MVSAPNet: A Multivariate Data-Driven Method for Detecting Disc Cutter Wear States in Composite Strata Shield Tunneling

Abstract

1. Introduction

- (1)

- We propose a new network, the Multivariate Selective Attention Prototype Network (MVSAPNet), which introduces a prototype learning approach to tunnel wear state classification, addressing class imbalance and small sample sizes.

- (2)

- A variable selection network is used to select input features, enhancing the model’s nonlinearity and interpretability while providing insights into the classification results.

- (3)

- The model is tested on tunneling data from composite strata in tunnels located in Shenzhen, Guangdong Province, and Fuzhou, Fujian Province, China, demonstrating superior performance compared to other classification models.

2. The Literature Review

2.1. Overview

2.2. Data Imbalance

2.3. Deep Learning

3. Materials and Methods

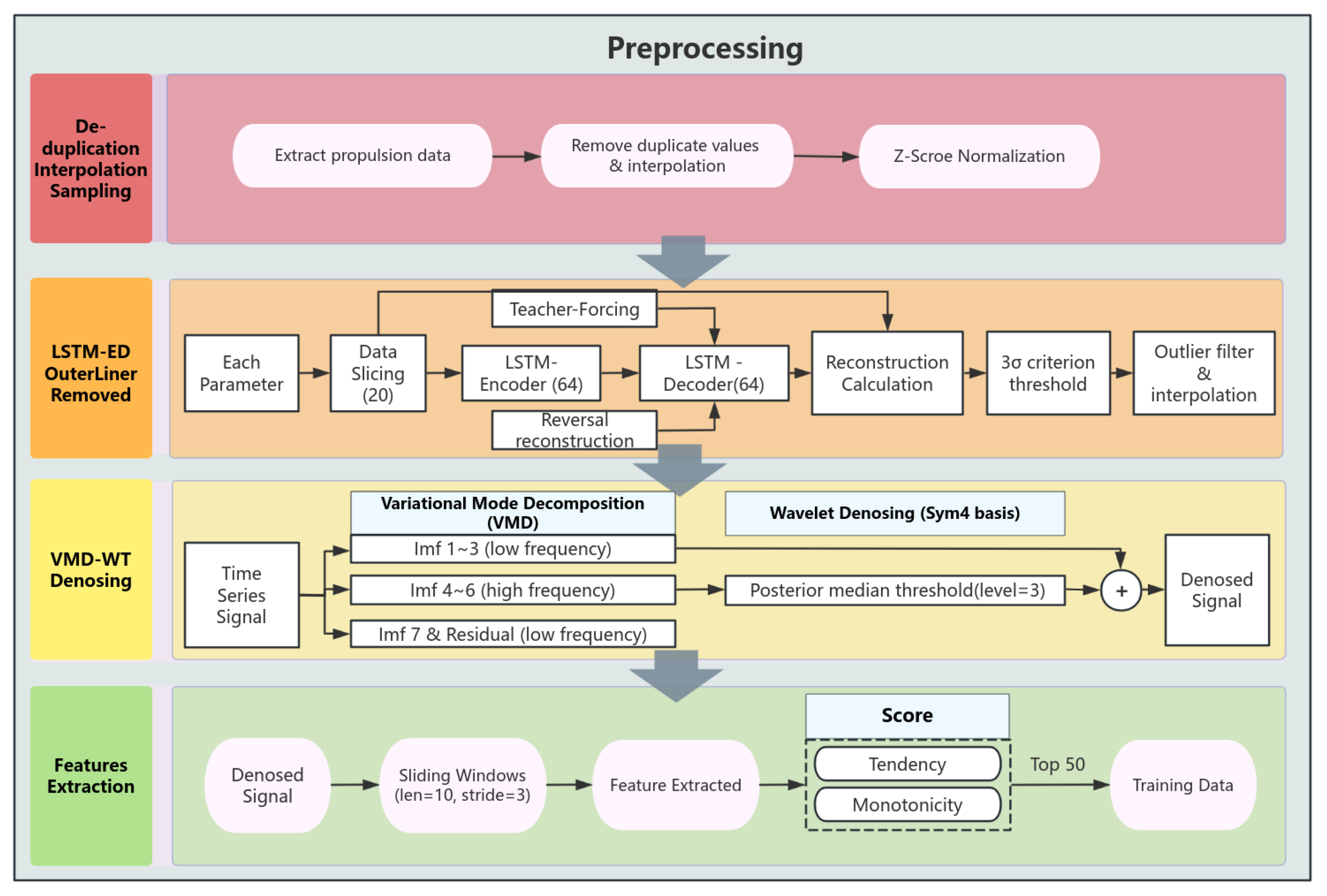

3.1. Preprocessing

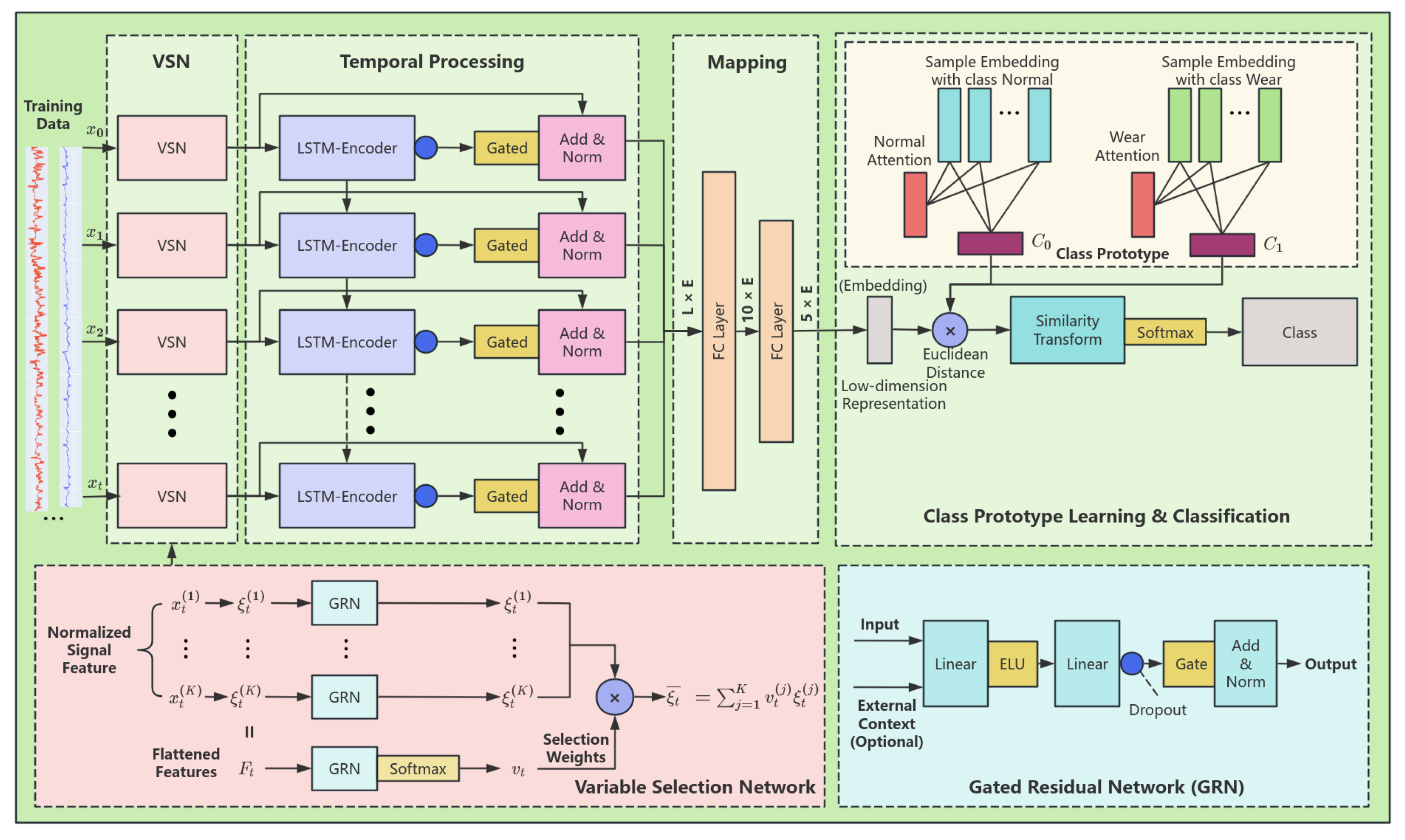

3.2. Multivariate Selective Attention Prototype Network

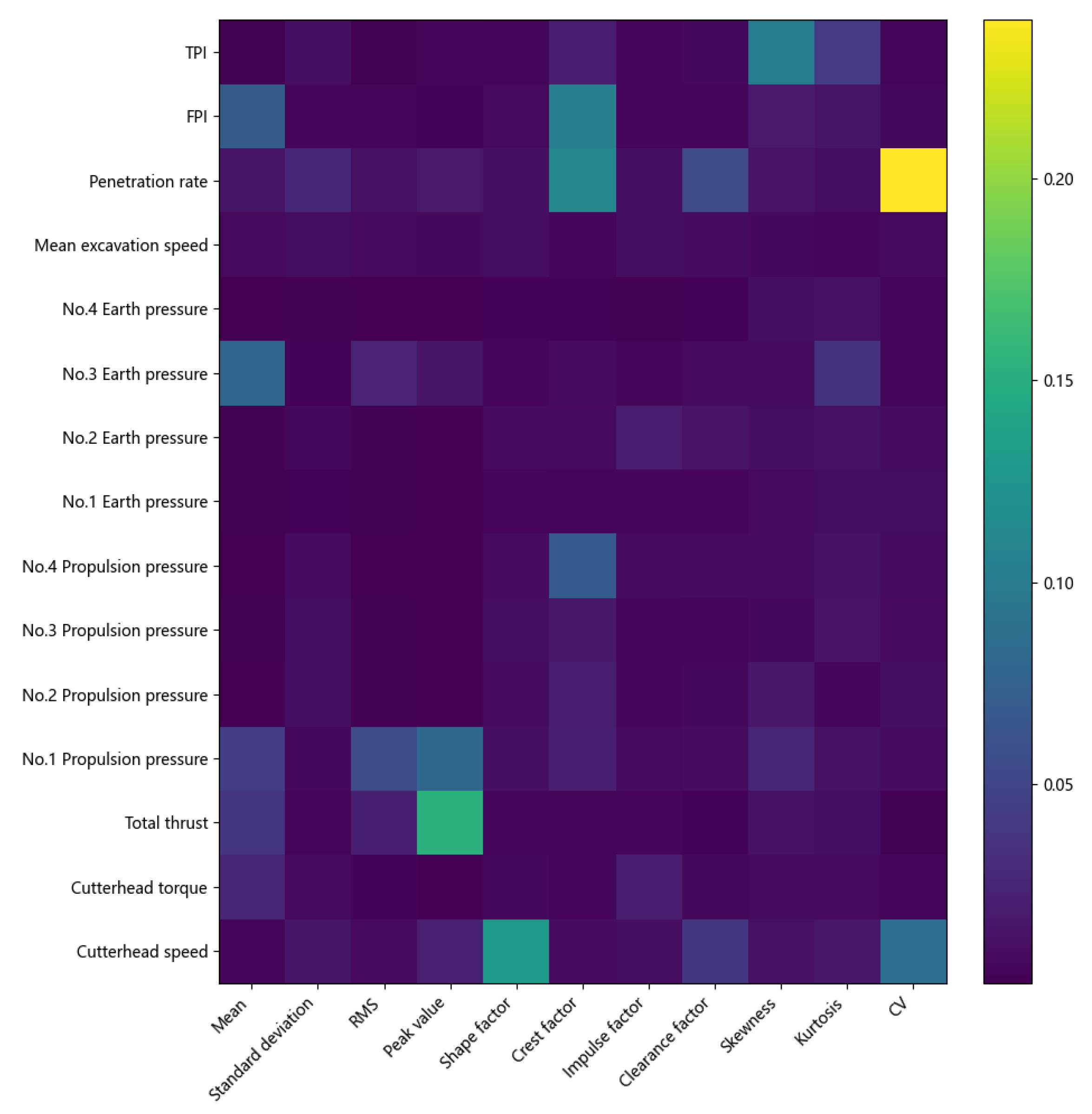

3.2.1. Variable Selection Network (VSN)

3.2.2. Temporal Processing

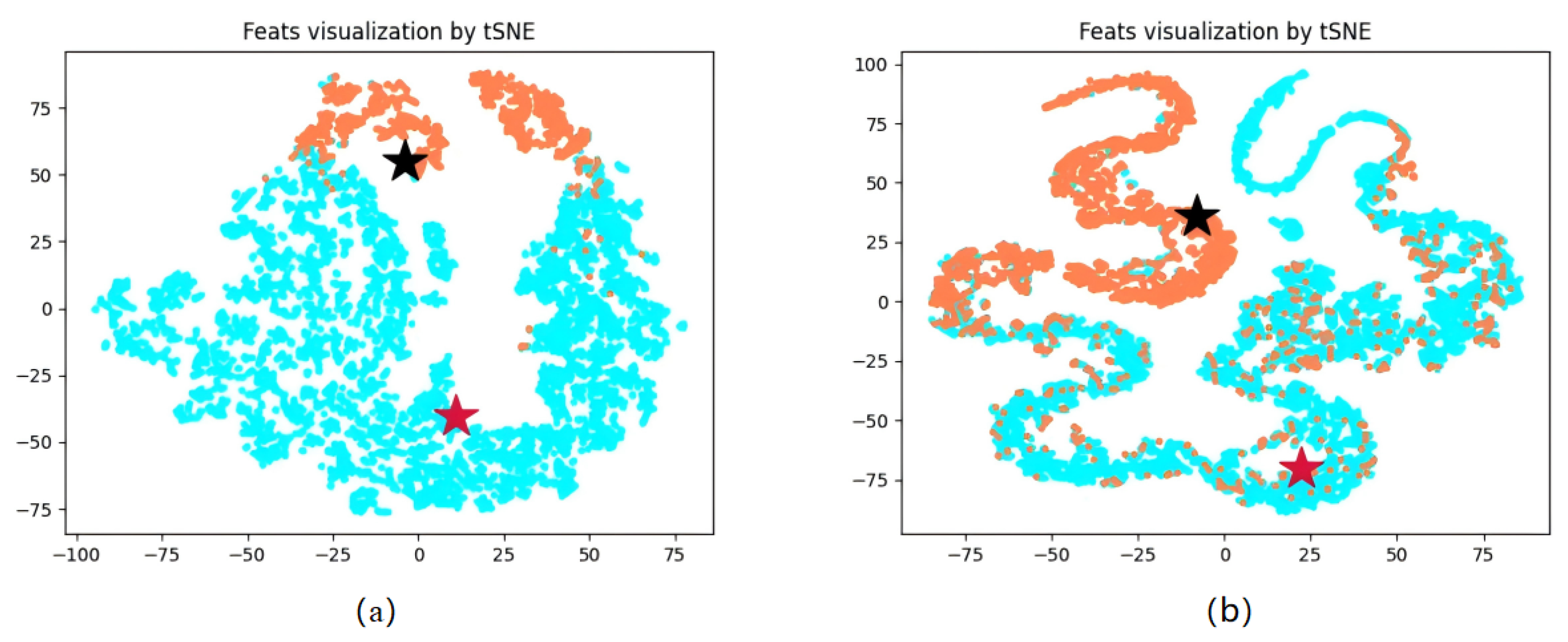

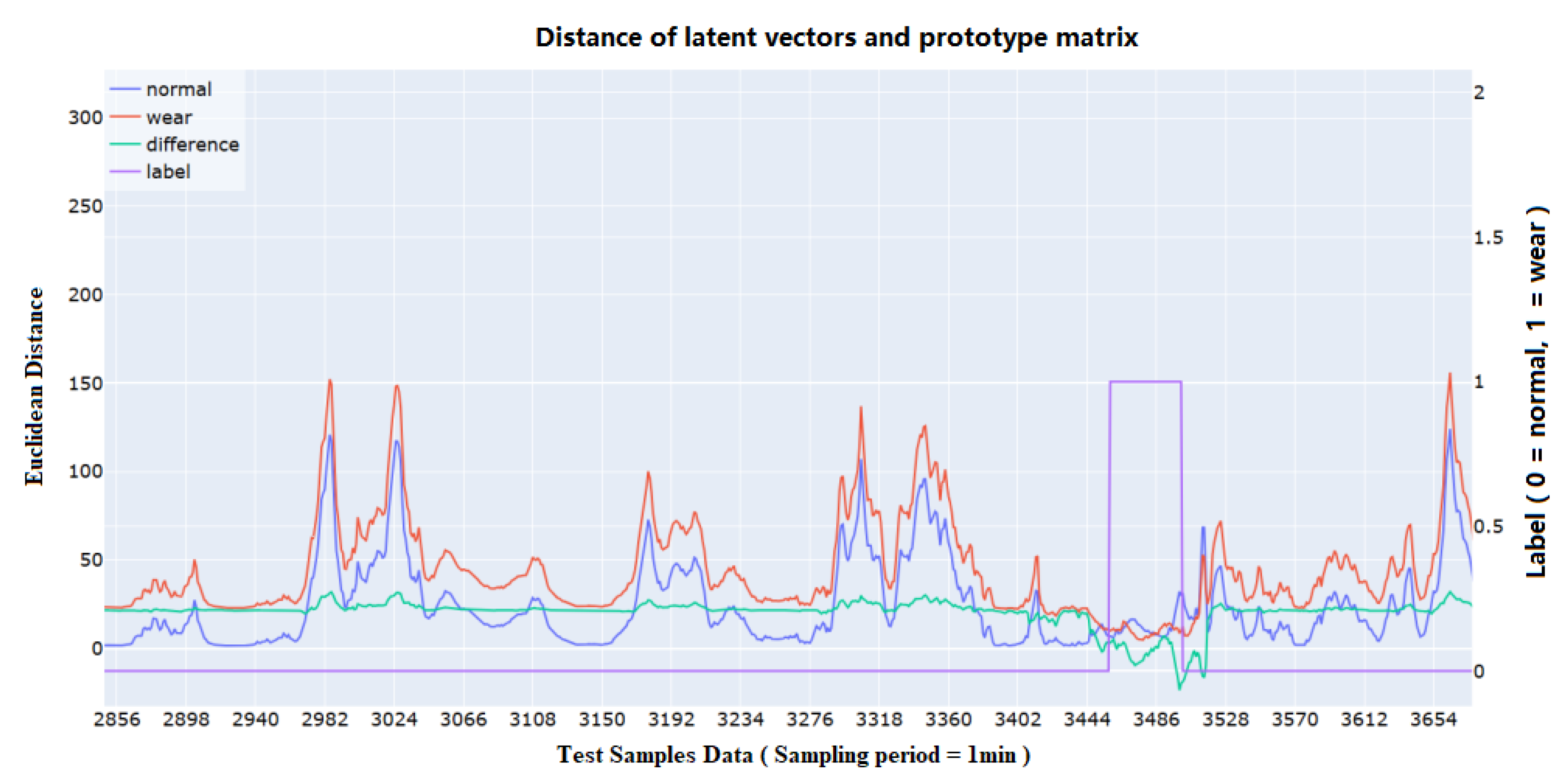

3.2.3. Class Prototype Learning

4. Results

4.1. Engineering Background

- (1)

- Empirical method: By consulting on site personnel and experts and combining data from periods of cutterhead inspection and downtime with the observed wear amount changes before and after inspections, the wear state intervals are estimated.

- (2)

- Formula-Based Method: Using the wear calculation formula [37], the wear state intervals are deduced based on the amount of wear measured during cutter replacement. (This project defines an average wear amount of 10 mm as the threshold for the wear state). However, the method may be affected by abnormal wear, leading to inaccuracies in the estimation.

- (3)

- Anomaly Detection Method: Based on related studies [38], this approach detects anomalies in shield operation. When an abnormal event occurs, the loss of the anomaly detection model increases significantly, providing a reference for identifying wear states. However, this method is also sensitive to other anomalies and therefore requires integration with empirical and formula-based methods for a comprehensive judgment.

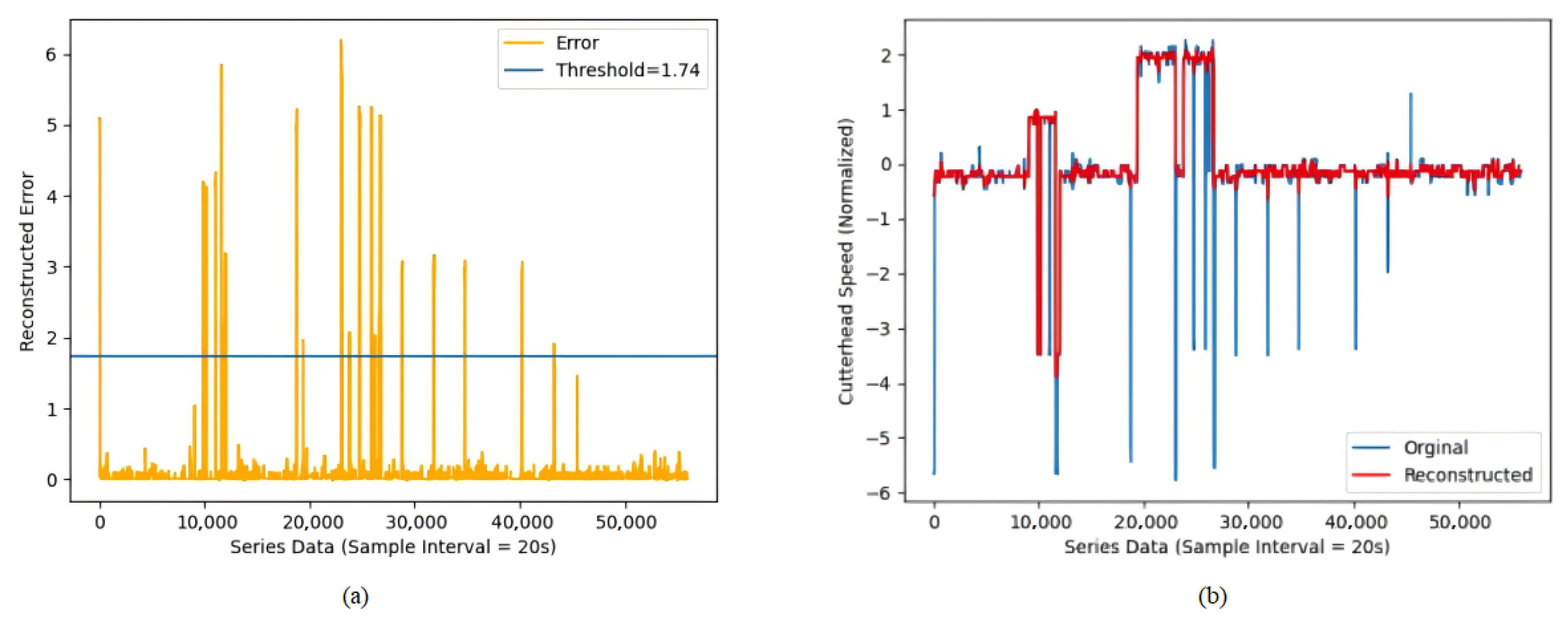

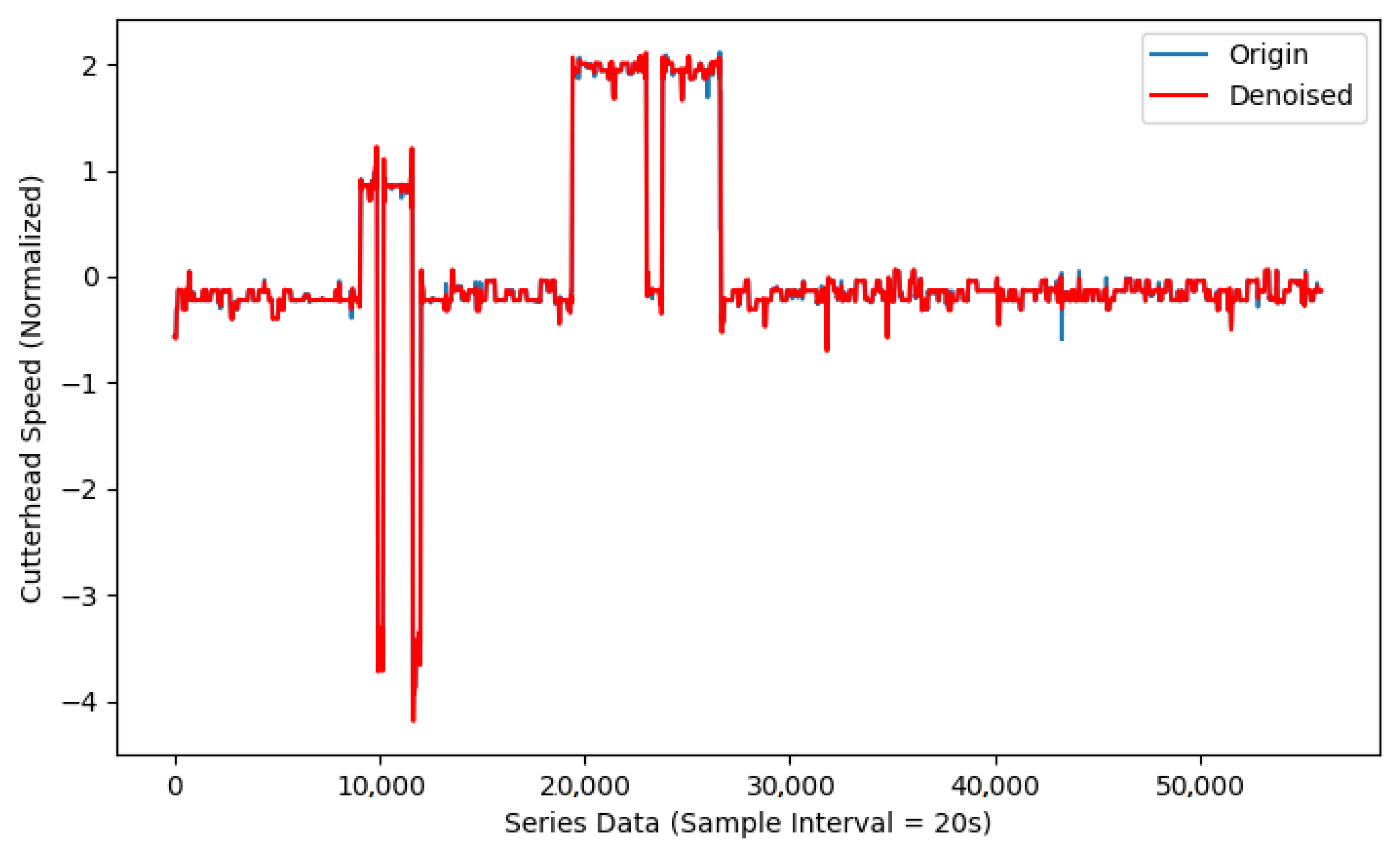

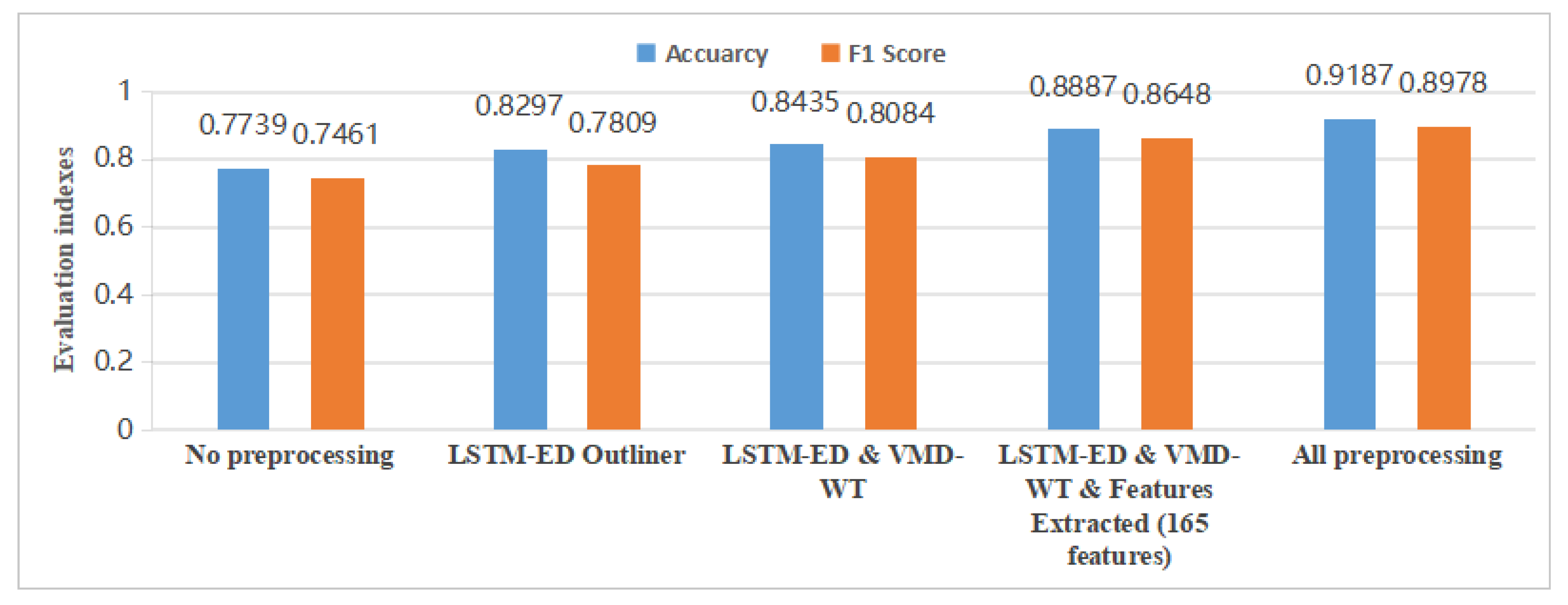

4.2. Data Preprocessing

4.3. Comparison Models

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Gong, G.; Yang, H.; Li, J.; Jing, L. From tunnel boring machine to tunnel boring robot: Perspectives on intelligent shield machine and its smart operation. J. Zhejiang-Univ.-Sci. A (Appl. Phys. Eng.) 2024, 25, 357–382. [Google Scholar] [CrossRef]

- Zhu, Y.-W.; Zheng, L.-B.; Zhang, H.T. Detection Technology Research on Cutting Tool Wear of New Shield Machine. Constr. Technol. 2014, 43, 121–123. [Google Scholar]

- Zheng, W.; Zhao, H.M.; Lan, H.; Tan, Q.; Shu, B.; Xia, Y.M. Design of On-line Monitoring System for Tunnel Boring Machine’s Disc Cutter Wear. Instrum. Tech. Sens. 2015, 2, 46–50. [Google Scholar]

- Wang, G.-H.; Lv, R.H. Laboratory Experimental Study on Ultrasonic Detection System for Wearing of Shield Cutter. Tunn. Constr. 2015, 35, 1089–1096. [Google Scholar]

- Li, Z.; Jia, J. Current status of patent technology of shield machine tool wear detection. China Sci. Technol. Inf. 2024, 21, 51–54. [Google Scholar]

- Wang, L.; Li, H.; Zhao, X.; Zhang, Q. Development of a prediction model for the wear evolution of disc cutters on rock TBM cutterhead. Tunn. Undergr. Space Technol. 2017, 67, 147–157. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, S.; Wang, D.; Zhu, G.; Zhang, D. Prediction Model of Tunnel Boring Machine Disc Cutter Replacement Using Kernel Support Vector Machine. Appl. Sci. 2022, 12, 2267. [Google Scholar] [CrossRef]

- She, L.; Zhang, S.; Wang, C.; Wu, Z.; Yu, L.; Wang, L. Prediction model for disc cutter wear during hard rock breaking based on plastic removal abrasiveness mechanism. Bull. Eng. Geol. Environ. 2022, 81, 432. [Google Scholar] [CrossRef]

- Su, W.; Li, X.; Jin, D.; Yang, Y.; Qin, R.; Wang, X. Analysis and prediction of TBM disc cutter wear when tunneling in hard rock strata: A case study of a metro tunnel excavation in Shenzhen, China. Wear 2020, 446–447, 203190. [Google Scholar] [CrossRef]

- Karami, M.; Zare, S.; Rostami, J. Introducing an empirical model for prediction of disc cutter life for TBM application in jointed rocks: Case study, Kerman water conveyance tunnel. Bull. Eng. Geol. Environ. 2021, 80, 3853–3870. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, C.; Jiang, Y.; Dong, L. Wang, S. Study on Wear Prediction of Shield Disc Cutter in Hard Rock and Its Application. Ksce J. Civ. Eng. 2022, 26, 1439–1450. [Google Scholar] [CrossRef]

- She, L.; Zhang, S.; Wang, C.; Li, Y.; Du, M. A new method for wear estimation of TBM disc cutter based on energy analysis. Tunn. Undergr. Space Technol. 2023, 131, 104840. Available online: https://api.semanticscholar.org/CorpusID:253415018 (accessed on 26 November 2024). [CrossRef]

- Wang, L.; Kang, Y.; Cai, Z.; Zhang, Q.; Zhao, Y.; Zhao, H.; Su, P. The energy method to predict disc cutter wear extent for hard rock TBMs. Tunn. Undergr. Space Technol. 2012, 28, 183–191. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, S.; Zhuo, A. A new index for cutter life evaluation and ensemble model for prediction of cutter wear. Tunn. Undergr. Space Technol. 2023, 131, 104830. [Google Scholar] [CrossRef]

- Kilic, K.; Toriya, H.; Kosugi, Y.; Adachi, T.; Kawamura, Y. One-Dimensional Convolutional Neural Network for Pipe Jacking EPB TBM Cutter Wear Prediction. Appl. Sci. 2022, 12, 2410. [Google Scholar] [CrossRef]

- Yu, H.; Tao, J.; Huang, S.; Qin, C.; Xiao, D.; Liu, C. A field parameters-based method for real-time wear estimation of disc cutter on TBM cutterhead. Autom. Constr. 2021, 124, 103603. [Google Scholar] [CrossRef]

- Mahmoodzadeh, A.; Mohammadi, M.; Ibrahim, H.H.; Abdulhamid, S.N.; Hama Ali, H.F.; Hasan, A.M.; Khishe, M.; Mahmud, H. Machine learning forecasting models of disc cutters life of tunnel boring machine. Autom. Constr. 2021, 128, 103779. [Google Scholar] [CrossRef]

- Gong, L. Health Assessment and Prediction of Cutter Head of Tunnel Boring Machine for High dimensional Spatiotemporal Data Analysis. Master’s Thesis, Xidian University, Xi’an, China, 2022. [Google Scholar]

- Chen, K.; Chang, J.-D.; Wang, H.-X.; Wu, L.Y. The Fault Diagnosis of Shield Disc Cutter Based on Neural Network. In Advances in Engineering Research; Cao, M., Ed.; Atlantis Press: Amsterdam, The Netherlands, 2017; Volume 105, pp. 752–756. [Google Scholar] [CrossRef]

- Qin, C.; Wu, R.; Huang, G.; Tao, J.; Liu, C. A novel LSTM-autoencoder and enhanced transformer-based detection method for shield machine cutterhead clogging. Sci. China Technol. Sci. 2023, 66, 512–527. [Google Scholar] [CrossRef]

- Han, Y.; Li, C.; Huang, Q.; Wen, R.; Zhang, Y. Boundary-enhanced prototype network with time-series attention for gearbox fault diagnosis under limited samples. J. Electron. Meas. Instrum. 2023, 37, 90–98. [Google Scholar] [CrossRef]

- Gee, A.-H.; Garcia-Olano, D.; Ghosh, J.; Paydarfar, D. Explaining Deep Classification of Time-Series Data with Learned Prototypes. Ceur Workshop Proc. 2019, 2429, 15–22. Available online: https://arxiv.org/abs/1904.08935 (accessed on 23 February 2025).

- Liu, B.-Y.; Wu, L.; Mu, S. Research on Small-Sample Credit Card Fraud Identification Based on Temporal Attention-Boundary-Enhanced Prototype Network. Mathematics 2024, 12, 3894. [Google Scholar] [CrossRef]

- Kim, Y.; Hong, J.; Shin, J.; Kim, B. Shield TBM disc cutter replacement and wear rate prediction using machine learning techniques. Geomech. Eng. 2022, 29, 249–258. [Google Scholar] [CrossRef]

- Srivastava, N.; Mansimov, E.; Salakhutdinov, R. Unsupervised learning of video representations using LSTMs. arXiv 2015, 843–852. Available online: https://arxiv.org/abs/1502.04681 (accessed on 22 February 2025).

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. IEEE Trans. Signal Process. 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Shi, G.; Qin, C.; Tao, J.; Liu, C. A VMD-EWT-LSTM-based multi-step prediction approach for shield tunneling machine cutterhead torque. Knowl.-Based Syst. 2021, 228, 107213. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, K.; Guo, H.; Liang, X. Combined prediction model of joint opening-closing deformation of immersed tube tunnel based on SSA optimized VMD, SVR and GRU. Ocean. Eng. 2024, 305, 117933. [Google Scholar] [CrossRef]

- Qin, C.; Huang, G.; Yu, H.; Zhang, Z.; Tao, J.; Liu, C. Adaptive VMD and multi-stage stabilized transformer-based long-distance forecasting for multiple shield machine tunneling parameters. Autom. Constr. 2024, 165, 105563. [Google Scholar] [CrossRef]

- Huang, Z.; Zhu, J.; Lei, J.; Li, X.; Tian, F. Tool wear predicting based on multi-domain feature fusion by deep convolutional neural network in milling operations. J. Intell. Manuf. 2020, 31, 953–966. [Google Scholar] [CrossRef]

- Wu, J.; Wu, C.; Cao, S.; Or, S.W.; Deng, C.; Shao, X. Degradation Data-Driven Time-To-Failure Prognostics Approach for Rolling Element Bearings in Electrical Machines. IEEE Trans. Ind. Electron. 2019, 66, 529–539. [Google Scholar] [CrossRef]

- Guo, L.; Lei, Y.; Li, N.; Yan, T.; Li, N. Machinery health indicator construction based on convolutional neural networks considering trend burr. Neurocomputing 2018, 292, 142–150. [Google Scholar] [CrossRef]

- Javed, K.; Gouriveau, R.; Zerhouni, N.; Nectoux, P. Enabling Health Monitoring Approach Based on Vibration Data for Accurate Prognostics. IEEE Trans. Ind. Electron. 2015, 62, 647–656. [Google Scholar] [CrossRef]

- Lim, B.; Arık, S.O.; Loeff, N.; Pfister, T. Temporal Fusion Transformers for interpretable multi-horizon time series forecasting. Int. J. Forecast. 2021, 37, 1748–1764. [Google Scholar] [CrossRef]

- Clevert, D.A.; Unterthiner, T.; Hochreiter, S. Fast and Accurate Deep Network Learning by Exponential Linear Units (ELUs). arXiv 2015. Available online: https://api.semanticscholar.org/CorpusID:5273326 (accessed on 18 November 2024).

- Zhang, X.-C.; Gao, Y.; Lin, J.; Lu, C.T. TapNet: Multivariate Time Series Classification with Attentional Prototypical Network. Proc. Aaai Conf. Artif. Intell. 2020, 34, 6845–6852. Available online: https://api.semanticscholar.org/CorpusID:210703726 (accessed on 22 October 2023). [CrossRef]

- Ren, D.-J.; Shen, S.; Arulrajah, A.; Cheng, W.-C. Prediction Model of TBM Disc Cutter Wear During Tunnelling in Heterogeneous Ground. Rock Mech. Rock Eng. 2018, 51, 3599–3611. [Google Scholar] [CrossRef]

- Xu, Z. Research on Abnormal Diagnosis Technology of Shield Machine Based on Multivariate Spatiotemporal Data Fusion. Master’s Thesis, Shanghai University, Shanghai, China, 2023. [Google Scholar]

- Karim, F.; Majumdar, S.; Darabi, H.; Chen, S. LSTM Fully Convolutional Networks for Time Series Classification. IEEE Access 2018, 6, 1662–1669. [Google Scholar] [CrossRef]

- Ismail Fawaz, H.; Lucas, B.; Forestier, G.; Pelletier, C.; Schmidt, D.F.; Weber, J.; Webb, G.I.; Idoumghar, L.; Muller, P.A.; Petitjean, F. InceptionTime: Finding AlexNet for time series classification. Data Min. Knowl. Discov. 2020, 34, 1936–1962. [Google Scholar] [CrossRef]

- Liu, M.; Ren, S.; Ma, S.; Jiao, J.; Chen, Y.; Wang, Z.; Song, W. Gated Transformer Networks for Multivariate Time Series Classification. arXiv 2021, arXiv:2103.14438. Available online: https://arxiv.org/abs/2103.14438 (accessed on 15 November 2024).

| Index | Feature | Equation | Index | Feature | Equation |

|---|---|---|---|---|---|

| 1 | Mean | 7 | Impulse factor | ||

| 2 | Standard deviation | 8 | Clearance factor | ||

| 3 | Root mean square | 9 | Skewness | ||

| 4 | Peak value | 10 | Kurtosis | ||

| 5 | Shape factor | 11 | CV | ||

| 6 | Crest factor |

| Number | Parameter |

|---|---|

| 1 | Cutterhead speed (r/min) |

| 2 | Cutterhead torque (kN · m) |

| 3 | Total thrust (kN) |

| 4–7 | Propulsion pressure of cylinders groups No. 1–No. 4 (MPa) |

| 8–11 | Earth pressure of excavation soil bin No. 1–No. 4 (bar) |

| 12 | Mean excavation speed (mm/min) |

| 13 | Penetration (mm/r) |

| 14 | FPI |

| 15 | TPI |

| Features | Monotonicity | Trend | Score |

|---|---|---|---|

| Standard deviation of mean excavation speed | 0.08 | 1 | 1.08 |

| Kurtosis of cutterhead torque | 0.1962 | 1.49 × | 0.1962 |

| Skewness of cutterhead torque | 0.1962 | 0.0007 | 0.1781 |

| Standard deviation of Earth pressure No. 1. | 0.0171 | 0.1610 | 0.1781 |

| … | … | … | … |

| Mean of Penetration | 0.0952 | 0.0358 | 0.1310 |

| Model | Accuarcy | F1-Score |

|---|---|---|

| LSTM-FCN | 0.8151 | 0.7917 |

| ALSTM-FCN | 0.8427 | 0.8230 |

| BiLSTM | 0.8422 | 0.8172 |

| ResNet | 0.8385 | 0.8104 |

| InceptionTime | 0.8642 | 0.8412 |

| TapNet | 0.8594 | 0.8350 |

| GTN | 0.8848 | 0.8556 |

| TARNet | 0.9023 | 0.8785 |

| MVSAPNet | 0.9187 | 0.8978 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Y.; Gao, X.; Ye, D. MVSAPNet: A Multivariate Data-Driven Method for Detecting Disc Cutter Wear States in Composite Strata Shield Tunneling. Sensors 2025, 25, 1650. https://doi.org/10.3390/s25061650

Xiong Y, Gao X, Ye D. MVSAPNet: A Multivariate Data-Driven Method for Detecting Disc Cutter Wear States in Composite Strata Shield Tunneling. Sensors. 2025; 25(6):1650. https://doi.org/10.3390/s25061650

Chicago/Turabian StyleXiong, Yewei, Xinwen Gao, and Dahua Ye. 2025. "MVSAPNet: A Multivariate Data-Driven Method for Detecting Disc Cutter Wear States in Composite Strata Shield Tunneling" Sensors 25, no. 6: 1650. https://doi.org/10.3390/s25061650

APA StyleXiong, Y., Gao, X., & Ye, D. (2025). MVSAPNet: A Multivariate Data-Driven Method for Detecting Disc Cutter Wear States in Composite Strata Shield Tunneling. Sensors, 25(6), 1650. https://doi.org/10.3390/s25061650