Drivers of China’s Industrial Carbon Emissions: Evidence from Joint PDA and LMDI Approaches

Abstract

1. Introduction

2. Literature

3. Methodology and Data

3.1. Shephard Distance Function

3.2. PDA Production Decomposition Model

3.3. Data

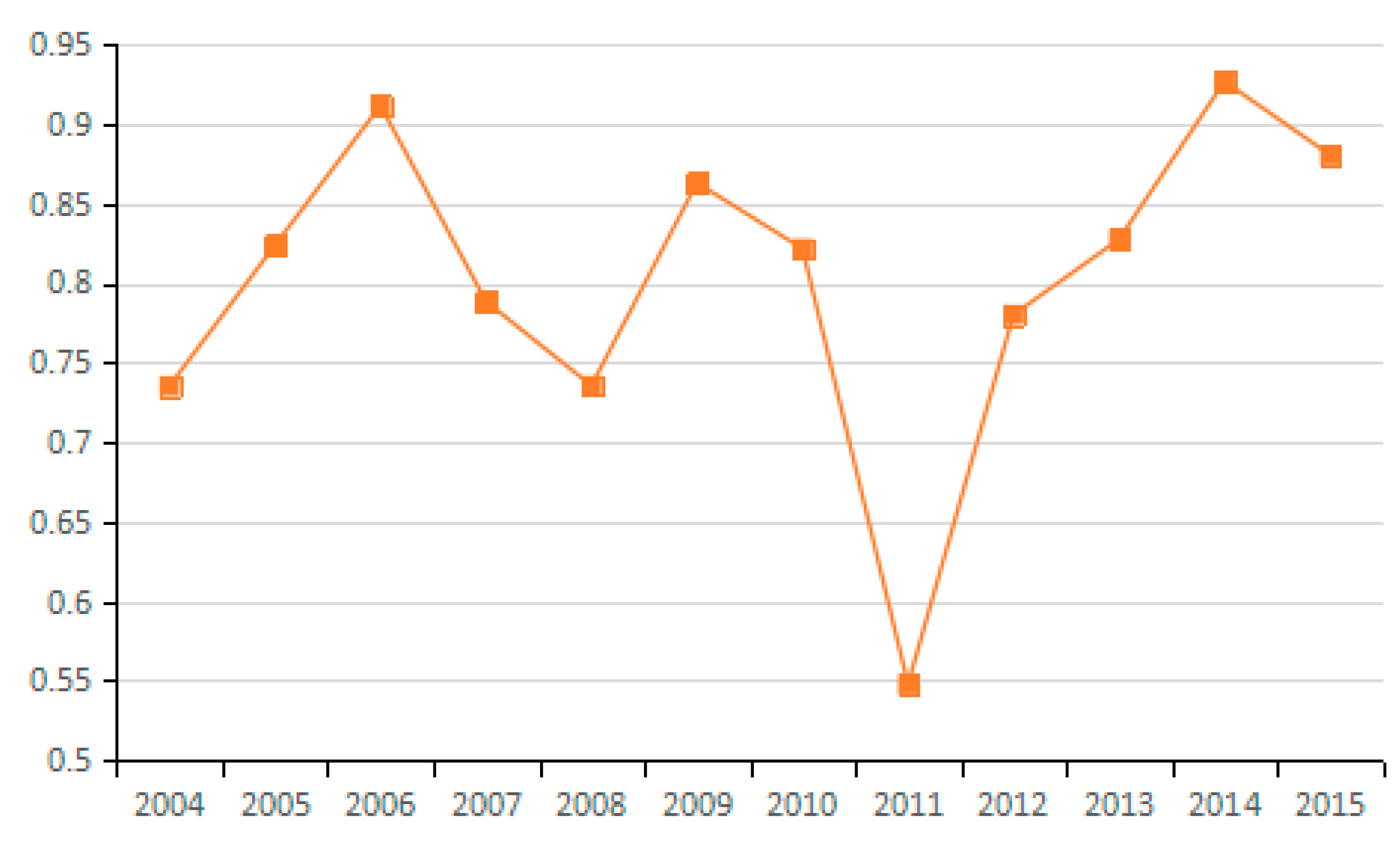

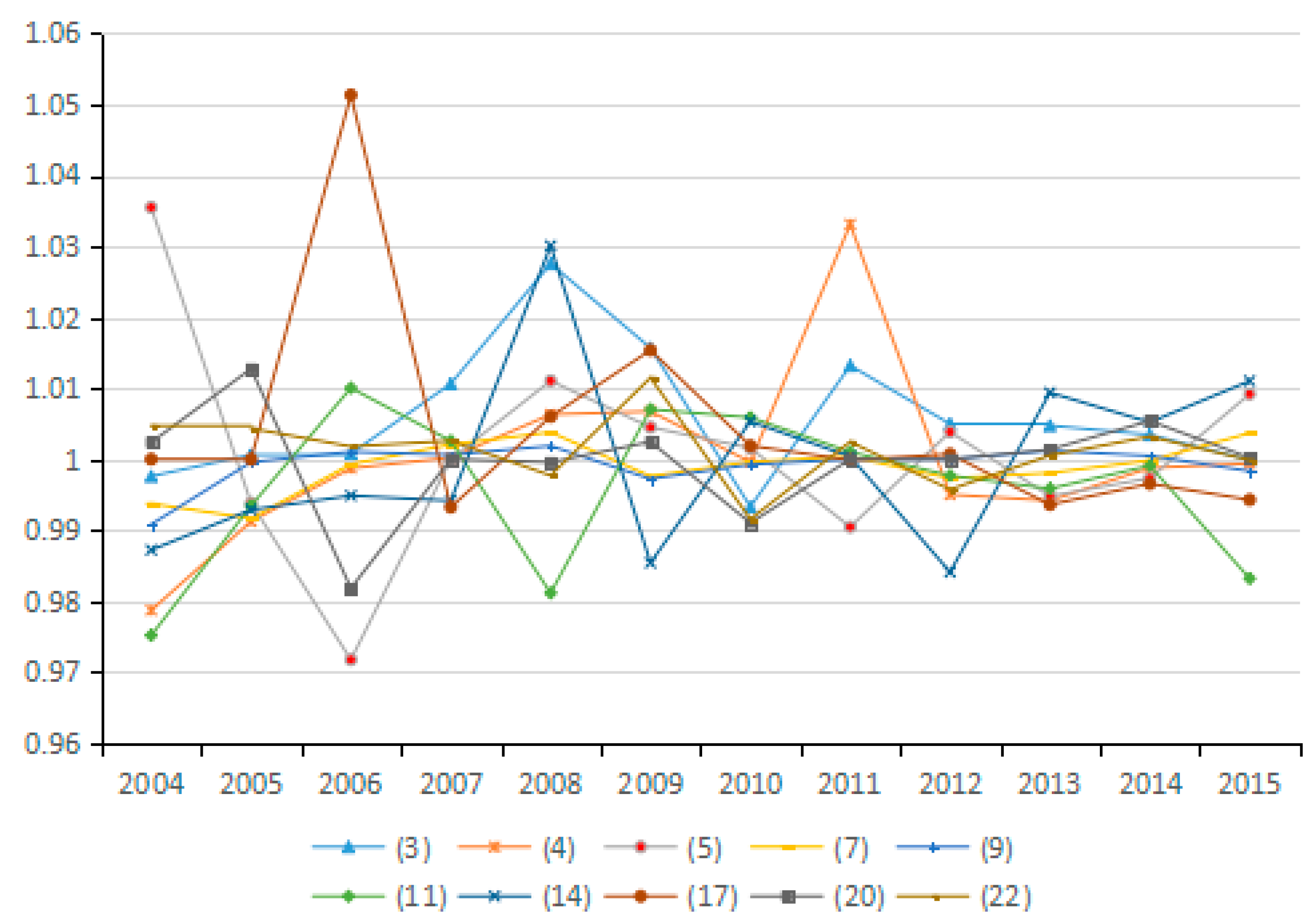

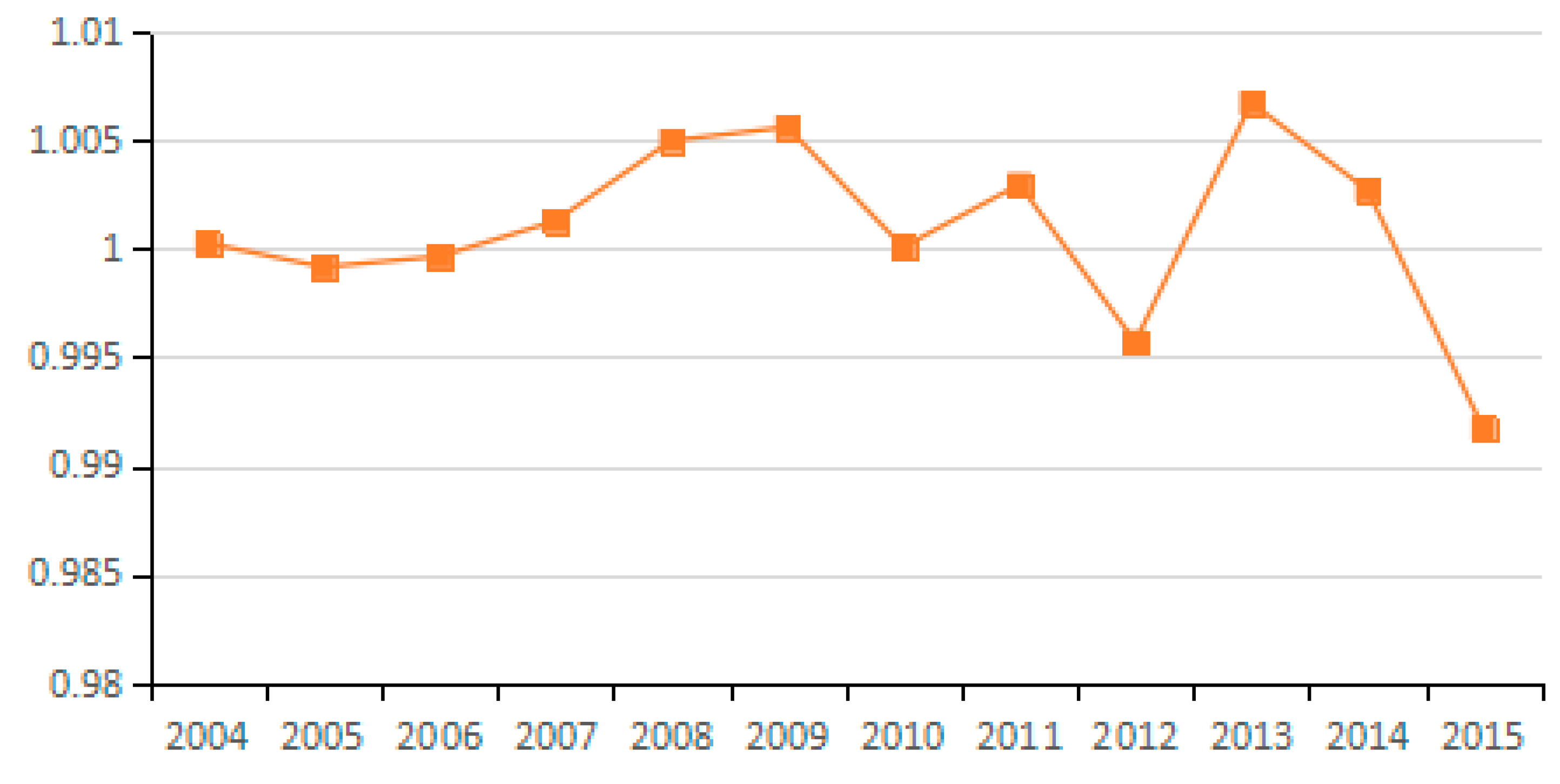

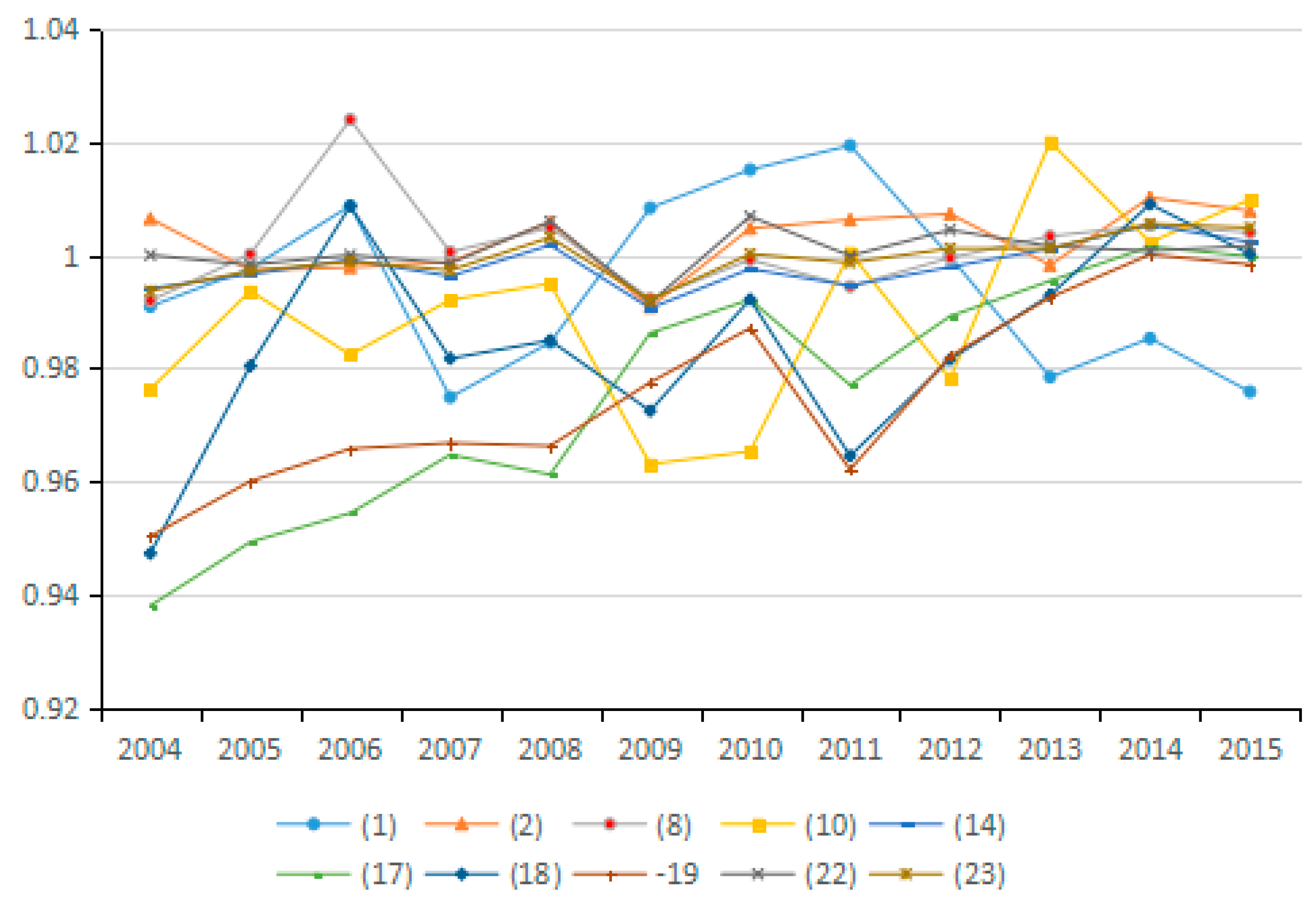

4. Results and Discussion

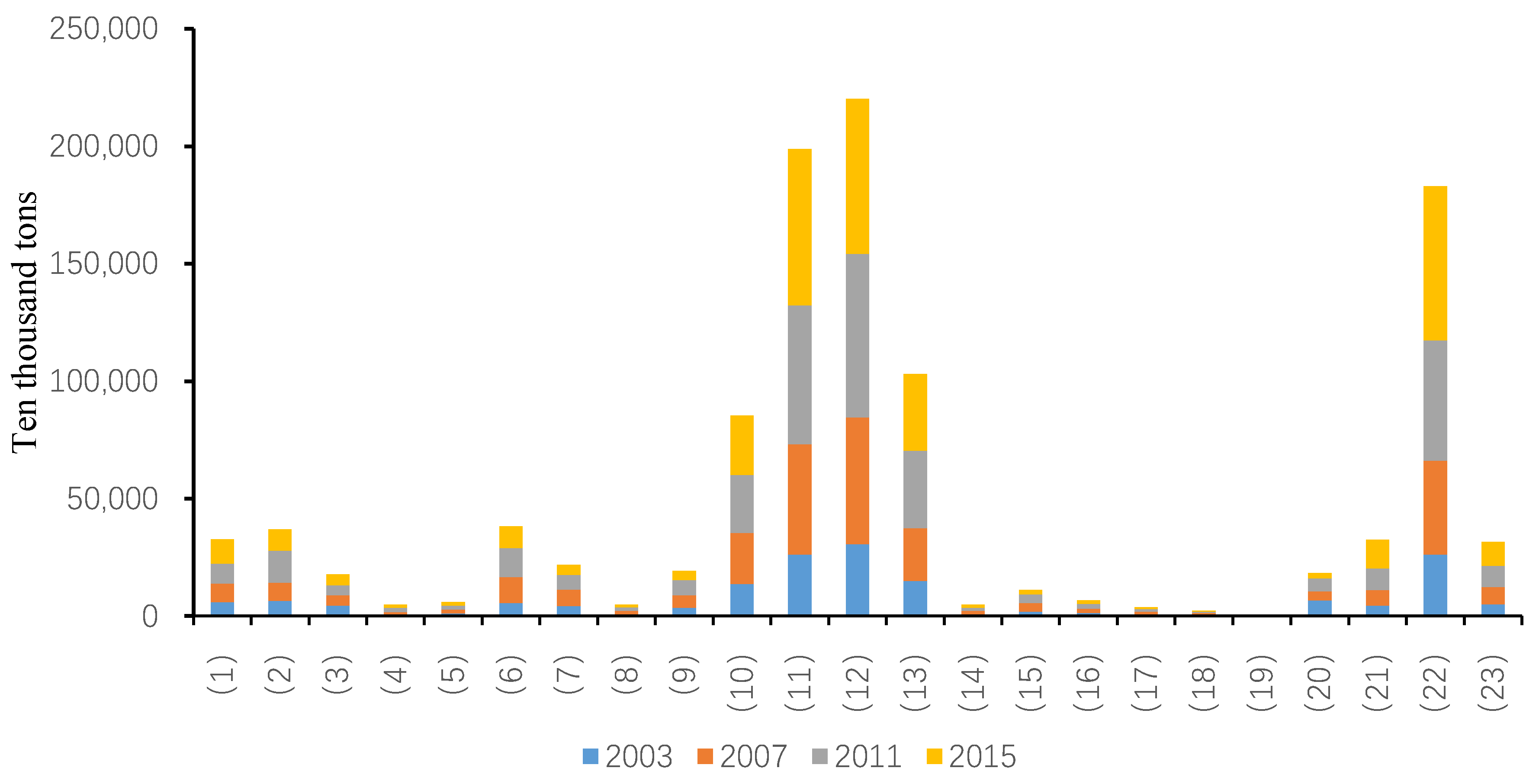

4.1. Analysis of Carbon Emissions from Different Industries

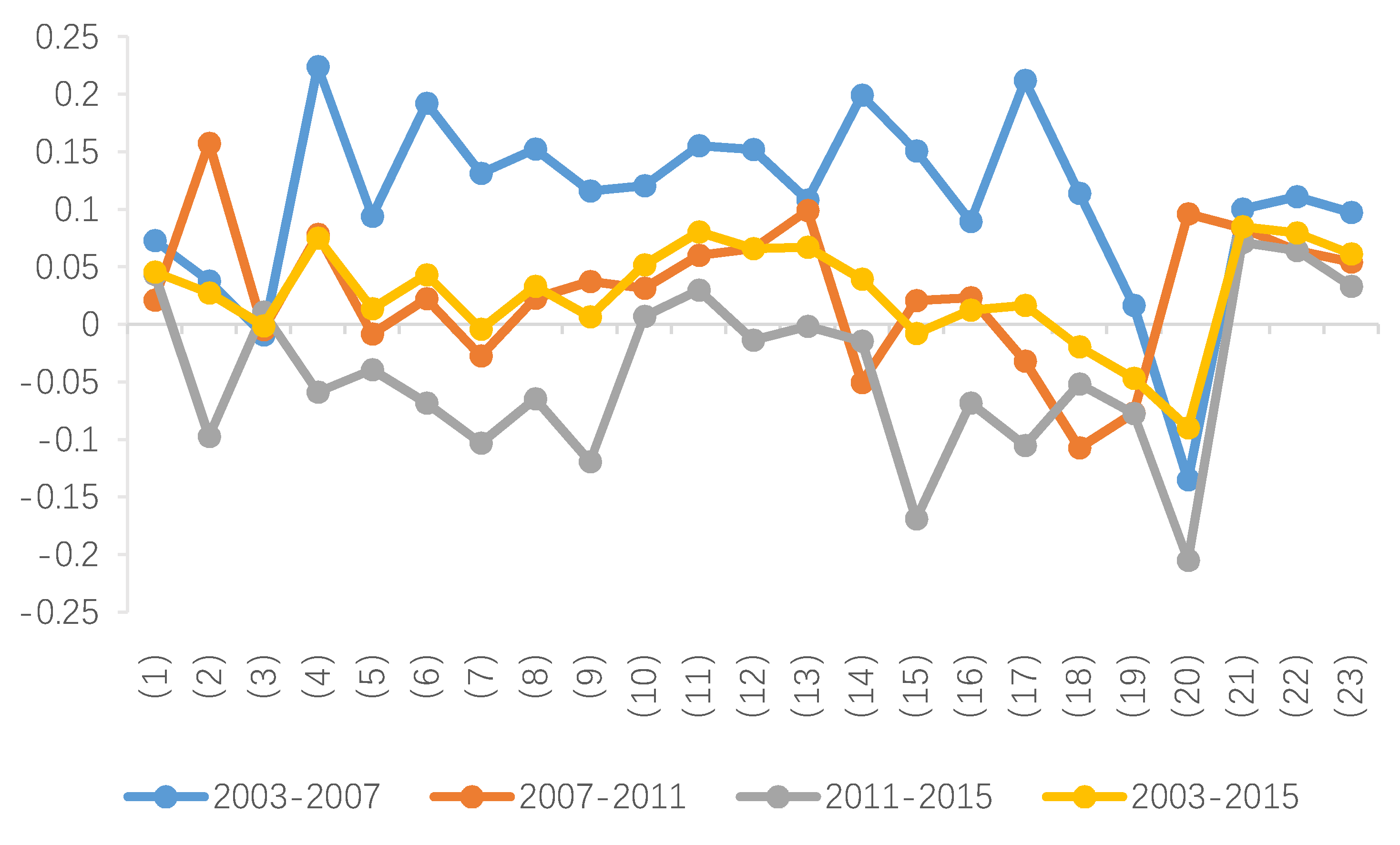

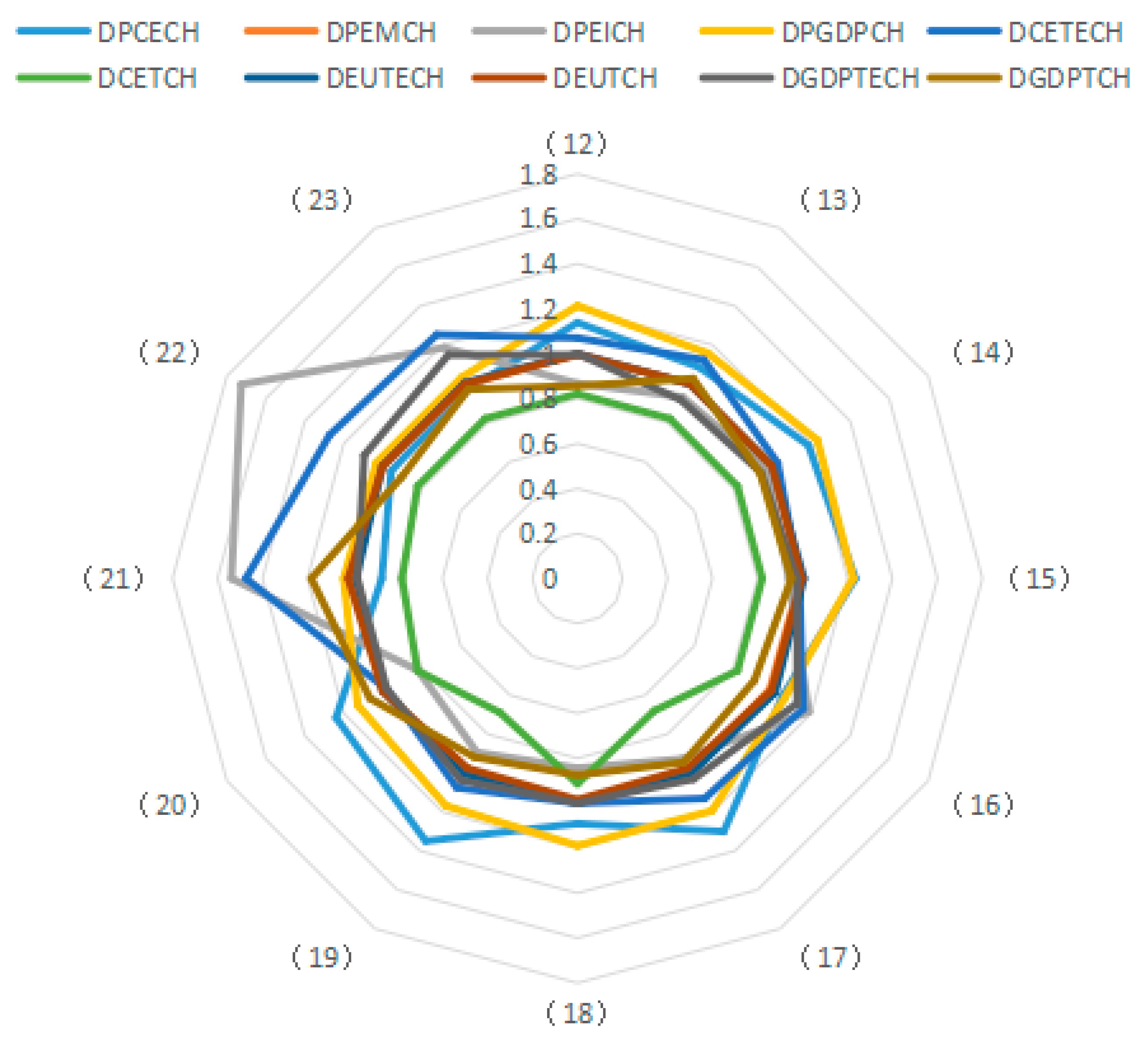

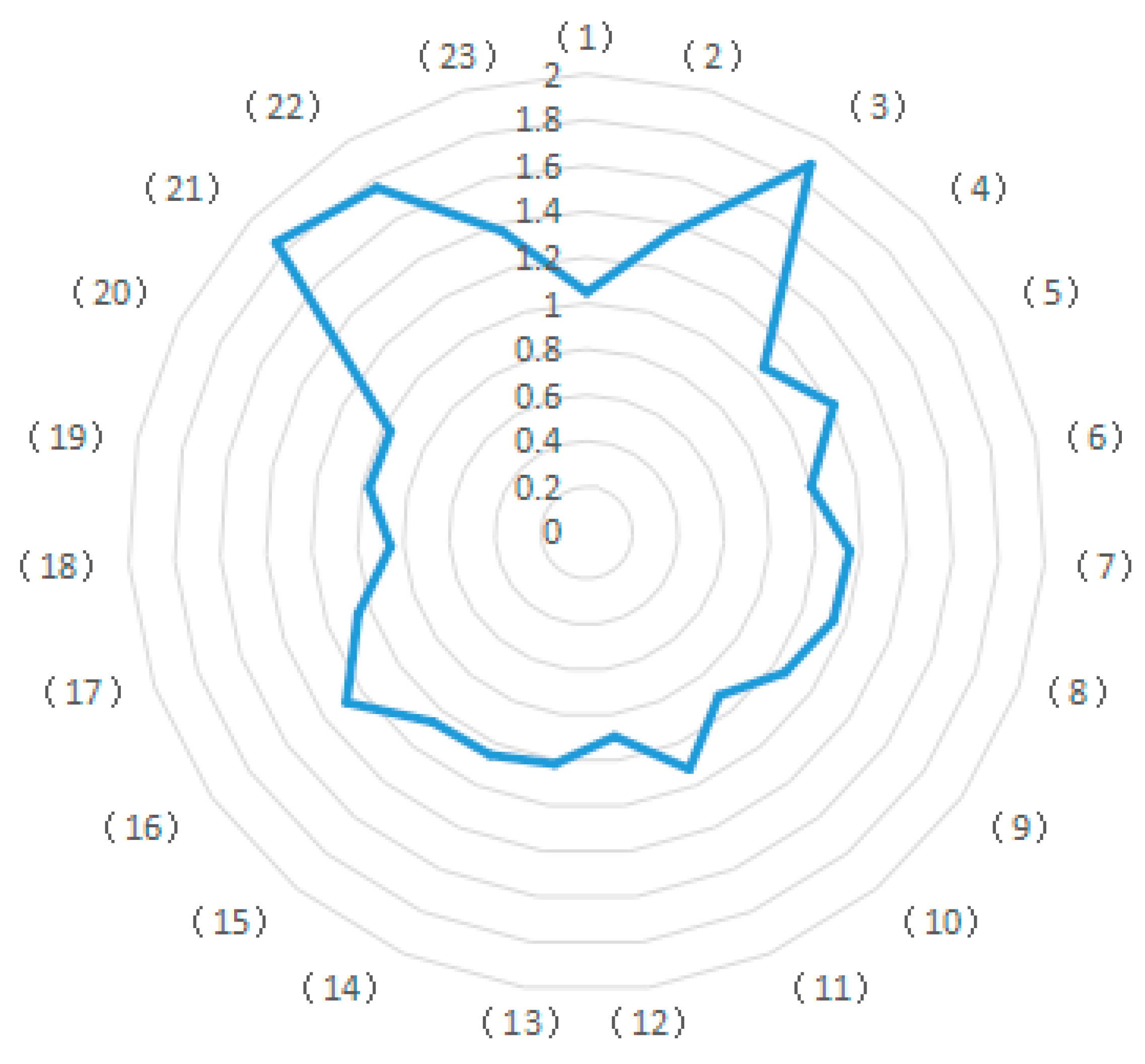

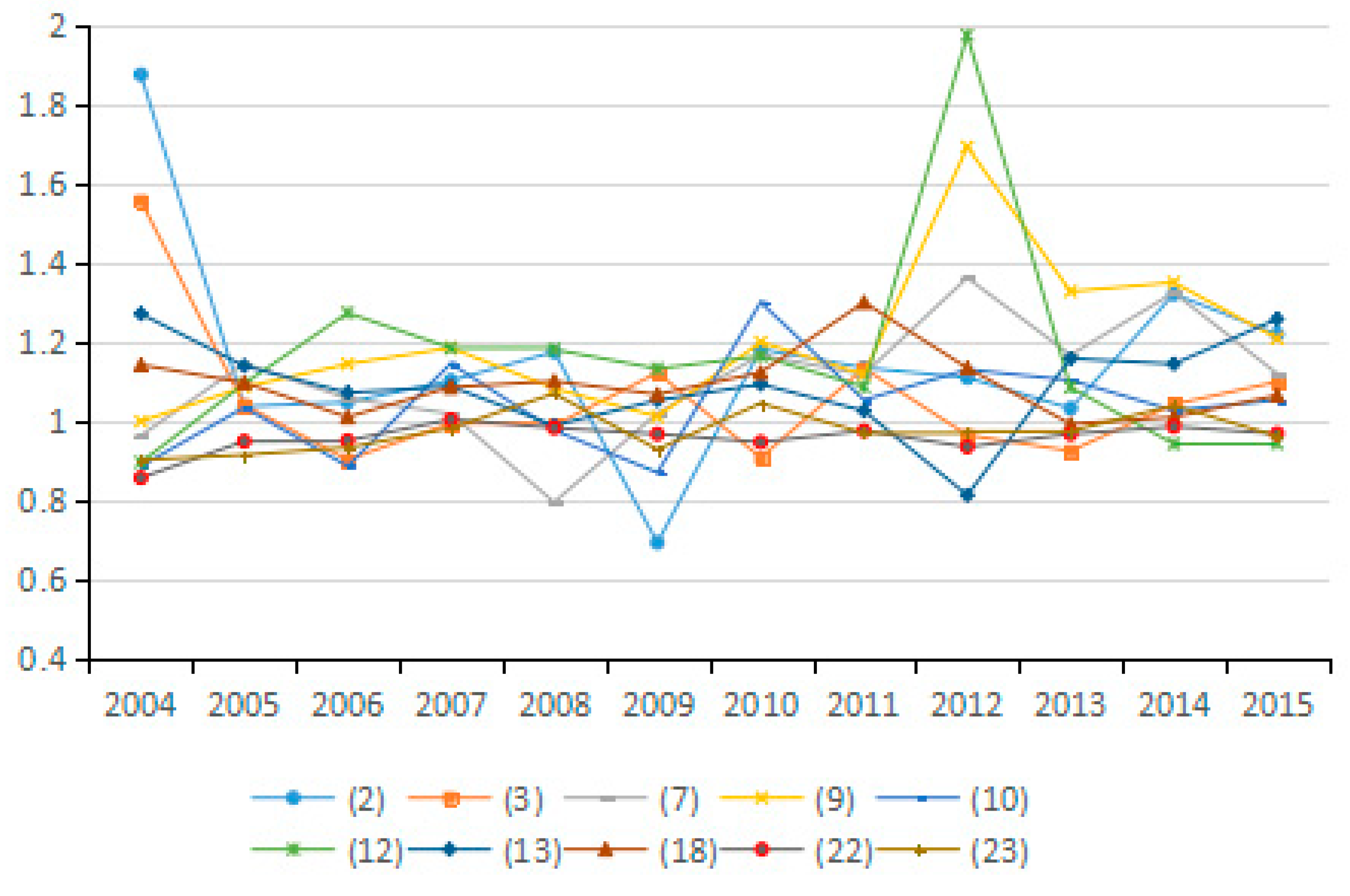

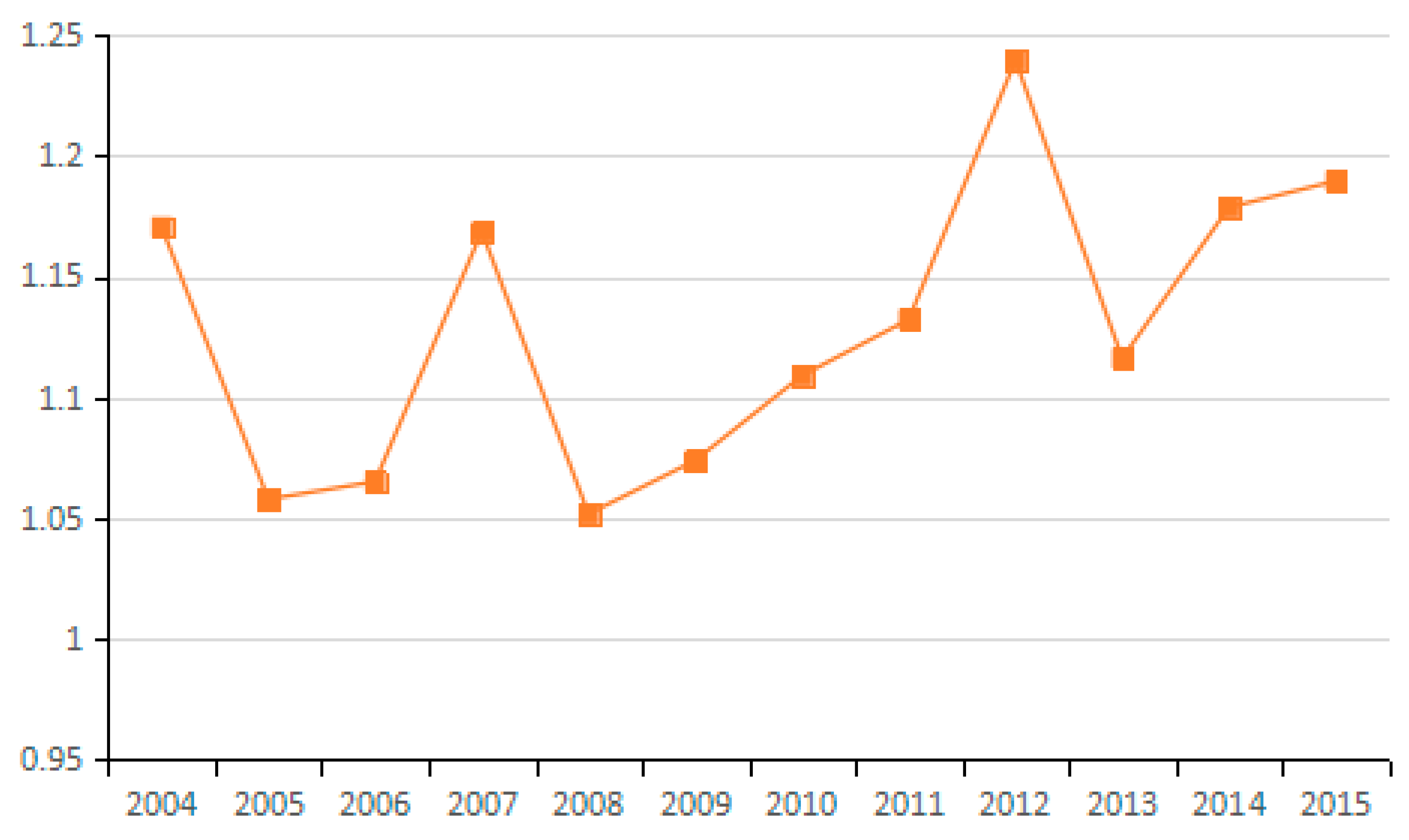

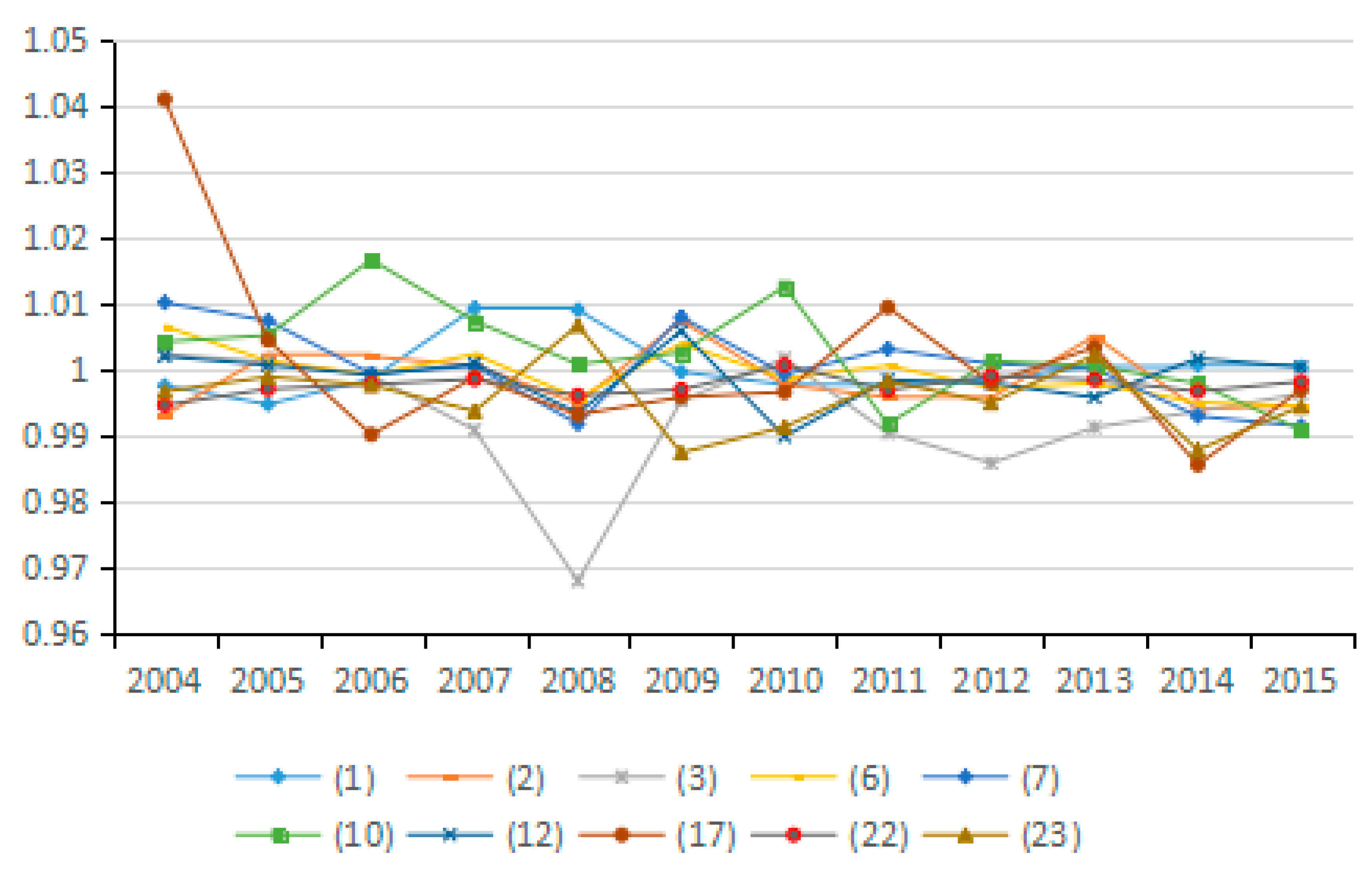

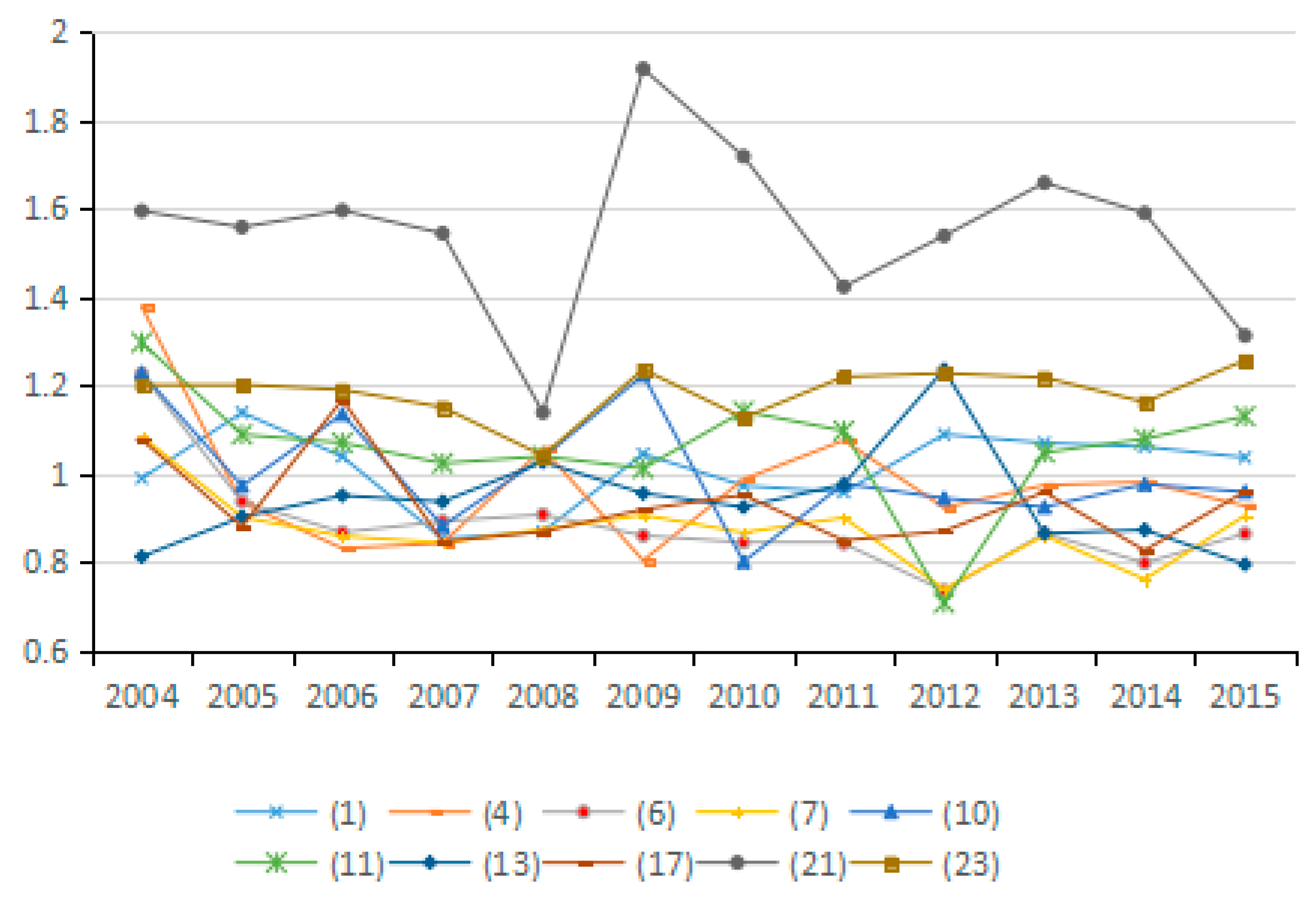

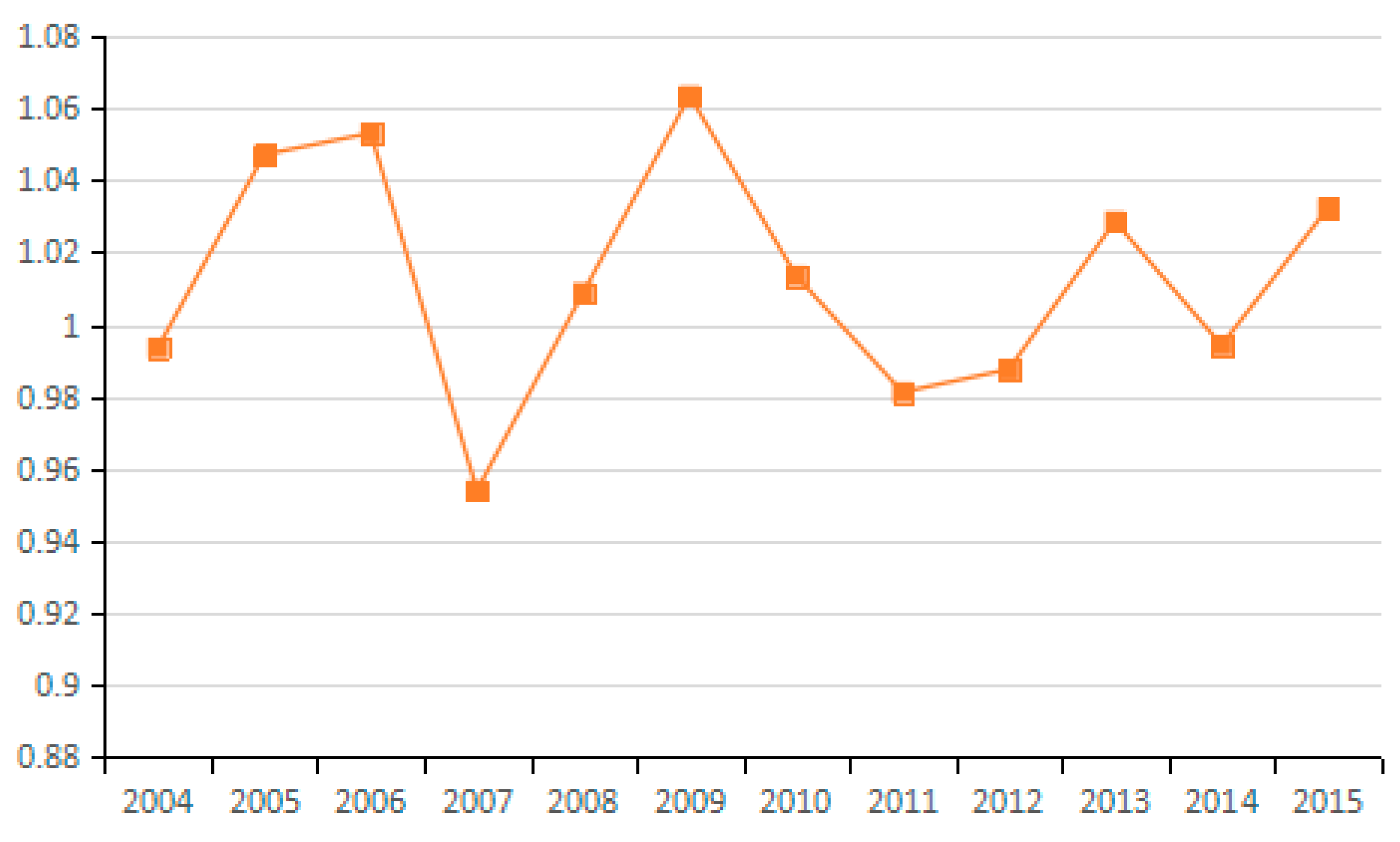

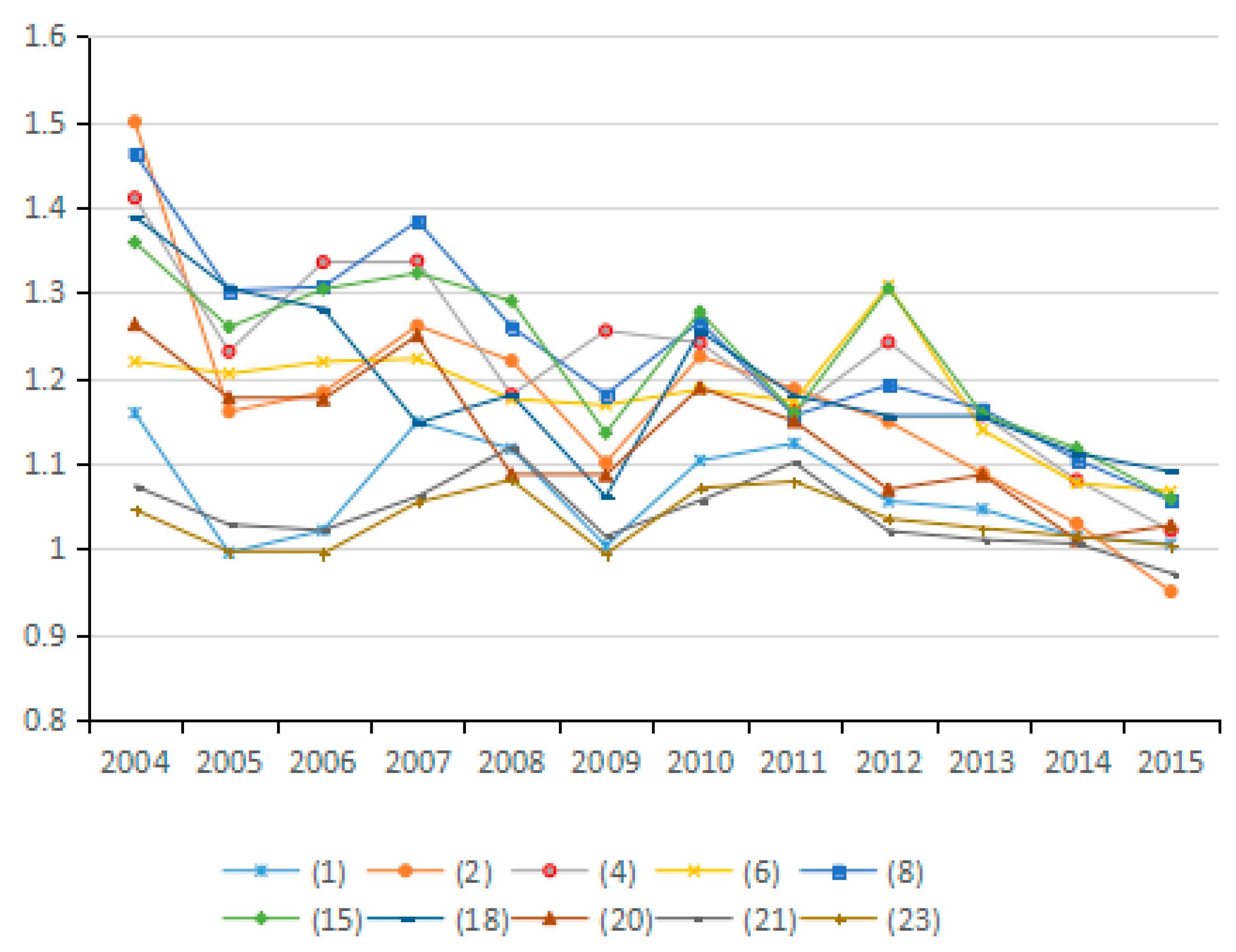

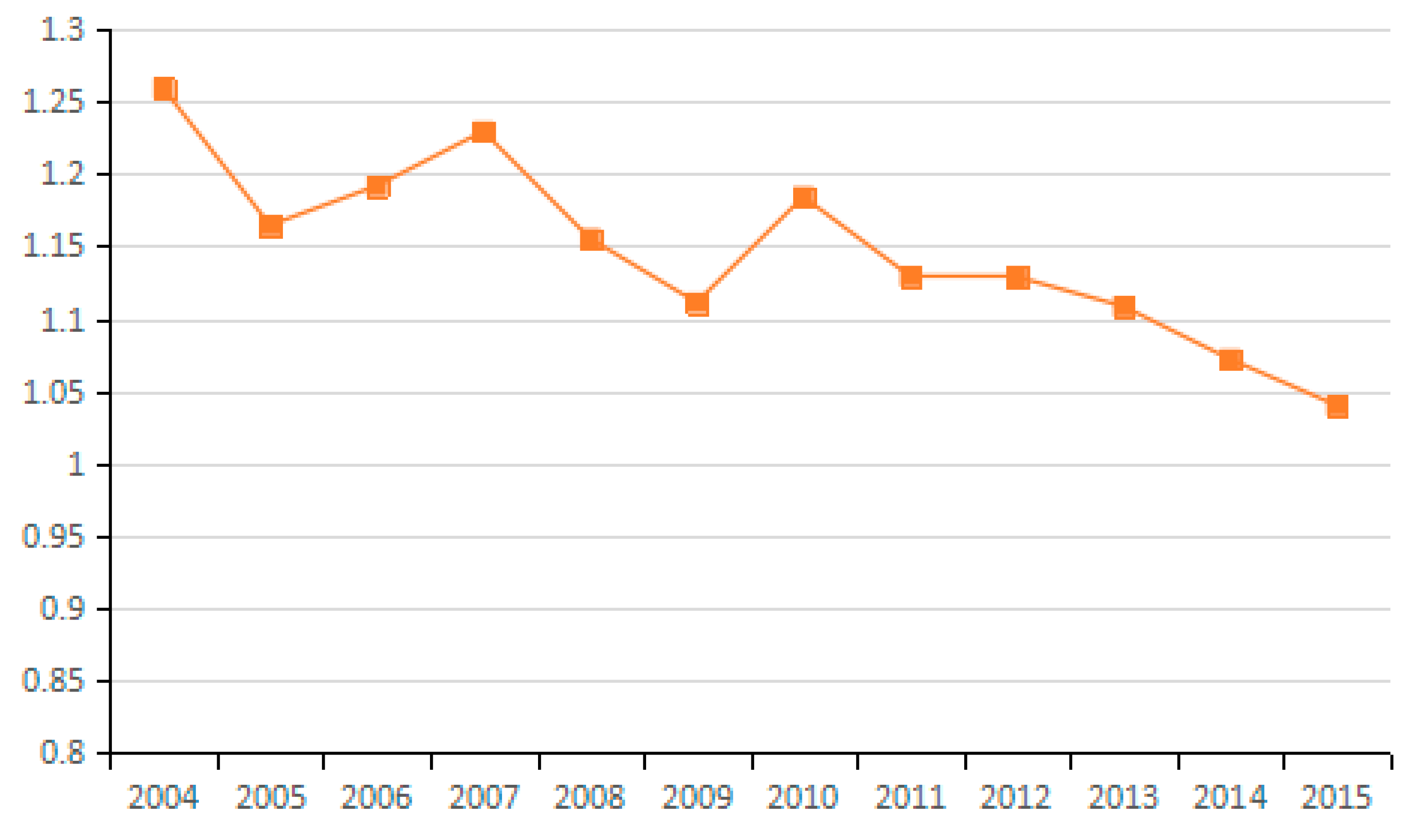

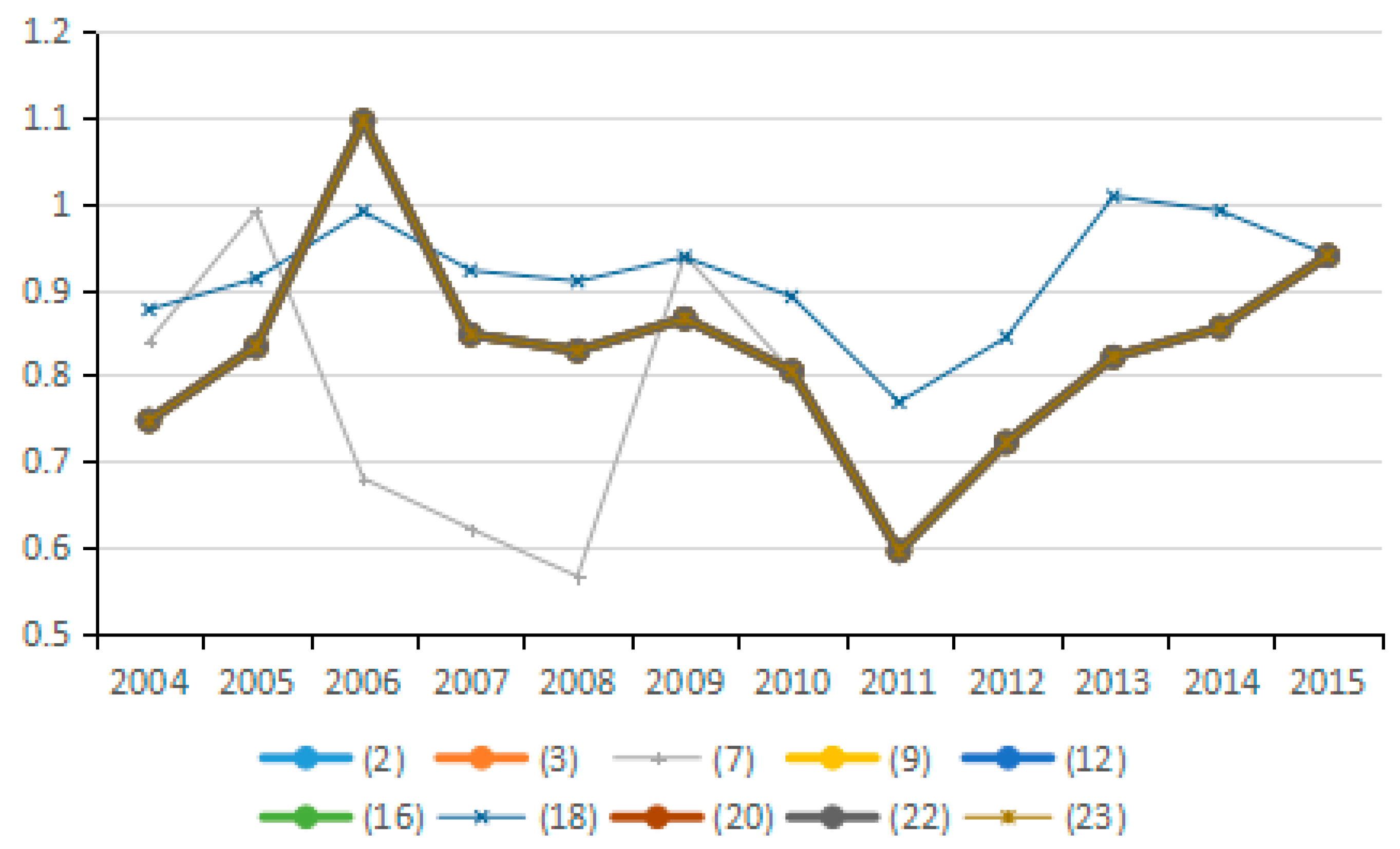

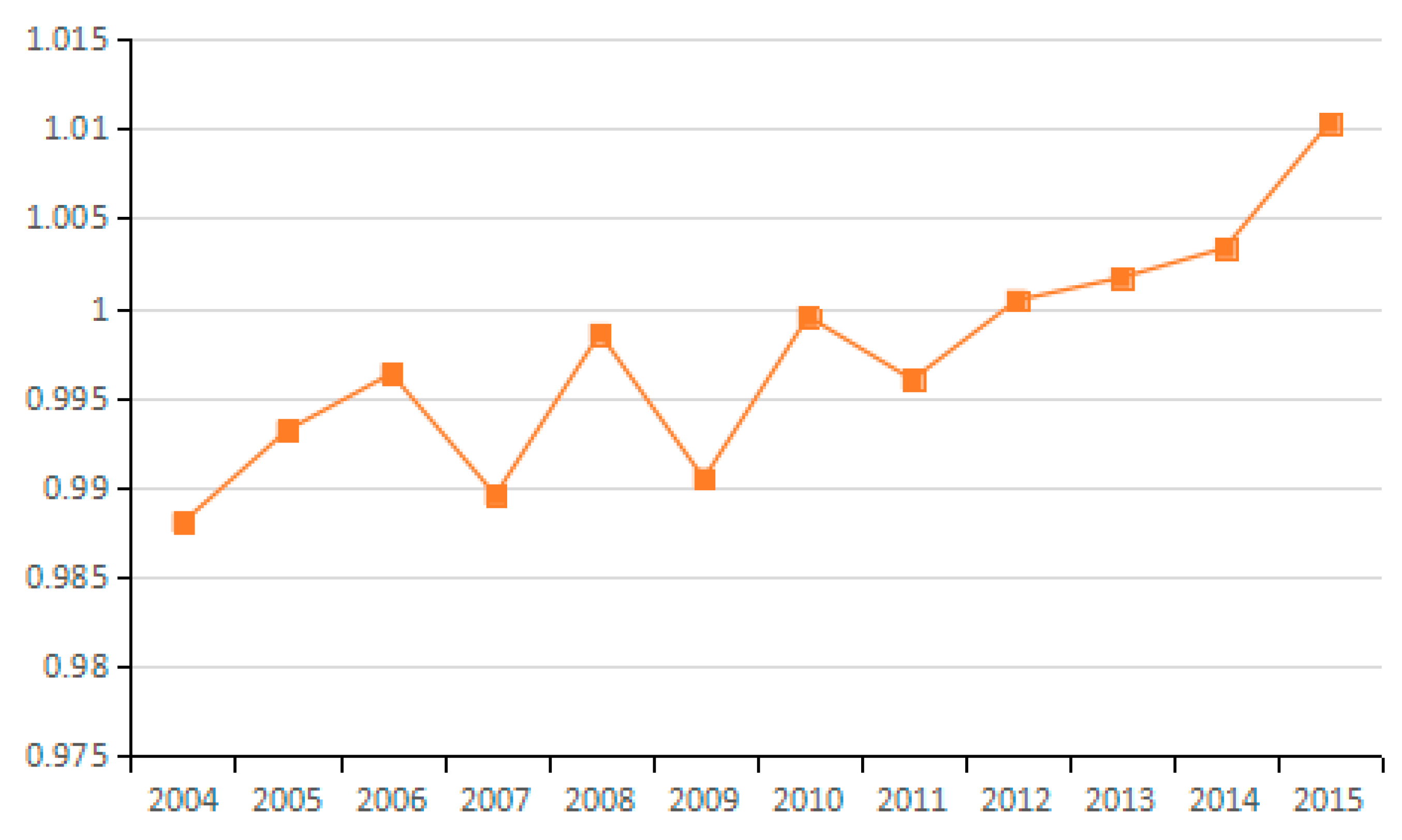

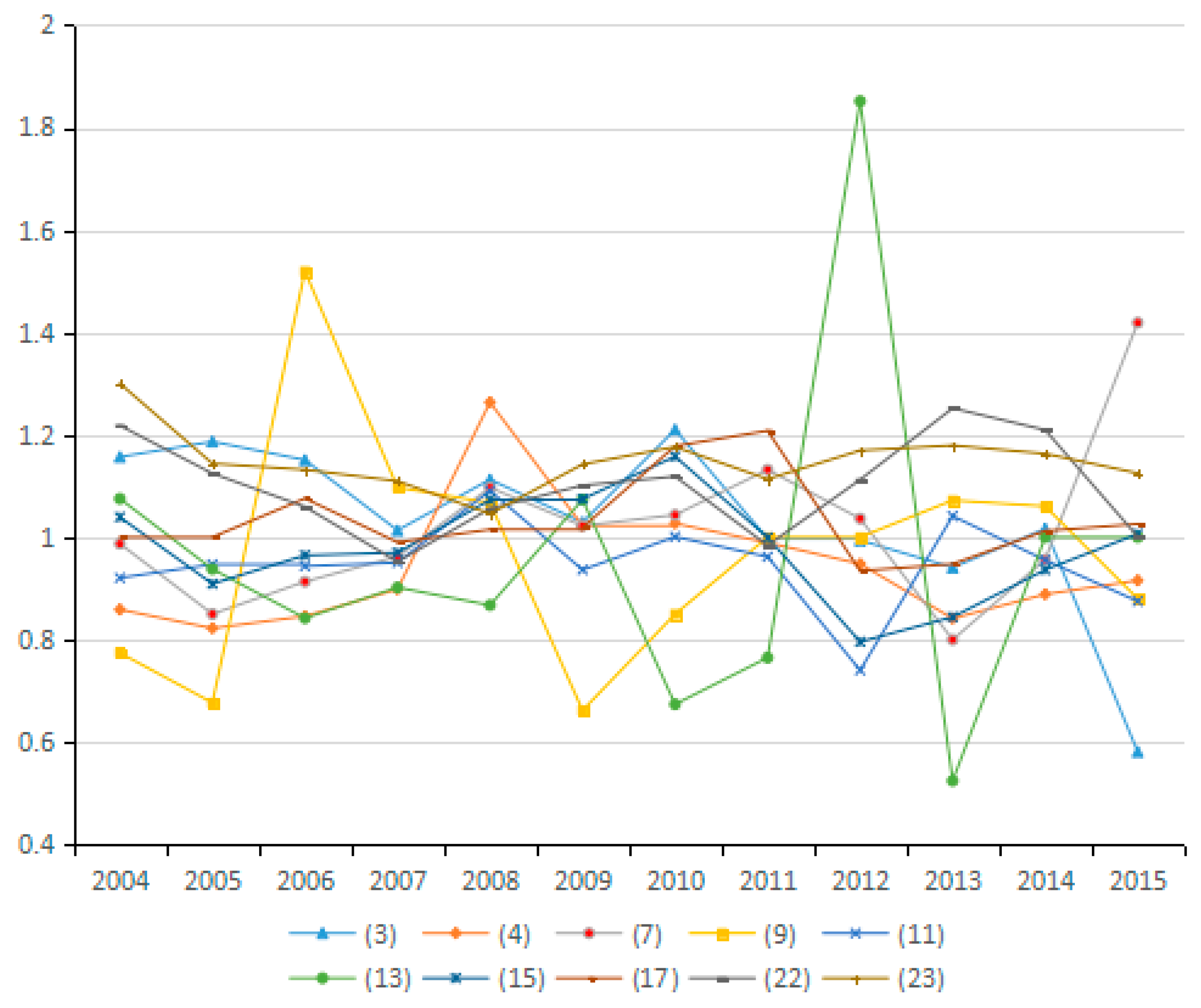

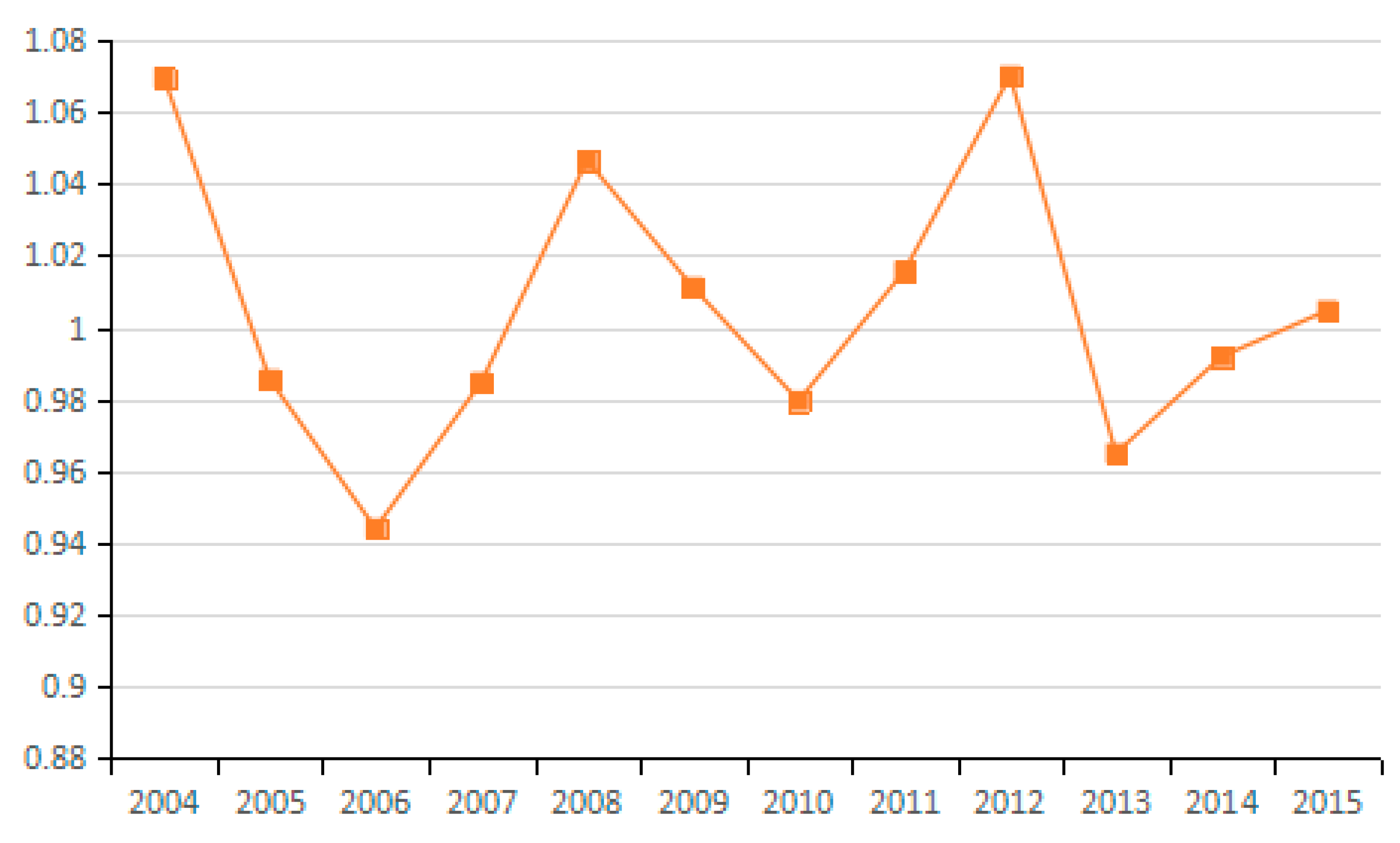

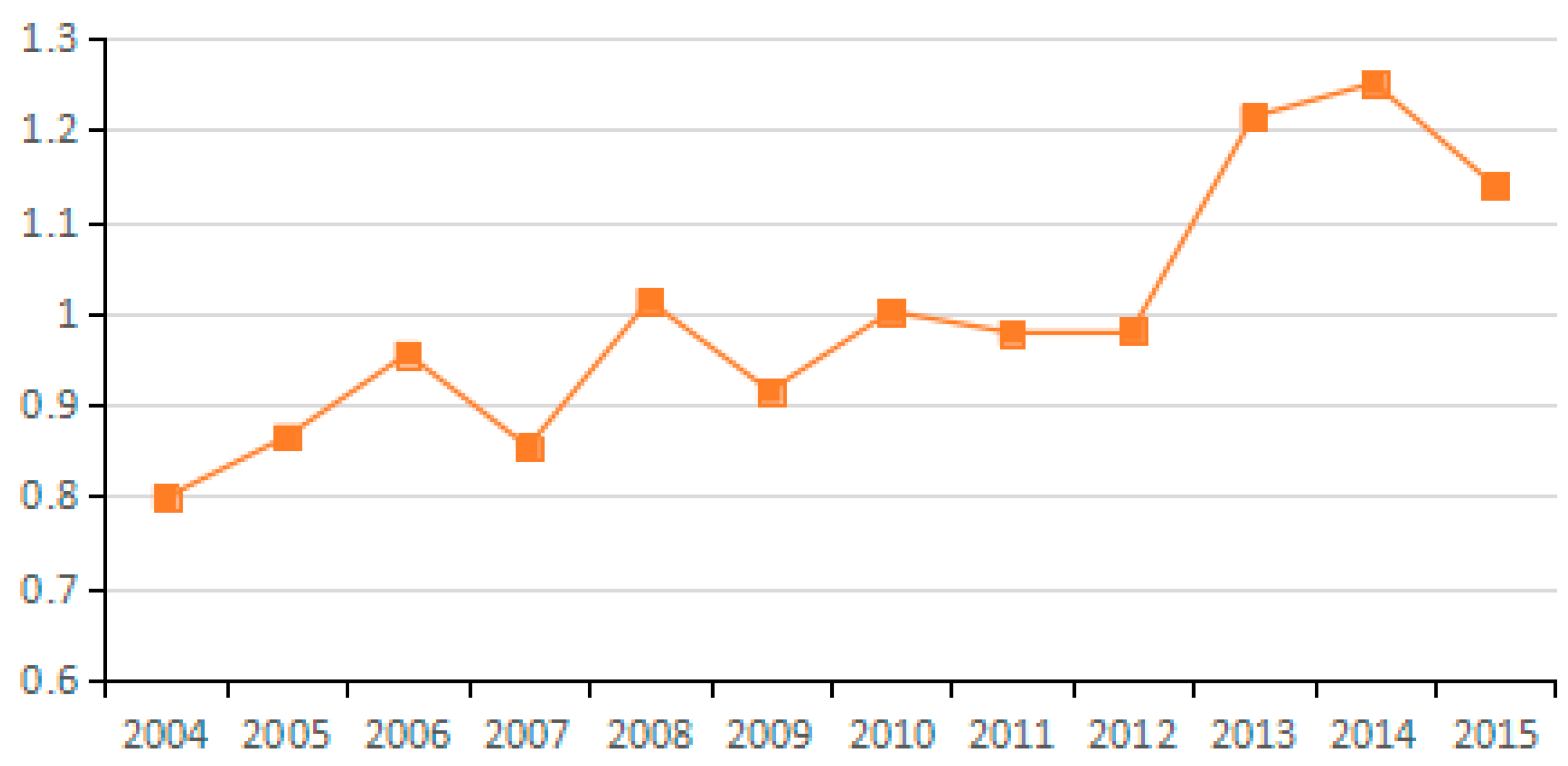

4.2. Driving Factors Analysis

5. Conclusions and Policy Implications

5.1. Conclusions

5.2. Policy Implications

5.2.1. Improving Economic Growth Quality and Balancing Economic Growth with Environmental Protection

5.2.2. Optimizing China’s Energy Mix and Vigorously Developing Clean Energy

5.2.3. Improving China’s Overall Innovation Capacity and Using Technology Changes to Reduce Carbon Emissions

5.2.4. Improving Carbon Trading Market and Allocating Carbon Emission Quotas Efficiently and Fairly

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dong, F.; Li, J.; Zhang, Y.J.; Wang, Y. Drivers analysis of CO2 emissions from the perspective of carbon density: The case of Shandong Province, China. Int. J. Environ. Res. Public Health 2018, 15, 1762. [Google Scholar] [CrossRef] [PubMed]

- Magazzino, C. The relationship among economic growth, CO2 emissions, and energy use in the APEC countries: A panel VAR approach. Environ. Syst. Decis. 2017, 37, 353–366. [Google Scholar] [CrossRef]

- Dong, F.; Dai, Y.; Zhang, S.; Zhang, X.; Long, R. Can a carbon emission trading scheme generate the Porter effect? Evidence from pilot areas in China. Sci. Total. Environ. 2019, 653, 565–577. [Google Scholar] [CrossRef] [PubMed]

- Dong, F.; Long, R.; Li, Z.; Dai, Y. Analysis of carbon emission intensity, urbanization and energy mix: Evidence from China. Nat. Hazards 2016, 82, 1375–1391. [Google Scholar] [CrossRef]

- Chen, W.; Wu, F.; Geng, W.; Yu, G. Carbon emissions in China’s industrial sectors. Resour. Conserv. Recycl. 2017, 117, 264–273. [Google Scholar] [CrossRef]

- Dong, F.; Bina, Z.; Yu, B.; Wang, Y.; Zhang, S.; Li, J.; Su, B. Can land urbanization help to achieve CO2 intensity reduction target or hinder it? Evidence from China. Resour. Conserv. Recycl. 2018, 134, 206–215. [Google Scholar] [CrossRef]

- Wu, C.B.; Huang, G.H.; Xin, B.G.; Chen, J.K. Scenario analysis of carbon emissions’ anti-driving effect on qingdao’s energy structure adjustment with an optimization model, part I: Carbon emissions peak value prediction. J. Clean. Prod. 2018, 172, 466–474. [Google Scholar] [CrossRef]

- Den Elzen, M.; Fekete, H.; Höhne, N.; Admiraal, A.; Forsell, N.; Hof, A.F.; Olivier, G.J.; Roselfsema, M.; Van Soest, H. Greenhouse gas emissions from current and enhanced policies of China until 2030: Can emissions peak before 2030? Energy Policy 2016, 89, 224–236. [Google Scholar] [CrossRef]

- Dong, F.; Long, R.; Bian, Z.; Xu, X.; Yu, B.; Wang, Y. Applying a Ruggiero three-stage super-efficiency DEA model to gauge regional carbon emission efficiency: Evidence from China. Nat. Hazards 2017, 87, 1453–1468. [Google Scholar] [CrossRef]

- Dong, F.; Long, R.; Yu, B.; Wang, Y.; Li, J.; Wang, Y.; Dai, Y.; Yang, Q.; Chen, H. How can China allocate CO2 reduction targets at the provincial level considering both equity and efficiency? Evidence from its Copenhagen Accord pledge. Resour. Conserv. Recycl. 2018, 129, 31–43. [Google Scholar] [CrossRef]

- Guo, R.; Zhao, Y.; Shi, Y.; Li, F.; Hu, J.; Yang, H. Low carbon development and local sustainability from a carbon balance perspective. Resour. Conserv. Recycl. 2017, 122, 270–279. [Google Scholar] [CrossRef]

- Dong, F.; Hua, Y.; Yu, B. Peak Carbon Emissions in China: Status, Key Factors and Countermeasures—A Literature Review. Sustainability 2018, 10, 2895. [Google Scholar] [CrossRef]

- Dong, F.; Wang, Y.; Su, B.; Hua, Y.; Zhang, Y. The process of peak CO2 emissions in developed economies: A perspective of industrialization and urbanization. Resour. Conserv. Recycl. 2019, 141, 61–75. [Google Scholar] [CrossRef]

- Wang, W.; Li, M.; Zhang, M. Study on the changes of the decoupling indicator between energy-related CO2 emission and GDP in China. Energy 2017, 128, 11–18. [Google Scholar] [CrossRef]

- Dong, F.; Long, R.; Chen, H.; Li, X.; Yang, Q. Factors affecting regional per-capita carbon emissions in China based on an LMDI factor decomposition model. PLoS ONE 2013, 8, e80888. [Google Scholar] [CrossRef] [PubMed]

- Hoekstra, R.; Jeroen, C.J.M.; Van Den, B. Comparing structural decomposition analysis and index. Energy Econ. 2003, 25, 39–64. [Google Scholar] [CrossRef]

- Zhu, Q.; Peng, X.; Lu, Z.; Wu, K. Factor Decomposition and Empirical Analysis of Carbon Emission Changes in China’s Energy Consumption. Resour. Sci. 2009, 31, 2072–2079. (In Chinese) [Google Scholar]

- Kaya, Y. Impact of Carbon Dioxide Emission Control on GNP Growth: Interpretation of Proposed Scenarios; IPCC Energy and Industry Subgroup, Response Strategies Working Group: Paris, France, 1989. [Google Scholar]

- Li, Y.; Zhang, L.; Cheng, X. Analysis of Factors Decomposition of China’s Carbon Emission Changes and Emission Reduction Paths Analysis. Resour. Sci. 2010, 32, 218–222. (In Chinese) [Google Scholar]

- Dong, F.; Yang, Q.; Long, R.; Chen, S. Decomposition and Dynamic Simulation of Carbon Emissions in China. China Popul. Resour. Environ. 2015, 25, 1–8. (In Chinese) [Google Scholar]

- González, P.F.; Landajo, M.; Presno, M.J. Tracking European union CO2 emissions through LMDI (logarithmic-mean Divisia index) decomposition. The activity revaluation approach. Energy 2014, 73, 741–750. [Google Scholar] [CrossRef]

- Mahony, T.O. Decomposition of Ireland’s carbon emissions from 1990 to 2010: An extended Kaya identity. Energy Policy 2013, 59, 573–581. [Google Scholar] [CrossRef]

- Jiang, J.; Ye, B.; Xie, D.; Tang, J. Provincial-level carbon emission drivers and emission reduction strategies in China: Combining multi-layer LMDI decomposition with hierarchical clustering. J. Clean. Prod. 2017, 169, 178–190. [Google Scholar] [CrossRef]

- Su, B.; Ang, B.W. Structural decomposition analysis applied to energy and emissions: Aggregation issues. Econ. Syst. Res. 2012, 24, 299–317. [Google Scholar] [CrossRef]

- Dong, F.; Yu, B.; Hadachin, T.; Dai, Y.; Wang, Y.; Zhang, S.; Long, R. Drivers of carbon emission intensity change in China. Resour. Conserv. Recycl. 2018, 129, 187–201. [Google Scholar] [CrossRef]

- Su, B.; Ang, B.W.; Li, Y. Input-output and structural decomposition analysis of Singapore’s carbon emissions. Energy Policy 2017, 105, 484–492. [Google Scholar] [CrossRef]

- Su, B.; Thomson, E. China’s carbon emissions embodied in (normal and processing) exports and their driving forces, 2006–2012. Energy Econ. 2016, 59, 414–422. [Google Scholar] [CrossRef]

- Xia, Y.; Fan, Y.; Yang, C. Assessing the impact of foreign content in China’s exports on the carbon outsourcing hypothesis. Appl. Energy 2015, 150, 296–307. [Google Scholar] [CrossRef]

- Sun, Z.R.; Zhou, D.Q.; Zhou, P. Driving forces of industrial CO2 emissions: A new production-based decomposition analysis method. J. Quant. Tech. Econ. 2012, 5, 63–74. (In Chinese) [Google Scholar]

- Wang, H.; Zhou, P. Multi-country comparisons of CO2 emission intensity: The production-theoretical decomposition analysis approach. Energy Econ. 2018, 74, 310–320. [Google Scholar] [CrossRef]

- Filippini, M.; Hunt, L.C. Measurement of energy efficiency based on economic foundations. Energy Econ. 2015, 52 (Suppl. 1), S5–S16. [Google Scholar] [CrossRef]

- Greening, L.A.; Davis, W.B.; Schipper, L. Decomposition of aggregate carbon intensity for the manufacturing sector: Comparison of declining trends from 10 OECD countries for the period 1971–1991. Energy Econ. 1998, 20, 43–65. [Google Scholar] [CrossRef]

- Hamilton, C.; Turton, H. Determinants of emissions growth in OECD countries. Energy Policy 2002, 30, 63–71. [Google Scholar] [CrossRef]

- Kim, K.; Kim, Y. International comparison of industrial CO2 emission trends and the energy efficiency paradox utilizing production-based decomposition. Energy Econ. 2012, 34, 1724–1741. [Google Scholar] [CrossRef]

- Kim, Y.; Worrell, E. International comparison of CO2 emission trends in the iron and steel industry. Energy Policy 2002, 30, 827–838. [Google Scholar] [CrossRef]

- Pasurka, C.A., Jr. Decomposing electric power plant emissions within a joint production framework. Energy Econ. 2006, 28, 26–43. [Google Scholar] [CrossRef]

- Fan, D. Driving factors of carbon emissions from energy consumption in China-Based on LMDI-PDA method. China Environ. Sci. 2013, 33, 1705–1713. (In Chinese) [Google Scholar]

- Zhou, P.; Ang, B.W. Decomposition of aggregate CO2 emissions: A productiontheoretical approach. Energy Econ. 2008, 30, 1054–1067. [Google Scholar] [CrossRef]

- Zhang, X.P.; Zhang, J.; Tan, Q.L. Decomposing the change of CO2 emissions: A joint production theoretical approach. Energy Policy 2013, 58, 329–336. [Google Scholar] [CrossRef]

- Wang, H.; Ang, B.W.; Zhou, P. Decomposing aggregate CO2 emission changes with heterogeneity: An extended production-theoretical approach. Energy J. 2018, 39, 59–79. [Google Scholar] [CrossRef]

- Ang, B.W.; Liu, N. Handling zero values in the logarithmic mean Divisia index decomposition approach. Energy Policy 2017, 35, 238–246. [Google Scholar] [CrossRef]

- Ang, B.W.; Liu, F.L.; Chew, E.P. Perfect decomposition techniques in energy and environmental analysis. Energy Policy 2003, 31, 1561–1566. [Google Scholar] [CrossRef]

- Ang, B.W. Decomposition analysis for policymaking in energy: Which is the preferred method? Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Ang, B.W. The LMDI approach to decomposition analysis: A practical guide. Energy Policy 2005, 33, 867–871. [Google Scholar] [CrossRef]

- China’s National Bureau of Statistics (CNBS). China Statistic Yearbook 2004–2016; China Statistical Press: Beijing, China, 2004–2016.

- China’s National Bureau of Statistics (CNBS). China Energy Statistic Yearbook 2004–2016; China Statistical Press: Beijing, China, 2004–2016.

- China’s National Bureau of Statistics (CNBS). China Industrial Statistical Yearbook 2004–2016; China Statistical Press: Beijing, China, 2004–2016.

- China’s National Bureau of Statistics (CNBS). Statistical Yearbook of the Chinese Investment in Fixed Assets 2004–2016; China Statistical Press: Beijing, China, 2004–2016.

- China’s National Bureau of Statistics (CNBS). China Population and Employment Statistics Yearbook 2004–2016; China Statistical Press: Beijing, China, 2004–2016.

- China’s National Bureau of Statistics (CNBS). China Price Statistics Yearbook 2004–2016; China Statistical Press: Beijing, China, 2004–2016.

- China’s National Bureau of Statistics (CNBS). China Input Output Table 2012; China Statistical Press: Beijing, China, 2015.

- Tian, Y. Estimation of China’s Sub-industry Capital Stock: 1990–2014. J. Quant. Tech. Econ. 2016, 390, 3–21. (In Chinese) [Google Scholar]

- Ma, X.M.; Bao, J.M.; Xiong, S.Q. Analysis of driving factors of China’s multi-region carbon emission based on LMDI decomposition. Mod. Manag. Sci. 2017, 212, 63–65. (In Chinese) [Google Scholar]

- Wang, Q.; Chiu, Y.H.; Chiu, C.R.; Tol, R.S.J.; Weyant, J.P. Driving factors behind carbon dioxide emissions in China: A modified production-theoretical decomposition analysis. Energy Econ. 2015, 51, 252–260. [Google Scholar] [CrossRef]

- Korhonen, P.; Moskowitz, H.; Wallenius, J. Multiple criteria decision support. A review. Eur. J. Oper. Res. 1992, 63, 361–375. [Google Scholar] [CrossRef]

- Nesticò, A.; Sica, F. The sustainability of urban renewal projects: A model for economic multi-criteria analysis. J. Prop. Invest. Financ. 2017, 35, 397–409. [Google Scholar] [CrossRef]

| Variable Symbol | Variable Name | Description |

|---|---|---|

| C | Carbon emissions | Calculate using standard coals with different energy sources and corresponding carbon emission factors |

| E | Energy consumption | Convert coal, oil, and natural gas into standard coal for totaling |

| Y | Economic scale | Actual industry added value in 1990 constant price |

| EM | Energy mix | Coal consumption/total energy consumption |

| EI | Energy intensity | Energy consumption/GDP |

| K | Capital stock | Cumulative capital of the industry |

| L | labor force | Average number of employees in the industry |

| Number | Industry | Number | Industry |

|---|---|---|---|

| (1) | Farming, Forestry, Animal Husbandry, Fishery Conservancy | (13) | Smelting and Pressing of Metals |

| (2) | Mining and Washing of Coal | (14) | Manufacture of Metal Products |

| (3) | Extraction of Petroleum and Natural Gas | (15) | Manufacture of Special Purpose Machinery and Manufacture of General Purpose Machinery |

| (4) | Mining and Processing of Metal Ores | (16) | Manufacture of Transportation Equipment |

| (5) | Mining and Processing of Non-metal Ores and Others | (17) | Manufacture of Electrical Machinery and Apparatus |

| (6) | Manufacture of Foods and Manufacture of tobacco | (18) | Manufacture of Computers, Communication and Other Electronic Equipment |

| (7) | Manufacture of Textile and Manufacture of products | (19) | Manufacture of Measuring Instruments and Machinery |

| (8) | Processing of Timber and Manufacture of Furniture | (20) | Production and Supply of Electric Power and Heat Power |

| (9) | Manufacture of Articles for Culture, Education, Arts and Crafts, Sport and Entertainment Activities | (21) | Construction |

| (10) | Processing of Petroleum, Coking and Processing of Nuclear Fuel | (22) | Transport, Storage and Post |

| (11) | Manufacture of Chemistry | (23) | Wholesale, Retail Trade and Hotel, Restaurants |

| (12) | Manufacture of Non-metallic Mineral Products |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, F.; Gao, X.; Li, J.; Zhang, Y.; Liu, Y. Drivers of China’s Industrial Carbon Emissions: Evidence from Joint PDA and LMDI Approaches. Int. J. Environ. Res. Public Health 2018, 15, 2712. https://doi.org/10.3390/ijerph15122712

Dong F, Gao X, Li J, Zhang Y, Liu Y. Drivers of China’s Industrial Carbon Emissions: Evidence from Joint PDA and LMDI Approaches. International Journal of Environmental Research and Public Health. 2018; 15(12):2712. https://doi.org/10.3390/ijerph15122712

Chicago/Turabian StyleDong, Feng, Xinqi Gao, Jingyun Li, Yuanqing Zhang, and Yajie Liu. 2018. "Drivers of China’s Industrial Carbon Emissions: Evidence from Joint PDA and LMDI Approaches" International Journal of Environmental Research and Public Health 15, no. 12: 2712. https://doi.org/10.3390/ijerph15122712

APA StyleDong, F., Gao, X., Li, J., Zhang, Y., & Liu, Y. (2018). Drivers of China’s Industrial Carbon Emissions: Evidence from Joint PDA and LMDI Approaches. International Journal of Environmental Research and Public Health, 15(12), 2712. https://doi.org/10.3390/ijerph15122712