Impact of Vaping Regimens on Electronic Cigarette Efficiency

Abstract

1. Introduction

2. Materials and Methods

2.1. Reference E-Liquid

2.2. Vaping Machine and Vaping Regimens

2.3. Atomizers

2.4. Experiments

3. Results

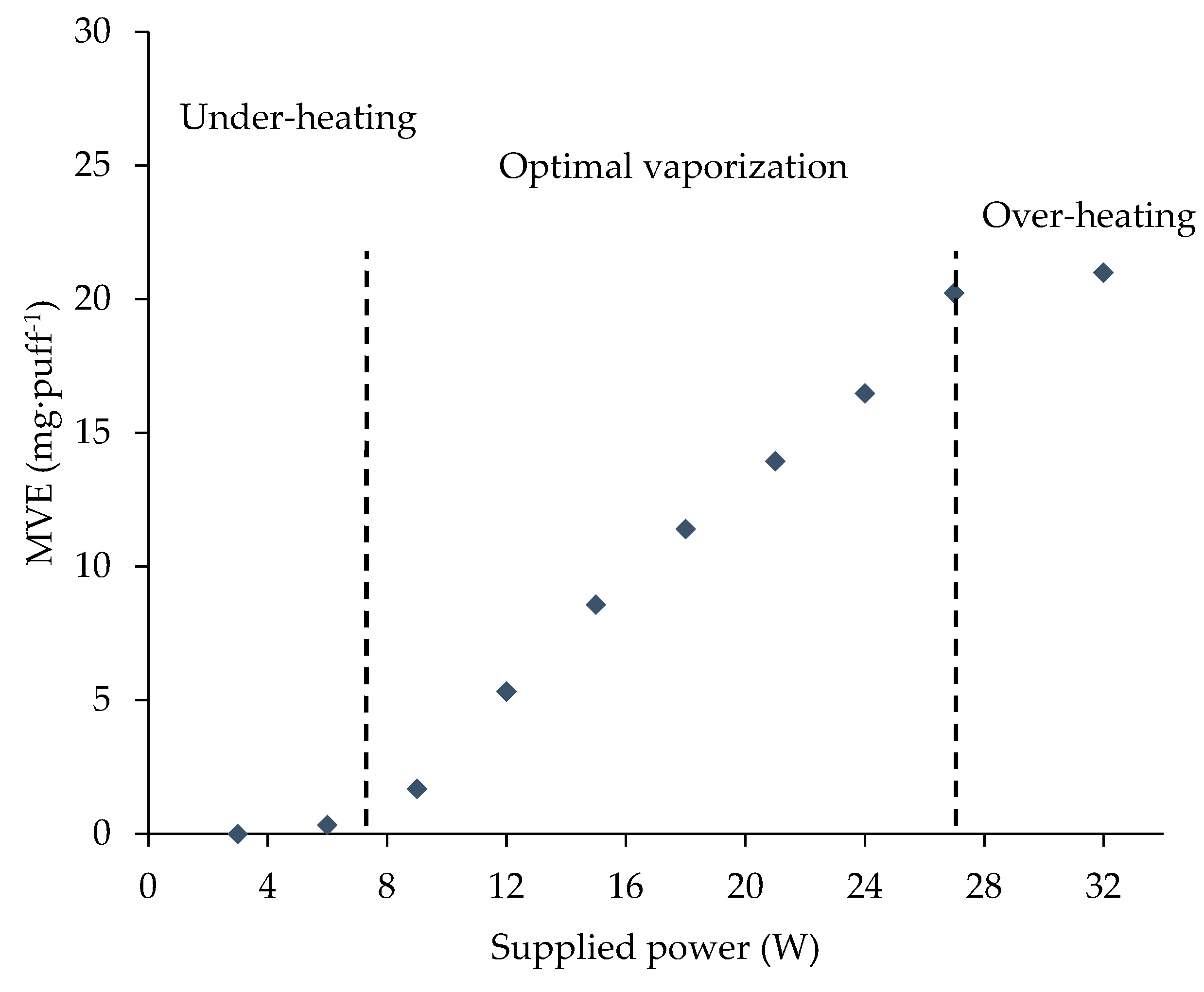

3.1. Influence of Inhalation Properties Using Cub1 Reference Atomizer at a Fixed Power of 15 W

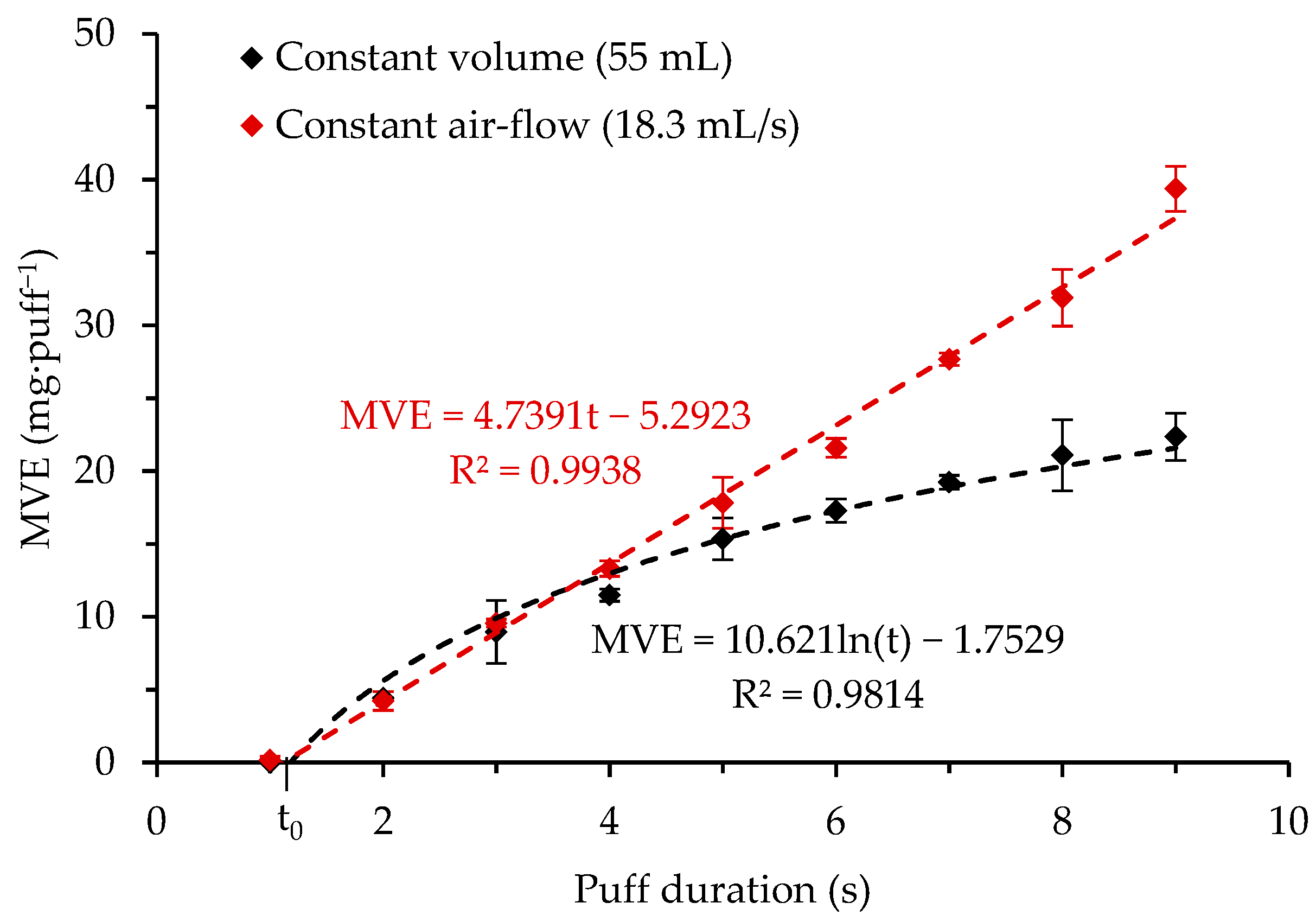

3.1.1. Influence of Puff Duration at a Fixed Puff Volume of 55 mL and at a Fixed Air-Flow Rate of 18.3 mL/s

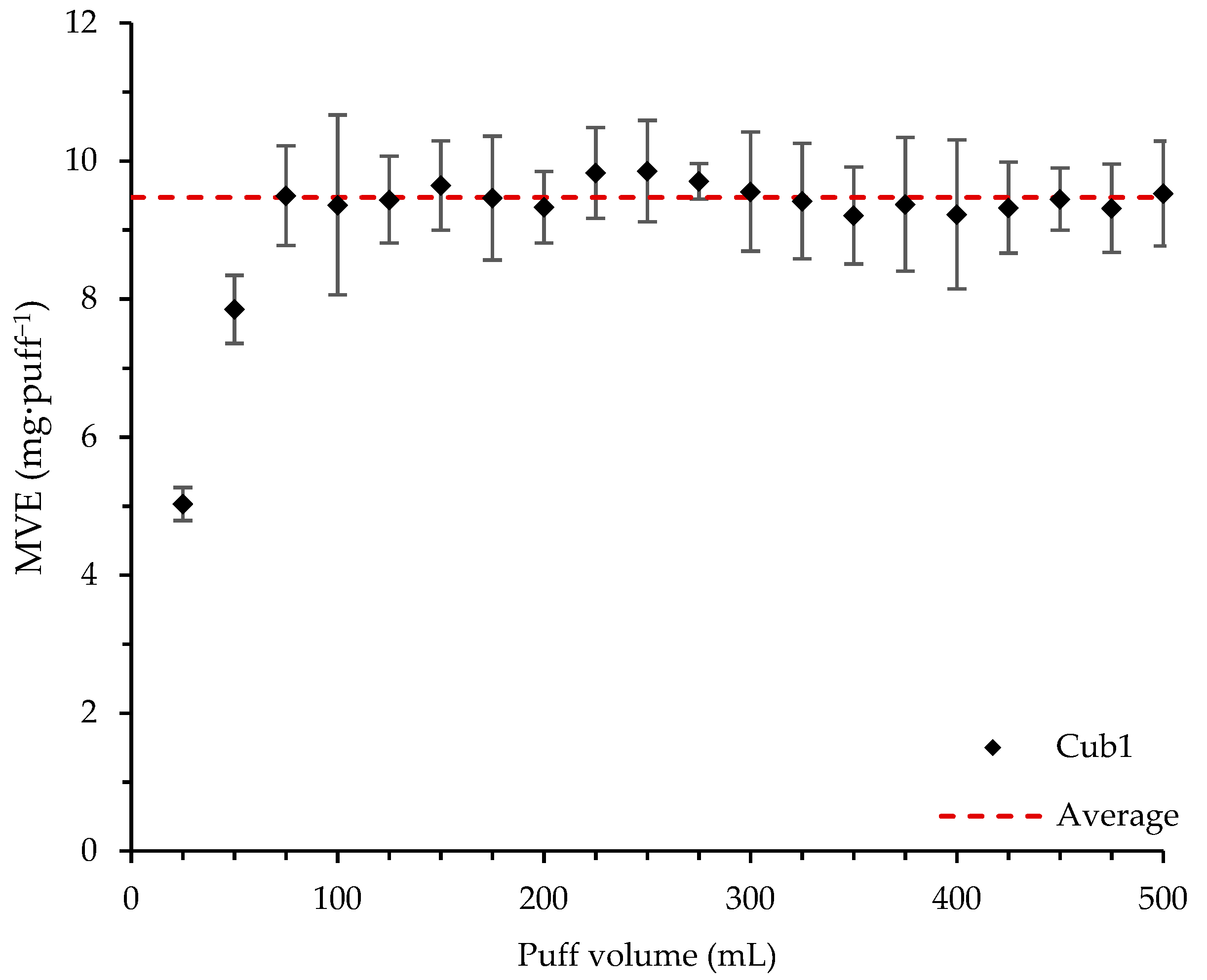

3.1.2. Influence of Puff Volume at a Fixed Puff Duration of 3 s

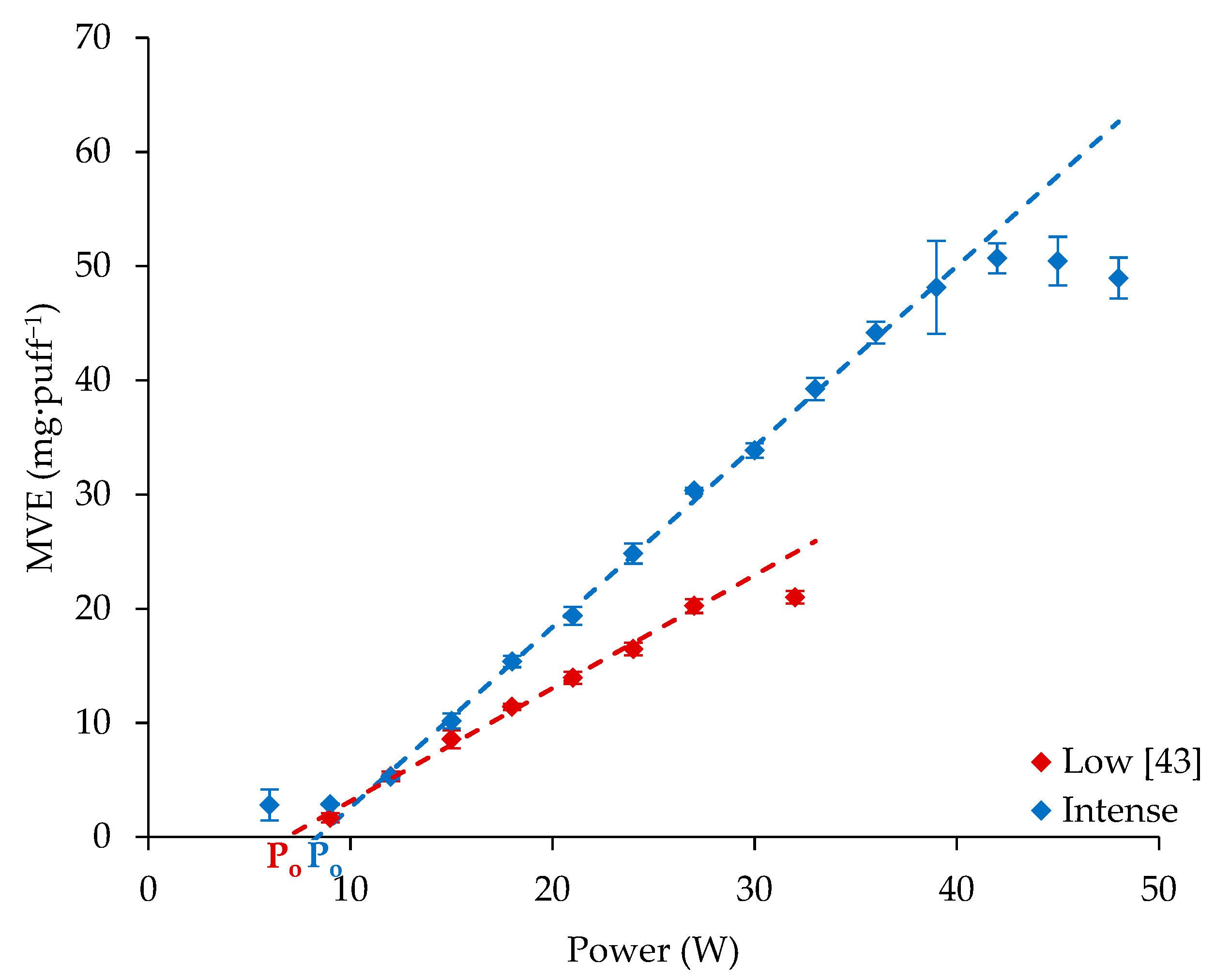

3.2. Comparison of Results Obtained Using Low and Intense Vaping Regimens with Cub1 Reference Atomizer

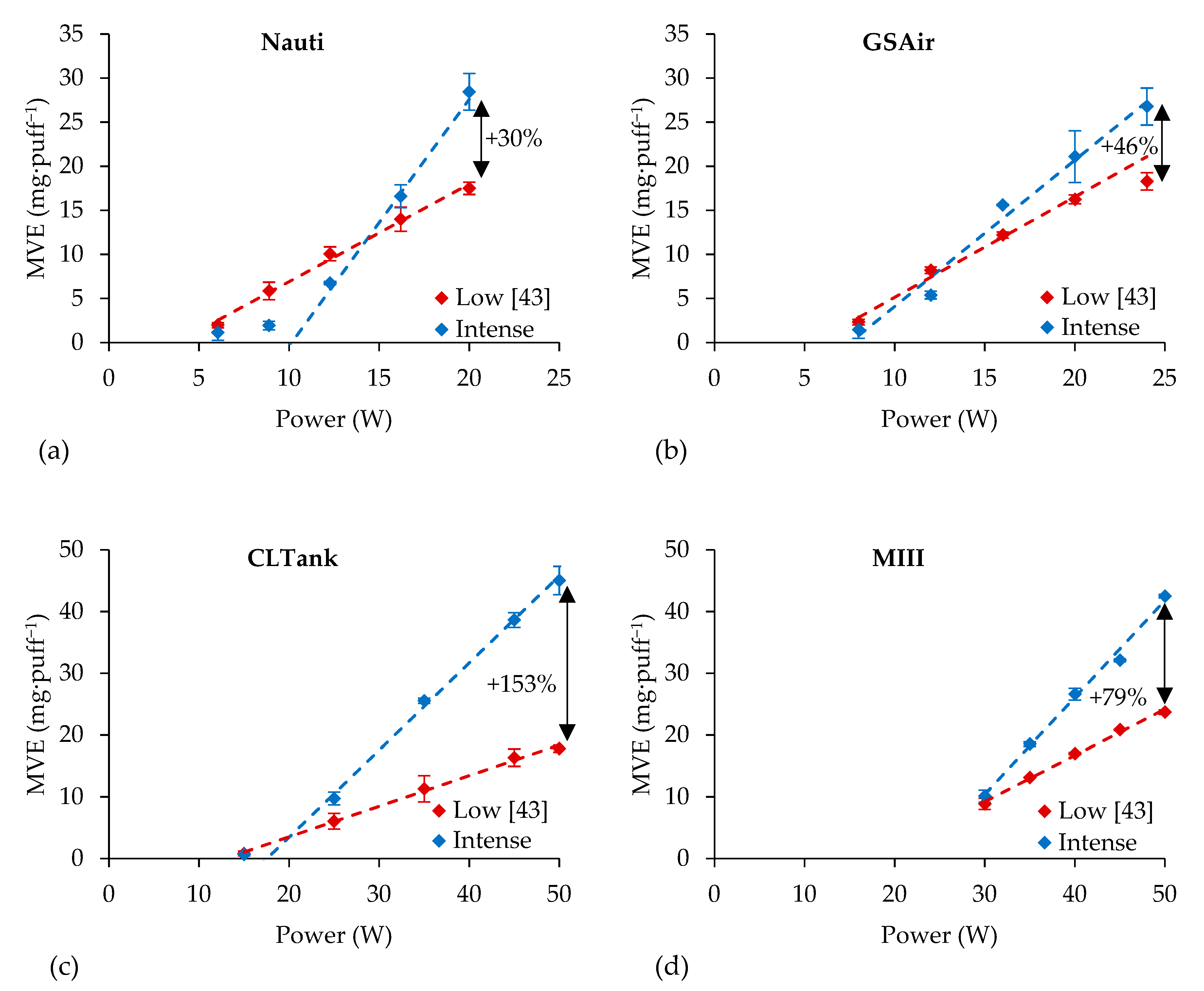

3.3. Comparison of the Results Obtained Applying the Low and Intense Vaping Regimens Using Different Atomizers

3.4. Impact of Inhalation Vaping Regimen on E-Cig Efficiency

4. Discussion

5. Conclusions

- The choice to use an intense instead of a standardized vaping regimen must be linked to a criterion of application. This criterion would be a technical characteristic of the e-cig and would allow a group of products to be defined. The inhalation resistance generated by the atomizers would be an interesting property that could lead to more or less inhalation effort by the users. Future experiments will be carried out on the measurement of atomizers’ resistance during inhalation.

- E-cig efficiencies were found to be lower than 100%, revealing energy lost in the tested atomizers. An identification and quantification of where energy is lost in an e-cig must be performed, and would allow a better understanding of the heat transfers occurring in an e-cig.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- National Academies of Sciences, Engineering, and Medicine. Public Health Consequences of E-Cigarettes; The National Academies Press: Washington, DC, USA, 2018; pp. 55–88. ISBN 978-0-309-46834-3. [Google Scholar]

- Ernst & Young LLP. Electronic Nicotine Delivery Systems (ENDS): An Update on a Rapidly Evolving Vapour Market; Ernst & Young Press: London, UK, 2016; pp. 1–25. [Google Scholar]

- Nascimento, W.V.; Cassiani, R.A.; Dantas, R.O. Gender Effect on Oral Volume Capacity. Dysphagia. 2012, 27, 384–389. [Google Scholar] [CrossRef]

- Association for Respiratory Technology & Physiology; Standards of Care—CPAP Devices (Technical and Performance)—Sleep Position Statements; Association for Respiratory Technology & Physiology Press: Lichfield, UK, 2018.

- Behar, R.Z.; Hua, M.; Talbot, P. Puffing Topography and Nicotine Intake of Electronic Cigarette Users. PLoS ONE 2015, 10, 1–18. [Google Scholar] [CrossRef]

- Lee, Y.H.; Gawron, M.; Goniewicz, M.L. Changes in puffing behavior among smokers who switched from tobacco to electronic cigarettes. Addict. Behav. 2015, 48, 1–4. [Google Scholar] [CrossRef]

- Robinson, R.J.; Hensel, E.C.; Morabito, P.N.; Roundtree, K.A. Electronic Cigarette Topography in the Natural Environment. PLoS ONE 2015, 10, e0129296. [Google Scholar] [CrossRef]

- Cunningham, A.; Slayford, S.; Vas, C.; Gee, J.; Costigan, S.; Prasad, K. Development, validation and application of a device to measure e-cigarette users’ puffing topography. Sci. Rep. 2016, 6, 35071. [Google Scholar] [CrossRef]

- Norton, K.J.; June, K.M.; O’Connor, R.J. Initial puffing behaviors and subjective responses differ between an electronic nicotine delivery system and traditional cigarettes. Tob. Induc. Dis. 2014, 12, 17. [Google Scholar] [CrossRef]

- Robinson, R.J.; Hensel, E.C.; Roundtree, K.A.; Difrancesco, A.G.; Nonnemaker, J.M.; Lee, Y.O. Week Long Topography Study of Young Adults Using Electronic Cigarettes in Their Natural Environment. PLoS ONE 2016, 11, e0164038. [Google Scholar] [CrossRef]

- Spindle, T.R.; Breland, A.B.; Karaoghlanian, N.V.; Shihadeh, A.L.; Eissenberg, T. Preliminary Results of an Examination of Electronic Cigarette User Puff Topography: The Effect of a Mouthpiece-Based Topography Measurement Device on Plasma Nicotine and Subjective Effects. Nicotine Tob. Res. 2015, 17, 142–149. [Google Scholar] [CrossRef]

- Farsalinos, K.E.; Spyrou, A.; Tsimopoulou, K.; Stefopoulos, C.; Romagna, G.; Voudris, V. Nicotine absorption from electronic cigarette use: Comparison between first and new-generation devices. Sci. Rep. 2014, 4, 4133. [Google Scholar] [CrossRef]

- Farsalinos, K.E.; Kistler, K.A.; Pennington, A.; Spyrou, A.; Kouretas, D.; Gillman, G. Aldehyde levels in e-cigarette aerosol: Findings from a replication study and from use of a new-generation device. Food Chem. Toxicol. 2018, 111, 64–70. [Google Scholar] [CrossRef]

- Gillman, I.G.; Kistler, K.A.; Stewart, E.W.; Paolantonio, A.R. Effect of variable power levels on the yield of total aerosol mass and formation of aldehydes in e-cigarette aerosols. Food Chem. Toxicol. 2016, 75, 58–65. [Google Scholar] [CrossRef] [PubMed]

- Talih, S.; Balhas, Z.; Salman, R.; Karaoghlanian, N.; Shihadeh, A. “Direct Dripping”: A High-Temperature, High-Formaldehyde Emission Electronic Cigarette Use Method. Nicotine Tob. Res. 2016, 18, 453–459. [Google Scholar] [CrossRef] [PubMed]

- Farsalinos, K.E.; Gillman, G. Carbonyl Emissions in E-cigarette Aerosol: A Systematic Review and Methodological Considerations. Front. Physiol. 2018, 8, 1119. [Google Scholar] [CrossRef] [PubMed]

- Kosmider, L.; Spindle, T.R.; Gawron, M.; Sobczak, A.; Goniewicz, M.L. Nicotine emissions from electronic cigarettes: Individual and interactive effects of propylene glycol to vegetable glycerin composition and device power output. Food Chem. Toxicol. 2018, 115, 302–305. [Google Scholar] [CrossRef]

- Goniewicz, M.L.; Knysak, J.; Gawron, M.; Kosmider, L.; Sobczak, A.; Kurek, J.; Prokopowicz, A.; Jablonska-Czapla, M.; Rosik-Dulewska, C.; Havel, C.; et al. Levels of selected carcinogens and toxicants in vapour from electronic cigarettes. Tob. Control 2014, 23, 133–139. [Google Scholar] [CrossRef]

- Jensen, R.P.; Strongin, R.M.; Peyton, D.H. Solvent Chemistry in the Electronic Cigarette Reaction Vessel. Sci. Rep. 2017, 7, 42549. [Google Scholar] [CrossRef]

- Alderman, S.L.; Song, C.; Moldoveanu, S.C.; Cole, S.K. Particle Size Distribution of E-Cigarette Aerosols and the Relationship to Cambridge Filter Pad Collection Efficiency. Contrib. Tob. Res. 2015, 26, 183–190. [Google Scholar] [CrossRef]

- Floyd, E.L.; Queimado, L.; Wang, J.; Regens, J.L.; Johnson, D.L. Electronic cigarette power affects count concentration and particle size distribution of vaping aerosol. PLoS ONE 2018, 13, e0210147. [Google Scholar] [CrossRef]

- Ingebrethsen, B.J.; Cole, S.K.; Alderman, S.L. Electronic cigarette aerosol particle size distribution measurements. Inhal. Toxicol. 2012, 24, 976–984. [Google Scholar] [CrossRef]

- Pourchez, J.; Parisse, S.; Sarry, G.; Perinel-Ragey, S.; Vergnon, J.M.; Clotagatide, A.; Prévôt, N. Impact of power level and refill liquid composition on the aerosol output and particle size distribution generated by a new-generation e-cigarette device. Aerosol. Sci. Technol. 2018, 52, 359–369. [Google Scholar] [CrossRef]

- Sosnowski, T.R.; Odziomek, M. Particle Size Dynamics: Toward a Better Understanding of Electronic Cigarette Aerosol Interactions with the Respiratory System. Front. Physiol. 2018, 9, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Beauval, N.; Verrièle, M.; Garat, A.; Fronval, I.; Dusautoir, R.; Anthérieu, S.; Garçon, G.; Lo-Guidice, J.M.; Allorge, D.; Locoge, N. Influence of puffing conditions on the carbonyl composition of e-cigarette aerosols. Int. J. Hyg. Environ. Health 2018, 222, 136–146. [Google Scholar] [CrossRef] [PubMed]

- AFNOR. XP D90-300-1—Electronic Cigarettes and e-Liquids-Part 1: Requirements and Test Methods for Electronic Cigarettes; European Association for the Co-ordination of Consumers Representation in Standardisation aisbl Press: Brussels, Belgium, 2015. [Google Scholar]

- AFNOR. XP D90-300-2—Electronic Cigarettes and e-Liquids-Part 2: Requirements and Test Methods for e-Liquids; European Association for the Co-ordination of Consumers Representation in Standardisation aisbl Press: Brussels, Belgium, 2015. [Google Scholar]

- AFNOR. XP D90-300-3—Electronic Cigarettes and e-Liquids-Part 3: Requirements and Test Methods for Emissions; European Association for the Co-ordination of Consumers Representation in Standardisation aisbl Press: Brussels, Belgium, 2016. [Google Scholar]

- BSI. PAS 54115:2015—Vaping Products, Including Electronic Cigarettes, e-Liquids, e-Shisha and Directly-Related Products. Manufacture, Importation, Testing and Labelling. Guide; British Standards Institution (BSI) Press: London, UK, 2015. [Google Scholar]

- ISO. ISO/DIS 20768—Vapour Products-Routine Analytical Vaping Machine-Definitions and Standard Conditions; International Organization for Standardization (ISO) Press: Geneva, Switzerland, 2018. [Google Scholar]

- CORESTA. No. 81—Routine Analytical Machine for E-Cigarette Aerosol Generation and Collection—Definitions and Standard Conditions; Cooperation Centre for Scientific Research Relative to Tobacco Press: Paris, France, 2015. [Google Scholar]

- Jesus, S.D.; Hsin, A.; Faulkner, G.; Prapavessis, H. A systematic review and analysis of data reduction techniques for the CReSS smoking topography device. J. Smok. Cess. 2015, 10, 12–28. [Google Scholar] [CrossRef]

- WHO TobLabNet. SOP 01—Standard Operating Procedure for Intense Smoking of Cigarettes; World Health Organization Press: Geneva, Switzerland, 2012. [Google Scholar]

- ISO. ISO/TR 19478-2—ISO and Health Canada Intense smoking Parameters-Part 2: Examination of Factors Contributing to Variability in the Routine Measurement of TPM, Water and NFDPM Smoke Yields of Cigarettes; International Organization for Standardization (ISO) Press: Geneva, Switzerland, 2015. [Google Scholar]

- Garner, C.; Reynolds, R.J.; Stevens, R.D. Technical Report—2014 Electronic Cigarette Aerosol Parameters Study; Cooperation Centre for Scientific Research Relative to Tobacco Press: Paris, France, 2015. [Google Scholar]

- Talih, S.; Balhas, Z.; Eissenberg, T.; Salman, R.; Karaoghlanian, N.; El Hellani, A.; Baalbaki, R.; Saliba, N.; Shihadeh, A. Effects of user puff topography, device voltage, and liquid nicotine concentration on electronic cigarette nicotine yield: Measurements and model predictions. Nicotine Tob. Res. 2015, 17, 150–157. [Google Scholar] [CrossRef] [PubMed]

- Havel, C.M.; Benowitz, N.L.; Jacob, P.; St. Helen, G. An Electronic Cigarette Vaping Machine for the Characterization of Aerosol Delivery and Composition. Nicotine Tob. Res. 2017, 19, 1224–1231. [Google Scholar] [PubMed]

- Korzun, T.; Lazurko, M.; Munhenzva, I.; Barsanti, K.C.; Huang, Y.; Jensen, R.P.; Escobedo, J.O.; Luo, W.; Peyton, D.H.; Strongin, R.M. E-Cigarette Airflow Rate Modulates Toxicant Profiles and Can Lead to Concerning Levels of Solvent Consumption. ACS. Omega. 2018, 3, 30–36. [Google Scholar] [CrossRef]

- Geiss, O.; Bianchi, I.; Barrero-Moreno, J. Correlation of volatile carbonyl yields emitted by e-cigarettes with the temperature of the heating coil and the perceived sensorial quality of the generated vapours. Int. J. Hyg. Environ. Health 2016, 219, 268–277. [Google Scholar] [CrossRef]

- Duell, A.K.; McWhirter, K.J.; Korzun, T.; Strongin, R.M.; Peyton, D.H. Sucralose-Enhanced Degradation of Electronic Cigarette Liquids during Vaping. Chem. Res. Toxicol. 2019, 32, 1241–1249. [Google Scholar] [CrossRef]

- Talih, S.; Salman, R.; Karaoghlanian, N.; El-Hellani, A.; Saliba, N.; Eissenberg, T.; Shihadeh, A. “Juice Monsters”: Sub-Ohm Vaping and Toxic Volatile Aldehyde Emissions. Chem. Res. Toxicol. 2017, 30, 1791–1793. [Google Scholar] [CrossRef]

- El-Hellani, A.; Al-Moussawi, S.; El-Hage, R.; Talih, S.; Salman, R.; Shihadeh, A.; Saliba, N.A. Carbon Monoxide and Small Hydrocarbon Emissions from Sub-ohm Electronic Cigarettes. Chem. Res. Toxicol. 2019, 32, 312–317. [Google Scholar] [CrossRef]

- Soulet, S.; Duquesne, M.; Toutain, J.; Pairaud, C.; Lalo, H. Influence of Coil Power Ranges on the E-Liquid Consumption in Vaping Devices. Int. J. Environ. Res. Public Health 2018, 15, 1853. [Google Scholar] [CrossRef] [PubMed]

- Soulet, S.; Pairaud, C.; Lalo, H. A Novel Vaping Machine Dedicated to Fully Controlling the Generation of E-Cigarette Emissions. Int. J. Environ. Res. Public Health 2017, 14, 1225. [Google Scholar] [CrossRef] [PubMed]

- Soulet, S.; Duquesne, M.; Toutain, J.; Pairaud, C.; Lalo, H. Experimental Method of Emission Generation Calibration Based on Reference Liquids Characterization. Int. J. Environ. Res. Public Health 2019, 16, 2262. [Google Scholar] [CrossRef] [PubMed]

- Kudra, D.T. Energy Aspects in Drying. Dry. Technol. 2004, 22, 917–932. [Google Scholar] [CrossRef]

- Dai, J.; Kim, K.H.; Szulejko, J.E.; Jo, S.H.; Kwon, K.; Choi, D.W. Quantification of nicotine and major solvents in retail electronic cigarette fluids and vaped aerosols. Microchem. J. 2018, 140, 262–268. [Google Scholar] [CrossRef]

- Renon, H.; Prausnitz, J.M. Local compositions in thermodynamic excess functions for liquid mixtures. AIChE J. 1968, 14, 135–144. [Google Scholar] [CrossRef]

- European Commission. Directive 2014/40/EU—Tobacco Products Directive; European Commission Press: Brussels, Belgium, 2014. [Google Scholar]

- Wang, P.; Chen, W.; Liao, J.; Matsuo, T.; Ito, K.; Fowles, J.; Shusterman, D.; Mendell, M.; Kumagai, K.A. Device-Independent Evaluation of Carbonyl Emissions from Heated Electronic Cigarette Solvents. PLoS ONE 2017, 12, e0169811. [Google Scholar] [CrossRef]

- Nimlos, M.R.; Blanksby, S.J.; Qian, X.; Himmel, M.E.; Johnson, D.K. Mechanisms of Glycerol Dehydration. J. Phys. Chem. A 2006, 110, 6145–6156. [Google Scholar] [CrossRef]

- Garrett, B.; Shatzer, H.; Bach, J.R. CHAPTER FOUR—Respiratory Treatment and Equipment. In Spinal Cord Injuries; Sisto, S.A., Druin, E., Sliwinski, M.M., Eds.; Mosby: Saint Louis, MO, USA, 2009; pp. 69–103. ISBN 978-0-323-00699-6. [Google Scholar]

| Pure Liquids | Acronym | CAS Number | Formula | Provider | Purity (%) |

|---|---|---|---|---|---|

| Nicotine | Nico | 54-11-5 | C10H14N2 | ALCHEM | ≥99.2% |

| Ethanol | EtOH | 64-17-5 | C2H6O | GROSSERON | 96% |

| Propylene glycol | PG | 57-55-6 | C3H8O2 | BRENNTAG | ≥99.8% |

| Glycerol | VG | 56-81-5 | C3H8O3 | AMI CHIMIE | 99.5% |

| Quaternary Mixtures | Volume Percent (%) | Density (g·cm−3) | Mass Percent (%) | Molar Mass (g·mol−1) | Mole Percent (%) | Molar Heat Capacity (J·mol−1·K−1) | Molar Enthalpy of Vaporization (kJ·mol−1) |

|---|---|---|---|---|---|---|---|

| Nico | 0.20 | 1.01 | 0.18 | 162.24 | 0.09 | - | 56.60 |

| EtOH | 10.00 | 0.79 | 7.09 | 46.07 | 12.24 | 110.46 | 42.85 |

| PG | 44.80 | 1.04 | 41.83 | 76.10 | 43.71 | 188.59 | 66.98 |

| VG | 45.00 | 1.26 | 50.90 | 92.09 | 43.96 | 219.39 | 90.21 |

| Manufacturer | Reference | Resistance | Metal | Wick | Notation | Min | Max |

|---|---|---|---|---|---|---|---|

| Joyetech | Cubis | 1 Ω | SS316L | Organic cotton | Cub1 | 10 W | 25 W |

| Kangertech | CL Tank | 0.5 Ω | SS316L | Organic cotton | CLTank | 15 W | 60 W |

| Eleaf | Melo III | 0.5 Ω | Kanthal | Organic cotton | MIII | 30 W | 100 W |

| Aspire | Nautilus | 1.8 Ω | Kanthal | Cotton | Nauti | 4.2 V (10 W) | 5 V (14 W) |

| Eleaf | GS Air | 1.5 Ω | Kanthal | Organic cotton | GS | 8 W | 20 W |

| Vaping Regimen | a (mg·W−1·puff−1) | Δa (mg·W−1·puff−1) | b (mg·puff−1) | Δb (mg·puff−1) | R2 | P0 (W) |

|---|---|---|---|---|---|---|

| Low [43] | 0.99 | 0.03 | −6.76 | 0.52 | 0.9962 | 6.81 |

| Intense | 1.58 | 0.03 | −13.20 | 0.91 | 0.9965 | 8.35 |

| Vaping Regimen | Device Acronyms | a (mg·W−1·puff−1) | Δa (mg·W−1·puff−1) | b (mg·puff−1) | Δb (mg·puff−1) | R2 | P0 (W) |

|---|---|---|---|---|---|---|---|

| Low [43] | Nauti | 1.11 | 0.05 | −4.16 | 0.71 | 0.9934 | 3.75 |

| GS | 1.14 | 0.08 | −6.27 | 1.16 | 0.9906 | 5.50 | |

| CLTank | 0.52 | 0.00 | −6.94 | 0.12 | 0.9999 | 13.35 | |

| MIII | 0.75 | 0.03 | −13.14 | 1.21 | 0.9913 | 17.52 | |

| Intense | Nauti | 2.80 | 0.18 | −28.40 | 2.92 | 0.9960 | 10.14 |

| GS | 1.66 | 0.12 | −12.49 | 2.12 | 0.9833 | 7.52 | |

| CLTank | 1.41 | 0.05 | −24.73 | 2.00 | 0.9975 | 17.54 | |

| MIII | 1.57 | 0.08 | −36.70 | 3.06 | 0.9931 | 23.38 |

| Cub1 | |||||||||||

| P (W) | 9 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | 33 | 36 | 39 |

| η (low regimen) | 10% | 23% | 30% | 33% | 35% | 36% | 39% | - | - | - | - |

| η (intense regimen) | - | 23% | 35% | 45% | 48% | 54% | 59% | 59% | 62% | 64% | 64% |

| Nauti | GSAir | ||||||||||

| P (W) | 6.1 | 8.9 | 12.3 | 16.2 | 20 | 8 | 12 | 16 | 20 | 24 | |

| η (low regimen) | 17% | 34% | 43% | 45% | 46% | 15% | 36% | 40% | 42% | - | |

| η (intense regimen) | - | - | 29% | 53% | 74% | - | 23% | 51% | 55% | 58% | |

| MIII | CLTank | ||||||||||

| P (W) | 30 | 35 | 40 | 45 | 50 | 15 | 25 | 35 | 45 | 50 | |

| η (low regimen) | 15% | 20% | 22% | 24% | 25% | 3% | 13% | 17% | 19% | 19% | |

| η (intense regimen) | 18% | 28% | 35% | 37% | 44% | - | 20% | 38% | 45% | 47% | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soulet, S.; Duquesne, M.; Toutain, J.; Pairaud, C.; Mercury, M. Impact of Vaping Regimens on Electronic Cigarette Efficiency. Int. J. Environ. Res. Public Health 2019, 16, 4753. https://doi.org/10.3390/ijerph16234753

Soulet S, Duquesne M, Toutain J, Pairaud C, Mercury M. Impact of Vaping Regimens on Electronic Cigarette Efficiency. International Journal of Environmental Research and Public Health. 2019; 16(23):4753. https://doi.org/10.3390/ijerph16234753

Chicago/Turabian StyleSoulet, Sébastien, Marie Duquesne, Jean Toutain, Charly Pairaud, and Maud Mercury. 2019. "Impact of Vaping Regimens on Electronic Cigarette Efficiency" International Journal of Environmental Research and Public Health 16, no. 23: 4753. https://doi.org/10.3390/ijerph16234753

APA StyleSoulet, S., Duquesne, M., Toutain, J., Pairaud, C., & Mercury, M. (2019). Impact of Vaping Regimens on Electronic Cigarette Efficiency. International Journal of Environmental Research and Public Health, 16(23), 4753. https://doi.org/10.3390/ijerph16234753