1. Introduction

The resin transfer molding (RTM) of wood strands capitalizes on the utilization of lower quality small-diameter timber from hazardous fuel thinning treatments and/or fast-growing plantation trees. RTM produces high-quality composite panels for applications such as automotive interior products, requiring thin panels with relatively high strength, stiffness, and dimensionally stability. These composite panels need the ability to be shaped during or after the production process according to the matrix type. Wood strands are wood flakes with a high aspect ratio (length/thickness ~ 350–400), similar to those used in the production of oriented strand board (OSB), but significantly thinner (by over 35%, depending on the target panel thickness) [

1,

2]. A high aspect ratio enables an efficient transfer of shear forces from the matrix to the fiber [

3]. The development of high-quality wood strand composite products provides new markets for the wood-based composite industry, produces high-performance biobased composite panels from low-quality small-diameter trees, and presents pathways to incorporate renewable materials into manufacturing products where synthetic fibers are typically utilized.

RTM is a liquid composite molding technique that provides an effective, low-cost manufacturing method for wood strand composites [

4]. RTM can produce near net shape parts with a high surface quality at high production rates. The high specific strength and stiffness of RTM products allows for weight reduction in automotive applications. Resin transfer molded wood composites are produced by injecting a low-viscosity thermosetting resin through a porous medium—a preform of consolidated wood strands—and allowing the reinforced polymer to cure in the mold. The porosity of the reinforcement (fiber preform) and the viscosity of the resin are the two most important factors that influence the permeability of the preform [

5]. The permeability of the reinforcement determines the flow rate and the wetting behavior of the resin through the preform and the mold filling time. The permeability of the RTM reinforcement is influenced by the preform architecture, resin properties, processing conditions, and mold design [

6]. The preform structure can be described by its porosity, fiber dimensions, and fiber orientation. Resin flow and bonding performance are influenced by its curing rate, viscosity, and fiber-wetting behavior, indirectly measured by the contact angle between the resin droplet and the substrate [

6,

7]. The processing conditions that influence permeability include injection and vacuum pressures and ambient temperature, which affects the resin viscosity and cure kinetics.

An important consideration when using natural fibers in RTM is their ability to act as a resin sink, absorbing fluid as it flows by, increasing the resistance to resin flow compared to synthetic fibers [

8]. In addition to reducing the overall resin flow rate, the saturation of natural fibers can cause swelling, which reduces the pore size and further restricts resin flow [

8]. The consequence of this behavior is that natural fiber preforms require additional injection time in comparison to synthetic fiber mats of the same fiber volume fraction and injection pressure. Most of the prior research has been conducted on the behavior and permeability of synthetic and natural fiber reinforcements in RTM, such as glass [

9], woven fabrics [

10], carbon [

11], jute [

8,

9], sisal [

4], and flax fibers [

12]. However, only one publicly available study [

7] has considered the use of wood strands as reinforcement in producing wood composite products using RTM.

Yang [

7] examined techniques to produce thin hybrid poplar wood strand preforms for use in resin transfer molding and determined that 6% polyvinyl acetate (PVAc) binder is sufficient to produce a preform that can be handled during its processing without disturbing its structure [

7]. Using wood strands bound with PVAc, Yang [

7] observed increased preform permeability with increased injection pressure and preform porosity. However, as density increases, preform porosity and, therefore, preform permeability decrease. A direct correlation was observed between the binder content of the preform and the amount that the preform viscoelastically expands in the thickness direction due to stress relaxation after pressing. Preform thickness expansion or rebound, while undesirable [

13], can be acceptable in RTM of a wood strand preform, as it will increase the porosity of the preform and allow for greater permeability. However, excessive expansion will create a preform that is thicker than the mold cavity and requires consolidation and high pressure prior to resin infusion. An issue with the PVAc binder is the difficulty in producing large preforms that hold their shape and are predictable in terms of their expansion behavior, allowing handling prior to molding [

7]. Although the preliminary findings for resin transfer molding of wood strand composite panels by Yang were positive [

7], there is still a deficiency in the knowledge necessary to repeatedly produce high-quality wood strand panels using RTM with desirable mechanical properties, resin penetration, and surface quality.

This study examines RTM processing parameters to form wood composite panels; the effects of binder content, binding agent, and preform consolidation on the repeatability and quality of RTM wood strand panels are considered.

2. Materials and Methods

Wood strands for the study were produced from small-diameter (150 to 250 mm diameter at breast height) ponderosa pine (

Pinus ponderosa Douglas ex C. Lawson) logs, as described by Weight and Yadama [

1,

2]. Briefly, to obtain consistent strand width, green lumber (25.4 mm nominal thickness) was fed into a CAE disc strander operating at a rotation speed of 500 rpm. The projection of the strander blades was adjusted manually so that average strand thickness was 0.38 mm. The dimensions of the wood strands were on the average 150 mm × 16 mm × 0.38 mm, with the grain of the wood running parallel to the long edge of the strands. Wood strands were conditioned to 12% moisture content (MC) in a temperature- and relative-humidity-controlled room. A binder was then applied in limited quantity to the strands in order to consolidate them into a mat or a preform for subsequent resin transfer molding. Yang [

7] examined techniques to produce thin wood strand preforms for use in resin transfer molding, and determined that 6% polyvinyl acetate (PVAc) binder is sufficient to produce a preform that can be handled during its processing without disturbing its structure. One problem associated with the use of a PVAc binder is the difficulty in producing consistent and stable preforms that can hold their form without falling apart prior to molding, therefore requiring a significant amount of binder in the preform. In this study, a reliable and repeatable RTM procedure was developed using an alternative binder—polyethylene (PE)—for preform fabrication. The use of PE powder as the preform binding agent provides a cost-effective and easy-to-use alternative to PVAc to bind the wood strands together into a preform, which can then be resin transfer molded into flat or profiled panels. Both low-density polyethylene (LDPE) and high-density polyethylene (HDPE) in powder form were evaluated for use as the binding agent. We suspected that LDPE would be more suitable to this process due to its lower melting temperature, which would reduce the energy consumption of the process.

2.1. Preform Production

Wood strands were consolidated into a 6.35 mm thick preform (a target density of 400 kg/m

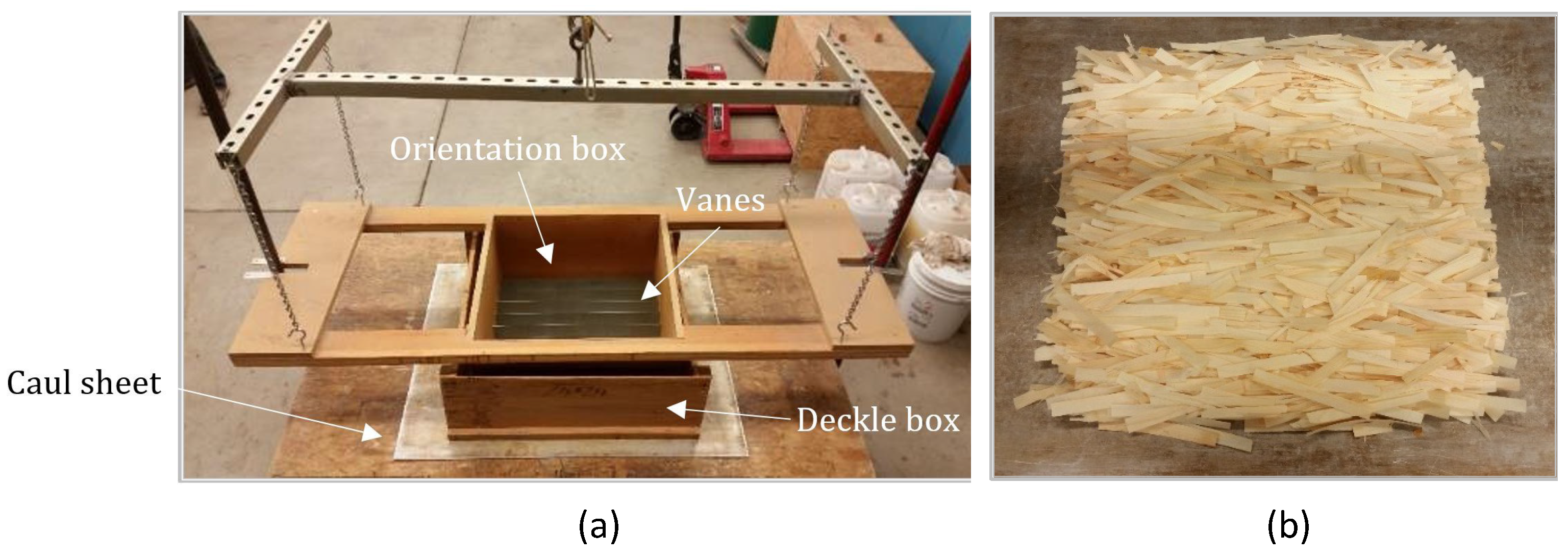

3) with a computer-controlled hydraulic press with oil heated platens (Pressman hot press), using commercially obtained LDPE and HDPE binders (in powder form) of 1%, 5%, and 20% weight fractions. The reason for varying the thermoplastic resin content was to determine the percentage of binder by mass necessary to sufficiently hold the preform together. Preforms consolidated and bound with HDPE were produced with only 1% binder content for comparison with LDPE-bound preforms. Wood strands were oriented by letting them fall freely onto a steel caul sheet through a 607 mm × 607 mm orientation box with metal vanes spaced 51 mm apart. The caul sheet was coated with a release agent and placed on an oscillating platform to ensure even distribution of strands as the preform was formed (

Figure 1). Four equal layers by mass of wood strands alternated with three equal layers by mass of PE powder, with the wood strands on the exterior to ensure even distribution of the binding agent. The oriented strand mat, prior to pressing into a preform, is also shown in

Figure 1.

During consolidation, the preforms were heated to 10 °C above the melting temperature of the binder (110 °C and 130 °C for LDPE and HDPE, respectively). The press was closed using a thickness-controlled pressing schedule that produced preforms slightly thicker than the cavity of the RTM mold to ensure preform contact with the RTM mold surfaces. The press was held in the closed position for 5 min to ensure complete melting of the PE. The preform was removed from the press and allowed to cool to room temperature between caul sheets. The preform was then trimmed to match the size of the RTM mold cavity, weighed, and its relaxed thickness was measured.

2.2. Panel Production

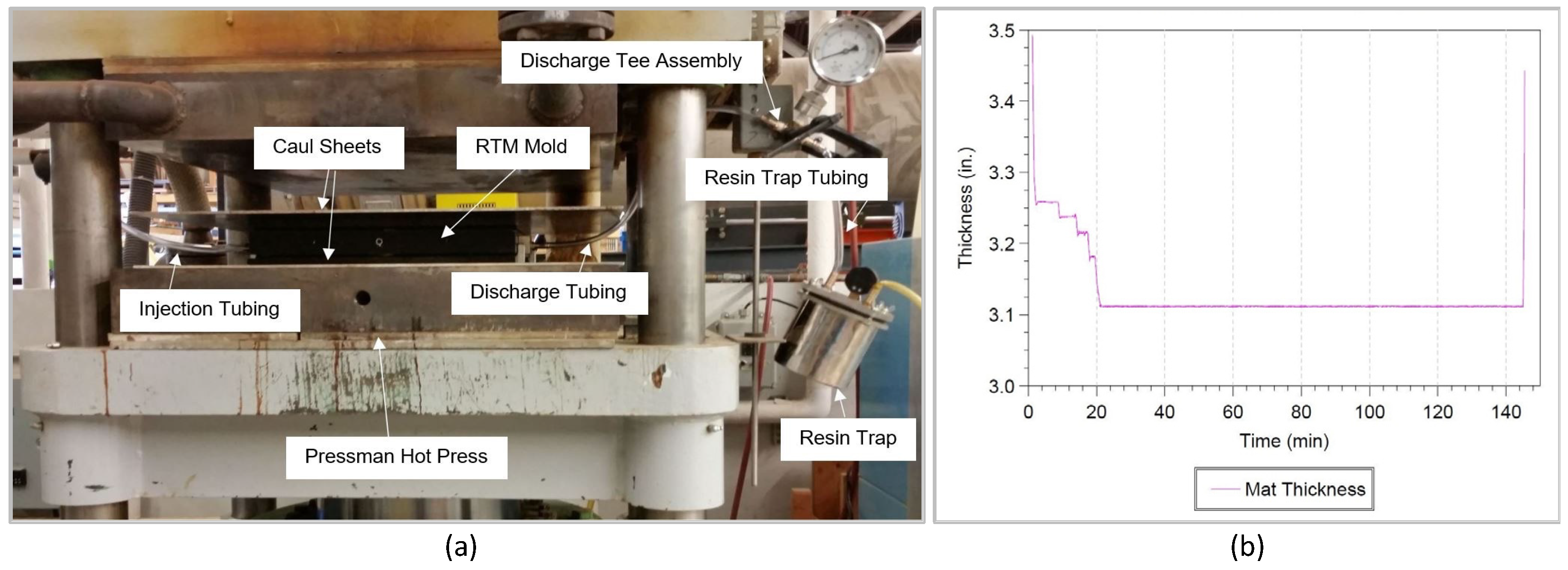

Panels were fabricated using an RTM mold constructed from Tuffcoat-anodized 6061 aluminum with an acrylic window for resin flow observation, and which encompassed a cavity measuring 135 mm × 300 mm × 6.4 mm. Vinyl tubing connected the discharge port of the mold to a pressure gauge and a vacuum pump with a resin trap, while the vinyl tubing on the injection port of the mold was sealed. The mold was placed vertically, with the injection port on the bottom. The RTM setup is shown in

Figure 2. The metal mold surfaces were coated with Chem-Trend MR 515 (Chem-Trend L.P., Howell, MI) mold release agent to facilitate the removal of the cured panel. LDPE release film, followed by nylon peel ply, was placed on the acrylic surface of the RTM mold cavity. The longitudinal edges of the preform were sealed with Y-204 Sealant Tape (Fiberglass Supply, Burlington, WA, USA) to reduce edge effects or resin running along the edges during injection. Derakane 411–350 epoxy vinyl ester resin (Ashland Inc., Covington, KY, USA) was mixed for one minute with the accelerators—0.2% cobalt naphthenate (Co-N, 6%, Sigma-Aldrich, St. Louis, MO, USA) and 0.025% dimethylaniline (DMA, 100%, Sigma-Aldrich)—and the catalyst, 2% methyl ethyl ketone peroxide (MEKP, 38%, TAP Plastics, Oakland, CA, USA). The accelerated and catalyzed resin was poured into a 2100cc Radius Pneumatic Injection System.

Learning from the RTM analysis, larger compression resin transfer molded (CRTM) panels were produced using an all-metal tool and applying the most suitable preform parameters as selected from the RTM results and were evaluated for their mechanical and moisture absorption properties and compared to other natural fiber and synthetic composites. The process to produce CRTM panels utilized the same process to produce preforms as the RTM panels but utilized a larger aluminum mold that was all metal. The preform was trimmed to a final size of 300 mm × 300 mm to fit into the mold cavity (305 mm × 305 mm). The aluminum mold was coated with Chem-Trend MR 515 mold release agent. The edges of the preform parallel to the resin flow were lined with malleable sealing tape to reduce edge effects (i.e., reduce race tracking), and the preform was placed in the mold cavity. Complete CRTM setup and the pressing schedule during CRTM are summarized in

Figure 3. All panels (produced using RTM and CRTM processes) were cured in their corresponding molds for two hours, with the injection and discharge ports closed. The panels were then removed from the mold and post-cured in a 90 °C oven for 5 h. After post-curing, the panels were trimmed and placed in a temperature- and humidity-controlled room at 21 °C and 65% relative humidity until the mass of the panels stabilized.

2.3. Preform Permeability and Panel Performance Evaluation

Darcy’s law was used to evaluate the permeability of the RTM preforms. One-dimensional permeability is often estimated using Darcy’s law or Carman–Kozeny equations to produce permeability constants specific to the resin and reinforcement [

7,

9,

14]. Permeability is often found using Darcy’s law from the distance of the resin flow front as a function of time. Since the flow front of the performs considered in this work was not one-dimensional, the resin volume flow rate,

Q, was used with Darcy’s law. Accordingly, the permeability,

k, was found according to:

where

L is the length of the porous medium,

A is the cross-sectional area perpendicular to flow, and Δ

P is the pressure differential across the porous media. Accordingly, flow requirements limit the density and fiber volume fraction that can be achieved through RTM [

6]. The injected resin volume is shown as a function of time in

Figure 4. The flow rate,

Q, was taken from the steady-state flow, fitted with a straight line through solid points in

Figure 4.

The specific permeability,

K, is the product of the permeability of the preform and the viscosity of the resin. Therefore, Darcy’s law in terms of the specific permeability of the preform can be written as follows:

where

μ is the viscosity of the resin,

W is the width of the mold cavity,

t is the thickness of the mold cavity, and

is the porosity of the preform. Constants to determine specific permeability are given in

Table 1.

The longitudinal modulus of rupture and the modulus of elasticity in bending of the RTM panels were evaluated as per ASTM D1037–12 [

16]. The longitudinal Izod impact energy, normalized by panel thickness, was obtained using ASTM D4812–11 [

17]. Following the guidelines of ASTM D1037–12, the moisture absorption and thickness swell properties of the panels were evaluated over the course of 24 h.

2.4. Statistical Analysis

The permeability constants and the mechanical properties for each type of preform were analyzed using an analysis of variance (ANOVA) to determine whether the trends observed in the data were statistically significant. Mechanical testing of CRTM panels was also conducted to understand the effect of processing pressure on the performance of the panels.

3. Results

An analysis of variance (ANOVA) was performed to determine which, if any, of the preform parameters were statistically significant. ANOVA was used to analyze the influence of both binder type and binder content on the permeability, fiber content, modulus of rupture, modulus of elasticity, maximum bending strain, Izod impact strength, moisture absorption, thickness swell, and density.

3.1. Preform Analysis

Preform thickness expansion or rebound is shown as a function of binder content and type in

Figure 5. As binder content increased, the magnitude of preform thickness expansion decreased. Although the preforms with HDPE expanded less than preforms with LDPE, the difference was not statistically significant compared to 5% LDPE (

p = 0.41). We estimated that preforms with 1% LDPE binder should be approximately 20% thicker than the mold cavity to ensure contact with the mold faces without excessive compression.

Since polyethylene—a nonpolar material—is hydrophobic, while wood—a polar material—is hydrophilic, the ability to form a chemical bond between the two is limited [

18]. However, as demonstrated by Escobar and Wolcott [

18], the structural stability of the wood strand and polyethylene composite is created not by chemical bonding, but by the mechanical interlocking of polyethylene and the pores or cavities on the surfaces of the wood strands. As polyethylene melts, the polymer chains loosen and can slide over one another. These polymer chains are orders of magnitude smaller in diameter than the intertracheid pits present in the radial face of the wood strands, and are thus able to penetrate the tracheids, mechanically bonding the wood strands together [

19]. By pulling a vacuum through softwood, Escobar and Wolcott [

18] showed that HDPE can penetrate several cell walls deep through the radial face of the specimen. This relatively loose mechanical interlocking provides a stiff and stable preform that maintains porosity when injected with resin during the RTM process.

3.2. Permeability Analysis

As indicated in

Figure 4, the resin flow rate was found 2–10 minutes into the injection process. The pressure differential was not constant at the beginning of the injection, causing increased resin flow at the beginning of the injection. The steady-state region stopped after 10 minutes due to the gelling of the vinyl ester resin. The volumetric flow rate was used with Equation (2) and the properties in

Table 1 to determine specific permeability.

Figure 6 compares the permeability of the RTM panels. Permeability was relatively independent of binder type and content, and no statistical significance was found (

p = 0.2), though a slightly higher permeability was observed in the 20% LDPE specimens. This could be because of greater void content introduced between the strands due to the presence of a greater quantity of solidified LDPE separating the strands. To achieve a constant preform density, the weight of the wood strands had to be reduced in order to compensate for the 20% LDPE preform, which probably increased the void content, resulting in a higher permeability value.

3.3. Mechanical Properties

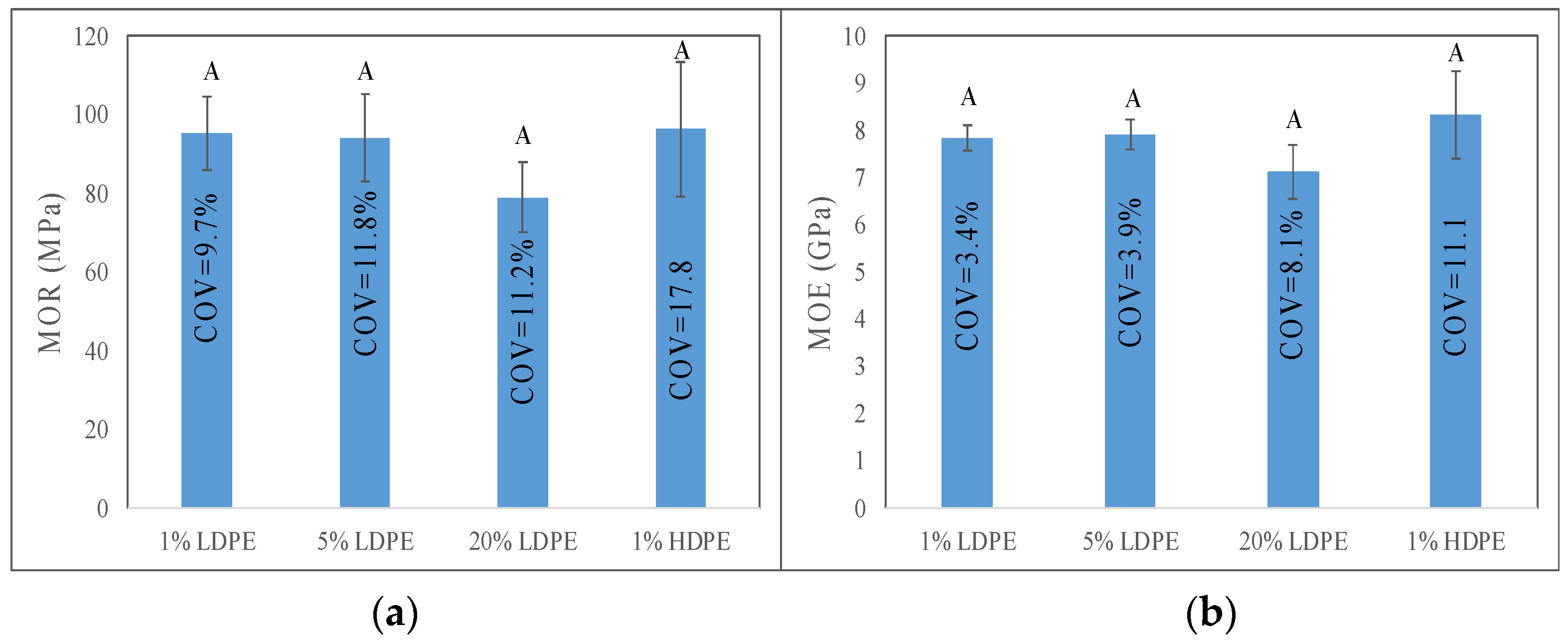

The modulus of rupture and the modulus of elasticity were calculated for each panel and are shown in

Figure 7. Although lower values of strength and modulus were observed for the 20% LDPE panels, there were no statistically significant differences in flexure properties (

p = 0.47 for MOR and

p = 0.3 for MOE) due to binder type or content.

To determine whether higher binder content would increase toughness, RTM specimens were subjected to Izod impact testing, as shown in

Figure 8. While the 20% LDPE panels had higher variation due to the presence of greater amounts of LDPE, resulting in poor interaction between the strands and the resin, no statistically significant (

p = 0.84) effect on the mean impact toughness due to binder type or content was observed.

3.4. Preform Parameter Selection

The RTM panels were produced to analyze the variables that would result in acceptable resin flow, wetting of the preform, and mechanical properties, which, after determining the most suitable parameters, were then reproduced in a larger CRTM panel. Although trends could be observed in the data, such as slightly increased permeability in the 20% LDPE preforms, according to the ANOVA analysis, the differences in permeability between binder types and contents were not statistically significant (p = 0.2). As mentioned previously, the intent was to use the minimum amount of binder sufficient to produce a preform that can be handled without disturbing its structure during the resin transfer molding process. Since there were no statistically significant benefits to the incorporation of more binder, and since 1% LDPE binder yielded lower variations in the mechanical properties of the panels tested in this study, 1% LDPE was used to form preforms for compression-assisted RTM or CRTM panels.

3.5. CRTM Properties

Using 1% LDPE preforms, 300 mm × 300 mm wood strand vinyl ester composite panels were produced. From these panels, longitudinal and transverse tensile, bending, and moisture absorption and thickness swell specimens were prepared and tested. From the physical properties of the final panels and the resin density, the fiber volume fraction (

Vf) was calculated as follows:

where

Vp is the volume of the panel,

mp is the mass of the final panel,

me is the mass of the preform, and

is the density of the resin.

The average fiber volume fraction of the CRTM panels was 37%, compared to an average fiber volume fraction of 28% for the RTM panels. This was attributed to the increased consolidation of the CRTM panels and removal of excess resin due to the added compression during the CRTM process. The average longitudinal and transverse tensile strength and modulus are shown in

Figure 9.

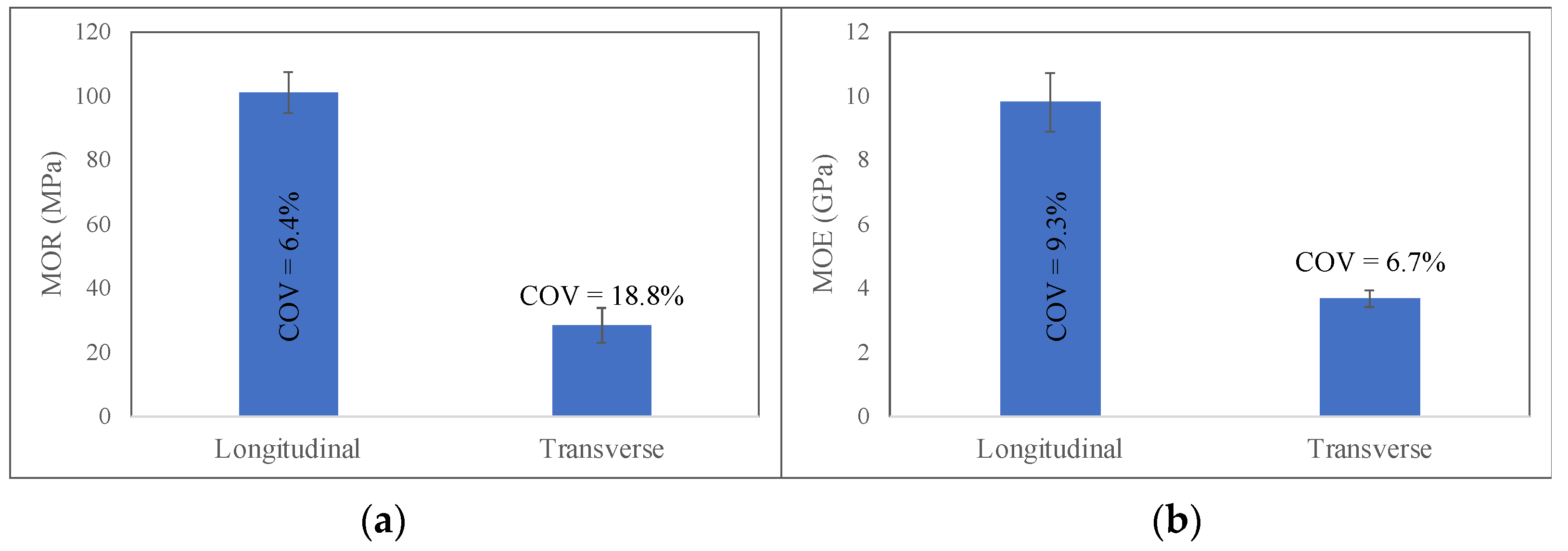

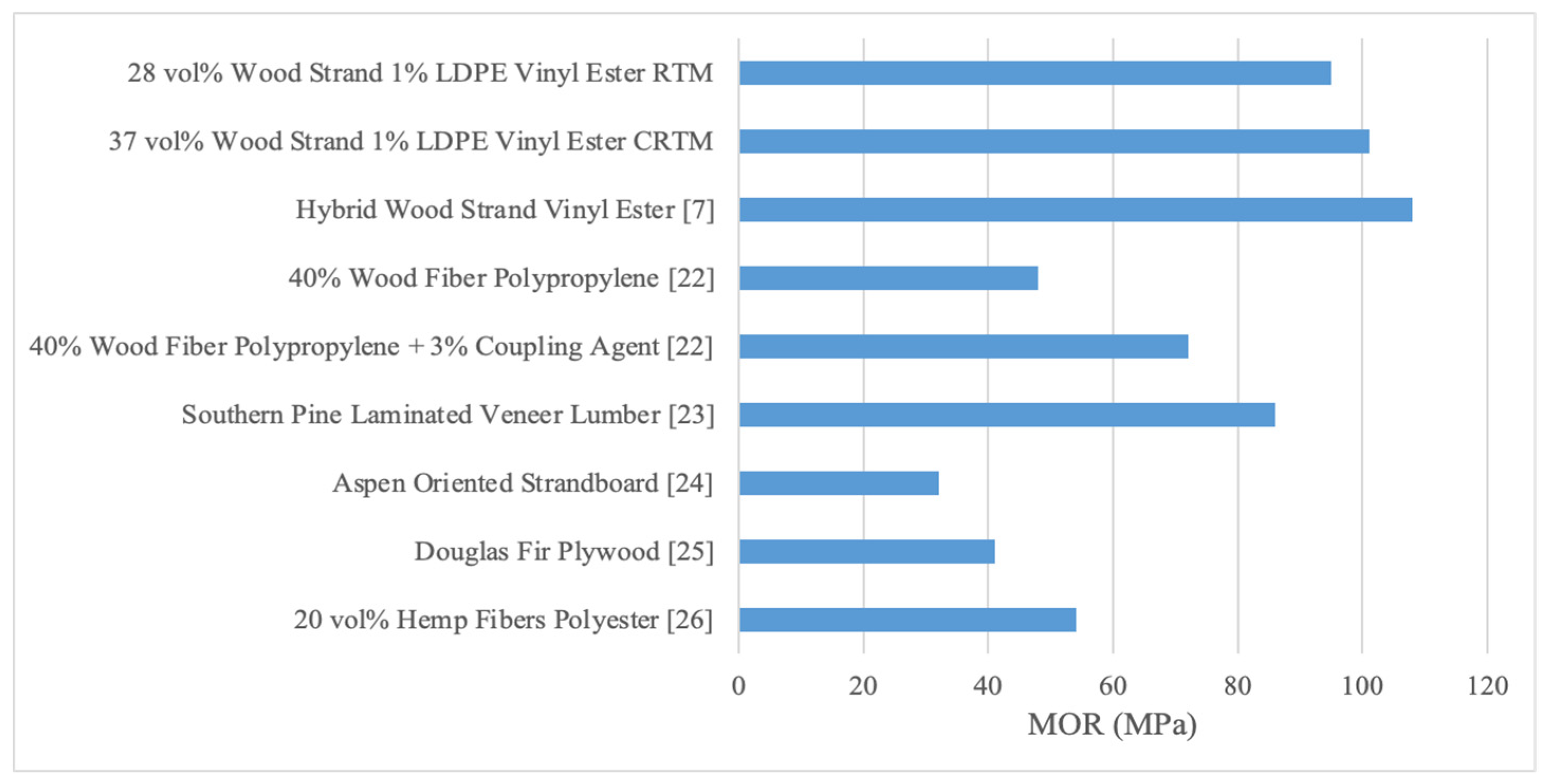

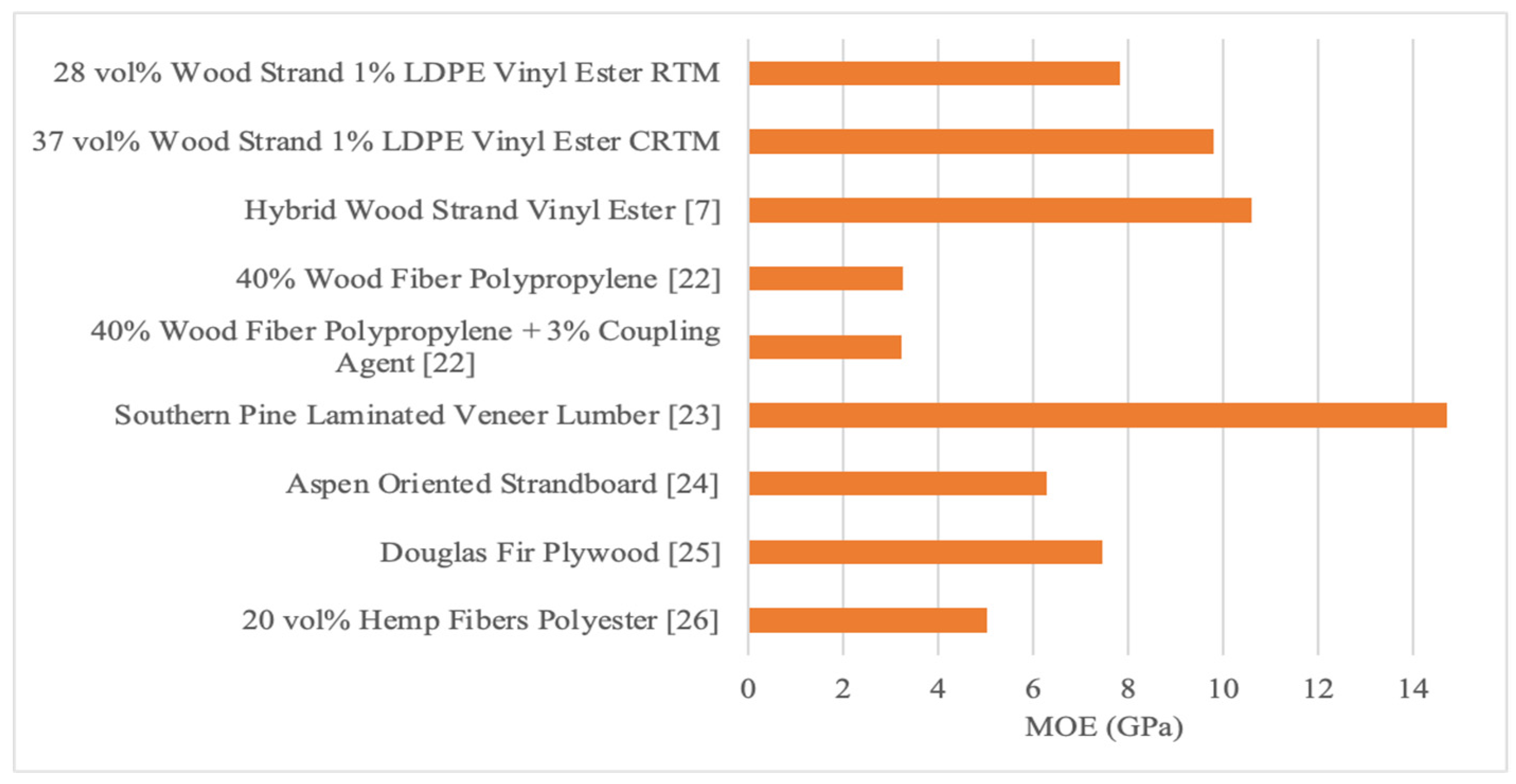

The modulus of rupture in bending of the panels in the longitudinal direction (~100 MPa) was approximately 3.5 times that of the transverse direction (

Figure 10), whereas the modulus of elasticity in bending in the longitudinal direction (~10 GPa) was approximately 2.5 times that of the transverse direction.

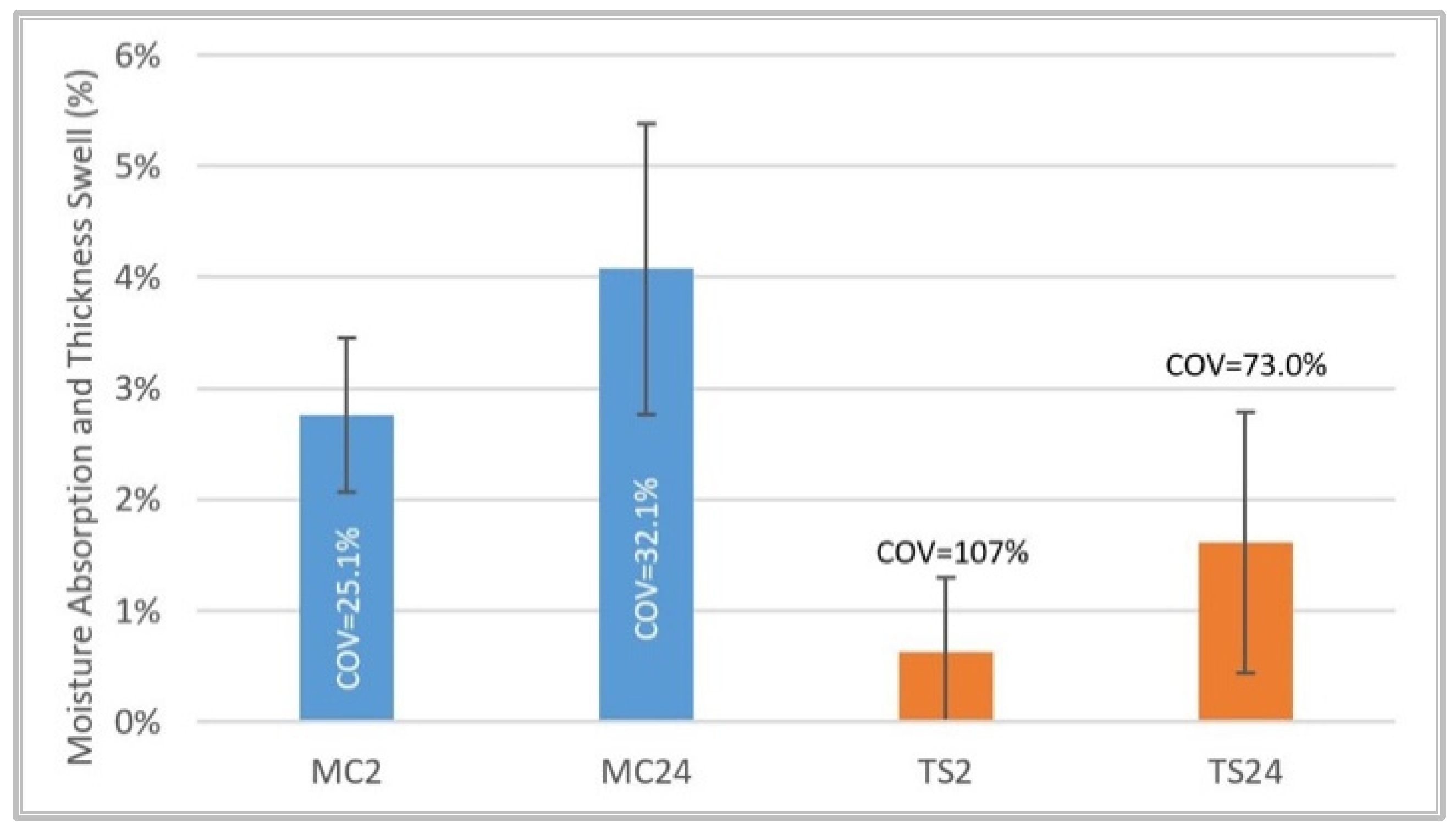

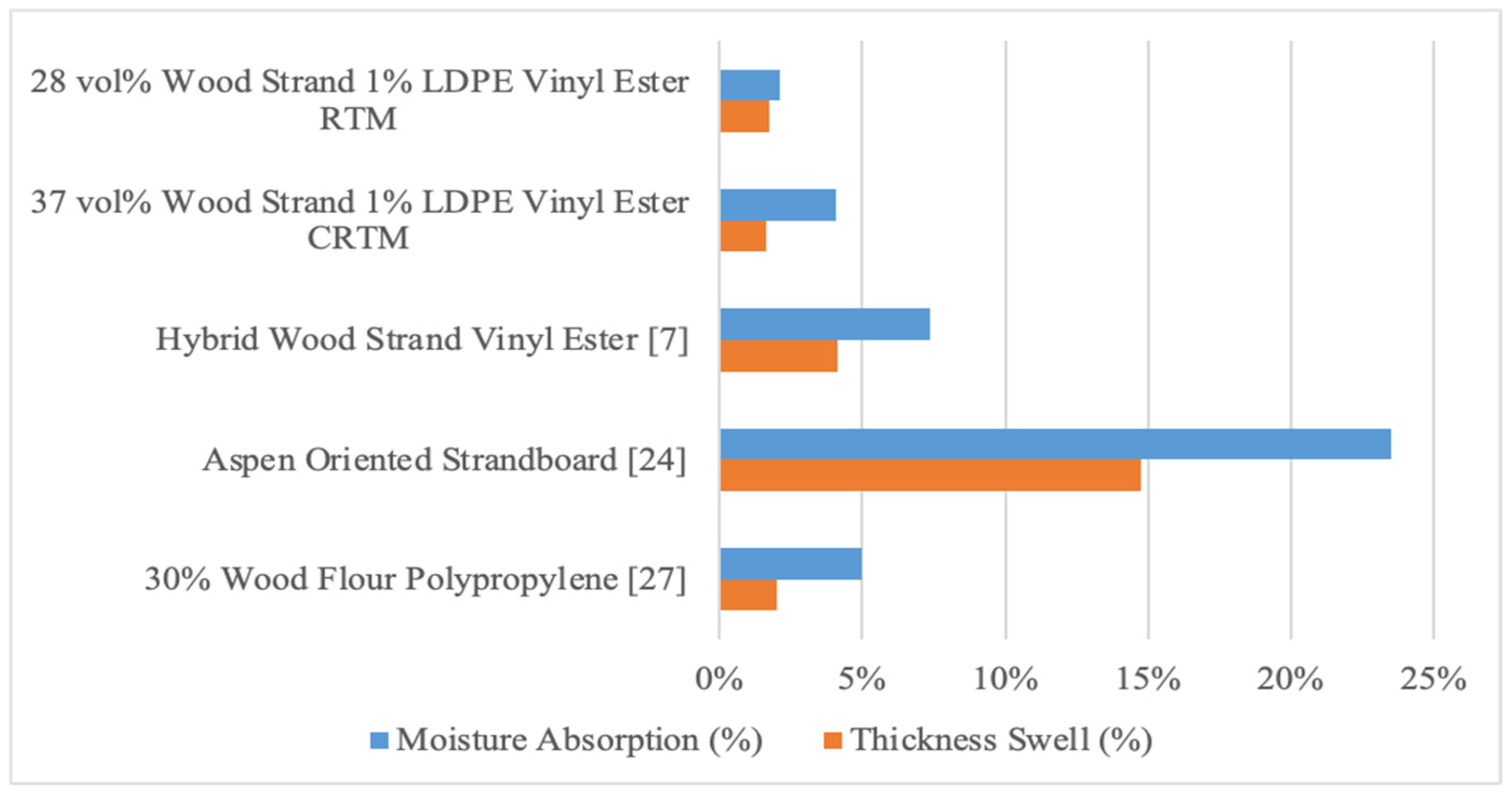

The moisture absorption and thickness swell properties of the CRTM panels were under 5%, even after a 24 h period (

Figure 11), indicating superior dimensional stability of these panels compared to typical wood composites produced using hot-pressing technology [

20,

21].

4. Discussion

The influence of PE content on the mechanical properties of RTM panels indicates that it is better to use the lowest amount of a thermoplastic binder necessary to achieve a preform that holds together for subsequent processing. Higher content of the binder seems to reduce the bond performance between the strands and the resin, leading to inferior mechanical properties and greater variation. Due to an excellent encapsulation of fiber with resin, RTM and CRTM yield panels that have superior dimensional stability. CRTM panels, due to the compression load applied during consolidation in the mold, produced panels with 10% more fiber volume fraction compared to RTM panels.

When compared to the mechanical properties of the RTM panels, the CRTM panels display the same trends, but generally perform better due to their higher fiber volume fraction and improved panel consolidation. Compared to other wood-based and synthetic composites, the wood strand–vinyl ester composite panels created using CRTM technology yielded better performance (

Figure 12,

Figure 13,

Figure 14 and

Figure 15). CRTM wood strand composite panels exhibit higher strength and modulus than the ponderosa pine lumber from which the strands were generated, oriented strand board, or plywood. The moisture absorption and thickness swell properties of CRTM panels are also significantly lower than those of typical commercially available wood-based composites such as oriented strand board. When compared to wood flour composites or hemp fiber composites, wood strand composites possess significantly greater performance.