A Detection Method for Open–Close States of High-Voltage Disconnector in Smoky Environments

Abstract

1. Introduction

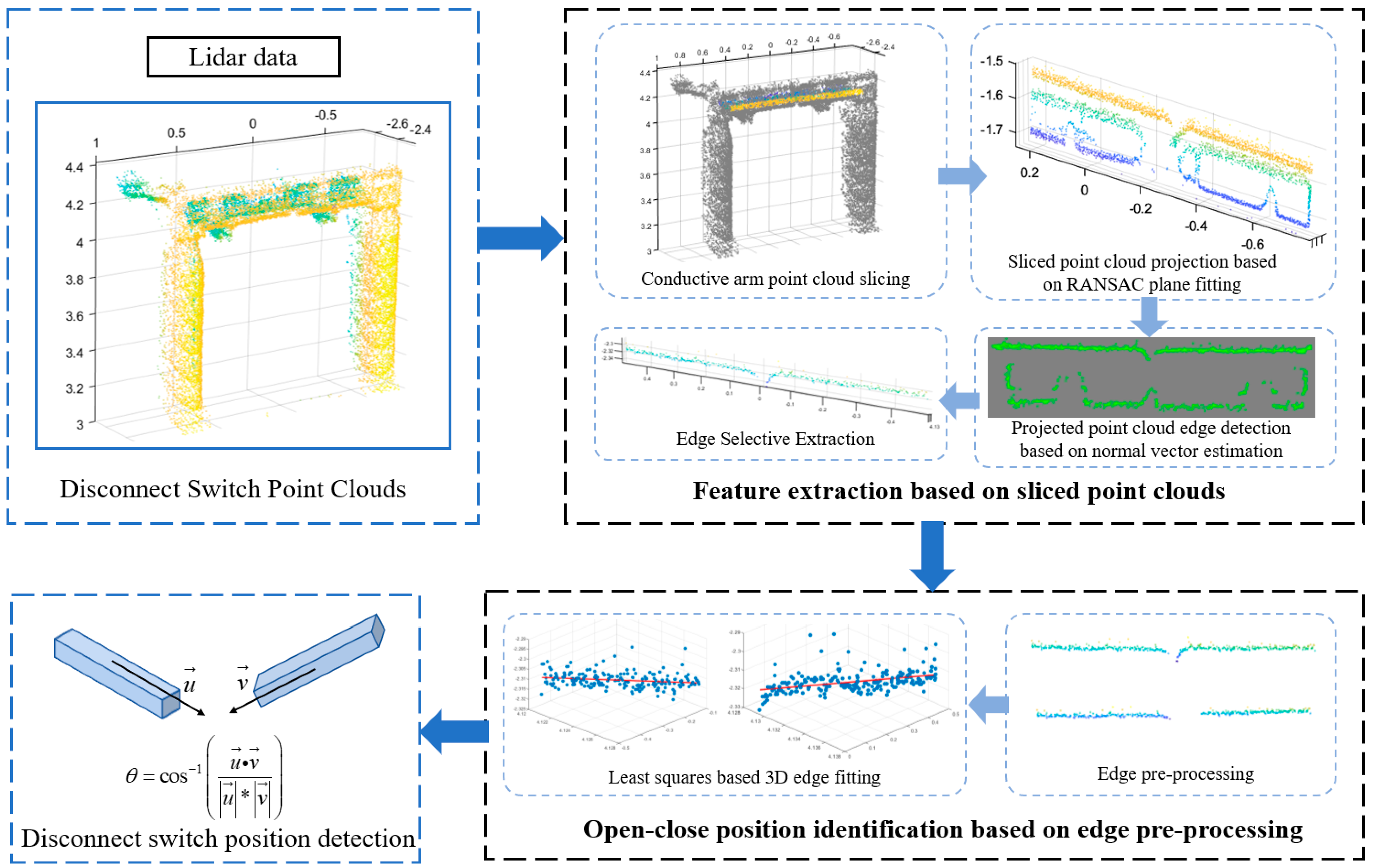

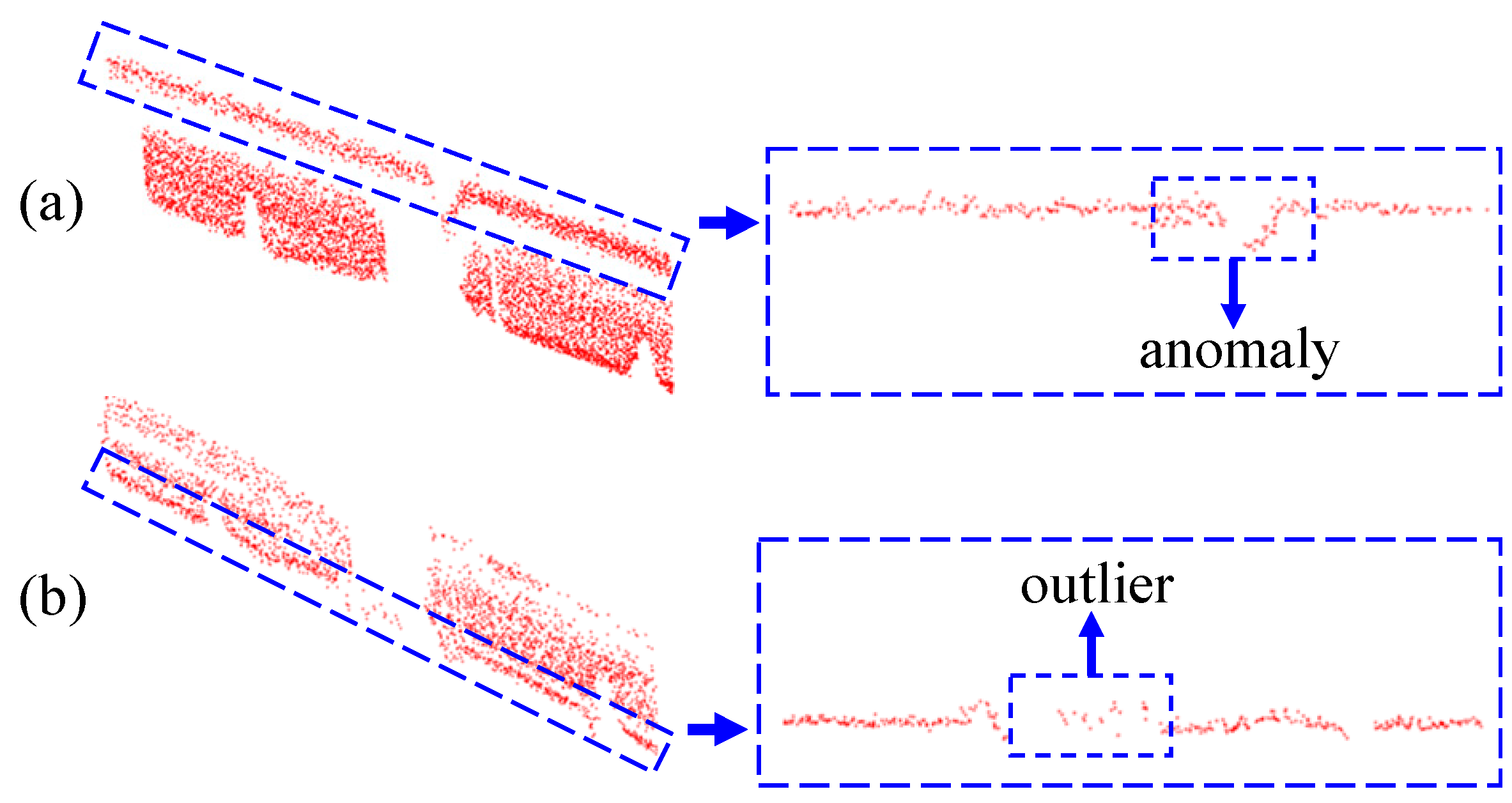

- Utilizing point cloud data from a disconnector, the impact of smoky environments on the data was analyzed. Subsequently, a two-stage process, designed to align with the structural characteristics of disconnectors, was proposed to address smoke interference.

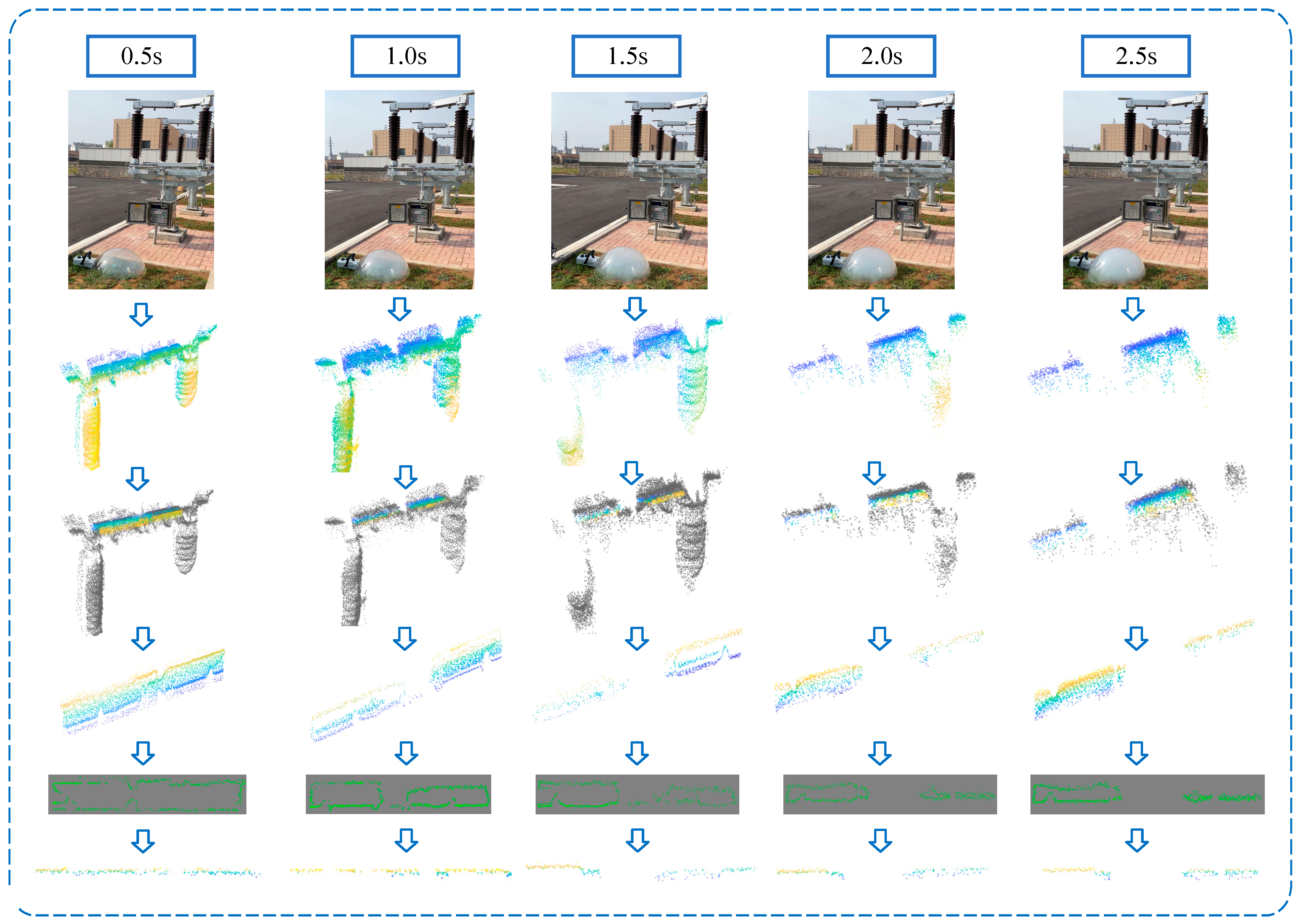

- Two methods have been established, one for feature extraction based on sliced point clouds and another for the open–close position identification method based on edge pre-processing. The aforementioned methods can enhance the accuracy of isolator and circuit breaker position determination for laser radar in smoky environments and reduce reliance on point cloud density.

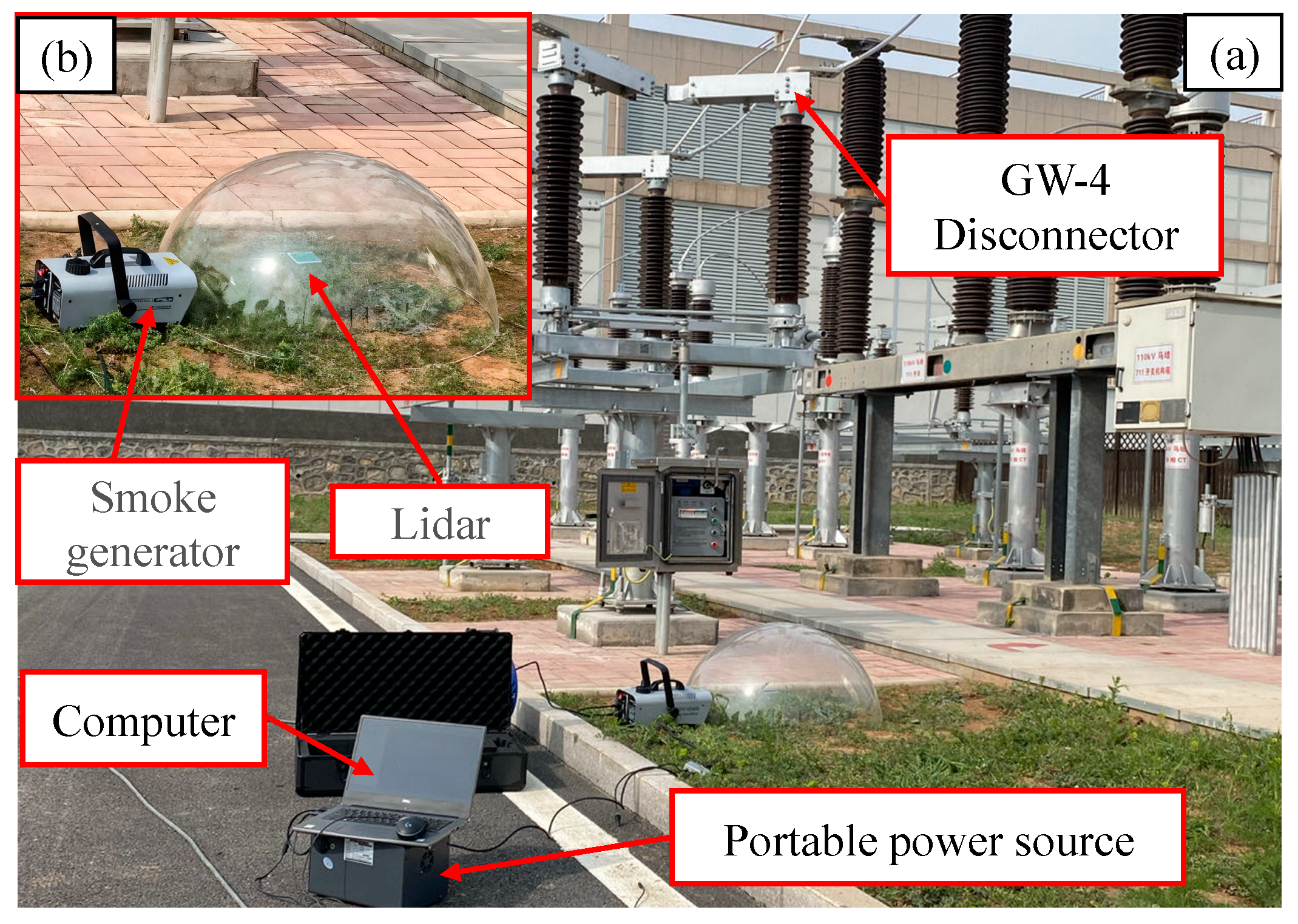

- A smoke environment simulation experimental platform was established, and the experimental results validated the feasibility and reliability of the methods proposed in this article. This research serves as a reference for the development of disconnector closing status monitoring technology based on LiDAR.

2. Methodology

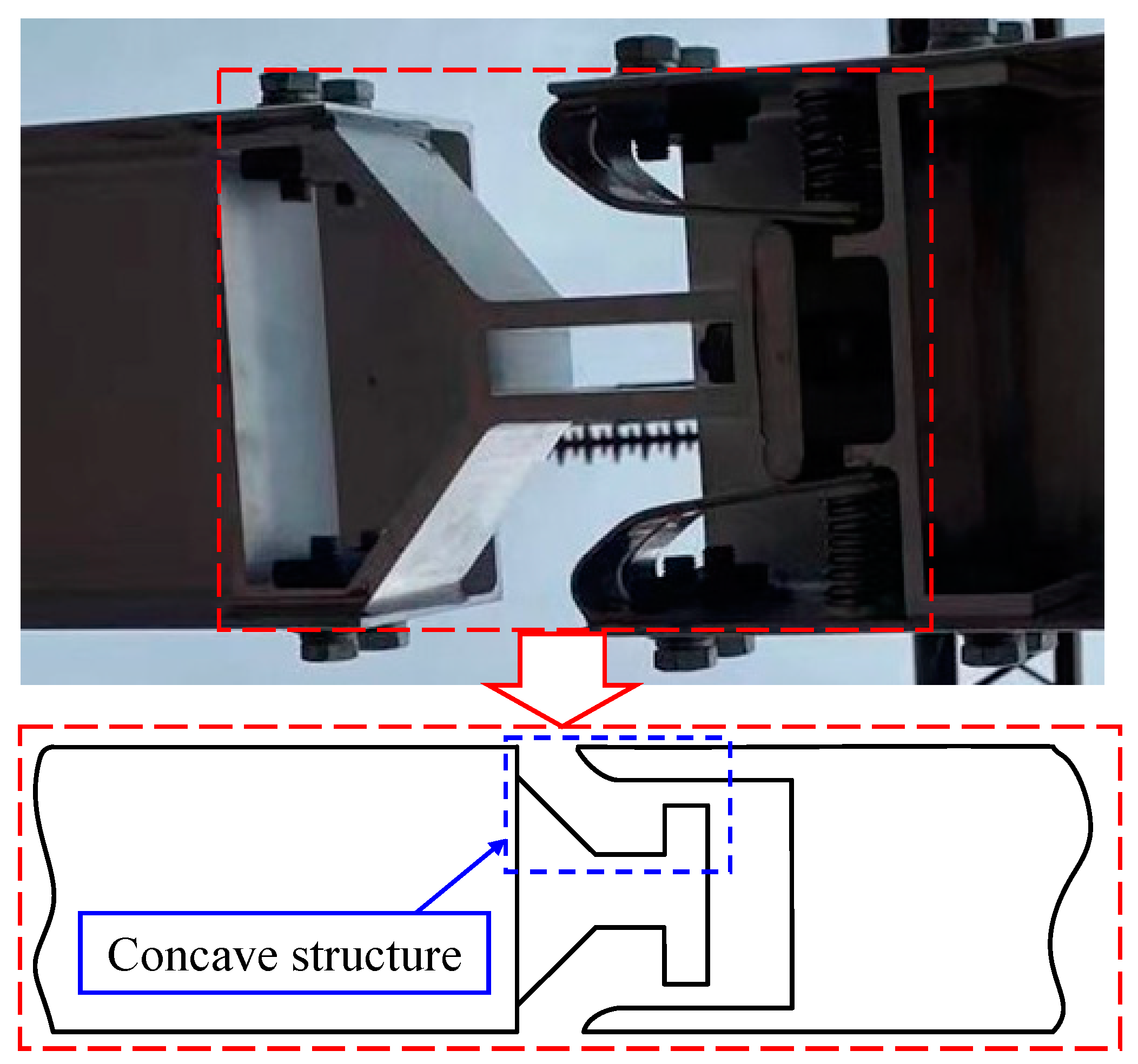

2.1. Feature Extraction Based on Sliced Point Clouds

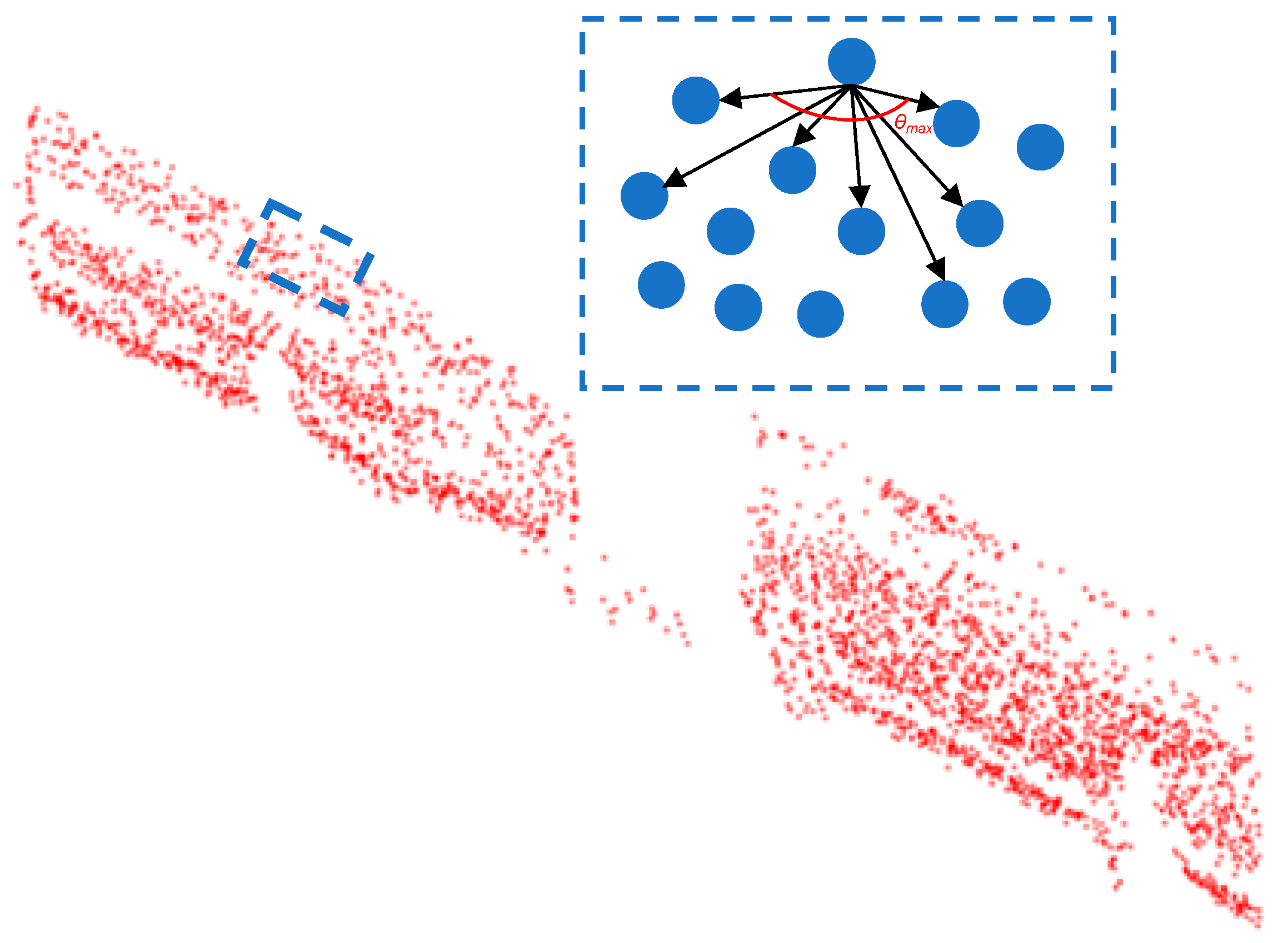

2.2. Open–Close Position Identification Method Based on Edge Pre-Processing

| Algorithm 1 3D Edge Fitting from Pre-Processed Point Clouds |

| Input: pre-processed edge point clouds P |

| Output: Spatial position of conductive arms L1, L2 |

| Initialize minimum clustering distance Dm |

| Perform Euclidean clustering: [lab, num] = pcsegdist(P, Dm); |

| for j = 1: num do |

| search set of cluste points Pj = {Pi∈P | lab[Pi] = = j}; |

| (x, y, z) = extractXYZ(Pj); |

| Constructing point cloud data matrix pd ← (x, y, z); |

| cen ← (, , ) |

| D ← pd − cen; |

| C ← (1/(n−1))DTD; |

| D ← USVT; |

| [v1,v2,v3]T ← [V1,1,V2,1,V3,1]T |

| Calculate center of mass coordinates (a, b, c); |

| lx ← at + v1t, ly ← bt + v2t, lz ← ct + v3t; |

| end for |

| return L1, L2; |

3. Tests and Analysis of Results

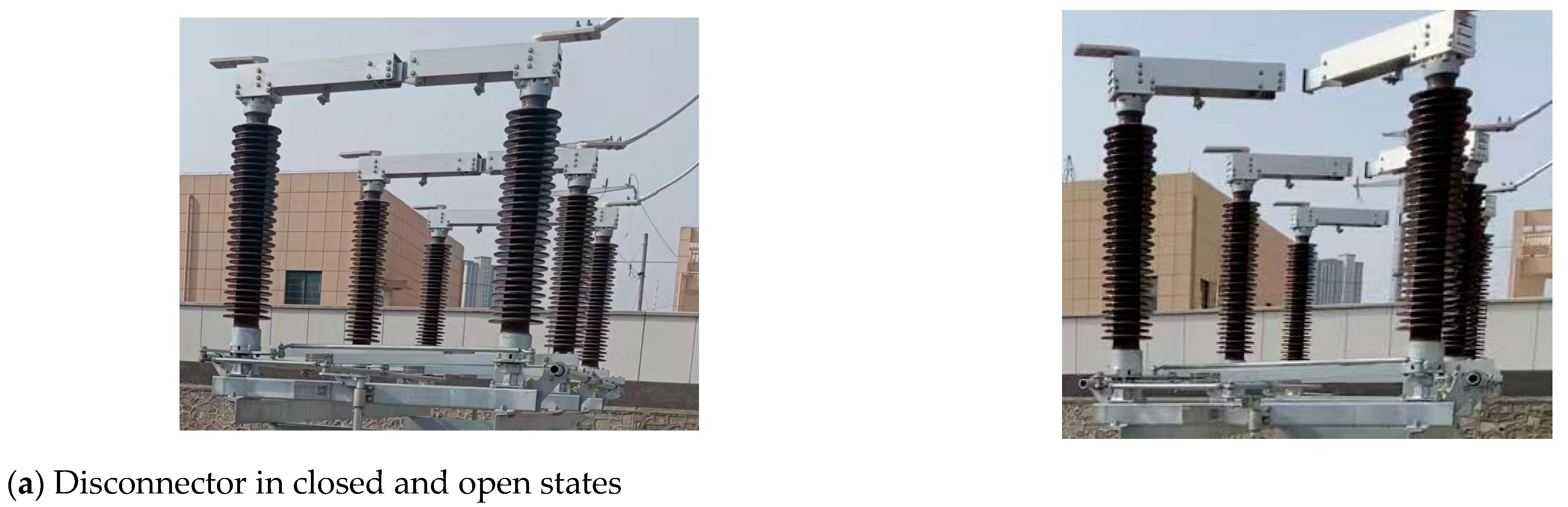

3.1. Construction of Experimental Platforms and Data Acquisition

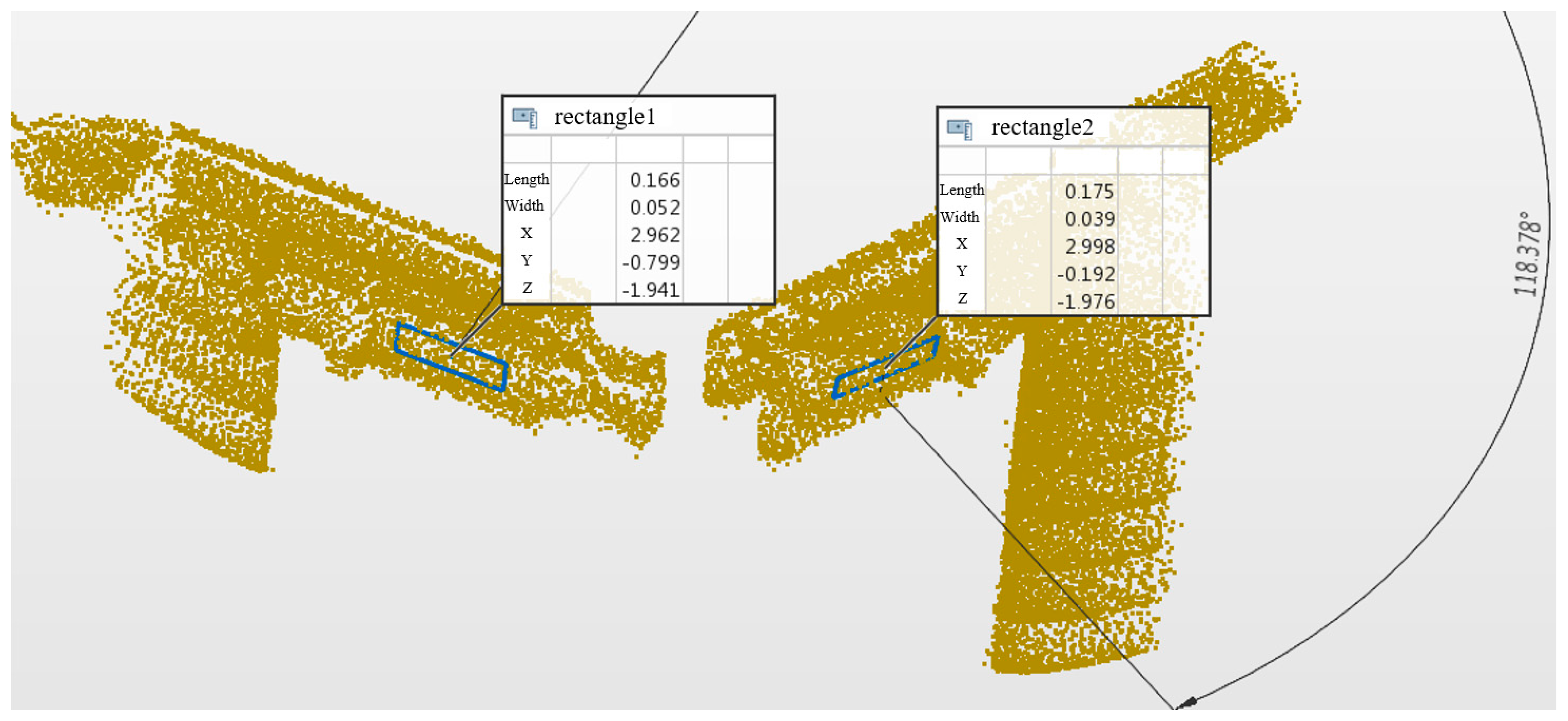

3.2. Disconnector Conductive Arm Feature Extraction

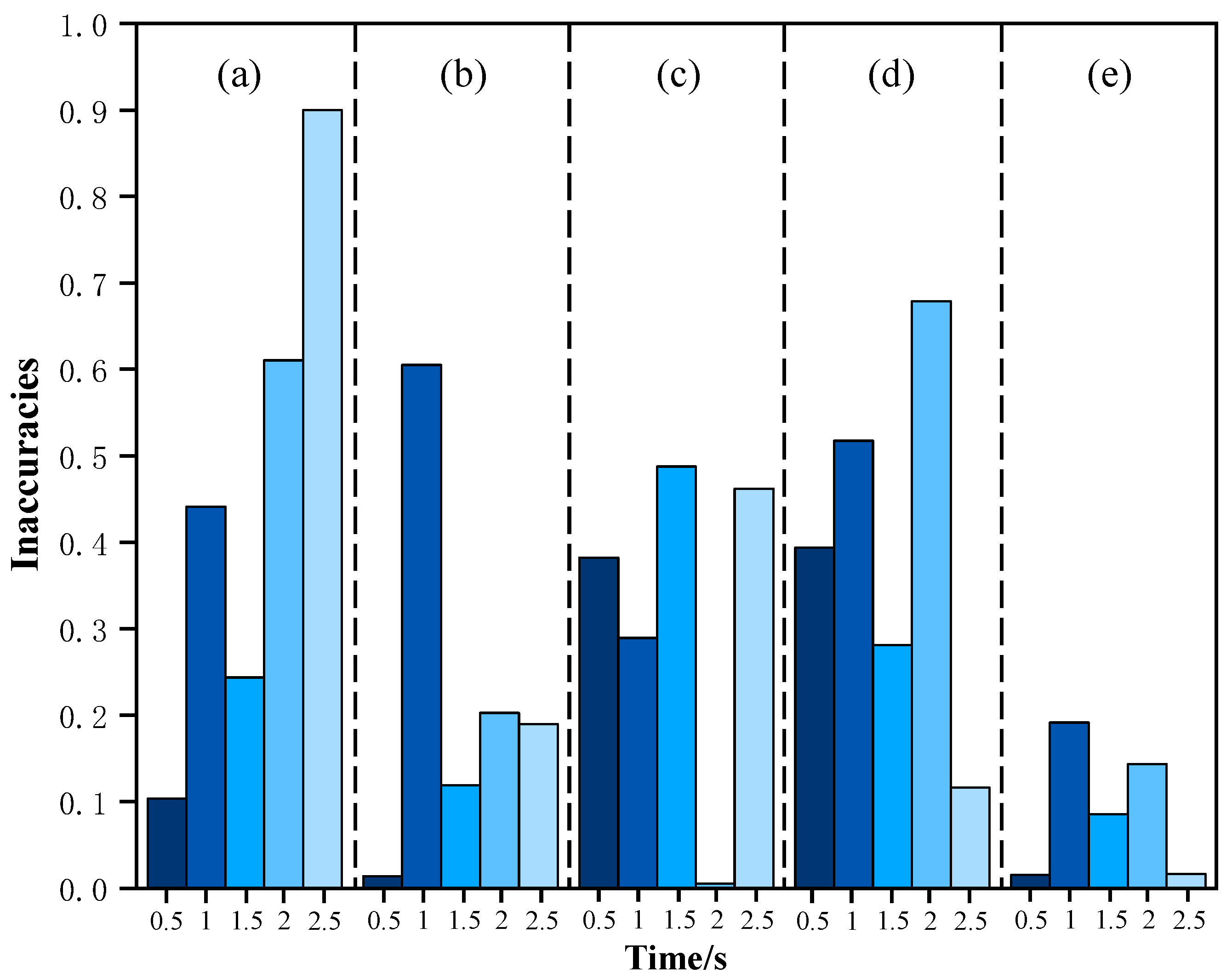

3.3. Open–Close Position Identification of Disconnector

4. Conclusions

- (1)

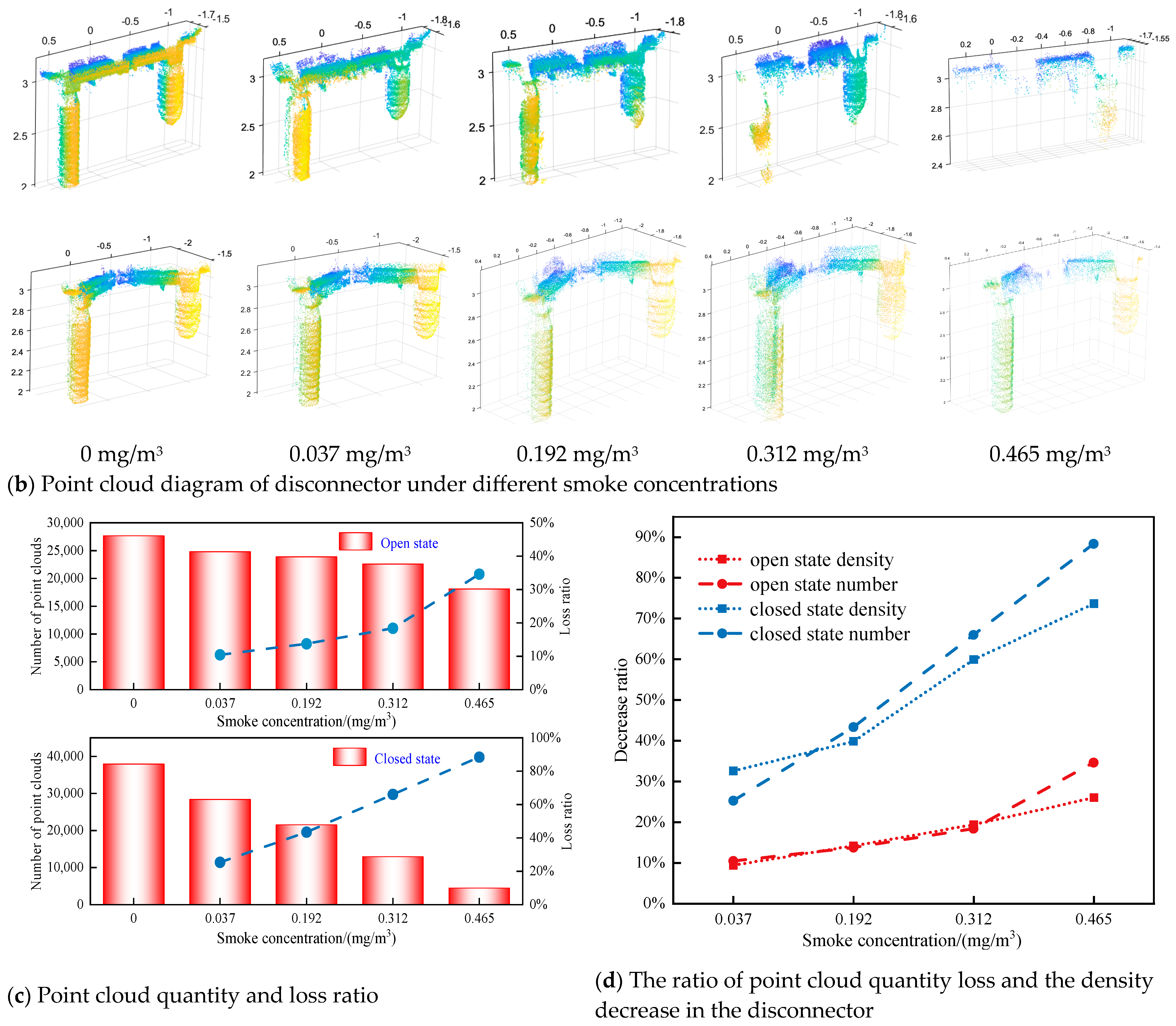

- Based on the LiDAR-derived point cloud data, an analysis was conducted to examine the impact of smoke in the environment, revealing that smoke interference leads to partial data loss in the point cloud.

- (2)

- A two-stage discrimination process is proposed. The edge features of the conductive arm are constructed through a feature extraction method based on sliced point clouds. By employing an open–close position identification method based on edge pre-processing, the calculation of the angle of the conductive arm is completed, thereby achieving the discrimination of the open and close states of the disconnector.

- (3)

- Smoke environment simulation experiments were performed to compare the results with manual measurements in PolyWorks. The findings validate that the method proposed in this article can effectively mitigate smoke interference and accurately discern the open and close states of the disconnector, demonstrating its feasibility and reliability.

- (4)

- Although the GW4 isolating switch, the most widely used type in substations, was selected as the validation object in this study, the proposed method for detecting the opening and closing states is also applicable to other isolating switches, such as GW5, GW6, GW16, and GW17 models, which rely on conductive arm movement for operation. In future work, efforts will be made to implement the proposed method across various isolating switch models, enabling the accurate detection of the opening and closing states for switches of different types and voltage levels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Runde, M. Failure frequencies for high-voltage circuit breakers, disconnectors, earthing switches, instrument transformers, and gas-insulated switchgear. IEEE Trans. Power Deliv. 2013, 28, 529–530. [Google Scholar] [CrossRef]

- Jürgensen, J.H.; Brodersson, A.L.; Nordström, L.; Hilber, P. Impact assessment of remote control and preventive maintenance on the failure rate of a disconnector population. IEEE Trans. Power Deliv. 2018, 33, 1501–1509. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, K.; Lin, S. Fault Diagnosis Method of Disconnector Based on CNN and D-S Evidence Theory. IEEE Trans. Ind. Appl. 2023, 59, 5691–5704. [Google Scholar] [CrossRef]

- Nassu, B.T.; Marchesi, B.; Wagner, R.; Gomes, V.B.; Zarnicinski, V.; Lippmann, L. A Computer Vision System for Monitoring Disconnect Switches in Distribution Substations. IEEE Trans. Power Deliv. 2021, 37, 833–841. [Google Scholar] [CrossRef]

- Tao, P.; Chaohui, L.; Yi, D.; Feng, L.; Sheng, D. Mechanical fault diagnosis of high voltage disconnector based on motor current detection. In Proceedings of the 2019 IEEE 3rd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 March 2019; pp. 1726–1729. [Google Scholar]

- Zhang, J.; Zhou, Z.; Sun, J. Three-Dimensional Segmentation and Global Clearance Analysis for Free-Bent Pipelines in Point-Cloud Scenarios. IEEE Trans. Instrum. Meas. 2023, 72, 1–12. [Google Scholar] [CrossRef]

- Semedo, S.M.V.; Oliveira, J.E.G.; Cardoso, F.J.A. Remote monitoring of high-voltage disconnect switches in electrical distribution substations. In Proceedings of the 2014 IEEE 23rd International Symposium on Industrial Electronics (ISIE), Istanbul, Turkey, 1–4 June 2014; pp. 2060–2064. [Google Scholar]

- Teng, Y.; Tan, T.-Y.; Lei, C.; Yang, J.-G.; Ma, Y.; Zhao, K.; Jia, Y.-Y.; Liu, Y. A Novel Method to Recognize the State of High-Voltage Isolating Switch. IEEE Trans. Power Deliv. 2019, 34, 1350–1356. [Google Scholar] [CrossRef]

- Cao, R.; Li, W.; Huang, Y.; Lu, D.; Lin, Q. Accurate Identification of Closing State of Horizontal Rotary Disconnectors in a Substation Based on Mask R-CNN. In Proceedings of the 2022 7th International Conference on Computational Intelligence and Applications (ICCIA), Nanjing, China, 24–26 June 2022; pp. 90–94. [Google Scholar]

- Nassu, B.T.; Lippmann, L.; Marchesi, B.; Canestraro, A.; Wagner, R.; Zarnicinski, V. Image-Based State Recognition for Disconnect Switches in Electric Power Distribution Substations. In Proceedings of the 2018 31st SIBGRAPI Conference on Graphics, Patterns and Images (SIBGRAPI), Parana, Brazil, 29 October–1 November 2018; pp. 432–439. [Google Scholar]

- Yuan, F.; Zhang, L.; Xia, X.; Huang, Q.; Li, X. A Wave-Shaped Deep Neural Network for Smoke Density Estimation. IEEE Trans. Image Process. 2020, 29, 2301–2313. [Google Scholar] [CrossRef]

- Shen, X.; Xu, Z.; Wang, M. An Intelligent Point Cloud Recognition Method for Substation Equipment Based on Multiscale Self-Attention. IEEE Trans. Instrum. Meas. 2023, 72, 1–12. [Google Scholar] [CrossRef]

- Shen, X.; Xu, Z. A multitemporal point cloud registration method for evaluation of power equipment geometric shape. IEEE Trans. Instrum. Meas. 2022, 71, 1–14. [Google Scholar] [CrossRef]

- Tian, H.; Li, W.; Ogunbona, P.O.; Wang, L. Detection and Separation of Smoke From Single Image Frames. IEEE Trans. Image Process. 2018, 27, 1164–1177. [Google Scholar] [CrossRef]

- Kutila, M.; Pyykönen, P.; Holzhüter, H.; Colomb, M.; Duthon, P. Automotive LiDAR performance verification in fog and rain. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018; pp. 1695–1701. [Google Scholar]

- Carballo, A.; Lambert, J.; Monrroy, A.; Wong, D.; Narksri, P.; Kitsukawa, Y.; Takeuchi, E.; Kato, S.; Takeda, K. LIBRE: The Multiple 3D LiDAR Dataset. In Proceedings of the 2020 IEEE Intelligent Vehicles Symposium (IV), Las Vegas, NV, USA, 19 October–13 November 2020; pp. 1094–1101. [Google Scholar]

- Li, Y.; Duthon, P.; Colomb, M.; Ibanez-Guzman, J. What Happens for a ToF LiDAR in Fog? IEEE Trans. Intell. Transp. Syst. 2021, 22, 6670–6681. [Google Scholar] [CrossRef]

- Kutila, M.; Pyykönen, P.; Ritter, W.; Sawade, O.; Schäufele, B. Automotive LIDAR sensor development scenarios for harsh weather conditions. In Proceedings of the 2016 IEEE 19th International Conference on Intelligent Transportation Systems (ITSC), Rio de Janeiro, Brazil, 1–4 November 2016; pp. 265–270. [Google Scholar]

- Jokela, M.; Kutila, M.; Pyykönen, P. Testing and Validation of Automotive Point-Cloud Sensors in Adverse Weather Conditions. Appl. Sci. 2019, 9, 2341. [Google Scholar] [CrossRef]

- Heinzler, R.; Schindler, P.; Seekircher, J.; Ritter, W.; Stork, W. Weather Influence and Classification with Automotive LiDAR Sensors. In Proceedings of the 2019 IEEE Intelligent Vehicles Symposium (IV), Paris, France, 9–12 June 2019; pp. 1527–1534. [Google Scholar]

- Wallace, A.M.; Halimi, A.; Buller, G.S. Full Waveform LiDAR for Adverse Weather Conditions. IEEE Trans. Veh. Technol. 2020, 69, 7064–7077. [Google Scholar] [CrossRef]

- Rasshofer, R.H.; Spies, M.; Spies, H. Influences of weather phenomena on automotive laser radar systems. Adv. Radio Sci. 2011, 9, 49–60. [Google Scholar] [CrossRef]

- Li, D.; Chen, F.; Zeng, N.; Qiu, Z.; He, H.; He, Y.; Ma, H. Study on polarization scattering applied in aerosol recognition in the air. Opt. Express 2019, 27, A581–A595. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Song, W.; Yan, W.; Lai, J.; Li, Z. The effect of smoke spatial distribution on pulse laser echo characteristics. In Proceedings of the 6th International Conference on Optical and Photonic Engineering, Shanghai, China, 8–11 May 2018. [Google Scholar] [CrossRef]

- Yang, M.Y.; Förstner, W. Plane detection in point cloud data. In Proceedings of the CCIE’10: Proceedings of the 2010 International Conference on Computing, Control and Industrial Engineering, Washington, DC, USA, 5–6 June 2010; pp. 95–104. [Google Scholar]

- Goo, J. Study on the real-time size distribution of smoke particles for each fire stage by using a steady-state tube furnace method. Fire Saf. J. 2015, 78, 96–101. [Google Scholar] [CrossRef]

- Xie, Q.; Yuan, H.; Song, L.; Zhang, Y. Experimental studies on time-dependent size distributions of smoke particles of standard test fires. Build. Environ. 2007, 42, 640–646. [Google Scholar] [CrossRef]

| Lidar Sensor Specifications | ||||

| Laser wavelength | 905 nm | Detection distance | 0.5–190 m | |

| Field of view | 70.4° (horizontal) × 77.2° (Vertical) | Angular resolution | 0.05° (horizontal) × 0.05° (Vertical) | |

| Range (100 klx) | 190 m/10% reflectivity 230 m/20% reflectivity 320 m/80% reflectivity | Range(0 klx) | 190 m/10% reflectivity 190 m/20% reflectivity 450 m/80% reflectivity | |

| Random error of ranging | <2 cm | Angle random error | <0.05° | |

| Point Cloud Quantity Loss Ratio and Point Cloud Density Reduction Rate | ||||

| Open state | Closed state | |||

| Smoke concentration/(mg/m3) | Quantity loss ratio | Density reduction rate | Quantity loss ratio | Density reduction rate |

| 0.037 | 10.42% | 9.41% | 25.27% | 32.58% |

| 0.192 | 13.73% | 14.19% | 43.34% | 39.84% |

| 0.312 | 18.39% | 19.39% | 65.99% | 59.93% |

| 0.465 | 34.63% | 26.02% | 88.38% | 73.65% |

| Groups | PolyWorks | Methodology of the Paper | ||||

|---|---|---|---|---|---|---|

| 0.5 s | 1 s | 1.5 s | 2 s | 2.5 s | ||

| a | 118.3783 | 118.2566 | 118.9003 | 118.6666 | 119.1008 | 119.4432 |

| b | 134.9114 | 134.8922 | 134.0945 | 134.7504 | 134.6374 | 134.6551 |

| c | 149.8362 | 149.2635 | 149.4025 | 149.1053 | 149.8284 | 150.5281 |

| d | 157.7589 | 158.3806 | 158.5272 | 157.3154 | 158.8298 | 157.5758 |

| e | 179.3378 | 179.3107 | 178.9945 | 179.4910 | 179.5950 | 179.3081 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Chen, Y.; Qi, J.; Zhou, K.; He, Z.; Jin, L. A Detection Method for Open–Close States of High-Voltage Disconnector in Smoky Environments. Sensors 2025, 25, 1280. https://doi.org/10.3390/s25051280

Wang L, Chen Y, Qi J, Zhou K, He Z, Jin L. A Detection Method for Open–Close States of High-Voltage Disconnector in Smoky Environments. Sensors. 2025; 25(5):1280. https://doi.org/10.3390/s25051280

Chicago/Turabian StyleWang, Lujia, Yifan Chen, Jianghao Qi, Kai Zhou, Zhijie He, and Lei Jin. 2025. "A Detection Method for Open–Close States of High-Voltage Disconnector in Smoky Environments" Sensors 25, no. 5: 1280. https://doi.org/10.3390/s25051280

APA StyleWang, L., Chen, Y., Qi, J., Zhou, K., He, Z., & Jin, L. (2025). A Detection Method for Open–Close States of High-Voltage Disconnector in Smoky Environments. Sensors, 25(5), 1280. https://doi.org/10.3390/s25051280