1. Introduction

In operational mines, groundwater flooding of the working area is prevented by continuous pumping operations. However, once this pumping ceases, when a mine is abandoned, the groundwater level in the mine begins to rise again—a phenomenon called “groundwater rebound.” When this phenomenon occurs, groundwater either gradually flows back into the underground voids that were generated, due to mining activities or flows back into the strata near the mine. As a result, the groundwater level rises up to the groundwater discharge point; this is the level above which groundwater flowing into the mine flows back out to the surface or into surrounding aquifers, and is typically associated with mines because of artificial structures, such as shafts or drifts, built for mining activities.

Predicting the groundwater rebound phenomenon in a mine area is important for two reasons. First, a plan for draining the groundwater flowing into the pit can be established based on this prediction. Second, in an abandoned mine, this prediction can be utilized to prevent the surrounding environment (water and soil) from being polluted by acid mine drainage. There have been many studies on the assessment and prevention of environmental pollution due to acid mine drainage [

1,

2,

3]. In particular, through prediction of the groundwater rebound phenomenon, we can forecast when groundwater that has flowed into a mining void after mine abandonment will fill the void and flow out and where this flow will occur. The combination of these predictions with mine drainage quality prediction technology enables the comprehensive assessment of changes in water quality resulting from mine outflow [

4].

The quantitative information provided by mine groundwater rebound prediction technology makes it one of several important technologies for preventing mine-associated damage in areas with abandoned mines. Many case studies have been reported that consider the development and field application of models for groundwater rebound prediction. Toran and Bradbury [

5] analyzed groundwater rebound in the vicinity of an abandoned lead and zinc mine using the MODFLOW model (United States Geological Survey, Virginia, United States), a representative finite difference groundwater flow model based on the Darcian groundwater flow equation [

6]. Similarly, Sherwood [

7] applied the MODFLOW model to predict the groundwater rebound associated with a large-scale coal field in the United Kingdom. Huisamen and Wolkersdorfer [

8] estimated the hydrogeochemical evolution of mine water over time, based on MODFLOW model using groundwater monitoring data and geochemical analyses. However, as the groundwater environment in mines is physically and hydraulically different from a “typical” groundwater environment, analysis of the mine groundwater rebound phenomenon using a conventional groundwater flow model, such as MODFLOW, presents many challenges [

4]. In particular, artificial structures built for mining activities, such as mine voids, shafts, and drifts, may have a significant effect on the hydraulic environment of groundwater in the mine. Although the flow of groundwater in the strata surrounding a mine void can be assumed to be a laminar groundwater flow, flow in the mine void itself is turbulent. Accordingly, for prediction of the mine groundwater rebound phenomenon, it is not appropriate to use existing groundwater flow models based on the conventional Darcian groundwater flow equation [

9], which assumes laminar flow; an alternative prediction method is required that accounts for the hydraulic characteristics specific to the mines.

To overcome the limitations of the MODFLOW model, MINEDW (Itasca Denver, Inc., Colorado, United States), a three-dimensional finite element groundwater flow code specifically for mining applications was developed [

10], based on the algorithms of Durbin and Berenbrock [

11]. It was designed to quantify the more detailed problems of the configuration of the phreatic surface and inflows to underground openings by supplementing inadequate discretization, poor representation of seepage faces, and the hydrodynamics of flow at discrete discharge points. A finite element grid facilitates the representation of complex geometries and highly-variable spatial discretization, which is particularly useful for mining applications with complex geologic structures and steep hydraulic gradients. In addition, MINEDW accounts for local resistance to flow at relatively constricted discharge points, such as drifts or drainholes, more effectively. However, although MINEDW has been specially designed to address the relatively unique hydrologic complexities of mining, it has limitations with respect to covering the relatively small portion of the region and requiring detailed data of the study area.

Younger and Adams [

12] made predictions of the groundwater rebound phenomenon for a coal field in Whittle and Shilbottle, UK. In this study, since it was possible to use detailed underground maps and groundwater level measurement data across many locations, changes in the groundwater level and surface runoff could be predicted at 2 h intervals using the physically based, fully 3D VSS-NET model of SHETRAN (Newcastle University, Newcastle upon Tyne, United Kingdom). In addition, Adams and Younger [

13] utilized the VSS-NET model to predict the groundwater rebound phenomenon in a tin mine in South Crofty, UK. However, although the VSS-NET model can perform precise analyses for small areas, its large data input requirements mean that the simulation efficiency drops sharply as the spatial scale increases.

The GRAM model, a semi-distributed model, was developed by Sherwood [

7] by simplifying the remaining mine area: the connection structure between the spatially distributed mine workings in the fully 3D groundwater flow model is excluded. The GRAM model (Newcastle University, Newcastle upon Tyne, United Kingdom) is a lumped parameter model that treats mine areas as interconnected ponds and pipes. To model the water flow in a pond or the outflow of water to the surface, the intra-pipe fluid flow equation is used. Several studies using the GRAM model have been carried out to analyze the mine groundwater rebound phenomenon associated with a coal field in South Yorkshire, UK [

14,

15,

16]. Although the GRAM model simplifies the underground environments as ponds and pipes, it still requires several parameters that are hard to acquire in abandoned mines. In addition, it only considers ponds to be interconnected with a horizontal pipe, of which both ends are at the same height. Recently, Choi et al. [

17,

18] developed a Windows console-type program using the FORTRAN language (International Business Machines Corporation (IBM), New York, United States) that facilitates the application of the GRAM model to abandoned mine areas. However, no such program has been developed with a Graphical User Interface (GUI); a GUI would simplify data processing and enable effective visualization of the analytical results. As a result, the GRAM model has been only rarely utilized for practical applications such as mine reclamation programs. Recently, a neural network model has been used to predict the groundwater rebound process at a restored open cut coal site [

19], and automated electrical resistivity tomography was considered as a means of monitoring groundwater rebound in an operational mine site [

20].

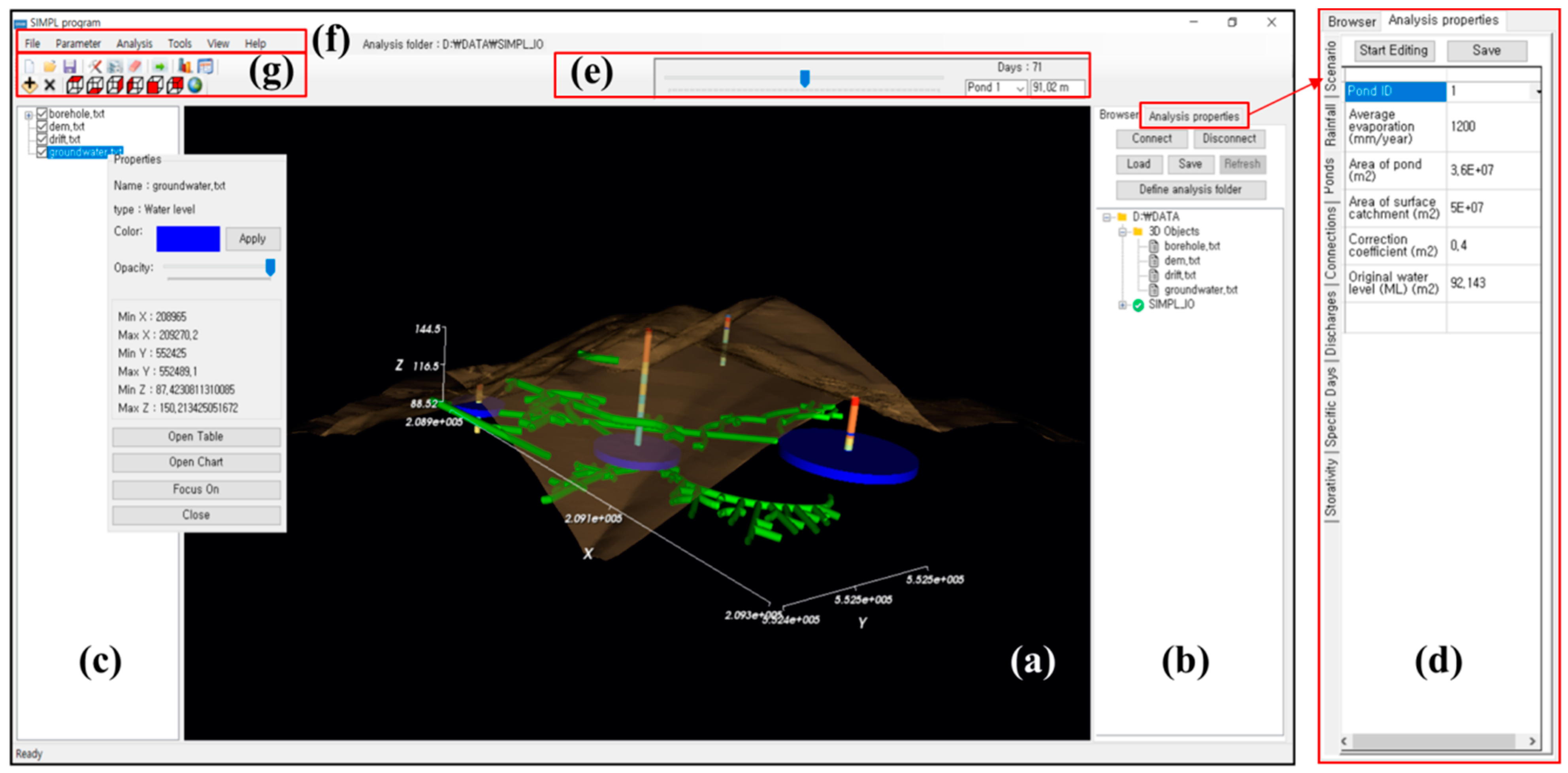

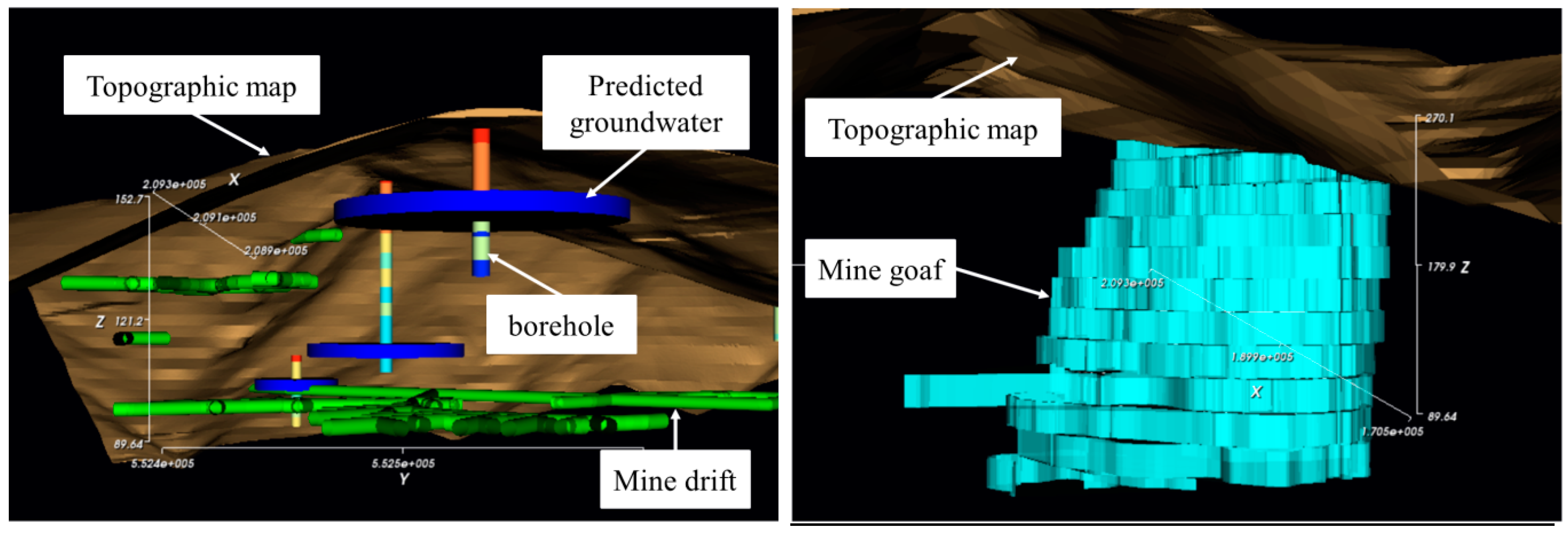

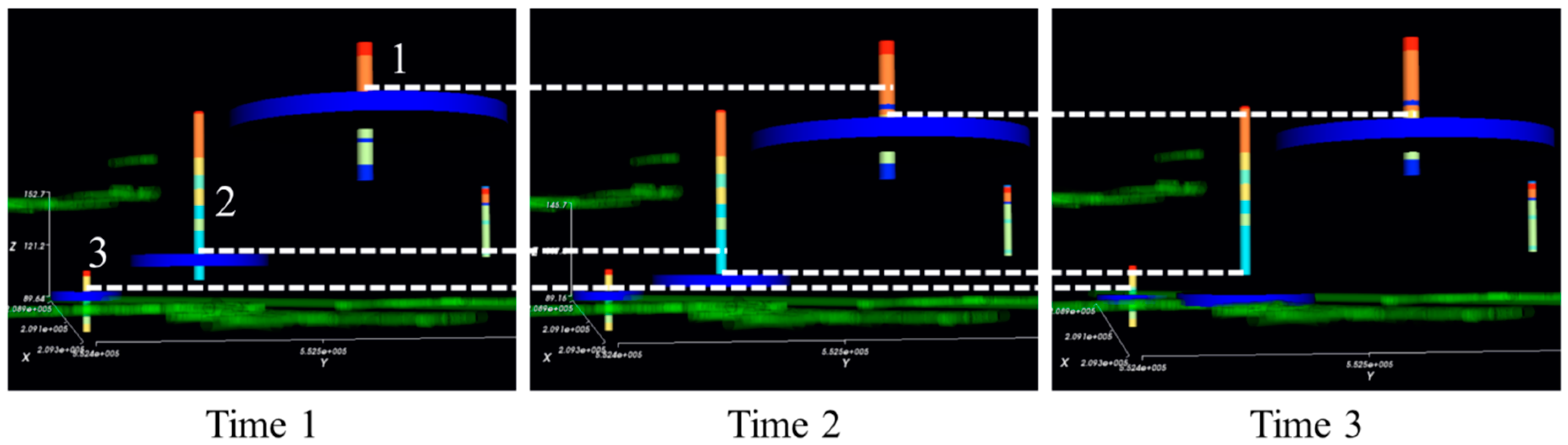

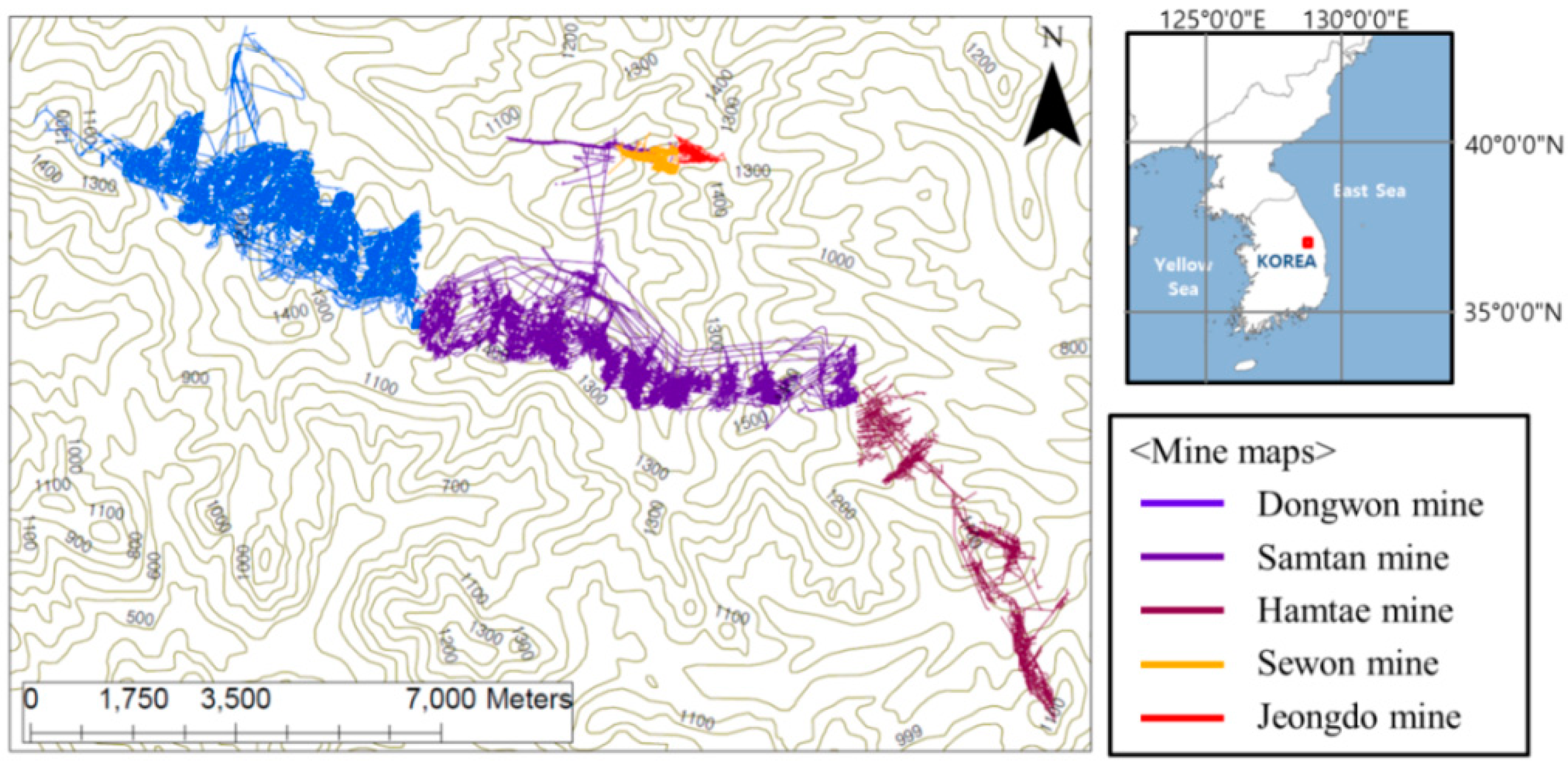

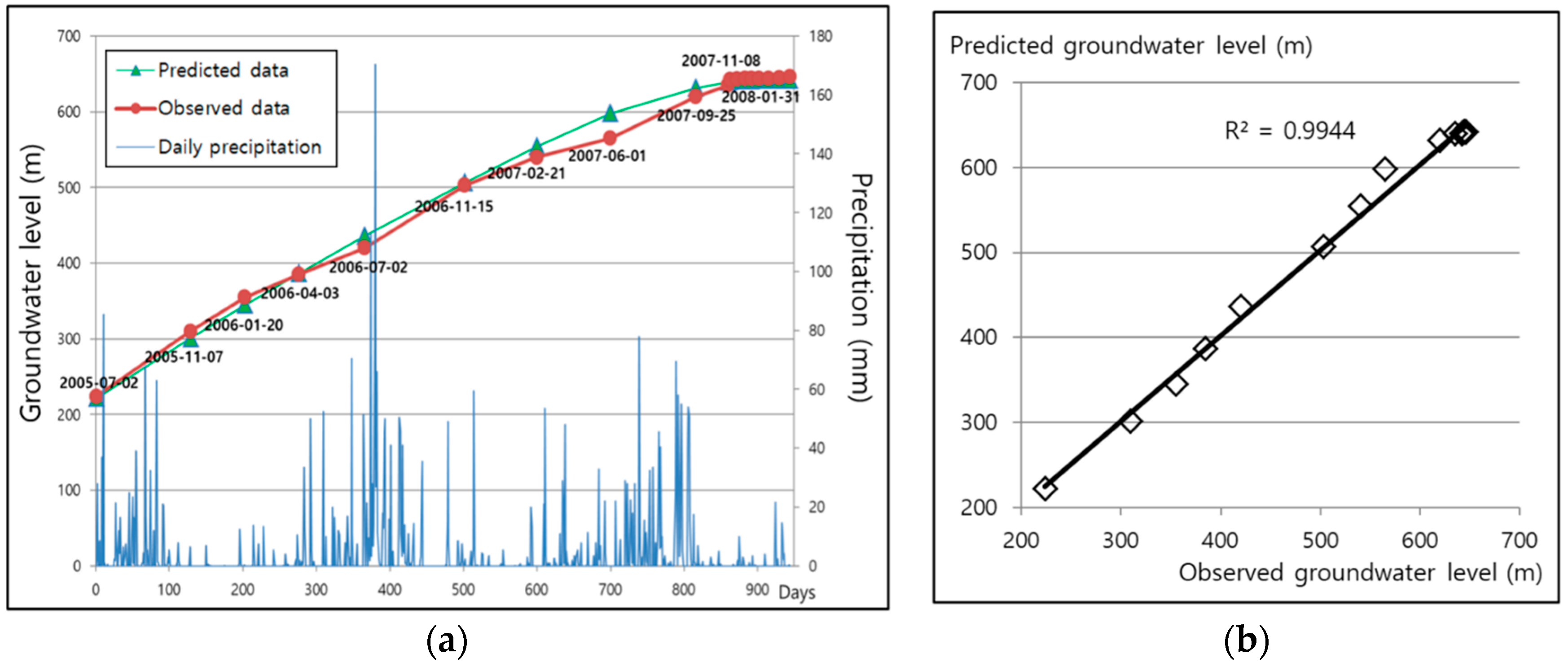

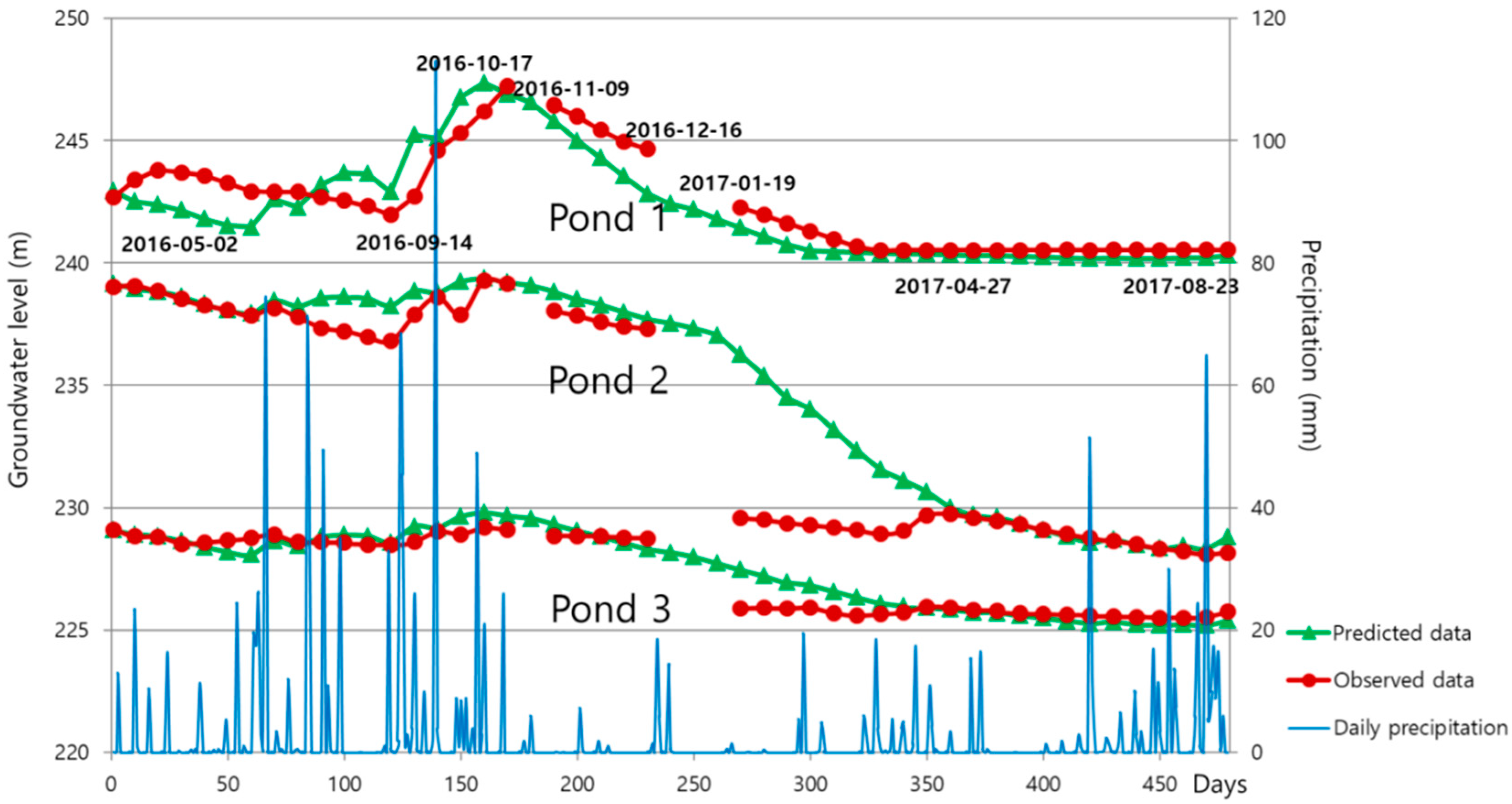

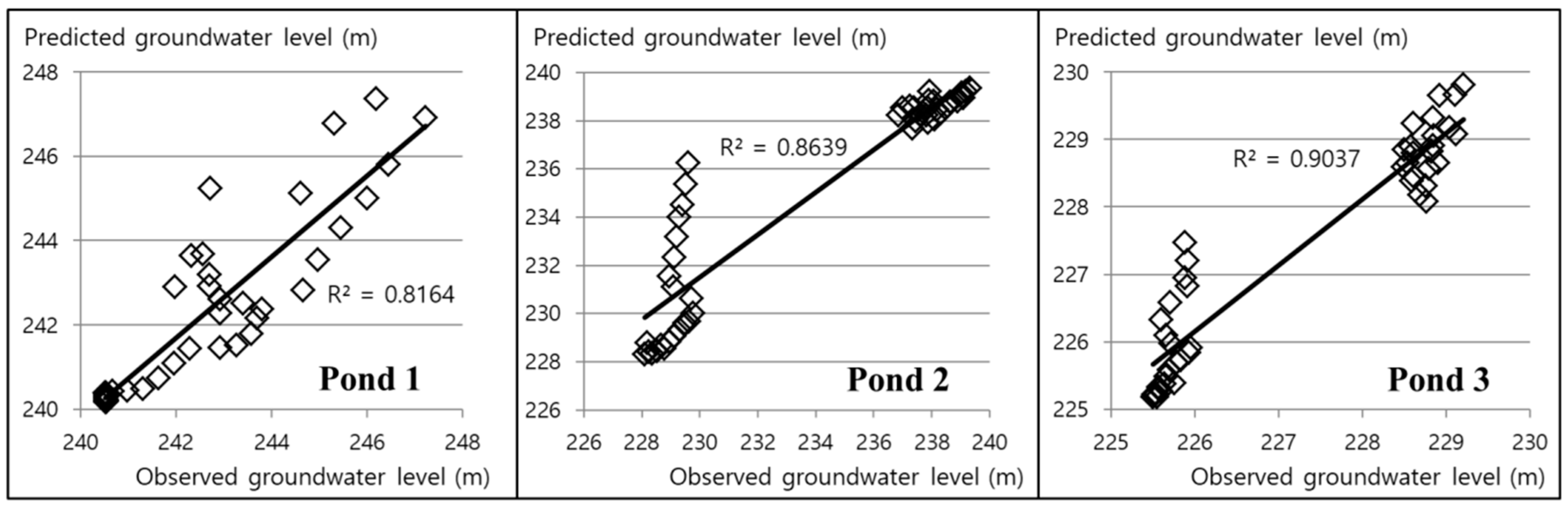

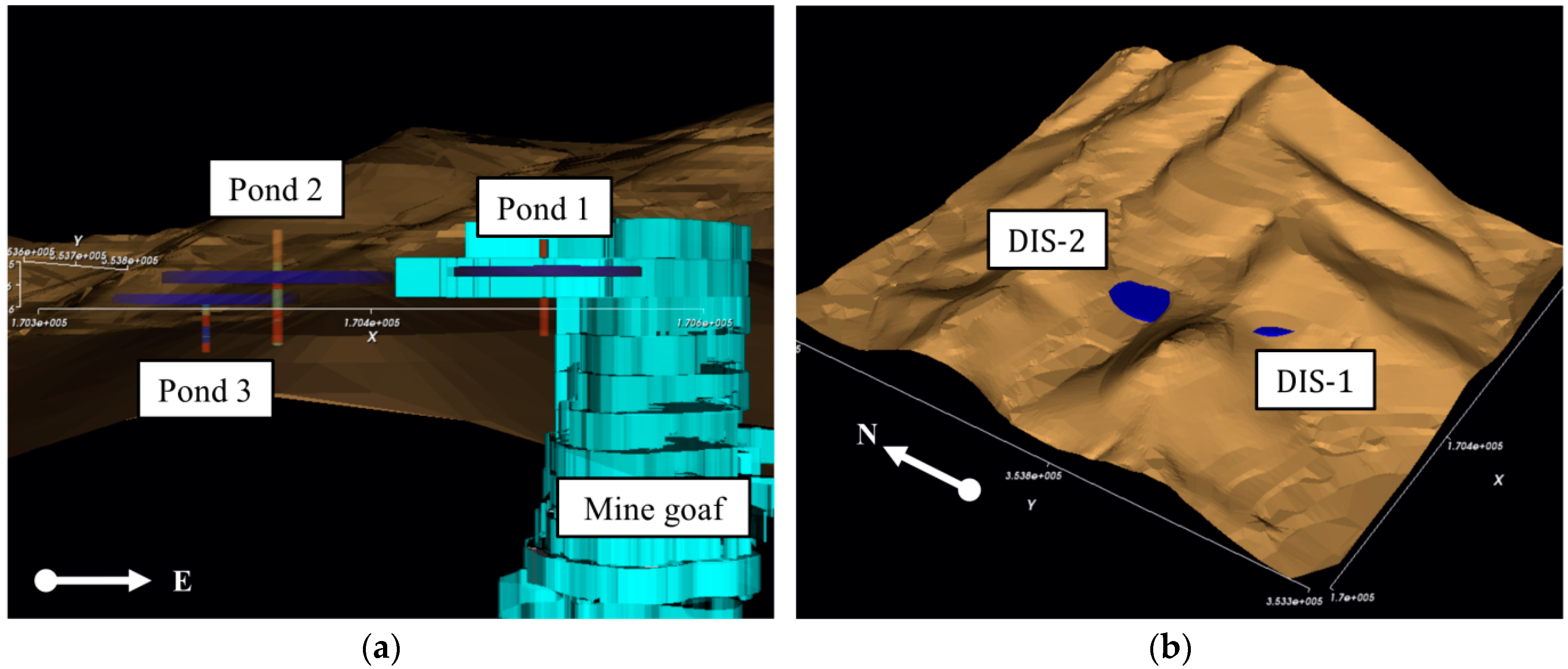

Since the possibility of data collection in abandoned mine sites is generally limited, the data input requirements of these models can be a disadvantage for field applications. The objective of this paper is to facilitate predictions of the groundwater rebound phenomena in abandoned mine areas by developing a new, user-friendly, simple program in which results can be visualized as intuitive 3D models. The results of the groundwater rebound represented by a 3D model can help researchers intuitively analyze the possibility of acid mine drainage generation in abandoned mines. We propose a new program, SIMPL (Simplified groundwater program In Mine workings using the Pipe equation and Lumped parameter model), by using a simplified model that demands very few parameters for predicting groundwater rebound in abandoned mines. It uses the only standard pipe equation, that does not need iteration to solve, for the direct modeling of the flow processes. The hydraulic conductivity of a pond is assumed to be sufficiently large in the model that the hydraulic gradient of the pond is ignorable. Therefore, there is no problem of acquiring various data, which arises when trying to apply traditional groundwater models to groundwater rebound. We also present results of a case study in the Dongwon coal mine and the Dalsung copper mine in the Republic of Korea, using our new SIMPL program to model groundwater levels at a range of spatial and temporal scales.

2. Principles of the Simplified Model

A simplified model, abstracting mine areas in the forms of ponds and pipes connected to each other, is used in this study. In this model, a pond represents a mine working surrounded by impermeable layers, and a pipe represents the discrete overflow points connecting the mine workings. For the mine workings, diverse geometric forms can be considered. Typical features that form interpond overflow points include drifts, boreholes, and permeable geological features, such as dykes, limestone beds, or an open fault. The conceptualization method of SIMPL for underground environments is similar to that of the GRAM model. A schematic diagram of the simplified model used in SIMPL is shown in

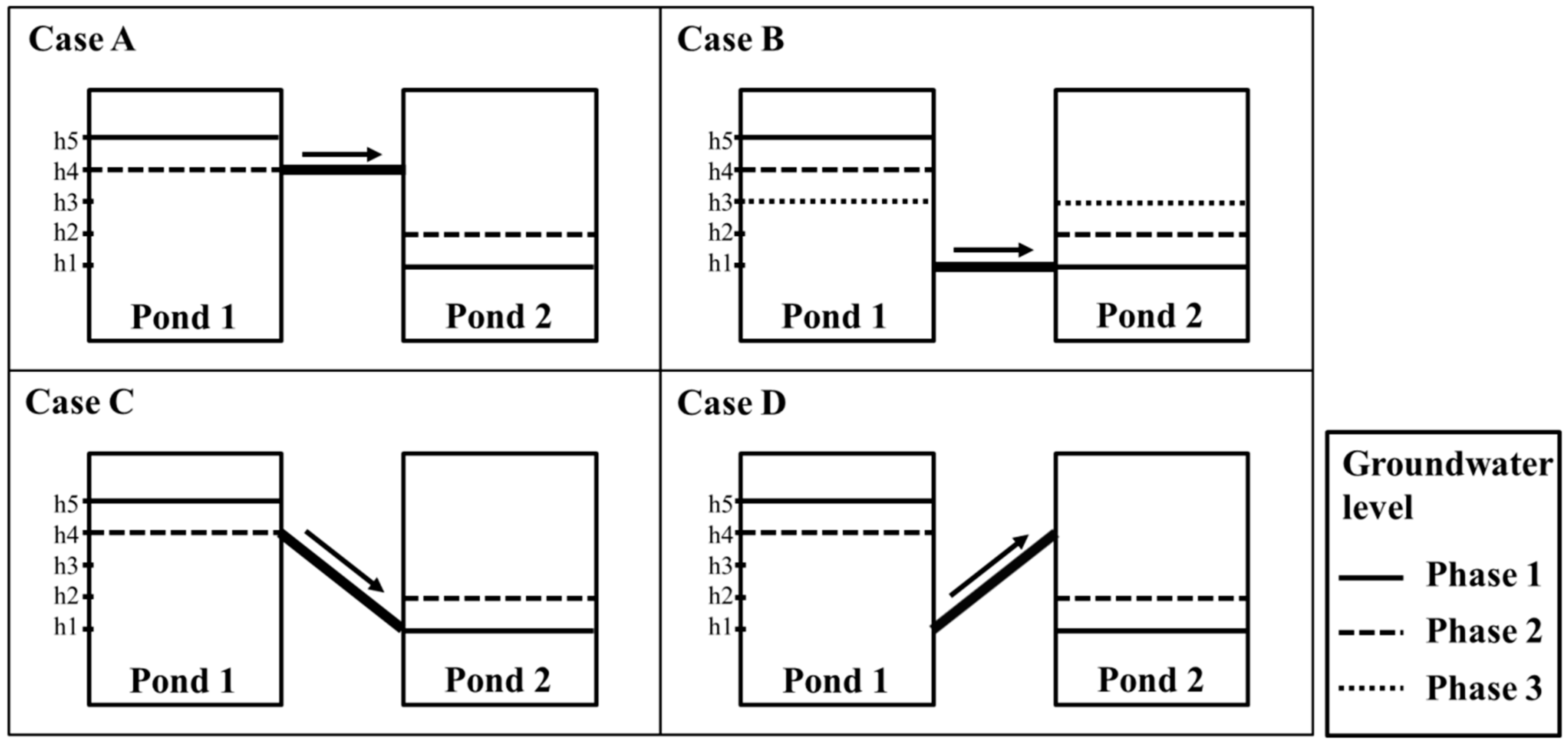

Figure 1. Unlike the GRAM model, which only considers a horizontal pipe, as in cases A and B in

Figure 1, SIMPL can additionally consider an inclined pipe, as in case C or D. Sometimes, a horizontal pipe cannot sufficiently explain the groundwater flow in abandoned mine workings. Access to deep mines is achieved through tunnels varying in inclination from horizontal to vertical, and a decline means that an inclined tunnel can be a pipe connecting ponds. In addition, permeable geological features, like an inclined fault plane, can also perform the role of the connecting pipe between ponds.

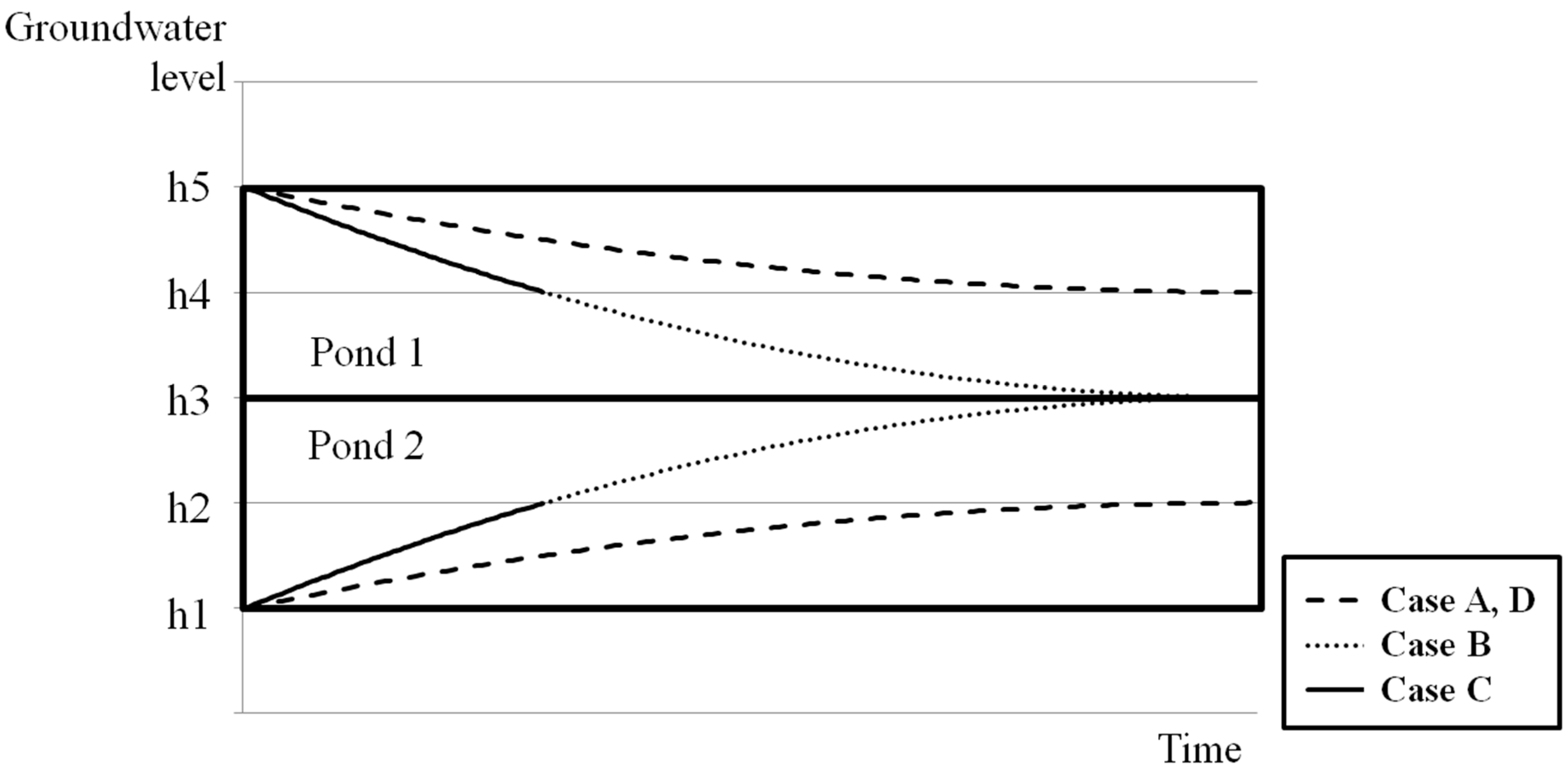

Figure 2 shows the groundwater level variations according to time for each case in

Figure 1. In these cases, the conditions of Ponds 1 and 2, such as the storage coefficient, pond area, and precipitation, are supposed to be equal. In addition, any inflow or outflow, except for the flow through the connecting pipe, was not considered. The pipe is fully flooded when groundwater is flowing along a pipe. The velocity of the flow in the pipe is determined by the hydraulic head difference between the ponds, according to the pipe flow equation. Because the hydraulic head difference between the two ponds is the same in cases A and D, both groundwater level variations are equal. The groundwater level of Pond 1 decreases until it reaches the height of the upper end of the pipe. Although the groundwater level variations in cases A and D are equal in this example, there can be a notable distinction with different conditions in the pond and pipe. The hydraulic head difference in case B or C is larger than that of case A or D. Therefore, the velocity of case B or C is higher than that of case A or D, and the groundwater level of Pond 1 decreases more rapidly in cases B and C. In case B, the groundwater level of Pond 1 decreases until it becomes equal to the level of Pond 2. On the other hand, in case C, the level of Pond 1 decreases until it reaches the height of the upper end of the pipe.

SIMPL predicts a mine groundwater rebound phenomenon according to the five-step calculation procedure using the pipe equation and lumped parameter. First, the amount of rainwater that flows into each pond representing a mine working is calculated. The amount of rainwater recharged into each pond is calculated by accounting for the rainfall that reaches the catchment area of each pond. The total rainfall during the period of interest is first determined, and then the effective rainfall is calculated by subtracting the evaporation from the amount of rainwater that reaches the earth’s surface. If the amount of evaporation is larger than the amount of rainfall, the effective rainfall is calculated to be zero. The amount of recharged rainwater is obtained by subtracting the surface runoff from the total effective rainfall. Second, if pumping work is in progress in the mine, the amount of groundwater that is discharged to the outside environment from each pond is calculated and deducted. Third, if groundwater flows into the mine from the sea, adjacent mines, or adjacent aquifers, the amount of groundwater that flows into each pond is calculated and added. Once the amount of groundwater existing in each pond is calculated up to the third step, the fourth step is then calculated by determining the amount of groundwater moving between the connected ponds using the pipe flow equation. Finally, the groundwater level in each pond is calculated by taking into account the amount of groundwater that has been transferred. If the groundwater level in a pond rises and overflows, in the fifth step, the amount of groundwater that flows out onto the earth’s surface is calculated using the pipe flow equation.

In the simplified model, the storage coefficient is determined through the calibration process of the input variables using the water level measurement data of the pond. Accordingly, to calibrate the storage coefficient, the existing measurement data for the water level are required. Especially in SIMPL, the hydraulic characteristics of a pond can be considered to be heterogeneous in the vertical direction. For example, if a roof collapse occurs as a result of mining works fully filling the goaf with cataclastic rocks, the storage coefficient may be much higher than that of the surrounding strata. To reflect such heterogeneity in the vertical direction, a pond is divided into multiple layers in the vertical direction in SIMPL. The calculation from the first step to the fifth step is repeatedly carried out for each pond for the predetermined simulation period.

The simplified model calculates the head loss in each pond connected with a pipe to model the movement of groundwater between ponds and the outflow of mine drainage to the land surface (Equation (1)). If groundwater is flowing along a pipe, the pipe must be fully flooded, since the height of the location at which the pipe is connected must be lower than the groundwater level in at least one of the connected ponds. The total head loss of the pond in Equation (1) is calculated by adding the friction head loss and the minor head losses, which occur during inflow and outflow. The friction head loss is calculated using the Darcy–Weisbach equation [

21]:

where

is the total head loss (m),

is the flow velocity of groundwater in the pipe (m/s),

is the coefficient of friction loss determined by the surface roughness and diameter of the pipe,

is the length (m) of the pipe,

is the acceleration of gravity, and

is the diameter (m) of the pipe. Each term in Equation (1) reflects the following:

is the head loss that occurs when the pond groundwater flows into the pipe (inlet loss);

is the head loss that occurs when the groundwater flows out of the pipe (outlet loss); and

represents the friction head loss that occurs in the pipe.

Equation (1) can be rearranged using the following expression to make velocity

If fluid flow is turbulent, the value of

can be determined using the Prandtl–Nikuradse or Colebrook–White equation. The Prandtl–Nikuradse equation assumes turbulent fluid flow [

21]. For a turbulent flow, the value of

is expressed as a function of roughness relative to pipe diameter

:

where

is the roughness coefficient (m) of the pipe surface. The Prandtl–Nikuradse equation does not require an iterative process to obtain the solution; the code used to solve the Prandtl–Nikuradse equation is thus very simple, and the calculation time is very short. However, this equation cannot be applied if the fluid flow is not turbulent.

The Colebrook–White equation is commonly used to calculate the turbulent fluid flow in a pipe. The Colebrook–White equation calculates the value of

by taking into account both rough and smooth turbulent flows:

where ν is the kinematic viscosity (m

2/s) of the groundwater, which is the ratio of the viscosity (

) to the unit weight

of the fluid. In the temperature and pressure conditions typical of most groundwater environments, changes in the kinematic viscosity are very small. Accordingly, the kinematic viscosity can be considered a constant. Freeze and Cherry [

22] reported that the kinematic viscosity of fluid was 1.124 × 10

−6 (m

2/s) for a temperature of 15.5 °C, density of 1000 kg/m

3, and viscosity of 1.146 × 10

−4 kgf·s/m

2.

To calculate the flow velocity in the pipe, the GRAM model uses either the Prandtl–Nikuradse equation or the Colebrook–White equation. However, although the codes used to solve the equations do not require many calculations, at least three parameters, like the length (

), diameter (

), and roughness coefficient (

) of the pipe, are required in the GRAM model. These parameters should be supposed before predicting the water level, and be modified after the calibration process to optimize them. Because of the difficulties in collecting data in an abandoned mine, it is very hard to define specific pipe characteristics representing the real connection between ponds. Therefore, it can be a wasteful task to modify each of the three parameters (

,

,

) to create an appropriate prediction in the GRAM model. In SIMPL, the parameters are more simplified as one parameter that unifies the other parameters. All parameters in Equation (2), except for the hydraulic head difference (

), were integrated into a parameter

based on the Prandtl–Nikuradse equation (Equation (3)). The velocity (Equation (2)) can be expressed as the following equation:

Because

is determined only by

and

in the Prandtl–Nikuradse equation,

represents a constant that incorporates the characteristics of the pipe. Therefore, the calibration process can be simplified and automated in SIMPL using

rather than by using the method of the GRAM model. The SIMPL program also provides another prediction option using the exponential Hazen–Williams formula:

where

is the Hazen–Williams flow coefficient for a pipe. Because

,

, and

are constant, the parameters of Equation (6), except for

, can also be simplified into one parameter for the iterative calculations in the calibration process.

5. Discussion

The sizes of mine workings are very diverse, ranging in size from several hundred square meters (small mine workings) to several thousand square kilometers (locally connected mines). Moreover, the time scale for consideration of the groundwater rebound phenomenon of mine workings is diverse, ranging from several months (small mine workings) to several decades (locally connected mines). Accordingly, for predicting mine groundwater rebound, it is important to select a suitable groundwater flow model in accordance with the spatial scale of the mine workings and the temporal scale of the predicted time. This is because it is difficult for one type of groundwater flow model to provide reliable groundwater rebound prediction results for all the conditions of the spatial and temporal scales.

The MODFLOW model is based on the conventional Darcian groundwater flow equation for large systems, using the finite difference method to solve the groundwater equation. This type of groundwater flow model is primarily used when the largest spatial scale and the longest temporal scale should be considered. MINEDW is a model based on both Darcian and non-Darcian conditions, using a three-dimensional finite element groundwater flow code to solve the equation. It can be used to predict local and regional environmental impacts of mine dewatering and to simulate the infilling of a pit lake after mining ceases. Particularly, a finite element grid is useful for mining applications with complex geological structures and discharge points, such as drifts or drainholes. A simplified model, such as the GRAM model or the model proposed in this study, is a lumped parameter model that abstracts mine areas in the forms of ponds and pipes connected to each other. Although the model is not appropriate for modeling the groundwater distributions at a large spatial scale, it is designed to effectively predict the variation in the groundwater level according to time. Especially in the proposed model of this study, the limitations of the GRAM model were supplemented. The model in this study can consider inclined pipes and simplify parameters for the calibration process. In addition, 3D visualization abilities of the SIMPL program can help intuitively understand groundwater rebound and acid mine drainage outflows.

These three types of models can be utilized, stage by stage, to complement each other for predicting the mine groundwater rebound phenomenon in abandoned mine areas. The result of groundwater modeling at a large spatial scale by MODFLOW can help to define the geometric domain and boundary conditions for the specific groundwater modeling of MINEDW. In addition, the result of MINEDW groundwater modeling can serve as useful information for SIMPL to select suitable areas for monitoring and predicting the groundwater rebound phenomenon.

The SIMPL program developed in this study can be utilized in mine reclamation planning. If the groundwater rebound is less likely to occur as a result of the SIMPL program, the application of the acid mine drainage control method is less necessary. If the groundwater rebound problem is critical, on the other hand, the result of the SIMPL prediction can be used for a preliminary selection of an acid mine drainage control method. In addition, the application timing of an acid mine drainage control method can be estimated according to the rate of groundwater rebound. Therefore, the result is expected to be a useful indicator that can prioritize many mines and support decision-making during the planning of mine reclamation programs.

6. Conclusions

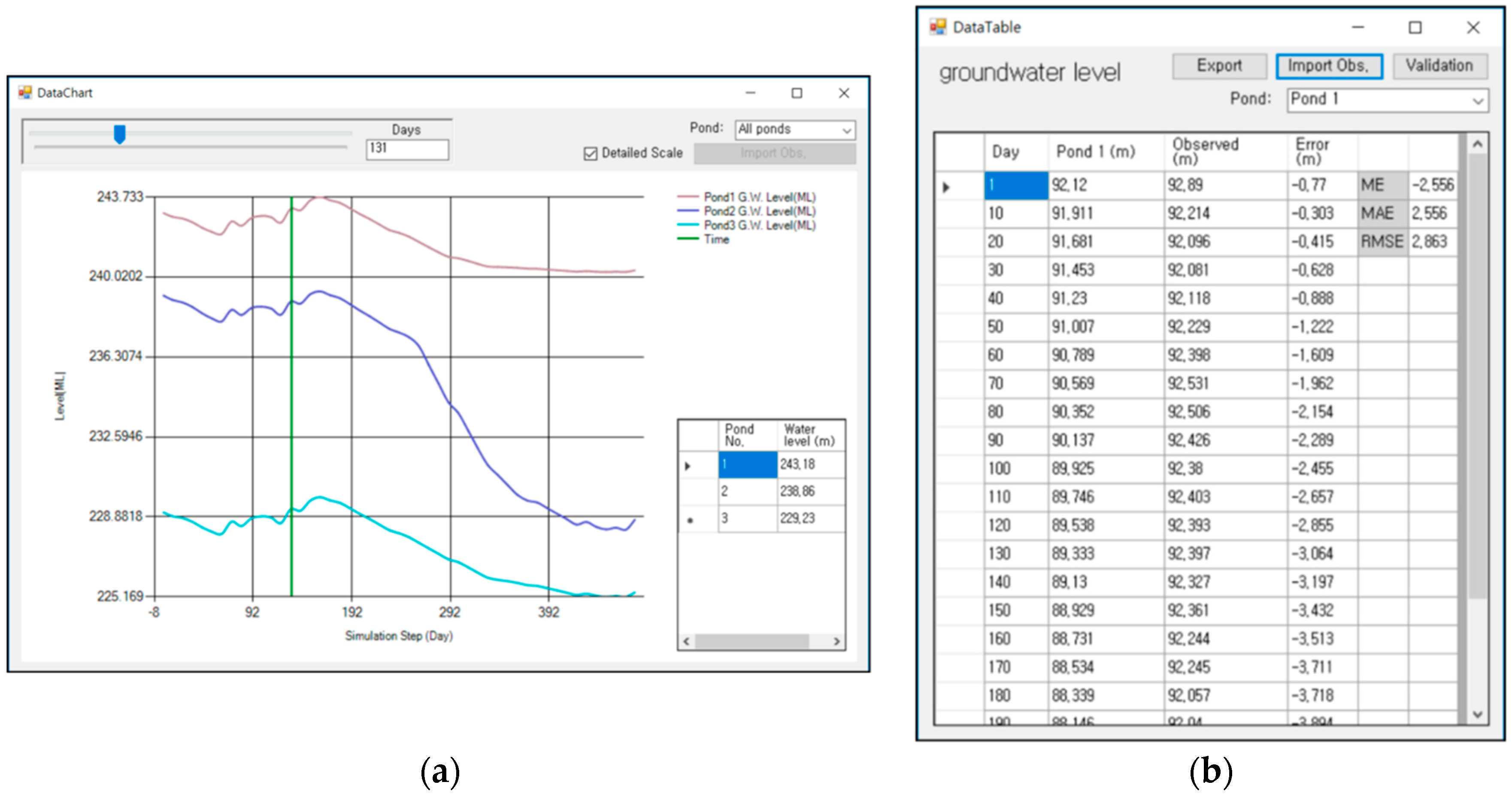

In this study, the SIMPL program was presented as a user-friendly 3D program created using Visual Basic 2013 and VTK to facilitate effective visualization of the results of groundwater level prediction analyses. In the simplified model, the data required for the modeling of the mine groundwater rebound phenomenon is relatively straightforward for the input, and the application of the model to abandoned mine areas is fairly simple. Most of the required input data and 3D objects can be generated by processing data, such as digital maps and drift maps, through GIS-based spatial analysis. To demonstrate a practical application of the software, the groundwater rebound phenomena in the Dongwon coal mine and Dalsung copper mine were simulated using the SIMPL program. Following comparison of the simulation results with field monitoring of the groundwater level data, changes in the simulated and observed groundwater levels were shown to be similar. The results demonstrate that SIMPL can be applied to abandoned mine areas in a range of spatial scales and environments.

While it is straightforward to apply SIMPL to the abandoned mine areas for which field survey data are difficult to obtain, we note that the simplified model has several limitations. First, it is difficult to accurately determine the storage coefficient of the mine at an actual mine site, so the groundwater rebound prediction result can vary greatly depending on the coefficient value that is input into the model. Second, the simplified model does not take into account groundwater supply sources, such as adjacent streams; these could influence the simulation results, because the model considers neither the groundwater that flows into the area from the streams nor the outflow of the groundwater to these streams. While many mines have artificial structures installed to prevent the inflow and outflow of groundwater from/to adjacent streams, this is not universal. Third, the simplified model assumes that there is no hydraulic gradient in a mine, but this is not always the case in real mines. This limitation could be compensated for by defining more ponds with monitoring instruments. It thus requires future improvement in several respects.

While there are some limitations to the simplified model, it is a remarkably powerful for simple and straightforward field applications considering groundwater rebound in the area surrounding a mine. The SIMPL program, which analyzes the groundwater level and visualizes the results as 3D objects, makes application of the groundwater rebound prediction more convenient and intuitive. The SIMPL program is, therefore, a useful new tool for practical applications, like mine reclamation programs. Since additional modules can be easily added to the SIMPL program, the software could be made even more applicable to abandoned mine areas following future work, with the addition of new modules incorporating, for example, geochemical modeling of acid mine drainage.