [PubMed]

- Masel, R. Principles of Adsorption and Reaction on Solid Surfaces; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Mishra, U.; Paul, S.; Bandyopadhaya, M. Removal of zinc ions from wastewater using industrial waste sludge: A novel approach. Environ. Prog. Sustain. Energy 2013, 32, 576–586. [Google Scholar] [CrossRef]

- Shahee, N.; Arsalan, R.; Khaliq, W.; Murtaza, H.; Iqbal, R.; Humza, M. Synthesis and characterization of bio-immobilized nano/micro inert and reactive additives for feasibility investigation in self-healing concrete. Constr. Build. Mater. 2019, 226, 492–506. [Google Scholar] [CrossRef]

- Leyva, R.; Sànches, C.; Hernàndez, M.; Guerrero, R. Remociòn de metales pesados de soluciòn acuosa por medio de clinoptilolitas naturales. Rev. Int. Contam. Ambient. 2021, 17, 129–136. [Google Scholar]

- An, Y.; Li, J.; Liu, N. A sustainability assessment methodology for prioritizing the technologies of groundwater contamination remediation. J. Clean. Prod. 2016, 112, 4647–4656. [Google Scholar] [CrossRef]

- Cordeiro, D.; Vieira, E. Combination of electrokinetic remediation with permeable reactive barriers to remove organic compounds from soils. Curr. Opin. Electrochem. 2020, 22, 143–159. [Google Scholar]

- Barba, S.; Carvela, M.; Villaseñor, J.; Rodrigo, M.; Cañizares, P. Fixed-bed biological barrier coupled with electrokinetics for the in situ electrobioremediation of 2,4-dichlorophenoxyacetic acid polluted soil. J. Chem. Technol. Biotechnol. 2019, 94, 2684–2692. [Google Scholar] [CrossRef]

- Huang, Y.; Zeng, Q.; Hu, L.; Xiong, D.; Zhong, H.; He, Z. Column study of enhanced Cr (VI) removal and removal mechanisms by Sporosarcina saromensis W5 assisted bio-permeable reactive barrier. J. Hazard. Mater. 2021, 405, 124115. [Google Scholar] [CrossRef] [PubMed]

- Rodrigo, S.; Saez, C.; Cañizares, P.; Rodrigo, M.A. Reversible electrokinetic adsorption barriers for the removal of organochlorine herbicide from spiked soils. Sci. Total Environ. 2018, 640, 629–636. [Google Scholar] [CrossRef] [PubMed]

- Vaskar, A.; Gupta, N.; Sass, B.; Janosy, R.; Hicks, J. Design Guidance for Application of Permeable Reactive Barriers for Ground Water Remediation; Defense Technical Information Center: Fort Belvoir, VA, USA, 2000.

| Parameters | Unit of Measure | Cabuya Fiber | Zeolites |

|---|---|---|---|

| Clinoptilolite Mordenite Sodium Mordenite | |||

| Effective porosity | 0.55 | 0.30 | |

| Density | kg/m3 | 16 | 100 |

| Mass of the reactive material | kg | 0.030 | 0.083 |

| Column diameter | m | 0.042 | |

| Column area | m2 | 0.0014 | |

| Height of the reactive column | m | 0.18 | |

| Reactive column volume | L | 25 | |

| Metal concentration | mg/L | Zn: 100; Cu: 30; Cd: 4 | |

| Flow rate | L/h | 0.0216 | |

| Velocity | m/h | 0.016 | |

| Reactive Material | Total Porosity | Effective Porosity | |

|---|---|---|---|

| Densimetric Method | Tracking Method | ||

| Cabuya fiber | 0.84 | 0.55 | 0.56 |

| Natural zeolite | 0.62 | 0.30 | 0.30 |

| Reactive Material | Zn | Cu | Cd | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Adsorption % | Contact Time (h) | qmax (mg/g) (C0 = 100 mg/L) | Adsorption % | Contact Time (h) | qmax (mg/g) (C0 = 50 mg/L) | Adsorption % | Contact Time (h) | qmax (mg/g) (C0 = 40 mg/L) | |

| Cabuya fiber | 100 | 30 | 13.3 | 99 | 24 | 6.7 | 99 | 24 | 5.2 |

| Clinoptilolite zeolite | 99 | 26 | 13.3 | 99 | 22 | 6.7 | 99 | 26 | 5.3 |

| Mordenite zeolite | 99 | 24 | 13.2 | 99 | 22 | 6.9 | 99 | 8 | 5.3 |

| Sodium mordenite zeolite | 99 | 30 | 13.2 | 99 | 26 | 6.7 | 99 | 22 | 5.3 |

| Calcareous limestone | 93 | 30 | 12.4 | 82 | 30 | 5.5 | 100 | 24 | 5.3 |

| 4A Synthetic zeolite | 85 | 30 | 11.3 | 99 | 30 | 6.5 | 100 | 26 | 5.2 |

| ZVI | 88 | 30 | 11.8 | 85 | 30 | 5.7 | 99 | 30 | 5.3 |

| Metal | Reactive Materials | Langmuir | Freundlich | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| qm | KL | RL | R2 | RMSE | Kf | n | R2 | RMSE | ||

| (mg/g) | (mg/L) | (L/g) | (g/L) | |||||||

| Zn | Cabuya fiber | 11.20 | 0.74 | 0.016 | 0.97 | 0.010 | 5.33 | 4.21 | 0.95 | 0.071 |

| Clinoptilolite | 12.53 | 3.13 | 0.004 | 0.95 | 0.010 | 8.00 | 5.12 | 0.88 | 0.020 | |

| Mordenite | 14.00 | 2.10 | 0.006 | 0.88 | 0.014 | 9.10 | 6.58 | 0.92 | 0.072 | |

| Sodium mordenite | 13.40 | 0.63 | 0.018 | 0.90 | 0.009 | 8.00 | 8.23 | 0.80 | 0.155 | |

| Cu | Cabuya fiber | 16.47 | 0.11 | 0.123 | 0.99 | 0.015 | 3.42 | 2.29 | 0.95 | 0.025 |

| Clinoptilolite | 15.60 | 0.59 | 0.028 | 0.96 | 0.029 | 4.21 | 2.41 | 0.93 | 0.188 | |

| Mordenite | 17.17 | 0.20 | 0.074 | 0.99 | 0.008 | 2.80 | 1.50 | 0.97 | 0.888 | |

| Sodium mordenite | 12.74 | 2.96 | 0.006 | 0.94 | 0.046 | 6.22 | 3.98 | 0.78 | 0.382 | |

| Cd | Cabuya fiber | 7.67 | 0.41 | 0.152 | 0.99 | 0.172 | 1.66 | 1.83 | 0.98 | 0.192 |

| Clinoptilolite | 15.58 | 0.13 | 0.287 | 0.99 | 0.019 | 2.65 | 2.29 | 0.92 | 0.364 | |

| Mordenite | 6.10 | 0.46 | 0.145 | 0.91 | 0.090 | 1.41 | 1.57 | 0.99 | 0.121 | |

| Sodium mordenite | 18.52 | 0.05 | 0.440 | 0.99 | 0.020 | 1.11 | 1.40 | 0.99 | 0.118 | |

| Metals | Reactive Material | Area (m2) | Mass (g) | Concentration (mg/L) | qmax (mg/g) | Mass Held by the Column (mg) | Dissolution Volume (L) | Q (L/h) | Test Duration Days Hours | Velocity (m/h) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Zn | Fiber | Cabuya | 0.0014 | 30 | 100 | 9.62 | 288.60 | 2.89 | 0.022 | 5.5 | 133.6 | 0.016 |

| Zeolites | Clinoptilolite | 83 | 10.40 | 863.20 | 8.63 | 16.65 | 399.63 | |||||

| mordenite | 83 | 10.42 | 864.86 | 8.65 | 16.68 | 400.00 | ||||||

| Sodium mordenite | 83 | 9.89 | 820.87 | 8.21 | 15.83 | 380.03 | ||||||

| Cu | Fiber | Cabuya | 0.0014 | 30 | 30 | 3.10 | 93 | 3.10 | 0.022 | 5.98 | 143.52 | 0.016 |

| Zeolites | Clinoptilolite | 83 | 3.25 | 269.75 | 8.99 | 17.35 | 416.28 | |||||

| mordenite | 83 | 3.15 | 261.45 | 8.72 | 16.81 | 403.47 | ||||||

| Sodium mordenite | 83 | 3.28 | 272.24 | 9.07 | 17.51 | 420.12 | ||||||

| Cd | Fiber | Cabuya | 0.0014 | 30 | 4 | 1.09 | 32.7 | 8.18 | 0.0216 | 15.77 | 378.47 | 0.016 |

| Zeolites | Clinoptilolite | 83 | 1.79 | 146.78 | 36.70 | 70.78 | 1698.84 | |||||

| Mordenite | 83 | 1.89 | 154.98 | 38.75 | 74.74 | 1793.75 | ||||||

| Sodium mordenite | 83 | 1.75 | 143.50 | 35.88 | 69.203 | 1660.88 | ||||||

| Metals | Reactive Materials | Maximum Adsorption Times (Hours) | Saturation Times (Hours) |

|---|---|---|---|

| Zn | Cabuya fiber | 237 | 755 |

| Clinoptilolite | 357 | 1170 | |

| Mordenite | 429 | 1800 | |

| Sodium mordenite | 405 | 1700 | |

| Cu | Cabuya fiber | 189 | 755 |

| Clinoptilolite | 833 | 1820 | |

| Mordenite | 515 | 1826 | |

| Sodium mordenite | 429 | 1705 | |

| Cd | Cabuya fiber | 245 | 515 |

| Clinoptilolite | 405 | 1789 | |

| Mordenite | 833 | 1802 | |

| Sodium mordenite | 930 | 1718 |

| Reactive Material | Metals | K (m/day) | i | λ1 (L/g h) | λ1 (L/g day) | ρ (kg/m3) | C0 (kg/m3) | Cf Limit (kg/m3) | ln(C0/Cf) (--) | S (m) |

|---|---|---|---|---|---|---|---|---|---|---|

| Cabuya fiber | Zn | 141.4 | 0.913 | 0.105 | 2.517 | 16 | 0.100 | 0.003 | 3.507 | 1.1 |

| Cu | 0.152 | 3.651 | 0.030 | 0.001 | 3.401 | 0.8 | ||||

| Cd | 0.149 | 3.576 | 0.004 | 0.00005 | 4.382 | 1.0 | ||||

| Clinoptilolite | Zn | 131.6 | 0.913 | 0.124 | 2.971 | 100 | 0.100 | 0.003 | 3.507 | 1.0 |

| Cu | 0.190 | 4.559 | 0.030 | 0.001 | 3.401 | 0.6 | ||||

| Cd | 0.072 | 1.726 | 0.004 | 0.00005 | 4.382 | 2.1 | ||||

| Mordenite | Zn | 131.5 | 0.913 | 0.145 | 3.479 | 100 | 0.100 | 0.003 | 3.507 | 0.8 |

| Cu | 0.185 | 4.445 | 0.030 | 0.001 | 3.401 | 0.6 | ||||

| Cd | 0.140 | 3.351 | 0.004 | 0.00005 | 4.382 | 1.1 | ||||

| Sodium mordenite | Zn | 131.5 | 0.913 | 0.137 | 3.278 | 100 | 0.100 | 0.003 | 3.507 | 0.9 |

| Cu | 0.109 | 2.625 | 0.030 | 0.001 | 3.401 | 1.1 | ||||

| Cd | 0.080 | 1.917 | 0.004 | 0.00005 | 4.382 | 1.9 |

| Parameters | Metals | Cabuya Fiber | Clinoptilolite Natural Zeolite | Mordenite Natural Zeolite | Sodium Mordenite Natural Zeolite |

|---|---|---|---|---|---|

| Cinput (mg/L) | Zn | 100 | 100 | 100 | 100 |

| Cu | 100 | 100 | 100 | 100 | |

| Cd | 1 | 1 | 1 | 1 | |

| qmax (mg/g) | Zn | 18.3 | 22.9 | 33.8 | 26.7 |

| Cu | 6.5 | 10.3 | 10.9 | 9.1 | |

| Cd | 1.1 | 1.7 | 1.7 | 1.5 | |

| Flow rate (L/min) | 0.17 | 0.17 | 0.17 | 0.17 | |

| Effective porosity | 0.55 | 0.30 | 0.55 | 0.30 | |

| Column height (m) | 0.14 | 0.06 | 0.14 | 0.06 | |

| Simulation height (m) | 1 | 1 | 1 | 1 | |

| Metals | Reactive Materials | Maximum Adsorption Times (Days) | Saturation Times (Days) |

|---|---|---|---|

| Zn | Cabuya fiber | 83 | 125 |

| Clinoptilolite | 800 | 1200 | |

| Mordenite | 429 | 1300 | |

| Sodium mordenite | 750 | 1200 | |

| Cu | Cabuya fiber | 33 | 63 |

| Clinoptilolite | 600 | 900 | |

| Mordenite | 750 | 1200 | |

| Sodium mordenite | 600 | 1000 | |

| Cd | Cabuya fiber | 2 | 41 |

| Clinoptilolite | (>800) | (>1200) | |

| Mordenite | (>750) | (>1300) | |

| Sodium mordenite | (>750) | (>1200) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayacela-Rojas, C.M.; Molinari, A.; Cortina, J.L.; Gibert, O.; Ayora, C.; Tavolaro, A.; Rivera-Velásquez, M.F.; Fallico, C. Removal of Transition Metals from Contaminated Aquifers by PRB Technology: Performance Comparison among Reactive Materials. Int. J. Environ. Res. Public Health 2021, 18, 6075. https://doi.org/10.3390/ijerph18116075

Mayacela-Rojas CM, Molinari A, Cortina JL, Gibert O, Ayora C, Tavolaro A, Rivera-Velásquez MF, Fallico C. Removal of Transition Metals from Contaminated Aquifers by PRB Technology: Performance Comparison among Reactive Materials. International Journal of Environmental Research and Public Health. 2021; 18(11):6075. https://doi.org/10.3390/ijerph18116075

Chicago/Turabian StyleMayacela-Rojas, Celia Margarita, Antonio Molinari, José Luis Cortina, Oriol Gibert, Carlos Ayora, Adalgisa Tavolaro, María Fernanda Rivera-Velásquez, and Carmine Fallico. 2021. "Removal of Transition Metals from Contaminated Aquifers by PRB Technology: Performance Comparison among Reactive Materials" International Journal of Environmental Research and Public Health 18, no. 11: 6075. https://doi.org/10.3390/ijerph18116075

APA StyleMayacela-Rojas, C. M., Molinari, A., Cortina, J. L., Gibert, O., Ayora, C., Tavolaro, A., Rivera-Velásquez, M. F., & Fallico, C. (2021). Removal of Transition Metals from Contaminated Aquifers by PRB Technology: Performance Comparison among Reactive Materials. International Journal of Environmental Research and Public Health, 18(11), 6075. https://doi.org/10.3390/ijerph18116075