Environmental Efficiency Assessment of Heavy Pollution Industry by Data Envelopment Analysis and Malmquist Index Analysis: Empirical Evidence from China

Abstract

1. Introduction

2. Literature Review

3. Empirical Design

3.1. Method

3.1.1. DEA Model with Undesirable Output

3.1.2. Malmquist Index

3.2. Index Selection

3.3. Data

4. Results and Analysis

4.1. Descriptive Statistics and Correlation Analysis

4.2. Static Analysis of Environmental Efficiency Changes in Heavy Pollution Industries

4.2.1. Overall Analysis of Environmental Efficiency in Heavy Pollution Industries

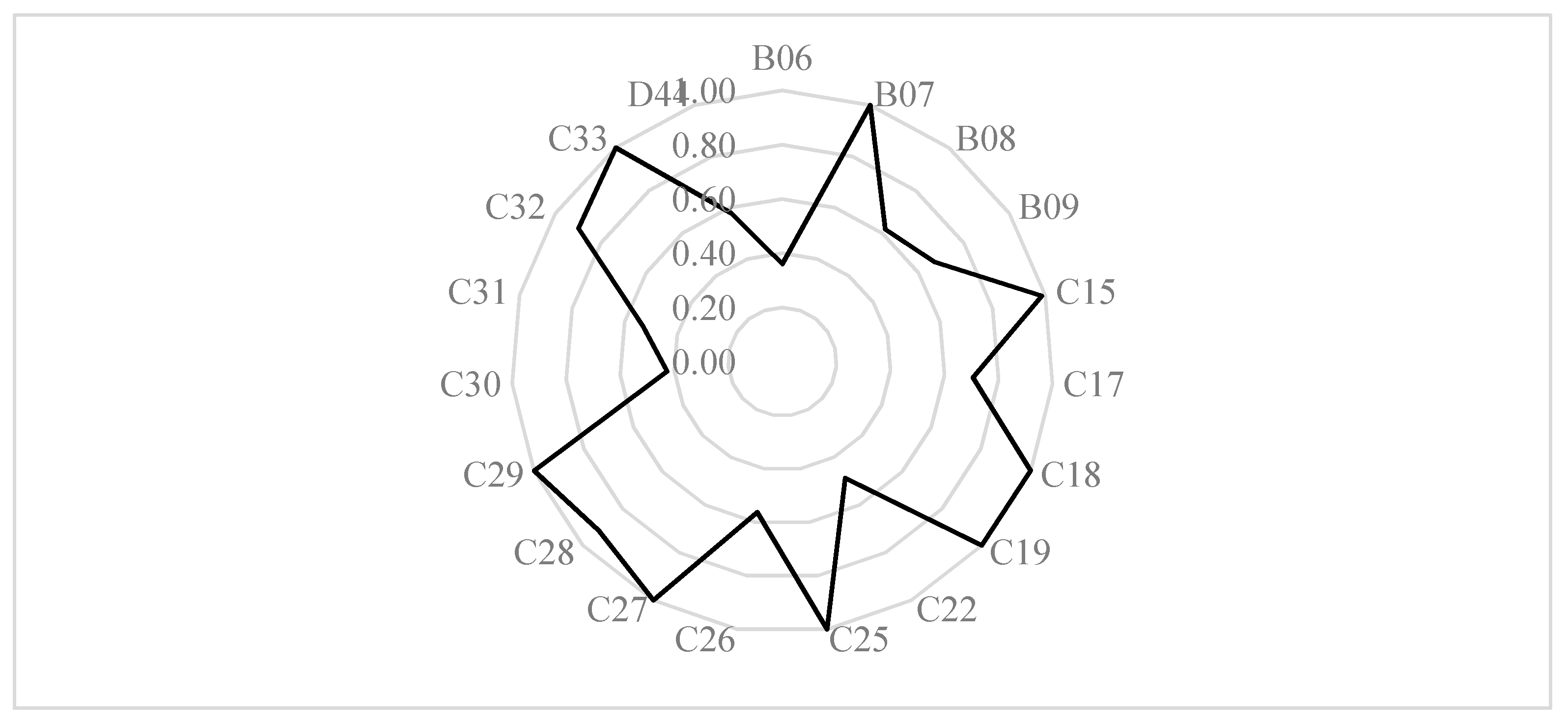

4.2.2. Environmental Efficiency Analysis of Heavy Pollution Sub-Industries

4.3. Dynamic Analysis of Environmental Efficiency Changes in Heavy Pollution Industry

4.3.1. Malmquist Index and Trend Analysis

4.3.2. Catch-Up Effect and Frontier Effect Index and Change Analysis

5. Conclusions and Suggestions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hasanov, F.J.; Mikayilov, J.I.; Mukhtarov, S.; Suleymanov, E. Does CO2 emissions–economic growth relationship reveal EKC in developing countries? Evidence from Kazakhstan. Environ. Sci. Pollut. Res. 2019, 26, 30229–30241. [Google Scholar] [CrossRef] [PubMed]

- Isik, C.; Ongan, S.; Özdemir, D. The economic growth/development and environmental degradation: Evidence from the US state-level EKC hypothesis. Environ. Sci. Pollut. Res. 2019, 26, 30772–30781. [Google Scholar] [CrossRef] [PubMed]

- Isik, C.; Ongan, S.; Ozdemir, D. The increases and decreases of the environment Kuznets curve (EKC) for 8 OECD countries. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Peng, H.; Temulun, T.; Liu, L.Q.; Mao, J.; Lu, Z.N.; Chen, H. How harmful is air pollution to economic development? New evidence from PM2.5 concentrations of Chinese cities. J. Clean. Prod. 2018, 172, 743–757. [Google Scholar] [CrossRef]

- Li, H.; Zhang, J.; Osei, E.; Yu, M. Sustainable development of China’s industrial economy: An empirical study of the period 2001. Sustainability 2018, 10, 764. [Google Scholar] [CrossRef]

- LI, J.J.; LUO, N.S. Analysis of Convergence, Spatial Spillover Effects and Causes of Chinese Regional Environmental Efficiency. Soft Sci. 2016, 30, 1–5. [Google Scholar]

- Hermoso-Orzáez, M.J.; García-Alguacil, M.; Terrados-Cepeda, J.; Brito, P. Measurement of environmental efficiency in the countries of the European Union with the enhanced data envelopment analysis method (DEA) during the period 2005. Environ. Sci. Pollut. Res. 2020, 1–25. [Google Scholar] [CrossRef]

- Iram, R.; Zhang, J.; Erdogan, S.; Abbas, Q.; Mohsin, M. Economics of energy and environmental efficiency: Evidence from OECD countries. Environ. Sci. Pollut. Res. 2020, 27, 3858–3870. [Google Scholar] [CrossRef]

- Park, Y.S.; Lim, S.H.; Egilmez, G.; Szmerekovsky, J. Environmental efficiency assessment of US transport sector: A slack-based data envelopment analysis approach. Transp. Res. Part D Transp. Environ. 2018, 61, 152–164. [Google Scholar] [CrossRef]

- Le, T.L.; Lee, P.P.; Peng, K.C.; Chung, R.H. Evaluation of total factor productivity and environmental efficiency of agriculture in nine East Asian countries. Agric. Econ. 2019, 65, 249–258. [Google Scholar]

- Wei, Y.; Li, Y.; Wu, M.; Li, Y. Progressing sustainable development of “the Belt and Road countries”: Estimating environmental efficiency based on the Super-slack-based measure model. Sustain. Dev. 2020, 28, 521–539. [Google Scholar] [CrossRef]

- Fukuyama, H.; Hashimoto, A.; Weber, W.L. Environmental efficiency, energy efficiency and aggregate well-being of Japanese prefectures. J. Clean. Prod. 2020, 271, 122810. [Google Scholar] [CrossRef]

- Twum, F.A.; Long, X.; Salman, M.; Mensah, C.N.; Kankam, W.A.; Tachie, A.K. The influence of technological innovation and human capital on environmental efficiency among different regions in Asia-Pacific. Environ. Sci. Pollut. Res. 2021, 28, 17119–17131. [Google Scholar] [CrossRef]

- An, Q.; Tao, X.; Dai, B.; Li, J. Modified distance friction minimization model with undesirable output: An application to the environmental efficiency of China’s regional industry. Comput. Econ. 2020, 55, 1047–1071. [Google Scholar] [CrossRef]

- Seklaoui, M.H.; Boutaleb, A.; Benali, H.; Alligui, F.; Prochaska, W. Environmental assessment of mining industry solid pollution in the mercurial district of Azzaba, northeast Algeria. Environ. Monit. Assess. 2016, 188, 621. [Google Scholar] [CrossRef] [PubMed]

- Hutton, M.; Shafahi, M. Water Pollution Caused by Leather Industry: A Review. In Energy Sustainability. Am. Soc. Mech. Eng. 2019, 59094, V001T10A002. [Google Scholar]

- Zhang, Y.; Song, Y.; Zou, H. Transformation of pollution control and green development: Evidence from China’s chemical industry. J. Environ. Manag. 2020, 275, 111246. [Google Scholar] [CrossRef] [PubMed]

- Sun, J. Research Progress on Environmental Efficiency at Home and Abroad. Sustain. Dev. 2020, 10, 45. [Google Scholar] [CrossRef]

- Wang, Y.; Wen, Z.; Cao, X.; Zheng, Z.; Xu, J. Environmental efficiency evaluation of China’s iron and steel industry: A process-level data envelopment analysis. Sci. Total Environ. 2020, 707, 135903. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, J. Environmental Efficiency Assessment of the US Pulp and Paper Industry Using an SBM-DEA Model. Environ. Sci. Pollut. Res. 2020, 15, 7796–7814. [Google Scholar]

- Chen, L.; Lai, F.; Wang, Y.M.; Huang, Y.; Wu, F.M. A two-stage network data envelopment analysis approach for measuring and decomposing environmental efficiency. Comput. Ind. Eng. 2018, 119, 388–403. [Google Scholar] [CrossRef]

- Wang, K.; Wei, Y.M.; Huang, Z. Environmental efficiency and abatement efficiency measurements of China’s thermal power industry: A data envelopment analysis based materials balance approach. Eur. J. Oper. Res. 2018, 269, 35–50. [Google Scholar] [CrossRef]

- Shah, S.A.A.; Longsheng, C. New environmental performance index for measuring sector-wise environmental performance: A case study of major economic sectors in Pakistan. Environ. Sci. Pollut. Res. 2020, 27, 41787–41802. [Google Scholar] [CrossRef]

- Singpai, B.; Wu, D.D. An integrative approach for evaluating the environmental economic efficiency. Energy 2020, 215, 118940. [Google Scholar] [CrossRef]

- Hu, Y.H.; Lu, F. Research in the influence of the data dimension-lessness and index correlation in DEA evaluation. China Econ. Stat. Q. 2017, 2, 56–72. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Dyckhoff, H.; Allen, K. Measuring ecological efficiency with data envelopment analysis (DEA). Eur. J. Oper. Res. 2001, 132, 312–325. [Google Scholar] [CrossRef]

- Zhou, M.; Wu, Y. Research on Eco-Efficiency Evaluation of Advanced Manufacturing Industry in China Based on SE-SBM Model. Ecol. Econ. 2020, 10, 63–69. [Google Scholar]

- Halická, M.; Trnovská, M. Negative features of hyperbolic and directional distance models for technologies with undesirable outputs. Cent. Eur. J. Oper. Res. 2018, 26, 887–907. [Google Scholar] [CrossRef]

- You, S.; Yan, H. A new approach in modelling undesirable output in DEA model. J. Oper. Res. Soc. 2011, 62, 2146–2156. [Google Scholar] [CrossRef]

- Färe, R.; Margaritis, D.; Rouse, P.; Roshdi, I. Estimating the hyperbolic distance function: A directional distance function approach. Eur. J. Oper. Res. 2016, 254, 312–319. [Google Scholar] [CrossRef]

- Jablonsky, J. A slack based model for measuring super-efficiency in data envelopment analysis. Mult. Criteria Decis. Mak. 2006, 5, 101–112. [Google Scholar]

- Malmquist, S. Index numbers and indifference surfaces. Trab. Estadística 2011, 4, 209–242. [Google Scholar] [CrossRef]

- Shen, N. Environmental Efficiency, Industrial Heterogeneity and Intensity of Optimal Regulation—Nonlinear Test Based on Industrial Panel-data. China Ind. Econ. 2012, 3, 56–68. [Google Scholar]

- Liu, R.J.; Zhang, Z.H. Panel Data Research on Economic-Environmental Efficiency of Chinese Industry by Sectors. J. Shanxi Univ. Financ. Econ. 2012, 34, 62–69. [Google Scholar]

- Wu, J.; Li, M.; Zhu, Q.; Zhou, Z.; Liang, L. Energy and environmental efficiency measurement of China’s industrial sectors: A DEA model with non-homogeneous inputs and outputs. Energy Econ. 2019, 78, 468–480. [Google Scholar] [CrossRef]

- Xiao, C.; Wang, Z.; Shi, W.; Deng, L.; Wei, L.; Wang, Y.; Peng, S. Sectoral energy-environmental efficiency and its influencing factors in China: Based on SU-SBM model and panel regression model. J. Clean. Prod. 2018, 182, 545–552. [Google Scholar] [CrossRef]

- Wang, J.; Dong, Z.; Jiang, H.; Lu, J. Historical evolution and reform of China’s environmental strategy and policy during the past seventy years (1949–2019). Res. Environ. Sci. 2019, 32, 1636–1644. [Google Scholar]

- Xie, L.; Chen, C.; Yu, Y. Dynamic assessment of environmental efficiency in Chinese industry: A multiple DEA model with a Gini criterion approach. Sustainability 2019, 11, 2294. [Google Scholar] [CrossRef]

- Kong, Q. Research on Environmental Efficiency of China’s Manufacturing Industry and Its Industry Differences. J. Bohai Univ. 2020, 3, 76–82. [Google Scholar]

| Indexes | N | Min | Max | Mean | Standard Deviation | ||

|---|---|---|---|---|---|---|---|

| Input indexes | Comprehensive energy consumption (E) | 285 | 217.60 | 69,342.42 | 9722.82 | 13,471.15 | |

| annual average number of employees (L) | 285 | 24.37 | 652.06 | 241.18 | 164.51 | ||

| the net fixed assets (C) | 285 | 110.4 | 74,494.94 | 6634.26 | 10,174.45 | ||

| Output indexes | Desirable output | main business income (I) | 285 | 178.54 | 83,564.54 | 16,586.61 | 17,394.61 |

| Undesirable output | wastewater discharge (W) | 285 | 3724.00 | 424,597.00 | 87,860.00 | 99,818.45 | |

| exhaust gas discharge (G) | 285 | 119.00 | 225,447.00 | 21,486.10 | 44,295.06 | ||

| solid waste discharge (S) | 285 | 0.00 | 619.00 | 43.25 | 92.80 | ||

| Industry | Input Indexes | Output Indexes | |||||

|---|---|---|---|---|---|---|---|

| Desirable Output | Undesirable Output | ||||||

| Comprehensive Energy Consumption | Annual Average Number of Employees | The Net Fixed Assets | Main Business Income | Wastewater Discharge | Exhaust Gas Discharge | Solid Waste Discharge | |

| B06 | 9258.86 | 463.84 | 7756.84 | 16,104.90 | 90,322.20 | 2125.81 | 281.32 |

| B07 | 4048.97 | 86.16 | 7901.38 | 8030.21 | 10,344.20 | 1106.69 | 1.11 |

| B08 | 1309.52 | 51.00 | 1171.85 | 4161.91 | 17,101.60 | 1864.21 | 103.75 |

| B09 | 875.28 | 49.12 | 855.74 | 3059.66 | 39,491.67 | 620.85 | 123.51 |

| C15 | 1140.35 | 117.92 | 2278.40 | 7819.24 | 58,747.00 | 1732.85 | 4.24 |

| C17 | 5753.66 | 554.52 | 5189.89 | 21,585.97 | 195,976.53 | 3029.13 | 5.26 |

| C18 | 687.69 | 387.33 | 1623.90 | 10,315.47 | 12,887.13 | 241.07 | 0.37 |

| C19 | 407.26 | 242.74 | 883.64 | 6733.85 | 20,608.47 | 278.81 | 0.44 |

| C22 | 3616.54 | 136.18 | 3089.79 | 7639.16 | 343,278.07 | 6134.15 | 10.34 |

| C25 | 14,535.07 | 80.98 | 5100.68 | 22,405.61 | 69,537.00 | 14,223.19 | 38.93 |

| C26 | 30,103.96 | 406.31 | 12,487.87 | 39,013.73 | 302,891.07 | 23,719.17 | 37.26 |

| C27 | 1463.04 | 156.36 | 2816.14 | 10,277.77 | 46,407.87 | 1908.18 | 2.12 |

| C28 | 1642.98 | 43.30 | 1359.89 | 4169.99 | 45,569.53 | 2661.06 | 1.77 |

| C29 | 3079.08 | 296.54 | 3615.71 | 15,117.05 | 10,872.33 | 2042.61 | 6.46 |

| C30 | 25,088.25 | 482.43 | 8689.09 | 25,505.22 | 36,205.40 | 80,011.65 | 44.97 |

| C31 | 47,911.09 | 321.40 | 13,493.64 | 41,030.80 | 141,051.13 | 103,341.23 | 88.78 |

| C32 | 11,198.76 | 161.57 | 5410.22 | 23,411.91 | 32,030.73 | 21,727.91 | 24.27 |

| C33 | 3053.99 | 283.38 | 3346.63 | 16,590.91 | 25,962.67 | 2966.74 | 3.40 |

| D44 | 19,559.18 | 261.27 | 38,979.63 | 32,172.27 | 170,055.33 | 138,500.55 | 43.51 |

| 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B06 | 0.124 | 0.148 | 0.164 | 0.210 | 0.269 | 0.276 | 0.291 | 0.379 | 0.387 | 0.450 | 1.000 | 0.581 | 0.402 | 0.407 | 0.320 |

| B07 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| B08 | 0.236 | 0.250 | 0.326 | 0.346 | 0.427 | 0.445 | 0.502 | 0.659 | 0.721 | 1.000 | 1.000 | 1.000 | 1.000 | 0.765 | 0.594 |

| B09 | 0.277 | 0.289 | 0.338 | 0.425 | 0.522 | 0.667 | 0.601 | 0.631 | 1.000 | 1.000 | 1.000 | 0.663 | 1.000 | 0.655 | 1.000 |

| C15 | 1.000 | 1.000 | 1.000 | 0.815 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| C17 | 0.396 | 0.507 | 1.000 | 0.488 | 0.549 | 0.585 | 0.571 | 0.529 | 0.585 | 0.665 | 1.000 | 0.702 | 1.000 | 1.000 | 1.000 |

| C18 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| C19 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| C22 | 0.398 | 0.424 | 1.000 | 0.389 | 0.441 | 0.445 | 0.451 | 0.462 | 0.452 | 0.487 | 0.510 | 0.479 | 0.452 | 0.451 | 0.469 |

| C25 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| C26 | 0.445 | 0.477 | 0.695 | 0.531 | 0.463 | 0.461 | 0.564 | 0.688 | 0.568 | 0.544 | 0.572 | 0.567 | 0.551 | 0.549 | 0.760 |

| C27 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| C28 | 0.534 | 0.654 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.825 | 0.779 | 1.000 |

| C29 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| C30 | 0.272 | 0.298 | 0.330 | 0.295 | 0.271 | 0.291 | 0.318 | 0.404 | 0.471 | 0.478 | 0.485 | 0.437 | 1.000 | 0.519 | 0.535 |

| C31 | 0.342 | 0.366 | 0.689 | 0.530 | 0.462 | 0.412 | 0.604 | 1.000 | 0.525 | 0.552 | 0.515 | 0.475 | 0.453 | 0.529 | 0.501 |

| C32 | 0.521 | 0.547 | 1.000 | 0.665 | 0.743 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| C33 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| D44 | 0.579 | 0.631 | 0.633 | 0.593 | 0.528 | 0.451 | 0.469 | 0.413 | 0.535 | 0.407 | 1.000 | 1.000 | 0.420 | 0.506 | 0.518 |

| Group | Specific Industry | Mean Environmental Efficiency |

|---|---|---|

| High Environmental Efficiency Group | Extraction of Petroleum and Natural Gas (B07); Manufacture of Textile, Wearing Apparel and Accessories (C18); Manufacture of Leather, Fur, Feather and Related Products and Footwear (C19); Processing of Petroleum, Coking and Processing of Nuclear Fuel (C25); Manufacture of Medicines (C27); Manufacture of Rubber and Plastics Products (C29); Manufacture of Metal Products (C33) | 1.000 |

| Middle Environmental Efficiency Group | Manufacture of Liquor, Beverages and Refined Tea (C15); Manufacture of Chemical Fibres (C28); Smelting and Pressing of Non-ferrous Metals (C32); Manufacture of Textile (C17); Mining and Processing of Non-Ferrous Metal Ores (B09); Mining and Processing of Ferrous Metal Ores (B08) | 0.800 |

| Low Environmental Efficiency Group | Production and Supply of Electric Power and Heat Power (D44); Manufacture of Raw Chemical Materials and Chemical Products (C26); Smelting and Pressing of Ferrous Metals (C31); Manufacture of Paper and Paper Products (C22); Manufacture of Non-metallic Mineral Products (C30); Mining and Washing of Coal (B06) | 0.491 |

| Year | Catch-Up | Frontier | MI |

|---|---|---|---|

| 2001–2002 | 1.028 | 1.083 | 1.112 |

| 2002–2003 | 1.054 | 1.175 | 1.235 |

| 2003–2004 | 1.081 | 1.116 | 1.205 |

| 2004–2005 | 1.043 | 1.254 | 1.302 |

| 2005–2006 | 1.007 | 1.164 | 1.170 |

| 2006–2007 | 1.018 | 1.158 | 1.178 |

| 2007–2008 | 1.020 | 1.132 | 1.152 |

| 2008–2009 | 1.044 | 0.983 | 1.016 |

| 2009–2010 | 0.998 | 1.211 | 1.204 |

| 2010–2011 | 0.992 | 1.198 | 1.187 |

| 2011–2012 | 1.001 | 1.047 | 1.047 |

| 2012–2013 | 1.000 | 0.985 | 0.985 |

| 2013–2014 | 0.985 | 1.014 | 0.997 |

| 2014–2015 | 0.998 | 0.983 | 0.981 |

| Industry | Catch-Up | Frontier | Malmquist |

|---|---|---|---|

| B07 | 0.982 | 1.146 | 1.140 |

| C18 | 1.008 | 1.106 | 1.112 |

| C19 | 1.000 | 1.074 | 1.075 |

| C25 | 0.974 | 1.101 | 1.073 |

| C27 | 1.000 | 1.117 | 1.117 |

| C29 | 1.000 | 1.111 | 1.111 |

| C33 | 1.004 | 1.089 | 1.094 |

| High Environmental Efficiency Group | 0.996 | 1.106 | 1.103 |

| C15 | 0.999 | 1.129 | 1.127 |

| C28 | 1.041 | 1.107 | 1.155 |

| C32 | 1.050 | 1.110 | 1.156 |

| C17 | 1.033 | 1.097 | 1.133 |

| B09 | 1.061 | 1.111 | 1.179 |

| B08 | 1.064 | 1.093 | 1.167 |

| Middle Environmental Efficiency Group | 1.042 | 1.108 | 1.153 |

| D44 | 1.003 | 1.184 | 1.167 |

| C26 | 1.019 | 1.089 | 1.100 |

| C31 | 1.018 | 1.085 | 1.101 |

| C22 | 1.008 | 1.113 | 1.121 |

| C30 | 1.040 | 1.085 | 1.115 |

| B06 | 1.060 | 1.093 | 1.161 |

| Low Environmental Efficiency Group | 1.024 | 1.108 | 1.128 |

| Average | 1.019 | 1.107 | 1.127 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Jiang, Y.; Guo, X.; Jiang, L. Environmental Efficiency Assessment of Heavy Pollution Industry by Data Envelopment Analysis and Malmquist Index Analysis: Empirical Evidence from China. Int. J. Environ. Res. Public Health 2021, 18, 5761. https://doi.org/10.3390/ijerph18115761

Xu J, Jiang Y, Guo X, Jiang L. Environmental Efficiency Assessment of Heavy Pollution Industry by Data Envelopment Analysis and Malmquist Index Analysis: Empirical Evidence from China. International Journal of Environmental Research and Public Health. 2021; 18(11):5761. https://doi.org/10.3390/ijerph18115761

Chicago/Turabian StyleXu, Jun, Yuchen Jiang, Xin Guo, and Li Jiang. 2021. "Environmental Efficiency Assessment of Heavy Pollution Industry by Data Envelopment Analysis and Malmquist Index Analysis: Empirical Evidence from China" International Journal of Environmental Research and Public Health 18, no. 11: 5761. https://doi.org/10.3390/ijerph18115761

APA StyleXu, J., Jiang, Y., Guo, X., & Jiang, L. (2021). Environmental Efficiency Assessment of Heavy Pollution Industry by Data Envelopment Analysis and Malmquist Index Analysis: Empirical Evidence from China. International Journal of Environmental Research and Public Health, 18(11), 5761. https://doi.org/10.3390/ijerph18115761