Mercury Pollution, Treatment and Solutions in Spent Fluorescent Lamps in Mainland China

Abstract

1. Introduction

2. Methods

2.1. Research Methods

2.2. Evaluation Method

3. Results and Discussion

3.1. Problems of FLs and SFLs

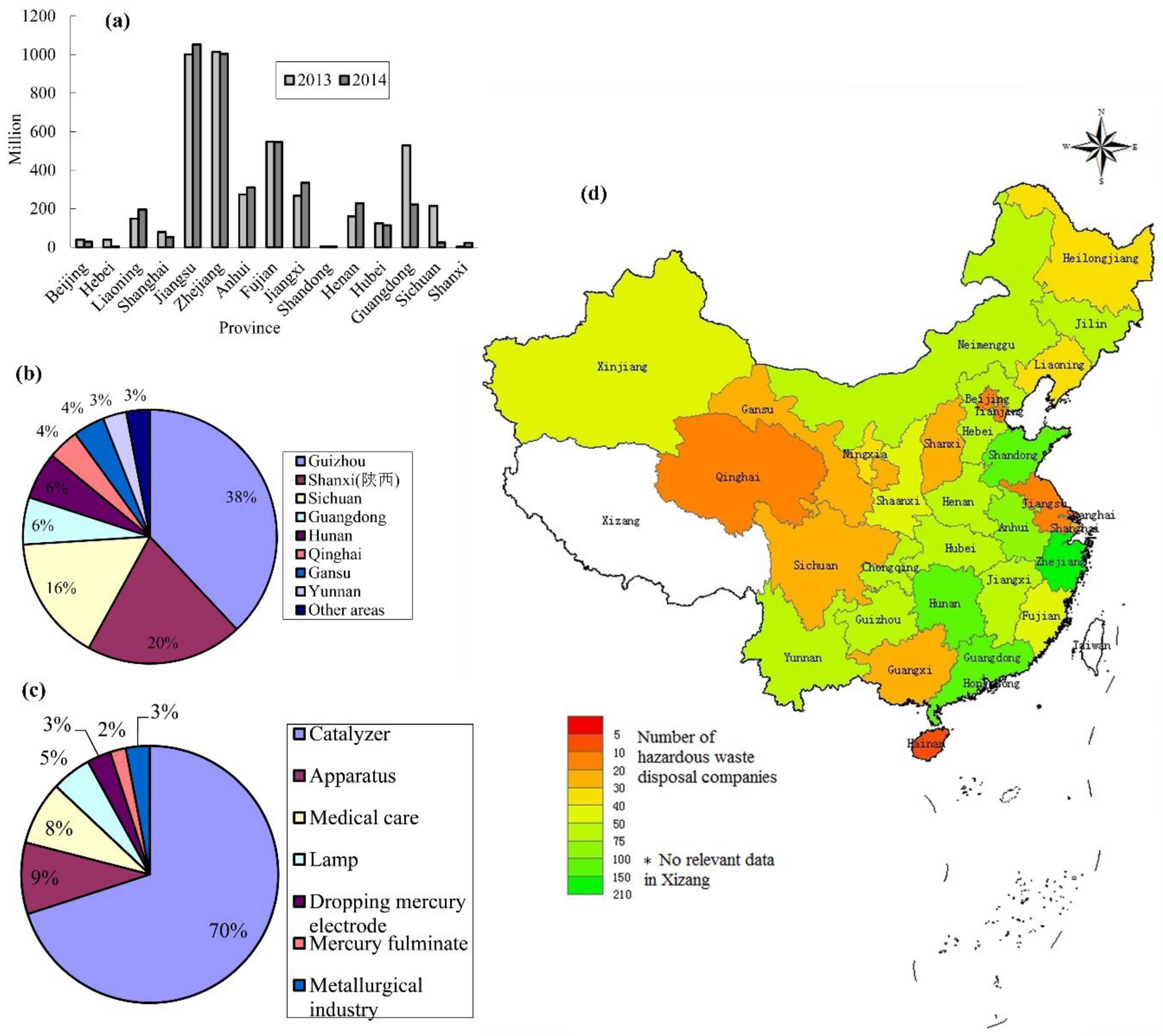

3.1.1. Energy Conservation and Mercury Emission from FLs and SFLs

3.1.2. SFL Collection

3.1.3. SFL Treatment

3.2. Comprehensive Evaluation

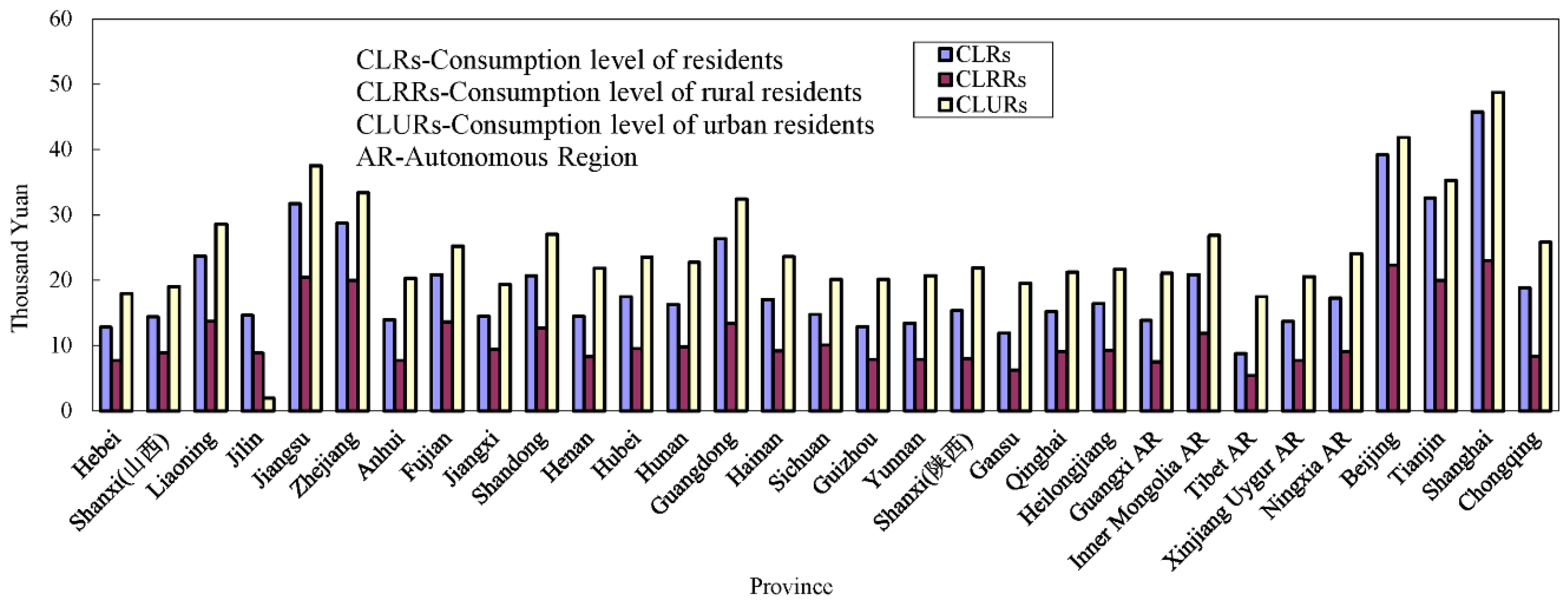

3.2.1. Determination of Evaluation Factors

Strength Analysis of the Evaluation Factors

Determination of Weight

3.2.2. Evaluation

3.3. Solutions to Control the Mercury Pollution from FLs and SFLs

- Establishing a recycling system for SFLs

- Improving the disposal capacity of mercury

- Improving the disposal technology of mercury

- Strengthening the management of mercury

- Developing the LED industry

3.3.1. Establishing a Recycling System for SFLs

3.3.2. Improving the Disposal Capacity of Mercury

3.3.3. Improving the Disposal Technology of Mercury

3.3.4. Strengthening the Management of Mercury

3.3.5. Developing the LED Industry

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, L. The Study on Rare Earth Phosphate Phosphors. Ph.D. Thesis, Zhejiang University, Zhejiang, China, October 2008. [Google Scholar]

- European Commission (EC). Energy-Saving Lamps & Health. 2013. Available online: http://ec.europa.eu/health/opinions/en/energy-saving-lamps/l-3/3-cfl-characteristics.htm (accessed on 3 December 2018).

- Hildenbrand, V.D.; Denissen, C.J.M.; van der Pol, A.J.H.P.; Hendriks, A.H.C.; van der Marel, C.; Snijders, J.H.M.; Tamminga, Y.; Brongersma, H.H.; Viitanen, M.M. Reduction of mercury loss in fluorescent lamps coated with thin metal-oxide films. J. Electrochem. Soc. 2003, 150, 147–155. [Google Scholar] [CrossRef]

- Sun, R.G.; Wang, D.Y.; Mao, W.; Ma, M.; Zhang, C.; Jiang, T. Diurnal characteristics of migration and transformation of mercury and effects of nitrate in Jialing River, Chongqing, China. Chemosphere 2015, 119, 634–641. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.Y.; Lin, K.N.; Yuan, D.X.; Gao, Y.Q.; Sun, L.M. Mercury isotope fractionation during transfer from post-desulfurized seawater to air. Mar. Pollut. Bull. 2016, 113, 81–86. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.J.; Ci, Z.J.; Wang, Z.W.; Zhang, X.S. Air-sea exchange of gaseous mercury in the East China Sea. Environ. Pollut. 2016, 212, 535–543. [Google Scholar] [CrossRef] [PubMed]

- Bravo, A.G.; Cosio, C.; Amouroux, D.; Zopfi, J.; Chevalley, P.-A.; Spangenberg, J.E.; Ungureanu, V.-G.; Dominik, J. Extremely elevated methyl mercury levels in water, sediment and organisms in a Romanian reservoir affected by release of mercury from a chlor-alkali plant. Water Res. 2014, 49, 391–405. [Google Scholar] [CrossRef] [PubMed]

- Arctic Monitoring, Assessment Programme/United Nations Environment Programme (AMAP/UNEP). Technical Background Report for the Global Mercury Assessment 2013; Oslo, Norway/UNEP Chemicals Branch: Geneva, Switzerland, 2013. [Google Scholar]

- Lindberg, S.; Bullock, R.; Ebinghaus, R.; Engstrom, D.; Feng, X.; Fitzgerald, W.; Pirrone, N.; Prestbo, E.; Seigneur, C. A synthesis of progress and uncertainties in attributing the sources of mercury in deposition. Ambio 2007, 36, 19–32. [Google Scholar] [CrossRef]

- Carpi, A. Mercury from combustion sources: A review of the chemical species emitted and their transport in the atmosphere. Water Air Soil Pollut. 1997, 98, 241–254. [Google Scholar] [CrossRef]

- Mason, R.P.; Sheu, G.R. Role of the ocean in the global mercury cycle. Glob. Biogeochem. Cycles 2002, 16, 1–14. [Google Scholar] [CrossRef]

- Lambert, K.F.; Evers, D.C.; Warner, K.A.; King, S.L.; Selin, N.E. Integrating mercury science and policy in the marine context: Challenges and opportunities. Environ. Res. 2012, 119, 132–142. [Google Scholar] [CrossRef] [PubMed]

- Driscoll, C.T.; Mason, R.P.; Chan, H.M.; Jacob, D.J.; Pirrone, N. Mercury as a global pollutant: Sources, pathways, and effects. Environ. Sci. Technol. 2013, 47, 4967–4983. [Google Scholar] [CrossRef] [PubMed]

- Cain, A.; Disch, S.; Twaroski, C.; Reindl, J.; Case, C.R. Substance flow analysis of mercury intentionally used in products in the United States. J. Ind. Ecol. 2007, 11, 61–75. [Google Scholar] [CrossRef]

- Dunmire, C.; Calwell, C.; Jacob, A.; Ton, M.; Reeder, T.; Fulbright, V. Mercury in Fluorescent Lamps: Environmental Consequences and Policy Implications for NRDC; Final Report Prepared for Natural Resources Defense Council; Ecos Consulting: Durango, CO, USA, 2003. [Google Scholar]

- Taghipour, H.; Amjad, Z.; Jafarabadi, M.A.; Gholampour, A.; Norouz, P. Determining heavy metals in spent compact fluorescent lamps (CFLs) and their waste management challenges: Some strategies for improving current conditions. Waste Manag. 2014, 34, 1251–1256. [Google Scholar] [CrossRef] [PubMed]

- Liang, Z. Investigation on the introduction of ring fluorescent lamp production line in China. China Light Light. 2003, 11–12. [Google Scholar]

- Moriwaki, T.; Hashimoto, T. Correlation between lumen output and adsorbed gases on phosphor in fluorescent lamps. J. Illum. Eng. Soc. 2013, 8, 207–213. [Google Scholar] [CrossRef]

- Bakk, I.P.; Benkö, N.; Nyulászi, L. The effect of contaminants on the mercury consumption of fluorescent lamps. J. Phys. D Appl. Phys. 2009, 42, 5501–5506. [Google Scholar] [CrossRef]

- The State Council of the People’s Republic of China. Notice of the State Council on Key Work in Building an Economical Society in the Near Future. 2005. Available online: http://www.gov.cn/zwgk/2005-09/08/content_30265.htm (accessed on 3 December 2018).

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Technical Guidelines for Investigation of Mercury Pollution Emission Sources in China. 2010. Available online: https://wenku.baidu.com/view/6c00f84d767f5acfa1c7cd1f.html (accessed on 3 December 2018).

- Zhang, Z.N.; Meng, N.; Zhou, P. Based on the fuzzy set-valued statistics and the fuzzy mathematics theory in air traffic control system safety appraisal application. Phys. Procedia 2012, 33, 511–520. [Google Scholar] [CrossRef]

- Huang, W.H.; Yang, Y.C. Mercury in coal of China. Coal Geol. China 2002, 14, 37–40. [Google Scholar]

- Zhang, L.L.; Yang, Y.Q. Recommendations on recycling for discarded fluorescent lamps. China Light Light. 2012, 23–24. [Google Scholar]

- National Bureau of Statistics of China. China Statistics Yearbook; China Statistics Press: Beijing, China, 2013. Available online: http://www.stats.gov.cn/tjsj/ndsj/2013/indexch.htm (accessed on 3 December 2018).

- Zhang, J.X.; Chen, S.; Kim, J.; Cheng, S.Y. Mercury flow analysis and reduction pathways for fluorescent lamps in mainland China. J. Clean. Prod. 2016, 133, 451–458. [Google Scholar] [CrossRef]

- National Development and Reform Commission (NDRC). Roadmap to Gradually Phase out Incandescent Light Bulbs in Mainland China (Draft for Comments). 2011. Available online: http://www.ndrc.gov.cn/fjbak/201108/t20110808_427541.html (accessed on 3 December 2018).

- Ministry of Industry and Information Technology of the People’s Republic of China/Ministry of Science and Technology of the People’s Republic of China/Ministry of Ecology and Environment of the People’s Republic of China (MIIT/MST/MEE). Roadmap to Gradually Reduce the Mercury Content in Fluorescent Lamps in China. 2013. Available online: http://www.miit.gov.cn/n1146290/n1146402/n1146435/c3319289/content.html (accessed on 3 December 2018).

- China’s National Standard. Requirements for Concentration Limits for Certain Hazardous Substances in Lighting Equipments; QB/T 2940-2008; China Light Industry Press: Beijing, China, 2008. [Google Scholar]

- Minamata Convention on Mercury. Text and Annexes. 2017. Available online: http://www.mercuryconvention.org/Convention/Text/tabid/3426/language/en-US/Default.aspx (accessed on 3 December 2018).

- Cheng, H.; Hu, Y. China needs to control mercury emissions from municipal solid waste (MSW) incineration. Environ. Sci. Technol. 2010, 44, 7994–7995. [Google Scholar] [CrossRef]

- Yang, W.J.; Sun, Y.; Ye, D.; Wang, J.; Zhang, W.; Li, X.L.; Wang, X.L. Mercury pollution of spent fluorescent lamps and its environmental health risk management countermeasures. J. Environ. Health 2017, 34, 1100–1102. [Google Scholar]

- National Bureau of Statistics of China (NBS). Output Data of Fluorescent Lamp in Various Provinces and Cities of China. 2013, 2014. Available online: http://data.stats.gov.cn/index.htm (accessed on 3 December 2018).

- Metal Encyclopedia. Distribution and Yield of Mercury Resources in China. 2015. Available online: http://baike.asianmetal.cn/metal/hg/resources&production.shtml (accessed on 3 December 2018).

- Metal Encyclopedia. Use and Application Fields of Mercury in China. 2015. Available online: http://baike.asianmetal.cn/metal/hg/application.shtml (accessed on 3 December 2018).

- National Bureau of Statistics of China (NBS). Population at the End of 2017. 2018. Available online: http://www.stats.gov.cn/tjsj/zxfb/201802/t20180228_1585631.html (accessed on 3 December 2018).

- Jiao, Y.W.; Sun, S.R. The problems of Chinese garbage siege and development strategies. Ecol. Econ. 2015, 31, 103–106. [Google Scholar]

- National Bureau of Statistics of China (NBS). Basic Information of Income and Expenditure of All and Subdivided Urban and Rural Residents. 2015. Available online: http://data.stats.gov.cn/easyquery.htm?cn=E0103 (accessed on 3 December 2018).

- Fankhauser, S.; Gennaioli, C.; Collins, M. The political economy of passing climate change legislation: Evidence from a survey. Glo. Environ. Chang. 2015, 35, 52–61. [Google Scholar] [CrossRef]

- Gittell, R.; Magnusson, M.; Merenda, M. Chapter 3, Section 3.1. In The Sustainable Business Case Book; Flat World Education, Inc.: Boston, MA, USA, 2013. [Google Scholar]

- Wang, P.; Liu, Q.; Qi, Y. Factors influencing sustainable consumption behaviors: A survey of the rural residents in China. J. Clean. Prod. 2014, 63, 152–165. [Google Scholar] [CrossRef]

- Han, F.G.; Chen, J.J.; Wang, Y. Research on the relationship between energy consumption and the quantity and quality of economic growth in China. China Collect. Econ. 2016, 19, 11–12. [Google Scholar]

- Yuan, C.Q.; Liu, S.F.; Fang, Z.G.; Xie, N.M. The relation between Chinese economic development and energy consumption in the different periods. Energy Policy 2010, 38, 5189–5198. [Google Scholar] [CrossRef]

- Rafindadi, A.A. Does the need for economic growth influence energy consumption and CO2 emissions in Nigeria? Evidence from the innovation accounting test. Renew. Sustain. Energy Rev. 2016, 62, 1209–1225. [Google Scholar] [CrossRef]

- Katsaitis, O.; Angastiniotis, M. On the impact of government spending on consumption patterns: Some exploratory results. Econ. Lett. 1990, 33, 271–275. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chiu, A.S.F.; Liang, D. Sustainable consumption and production in business decision-making models. Resour. Conserv. Recycl. 2018, 128, 118–121. [Google Scholar] [CrossRef]

- Ding, Q.; Cai, W.J.; Wang, C.; Sanwal, M. The relationships between household consumption activities and energy consumption in china—An input-output analysis from the lifestyle perspective. Appl. Energy 2017, 207, 520–532. [Google Scholar] [CrossRef]

- Tiba, S.; Omri, A. Literature survey on the relationships between energy, environment and economic growth. Renew. Sustain. Energy Rev. 2017, 69, 1129–1146. [Google Scholar] [CrossRef]

- Wang, Z.H.; Dong, X.Y.; Yin, J.H. Antecedents of urban residents’ separate collection intentions for household solid waste and their willingness to pay: Evidence from China. J. Clean. Prod. 2016, 173, 256–264. [Google Scholar] [CrossRef]

- Qu, Y.; Zhu, Q.H.; Sarkis, J.; Geng, Y.; Zhong, Y.G. A review of developing an e-wastes collection system in Dalian, China. J. Clean. Prod. 2013, 52, 176–184. [Google Scholar] [CrossRef]

- Tian, X.; Wu, Y.F.; Qu, S.; Liang, S.; Xu, M.; Zuo, T.Y. The disposal and willingness to pay for residents’ scrap fluorescent lamps in China: A case study of Beijing. Resour. Conserv. Recycl. 2016, 114, 103–111. [Google Scholar] [CrossRef]

- Nilsson, A.; Gifford, R. Personal and social factors that influence pro-environmental concern and behaviour: A review. Int. J. Psychol. 2014, 49, 141–157. [Google Scholar]

- Drews, S.; van den Bergh, J.C.J.M. Public views on economic growth, the environment and prosperity: Results of a questionnaire survey. Glob. Environ. Chang. 2016, 39, 1–14. [Google Scholar] [CrossRef]

- Kelly, D.L. The United States in a warming world: The political economy of government, business, and public responses to climate change. J. Econ. Lit. 2014, 53, 675–687. [Google Scholar]

- Chengdu Bureau of Environmental Protection. China Fluorescent Lamp Collection and Treatment Demonstration Project (Chengdu Section). 2014. Available online: http://www.cdepb.gov.cn/cdepbws/Web/Template/GovDefaultInfo.aspx?cid=632&aid=29465 (accessed on 3 December 2018).

- National Bureau of Statistics of China (NBS). The First National Census of Pollution Sources in China. 2010. Available online: http://www.stats.gov.cn/tjsj/tjgb/qttjgb/qgqttjgb/201002/t20100211_30641.html (accessed on 3 December 2018).

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Explanation of “Guidelines on Available Technologies of Pollution Prevention for Mercury-containing Waste Disposal (Draft for Comments)”. 2014. Available online: http://www.mee.gov.cn/gkml/hbb/bgth/201409/W020140911408668191789.pdf (accessed on 3 December 2018).

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Guidelines on Available Technologies of Pollution Prevention for Mercury-Containing Waste Disposal (Draft for Comments)”. 2014. Available online: http://www.mee.gov.cn/gkml/hbb/bgth/201409/W020140911408667878767.pdf (accessed on 3 December 2018).

- Ozgur, C.; Coskun, S.; Akcil, A.; Beyhan, M.; Üncü, I.S.; Civelekoglu, G. Combined oxidative leaching and electrowinning process for mercury recovery from spent fluorescent lamps. Waste Manag. 2016, 57, 215–219. [Google Scholar] [CrossRef]

- Rabah, M.A. Recovery of aluminium, nickel–copper alloys and salts from spent fluorescent lamps. Waste Manag. 2004, 24, 119–126. [Google Scholar] [CrossRef]

- Wu, Y.F.; Yin, X.F.; Zhang, Q.J.; Wang, W.; Mu, X.Z. The recycling of rare earths from waste tricolor phosphors in fluorescent lamps: A review of processes and technologies. Resour. Conserv. Recycl. 2014, 88, 21–31. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). General Specifications of Engineering and Technology for Hazardous Waste Disposal. 2014. Available online: http://www.mee.gov.cn/gzfw_13107/kjbz/qthjbhbz/hjbhgcjsgf/201605/t20160522_342692.shtml (accessed on 3 December 2018).

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Letter on the Implementation of the “Integrated Emission Standard of Air Pollutants”. 2011. Available online: http://www.mee.gov.cn/gkml/hbb/bgth/201112/t20111230_222022.htm (accessed on 3 December 2018).

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Ambient Air Quality Standards. 2012. Available online: http://english.mee.gov.cn/Resources/standards/Air_Environment/quality_standard1/201605/t20160511_337502.shtml (accessed on 3 December 2018).

- Xue, J. Introduction on Construction of Management Information System of waste Electrical and Electronic Products in Ministry of Environmental Protection (PPT); National Center of Solid Waste Management: Beijing, China, 2011. Available online: http://www.doc88.com/p-7973706384594.html (accessed on 3 December 2018).

- Ministry of Industry and Information Technology of the People’s Republic of China/Ministry of Science and Technology of the People’s Republic of China/Ministry of Ecology and Environment of the People’s Republic of China (MIIT/MST/MEE). Catalogue of Toxic and Hazardous Raw Materials (Products) Substitutes Encouraged by the State (2012 Edition). Beijing, China, 2012. Available online: http://www.miit.gov.cn/n1146295/n1652858/n1652930/n4509627/c4510781/content.html (accessed on 3 December 2018).

- Ministry of Industry and Information Technology of the People’s Republic of China/Ministry of Science and Technology of the People’s Republic of China/Ministry of Ecology and Environment of the People’s Republic of China (MIIT/MST/MEE). Catalogue of Toxic and Hazardous Raw Materials (Products) Substitutes Encouraged by the State (2016 Edition). Beijing, China, 2016. Available online: http://www.miit.gov.cn/n1146295/n1652858/n1652930/n4509627/c5438769/content.html (accessed on 3 December 2018).

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Technical Requirement for Environmental Labeling Products Lighting Source. 2012. Available online: http://kjs.mee.gov.cn/hjbhbz/bzwb/other/hjbz/201207/t20120717_233534.shtml (accessed on 3 December 2018).

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). The National Hazardous Waste List. 2016. Available online: http://www.mee.gov.cn/gkml/sthjbgw/qt/201606/t20160621_354844.htm (accessed on 3 December 2018).

- OFweek. Analysis of the Current Situation and Development Trend of LED Packaging Industry in China. 2017. Available online: https://lights.ofweek.com/2017-07/ART-220003-8420-30157196.html (accessed on 3 December 2018).

- Zhan, L.; Xia, F.F.; Ye, Q.Y.; Xiang, X.S.; Xie, B. Novel recycle technology for recovering rare metals (Ga, In) from waste light-emitting diodes. J. Hazard. Mater. 2015, 299, 388–394. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zheng, Y.Q.; Lin, Y.; Zhang, H.; Zhang, J.H. Fabrication and characterization of double-sided organic light-emitting diodes using silver and nickel as the metal linking layer. Displays 2016, 44, 37–41. [Google Scholar] [CrossRef]

| Factor | The Difficulty between Energy Conservation and Mercury Emission | The Difficulty of SFL Collection | The Difficulty of SFL Treatment | |||

|---|---|---|---|---|---|---|

| Membership | High | Low | High | Low | High | Low |

| Public | 0.8 | 0.2 | 0.8 | 0.2 | 0.7 | 0.3 |

| Economy | 0.9 | 0.1 | 0.5 | 0.5 | 0.6 | 0.4 |

| Government | 0.2 | 0.8 | 0.4 | 0.6 | 0.5 | 0.5 |

| Business | 0.4 | 0.6 | 0.2 | 0.8 | 0.5 | 0.5 |

| Environment | 0.4 | 0.6 | 0.8 | 0.2 | 0.4 | 0.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Jia, P.; Zhao, F.; Kang, Y. Mercury Pollution, Treatment and Solutions in Spent Fluorescent Lamps in Mainland China. Int. J. Environ. Res. Public Health 2018, 15, 2766. https://doi.org/10.3390/ijerph15122766

Li Z, Jia P, Zhao F, Kang Y. Mercury Pollution, Treatment and Solutions in Spent Fluorescent Lamps in Mainland China. International Journal of Environmental Research and Public Health. 2018; 15(12):2766. https://doi.org/10.3390/ijerph15122766

Chicago/Turabian StyleLi, Zhongguo, Puqi Jia, Fu Zhao, and Yikun Kang. 2018. "Mercury Pollution, Treatment and Solutions in Spent Fluorescent Lamps in Mainland China" International Journal of Environmental Research and Public Health 15, no. 12: 2766. https://doi.org/10.3390/ijerph15122766

APA StyleLi, Z., Jia, P., Zhao, F., & Kang, Y. (2018). Mercury Pollution, Treatment and Solutions in Spent Fluorescent Lamps in Mainland China. International Journal of Environmental Research and Public Health, 15(12), 2766. https://doi.org/10.3390/ijerph15122766