Detection and Classification of Human Body Odor Using an Electronic Nose

Abstract

:1. Introduction

2. Experimental

2.1. E-Nose System

2.2. Humidity Control

2.3. Human Body Odor Collection

2.4. Evaluation of Sensor Response to Body Odor Strength

3. Results and Discussion

3.1. Humidity Control

3.2. Evaluation of Sensor Response to Body Odor Strength

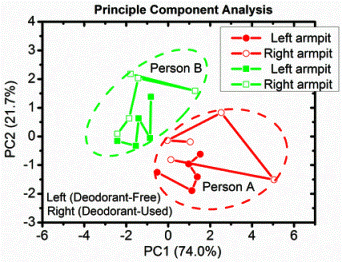

3.3. Detection and Classification of Human Body Odor

- Get data from matrix, XM×N. The row M represents different repetition of the experiment and the column N represents the number of independent sensors. In our case, M equals to 20 and N equals to 5.

- Normalize the data matrix, Norm(XM×N), by the mean subtraction. The mean of each N column is calculated and subtracted from the data set. Hence, the new data set has a zero value of mean.

- Calculate the covariance matrix, Cov(XM×N), and calculate eigenvectors and eigenvalues of the covariance matrix. The calculated eigenvectors must be unit eigenvectors.

- Rearrange the eigenvectors and eigenvalues. The eigenvectors are ordered by eigenvalues from highest to lowest, .

- Obtain the PCA result by matrix multiplication and transpose, . The obtained new dataset with orthogonal linear transformation are usually plotted in two or three dimensions containing the most relevant of the data set.

4. Conclusions

Acknowledgments

References and Notes

- Barié, N.; Bücking, M.; Rapp, M. A Novel Electronic Nose Based on Miniaturized SAW Sensor Arrays Coupled with SPME Enhanced Headspace-analysis and Its Use for Rapid Determination of Volatile Organic Compounds in Food Quality Monitoring. Sens. Actuat. B 2006, 114, 482–488. [Google Scholar]

- Vestergaard, J.S.; Martens, M.; Turkki, P. Application of an Electronic Nose System for Prediction of Sensory Quality Changes of a Meat Product (Pizza Topping) During Storage. LWT 2007, 40, 1095–1101. [Google Scholar]

- Vinaixa, M.; Vergara, A.; Duran, C.; Llobet, E.; Badia, C.; Brezmes, J.; Vilanova, X.; Correig, X. Fast Detection of Rancidity in Potato Crisps Using E-noses Based on Mass Spectrometry or Gas Sensors. Sens. Actuat. B 2005, 106, 67–75. [Google Scholar]

- Panigrahi, S.; Balasubramanian, S.; Gu, H.; Logue, C.M.; Marchello, M. Design and Development of a Metal Oxide Based Electronic Nose for Spoilage Classification of Beef. Sens. Actuat. B 2006, 119, 2–14. [Google Scholar]

- Barbri, N.E.; Llobet, E.; Bari, N.E.; Correig, X.; Bouchikhi, B. Electronic Nose Based on Metal Oxide Semiconductor Sensors as an Alternative Technique for the Spoilage Classification of Red Meat. Sensors 2008, 8, 142–156. [Google Scholar]

- Martí, M.P.; Busto, O.; Guasch, J.; Boqué, R. Electronic Noses in the Quality Control of Alcoholic Beverages. Trends Anal. Chem 2005, 24, 57–66. [Google Scholar]

- Yu, H.; Wang, J. Discrimination of LongJing Green-Tea Grade by Electronic Nose. Sens. Actuat. B 2007, 122, 134–140. [Google Scholar]

- García, M.; Aleixandre, M.; Gutiérrez, J.; Horrillo, M.C. Electronic Nose for Wine Discrimination. Sens. Actuat. B 2006, 113, 911–916. [Google Scholar]

- Dutta, R.; Hines, E.L.; Gardner, J.W.; Kashwan, K.R.; Bhuyan, M. Tea Quality Prediction Using a Tin Oxide-based Electronic Nose: an Artificial Intelligence Approach. Sens. Actuat. B 2003, 94, 228–237. [Google Scholar]

- Scorsone, E.; Pisanelli, A.M.; Persaud, K.C. Development of an Electronic Nose for Fire Detection. Sens. Actuat. B 2006, 116, 55–61. [Google Scholar]

- Zhang, S.; Xie, C.; Zeng, D.; Zhang, Q.; Li, H.; Bi, Z. A Feature Extraction Method and a Sampling System for Fast Recognition of Flammable Liquids with a Portable E-nose. Sens. Actuat. B 2007, 124, 437–443. [Google Scholar]

- Zhou, H.; Homer, M.L.; Shevade, A.V.; Ryan, M.A. Nonlinear Least-Squares Based Method for Identifying and Quantifying Single and Mixed Contaminants in Air with an Electronic Nose. Sensors 2006, 6, 1–18. [Google Scholar]

- Negri, R.M.; Reich, S. Identification of Pollutant Gases and its Concentrations with a Multisensor Array. Sens. Actuat. B 2001, 75, 172–178. [Google Scholar]

- Chan, H.P.; Lewis, C.; Thomas, P.S. Exhaled Breath Analysis: Novel Approach for Early Detection of Lung Cancer. Lung Cancer 2009, 63, 164–168. [Google Scholar]

- Hanson, C.W. Method and System of Diagnosing Intrapulmonary Infection Using an Electronic Nose. US Patent 6620109,. 2003. [Google Scholar]

- Pavlou, A.; Turner, A.P.F.; Barr, H. Diagnosis of Gastric and Lung Disorders. WO Patent 032091,. 2000. [Google Scholar]

- Turner, A.P.F.; Magan, N. Electronic Noses and Disease Diagnostics. Nat. Rev. Microbiol 2004, 2, 161–166. [Google Scholar]

- Xu, X.; Tian, F.; Yang, S.X.; Li, Q.; Yan, J.; Ma, J. A Solid Trap and Thermal Desorption System with Application to a Medical Electronic Nose. Sensors 2008, 8, 6885–6898. [Google Scholar]

- Doty, R.L.; Ford, M.; Preti, G.; Huggins, G.R. Changes in the Intensity and Pleasantness of Human Vaginal Odors during the Menstrual Cycle. Science 1975, 190, 1316–1318. [Google Scholar]

- Chen, D.; Haviland-Jones, J. Human Olfactory Communication of Emotion. Percept. Mot. Skills 2000, 91, 771–781. [Google Scholar]

- Delac, K.; Grgic, M. A Survey of Biometric Recognition Methods. 46th International Symposium Electronics in Marine. ELMAR-2004, Zadar, Croatia, June 16–18, 2004; pp. 184–193.

- Natale, C.D.; Mantini, A.; Macagnano, A.; Antuzzi, D.; Paolesse, R.; D'Amico, A. Electronic Nose Analysis of Urine Samples Containing Blood. Phys. Meas 1999, 20, 377–384. [Google Scholar]

- Phillips, M.; Cataneo, R.N.; Cummin, A.R.C.; Gagliardi, A.J.; Gleeson, K.; Greenberg, J.; Maxfield, R.A.; Rom, W.N. Detection of Lung Cancer with Volatile Markers in the Breath. Chest 2003, 123, 2115–2123. [Google Scholar]

- Phillips, M.; Cataneo, R.N.; Ditkoff, B.A.; Fisher, P.; Greenberg, J.; Gunawardena, R.; Kwon, C.S.; Rahbari-Oskoui, F.; Wong, C. Volatile Markers of Breast Cancer in the Breath. Breast J 2003, 9, 184–191. [Google Scholar]

- Jin, Z.; Shimbo, T.; Hosoe, Y.; Oyabu, T. Breath Odor Characteristics after Drinking and Identification of Sake Quantity. Sens. Actuat. B 2005, 108, 265–270. [Google Scholar]

- Natale, C.D.; Macagnano, A.; Paolesse, R.; Tarizzo, E.; Mantini, A.; D’Amico, A. Human Skin Odor Analysis by Means of an Electronic Nose. Sens. Actuat. B 2000, 65, 216–219. [Google Scholar]

- Penn, D.J.; Oberzaucher, E.; Grammer, K.; Fischer, G.; Soini, H.A.; Wiesler, D.; Novotny, M.V.; Dixon, S.J.; Xu, Y.; Brereton, R.G. Individual and Gender Fingerprints in Human Body Odour. J. R. Soc. Interf 2007, 4, 331–340. [Google Scholar]

- Pearce, T.C.; Schiffman, S.S.; Nagle, H.T.; Gardner, J.W. Handbook of Machine Olfaction, Electronic Nose Technology; Wiley-VCH: Weinheim, Germany, 2002. [Google Scholar]

- Curran, A.M.; Rabin, S.I.; Prada, P.A.; Furton, K.G. Comparison of the Volatile Organic Compounds Present in Human Odor Using Spme-GC/MS. J. Chem. Ecol 2005, 31, 1607–1619. [Google Scholar]

- Kim, K.H.; Park, S.Y. A Comparative Analysis of Malodor Samples between Direct (Olfactometry) and Indirect (Instrumental) Methods. Atmos. Environ 2008, 42, 5061–5070. [Google Scholar]

- Nicell, J.A. Expressions to relate population responses to odor concentration. Atmos. Environ 2003, 37, 4955–4964. [Google Scholar]

- Henshaw, P.; Nicell, J.; Sikdar, A. Parameters for the Assessment of Odour Impacts on Communities. Atmos. Environ 2006, 40, 1016–1029. [Google Scholar]

- Akutsu, T.; Sekiguchi, K.; Ohmori, T.; Sakurada, K. Individual Comparisons of the Levels of (E)-3-Methyl-2-Hexenoic Acid, an Axillary Odor–Related Compound, in Japanese. Chem. Senses 2006, 31, 557–563. [Google Scholar]

- Natsch, A.; Gfeller, H.; Gygax, P.; Schmid, J.; Acuna, G. A Specific Bacterial Aminoacylase Cleaves Odorant Precursors Secreted in the Human Axilla. J. Biol. Chem 2003, 278, 5718–5727. [Google Scholar]

- Hasegawa, Y.; Yabuki, M.; Matsukane, M. Identification of New Odoriferous Compounds in Human Axillary Sweat. Chem. Biodiv 2004, 1, 2042–2050. [Google Scholar]

- Hooper, D.C.; Johnson, G.A.; Peter, D. Detergent Product Containing Deodorant Compositions. US Patent 4322308,. 1982. [Google Scholar]

- Amoore, J.E. Specific Anosmia: A Clue to the Olfactory Code. Nature 1967, 214, 1095–1098. [Google Scholar]

- Leyden, J.J.; McGinley, K.J.; Hölzle, E.; Labows, J.N.; Kligman, A.M. The Microbiology of the Human Axilla and Its Relationship to Axillary Odor. J. Invest. Dermatol 1981, 77, 413–416. [Google Scholar]

- Hooper, D.C.; Johnson, G.A.; Peter, D. Deodorant Compositions. US Patent 4278658,. 1981. [Google Scholar]

- Schoutena, B.; Jacobs, B. Biometrics and their Use in E-Passports. Image Vision Comput 2009, 27, 305–312. [Google Scholar]

| Sensor | Target Gas | Typical Detection Ranges | Heater Power Consumption |

|---|---|---|---|

| TGS 813 | Combustible gases | 500–10,000 ppm | 835 mW |

| TGS 822 | Organic solvent vapors | 50–5,000 ppm | 660 mW |

| TGS 825 | Hydrogen sulfide | 5–100 ppm | 660 mW |

| TGS 880 | Cooking vapors | 10–1,000 ppm | 835 mW |

| TGS 2602 | Air contaminants | 1–30 ppm | 280 mW |

| Level | Concentration of aqueous isovaleric acid solution (mM) | Subjective impression |

|---|---|---|

| 0 | 0 | No odor |

| 1 | 0.12 | Slight |

| 2 | 0.48 | Definite |

| 3 | 1.99 | Moderate |

| 4 | 7.88 | Strong |

| 5 | 32.33 | Very strong |

| Background humidity | TGS813 | TGS825 | TGS2602 | TGS880 | TGS822 | Humidity sensor |

|---|---|---|---|---|---|---|

| 25% | 3.948 (±55%) | 2.211 (±38%) | 3.727 (±38%) | 4.765 (±37%) | 5.529 (±43%) | 2.823 (±51%) |

| 50% | 0.526 (±16%) | 0.104 (±23%) | 0.264 (±27%) | 0.702 (±25%) | 2.150 (±25%) | 0.550 (±20%) |

| 75% | 0.158 (±4%) | 0.057 (±8%) | 0.581 (±4%) | 0.160 (±5%) | 0.185 (±7%) | 0.293 (±7%) |

© 2009 by the authors; licensee MDPI, Basel, Switzerland This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wongchoosuk, C.; Lutz, M.; Kerdcharoen, T. Detection and Classification of Human Body Odor Using an Electronic Nose. Sensors 2009, 9, 7234-7249. https://doi.org/10.3390/s90907234

Wongchoosuk C, Lutz M, Kerdcharoen T. Detection and Classification of Human Body Odor Using an Electronic Nose. Sensors. 2009; 9(9):7234-7249. https://doi.org/10.3390/s90907234

Chicago/Turabian StyleWongchoosuk, Chatchawal, Mario Lutz, and Teerakiat Kerdcharoen. 2009. "Detection and Classification of Human Body Odor Using an Electronic Nose" Sensors 9, no. 9: 7234-7249. https://doi.org/10.3390/s90907234

APA StyleWongchoosuk, C., Lutz, M., & Kerdcharoen, T. (2009). Detection and Classification of Human Body Odor Using an Electronic Nose. Sensors, 9(9), 7234-7249. https://doi.org/10.3390/s90907234