Abstract

Maritime safety is a significant topic in the maritime industry since the numerous dangers at sea could lead to loss of property, environmental pollution, and even casualties. Existing research illustrates that human factors are the primary reasons of maritime accidents. Indeed, numerous maritime accidents can be classified into different types of human factors. In this context, the Human Factors Analysis and Classification System for Maritime Accidents (HFACS-MA) model is introduced in this paper. The HFACS-MA framework consists of five levels, complying with the core concepts of HFACS and the guiding principles of the International Maritime Organization (IMO). Based on the five levels of the framework, this research explores the underlying causes of Chinese Eastern Star, Korean Sewol, and Thai Phoenix accidents, and a comparative analysis is conducted. The analysis demonstrates the utility of applying the HFACS-MA model to the maritime industry, and the results emphasize the importance of the following categories: legislation gaps, organizational process, inadequate supervision, communication (ships and VTS), decision errors, and so on. Consequently, the research enables increased support for HFACS-MA and its application and provides valuable information for safety management and policy development in the maritime industry at different levels.

1. Introduction

The maritime industry is the global economic lifeblood, transporting about 90% of global trade, so maritime safety is a vital factor for the sustainable development of international economics and trade [1]. The maritime industry includes several components such as crew members, maritime regulatory bodies, ships, ship owners, and classification societies, and these components have different effects on safety performance [2]. Maritime safety has always been an important aspect for the maritime industry because there are numerous dangers that can drastically lead to casualties, environmental pollution, as well as tremendous property damage [2,3,4]. According to the literature review of accident analysis in the maritime industry, most maritime accidents are caused by human errors [5,6,7]. Therefore, it is essential to understand human error and organizational factors contributing to accidents for effective management and policy development in the maritime industry [8].

The International Maritime Organization (IMO), whose intention it is to create a fair and effective regulatory framework for the maritime industry in order to decrease human errors, has issued a number of maritime conventions. The four main maritime regulatory conventions are International Convention for the Prevention of Marine Pollution from Ships (MARPOL), Convention on the International Regulations for Preventing Collisions at Sea (COLREG), International Convention on Standards of Training, Certification and Watchkeeping for Seafarers (STCW), and International Convention for Safety of Life at Sea (SOLAS) [2]. In particular, the SOLAS convention refers to numerous requirements for maritime accident prevention aiming to reduce human errors and improve safety awareness [9,10,11,12]. Furthermore, the SOLAS convention provides the minimum safety standards for the construction, machine, equipment, operation, and maintenance of ships, and hence SOLAS is regarded as the most significant convention involving the safety of ships [11]. According to the ship accident data investigated by Tzannatos and Kokotos, the number of accidents is significantly reduced after the International Safety Management (ISM) Code was implemented in 1998 [13,14]. Although the maritime authorities have adopted a set of regulations and rules to regulate safety standards, these regulations or rules are not fully effective, and consequently, maritime accidents caused by human errors continue to happen and have not yet fallen to an acceptable level [15,16]. In order to reduce maritime accidents as far as possible, it is necessary to pay attention to the types of human errors [17].

This paper takes three catastrophic maritime accidents as examples to identify different kinds of human and organizational factors in the maritime industry: the Chinese Eastern Star, the Korean Sewol, and the Thai Phoenix accidents. There are several reasons for selecting the three accidents. Firstly, all the three maritime accidents happened in recent years and resulted in loss of property and heavy casualties. Secondly, the three accidents occurred in China, Korea, and Thailand, respectively, and they are all located in the Asian region with similar social contexts. After the capsizing of Eastern Star and Sewol, several scholars conducted detailed analysis on the accident causes [18,19,20,21]. However, few researchers conducted a comparative analysis on the causes of the three major maritime accidents. Therefore, this paper discusses an in-depth analysis of the underlying causes of the three maritime accidents that happened in three different countries, attempting to explore the similarities and differences about the accident causes under the similar social context. The investigation data of this paper are based upon accident investigation reports, some news articles, and communication with relevant scholars. This study is expected to make a contribution to safety management in the maritime industry. In addition, the abbreviations involved in this paper are presented in Table 1.

Table 1.

List of abbreviations involved in this paper.

2. Brief Introduction of Eastern Star, Sewol, and Phoenix Ferry Accidents

2.1. The Eastern Star Accident in China

On 1 June 2015 (Beijing time), the Eastern Star, which is owned by the CESC, departed from Nanjing City and was sailing to Chongqing City. At 21:30, the Eastern Star encountered a squall line system accompanied by strong convective weather, tornadoes, as well as torrential rain. Influenced by strong storms, the Eastern Star capsized in a short time when the ship navigated in the Jianli waters affiliated to the Yangtze River of China. The Eastern Star is a large-scale travel ship that was initially built by the Chuandong shipyard in 1994 and renovated in 1997, 2008, and 2015, respectively. The passengers on board were mostly old people from a travel agency named Sunset Red and most of them were sleeping when the accident happened. The accident caused 442 deaths and was deemed to be the most serious maritime accident since 1949 [21]. The severe weather is recognized to be the leading cause of the accident according to the accident investigation report.

2.2. The Sewol Accident in South Korea

At 08:58 on 16 April 2014, the Sewol with 476 persons capsized on the way from Incheon port to Jeju Island, and 325 out of the 476 passengers were high school students who were going on a school trip. As an 18-year-old Japanese ship, the Sewol was purchased by the Cheonghaejin Marine Company in 2012. Subsequently, the Cheonghaejin made a series of modifications in a Korean yard to boost capacity in 2013, resulting in the Sewol’s instability [22]. When leaving the port, the Sewol loaded 2142.7 tons of cargo, which was twice the loading limit (987 tons) [20]. During the navigation, Sewol lost its balance when the inexperienced helmsman made a sharp turn. When the captain communicated with VTS for help, the captain made wrong decisions, specifically, the passengers were instructed to stay in the cabins. When the captain told passengers to evacuate, it was too late—at this time the captain and crew members abandoned the ship and fled. The accident caused 304 deaths, and most of the casualties were high school students. The disaster is recognized to be a national disaster in South Korea [18,23].

2.3. The Phoenix Accident in Thailand

On 5 July 2018, the Phoenix went to sea illegally in spite of the weather warning. At 17:45, the ship encountered a severe storm on the way back to Phuket and capsized near Coral Island, resulting in 47 deaths [24]. The severe weather was recognized to be the direct cause of the accident [25]. In addition, the crew members did not promptly remind tourists to pay attention to safety and take necessary measures, and many tourists still stayed in the cabin when the ship was about to tilt instead of running to the board, and even many passengers did not wear the lifejacket when the ship was sinking. In addition, the VTS at chalong dock did not receive the distress signal, and the location of the Phoenix disappeared from the positioning system, which may be caused by the severe storm. Moreover, the Marine Office did not take the initiative to contact the Phoenix, which delayed the accident rescue. The Phoenix ferry accident was considered to be the worst travel accident in Thailand’s history.

2.4. Overview of the Three Accidents

The overview of the three maritime accidents is presented in Table 2.

Table 2.

A brief description of the three maritime accidents.

3. Methodology

It is significant to choose an accident model because the choice of the model determines the methods of data collection, and the conclusions and the preventive measures could be different. In other words, ‘what-you-look-for’ determines ‘what-you-find’, and ‘what-you-look-for’ depends on the selected method or model employed in accident analysis [11,26]. Therefore, it is significant to select a model before conducting an accident investigation. Due to the characteristics of reliability and effectiveness, Human Factors Analysis and Classification System (HFACS) was considered to be one of the preferred models when identifying the human errors and organizational factors as soon as gathering accident information [27].

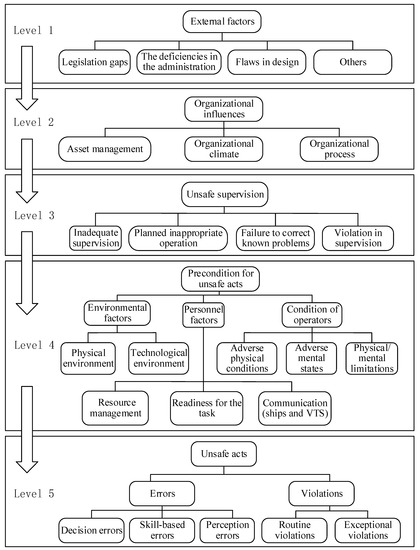

HFACS, which is recognized as an epidemiological model, enables one to analyze the visible and underlying causes [28]. In 1997, the HFACS was initially developed by Shappell and Wiegmann on the basis of the Swiss Cheese Model to investigate and analyze the data of the military aviation accidents. The HFACS was gradually applied in other domains, such as civil aviation [29,30,31], maritime industry [32,33], coal mining [34,35,36], medicine [37,38,39], construction industry [40], and railway [41]. However, when applied to other domains, the adapted HFACS model has been proposed by analysts for the purpose of adapting to the characteristics of certain domains. In the maritime domain, there exist many national rules, international agreements, and regulations to ensure the operation of maritime industry. Therefore, according to the features of maritime accidents, this research employs the Human Factors Analysis and Classification System for Maritime Accidents (HFACS-MA) framework to analyze the maritime accidents. The framework is composed of five levels, complying with the core concepts of HFACS and the guiding principles of IMO. In addition, the HFACS-MA model has wide applicability for maritime accidents, including the ship grounding, collisions, and grounding accidents; thus, HFACS-MA framework is a universal model for maritime accidents. Furthermore, HFACS-MA is not limited to management and regulatory mechanisms of countries according to the levels of the framework. Therefore, this paper adopts the HFACS-MA framework to analyze the three maritime accidents. Figure 1 presents the overview of the HFACS-MA framework, and Table 3 provides a concise description of categories involved in the five levels of the framework.

Figure 1.

The overview of the Human Factors Analysis and Classification System (HFACS-MA) framework.

Table 3.

A concise description of categories involved in the five levels of the HFACS-MA framework.

With respect to the HFACS-MA framework, some changes have been made by comparing it with the original HFACS model. Firstly, the level of external factors is added into the HFACS-MA framework to capture the contributing factors that go beyond the scope of the organizational level, the additional level follows the application of HFACS model in the mining industry and railroad industry [34,41], and is modified according to the situation of maritime industry. The external factors level is grouped into four subcategories: legislation gaps, the deficiencies in the administration, flaws in design, and others. Legislation gaps seek to identify the defects of the current rules or guidelines that provide guidance for the maritime industry and the related organizations. The Herald disaster that happened in 1987 suggested that legislation gaps were the main contributing factors for the maritime accidents [28]. The deficiencies in the administration emphasize the failures that relevant authorities fail to perform their duties to ensure the implementation of the existing rules or guidelines, and these defects are recognized to be the contributing factors of some accidents. When identifying the factors related to the weak system design, the flaws in design should be paid more attention and added to the HFACS framework [42]. These defects are often observed and are deemed as the causation factors of an accident, for instance, weak considerations for ergonomics. In addition, some factors that are illustrated in the accident investigation report are categorized as the ‘others’ subcategory since they do not belong to the categories above, for instance, an improper installation at the shipyard falls into this category. Secondly, the category of personal factors is composed of communication (ships and VTS), resource management, and readiness for the task. In the maritime industry, communication among ships and with VTS is crucial, and poor communication could result in lack of coordination [27]. Therefore, the communication (ships and VTS) is added to the HFACS-MA framework. The category of resource management is composed of teamwork, communication, and coordination. When the condition of the ship changes, the team will act accordingly and make use of relevant technical, human, and material resources to ensure voyage safety. The category of readiness for the task includes the physical or mental factors that result in failure to be ready for performing the task, for instance, drug use falls into this category.

4. Application and Discussion

In this section, the utility of applying the HFACS-MA model to the three maritime accidents is demonstrated. In order to extract the causation factors accurately, four safety experts are invited to analyze the three maritime accidents based on the HFACS-MA framework. Each safety expert needs to extract the causation factors independently according to the accident investigation report and some news articles, and an in-depth discussion about the causation factors is conducted among the four safety experts. When the causation factors are determined, they are classified into the appropriate level based on experts’ experience, and a comparative analysis is carried out. Practical implications and limitations are discussed.

4.1. Cause Analysis of the Eastern Star Accident in China

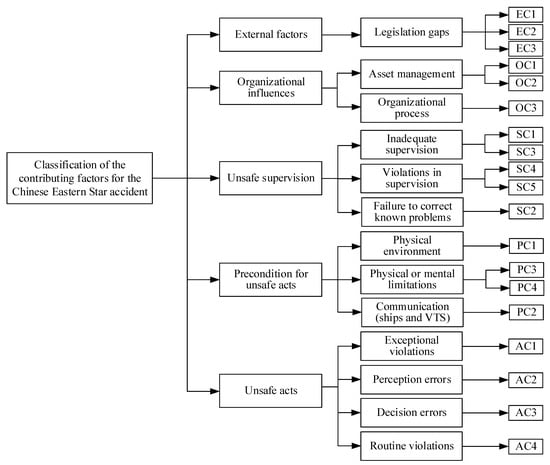

In terms of the Chinese Eastern Star accident, 19 accident causation factors are identified according to experts’ experience, and the accident causation factors are listed in Table 4. The classification of the contributing factors for the Chinese Eastern Star accident is shown in Figure 2.

Table 4.

The detailed list of the causation factors associated with the Eastern Star accident.

Figure 2.

The classification of the contributing factors for the Chinese Eastern Star accident.

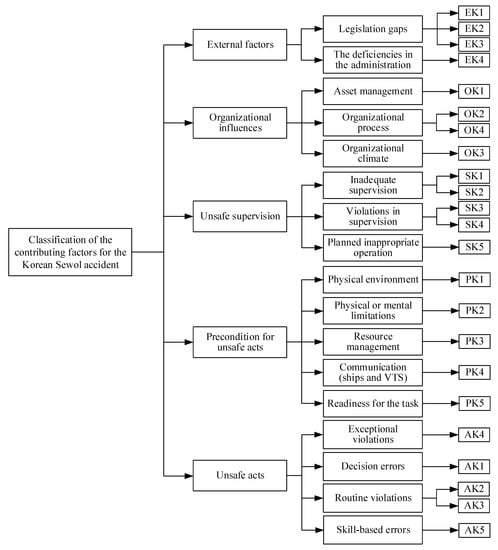

4.2. Cause Analysis of the Sewol Accident in South Korea

With respect to the Sewol accident in South Korea, the disaster is the result of neglecting safety by government, supervising authorities, Chonghaejin, and the crew members [18]. Based on the 5 levels of the HFACS-MA model, 23 causation factors of the Sewol accident are identified, as listed in Table 5, and the classification of the contributing factors for the Korean Sewol accident is presented in Figure 3.

Table 5.

The detailed list of the causation factors associated with the Sewol accident.

Figure 3.

The classification of the contributing factors for the Korean Sewol accident.

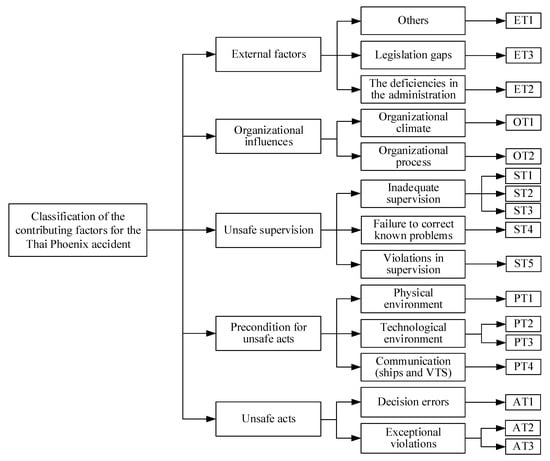

4.3. Cause Analysis of the Phoenix Accident in Thailand

Regarding the Phoenix ferry accident, 17 causation factors are identified based on the five levels of the HFACS-MA framework. Table 6 presents the detailed list of the causation factors, and the classification of the contributing factors is shown in Figure 4.

Table 6.

The detailed list of the causation factors associated with the Phoenix accident.

Figure 4.

The classification of the contributing factors for the Thai Phoenix accident.

4.4. Comparative Analysis about the Causes of Three Accidents

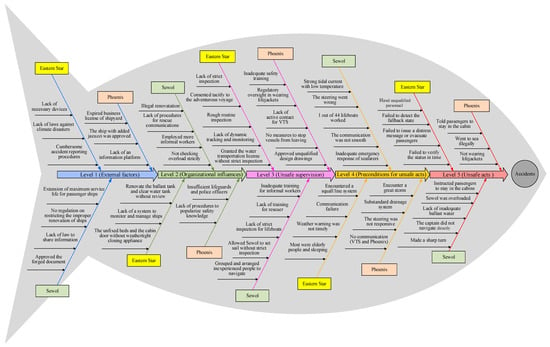

Based on the cause analysis of the three accidents using the HFACS-MA framework, comparative analysis about the causes of three accidents is conducted, and the analysis results are presented in the form of an adapted fishbone diagram, which is shown in Figure 5. In the adaptation of the fishbone diagram, the “eye” of the fish represents the occurrence of accidents, and the main bone, which is located in the diagram axis, is composed of five arrows with different colors; from the beginning of the diagram axis to the end, the five arrows are in accordance with the five levels of the HFACS model. For the fishbone diagram, we employed the causation factors of the three accidents to fill in the bones of the fish. In addition, the demographics of the causation factors associated with the three accidents are computed and presented in Table 7. In terms of the distribution of the causation factors, there exist similarities and differences in the three accidents. As seen in Table 7, the level of unsafe supervision is the most frequent level for the three accidents, followed by the level of precondition for unsafe acts and unsafe acts. In the following, we make a discussion from the five levels of the HFACS-MA framework.

Figure 5.

The adapted fishbone diagram about the contributing factors of three ferry accidents.

Table 7.

The demographic of the causation factors associated with the three accidents using HFACS-MA.

Regarding the level of external factors, legislation gaps are the primary category associated with the three accidents, especially in the Eastern Star accident and Sewol accident, as seen in Table 7. The Eastern Star accident illustrated that China lacked a specific law to enhance the ability of defending against meteorological disasters; additionally, the necessary devices required by IMO, such as the Global Maritime Distress and Safety System (GMDSS), were not mandatory for Chinese vessels because no corresponding regulations were required by Chinese law. Regarding the Sewol accident, the maximum allowable age of passenger ships was modified to 30 years rather than the previous 20 years by law [18]. The Ships Safety Act in Korea did not limit the improper renovation of ships, and the KSA and KCG did not realize the new capacity limit after renovation. Additionally the Korean laws did not require the supervising authorities to share information effectively. Therefore, it is important to establish and improve the related legislation for maritime safety.

At the level of organizational influences, Table 7 indicates that organizational process is the most commonly organizational factor for the three accidents, which is in line with the existing findings [31]. The CESC did not establish the system to monitor and manage the Eastern Star, the KCG lacked the standard procedures to communicate with Sewol when they received the distress call, and the TC BLUE DREAM company lacked the basic procedures to popularize safety knowledge when the passengers boarded the Phoenix. Therefore, it is important to establish the corresponding procedures for maritime safety, such as safety management system and rescue communications. In addition, the Eastern Star accident and Sewol accident emphasize the defects in the asset management. Both the Eastern Star and Sewol were illegally renovated, which could make the ship easier to capsize. Therefore, the safety limits of the ship should follow the ship’s original design, if the ship is renovated properly, the risk assessment should be conducted routinely to guarantee safety.

As for the level of unsafe supervision, the most frequent categories involved in the three accidents are inadequate supervision and violations in supervision. The efficiency of organizational supervision is one of the influencing factors for the system safety and performance [35]. Figure 5 and Table 7 illustrate that the inadequate supervision is the most frequently supervisory factor associated with the three accidents, which is in accordance with the previous findings [31]. Taking the Eastern Star for example, CSIB and WSIB did not strictly carry out the ship inspection according to the requirements, and they did not find that CESC changed the ballast tank and water tank without authorization; the cabin doors were not equipped with weathertight closing appliance; the bed was not fixed tightly. Furthermore, the three accidents verified the importance of safety training. Taking the Sewol accident for example, more than half of the crew members on the Sewol were informal workers, and the Cheonghaejin company did not provide adequate training for them [18]; thus, the crew on board did not provide immediate and accurate actions during emergency; additionally, the rescue workers provided poor initial rescue operation due to the lack of adequate training and climbing equipment [19]. In addition, violations in supervision were also key contributing factors in the three accidents, which increased the possibility of accidents to some extent. In the safety critical domains, the guidelines of enhancing supervision emphasize the importance of minimizing the violations in supervision.

With respect to the level of precondition for unsafe acts, it was the most vulnerable level since the faults in the ship’s hardware could be inspected at a glance. Table 7 demonstrates that physical environment and communication (ships and VTS) are the primary categories associated with the three accidents. In terms of the environmental factors, the physical environment factors featured remarkably in the three accidents, specifically, Eastern Star, Sewol, and Phoenix encountered the inclement weather such as the squall line system, which made the ships be under unsafe conditions. In addition, communication among ships and with VTS failed to provide effective support for coordination and accident rescue, which increased the accident losses. Previous research has indicated that the communication among ships and with VTS is essential, which can provide timely information for accident rescue to reduce accident losses.

As the Swiss Cheese Model (SCM) suggests, the defects in the external factors, organizational influences, unsafe supervision, and precondition for unsafe acts result in unsafe acts [46]. Therefore, we should focus our efforts on some critical categories at these levels to reduce unsafe behavior. Table 7 demonstrates that the decision errors and exceptional violations were the main categories at the level of unsafe acts. Decision errors in the three accidents mainly refer to the failure in evacuating passengers in time, and violations are usually related to failure in following organizational procedures. Due to the lack of professional training under the emergency situation, the captain and crew members made wrong decisions and failed to take the proper actions when the emergency emerged. In addition, the violations played an important role in the probability of accidents as all the three accidents related to the deliberate violations of rules and regulations, including the routine violations and exceptional violations. Furthermore, the consequences of the exceptional violations are unpredictable and often cause serious consequences.

4.5. Practical Implications

This research explores the underlying causes of three maritime accidents by employing the HFACS-MA model, and the results indicate that the HFACS-MA model is applicative in analyzing the maritime accidents. In addition, we conducted a comparative analysis on the accident causes, attempting to explore the similarities and differences about the accident causes under the similar social context. Furthermore, the demographic of the causation factors were computed, and the key categories associated with the three accidents were identified.

Regarding the three accidents, the main focus concentrated on establishing the corresponding legislations, policies, regulations, and safety culture within the maritime industry. Firstly, the legislations that related to maritime safety should be established and improved, which attempts to provide guidelines for maritime safety. Secondly, the standard procedures should be established and improved, including safety management system and rescue communications, and the in-depth risk assessment should be conducted routinely. Thirdly, the crew members on board should receive regular safety training to improve their safety knowledge and safety awareness and finally reduce unsafe acts. In addition, the rescue workers should be properly trained to improve the rescue operations level. Fourthly, it is significant to improve the meteorological warning capability and establish the information distributing platform of meteorological warning. Consequently, this research contributes to safety management and policy development in the maritime industry at different levels.

4.6. Limitations

Some materials of this research come from news articles, and one of the limitations is the inadequate data due to the translation obstacle of local language in Korea and Thailand when collecting evidence, which limits the depth of conclusions that we can draw. Furthermore, there are still many unresolved questions associated with the three accidents, such as the path of each accident and the risk assessment of human factors. In addition, this research is limited to accidents caused by Cruise ship and Ro-Ro passenger vessel only. Therefore, if the scope of research is expanded to multiple types of vessels, it is possible to establish effective maritime safety measures for maritime safety. Finally, HFACS was the only method used in this research. While this research was practical, it might be helpful to compare different analytical methods such as 2–4 Model [47], AcciMap [48], STAMP [49], and FRAM [50].

5. Conclusions

In this paper, the HFACS-MA model is introduced to explore the underlying causes of Chinese Eastern Star, Korean Sewol, and Thai Phoenix ferry accidents, indicating that the HFACS-MA model is applicable for maritime accident analysis. A comparative analysis on the accident causes of the three accidents was conducted, and the demographic of the causation factors were computed, and additionally the key categories were identified. Consequently, the research can increase support for HFACS-MA and its application, and provide valuable information for safety management and policy development in the maritime industry at different levels.

At the level of external factors, it is important to improve the legislation in the maritime industry, especially in the Eastern Star accident and Sewol accident. At the level of organizational influences, the defects in the organizational process are the key contributing factors for the three accidents, and additionally the Eastern Star accident and Sewol accident emphasize the defects in the asset management. At the level of unsafe supervision, the inadequate supervision and violations in supervision are the primary reasons for the three accidents, and it highlights the importance of adequate safety training for maritime safety. Regarding the precondition for unsafe acts, the physical environment factors featured remarkably in the three accidents, and meanwhile communication (ships and VTS) play an important part in coordination and accident rescue. At the level of unsafe acts, it emphasizes the importance of the following factors: the decision errors and violations. Efforts to reduce unsafe acts should concentrate some critical HFACS categories at the lower levels.

Although this research analyzes the causes of three accidents in detail, there are still many unresolved questions associated with the three accidents, such as the path of each accident and risk assessment of human factors. At the same time, this research provides some new insights to encourage further research to establish effective measures for national and international maritime safety.

Author Contributions

R.T. and X.W. conceived the key ideas and the paper structure; B.Z. and X.Z. discussed the method; X.Z. and L.W. discussed the application of the method; R.T. and X.W. wrote the paper; X.W. and L.W. reviewed the process. All authors have read and agree to the published version of the manuscript.

Funding

The study was financially supported by the National Natural Science Foundation of China (No. 51674268).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jiang, M.; Lu, J. Maritime accident risk estimation for sea lanes based on a dynamic Bayesian network. Marit. Policy Manag. 2020, 1–16. [Google Scholar] [CrossRef]

- Akyuz, E. A hybrid accident analysis method to assess potential navigational contingencies: The case of ship grounding. Saf. Sci. 2015, 79, 268–276. [Google Scholar] [CrossRef]

- Hetherington, C.; Flin, R.; Mearns, K. Safety in shipping: The human element. J. Saf. Res. 2006, 37, 401–411. [Google Scholar] [CrossRef] [PubMed]

- Wang, J. Offshore safety case approach and formal safety assessment of ships. J. Saf. Res. 2002, 33, 81–115. [Google Scholar] [CrossRef]

- Akyuz, E. A marine accident analysing model to evaluate potential operational causes in cargo ships. Saf. Sci. 2017, 92, 17–25. [Google Scholar] [CrossRef]

- Akyuz, E.; Celik, E. A modified human reliability analysis for cargo operation in singlepoint mooring (SPM) off-shore units. Appl. Ocean Res. 2016, 58, 11–20. [Google Scholar] [CrossRef]

- Corovic, B.; Djurovic, P. Research of marine accidents through the prism of human factors. Promet Traffic Transp. 2013, 25, 369–377. [Google Scholar] [CrossRef]

- Macrae, C. Human factors at sea: Common patterns of error in groundings and collisions. Marit. Policy Manag. 2009, 36, 21–38. [Google Scholar] [CrossRef]

- Akyuz, E.; Celik, M.; Akgun, I.; Cicek, K. Prediction of human error probabilities in a critical marine engineering operation on-board chemical tanker ship: The case of ship bunkering. Saf. Sci. 2018, 110, 102–109. [Google Scholar] [CrossRef]

- Karahalios, H. The contribution of risk management in ship management: The case of ship collision. Saf. Sci. 2014, 63, 104–114. [Google Scholar] [CrossRef]

- Chauvin, C.; Lardjane, S.; Morel, G.; Clostermann, J.-P.; Langard, B. Human and organizational factors in maritime accidents: Analysis of collisions at sea using the HFACS. Accid. Anal. Prev. 2013, 59, 26–37. [Google Scholar] [CrossRef] [PubMed]

- Karahalios, H.; Yang, Z.L.; Williams, V.; Wang, J. A proposed system of hierarchical scorecards to assess the implementation of maritime regulations. Saf. Sci. 2011, 49, 450–462. [Google Scholar] [CrossRef]

- Soner, O.; Asan, U.; Çelik, M. Use of HFACS–FCM in fire prevention modelling on board ships. Saf. Sci. 2015, 77, 25–41. [Google Scholar] [CrossRef]

- Tzannatos, E.; Kokotos, D. Analysis of accidents in Greek shipping during the pre- and post-ISM period. Mar. Policy. 2009, 33, 679–684. [Google Scholar] [CrossRef]

- Gaonkar, R.S.P.; Xie, M.; Ng, M.M.; Habibullah, M.S. Subjective operational reliability assessment of maritime transportation system. Expert Syst. Appl. 2011, 38, 13835–13846. [Google Scholar] [CrossRef]

- Noroozi, A.; Khan, F.; MacKinnon, S.; Amyotte, P.; Deacon, T. Determination of human error probabilities in maintenance procedures of a pump. Process. Saf. Environ. Prot. 2014, 92, 131–141. [Google Scholar] [CrossRef]

- Akyuz, E. Quantitative human error assessment during abandon ship procedures in maritime transportation. Ocean Eng. 2016, 120, 21–29. [Google Scholar] [CrossRef]

- Lee, S.; Moh, Y.B.; Tabibzadeh, M.; Meshkati, N. Applying the AcciMap methodology to investigate the tragic Sewol Ferry accident in South Korea. Appl. Ergon. 2017, 59, 517–525. [Google Scholar] [CrossRef]

- Kee, D.; Jun, G.T.; Waterson, P.; Haslam, R. A systemic analysis of South Korea Sewol ferry accident–Striking a balance between learning and accountability. Appl. Ergon. 2017, 59, 504–516. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.E.; Nazir, S.; Øvergård, K.I. A STAMP-based causal analysis of the Korean Sewol ferry accident. Saf. Sci. 2016, 83, 93–101. [Google Scholar] [CrossRef]

- Suo, X.; Fu, G.; Wang, C.; Jia, Q. An application of 24Model to analyse capsizing of the Eastern Star ferry. Pol. Marit. Res. 2017, 24, 116–122. [Google Scholar] [CrossRef]

- Hwang, K.I. Comparative study on predictions of passengers’ evacuation performances before and after the remodeling of MV Sewol. J. Korean Soc. Mar. Eng. 2015, 39, 105–114. [Google Scholar] [CrossRef]

- Hyungju, K.; Stein, H.; Bouwer, U.I. Assessment of accident theories for major accidents focusing on the MV SEWOL disaster: Similarities, differences and discussion for a combined approach. Saf. Sci. 2016, 82, 410–420. [Google Scholar] [CrossRef]

- Luo, Y.; He, J. A study on the impact of tourism security events on destination image from the perspective of tourist perception: Taking the cruise ferry accident in Phuket, Thailand as an example. Tour. Overv. 2019, 6, 50–51. (In Chinese) [Google Scholar]

- Su, Y.; Yang, X.; Xie, D. Strategy analysis of strengthening the safety management of marine tourism in tourism enterprises: Taking the cruise ferry accident in Phuket, Thailand as an example. Tour. Overv. 2019, 2, 16. (In Chinese) [Google Scholar]

- Lundberg, J.; Rollenhagen, C.; Hollnagel, E. What-You-Look-For-Is-What-You-Find: The consequences of underlying accident models in eight accident investigation manuals. Saf. Sci. 2009, 47, 1297–1311. [Google Scholar] [CrossRef]

- Yıldırım, U.; Başar, E.; Uğurlu, Ö. Assessment of collisions and grounding accidents with human factors analysis and classification system (HFACS) and statistical methods. Saf. Sci. 2019, 119, 412–425. [Google Scholar] [CrossRef]

- Chen, S.; Wall, A.; Davies, P.; Yang, Z.; Wang, J.; Chou, Y. A human and organizational factors (HOFs) analysis method for marine casualties using HFACS-Maritime Accidents (HFACS-MA). Saf. Sci. 2013, 60, 105–114. [Google Scholar] [CrossRef]

- Lenne, M.G.; Ashby, K.; Fitzharries, M. Analysis of general aviation crashes in Australia using the human factors analysis and classification system. Int. J. Aviat. Psychol. 2008, 18, 340–352. [Google Scholar] [CrossRef]

- Olsen, N.S. Coding ATC incident data using HFACS: Inter-coder consensus. Saf. Sci. 2011, 49, 1365–1370. [Google Scholar] [CrossRef]

- Li, W.C.; Harris, D.; Yu, C.S. Routes to failure: Analysis of 41 civil aviation accidents from the Republic of China using the human factors analysis and classification system. Accid. Anal. Prev. 2008, 40, 426–434. [Google Scholar] [CrossRef]

- Akyuz, E.; Celik, M. Utilisation of cognitive map in modelling human error in marine accident analysis and prevention. Saf. Sci. 2014, 70, 19–28. [Google Scholar] [CrossRef]

- Celik, M.; Cebi, S. Analytical HFACS for investigating human errors in shipping accidents. Accid. Anal. Prev. 2009, 41, 66–75. [Google Scholar] [CrossRef] [PubMed]

- Patterson, J.M.; Shappell, S.A. Operator error and system deficiencies: Analysis of 508 mining incidents and accidents from Queensland, Australia using HFACS. Accid. Anal. Prev. 2010, 42, 1379–1385. [Google Scholar] [CrossRef] [PubMed]

- Lenné, M.G.; Salmon, P.M.; Liu, C.C.; Trotter, M. A systems approach to accident causation in mining: An application of the HFACS method. Accid. Anal. Prev. 2012, 48, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Cheng, W.; Yu, Y.; Xu, Q. Human factors analysis of major coal mine accidents in China based on the HFACS-CM model and AHP method. Int. J. Ind. Ergon. 2018, 68, 270–279. [Google Scholar] [CrossRef]

- ElBardissi, A.W.; Wiegmann, D.A.; Dearani, J.A.; Daley, R.C.; Sundt, T.M. Application of the human factors analysis and classification system methodology to the cardiovascular surgery operating room. Ann. Thorac. Surg. 2007, 83, 1412–1419. [Google Scholar] [CrossRef]

- Mitchell, R.J.; Williamson, A.; Molesworth, B. Use of a human factors classification framework to identify causal factors for medication and medical device-related adverse clinical incidents. Saf. Sci. 2015, 79, 163–174. [Google Scholar] [CrossRef]

- Hsieh, M.C.; Wang, E.M.Y.; Lee, W.C.; Li, L.W.; Hsieh, C.Y.; Tsai, W.; Wang, C.P.; Huang Liu, T.C. Application of HFACS, fuzzy TOPSIS, and AHP for identifying important human error factors in emergency departments in Taiwan. Int. J. Ind. Ergon. 2018, 67, 171–179. [Google Scholar] [CrossRef]

- Zhou, J.L.; Bai, Z.H.; Zhi-Yu, S. A hybrid approach for safety assessment in high-risk hydropower-construction-project work systems. Saf. Sci. 2014, 64, 163–172. [Google Scholar] [CrossRef]

- Reinach, S.; Viale, A. Application of a human error framework to conduct train accident/incident investigations. Accid. Anal. Prev. 2006, 38, 396–406. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Zhang, D.; Goerlandt, F.; Yan, X.; Kujala, P. Use of HFACS and fault tree model for collision risk factors analysis of icebreaker assistance in ice-covered waters. Saf. Sci. 2019, 111, 128–143. [Google Scholar] [CrossRef]

- Ergai, A.; Cohen, T.; Sharp, J.; Wiegmann, D.; Gramopadhye, A.; Shappell, S. Assessment of the Human Factors Analysis and Classification System (HFACS): Intra-rater and inter-rater reliability. Saf. Sci. 2016, 82, 393–398. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, G.; Xue, Y. Human and organizational factors in Chinese hazardous chemical accidents: A case study of the ‘8.12’Tianjin Port fire and explosion using the HFACS-HC. Int. J. Occup. Saf. Ergon. 2018, 24, 329–340. [Google Scholar] [CrossRef] [PubMed]

- Theophilus, S.C.; Esenowo, V.N.; Arewa, A.O.; Ifelebuegu, A.O.; Nnadi, E.O.; Mbanaso, F.U. Human factors analysis and classification system for the oil and gas industry (HFACS-OGI). Reliab. Eng. Syst. Saf. 2017, 167, 168–176. [Google Scholar] [CrossRef]

- Uğurlu, Ö.; Yıldız, S.; Loughney, S.; Wang, J. Modified human factor analysis and classification system for passenger vessel accidents (HFACS-PV). Ocean Eng. 2018, 161, 47–61. [Google Scholar] [CrossRef]

- Wang, J.; Yan, M. Application of an Improved Model for Accident Analysis: A Case Study. Int. J. Environ. Res. Public Health 2019, 16, 2756. [Google Scholar] [CrossRef] [PubMed]

- Goncalves Filho, A.P.; Jun, G.T.; Waterson, P. Four studies, two methods, one accident–An examination of the reliability and validity of Accimap and STAMP for accident analysis. Saf. Sci. 2019, 113, 310–317. [Google Scholar] [CrossRef]

- Leveson, N.G. A new accident model for engineering safer systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Lee, J.; Chung, H. A new methodology for accident analysis with human and system interaction based on FRAM: Case studies in maritime domain. Saf. Sci. 2018, 109, 57–66. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).