Design and Validation of a Pressure-Driven Liquid Metering System with Heated PTFE Tubing for Laboratory Automation

Abstract

1. Introduction

2. System Design for Laboratory Automation

2.1. Device Architecture

2.2. Liquid-Transfer Testbed

3. Pressure-Driven Flow Model

3.1. Thermal- and Slip-Augmented Model

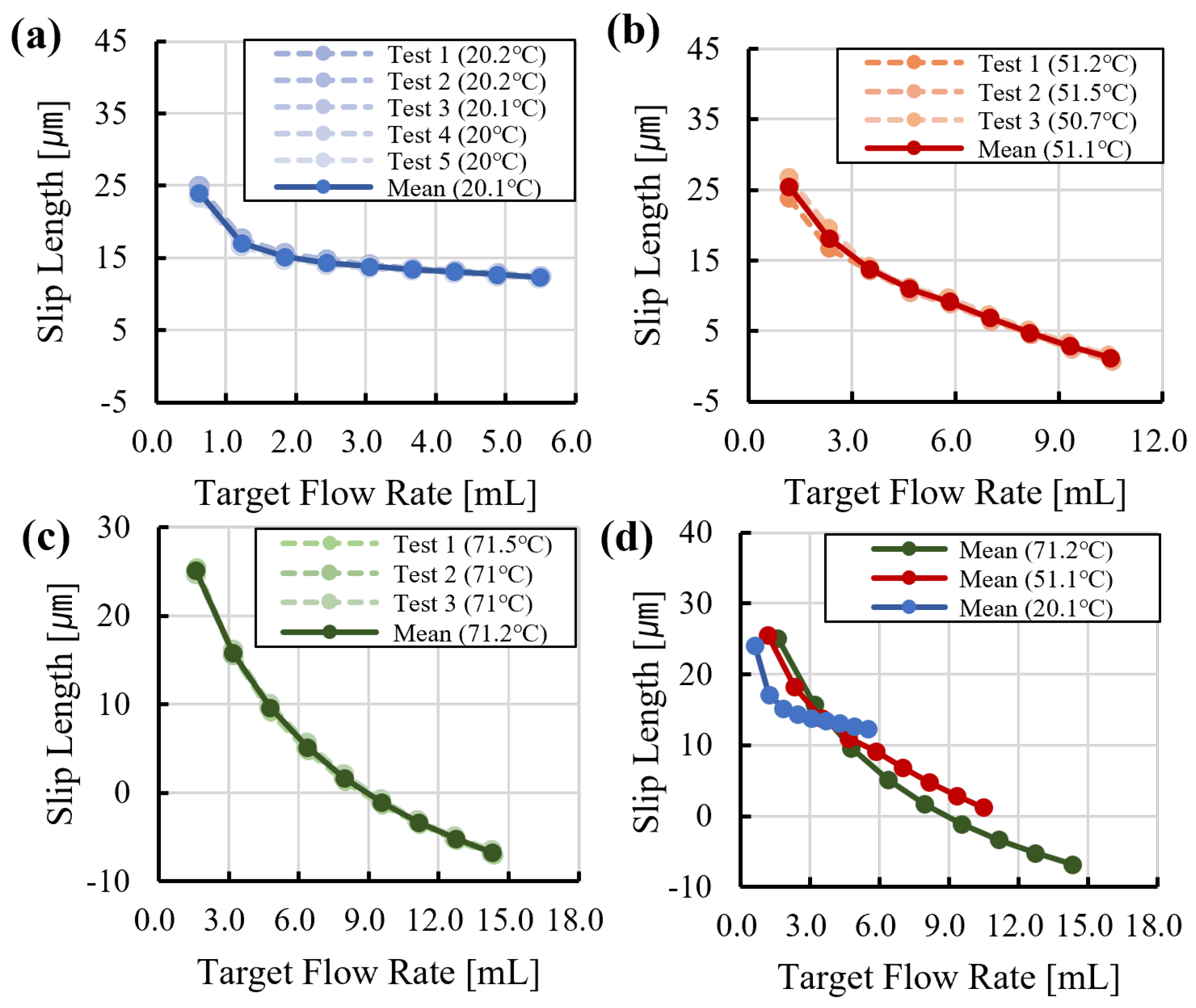

3.2. Slip-Length Identification by Linear Regression

4. Experimental Results and Discussion

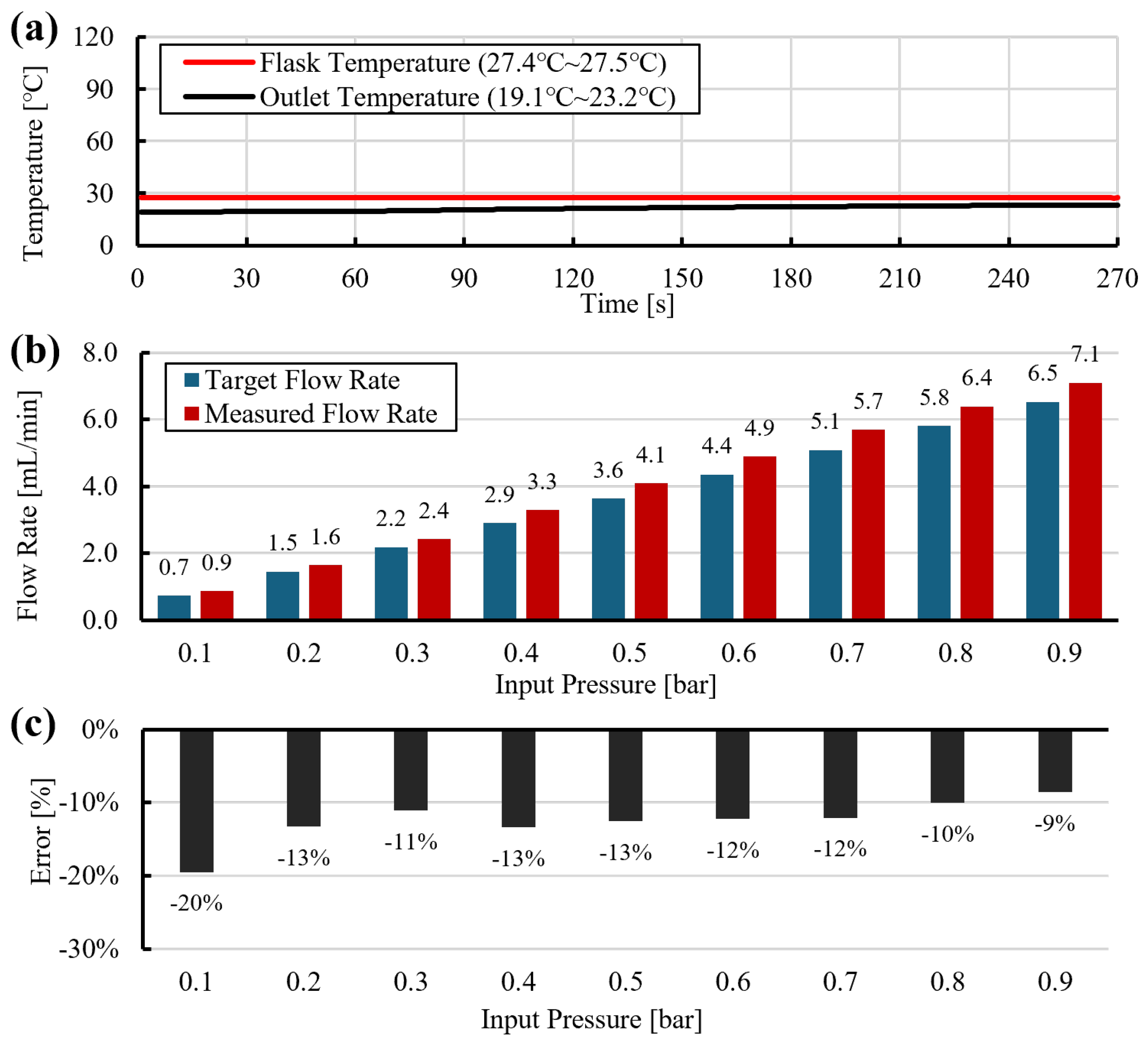

4.1. Dispensing Without Heating Tube

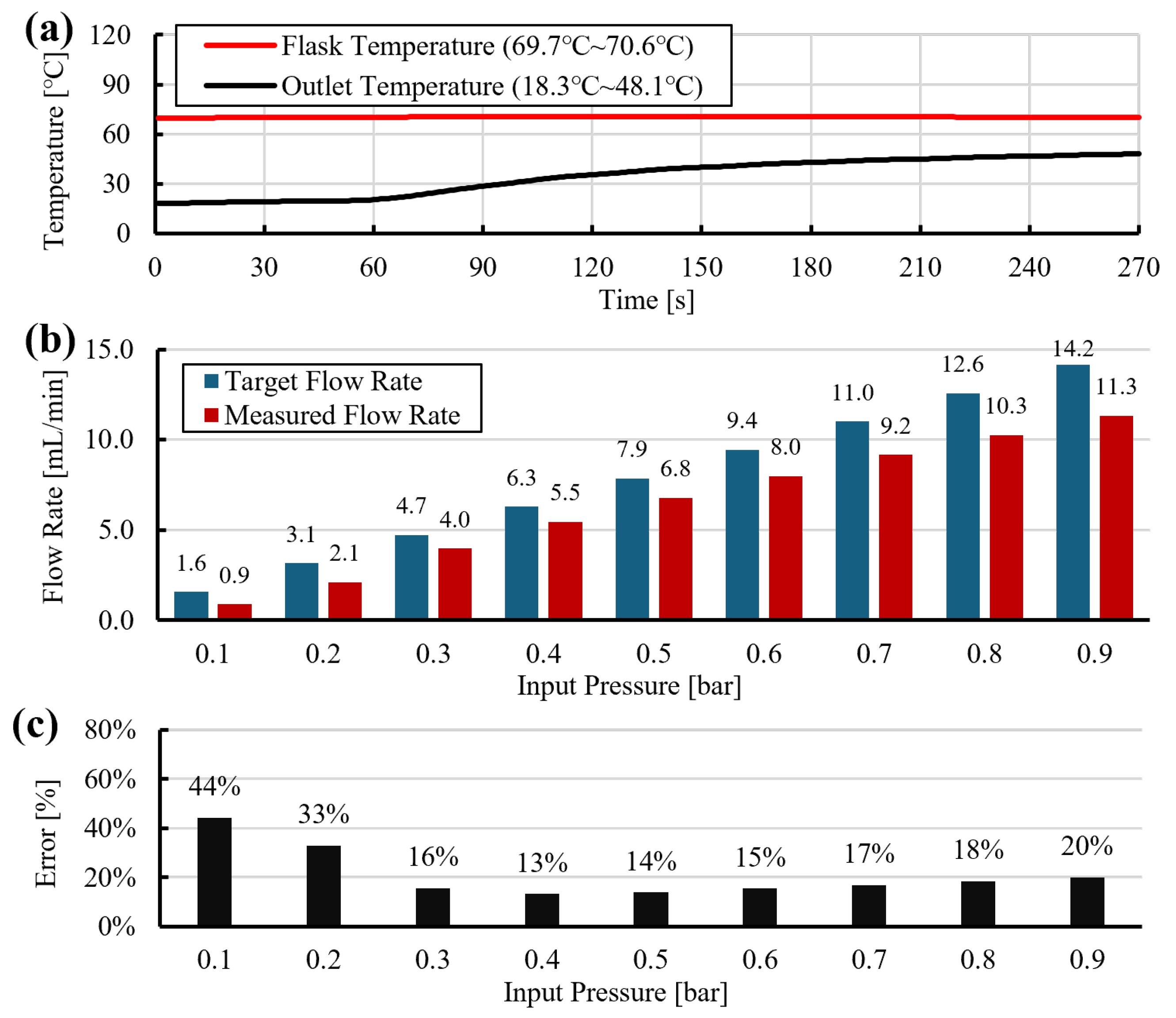

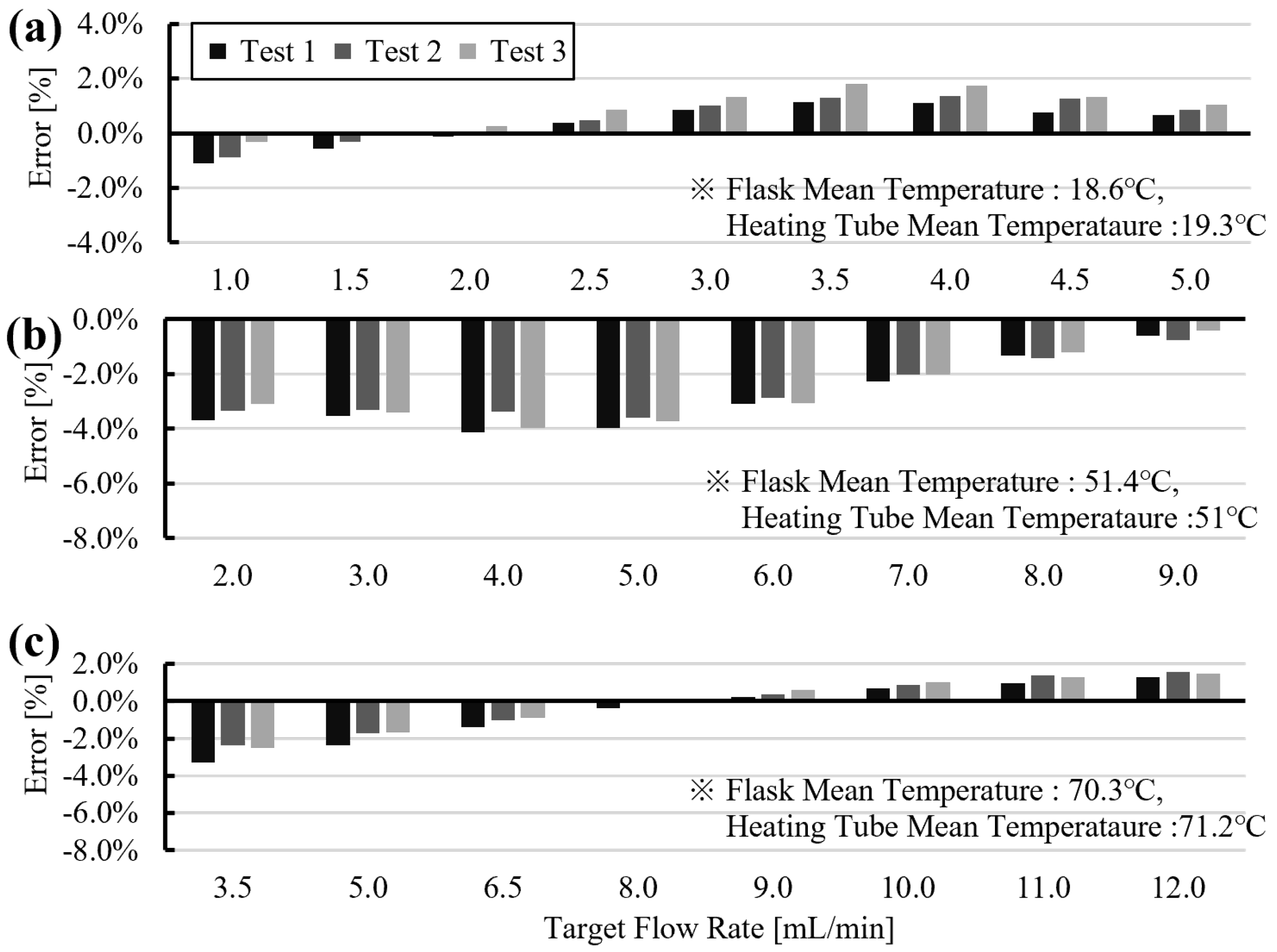

4.2. Dispensing Experiments with Heated Tube

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISO 8655-6:2022; Piston-Operated Volumetric Apparatus—Part 6: Gravimetric Reference Measurement Procedure for the Determination of Volume. International Organization for Standardization: Geneva, Switzerland, 2022.

- Guan, X.L.; Chang, D.P.S.; Mok, Z.X.; Lee, B. Assessing variations in manual pipetting: An under-investigated requirement of good laboratory practice. J. Mass Spectrom. Adv. Clin. Lab. 2023, 30, 25–29. [Google Scholar] [CrossRef]

- Yoshikawa, N.; Darvish, K.; Vakili, M.G.; Garg, A.; Aspuru-Guzik, A. Digital pipette: Open hardware for liquid transfer in self-driving laboratories. Digit. Discov. 2023, 2, 1745–1751. [Google Scholar] [CrossRef]

- Kopyl, A.; Yew, Y.; Ong, J.W.; Hiscox, T.; Young, C.; Muradoglu, M.; Ng, T.W. Automated Liquid Handler from a 3D Printer. J. Chem. Educ. 2024, 101, 640–646. [Google Scholar] [CrossRef]

- Naranbat, D.; Phelps, B.; Murphy, J.; Tripathi, A. How to convert a 3D printer to a personal automated liquid handler for life science workflows. SLAS Technol. 2025, 30, 100239. [Google Scholar] [CrossRef] [PubMed]

- Villanueva-Cañas, J.L.; Gonzalez-Roca, E.; Gastaminza Unanue, A.; Titos, E.; Martínez Yoldi, M.J.; Vergara Gómez, A.; Puig-Butillé, J.A. Implementation of an open-source robotic platform for SARS-CoV-2 testing by real-time RT-PCR. PLoS ONE 2021, 16, e0252509. [Google Scholar] [CrossRef]

- Jonguitud-Borrego, N.; Malcı, K.; Anand, M.; Baluku, E.; Webb, C.; Liang, L.; Barba-Ostria, C.; Guaman, L.P.; Hui, L.; Rios-Solis, L. High-throughput and automated screening for COVID-19. Front. Med. Technol. 2022, 4, 969203. [Google Scholar] [CrossRef]

- Wells, K.C.; Kharma, N.; Jaunky, B.B.; Nie, K.; Aguiar-Tawil, G.; Berry, D. BioCloneBot: A versatile, low-cost, and open-source automated liquid handler. HardwareX 2024, 18, e00516. [Google Scholar] [CrossRef]

- Dettinger, P.; Kull, T.; Arekatla, G.; Ahmed, N.; Zhang, Y.; Schneiter, F.; Wehling, A.; Schirmacher, D.; Kawamura, S.; Loeffler, D.; et al. Open-source personal pipetting robots with live-cell incubation and microscopy compatibility. Nat. Commun. 2022, 13, 2999. [Google Scholar] [CrossRef] [PubMed]

- Xie, I.H.; Wang, M.H.; Carpenter, R.; Wu, H.Y. Automated calibration of TECAN Genesis liquid handling workstation utilizing an online balance and density meter. Assay Drug Dev. Technol. 2004, 2, 71–80. [Google Scholar] [CrossRef] [PubMed]

- Bessemans, L.; Jully, V.; de Raikem, C.; Albanese, M.; Moniotte, N.; Silversmet, P.; Lemoine, D. Automated Gravimetric Calibration to Optimize the Accuracy and Precision of TECAN Freedom EVO Liquid Handler. J. Lab. Autom. 2016, 21, 693–705. [Google Scholar] [CrossRef][Green Version]

- Alam, M.N.H.Z.; Hossain, F.; Vale, A.; Kouzani, A. Design and fabrication of a 3D printed miniature pump for integrated microfluidic applications. Int. J. Precis. Eng. Manuf. 2017, 18, 1287–1296. [Google Scholar] [CrossRef]

- Hwang, S.F.; Ji, Y.M. Experimental investigation on the design of nozzle/diffuser for micropumps. Int. J. Precis. Eng. Manuf. 2014, 15, 717–723. [Google Scholar] [CrossRef]

- Chien, H.L.; Lee, Y.C. A ball valve micro-pump based on axially symmetrical nozzle fabricated by excimer laser micromachining technology. Int. J. Precis. Eng. Manuf. 2017, 18, 1315–1320. [Google Scholar] [CrossRef]

- Chemyx Inc. Fusion 200X: Two-Channel/Dual Syringe Pump. Available online: https://chemyx.com/syringe-pumps/fusion-200x/ (accessed on 21 December 2025).

- Avantor/VWR. Masterflex® Touch-Screen Syringe Pumps, Model MFLX74905-54. Available online: https://sg.vwr.com/store/item/EU7106042/masterflex-touch-screen-syringe-pumps-avantor (accessed on 21 December 2025).

- IMI Norgren. Cadent™ 3 Syringe Pump. Available online: https://cdn.norgren.com/pdf/ds-cadent3.pdf (accessed on 21 December 2025).

- Hamilton Company. PSD/4 Precision Syringe Pump. Available online: https://www.hamiltoncompany.com/oem-components/syringe-pumps/psd4 (accessed on 21 December 2025).

- Zeng, W.; Li, S.; Wang, Z. Characterization of syringe-pump-driven versus pressure-driven microfluidic flows. In Proceedings of the International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 5–7 August 2015; pp. 711–715. [Google Scholar] [CrossRef]

- Li, Z.; Mak, S.Y.; Sauret, A.; Shum, H.C. Syringe-pump-induced fluctuation in all-aqueous microfluidic system: Implications for flow rate accuracy. Lab Chip 2014, 14, 744–749. [Google Scholar] [CrossRef]

- Kim, C.; Hwang, D.H.; Lee, S.; Kim, S.J. Water-head pumps provide precise and fast microfluidic pumping and switching versus syringe pumps. Microfluid. Nanofluid. 2016, 20, 4. [Google Scholar] [CrossRef]

- Bong, K.W.; Chapin, S.C.; Pregibon, D.C.; Baah, D.; Floyd-Smith, T.M.; Doyle, P.S. Compressed-air flow control system. Lab Chip 2011, 11, 743–747. [Google Scholar] [CrossRef]

- Meera, C.S.; Sunny, S.; Singh, R.; Sairam, P.S.; Kumar, R.; Emmanuel, J. Automated precise liquid transferring system. In Proceedings of the IEEE 6th India International Conference on Power Electronics (IICPE), Kurukshetra, India, 8–10 December 2014; pp. 1–6. [Google Scholar] [CrossRef]

- de Haan, P.; Mulder, J.P.S.H.; Lötters, J.C.; Verpoorte, E. A highly stable, pressure-driven, flow control system based on Coriolis mass flow sensors for organs-on-chips. SSRN 2023, Preprint. [Google Scholar] [CrossRef]

- Naz, S.A.; Huynh, V.T.; Doeven, E.H.; Adams, S.; Kouzani, A.Z.; Guijt, R.M. Development of a robust closed loop pressure control system for droplet generation. Sens. Actuators A Phys. 2025, 390, 116596. [Google Scholar] [CrossRef]

- Jeon, E.C.; Lee, J.R.; Je, T.J.; Choi, D.S.; Ham, Y.B.; Lee, E.S.; Choi, S.K.; Kim, H. Quantitative analys is on air-dispensing parameters for manufacturing dome lenses of chip-on-board LED system. Int. J. Precis. Eng. Manuf. 2014, 15, 2437–2441. [Google Scholar] [CrossRef]

- Wang, J.; Li, M.; Nguyen, T. Mechanisms of droplet formation and deposition in drop-on-demand needle-valve inkjets for precision 3D microprinting. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 1433–1446. [Google Scholar] [CrossRef]

- Chen, X.B.; Kai, J. Modeling of positive-displacement fluid dispensing processes. IEEE Trans. Electron. Packag. Manuf. 2004, 27, 157–163. [Google Scholar] [CrossRef]

- Svensson, K.; Södergren, S.; Hjort, K. Thermally controlled microfluidic back pressure regulator. Sci. Rep. 2022, 12, 569. [Google Scholar] [CrossRef]

- Södergren, S.; Svensson, K.; Hjort, K. Microfluidic active pressure and flow stabiliser. Sci. Rep. 2021, 11, 22504. [Google Scholar] [CrossRef]

- Büker, O.; Stolt, K.; Batista, E.; Sepulveda, J.; Giuliano, C.B.; Morin, A.; Nobre, D.; Navas, H. Investigations on the performance of a newly developed pressure-driven flow controller used in microfluidic applications. Meas. Sens. 2025, 38, 101645. [Google Scholar] [CrossRef]

- Lauga, E.; Stone, H.A. Effective slip in pressure-driven Stokes flow. J. Fluid Mech. 2003, 489, 55–77. [Google Scholar] [CrossRef]

- Wang, R.; Chai, J.; Luo, B.; Liu, X.; Zhang, J.; Wu, M.; Wei, M.; Ma, Z. A review on slip boundary conditions at the nanoscale: Recent development and applications. Beilstein J. Nanotechnol. 2021, 12, 1237–1251. [Google Scholar] [CrossRef] [PubMed]

- Vega-Sánchez, C.; Peppou-Chapman, S.; Zhu, L.; Neto, C. Nanobubbles explain the large slip observed on lubricant-infused surfaces. Nat. Commun. 2022, 13, 351. [Google Scholar] [CrossRef]

- Gluzdov, D.S.; Gatapova, E.Y. A slip length analysis of microchannel flow with smooth and structured surfaces. Phys. Fluids 2024, 36, 122024. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, H.; Lan, L.; Wen, B. Slip effect of surface nanobubbles: A lattice Boltzmann study. Phys. Fluids 2025, 37, 032021. [Google Scholar] [CrossRef]

- Zhong, S.; Guo, S.; Sun, T.; Huang, H.W.; Shi, Q.; Huang, Q. Precision transition of bicelle to liposome as carriers of a hydrophilic biologically active compound by microfluidic mixing integrated micro-structure. IEEE ASME Trans. Mechatron. 2025, 30, 6688–6699. [Google Scholar] [CrossRef]

- White, F.M. Fluid Mechanics, 6th ed.; McGraw–Hill: New York, NY, USA, 2008. [Google Scholar]

- Yaws, C.L.; Lin, X.; Bu, L. Calculate viscosities for 355 liquids. Chem. Eng. 1994, 101, 119–120, 122, 124, 126, 128. [Google Scholar]

| Parameter | Test | Symbol | Value | Unit |

|---|---|---|---|---|

| Tube radius (at ) | 0.285 | mm | ||

| Tube length (at ) | 2.5 | m | ||

| Viscosity | Test 1 | |||

| Test 2 | ||||

| Test 3 | ||||

| Test 4 | ||||

| Thermal expansion coefficient |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Baek, J.; Kim, T.; Jeong, S.; Kim, I.; Cho, S.H.; Yoo, S. Design and Validation of a Pressure-Driven Liquid Metering System with Heated PTFE Tubing for Laboratory Automation. Sensors 2026, 26, 700. https://doi.org/10.3390/s26020700

Baek J, Kim T, Jeong S, Kim I, Cho SH, Yoo S. Design and Validation of a Pressure-Driven Liquid Metering System with Heated PTFE Tubing for Laboratory Automation. Sensors. 2026; 26(2):700. https://doi.org/10.3390/s26020700

Chicago/Turabian StyleBaek, Joonki, Taegyun Kim, Seungwon Jeong, Ikhyun Kim, Shin Hum Cho, and Sungkeun Yoo. 2026. "Design and Validation of a Pressure-Driven Liquid Metering System with Heated PTFE Tubing for Laboratory Automation" Sensors 26, no. 2: 700. https://doi.org/10.3390/s26020700

APA StyleBaek, J., Kim, T., Jeong, S., Kim, I., Cho, S. H., & Yoo, S. (2026). Design and Validation of a Pressure-Driven Liquid Metering System with Heated PTFE Tubing for Laboratory Automation. Sensors, 26(2), 700. https://doi.org/10.3390/s26020700