1. Introduction

Coal mines have always played a vital role in promoting the development of various countries. they are an important energy source for countries in the world. In China, coal is the pillar industry of economic development, and it represents economic development prospects and provides important guarantees for China’s economic and social development and energy supply security [

1,

2]. China’s coal production capacity accounts for 30% of global production capacity and is also the largest coal-consuming country, with coal consumption accounting for about 60% of China’s energy consumption. At the same time, the coal industry has remained in an irreplaceable position for a long time, and China’s coal-based energy situation will not change fundamentally [

3,

4]. Nevertheless, the coal mine accident casualty rate in China has reached more than 70% of the global total. [

5]. Complex working conditions, the harsh working environment, and many dangerous factors have formed a severe production situation in coal mines [

6,

7]. This situation has not only caused adverse social impacts, but also widespread concern in the international community, directly affecting the image of the Chinese government and foreign trade of enterprises. Among the many types of accidents, gas explosions are considered to be the most serious type of accident in coal mines [

8,

9,

10]. Not only for Chinese coal mines, but also for many other countries, gas explosions are a serious threat [

11,

12,

13,

14,

15]. For example, mining is a very important industry in Poland. One of the most common hazards in a coal mine accident is methane, so the fatality rate of gas explosion accidents is very high. When the situation is serious, it may account for half of the number of coal mine accidents in the same period. Similarly, gas explosion accidents in some countries such as Russia and the Ukraine are also serious.

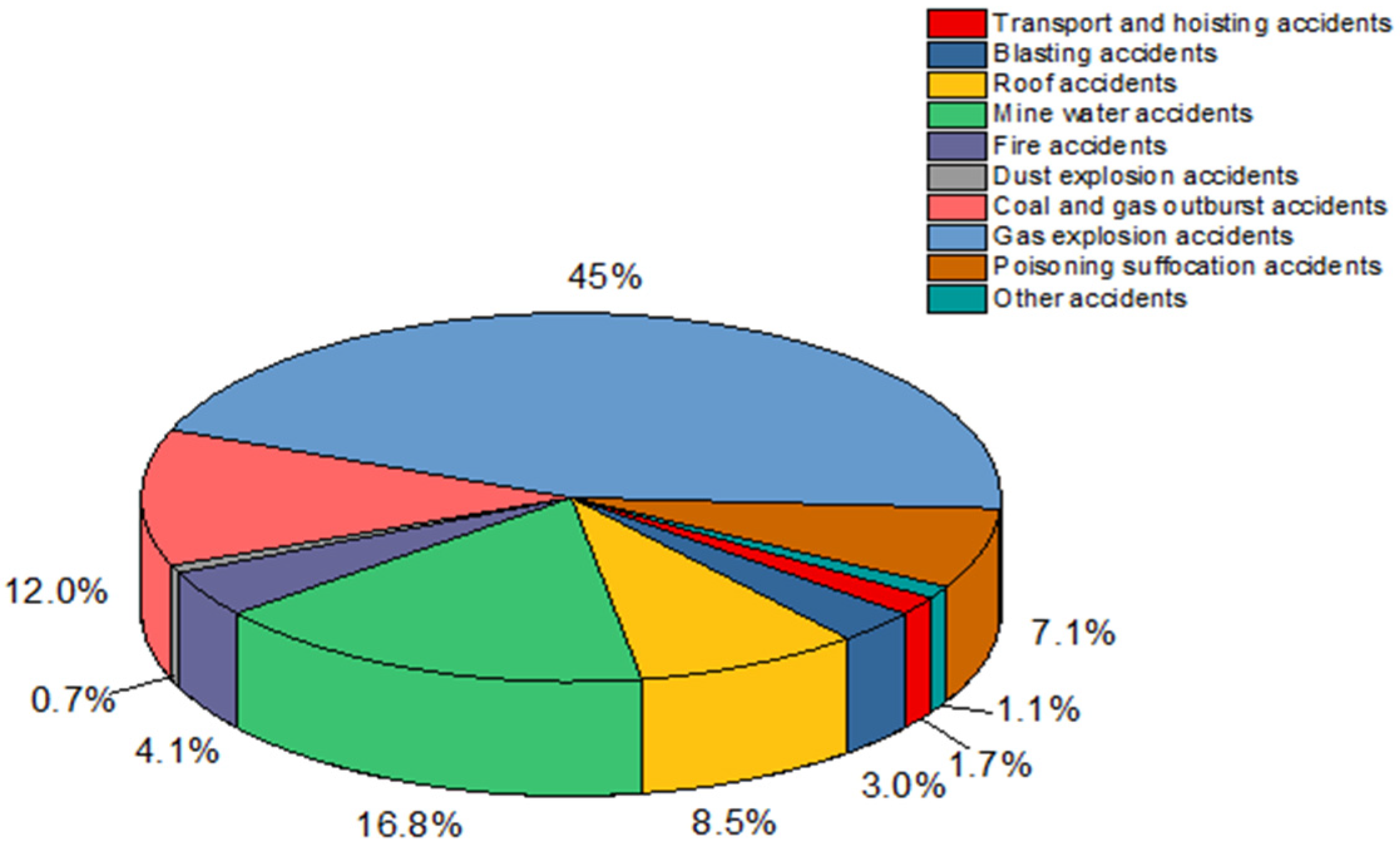

Figure 1 is based on the “Statistical Yearbook of China’s Coal Industry”, which calculates the percentage of deaths caused by several different types of accidents in China’s coal mines from 2001 to 2018. It is obvious that gas explosion accidents are more likely to occur than other accidents [

16].

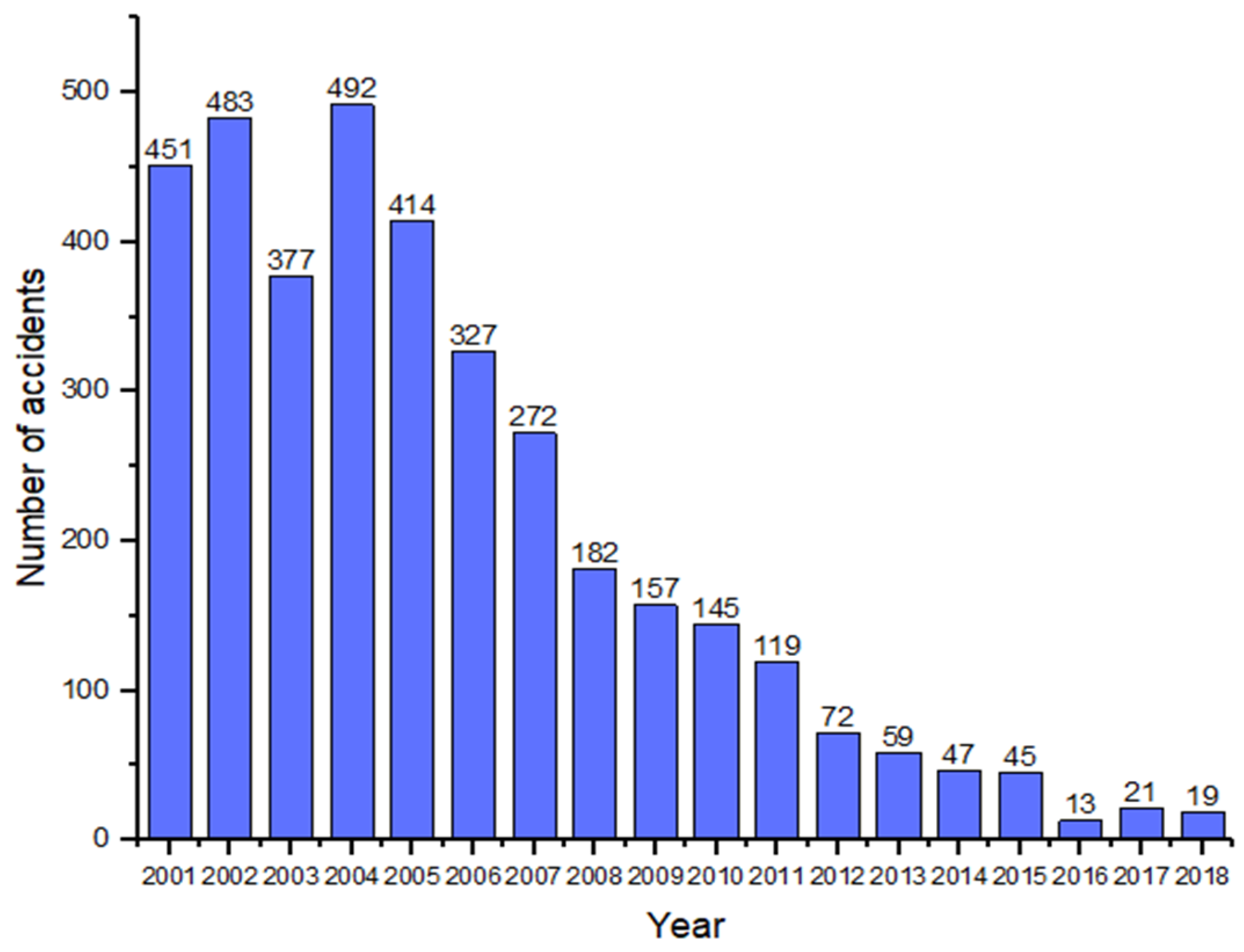

This paper shows statistics data on the occurrence of coal mine accidents in China from 2001 to 2018 and presents them in the form of a histogram. It can also be seen in

Figure 2 that gas explosion accidents have been declining year by year. The reasons for this situation are that more attention has been paid to mine accidents, and more advanced equipment and technology have been invested in China. Further, Coal mine accidents around the world have been well controlled and prevented, and many countries have adopted advanced coal mine production equipment and technology to ensure the safety of miners. However, for coal mine production accidents in China, gas explosion accidents are still a prominent problem in the field of coal mine safety and occupy an absolute proportion in major and special mine accidents [

2,

17]. Therefore, in order to prevent the occurrence of gas explosion accidents, it is necessary to go deep into the accident-causing mechanisms and consider the causes of accidents [

18]. The three basic elements of a gas explosion accident are gas, ignition source, and sufficient oxygen. The generation of the fire source is controllable, and the causes are almost all related to human activities [

19,

20]. Simultaneously, some studies have proved that the proportion of human factors causing gas explosion accidents is about 97% [

21]. Therefore, reducing people’s unsafe behaviors has become the key to preventing gas explosions [

22]. However, the actual situation of gas explosion accident research is that more than 80% of scientific research projects aim to solve the unsafe state of objects and fewer than 20% of scientific research projects aim to study the behavioral causes of accidents. Some scholars have investigated coal mine gas explosions and determined that the accidents occurred because of unsafe human behaviors. For example, Meng et al. [

23] believed that many unsafe behaviors would lead to gas explosions and made a risk assessment of unsafe behaviors. Yin et al. [

10] counted the gas explosion accidents from 2000 to 2014 and clearly analyzed the unsafe behaviors. The above studies show that safety must be considered from the perspective of unsafe human behaviors in order to prevent gas explosion accidents [

8].

Risk assessment is an important means to study unsafe behaviors [

24]. It is the main research content in the field of coal mine safety. Meanwhile, it is also important to reduce gas explosion accidents by conducting a risk assessment of unsafe behaviors [

25,

26]. However, many studies only consider the assessment of unsafe behaviors of coal mine systems, but do not assess the risk of each working type [

27,

28]. It can also be said that most of these studies assess risks from a systematic point of view [

29,

30,

31], and few studies have been conducted to assess the risk of unsafe behaviors involved in a type of disaster [

32]. In this study, 200 gas explosion accidents were selected, and unsafe behaviors were extracted and classified; then, the key working types related to gas explosion were summarized. The accident losses will be quantified, and a risk assessment model will be established based on the Monte Carlo method to assess the risk of different working types. It is worth noting that the risk assessment method used in this paper is probabilistic risk assessment. It can comprehensively characterize the distributions and values of parameters and directly deal with the uncertainty of each risk factor, which will make the results more scientific and credible. The results of this paper can help us better understand the risks of unsafe behaviors associated with gas explosions and help to provide a basis for effective control of unsafe behaviors in gas explosion accidents.

4. Result and Discussion

4.1. Unsafe Behavior Risk Assessment Results

4.1.1. The Possibility and Hazard Index of Unsafe Behavior

In this study, Crystal Ball software 11.1 (ORACLE, Redwood City, CA, USA) was used to test the goodness-of-fit test for data, and the distributions of these factor’s parameters were more consistent. The results show that the parameter’s distributions of the four key working types related to coal mine gas explosion accidents are most consistent with triangular distribution, and the probabilities of unsafe behaviors are shown in

Table 8.

From the results in

Table 8, it can be seen that ventilation is the most common type of work to cause gas explosion accidents, both from the point of view of the occurrence of unsafe behavior and from the perspective of the revised occurrence probability. The possible reason for the results in this table is that ventilation is the most important factor for preventing gas explosions in coal mines. Ventilation problems can occur due to faulty ventilating equipment and the unsafe behavior of workers. The number of unsafe behaviors in gas prevention and fire extinguishing ranks second, because the basic element of a gas explosion accident is the ignition source, and the workers in the gas prevention and fire extinguishing working types have imperfect preventive measures, which will be likely to lead to a gas explosion accident. The probabilities of unsafe behavior in the blasting and electrician working types are relatively small. The reason for this difference in results may be that the blasting equipment and electrical equipment in modern coal mines are relatively advanced, which can effectively guarantee the safety of coal mine production and miners.

According to the relevant data of coal mine gas explosions and the actual production situation of coal mines, the authors analyzed the possibility and severity of gas explosion accidents caused by unsafe behaviors and determined the value of the accident hazard index. At the same time, the values were tested again by the Crystal Ball software 11.1; meanwhile, the accident hazard index obeyed normal distribution. The results are shown in

Table 9.

4.1.2. Risk Value of Unsafe Behavior

According to Formulas (3) and (4) for the calculation of the risk value of unsafe behaviors, the Monte Carlo method is used to carry out a statistical simulation on the risk model composed of the unsafe behaviors’ revised probability for the key working types and the value of the accident hazard index, setting the maximum number of simulations to 10,000, with a confidence interval of 95%. Simultaneously, on the basis of the probabilistic risk assessment model of unsafe behaviors, the risk of unsafe behaviors in each post is obtained. The results are shown in

Table 10, and the risk values show lognormal distributions.

It can be seen from the table that for the key working types related to gas explosion accidents, the unsafe behavior risk value of the ventilation type is the largest. Among these risks, the risks of OIW and UUD unsafe behaviors are relatively high at 4.35 × 10−1 and 1.51 × 10−1 respectively. Secondly, the risk of unsafe behaviors exists in the blasting working type, and the risk of unsafe behaviors in types UUD and OIW are higher at 2.25 × 10−1 and 1.49 × 10−1. In third place is the risk value of gas prevention and fire extinguishing, and the risk of OIW unsafe behaviors is higher. Finally, the risk value of the electrician working type is still the highest risk of unsafe behavior in OIW.

From the perspective of the type of unsafe behaviors, the occurrence frequency and possibility of the OIW and UUD types of unsafe behaviors are higher. For example, the risk values of ventilation, gas prevention and fire extinguishing, blasting, and electrician for OIW unsafe behavior are 4.35 × 10−1, 3.35 × 10−1, 1.49 × 10−1 and 9.96 × 10−2, respectively. The risk value caused by the unsafe behavior of UUD is also relatively high, and the risk value caused by the other unsafe behaviors is relatively low; these values are not listed one by one. However, it is worth noting that the impacts of different types of unsafe behaviors among these four key working types are distinguishing. That is to say, if measures are taken to avoid the occurrence of gas explosion accidents, it is necessary to take precautions against the characteristics of different working types.

Figure 4 shows the unsafe behaviors’ risk in four key working types; this figure contains the minimum risk, quarter, median, three-quarters and maximum risk value for each type of work, and characterizes the distribution of risk. The results of

Figure 3 can also support the conclusion above. The risk values of the four working types occur in the order of ventilation > gas prevention and fire extinguishing > blasting > electrician. Ventilation types have the greatest risk, while the risk values for each type of unsafe behavior risk for the electrician type show little difference, thus producing the results shown in the figure.

Based on the above results, the ventilation in coal mines is the key to preventing gas explosion accidents. For the unsafe ventilation behaviors, it is recommended to check the ventilation facilities in time and operate the ventilation machines according to the regulations. Avoiding unsafe behaviors during actual operations is critical to preventing gas accumulation and reducing gas anomalies in underground mines. Undoubtedly, it is also important to prevent gas prevention and fire extinguishing, as well as blasting and electrical operations, whose purpose is to control the generation of fire sources. Mine workers should strengthen the monitoring and inspection of gas and fire sources to avoid gas explosions.

4.2. Sensitivity Analysis

Sensitivity analysis can obtain the parameters that affect the results of risk assessment, and then one can take appropriate measures to improve the factors related to each parameter [

53,

54].

Figure 5 shows the sensitivity of each factor.

The accident loss index has the greatest impact on the risk results, reaching 43.71%, while the sensitivities of the remaining parameters are relatively small, including parameters a, b, c, d, e, f, g, h, all of which are negatively sensitive and have a negative impact on the results. Among these above parameters, the effects of f (working environment factor) and d (workload factor) are large at −14.13% and −12.11%, respectively. Secondly, h (skill knowledge factor) and c (safety reward factor) also had moderately negative effects on the results, which were −9.21% and −8.24% respectively. Finally, a (regulatory factors), b (educational training factors), g (safety physiology and psychological factors), and e (equipment factors) had less negative impact on risk outcomes. The results are also consistent with those of the studies on the probability of unsafe behaviors in key working types.

Through the analysis of the above data, several points can be obtained: the same parameter has distinct effects on workers in different working types. Therefore, to avoid the occurrence of coal mine gas explosion accidents, it is necessary to design diverse methods and measures in a targeted manner; because of the great influence of the working environment and workload, coal mine enterprises should improve the working environment and change the workload according to the working characteristics of different working types. For example, because blasting workers are in a dangerous working environment with noise and pollution for a long time, they need to improve their protective equipment, or switch their jobs in a timely manner, so as to avoid causing coal miners to be engaged in the same kind of work all the time.

4.3. Uncertainty Analysis

The results of this study have theoretical and practical significance. Previous studies have rarely conducted risk assessment of unsafe behavior, but this paper selected 200 gas explosion accidents from the perspective of unsafe behaviors risk and analyzed the unsafe behaviors involved. This study is representative and provides ideas and methods for the risk assessment of unsafe behaviors of other accidents in coal mines.

In the probabilistic risk assessment process, the sample size is very important and will have a great impact on the assessment results, but the research in this paper may have an impact on the results because of the insufficient sample size. From the samples collected in this paper, the author summarizes four key working types based on the unsafe behaviors extracted. If more samples are collected, the number of unsafe behaviors and the key working types will be greater. Secondly, the selection of influencing factors of unsafe behaviors and the relationship between factors will lead to uncertainty. Although the relationships between various factors have been obtained on the basis of previous research, these relationships have not been verified, which is also an important reason for uncertainty. Finally, the probability of accidents caused by unsafe behaviors and the quantitative index of accident losses are also obtained and calculated by experts’ scores and questionnaires. All of the above may make the results subjective.

Further research and analysis is still needed to address these uncertainties. For example, the big data method is used to identify and collect unsafe behaviors in order to reduce the uncertainty caused by the sample size of unsafe behaviors [

55]. Simultaneously, the factors and relationships that affect the unsafe behavior of coal miners are deeply considered, and the influencing factors are deeply normalized and weighted. In addition, it is necessary to further determine the accident loss quantification index.

4.4. Unsafe Behavior Risk Management

This article takes coal mine gas explosion accidents as the research background and evaluates the risk of the unsafe behaviors of coal miners. The risk results are provided by the probability of workers’ unsafe behaviors and the loss of accidents caused by unsafe behaviors. The preceding part of the article has shown that the occurrence of unsafe behaviors is related to personal factors, organizational factors, and environmental factors, and the number of unsafe behaviors in these four key working types is in the order of ventilation > gas prevention and fire extinguishing > blasting > electrician. Coal mine enterprises should develop corresponding measures to prevent the occurrence of gas explosion accidents according to the characteristics of different working types. As far as we know, for coal mining companies, safety culture and safety climate are indispensable supports for the continuous realization of safety production. Because only relying on scientific and technological means cannot achieve real safety, safety culture and scientific management methods are needed to make workers clearly understand their responsibilities and prevent accidents. Scientific and effective safety management methods, specific safety management objectives, favorable safety production environments, safety culture, and safety climate form a safety management system. A perfect safety management system is constructed by management and workers, whose function is to improve the production performance of enterprises and reduce the occurrence of unsafe behaviors. However, the most important measure is to curb the occurrence of unsafe behaviors.

The most effective study of unsafe behaviors is Behavior-Based Safety (BBS), which is based on human factor engineering and behavior-based theory and gradually builds into a systematic safety management system [

56]. BBS mainly conducts research on unsafe human behaviors and aims at cultivating people’s safety awareness as the main perspective to continuously improve the overall safety level [

57]. By exploring the rules of behaviors development, qualitative analysis and quantitative measurement of behaviors can be carried out, and then the method for correcting behaviors can be standardized. Implementing BBS management processes can improve miners’ thinking and behavior modes to achieve the effect of accident prevention and improve the safety production performance of coal mine enterprises [

21]. BBS not only pays attention to the correction of miners’ unsafe behaviors, but also pays attention to the establishment of safety psychology, which has a positive impact on the working attitude of miners. Ultimately, making behavioral safety management the first priority of the enterprise can essentially reduce the generation of unsafe behaviors.

5. Conclusions

This paper assesses risks from the perspective of unsafe human behaviors, which is innovative compared with previous studies. Firstly, 200 coal mine gas explosion accidents were selected to extract unsafe behaviors and key working types. Secondly, the model for calculating the probability of unsafe behaviors was improved, and the probabilities of unsafe behaviors were corrected effectively. At the same time, the quantitative accident loss indexes caused by unsafe behaviors were obtained. Finally, the risk assessment model of unsafe behaviors was established and combined with the Monte Carlo simulation method to obtain the evaluation results. This method filled in the gap of the relevant research fields. The research results can help coal mine enterprises effectively avoid the occurrence of gas explosion accidents and also provide a method for risk assessment that has practical significance for other accidents in coal mines.

The results showed that among the four key working types related to gas explosions, the order of the number of unsafe behaviors occurring is as follows: ventilation > gas prevention and fire extinguishing > blasting > electrician. The risk assessment results were also in the above order. Considering the types of unsafe behaviors, the occurrence probability of unsafe behaviors in OIW and UUD were relatively high in four key working types. Sensitivity analysis showed that the impact of the accident loss index was the biggest, accounting for 43.71%, followed by f (work environment factor) and d (workload factor), which had negative impacts on the results, respectively −14.13% and −12.11%.

According to the results obtained in this paper, coal mine enterprises should attempt to prevent unsafe behaviors according to the characteristics of different working types. For example, in view of the unsafe behaviors of ventilation, it is suggested that ventilation facilities should be checked in time and ventilators should be operated according to regulations. More importantly, scientific and effective safety management methods, specific safety management objectives, favorable safety production environment, safety culture, and safety climate are all important factors in the formation of a sound safety management system. Constructing a complete safety management system is an important measure to effectively improve the performance of coal enterprises and reduce the occurrence of miners’ unsafe behaviors. In a word, this research provides reference value for the safety management of coal mine enterprises.