Maltitol: Analytical Determination Methods, Applications in the Food Industry, Metabolism and Health Impacts

Abstract

1. Introduction

2. Analytical Methods for Maltitol Determination

3. Applications in the Food Industry and Safety

4. Metabolism

5. Impacts on Health

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ding, S.; Peng, B.; Li, Y.; Yang, J. Evaluation of specific volume, texture, thermal features, water mobility, and inhibitory effect of staling in wheat bread affected by maltitol. Food Chem. 2019, 283, 123–130. [Google Scholar] [CrossRef]

- Rozzi, N.L. Sweet Facts about Maltitol. Food Prod. Des. 2007, 17, 10. [Google Scholar]

- Thabuis, C.; Rodriguez, B.; Gala, T.; Salvi, A.; Parashuraman, M.; Wils, D.; Guerin-Deremaux, L. Evaluation of glycemic and insulinemic responses of maltitol in Indian healthy volunteers. Int. J. Diabetes Dev. Ctries. 2015, 35, 482–487. [Google Scholar] [CrossRef]

- Kearsley, M.W.; Deis, R.C. Maltitol powder. In Sweeteners and Sugar Alternatives in Food Technology, 2nd ed.; O’Donnell, K., Kearsley, M.W., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2012; pp. 295–308. [Google Scholar]

- Livesey, G. Glycaemic responses and toleration. In Sweeteners and Sugar Alternatives in Food Technology, 2nd ed.; O’Donnell, K., Kearsley, M.W., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2012; pp. 3–26. [Google Scholar]

- Livesey, G. Health potential of polyols as sugar replacers, with emphasis on low glycaemic properties. Nutr. Res. Rev. 2003, 16, 163–191. [Google Scholar] [CrossRef] [PubMed]

- Matsuo, T. Lactic acid production from sugar alcohol, maltitol and lactitol, in human whole saliva. Shigaku 1973, 60, 760. [Google Scholar]

- Oku, T.; Akiba, M.; Lee, M.H.; Moon, S.J.; Hosoya, N. Metabolic fate of ingested [14C]-maltitol in man. J. Nutr. Sci. Vitaminol. 1991, 37, 529–544. [Google Scholar] [CrossRef]

- Koutsou, G.A.; Storey, D.M.; Lee, A.; Zumbe, A.; Flourie, B.; LeBot, Y.; Olivier, P. Dose-related gastrointestinal response to the ingestion of either isomalt, lactitol or maltitol in milk chocolate. Eur. J. Clin. Nutr. 1996, 50, 17. [Google Scholar]

- Ruskone-Fourmestraux, A.; Attar, A.; Chassard, D.; Coffin, B.; Bornet, F.; Bouhnik, Y. A digestive tolerance study of maltitol after occasional and regular consumption in healthy humans. Eur. J. Clin. Nutr. 2003, 57, 26–30. [Google Scholar] [CrossRef] [PubMed]

- Storey, D.M.; Koutsou, G.A.; Lee, A.; Zumbe, A.; Olivier, P.; Le Bot, Y.; Flourie, B. Tolerance and breath hydrogen excretion following ingestion of maltitol incorporated at two levels into milk chocolate consumed by healthy young adults with and without fasting. J. Nutr. 1998, 128, 587–592. [Google Scholar] [CrossRef][Green Version]

- Thabuis, C.; Cazaubiel, M.; Pichelin, M.; Wils, D.; Guerin-Deremaux, L. Short-term digestive tolerance of chocolate formulated with maltitol in children. Int. J. Food Sci. Nutr. 2010, 61, 728–738. [Google Scholar] [CrossRef]

- Imfeld, T.N. Clinical caries studies with polyalcohols. A literature review. Schweiz. Monatsschr. Zahnmed. 1994, 104, 941–945. [Google Scholar] [PubMed]

- Ito, I.; Ito, A.; Unezaki, S. Preparation and evaluation of gelling granules to improve oral administration. Drug Discov. Ther. 2015, 9, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Portmann, M.O.; Kilcast, D. Psychophysical characterization of new sweeteners of commercial importance for the EC food industry. Food Chem. 1996, 56, 291–302. [Google Scholar] [CrossRef]

- Lee, A.; Wils, D.; Zumbe, A.; Storey, D.M. The comparative gastrointestinal responses of children and adults following consumption of sweets formulated with sucrose, isomalt and lycasin HBC. Eur. J. Clin. Nutr. 2002, 56, 755–764. [Google Scholar] [CrossRef][Green Version]

- Beards, E.; Tuohy, K.; Gibson, G. A human volunteer study to assess the impact of confectionery sweeteners on the gut microbiota composition. Br. J. Nutr. 2010, 104, 701–708. [Google Scholar] [CrossRef]

- Thabuis, C.; Herbomez, A.C.; Desailly, F.; Ringard, F.; Wils, D.; Guérin-Deremaux, L. Prebiotic-like effects of SweetPearl® Maltitol through changes in caecal and fecal parameters. Food Nutr. Sci. 2012, 3, 1375. [Google Scholar] [CrossRef]

- Shah, R.; de Jager, L.S. Recent analytical methods for the analysis of sweeteners in food: A regulatory perspective. Food Drug Adm. Papers. 2017, 5, 13–32. [Google Scholar]

- Kokotou, M.G.; Asimakopoulos, A.G.; Thomaidis, N.S. Sweeteners. In Food Analysis by HPLC; Nollet, L.M.L., Toldrá, F., Eds.; CRC Press: Boca Raton, FL, USA, 2012; pp. 493–513. [Google Scholar]

- Nikoleli, G.-P.; Nikolelis, D.P. Low Calorie Nonnutritive Sweeteners. In Sweeteners: Nutritional Aspects, Applications, and Production Technology; Varzakas, T., Labropoulos, A., Anestis, S., Eds.; CRC Press: Boca Raton, FL, USA, 2012; pp. 80–117. [Google Scholar]

- Kokotou, M.G.; Asimakopoulos, A.G.; Thomaidis, N.S. Intense Sweeteners. In Handbook of Food Analysis; Nollest, L.M.L., Toldrá, F., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 219–232. [Google Scholar]

- Grembecka, M. Sugar Alcohols. In Encyclopedia of Analytical Science, 3rd ed.; Worsfold, P., Poole, C., Townshend, A., Miró, M., Eds.; Elsevier: Amsterdan, The Netherlands, 2019; pp. 290–299. [Google Scholar]

- Zygler, A.; Wasik, A.; Namieśnik, J. Analytical methodologies for determination of artificial sweeteners in foodstuffs. TrAC-Trends Anal. Chem. 2009, 28, 1082–1102. [Google Scholar] [CrossRef]

- Grembecka, M.; Lebiedzińska, A.; Szefer, P. Simultaneous separation and determination of erythritol, xylitol, sorbitol, mannitol, maltitol, fructose, glucose, sucrose and maltose in food products by high performance liquid chromatography coupled to charged aerosol detector. Microchem. J. 2014, 117, 77–82. [Google Scholar] [CrossRef]

- Andersen, R.; Sørensen, A. Separation and determination of alditols and sugars by high-pH anion-exchange chromatography with pulsed amperometric detection. J. Chromatogr. A 2000, 897, 195–204. [Google Scholar] [CrossRef]

- Nojiri, S.; Taguchi, N.; Oishi, M.; Suzuki, S. Determination of sugar alcohols in confectioneries by high-performance liquid chromatography after nitrobenzoylation. J. Chromatogr. A 2000, 893, 195–200. [Google Scholar] [CrossRef]

- Otles, S.; Ozyurt, V.H. Sampling and Sample Preparation. In Handbook of Food Chemistry; Cheung, P.C.K., Mehta, B.M., Eds.; Springer: Berlin, Germany, 2015; pp. 151–164. [Google Scholar]

- Joshi, K.; Kumari, A.; Arora, S.; Singh, A.K. Development of an analytical protocol for the estimation of maltitol from yoghurt, burfi and flavoured milk. LWT-Food Sci. Technol. 2016, 70, 41–45. [Google Scholar] [CrossRef]

- Albero, B.; Sánchez-Brunete, C.; García-Valcárcel, A.I.; Pérez, R.A.; Tadeo, J.L. Ultrasound-assisted extraction of emerging contaminants from environmental samples. TrAC-Trends Anal. Chem. 2015, 71, 110–118. [Google Scholar] [CrossRef]

- Martínez Montero, C.; Rodríguez Dodero, M.C.; Guillén Sánchez, D.A.; Barroso, C.G. Analysis of low molecular weight carbohydrates in food and beverages: A review. Chromatographia 2004, 59, 15–30. [Google Scholar]

- Hadjikinova, R.; Petkova, N.; Hadjikinov, D.; Denev, P.; Hrusavov, D. Development and validation of HPLC-RID method for determination of sugars and polyols. J. Pharm. Sci. Res. 2017, 9, 1263–1269. [Google Scholar]

- Koh, D.-W.; Park, J.-W.; Lim, J.-H.; Yea, M.-J.; Bang, D.-Y. A rapid method for simultaneous quantification of 13 sugars and sugar alcohols in food products by UPLC-ELSD. Food Chem. 2018, 240, 694–700. [Google Scholar] [CrossRef] [PubMed]

- Pitsch, J.; Weghuber, J. Hydrophilic interaction chromatography coupled with charged aerosol detection for simultaneous quantitation of carbohydrates, polyols and ions in food and beverages. Molecules 2019, 24, 4333. [Google Scholar] [CrossRef]

- Cataldi, T.R.; Campa, C.; Casella, I.G.; Bufo, S.A. Determination of maltitol, isomaltitol, and lactitol by high-pH anion-exchange chromatography with pulsed amperometric detection. J. Agric. Food Chem. 1999, 47, 157–163. [Google Scholar] [CrossRef]

- Shah, R.; Farris, S.; De Jager, L.S.; Begley, T.H. A novel method for the simultaneous determination of 14 sweeteners of regulatory interest using UHPLC-MS/MS. Food Addit. Contam. Part A 2015, 32, 141–151. [Google Scholar] [CrossRef]

- Coelho, A.G.; DeJesus, D.P. A simple method for determination of erythritol, maltitol, xylitol, and sorbitol in sugar free chocolates by capillary electrophoresis with capacitively coupled contactless conductivity detection. Electrophoresis 2016, 37, 2986–2991. [Google Scholar] [CrossRef]

- Cortés-Herrera, C.; Artavia, G.; Leiva, A.; Granados-Chinchilla, F. Liquid chromatography analysis of common nutritional components, in feed and food. Foods 2019, 8, 1. [Google Scholar] [CrossRef] [PubMed]

- Sanz, M.L.; Martínez-Castro, I. Recent developments in sample preparation for chromatographic analysis of carbohydrates. J. Chromatogr. A 2007, 1153, 74–89. [Google Scholar] [CrossRef]

- Pokrzywnicka, M.; Koncki, R. Disaccharides determination: A review of analytical methods. Crit. Rev. Anal. Chem. 2018, 48, 186–213. [Google Scholar] [CrossRef] [PubMed]

- Grembecka, M. Sugar alcohols—their role in the modern world of sweeteners: A review. Eur. Food Res. Technol. 2015, 241, 1–14. [Google Scholar] [CrossRef]

- Nowak, P.M.; Woźniakiewicz, M.; Gładysz, M.; Janus, M.; Kościelniak, P. Improving repeatability of capillary electrophoresis—A critical comparison of ten different capillary inner surfaces and three criteria of peak identification. Anal. Bioanal. Chem. 2017, 409, 4383–4393. [Google Scholar] [CrossRef] [PubMed]

- Prado, M.S.A.; Steppe, M.; Tavares, M.F.M.; Kedor-Hackmann, E.R.M.; Santoro, M.I.R.M. Comparison of capillary electrophoresis and reversed-phase liquid chromatography methodologies for determination of diazepam in pharmaceutical tablets. J. Pharm. Biomed. Anal. 2005, 37, 273–279. [Google Scholar] [CrossRef] [PubMed]

- Velikinac, I.; Čudina, O.; Janković, I.; Agbaba, D.; Vladimirov, S. Comparison of capillary zone electrophoresis and high performance liquid chromatography methods for quantitative determination of ketoconazole in drug formulations. Farmaco 2004, 59, 419–424. [Google Scholar] [CrossRef]

- Food Additives. What is Maltitol (E965) in Food? Uses, Health benefits, Safety, Side Effects. Available online: https://foodadditives.net/sugar-alcohols/maltitol/ (accessed on 1 May 2020).

- Zumbe, A.; Lee, A.; Storey, D. Polyols in confectionery: The route to sugar-free, reduced sugar and reduced calorie confectionery. Br. J. Nutr. 2001, 85, S31–S45. [Google Scholar] [CrossRef]

- Ruiz-Ojeda, F.J.; Plaza-Díaz, J.; Sáez-Lara, M.J.; Gil, A. Effects of sweeteners on the gut microbiota: A review of experimental studies and clinical trials. Adv. Nutr. 2019, 10 (Suppl. 1), S31–S48. [Google Scholar] [CrossRef]

- Aidoo, R.P.; Depypere, F.; Afoakwa, E.O.; Dewettinck, K. Industrial manufacture of sugar-free chocolates–Applicability of alternative sweeteners and carbohydrate polymers as raw materials in product development. Trends Food Sci. Technol. 2013, 32, 84–96. [Google Scholar] [CrossRef]

- Son, Y.J.; Choi, S.Y.; Yoo, K.M.; Lee, K.W.; Lee, S.M.; Hwang, I.K.; Kim, S. Anti-blooming effect of maltitol and tagatose as sugar substitutes for chocolate making. LWT-Food Sci. Technol. 2018, 88, 87–94. [Google Scholar] [CrossRef]

- Pirouzian, H.R.; Peighambardoust, S.H.; Azadmard-Damirchi, S. Rheological properties of sugarfree milk chocolate: Comparative study and optimisation. Czech J. Food Sci. 2017, 35, 440–448. [Google Scholar]

- Dobreva, V.; Hadjikinova, M.; Slavov, A.; Hadjikinov, D.; Dobrev, G.; Zhekova, B. Functional properties of maltitol. Agric. Sci. Technol. 2013, 5, 168–172. [Google Scholar]

- Whelan, A.P.; Vega, C.; Kerry, J.P.; Goff, H.D. Physicochemical and sensory optimisation of a low glycemic index ice cream formulation. Int. J. Food Sci. Technol. 2008, 43, 1520–1527. [Google Scholar] [CrossRef]

- Flambeau, M.; Respondek, F.; Wagner, A. Maltitol syrups. In Sweeteners and Sugar Alternatives in Food Technology, 2nd ed.; O’Donnell, K., Kearsley, M.W., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2012; pp. 309–330. [Google Scholar]

- Hadjikinova, R.; Stankov, S.; Popova, V.; Ivanova, T.; Stoyanova, A.; Mazova, N.; Marudova, M.; Damyanova, S. Physicochemical and textural properties of reduced sugar jellies from Physalis peruviana L. fruit. Ukr. Food J. 2019, 8, 560–570. [Google Scholar] [CrossRef]

- EFSA. Call for Technical and Toxicological Data on Sweeteners Authorised as Food Additives in the EU. June 2017. Available online: https://www.efsa.europa.eu/sites/default/files/engage/170621.pdf (accessed on 1 May 2020).

- Petković, M. Alternatives for Sugar Replacement in Food Technology: Formulating and Processing Key Aspects. In Food Engineering, 1st ed.; Coldea, T.E., Ed.; IntechOpen, Ltd.: London, UK, 2019. [Google Scholar] [CrossRef]

- Keijser, B.J.; van den Broek, T.J.; Slot, D.E.; van Twillert, L.; Kool, J.; Thabuis, C.; Ossendrijver, M.; van der Weijden, F.A.; Montijn, R.C. The impact of maltitol-sweetened chewing gum on the dental plaque biofilm microbiota composition. Front. Microbiol. 2018, 9, 381. [Google Scholar] [CrossRef]

- Mooradian, A.D.; Smith, M.; Tokuda, M. The role of artificial and natural sweeteners in reducing the consumption of table sugar: A narrative review. Clin. Nutr. ESPEN 2017, 18, 1–8. [Google Scholar] [CrossRef]

- Theka, T.; Rodgers, A. Glycaemia and phosphatemia after oral glucose and maltitol ingestion in subjects from two different race groups: Preliminary evidence of inter-race differences in metabolism and possible implications for urinary stone disease. Int. Urol. Nephrol. 2017, 49, 1369–1374. [Google Scholar] [CrossRef]

- Deo, P.N.; Deshmukh, R. Oral microbiome: Unveiling the fundamentals. J. Oral Maxillofac. Pathol. 2019, 23, 122. [Google Scholar]

- Huttenhower, C.; Gevers, D.; Knight, R.; Abubucker, S.; Badger, J.H.; Chinwalla, A.T.; Creasy, H.H.; Earl, A.M.; FitzGerald, M.G.; Fulton, R.S.; et al. Structure, function and diversity of the healthy human microbiome. Nature 2012, 486, 207. [Google Scholar]

- Segata, N.; Waldron, L.; Ballarini, A.; Narasimhan, V.; Jousson, O.; Huttenhower, C. Metagenomic microbial community profiling using unique clade-specific marker genes. Nat. Methods 2012, 9, 811. [Google Scholar] [CrossRef]

- Widowati, W.; Akbar, S.H.; Tin, M.H. Saliva pH Changes in Patients with High and Low Caries Risk After Consuming Organic (Sucrose) and Non-Organic (Maltitol) Sugar. Int. Med. J. Malays. 2013, 12. [Google Scholar]

- Sardana, V.; Balappanavar, A.Y.; Patil, G.B.; Kulkarni, N.; Sagari, S.G.; Gupta, K.D. Impact of a modified carbonated beverage on human dental plaque and salivary pH: An in vivo study. J. Indian Soc. Pedod. Prev. Dent. 2012, 30, 7. [Google Scholar] [PubMed]

- Maguire, A.; Rugg-Gunn, J.; Wright, G. Adaptation of dental plaque to metabolise maltitol compared with other sweeteners. J. Dent. 2000, 28, 51–59. [Google Scholar] [CrossRef]

- Wolff, M.S.; Larson, C. The cariogenic dental biofilm: Good, bad or just something to control? Braz. Oral Res. 2009, 23, 31–38. [Google Scholar] [CrossRef] [PubMed]

- Thabuis, C.; Cheng, C.Y.; Wang, X.; Pochat, M.; Han, A.; Miller, L.; Wils, D.; Guerin-Deremaux, L. Effects of maltitol and xylitol chewing-gums on parameters involved in dental caries development. Eur. J. Paediatr. Dent. 2013, 14, 303–308. [Google Scholar]

- Söderling, E.; Hirvonen, A.; Karjalainen, S.; Fontana, M.; Catt, D.; Seppä, L. The effect of xylitol on the composition of the oral flora: A pilot study. Eur. J. Dent. 2011, 5, 24–31. [Google Scholar] [CrossRef]

- Haghgoo, R.; Afshari, E.; Ghanaat, T.; Aghazadeh, S. Comparing the efficacy of xylitol-containing and conventional chewing gums in reducing salivary counts of Streptococcus mutans: An in vivo study. J. Int. Soc. Prev. Community Dent. 2015, 5 (Suppl. 2), S112. [Google Scholar]

- Mäkinen, K.K. Gastrointestinal disturbances associated with the consumption of sugar alcohols with special consideration of Xylitol: Scientific review and instructions for dentists and other health-care professionals. Int. J. Dent. 2016, 2016, 5967907. [Google Scholar] [CrossRef]

- Trahan, L.; Bourgeau, G.; Breton, R. Emergence of multiple xylitol-resistant (fructose PTS-) mutants from human isolates of mutans streptococci during growth on dietary sugars in the presence of xylitol. J. Dent. Res. 1996, 75, 1892–1900. [Google Scholar] [CrossRef]

- Miyasawa-Hori, H.; Aizawa, S.; Takahashi, N. Difference in the xylitol sensitivity of acid production among Streptococcus mutans strains and the biochemical mechanism. Oral Microbiol. Immunol. 2006, 21, 201–205. [Google Scholar] [CrossRef] [PubMed]

- Grabitske, H.A.; Slavin, J.L. Gastrointestinal effects of low-digestible carbohydrates. Crit. Rev. Food Sci. Nutr. 2009, 49, 327–360. [Google Scholar] [CrossRef] [PubMed]

- Beaugerie, L.; Flourié, B.; Marteau, P.; Pellier, P.; Franchisseur, C.; Rambaud, J.C. Digestion and absorption in the human intestine of three sugar alcohols. Gastroenterology 1990, 99, 717–723. [Google Scholar] [CrossRef]

- Hammer, H.F.; Santa Ana, C.A.; Schiller, L.R.; Fordtran, J.S. Studies of osmotic diarrhea induced in normal subjects by ingestion of polyethylene glycol and lactulose. J. Clin. Investig. 1989, 84, 1056–1062. [Google Scholar] [CrossRef] [PubMed]

- Stone-Dorshow, T.; Levitt, M.D. Gaseous response to ingestion of a poorly absorbed fructo-oligosaccharide sweetener. Am. J. Clin. Nutr. 1987, 46, 61–65. [Google Scholar] [CrossRef]

- Hosoya, N. Effect of sugar alcohols on the intestine. In Chàvez, Bourges, Basta, Nutrition. Proc. 9th Int. Congr. Nutr., Mexico 1972; Vol. 1: Review of basic knowledge; Karger: Basel, Switzerland, 1975; pp. 164–168. [Google Scholar]

- Rennhard, H.H.; Bianchine, J.R. Metabolism and caloric utilization of orally administered carbon-14-labeled maltitol in rat, dog, and man. J. Agric. Food Chem. 1976, 24, 287–291. [Google Scholar] [CrossRef]

- Nishimura, N.; Tanabe, H.; Sasaki, Y.; Makita, Y.; Ohata, M.; Yokoyama, S.; Asano, M.; Yamamoto, T.; Kiriyama, S. Pectin and high-amylose maize starch increase caecal hydrogen production and relieve hepatic ischaemia–reperfusion injury in rats. Br. J. Nutr. 2012, 107, 485–492. [Google Scholar] [CrossRef]

- Tanabe, H.; Sasaki, Y.; Yamamoto, T.; Kiriyama, S.; Nishimura, N. Suppressive effect of high hydrogen generating high amylose cornstarch on subacute hepatic ischemia-reperfusion injury in rats. Biosci. Microbiota Food Health 2012, 31, 103–108. [Google Scholar] [CrossRef][Green Version]

- Nishimura, N.; Tanabe, H.; Adachi, M.; Yamamoto, T.; Fukushima, M. Colonic hydrogen generated from fructan diffuses into the abdominal cavity and reduces adipose mRNA abundance of cytokines in rats. J. Nutr. 2013, 143, 1943–1949. [Google Scholar] [CrossRef]

- Hanefeld, M.; Cagatay, M.; Petrowitsch, T.; Neuser, D.; Petzinna, D.; Rupp, M. Acarbose reduces the risk for myocardial infarction in type 2 diabetic patients: Meta-analysis of seven long-term studies. Eur. Heart J. 2004, 25, 10–16. [Google Scholar] [CrossRef]

- Lupton, J.R.; Brooks, J.A.; Butte, N.F.; Caballero, B.; Flatt, J.P.; Fried, S.K. Dietary Reference Intakes for Energy, Carbohydrate, Fiber, Fat, Fatty Acids, Cholesterol, Protein, and Amino Acids; National Academy Press: Washington, DC, USA, 2002; pp. 589–768. [Google Scholar]

- Matsumoto, M.; Fujita, A.; Yamashita, A.; Kameoka, S.; Shimomura, Y.; Kitada, Y.; Tamada, H.; Nakamura, S.; Tsubota, K. Effects of functional milk containing galactooligosaccharide, maltitol, and glucomannan on the production of hydrogen gas in the human intestine. J. Funct. Foods 2017, 35, 13–23. [Google Scholar] [CrossRef]

- Joint, F.A.O. WHO Expert Committee on Food Additives, & World Health Organization (JECFA). In Evaluation of Certain Food Additives: Twenty-Fourth Report of the Joint FAO; World Health Organization: Geneva, Switzerland, 1980. [Google Scholar]

- Joint, F.A.O. WHO Expert Committee on Food Additives, & World Health Organization (JECFA). In Proceedings of the Toxicological evaluation of certain food additives and contaminants/prepared by the 29th meeting of the Joint FAO/WHO Expert Committee on Food Additives, Geneva, Switzerland, 3–12 June 1985. [Google Scholar]

- Joint, F.A.O. WHO Expert Committee on Food Additives, & World Health Organization (JECFA). In Evaluation of Certain Food Additives Food Additives, Forty-Ninth Report of the Joint fao/WHO Expert Committee on Food Additives; WHO Technical Report Series; World Health Organization: Geneva, Switzerland, 1999; p. 884. [Google Scholar]

- Awuchi, C.G.; Echeta, K.C. Current Developments in Sugar Alcohols: Chemistry. Nutrition, and Health Concerns of Sorbitol, Xylitol, Glycerol, Arabitol, Inositol, Maltitol, and Lactitol. Int. J. Adv. Acad. Res. 2019, 5, 1–33. [Google Scholar]

- Carocho, M.; Morales, P.; Ferreira, I.C. Sweeteners as food additives in the XXI century: A review of what is known, and what is to come. Food Chem. Toxicol. 2017, 107, 302–317. [Google Scholar] [CrossRef] [PubMed]

- Washburn, C.; Christensen, N. Sugar Substitutes: Artificial Sweeteners and Sugar Alcohols; Cooperative extension of Utah State University: Logan, UT, USA, 2012. [Google Scholar]

- Lee, E.J.; Jin, B.H.; Paik, D.I.; Hwang, I.K. Preventive effect of sugar-free chewing gum containing maltitol on dental caries in situ. Food Sci. Biotechnol. 2009, 18, 432–435. [Google Scholar]

- Van Loveren, C. Sugar alcohols: What is the evidence for caries-preventive and caries-therapeutic effects? Caries Res. 2004, 38, 286–293. [Google Scholar] [CrossRef]

- Izumitani, A.; Fujiwara, T.; Minami, T.; Suzuki, S.; Ooshima, T.; Sobue, S. Non-cariogenicity of maltitol in vitro and animal experiments. Shoni Shikagaku Zasshi 1989, 27, 1018–1024. [Google Scholar]

- Ooshima, T.; Izumitani, A.; Minami, T.; Yoshida, T.; Sobue, S.; Fujiwara, T.; Hamada, S. Noncariogenicity of maltitol in specific pathogen-free rats infected with mutans streptococci. Caries Res. 1992, 26, 33–37. [Google Scholar] [CrossRef]

- Li, X.J.; Zhong, B.; Xu, H.X.; Yi, M.; Wang, X.P. Comparative effects of the maltitol chewing gums on reducing plaque. Huaxi Kouqiang Yixue Zazhi 2010, 28, 502–504. [Google Scholar]

- Keukenmeester, R.S.; Slot, D.E.; Rosema, N.A.M.; Van Loveren, C.; Van der Weijden, G.A. Effects of sugar-free chewing gum sweetened with xylitol or maltitol on the development of gingivitis and plaque: A randomized clinical trial. Int. J. Dent. Hyg. 2014, 12, 238–244. [Google Scholar] [CrossRef]

- Matsuo, T. Estimation of glycemic response to maltitol and mixture of maltitol and sucrose in healthy young subjects. Tech. Bull. Fac. Kagawa Univ. 2003, 55, 57–61. [Google Scholar]

- Quílez, J.; Bullo, M.; Salas-Salvadó, J. Improved postprandial response and feeling of satiety after consumption of low-calorie muffins with maltitol and high-amylose corn starch. J. Food Sci. 2007, 72, S407–S411. [Google Scholar] [CrossRef] [PubMed]

- Secchi, A.; Pontiroli, A.E.; Cammelli, L.; Bizzi, A.; Cini, M.; Pozza, G. Effects of oral administration of maltitol on plasma glucose, plasma sorbitol, and serum insulin levels in man. Klin. Wochenschr. 1986, 64, 265–269. [Google Scholar] [CrossRef] [PubMed]

- Wheeler, M.L.; Fineberg, S.E.; Gibson, R.; Fineberg, N. Metabolic response to oral challenge of hydrogenated starch hydrolysate versus glucose in diabetes. Diabetes Care 1990, 13, 733–740. [Google Scholar] [CrossRef] [PubMed]

- Mimura, G.; Koga, T.; Oshikawa, K.; Kido, S.; Sadanaga, T.; Jinnouchi, T.; Kawaguchi, K.; Mori, N. Maltitol tests with diabetics. Jpn. J. Nutr. Diet. 1972, 30, 145–152. [Google Scholar] [CrossRef][Green Version]

- Vessby, B.; Karlstrom, B.; Skarfors, E. Comparison of the effects of maltitol with those of sucrose, fructose and sorbitol on blood glucose and serum insulin concentrations in healthy and non-insulin dependent diabetic subjects: Studies after an oral load and after addition to a standard breakfast meal. Diabetes Nutr. Metab. Clin. Exp. 1990, 3, 231–237. [Google Scholar]

- Moon, S.; Lee, M.; Huh, K.; Lee, K. Effects of maltitol on blood glucose and insulin responses in normal and diabetic subjects. Korean J. Nutr. 1990, 23, 270–278. [Google Scholar]

- Kang, Y.R.; Jo, S.H.; Yoo, J.I.; Cho, J.B.; Kim, E.J.; Apostolidis, E.; Kwon, Y.I. Anti-hyperglycemic effect of selected sugar alcohols (829.32). FASEB J. 2014, 28 (Suppl. 1), 829–832. [Google Scholar]

- Chukwuma, C.I.; Ibrahim, M.A.; Islam, M.S. Maltitol inhibits small intestinal glucose absorption and increases insulin mediated muscle glucose uptake ex vivo but not in normal and type 2 diabetic rats. Int. J. Food Sci. Nutr. 2017, 68, 73–81. [Google Scholar] [CrossRef]

- Rider, A.K.; Schedl, H.P.; Nokes, G.; Shining, S. Small intestinal glucose transport: Proximal-distal kinetic gradients. J. Gen. Physiol. 1967, 50, 1173–1182. [Google Scholar] [CrossRef]

- Levin, R. Digestion and absorption of carbohydrate from embryo to adult. In Digestion in the Fowl, 1st ed.; Boorman, R.N., Freeman, B.M., Eds.; British Poultry Science Ltd.: Edinburgh, UK, 1976; pp. 63–116. [Google Scholar]

- Cohen, M.I.; Mcnamara, H.; Finberg, L. Intestinal osmolality and carbohydrate absorption in rats treated with polymerized glucose. Pediatr. Res. 1978, 12, 24–26. [Google Scholar] [CrossRef][Green Version]

- Kamoi, M. Study on metabolism of maltitol Part 1: Fundamental experiment. J. Jpn. Diab. Soc. 1975, 18, 243–249. [Google Scholar]

- Lian-Loh, R.; Birch, G.G.; Coates, M.E. The metabolism of maltitol in the rat. Br. J. Nutr. 1982, 48, 477–481. [Google Scholar] [CrossRef] [PubMed]

- Salminen, E.; Salminen, S.; Porkka, L.; Koivistoinen, P. The effects of xylitol on gastric emptying and secretion of gastric inhibitory polypeptide in the rat. J. Nutr. 1984, 114, 2201–2203. [Google Scholar] [CrossRef] [PubMed]

- Shafer, R.B.; Levine, A.S.; Marlette, J.M.; Morley, J.E. Effects of xylitol on gastric emptying and food intake. Am. J. Clin. Nutr. 1987, 45, 744–747. [Google Scholar] [CrossRef]

- Ranganath, L.; Norris, F.; Morgan, L.; Wright, J.; Marks, V. Delayed gastric emptying occurs following acarbose administration and is a further mechanism for its anti-hyperglycaemic effect. Diabetic Med. 1998, 15, 120–124. [Google Scholar] [CrossRef]

- Aronoff, S.L.; Berkowitz, K.; Shreiner, B.; Want, L. Glucose metabolism and regulation: Beyond insulin and glucagon. Diabetes Spectr. 2004, 17, 183–190. [Google Scholar] [CrossRef]

- Gual, P.; Le Marchand-Brustel, Y.; Tanti, J.F. Positive and negative regulation of glucose uptake by hyperosmotic stress. Diabetes Metab. 2003, 29, 566–575. [Google Scholar] [CrossRef]

- Takizawa, Y.; Hachiya, N. Bacterial reversion assay and micronucleus test carried out on hydrogenated glucose syrups ‘Malti-Towa’(powder) and maltitol crystal. Mutat. Res./Genet. Toxicol. 1984, 137, 133–137. [Google Scholar] [CrossRef]

- Canimoglu, S.; Rencuzogullari, E. The cytogenetic effects of food sweetener maltitol in human peripheral lymphocytes. Drug Chem. Toxicol. 2006, 29, 269–278. [Google Scholar] [CrossRef]

- Canimoglu, S.; Rencuzogullari, E. The genotoxic and teratogenic effects of maltitol in rats. Toxicol. Ind. Health 2013, 29, 935–943. [Google Scholar] [CrossRef]

- Lorenzi, M.; Cagliero, E.; Toledo, S. Glucose toxicity for human endothelial cells in culture: Delayed replication, disturbed cell cycle, and accelerated death. Diabetes 1985, 34, 621–627. [Google Scholar] [CrossRef] [PubMed]

- Rencuzogullari, E.; Tüylü, B.A.; Topaktaş, M.; Ila, H.B.; Kayraldız, A.; Arslan, M.; Diler, S.B. Genotoxicity of aspartame. Drug Chem. Toxicol. 2004, 27, 257–268. [Google Scholar] [CrossRef] [PubMed]

- Tucker, J.D.; Christensen, M.L. Effects of anticoagulants upon sister-chromatid exchanges, cell-cycle kinetics, and mitotic index in human peripheral lymphocytes. Mutat. Res. Lett. 1987, 190, 225–228. [Google Scholar] [CrossRef]

- Damasceno, D.C.; Gonçalves, M.A.; Durante, L.C.; Castro, N.C.; Moura, C.H.; Oliveira, C.B. Effects of a saccharin and cyclamate mixture on rat embryos. Vet. Hum. Toxicol. 2003, 45, 157–159. [Google Scholar] [PubMed]

| Analyte | Matrix | Technique | Sample Preparation | Mobile Phase/ Electrolyte | Column/ Capillary | Analytical Parameters | Ref. |

|---|---|---|---|---|---|---|---|

| Xylitol Meso-erythritol D-glucitol D-mannitol Maltitol Parachinit | Confectionery products | HPLC-UV (260 nm) | Extraction with 30% ethanol, followed by centrifugation, evaporation, and derivatisation with a 10% solution of p-nitro-benzoyl chloride. Excess reagent was destroyed and the sample was evaporated. The residue was dissolved in chloroform and purified in an SPE cartridge. | Acetonitrile–water (67:33) | GL Sciences stainless-steel column (250 × 4.5 mm) packed with Inertsil Ph-3 | LOD 0.1% LOQ n.a. Recovery 73.2–109.0% RSD ≤ 9.0% | [27] |

| Maltitol | Milk Burfi Yoghurts | HPLC-RI | Extraction with water under sonication for 20 min at 40 °C. Treatment with Carrez reagents to remove proteins was applied, followed by filtration (filter paper and 0.22 µm syringe filter). | Acetonitrile–water (75:25) | Waters Spherisorb Amino column (5 µm, 250 × 4.6 mm) with a guard column Waters µBondpack (10 µm NH2) | LOD 10 µg/mL LOQ 25 µg/mL Recovery 97.81–98.54% RSD ≤ 1.93% | [29] |

| Lactose Sucrose Fructose Glucose Xylitol Isomalt Sorbitol Erythritol Maltitol | Desserts | HPLC-RI | Extraction with distilled water (50 °C) in a water bath 60 °C for 15 min, precipitation with sodium hydroxide and zinc sulphate, and filtration (0.45 µm membrane filters). | Distilled water | Shodex Sugars SP0810 column (300 × 8.0 mm) with lead (II) ions and a guard column Shodex SP-G (5 μm, 50 × 6 mm) | LOD 0.01–0.17 mg/mL LOQ 0.03–0.56 mg/mL Recovery 91–109% RSD ≤ 8% | [32] |

| Fructose Sucrose Glucose Lactose Maltose Erythritol Sorbitol Xylitol Inositol Mannitol Lactitol Isomalt Maltitol | Sweets Jellies Gums Chocola1te Processed chocolate products Snacks | UPLC-ELSD | Extraction with water at 80 °C for 30 min (gums and sweets) or 50% alcohols at 80 °C for 30 min after fat removal (chocolate and processed chocolate products), centrifugation, and filtration (0.22 µm PVDF syringe filter). | Acetonitrile (eluent A) and water (eluent B) both containing 0.05% (v/v) ethanolamine and triethylamine as modifiers | Acquity BEH Amide column (1.7 μm, 150 × 2.1 mm) | LOD 0.006–0.018% LOQ 0.020–0.059% Recovery 89.13–105.32% RSD ≤ 1.55% | [33] |

| Maltose Sucrose Fructose Glucose Xylitol Sorbitol Erythritol Mannitol Maltitol | Fruit juices Fruit beverages Nectars Dietary supplements (syrups) | HPLC-CAD | Filtration (through filter paper to remove solid particles), dilution with 75% acetonitrile, and second filtration (0.45 µm membrane filters). | Water (eluent A) and acetonitrile (eluent B) | Shodex Asahipak NH2P-50 4E column (5 μm, 250 × 4.6 mm) | LOD 0.12–0.44 μg/mL LOQ 0.40–1.47 μg/mL Recovery 95.6–105% RSD ≤ 4.97% | [25] |

| Cl− K+ Br− SO42− NO3− Erythrose Arabinose Fructose Galactose Glucose Lactose Isomaltulose Maltose Lyxose Maltotriose Mannose Rhamnose Raffinose Ribose Sucrose Xylose Sorbose Erythritol Inositol Lactitol Mannitol Maltitol Xylitol Sorbitol Acarbose | Energy drinks Beer Soft drinks Wine Coffee Milk Smoothies Tea Fruit juices Ketchup Yoghurts Honey | HILIC-CAD | Dilution in 60% acetonitrile and centrifugation. Samples with gas were degassed in an ultrasonic bath prior to dilution. | 85% acetonitrile (eluent A) and 60% acetonitrile (eluent B), both with 10 mM of ammonium acetate adjusted to pH 8.25 with ammonium hydroxide | WATERS Acquity UPLC BEH Amide column (1.7 µm, 150 × 2.1 mm) and an Acquity UPLC BEH Amide VanGuard precolumn | LOD 0.032–2.675 mg/L LOQ 0.107–8.918 mg/L Recovery n.a. RSD ≤ 4.94% | [34] |

| Glucose Xylose Fructose Sucrose Lactose Sorbitol Lactitol Isomaltitol Maltitol | Biscuits Cakes Creams Toffees Chocolate Roasted malt Chicory | HPAEC-PAD | Extraction with water under sonication, centrifuged and filtered. Treatment with Carrez reagents to remove proteins and fats was applied to some products, followed by dilution and filtration (0.2 µm nylon membranes). | 40 mM of sodium hydroxide + 1 mM of barium acetate | Dionex CarboPac PA100 column (250 × 4 mm) and a guard column CarboPac PA100 column (50 × 4 mm) A gold working electrode and a silver/silver chloride reference electrode were employed. The optimal detection potential was +0.10 V. | LOD 10–20 pmol LOQ n.a. Recovery n.a. RSD ≤ 2% | [35] |

| Glucose Lactose Sucrose Maltose Xylitol Sorbitol Mannitol Lactitol Isomaltitol Maltitol | Desserts Cakes Sweets Liquorice Wine Gums Chocolate Pastilles | HPAEC-PAD | Extraction with water (60 °C) for 4 h at room temperature, centrifugation, filtration (through a folded filter S&S, 592.5, diameter = 125 mm), dilution and second filtration (0.2 µm Minisart). | 100% 1M of NaoH (eluent A) and 100% water (eluent B) | Dionex CarboPac MA1 column (250 × 4 mm) and a guard column Dionex CarboPac MA1 (50 × 4 mm) | LOD 0.3–1.1 mg/l LOQ 1–4 mg/L Recovery 85.8–107% RSD ≤ 5.2% | [26] |

| Cyclamate Saccharin Sucralose Dulcin Aspartame Neoheperidine Dihydrochalcone Acesulfame potassium Alitame Neotame Rebaudioside A Stevioside Erythritol Xylitol Maltitol | Carbonated and non-carbonated beverages Hard sweets Yoghurts | UHPLC-MS/MS | Beverages were simply diluted with water, except those containing gas, which were first sonicated to remove it. Hard sweets were dissolved in water, vortexed and diluted. Yoghurts were processed using solid phase extraction (SPE). All samples were filtered (0.20 µm membrane filters) prior to injection. | 10 mM of ammonium acetate in water/methanol (98/2, v/v) (eluent A) and 10 mM of ammonium acetate in water/methanol (1/99, v/v) (eluent B) | Waters Acquity UPLC BEH C18 column (1.7 µm, 100 × 2.1 mm) with a Vanguard pre-column (1.7 µm, 5 × 2.1 mm) | LOD 0.1–1.8 ng/mL (drinks) and 0.1–2.5 ng/g (sweets and yoghurts) LOQ n.a. Recovery 70–114% RSD ≤ 15% | [36] |

| Erythritol Xylitol Sorbitol Maltitol | Chocolate | CE-C4D | Extraction with water and ultrasound, followed by filtration (0.22 µm membrane filters) and dilution. | 25 mM of sodium borate, pH adjusted to 8.5 with boric acid | Fused silica capillary column (70 cm × 50 µm) C4D parameters were 2 V (peak to peak), 628 kHz | LOD 2.7–4.8 µg/g LOQ 9–15.9 µg/g Recovery 70–116% RSD ≤ 19% | [37] |

| Physico-Chemical Properties | Sucrose | Maltitol |

|---|---|---|

| Molecular weight | 342 | 344 |

| Sweetness | 1.0 | 0.9 |

| Solubility at 22 °C | 67% | 65% |

| Melting point (°C) | 168–170 | 144–152 |

| Heat of solution (cal/g) | 4.3 | −5.5 |

| * ERH for water uptake (20 °C) | 84% | 89% |

| Calories (kcal/g) | 4.0 | 2.4 (EU) |

| Glycaemic index (GI) | 68 | 35 |

| Molecular formula | C12H22O11 | C12H24O11 |

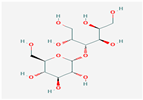

| Chemical structure |  |  |

| Food Product | Impact of the Replacement on Quality Attributes |

|---|---|

| Reduced sugar baked goods | improved taste and reduced staling |

| Chocolate powder | improved textural and sensory properties |

| Milk powder | improved rheological properties |

| Frozen dairy foods and ice cream | improved creaminess, lower glycaemic index |

| Drinkable yoghurts and flavoured milk | reduced calorific content, better texture and sweetness profile |

| Candies and hard sweets | visual appearance is maintained during thermal processing |

| Pectin jellies | lower energy value, better physicochemical properties |

| Marshmallow | fine granulometry maltitol powder and increased stability |

| Maltitol Consumption Benefits | Reference(s) |

|---|---|

| Does not reduce the saliva pH | [65] |

| Excellent relation with different ingredient of foodstuff | [29] |

| It is not fermented in the oral cavity | [66] |

| The oral cave micro-organisms cannot produce an adjustment to metabolise the maltitol | [65] |

| Possible probiotic effects | [17] |

| Produces less energy in small intestine | [17] |

| Partially hydrolysed in the stomach | [78] |

| Partially absorbed in the small intestine | [78] |

| Easily absorbed and utilised by the microbiota | [78] |

| Improvement of the H2 production by intestinal microbiomes | [84] |

| Attribute | Reference(s) |

|---|---|

| Not cariogenic | [89,90] |

| Prevents tooth decay | [6,88,91,95,96] |

| Antihyperglycaemic | [3,6,97,98,104,105] |

| Insulin-mediated glucose uptake | [105] |

| Not genotoxic | [118] |

| Not cytotoxic | [118] |

| Not teratogenic | [118] |

| Decreases foetus weight | [118] |

| Causes growth retardation at high doses (4 g/kg body weight) | [118] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saraiva, A.; Carrascosa, C.; Raheem, D.; Ramos, F.; Raposo, A. Maltitol: Analytical Determination Methods, Applications in the Food Industry, Metabolism and Health Impacts. Int. J. Environ. Res. Public Health 2020, 17, 5227. https://doi.org/10.3390/ijerph17145227

Saraiva A, Carrascosa C, Raheem D, Ramos F, Raposo A. Maltitol: Analytical Determination Methods, Applications in the Food Industry, Metabolism and Health Impacts. International Journal of Environmental Research and Public Health. 2020; 17(14):5227. https://doi.org/10.3390/ijerph17145227

Chicago/Turabian StyleSaraiva, Ariana, Conrado Carrascosa, Dele Raheem, Fernando Ramos, and António Raposo. 2020. "Maltitol: Analytical Determination Methods, Applications in the Food Industry, Metabolism and Health Impacts" International Journal of Environmental Research and Public Health 17, no. 14: 5227. https://doi.org/10.3390/ijerph17145227

APA StyleSaraiva, A., Carrascosa, C., Raheem, D., Ramos, F., & Raposo, A. (2020). Maltitol: Analytical Determination Methods, Applications in the Food Industry, Metabolism and Health Impacts. International Journal of Environmental Research and Public Health, 17(14), 5227. https://doi.org/10.3390/ijerph17145227