Macro Risk: A Versatile and Universal Strategy for Measuring the Overall Safety of Hazardous Industrial Installations in China

Abstract

:1. Introduction

2. Theory and Methodology

2.1. Macro Risk

- With total risk unchanged in an area, assume that all congeneric installations are identical and that each individual has the same risk. Under this assumption, the same risk is thus the required average risk, namelywhere N represents the number of installations in a certain area, Ri indicates the risk of the ith installation, and denotes the average risk;

- How is it ensured that total risk is unchanged? A simple way is to utilize the historical accident data (annual data) of the installations to calculate average risk. This can be used because risk is closely related to accident probability and consequences (Equation (1));

- Calculate the average risk based on probability theory. According to the two steps above, the problem is then transformed into an independent repetitive trial for an individual. Combining Equation (1) with related probability theory [38], we can finally obtain an expression for calculating the macro risk, as follows:where Rm represents the macro risk of a certain type of installation, p indicates the frequency of accidents per year, E(L) denotes the expected value of L per year, M is the number of installation-related accidents per year in the area, Lj is the loss of the jth accident, and Lt is the total loss of accidents per year in the area.

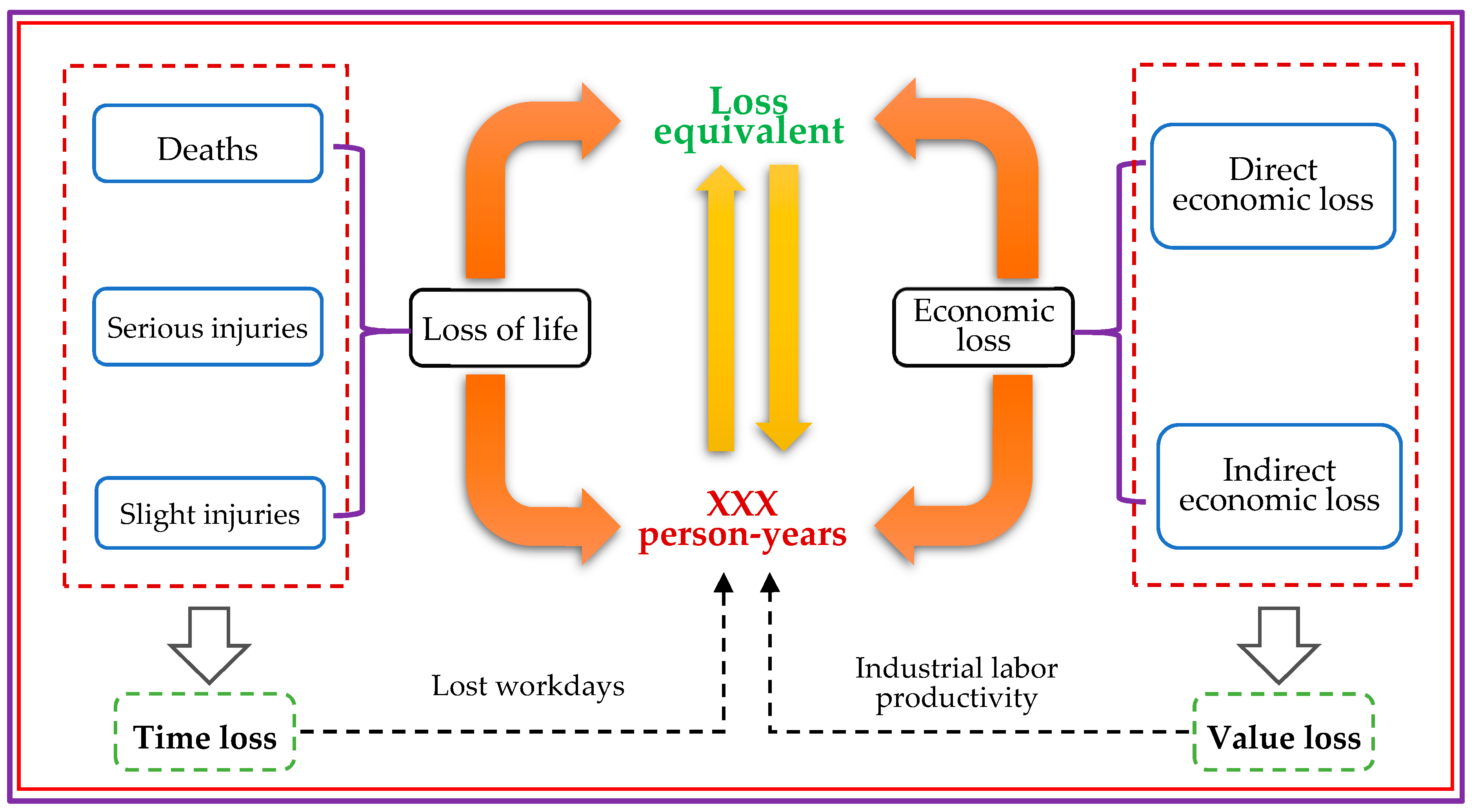

2.2. Loss Equivalent

3. Dimensional Normalization of Varied Losses

3.1. Loss of Life

3.2. Economic Loss

4. Discussion

5. Practical Applications

5.1. Macro Risk of Boilers in China

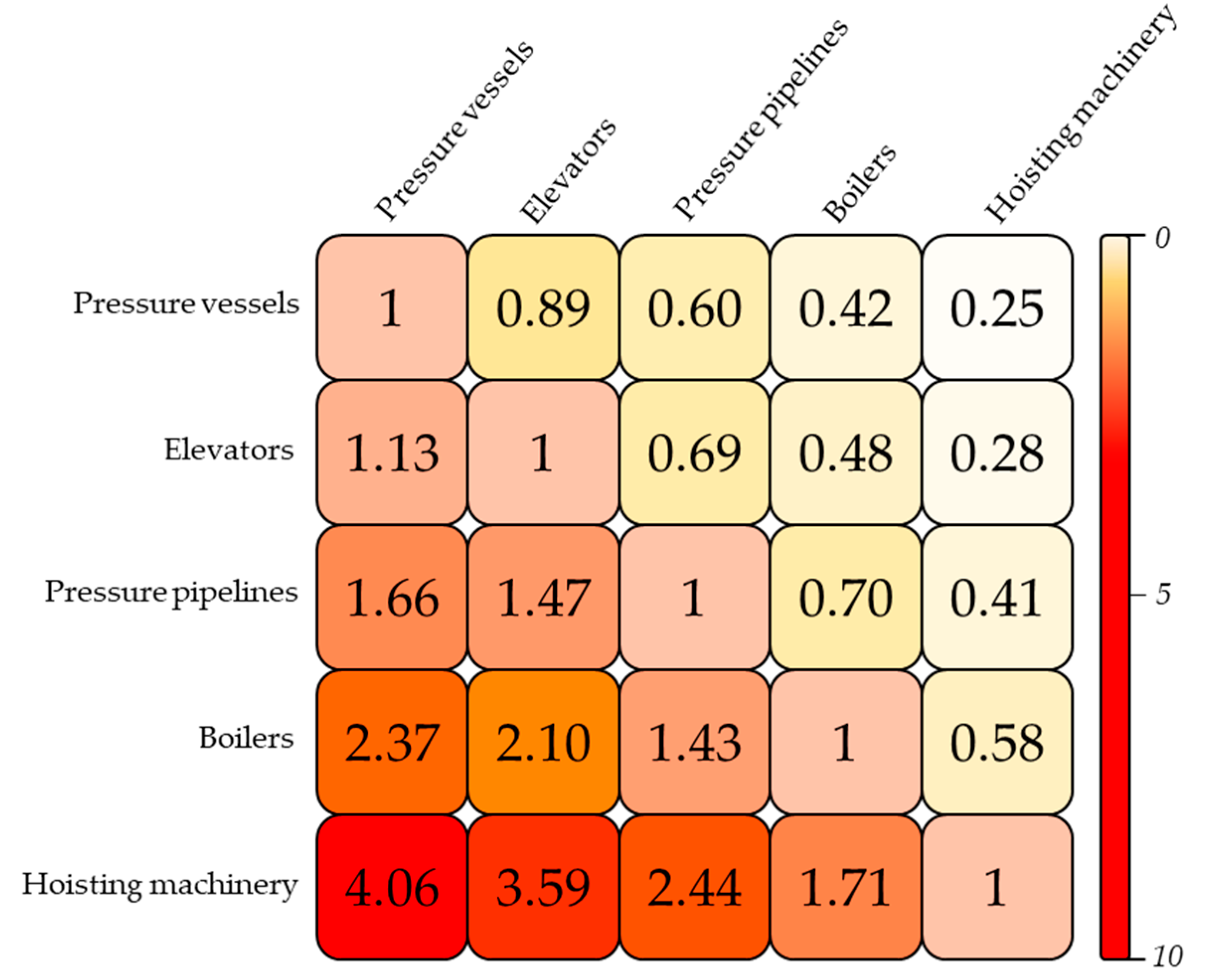

5.2. Absolute Risk and Relative Risk

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Treasury Board. Integrated Risk Management Framework; Technical Report; Treasury Board of Canada: Ottawa, Canada, 2001. [Google Scholar]

- Villa, V.; Paltrinieri, N.; Khan, F.; Cozzani, V. Towards dynamic risk analysis: A review of the risk assessment approach and its limitations in the chemical process industry. Saf. Sci. 2016, 89, 77–93. [Google Scholar] [CrossRef]

- IEC 60300-3-9. Dependability Management—Application Guide: Risk Analysis of Technological Systems, 1st ed.; International Electrotechnical Commission: Geneva, Switzerland, 1995. [Google Scholar]

- Johansen, I.L. Foundations and Fallacies of Risk Acceptance Criteria; ROSS (NTNU) 201001; NTNU: Trondheim, Norway, 2010. [Google Scholar]

- Øien, K. A framework for the establishment of organizational risk indicators. Reliab. Eng. Syst. Saf. 2001, 74, 147–167. [Google Scholar] [CrossRef]

- Jonkman, S.N.; van Gelder, P.H.; Vrijling, J.K. An overview of quantitative risk measures for loss of life and economic damage. J. Hazard. Mater. 2003, 99, 1–30. [Google Scholar] [CrossRef]

- Zhao, J.; Luo, S.; Gong, Y.; Li, F.; Luo, Y.; Huang, Y. Research on three dimensional risk ranking model of tanks major hazards. Chin. Saf. Sci. J. 2015, 25, 135–140. [Google Scholar]

- Campbell, S. Determining overall risk. J. Risk Res. 2005, 8, 569–581. [Google Scholar] [CrossRef]

- Kirchsteiger, C. Workshop summary evaluation and how to proceed international workshop on promotion of technical harmonisation on risk-based decision-making. Saf. Sci. 2002, 40, 383–395. [Google Scholar] [CrossRef]

- Lowrance, W.W. Of Acceptable Risk—Science and the Determination of Safety; Los Altos: California, CA, USA, 1976. [Google Scholar]

- Rowe, W.D. An Anatomy of Risk; John Wiley & Sons: New York, NY, USA, 1977. [Google Scholar]

- Willis, H.H. Guiding resource allocations based on terrorism risk. Risk Anal. 2007, 27, 597–606. [Google Scholar] [CrossRef]

- Bottelberghs, P.H. Risk analysis and safety policy developments in The Netherlands. J. Hazard. Mater. 2000, 71, 59–84. [Google Scholar] [CrossRef]

- Piers, M. Methods and Models for the Assessment of Third Party Risk due to Aircraft Accidents in the Vicinity of Airports and Their Implications for Societal Risk. In Quantified Societal Risk and Policy Making; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1998. [Google Scholar]

- Khan, A.; Jamal, S.Q. Risk assessment for dam failure using probability approach. In Proceedings Applications of Statistics and Probability; Balkema: Rotterdam, The Netherlands, 2000; p. 1151. [Google Scholar]

- Laheij, G.M.H.; Post, J.G.; Ale, B.J.M. Standard methods for land-use planning to determine the effects on societal risk. J. Hazard. Mater. 2000, 71, 269–282. [Google Scholar] [CrossRef]

- Yelokhin, A.N. Complex risk analysis for Novgorodsky’s region’s population. In Proceedings of the Annual Meeting of the Society for Risk Analysis-Europe; New Risk Frontiers: Stockholm, Sweden, 1997. [Google Scholar]

- NORSOK Z-013. Risk and Emergency Preparedness Analysis; Norsok Standard, Standard Norge: Oslo, Norway, 2010. [Google Scholar]

- The State Council of China. Guidelines for Curbing Major and Extraordinarily Serious Accidents; Chinese Government Document; The State Council of China: Beijing, China, 2016.

- The State Council of China. Suggestions on Building a Dual Prevention Mechanism for the Implementation of Guidelines for Curbing Major and Extraordinarily Serious Accidents; Chinese Government Document; The State Council of China: Beijing, China, 2016.

- Communist Party of China Central Committee the State Council of China. Opinions on Promoting the Reform and Development in the Safe Production Field; Chinese Government Document; The State Council of China: Beijing, China, 2016.

- The State Council of China. The 13th Five-Year Plan on Safe Production; Chinese Government Document; The State Council of China: Beijing, China, 2017.

- China’s State Administration of Work Safety. Notice on Further Strengthening the Safety Production of Central Enterprises; Chinese Government Document; The State Council of China: Beijing, China, 2017.

- Dionne, G. Risk management: History, definition, and critique. Risk Manag. Insurance Rev. 2013, 16, 147–166. [Google Scholar] [CrossRef]

- Harrington, S.; Niehaus, G. Risk Management and Insurance; Irwin/McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Mehr, R.I.; Hedges, B.A. Risk Management in the Business Enterprise; Irwin: Homewood, IL, USA, 1963. [Google Scholar]

- Williams, A.; Heins, M.H. Risk Management and Insurance; McGraw-Hill: New York, NY, USA, 1964. [Google Scholar]

- Chen, N.; Chen, L.; Ma, Y.; Chen, A. Regional disaster risk assessment of china based on self-organizing map clustering, visualization and ranking. Int. J. Disaster Risk Reduct. 2019, 33, 196–206. [Google Scholar] [CrossRef]

- Grünthal, G.; Thieken, A.H.; Schwarz, J.; Radtke, K.S.; Smolka, A.; Merz, B. Comparative risk assessments for the city of cologne—Storms, floods, earthquakes. Nat. Hazards 2006, 38, 21–44. [Google Scholar] [CrossRef]

- Li, M.; Yu, H.; Jin, H.; Liu, P. Methodologies of safety risk control for china’s metro construction based on bim. Saf. Sci. 2018, 110, 418–426. [Google Scholar] [CrossRef]

- Luo, Y. Risk Analysis and Safety Assessment; Chemical Industry Press: Beijing, China, 2017. [Google Scholar]

- ISO 31000-2009. Risk Management—Principles and Guidelines; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- GB/T 23694-2013. Risk Management—Vocabulary; Chinese Standard SAC/TC 310: Beijing, China, 2013. [Google Scholar]

- MIL-STD-882E. Standard Practice for System Safety; US Department of Defense: Washington, DC, USA, 2012.

- Luo, Y. Safety Science; Science Press: Beijing, China, 2015. [Google Scholar]

- Wilson, R.; Crouch, A. Risk/Benefit Analysis; Ballinger Publishing Company: Cambridge, UK, 1982; p. 9. [Google Scholar]

- Rausand, M. Risk Assessment: Theory, Methods, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Casella, G.; Berger, R.L. Statistical Inference, 2nd ed.; Duxbury Press: Pacific Grove, CA, USA, 2002; p. 55. [Google Scholar]

- Ball, D.J.; Floyd, P.J. Societal Risk; Technical Report for Health and Safety Executive: London, UK, 1998. [Google Scholar]

- Jorissen, R.E.; Stallen, P.J.M. Quantified societal risk and policy making. Technol. Risk Soc. 1998, 12, 310. [Google Scholar]

- GB 6721-86. Statistical Standard of Economic Losses from Injury-Fatal Accidents of Enterprise Staff and Workers; Chinese Standard, China National Bureau of Standards: Beijing, China, 1986.

- State Administration of Quality Supervision, Inspection and Quarantine. Chinese Yearbook of Quality Supervision, Inspection and Quarantine; China Standards Press: Beijing, China, 2012.

- Gosselin, M. Analyse des Avantages et des Coûts de la Santé et de la Sécurité au Travail en Entreprise: Développement de L’outil D’analyse; Rapport de Recherche R-375 for IRSST: Montréal, QC, Canada, 2004. [Google Scholar]

- Heinrich, H.W. Industrial Accident Prevention: A Scientific Approach; McGraw Hill: New York, NY, USA, 1941. [Google Scholar]

- Horm, J.W.; Sondik, E.J. Person-years of life lost due to cancer in the united states. Am. J. Public. Health 1989, 79, 1490–1493. [Google Scholar] [CrossRef]

- GB/T 15499-1995. The Lost Workdays STANDARD for Injury Accidents; Chinese Standard, China State Bureau of Technical Supervision: Beijing, China, 1995.

- Guo, H.; Tanaka, S.; Halperin, W.E.; Cameron, L.L. Back pain in the us industry and estimate of lost work days. Am. J. Public. Health. 1999, 89, 1029–1035. [Google Scholar] [CrossRef]

- Coleman, P.J.; Kerkering, J.C. Measuring mining safety with injury statistics: Lost workdays as indicators of risk. J. Saf. Res. 2007, 38, 523–533. [Google Scholar] [CrossRef]

- Santana, V.S.; Araújofilho, J.B.; Silva, M.; Albuquerqueoliveira, P.R.; Barbosabranco, A.; Nobre, L.C. Mortality, years of life lost, and incidence of occupational accidents in the state of bahia, Brazil. Cad. Saude Publica 2007, 23, 2643–2652. [Google Scholar] [CrossRef]

- US. Department of Labor Bureau of Labor Statisticas [BLS]. Standardization of Industrial Accident Statistics; Bulletin No. 276; Government Printing Office: Washington, DC, USA, 1920.

- GB 6441-86. The Classification for Casualty Accidents of Enterprise Staff and Workers; Chinese Standard, China National Bureau of Standards: Beijing, China, 1986.

- Jallon, R.; Imbeau, D.; Marcellis-Warin, N.D. Development of an indirect-cost calculation model suitable for workplace use. J. Saf. Res. 2011, 42, 149–164. [Google Scholar] [CrossRef]

- Oxenburgh, M.S.; Guldberg, H.H. The economic and health effects on introducing a safe manual handling code of practice. Int. J. Ind. Ergonom. 1993, 12, 241–253. [Google Scholar] [CrossRef]

- Dorman, P. The Economics of Safety, Health and Wellbeing at Work; International Labour Organization: Geneva, Switzerland, 2000. [Google Scholar]

- Brody, B.; Létourneau, Y.; Poirier, A. Les coûts Indirects des Accidents du Travail; Rapport de Recherche R-044 for IRSST: Montréal, QC, Canada, 1990. [Google Scholar]

- Head, L.; Harcourt, M. The direct and indirect costs of workplace accidents in New Zealand. In Proceedings of the 11th AIRAANZ Conference, Brisbane, Australia, 30 January–1 February 1997. [Google Scholar]

- National Safety Council [NSC]. Injury Facts; National Safety Council: Chicago, IL, USA, 1985. [Google Scholar]

- Hinze, J. Indirect Costs of Construction Accidents; The construction Industry Institute (CII): Austin, TX, USA, 1991. [Google Scholar]

- The State Council of China. Regulations on Safety Supervision over Special Equipment; Chinese Legal Publishing House: Beijing, China, 2009.

- State Administration of Quality Supervision, Inspection and Quarantine. Chinese Yearbook of Quality Supervision, Inspection and Quarantine 2007; China Standards Press: Beijing, China, 2007.

- State Administration of Quality Supervision, Inspection and Quarantine. Chinese Yearbook of Quality Supervision, Inspection and Quarantine 2008; China Standards Press: Beijing, China, 2008.

- State Administration of Quality Supervision, Inspection and Quarantine. Chinese Yearbook of Quality Supervision, Inspection and Quarantine 2009; China Standards Press: Beijing, China, 2009.

- State Administration of Quality Supervision, Inspection and Quarantine. Chinese Yearbook of Quality Supervision, Inspection and Quarantine 2010; China Standards Press: Beijing, China, 2010.

- State Administration of Quality Supervision, Inspection and Quarantine. Chinese Yearbook of Quality Supervision, Inspection and Quarantine 2011; China Standards Press: Beijing, China, 2011.

- Wang, Y.; Zhang, L.; Li, X. Analysis of Economic Loss of Accident Based on Direct and Indirect Coefficient Method. J. North China Inst. Sci. Technol. 2017, 14, 86–90. [Google Scholar]

- Pei, J.; Wang, G.; Luo, S.; Luo, Y. Societal risk acceptance criteria for pressure pipelines in China. Saf. Sci. 2018, 109, 20–26. [Google Scholar] [CrossRef]

| Year | Names | Agencies That Issue Documents | Key Points on Risk Management |

|---|---|---|---|

| 2016 | Guidelines for curbing major and extraordinarily serious accidents [19] | The State Council of China |

|

| 2016 | Suggestions on building a dual prevention mechanism for the implementation of guidelines for curbing major and extraordinarily serious accidents [20] | The State Council of China |

|

| 2016 | Opinions on promoting reform and development in the safe production field [21] | Communist Party of China Central Committee, the State Council of China |

|

| 2017 | The 13th five-year plan on safe production [22] | The State Council of China |

|

| 2017 | Notice on further strengthening the safety production of central enterprises [23] | China’s State Administration of Work Safety |

|

| Year | N | ld | lr1 | la (Chinese Yuan (CNY)) | ILP (CNY) |

|---|---|---|---|---|---|

| 2011 | 62.03 × 104 | 24 | 54 | 723.3 × 104 | 10.07 × 104 |

| 2010 | 60.73 × 104 | 24 | 38 | 649.3 × 104 | 8.77 × 104 |

| 2009 | 59.52 × 104 | 23 | 64 | 566.35 × 104 | 7.60 × 104 |

| 2008 | 57.82 × 104 | 24 | 60 | 515.23 × 104 | 7.30 × 104 |

| 2007 | 53.41 × 104 | 19 | 35 | 66.3 × 104 | 6.27 × 104 |

| 2006 | 54.30 × 104 | 20 | 60 | 446.2 × 104 | 5.52 × 104 |

| Year | N | ld | lr | la (CNY) |

|---|---|---|---|---|

| 2010 | 150 × 104 | 83 | 27 | 2839.78 × 104 |

| 2009 | 135.27 × 104 | 85 | 42 | 1786.68 × 104 |

| 2008 | 118.28 × 104 | 74 | 31 | 7085.87 × 104 |

| 2007 | 95.79 × 104 | 94 | 33 | 1267.4 × 104 |

| 2006 | 82.36 × 104 | 80 | 35 | 1001.3 × 104 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Pei, J. Macro Risk: A Versatile and Universal Strategy for Measuring the Overall Safety of Hazardous Industrial Installations in China. Int. J. Environ. Res. Public Health 2019, 16, 1680. https://doi.org/10.3390/ijerph16101680

Wang G, Pei J. Macro Risk: A Versatile and Universal Strategy for Measuring the Overall Safety of Hazardous Industrial Installations in China. International Journal of Environmental Research and Public Health. 2019; 16(10):1680. https://doi.org/10.3390/ijerph16101680

Chicago/Turabian StyleWang, Guantao, and Jingjing Pei. 2019. "Macro Risk: A Versatile and Universal Strategy for Measuring the Overall Safety of Hazardous Industrial Installations in China" International Journal of Environmental Research and Public Health 16, no. 10: 1680. https://doi.org/10.3390/ijerph16101680

APA StyleWang, G., & Pei, J. (2019). Macro Risk: A Versatile and Universal Strategy for Measuring the Overall Safety of Hazardous Industrial Installations in China. International Journal of Environmental Research and Public Health, 16(10), 1680. https://doi.org/10.3390/ijerph16101680