1. Introduction

Monitoring liquid levels and controlling liquid volumes in tanks is crucial wherever liquids need to be stored and processed in a variety of industries. Liquid level monitoring methods have a wide range of applications, from wastewater treatment plants and the petrochemical industry to food processing plants, from pharmaceutical laboratories and biochemical processing to industrial silos [

1,

2]. Precise measurements not only ensure process efficiency and safety, but also contribute to cost optimization and prevent raw material waste. In this context, the development of measurement technologies plays a key role in enabling precise monitoring and control of liquid levels and quantities in tanks. Based on a review of the literature, it can be observed that most of the research methods on this topic were developed before 2010, but between 2012 and 2017, 44 articles were published, and between 2018 and 2022, up to 74 articles were published in various scientific journals [

3]. This shows that research on liquid-level methods and sensors has increased dramatically over the past five years and is currently a desirable area of research.

Various electronic sensors are used to measure the volume of liquids in tanks by measuring their level of fill. These sensors operate using various physical phenomena, such as magnetostriction, the generation of ultrasonic waves, microwaves and light, changes in electrical capacitance, and changes in hydrostatic pressure. The most commonly used are hydrostatic probes, capacitive and floating level sensors, pressure transducers, optical sensors, microwave radar gauges, and ultrasonic transducers [

4]. These can be sensors mounted inside or outside the tank, immersed or not immersed in the liquid, and floating on its surface. Liquid level sensors are classified in various ways [

3]. Based on the relationship between the user (operator) and the measurement, level sensors can be classified as contact and non-contact measurements. The sensor can also perform continuous or point measurements. Point-level measurement indicates a measurement taken as high or low, empty, or available in relation to switches/circuit breakers and protective alarms, e.g., to prevent leaks. Furthermore, the point measurement does not provide any information on the amount of liquid in the tank. Continuous liquid level measurement, on the other hand, allows the volume to be monitored over time. Level sensors can also be classified as direct—measuring directly, and indirect—measuring liquid parameters and estimating its volume based on these parameters. Various classifications of the most commonly used liquid level sensors are shown in [

3]. The same source also provides a description of how they work.

Liquid level sensors have parameters that vary greatly depending on the manufacturer, mode of operation and intended applications, providing liquid level measurement accuracy 0.1–1.0 mm, measurement resolution 0.012–0.1 mm, and measurement repeatability 0.05–0.3 mm. Internal magnetostrictive floating probes are most commonly used in gas station fuel tanks due to their ability to monitor fuel level simultaneously and continuously, as well as the parameters and vapors remaining in the tank [

5]. This is also particularly justified due to the need for access to the probe, which must be calibrated or replaced if necessary.

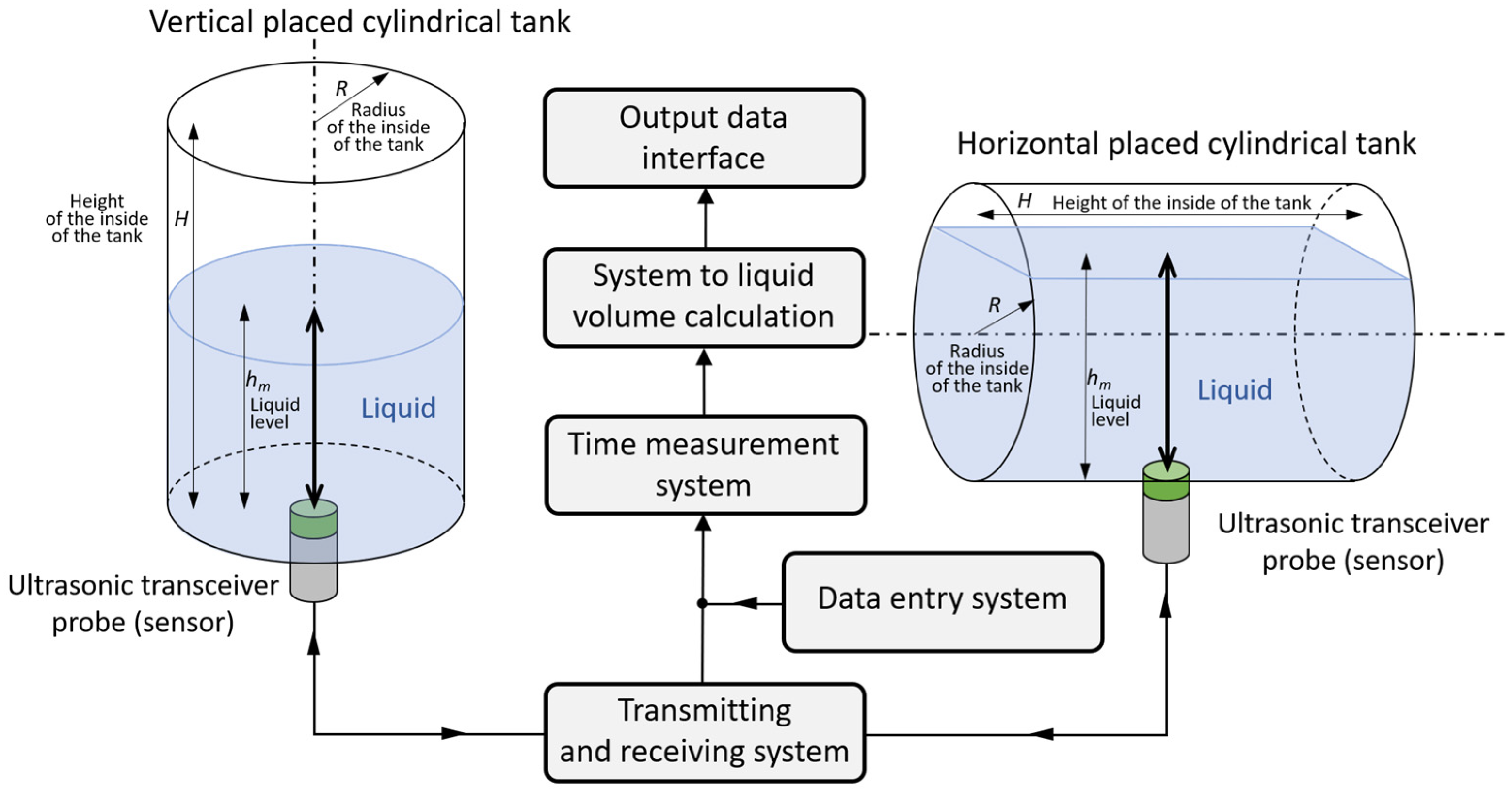

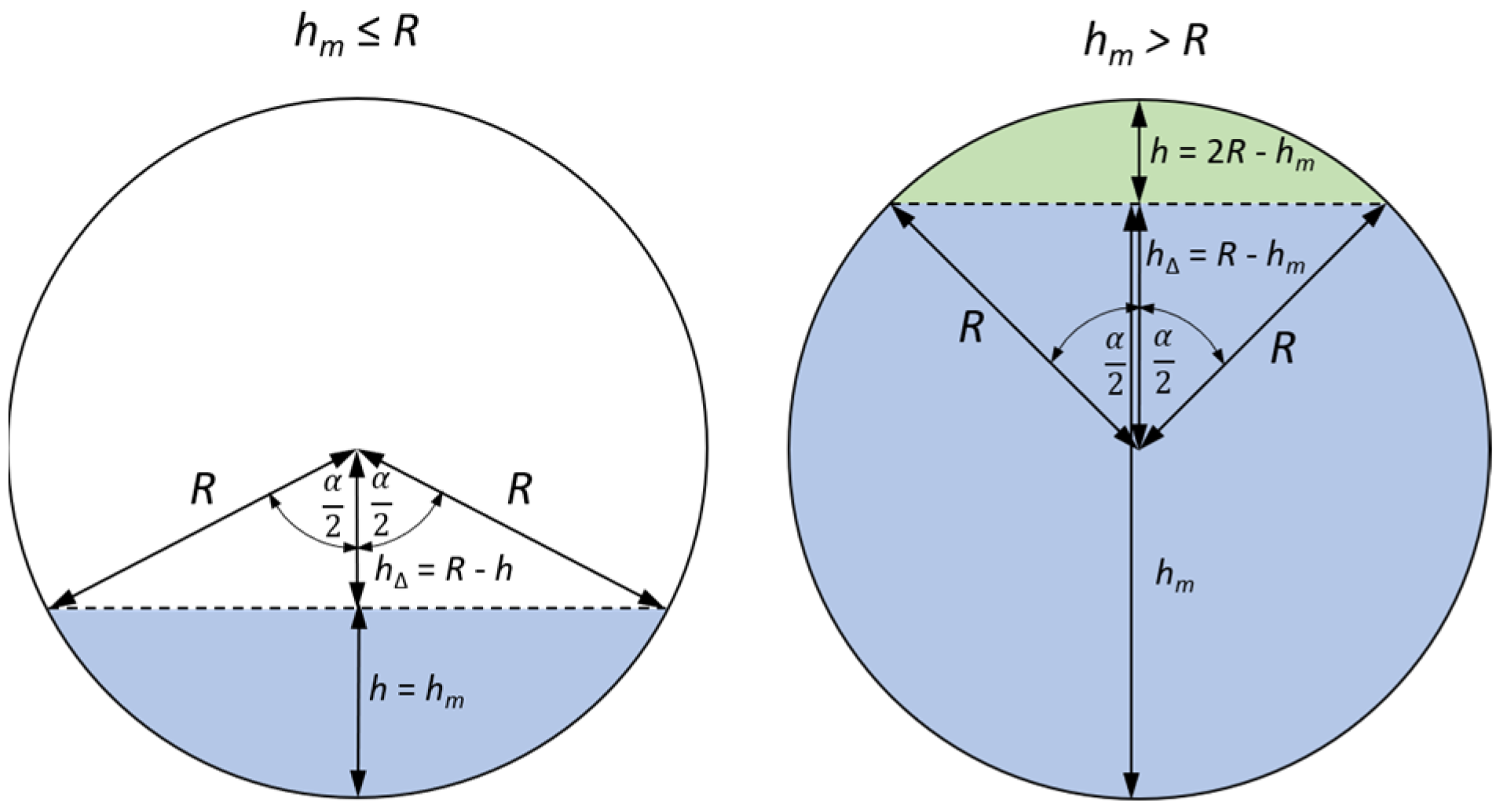

The most significant measurement technique accepted by various researchers is the ultrasonic level sensor [

6], which uses ultrasonic waves to measure liquid levels. The use of ultrasound is very advantageous when measuring the level of liquids, e.g., explosive, flammable, or aggressive, due to the possibility of safely introducing these waves through the wall of the tank from the liquid side, i.e., from the bottom of the tank. In this method, the level and volume of liquid in the tank are measured using a sensor in the form of a piezoelectric transducer. The sensor sends a short sinusoidal pulse of a specific frequency. The pulse reflects off the surface of the liquid and returns to the sensor. The essence of measuring the amount of liquid in the tank is to precisely measure the time between the start of the transmitted and received ultrasonic wave pulses (echoes). The time it takes for the ultrasonic signal to travel from the transmitter to the receiver is defined as the transit time or the time of flight (TOF). Due to energy loss, time shift, and frequency dispersion during propagation, the actual received ultrasonic pulse will always exhibit waveform changes and noise interference, making it challenging to achieve satisfactory accuracy using traditional methods. In addition, many factors influence the accuracy and errors of the measurement, including the operating frequency and size of the sensor, which determine the length and shape of the pulse. Therefore, the accurate determination of ultrasonic TOF is a key technique in ultrasonic applications [

7], particularly in measuring the level of fill of liquid tanks. For example, for a large horizontal cylindrical fuel tank with a capacity of 120 m

3 (radius

R = 1.5 m, height or length

H = 16.98 m) [

8], when filled halfway and with a liquid level measurement error in the tank of only Δ

hm = ±1 mm, the liquid volume measurement error can be estimated as Δ

Vl ≈ ±51 dm

3. For the same vertically positioned tank, the error in measuring the volume of liquid does not depend on the filling of the tank and is Δ

Vl ≈ ±7 dm

3.

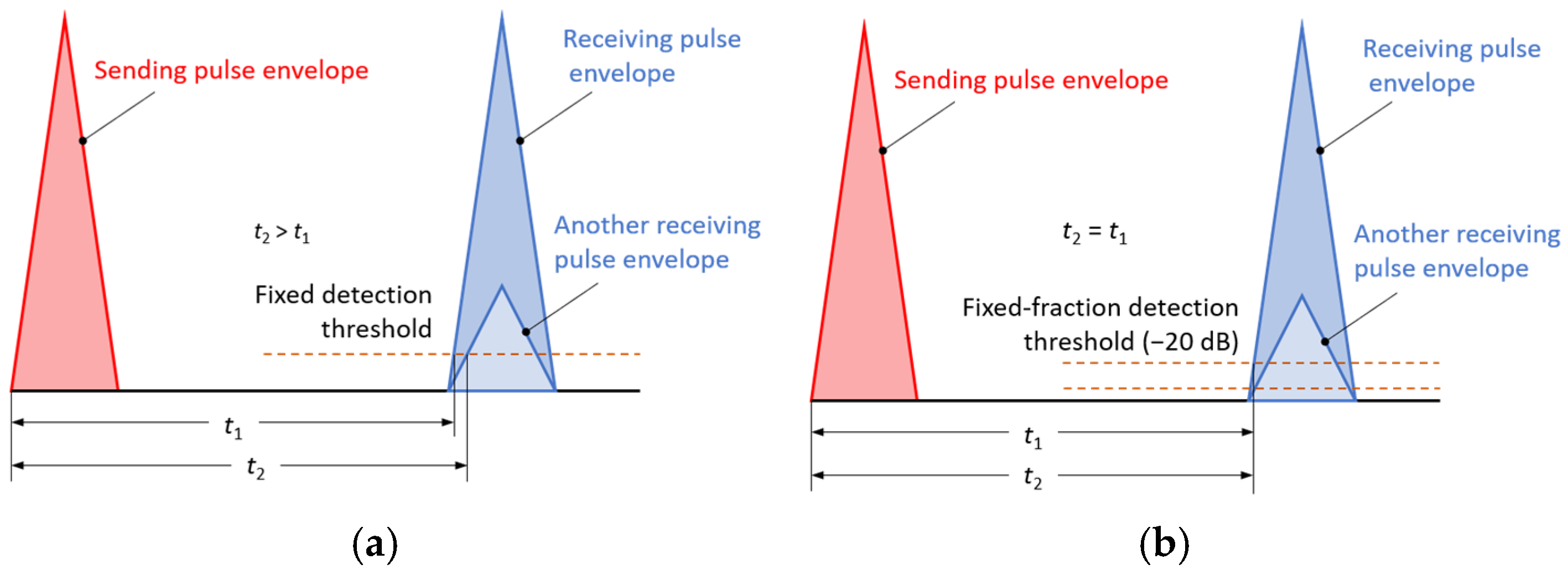

The basic ultrasonic method used to measure liquid levels in tanks is the threshold detection method, which is also used in radar systems and identifies the received signal when the echo amplitude exceeds a set threshold level [

7,

9] or reaches its maximum value (peak method). Many improved threshold methods have also been developed, such as the double threshold method [

10], the dynamic threshold method [

11], and the variable coefficient threshold method [

12]. Although threshold methods are the simplest, they are also the most susceptible to interference caused by noise and changes in the shape of the detected pulse.

Another category of TOF measurement methods includes correlation methods [

13], which were first used in radar technology. Later, more advanced correlation methods were proposed and applied in TOF measurements, such as frequency modulation-based cross-correlation [

14], phase correlation method [

15], and cross-correlation with sine wave matching techniques [

16]. Although correlation methods are less susceptible to interference, their accuracy is limited by the sampling frequency and requires real-time reference signal updates according to different application conditions, causing deviations in TOF detection.

The third category includes the most accurate but also the most complex methods of TOF estimation based on parameter estimation using an accurate ultrasonic echo model [

17,

18] and efficient and accurate optimization algorithms [

19,

20,

21]. In these methods, a reasonable empirical model of the ultrasonic signal is first selected, and then efficient algorithms are used to fit the received ultrasonic signal to obtain the transit time. These methods ensure not only high measurement accuracy, but also strong resistance to interference [

22]. Nevertheless, they require extensive calculations and costly digital signal processing, which significantly degrades their real-time performance. Furthermore, the convergence results of these methods are highly dependent on good initialization, and the echo model used for fitting must be updated under different application conditions, which negatively affects real-time performance.

The methods of estimating the energy distribution in the ultrasonic signal can be used to calculate the TOF of ultrasonic pulses, instead of threshold methods. Such methods allow for the separation of different types of waves from the acoustic signal too and are used in geophysics to detect seismic waves generated by earthquakes. These signals contain P-waves and S-waves. P-waves are faster compression waves that arrive first, whereas S-waves are slower shear waves that arrive later and are often more destructive. A review, testing, and evaluation of the precision of such methods as applied to arrival time detection for downhole microseismic data can be found in [

23]. These methods can be classified as single-level window-based methods, which require the window size and location to be specified in order to compute the data, e.g., energy ratio (ER) methods, single-level non-window-based methods (e.g., Akaike information criterion), multi-level methods (from multiple sensors or multiple locations) or matrix-based methods (e.g., cross-correlation-based approaches) and hybrid methods combining several single-level methods (e.g., Akazawa method) [

23].

There are also many hybrid algorithms in the literature that combine information from different individual algorithms to obtain more accurate and precise TOF measurements [

24,

25,

26,

27,

28,

29,

30,

31,

32,

33].

A review of the literature on many different measurement methods confirms the view that no single algorithm is optimal for all conditions, and the accurate determination of TOF remains a challenge. It depends on the specific application (device, implementation, computational complexity, measurement signal parameters). Therefore, understanding the parameters and limitations of these algorithms can help improve data processing results. Similarly, knowing the speed of any algorithm is important, especially if the goal is to perform real-time data analysis to provide up-to-date feedback during measurements. Based on the review of various algorithms above, it was found that the information criteria used in statistics for model selection can be used to precisely determine the pulse transit time in this method. The most popular information criteria are the Akaike Information Criterion (AIC) and the Bayesian Schwartz Criterion (BIC) [

34]. These criteria are considered the most reliable tests of the type and structure of the model and are simple to calculate. They can be adapted for automatic detection of the start of the receiving pulse, which may allow independence from the pulse parameters. The AIC algorithm has been tested to detect the onset of pulses in in vivo breast imaging using ultrasound transmission tomography (UTT) [

35,

36]. However, TOF measurements using the Akaike method proved to be insufficiently accurate due to the phenomenon of ultrasound beam refraction in this application [

37]. This phenomenon causes small-amplitude disturbances before the actual start of the pulse. However, such interference does not occur when measuring the level of a quasi-homogeneous liquid in a tank. The liquid has a large surface area, the reflection coefficient at the boundary is high, and the attenuation of ultrasound in the liquid is low; therefore, the pulse energy and the signal-to-noise ratio (SNR) are high. The rise time of the pulse reflected from the liquid surface is short and undisturbed. In addition, unlike seismic signals, for example, the signal reflected from the liquid surface is uncomplicated and consists only of single, short pulses reflected multiple times from the liquid surface. The detection of the first echo is easy in this case.

Therefore, it can be assumed that the AIC method can be useful for measuring liquid levels in embedded systems operating in real time and that it can be more accurate and versatile in various measurement conditions than threshold methods, which was the aim of this research.

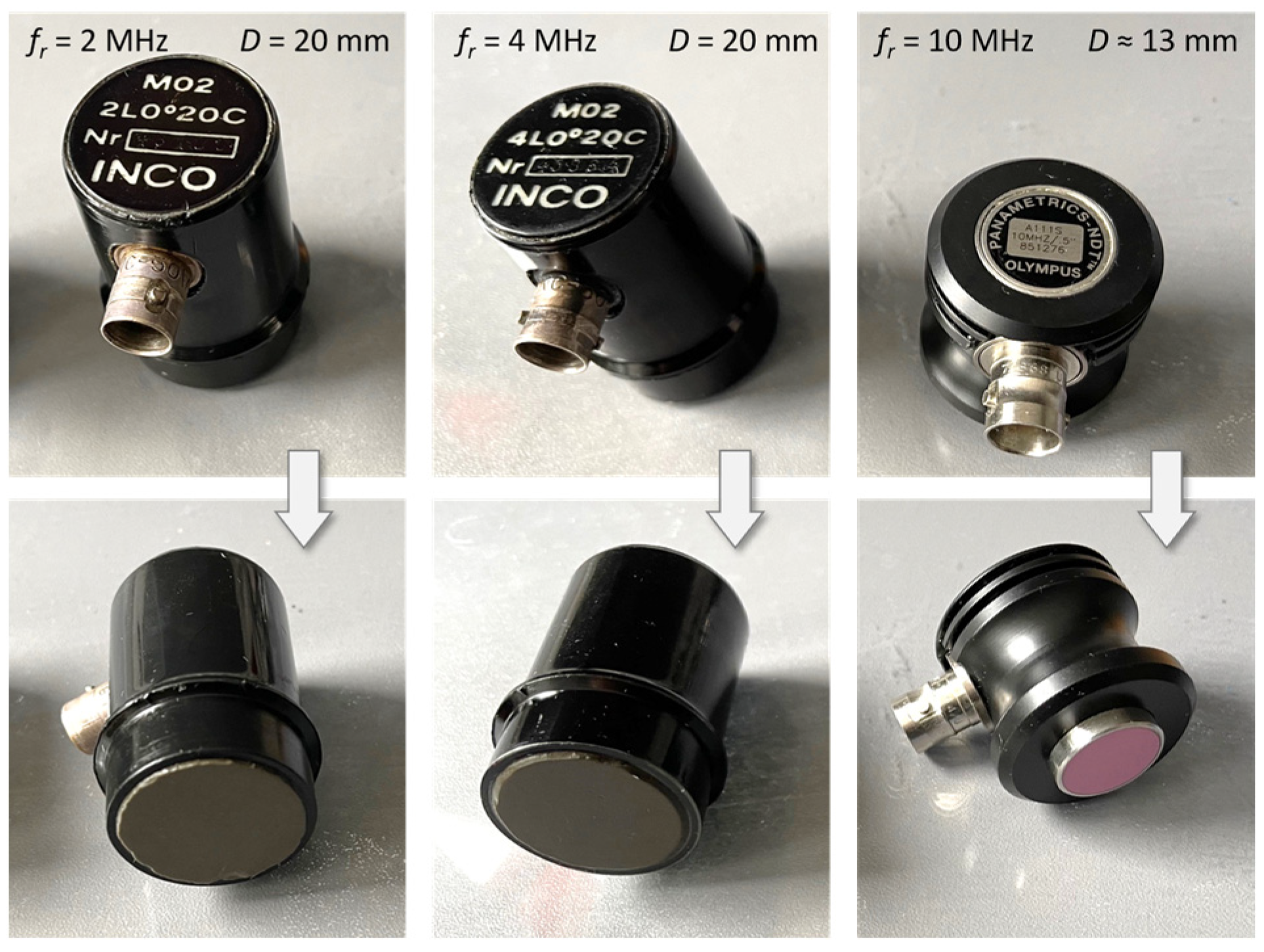

In this paper, the authors tested several ultrasonic piezoelectric transducers with different operating frequencies, which generate different pulses in measurements of the liquid level in a cylindrical tank. It is usually important to choose the right ultrasonic sensor and operating frequency for accurate measurement. It is known that too low a frequency when measuring time based on a fixed pulse amplitude threshold causes large errors. On the other hand, too high a frequency worsens pulse detection, which is more attenuated and reduces SNR. It will be interesting to see whether automatic measurement using the AIC method, which is little known in such applications, will enable accurate liquid level measurements to be taken in a more universal way. In this paper, ultrasonic test measurements were performed for a cylindrical tank filled with water and extraction gasoline. A horizontally placed tank was selected because of the more difficult method of measuring and converting the liquid level in the tank to its occupied volume. This allowed for a comparison of the AIC method with the most commonly used threshold method and for an estimation of the accuracy of level and liquid volume measurements in the tank using these methods in relation to the parameters of several selected ultrasonic sensors. This is a novelty compared to other studies in the field of TOF detection. The results of the measurements and calculations showed that the AIC method is less sensitive to interference and changes in the shape of ultrasonic pulses reflected from the surface of the liquid and allows for automatic determination of the volume of liquid in the tank with better accuracy than the threshold method. It has also been demonstrated that the computational complexity of the AIC algorithm is low and is suitable for real-time embedded systems for liquid level measurement.

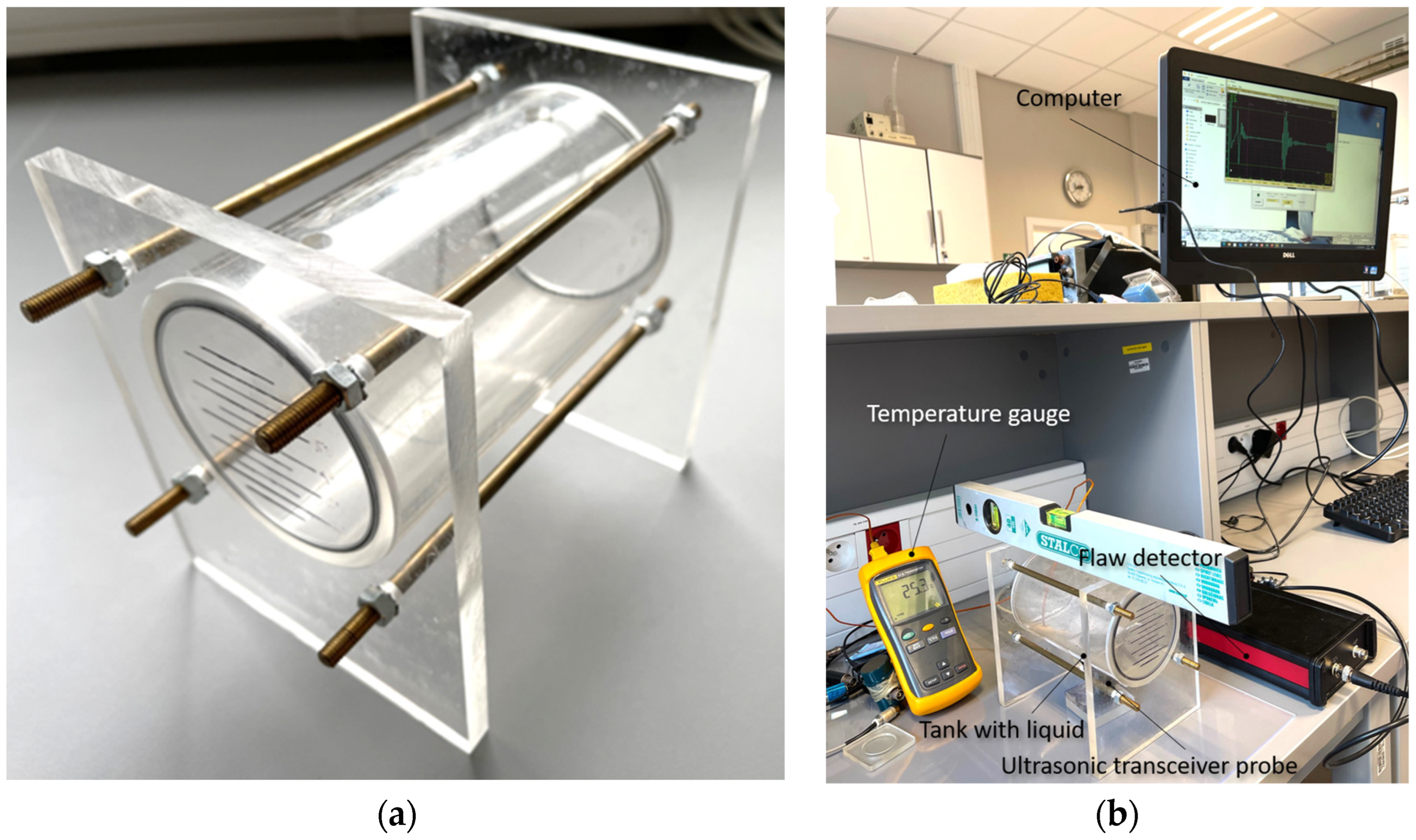

3. Measurements and Calculations

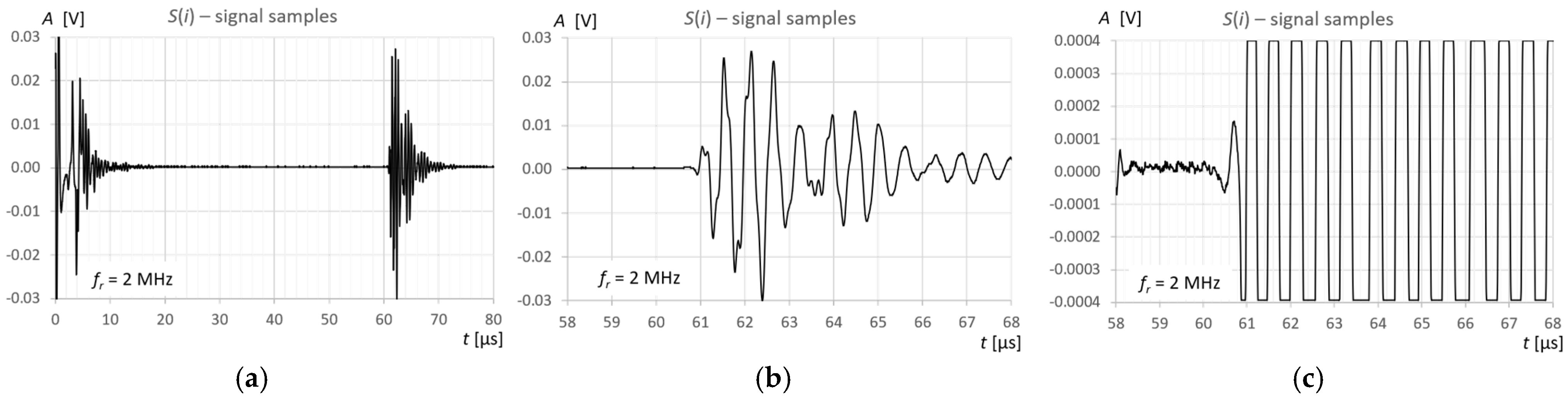

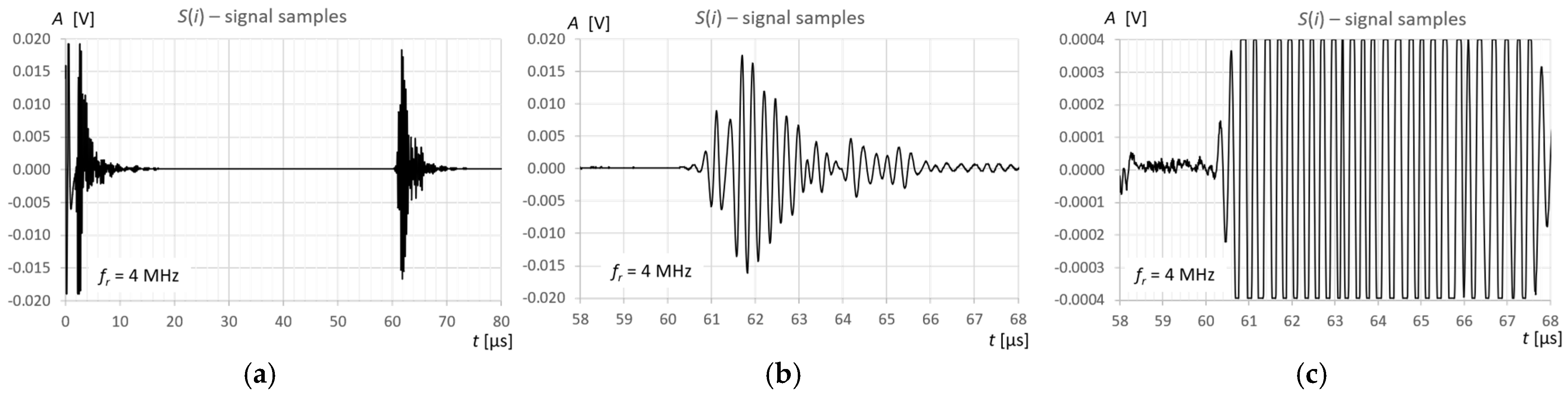

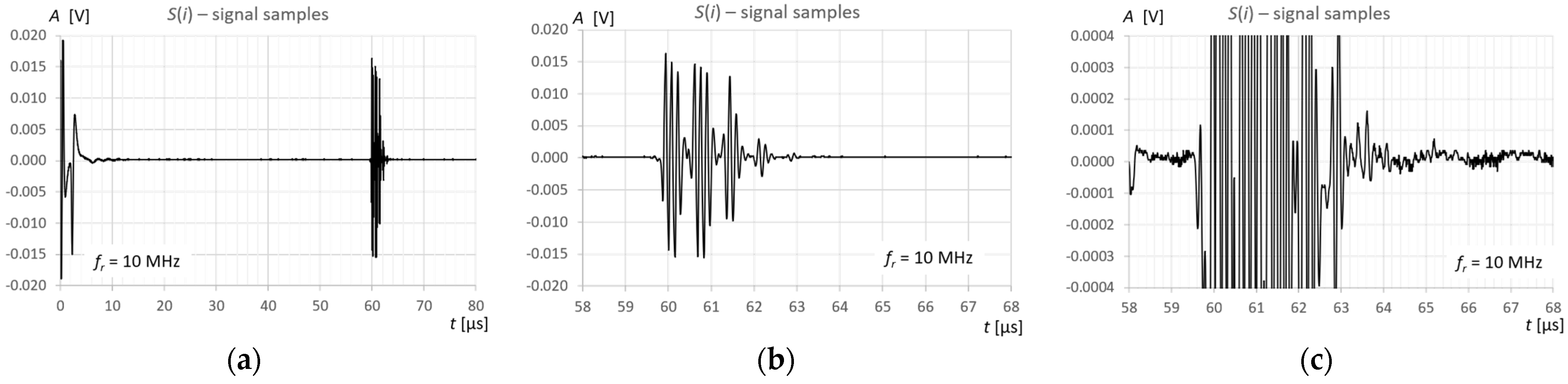

Measurements and calculations for six fill levels in a horizontally placed tank (

Figure 2) were performed using the prototype ultrasonic flaw detector described in

Section 2.1, configured with three different ultrasonic sensors (

Figure 3). Ultrasonic pulses reflected from the surface of the liquid in the tank were recorded each time in three different measurement time windows: long—covering the transmitted pulse and the pulse reflected from the surface of the liquid (view window), measuring—covering only the reflected pulse, zoomed—covering the reflected pulse in amplitude magnification.

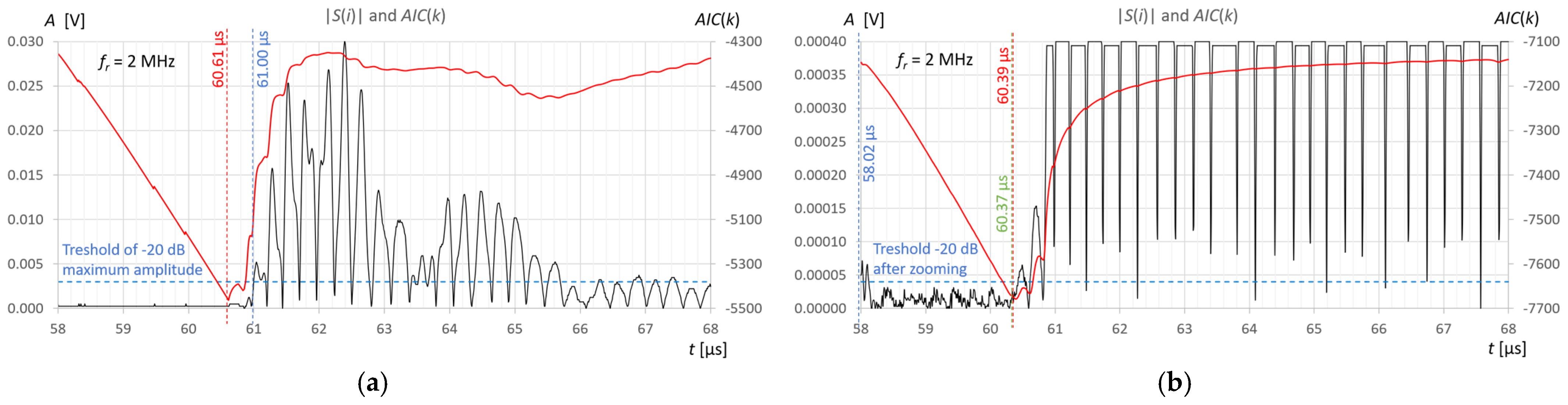

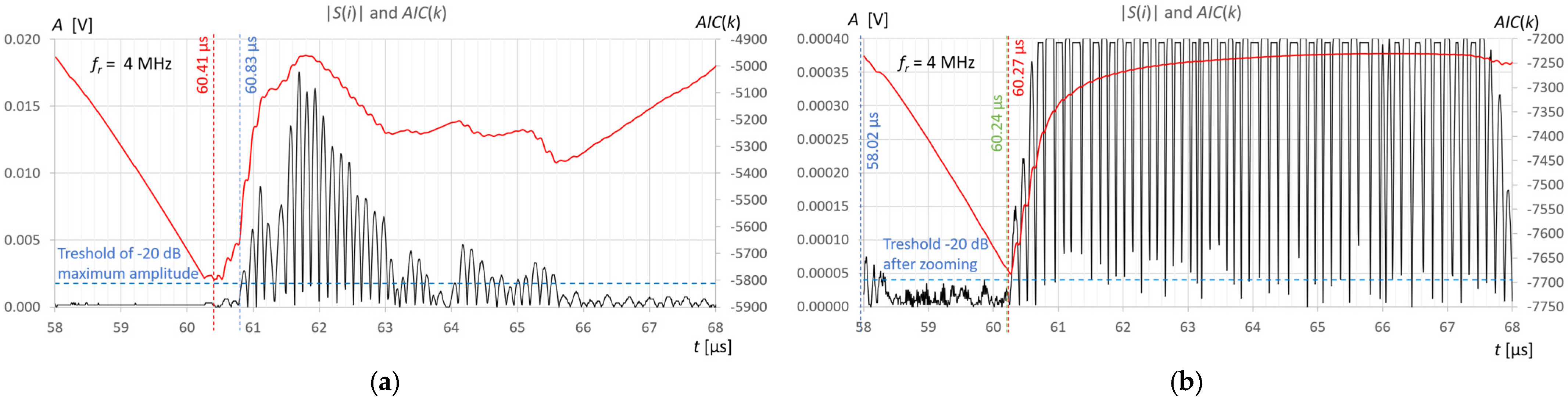

Figure 6,

Figure 7 and

Figure 8 show an example recording of such pulses from water level measurements in the tank (approximately 45 mm from the bottom, which in this case corresponds to a

VREF = 410 mL reference volume) for the three ultrasonic sensors. In the measurement window and in the zoomed window, automatic measurements of the transit time were made using the fixed-fractional threshold method with the amplitude threshold set at 10% (−20 dB) of the maximum amplitude of the pulse reflected from the liquid surface in a given window (

Section 2.4) and the AIC method (

Section 2.5). Furthermore, in the zoomed window, subjective visual recognition of the beginning of the pulse was performed, ignoring any possible interference, and the first zero-crossing [

26] for this pulse was searched for.

Figure 9,

Figure 10 and

Figure 11 show example results of pulse start detection in water for the three ultrasonic sensors. This pulse is also shown in

Figure 6b,c,

Figure 7b,c and

Figure 8b,c.

The ultrasonic pulse return times obtained in this way, reflected on the liquid surface, were converted into the volume of liquid in the tank using the algorithm described in

Section 2.3 and compared with the reference volume values

VREF in

Table 2 for water and in

Table 3 for extraction gasoline.

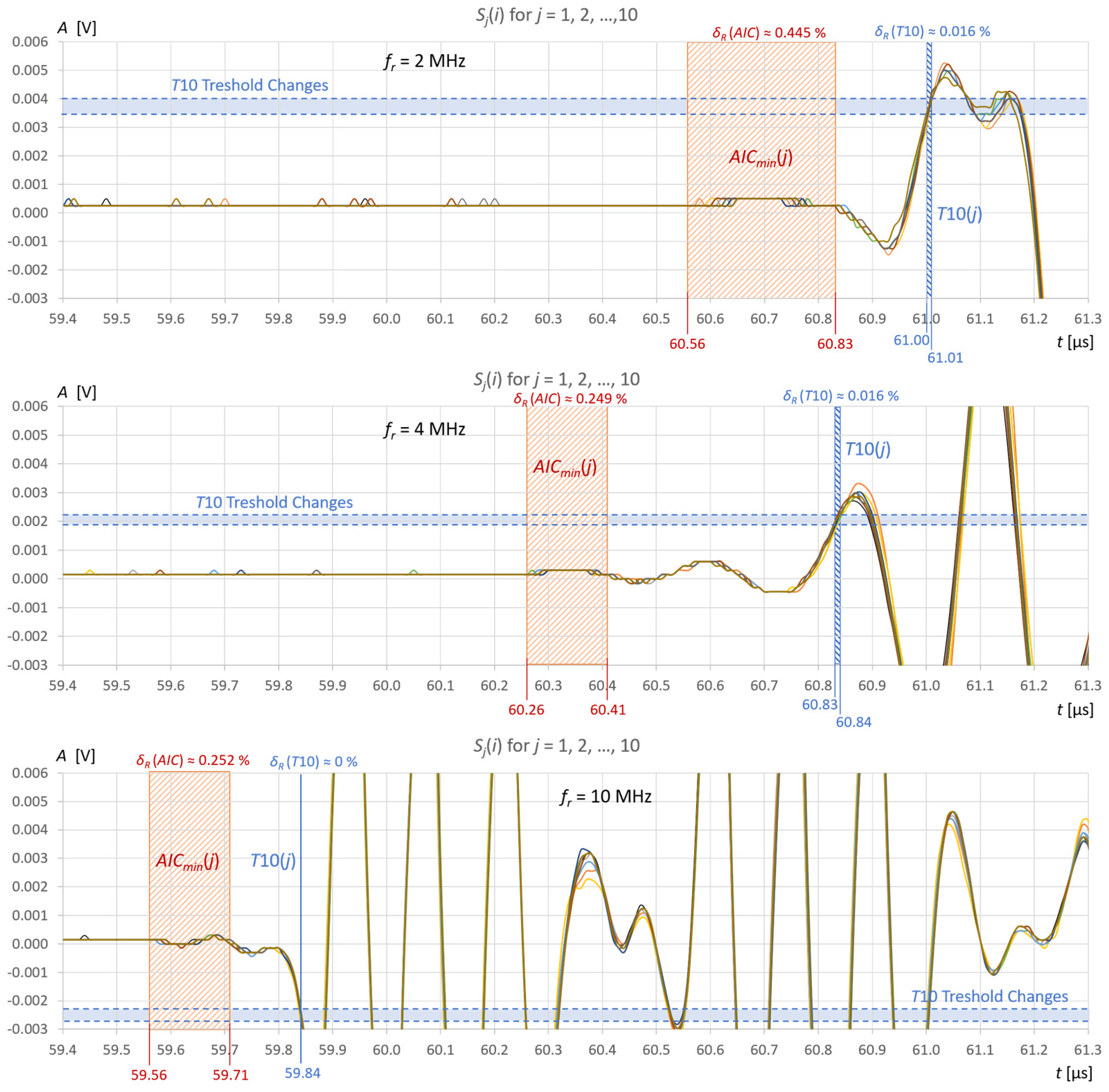

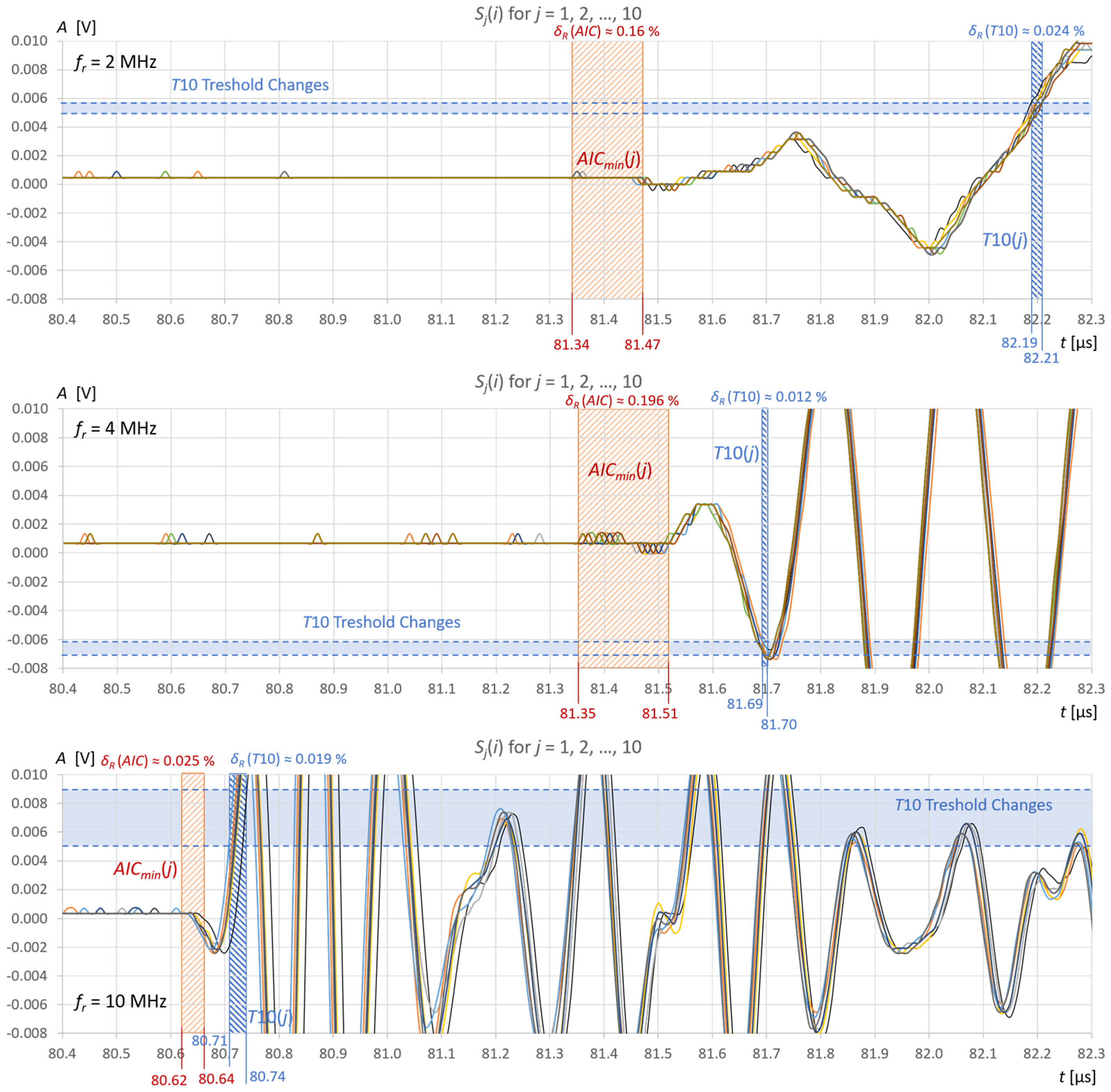

The stability of liquid level detection in the tank under steady measurement conditions was also verified using the AIC method and the fixed-fractional threshold method with a 10% amplitude threshold (T10).

Figure 12 and

Figure 13 show common graphs of

j = 10 recordings of ultrasonic pulses reflected from the surface of the water (

Figure 12) and the extraction gasoline in the tank (

Figure 13) for three ultrasonic sensors.

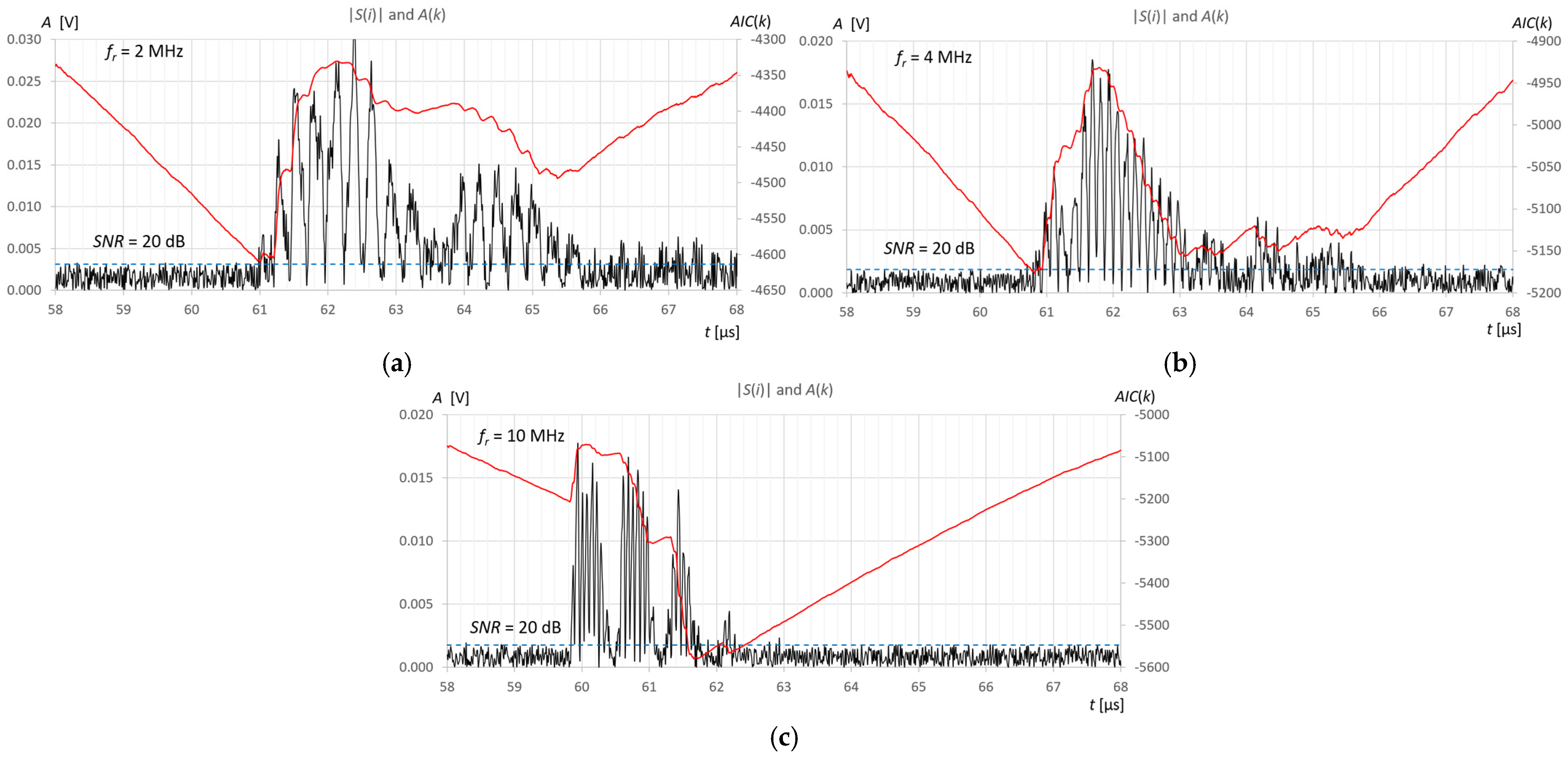

In order to examine the performance of the AIC and TC10 methods in a noisy signal, artificially generated white noise with an amplitude allowing an SNR range of 5 dB to 60 dB with a step of 5 dB was added to the recorded measurement signals.

Figure 14 shows an example of pulses reflected from the surface of 415 mL of water in a tank for three ultrasonic sensors and an SNR level value of 20 dB.

4. Results

By analyzing the results of the measurements and calculations obtained, it can be concluded that the

AIC(

k) function allows a clear minimum to be obtained at the actual start of the ultrasonic pulse in an automatic and universal manner, regardless of the frequency of the measuring sensor. As can be seen in

Figure 9b and

Figure 11b in the zoomed window, the result of the AIC measurement (red) almost coincides with subjective recognition of the pulse start (green); the differences of approximately 20–30 ns correspond to approximately two to three times the distance between the samples at the applied signal sampling frequency

fs = 100 MHz. The disturbances visible in the zoomed window do not affect the measurement result using the AIC method. In the case of the fixed-fractional threshold method with a 10% threshold set in relation to the upper limit of the zoomed amplitude window (

A ≈ 0.0004 V), each interference pulse with an amplitude exceeding this threshold significantly distorts the measurement of the start time of the ultrasonic pulse (see

Figure 9b and

Figure 10b).

However, for automatic measurements, it is easiest to use a standard measurement window that covers the pulse reflected from the liquid surface (

Figure 9a,

Figure 10a and

Figure 11a). The algorithm to set such a time window is simple. It usually involves finding the maximum signal amplitude after the sending pulse (detection of the measured pulse) and setting a window with a fixed number of signal samples before and after the sample with the maximum amplitude. The number of window samples is selected depending on the length of the measured pulse in such a way that signal samples are available for the measurement pulse part, along with a certain number of samples before its start. As can be seen in

Figure 9a,

Figure 10a and

Figure 11a in the standard measurement window, the result of the AIC measurement (red) differs from the subjective recognition of the start of the pulse (green color in

Figure 9b,

Figure 10b and

Figure 11b) by approximately 200 ns, which corresponds to a twenty-fold distance between samples at the applied signal sampling frequency. The measurement error is still small and amounts to approximately +0.33% in relation to the measured time value. When using the threshold method in a standard window with a 10% threshold set in relation to the maximum pulse amplitude (blue color in

Figure 9a,

Figure 10a and

Figure 11a), the algorithm jumps forward by several half-pulse periods, and the T10 measurement result differs from the value of subjective recognition of the pulse start (green in

Figure 9b,

Figure 10b and

Figure 11b) by approximately 300–1600 ns, depending on the frequency of the probe used and the pulse shape. The fixed-fractional threshold method is sensitive to pulse rise time, unlike the AIC method.

In the subjective method of determining the start of the pulse by detecting the first zero-crossing (green color in

Figure 9b,

Figure 10b and

Figure 11b), the difficulty lies in correctly recognizing the first half-cycle of the pulse, which may be hidden in noise and interference.

In

Figure 9a and

Figure 10a, it is clearly visible, for example, that the measured pulse is elongated due to multiple reflections in the 2-millimeter wall of the tank. However, it does not affect the error in detecting the start of the pulse.

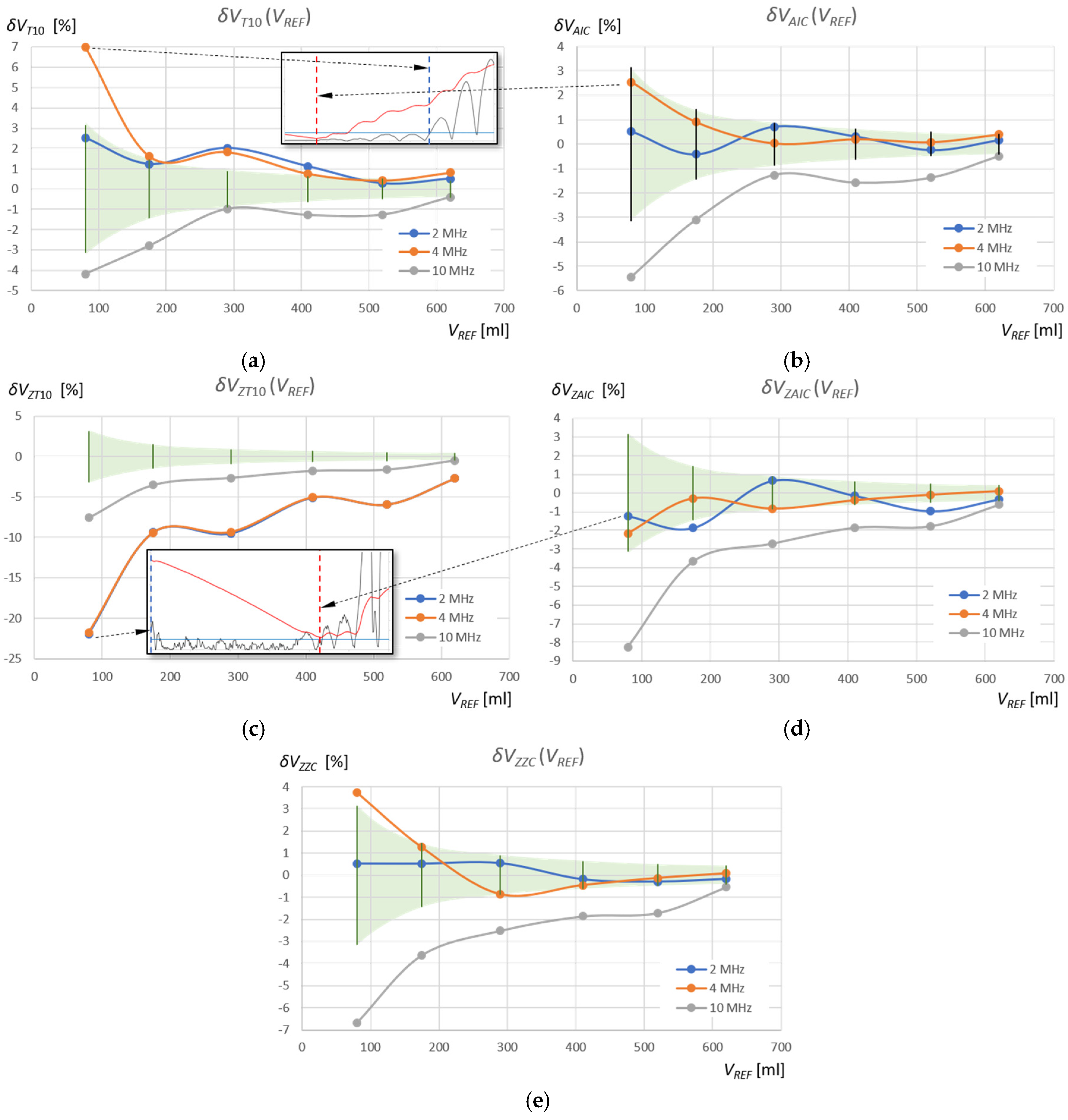

From the point of view of measuring the volume of the liquid in a tank, it is important to know how these ultrasonic liquid level measurements translate into the accuracy of the volume measurement. This problem was analyzed by calculating the relative percentage errors in the measurement of the liquid volume in relation to the reference measurements of the filling volume tank (

VREF) using laboratory vessels (

Table 2 and

Table 3) that allow the measurement of a fixed liquid volume with an accuracy of 5 mL (i.e., Δ

VREF = ±2.5 mL):

where the index “

WM” (Window Method) denotes the detection method used in a given measurement window, that is, “T10” and “AIC” in the standard measurement window, and “ZT10,” “ZAIC,” and “ZZC” in the zoomed window (see

Table 2 and

Table 3). The results of these calculations for the measurements of the volume of water and the volume of the extraction gasoline are shown in

Figure 15 and

Figure 16, respectively. Additionally, the figures show the relative percentage error of the reference volume measurement for the measured

VREF values (green area), calculated using the following equation:

The relative percentage errors in measuring the volume of water in the tank using the AIC method in the standard measurement window (

) fall within the reference volume measurement error range (

) for ultrasonic sensors with frequencies of 2 MHz and 4 MHz (

Figure 15b), as in the case of the subjective ZZC measurement method in the zoomed window (

) (

Figure 15e), where only 1 measurement for

fr = 4 MHz and

V = 80 mL is slightly above this range. For the T10 threshold method in the same window ((

) and for the same frequencies, there are often significant deviations of several pulse periods (

Figure 15a), which is further highlighted by the magnification of the pulse start for the 4 MHz sensor in the measurement of water volume

VREF = 80 mL. As can be seen, these errors are caused by a shift in the detection of the pulse start time as a result of a slow pulse rise time and initial pulse amplitudes below the detection threshold. Therefore, the water volume values measured using the T10 method for frequencies of 2 MHz and 4 MHz are overestimated. The AIC method detects the start of the pulse much more accurately by detecting its very small rise amplitude. In the zoomed measurement window, the errors

are within the reference volume measurement error range

for most measurement points and frequencies of 2 MHz and 4 MHz (

Figure 15d). However, in this case, the amplitude of the pulse start is at the level of quantization noise, which affects minor detection errors (see the first and the second rows in

Figure 12).

In turn, the threshold method in the zoomed measurement window ZT10 for frequencies of 2 MHz and 4 MHz shows significant deviations from the error field

(

Figure 15c), which is further illustrated by the enlargement of the pulse start for the 2 MHz sensor and the water volume measurement

VREF = 80 mL. In this case, disturbances appearing at the beginning of the zoomed measurement window are detected above the threshold. Therefore, the values of the measured water volume using the ZT10 method for frequencies of 2 MHz and 4 MHz are significantly underestimated.

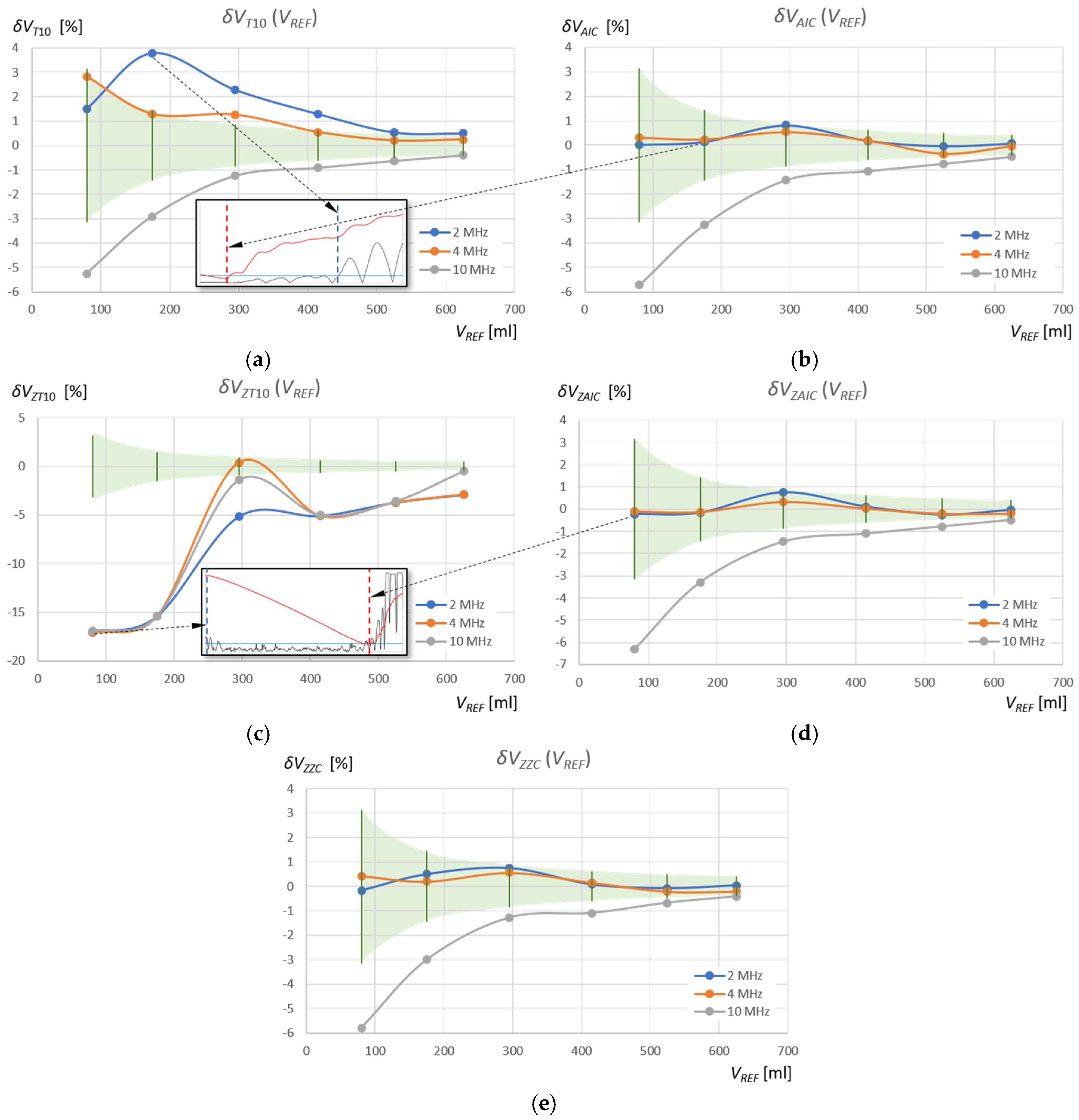

The relative percentage errors in measuring the volume of extraction gasoline in a tank using the AIC method in a standard measurement window (

) oscillate around zero reference volume measurement error (

) for ultrasonic sensors with frequencies of 2 MHz and 4 MHz (

Figure 16b), as in the case of the subjective ZZC measurement method ((

) in the zoomed window (

Figure 16e). For the T10 threshold method in the same window ((

) and for the same frequencies, there are often significant deviations of several pulse periods (

Figure 16a), which as in the case of water, is additionally shown in the form of an enlargement of the pulse start for a sensor with a frequency of 2 MHz in the measurement of gasoline volume

VREF = 175 mL. These errors are caused by a shift in the detection of the pulse start time as a result of the slow pulse rise time and the amplitudes of the initial pulse periods lying below the detection threshold, as in the case of water. Therefore, the values of the measured volume of extraction gasoline using the T10 method for frequencies of 2 MHz and 4 MHz are overestimated.

In the case of extraction gasoline, the AIC method very accurately detects the start of the pulse by detection of its very small rise amplitude. In the zoomed window, the errors

for frequencies of 2 MHz and 4 MHz are equally small and almost the same as the errors

in the standard measurement window (compare

Figure 16b,d), due to the short rise time of pulses in extraction gasoline. In turn, the threshold method in the zoomed window ZT10 for frequencies of 2 MHz and 4 MHz shows significant deviations from the error field

(

Figure 16c), similar to water, which is additionally highlighted in the form of an enlargement of the pulse start for the 4 MHz sensor in the measurement of the extraction gasoline volume

VREF = 80 mL. In this case, too, disturbances appearing at the beginning of the zoomed window are detected above the threshold, and the values of the measured gasoline volume using the ZT10 method for frequencies of 2 MHz and 4 MHz are significantly underestimated.

It is interesting to note that for a sensor with a frequency of 10 MHz, the percentage volume measurement errors for water and gasoline show a very similar dependence on

VREF, with the exception of the ZT10 method, where the previously discussed errors of detecting random disturbances before the measurement pulse occur (see

Figure 15 and

Figure 16). The start of the pulse for the 10 MHz frequency is detected very early, which decreases the measured liquid volumes. However, this is the result of a constant systematic error, as can be clearly seen in

Figure 12 and

Figure 13. The 10 MHz ultrasonic transducer designed for non-destructive material testing is equipped with a fairly thick protective and distancing layer of material with a significantly higher ultrasonic propagation speed than in the tested liquids (

Figure 3). This layer accelerates the ultrasonic wave pulse as it passes from the surface of the piezoelectric transducer to the liquid level and back. Multiple reflections in this layer can be seen in the pulse in

Figure 11a. Additionally, a thin layer of gel was used to mechanically couple the active surface of the flat probe with the outer surface of the tank wall. If we introduce a correction of +0.7 μs for all pulse return time measurements for a frequency of 10 MHz in water, and +1.0 μs in extraction gasoline, the error values for different methods and measurement windows from

Figure 15 and

Figure 16 will decrease significantly (see

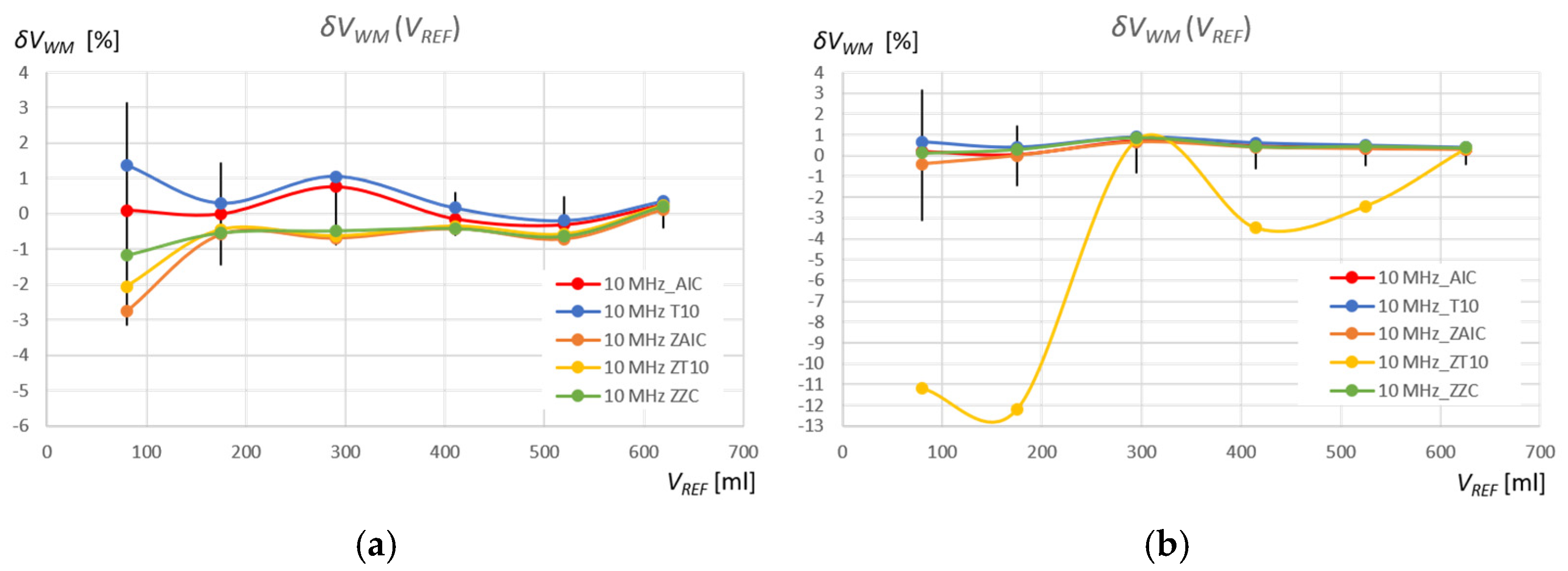

Figure 17), indicating that the best of the tested measurement methods for measuring the volume of liquid in a tank is the AIC method in the standard measurement window for a frequency of 10 MHz (red curve).

Figure 18 shows the relative percentage errors in the measurement of the volume of water in the tank relative to the reference measurements of the tank fill volume

VREF (Equation (12)) depending on the SNR of the measurement signal (see

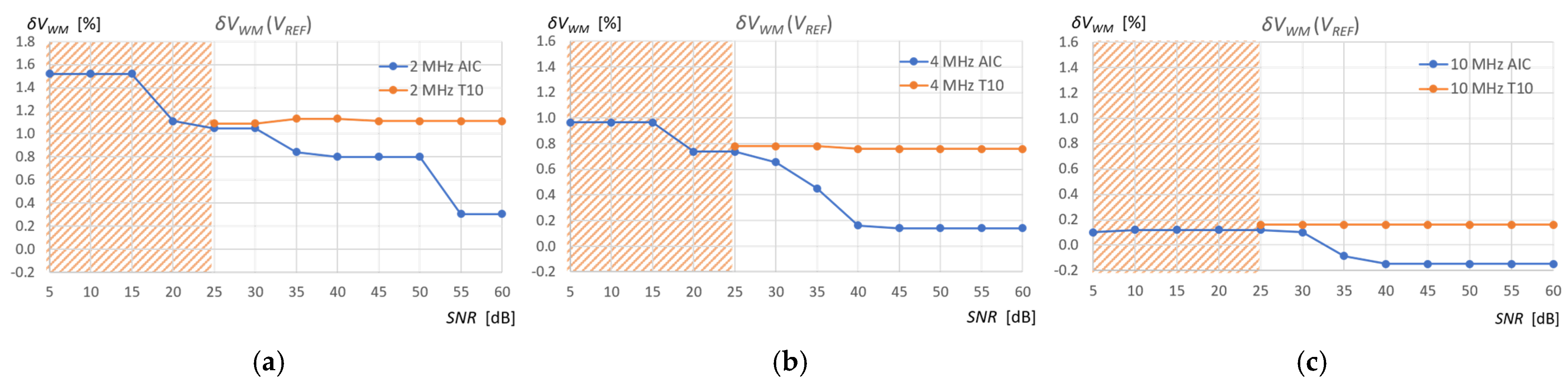

Figure 15), for two detection methods (AIC and T10) used in the standard measurement window, and for three ultrasonic sensors (2, 4, 10 MHz), applied the corrections described above for the 10 MHz sensor. The relationships between these errors are similar in the case of the extraction gasoline measurements.

5. Discussion

Based on the research conducted in this study, it can be concluded that the use of the AIC method to determine the return time of an ultrasonic pulse reflected from the surface of a liquid in a tank allows its volume to be determined with an accuracy of fractions of a percent. This method is not a threshold method and is based on statistical analysis of signal changes over time. The accuracy obtained in ultrasonic measurements using the AIC method is better than that obtained using the commonly used fixed-fraction amplitude threshold method.

The AIC method is universal and does not show a significant dependence on the applied ultrasonic wave frequency, unlike the threshold method. In the threshold method, the detected pulse start time is always increased due to the need to detect the first half of the absolute amplitude value of the first half-cycle of the pulse exceeding the set threshold above noise and interference. This always results in a liquid volume measurement that is greater than the actual volume. Therefore, the threshold method is sensitive to the shape of the pulse and depends on the value of the set percentage threshold. The longer the pulse rise time, the greater the errors in pulse start detection (delays). In the case of interference with an amplitude exceeding the set detection threshold and occurring before the measured pulse, the threshold method shows variable systematic errors of up to several percent, which in turn decrease the liquid volume by several percent.

Multiple reflections of the ultrasonic pulse in the tank wall (

Figure 9a and

Figure 10a) or in the protective layer of the sensor (

Figure 11a) prolong the recorded receiving pulse and introduce signal envelope modulation. This can cause the global minimum of the

AIC(

k) function to shift significantly towards longer TOF, determining the start of the next reflection (

Figure 11a). To avoid such errors, the measurement window should be shortened to one pulse period after the maximum detected signal.

In the case of measurements of the volume of extraction gasoline in the tank, more accurate results were obtained than in the case of measurements of the volume of water (see

Figure 15 and

Figure 16). This is due to the propagation speed of the ultrasonic wave in the extraction gasoline, which is approximately 0.75 times lower than the speed of the ultrasonic wave in water. Measurement errors of larger echo return times in gasoline will therefore be smaller in relation to the shift in the detection of the pulse start by a fixed time (AIC) or a fixed part of its half-periods (TF10).

The repeatability of water level measurements in the tank using the AIC method is 0.202 mm for the 2 MHz sensor and 0.112 mm for the 4 MHz and 10 MHz sensors (

Figure 12). Similar measurement accuracy values can be expected, but they cannot be precisely determined because in this study no reference method for measuring liquid levels was used. For the threshold method, the repeatability of the measurements is much better, but the variable systematic error associated with the amplitude threshold ranges is approximately +0.24 μs to +0.53 μs, which translates into a water level measurement error of approximately +0.15 mm for the 10 MHz sensor, +0.38 mm for a 4 MHz sensor, and +0.55 mm for a 2 MHz sensor (

Figure 12). The repeatability of the extraction gasoline level measurements in the tank using the AIC method is 0.730 mm for the 2 MHz sensor, 0.090 mm for the 4 MHz sensor, and 0.011 mm for the 10 MHz sensor (

Figure 13). For the threshold method, the repeatability of the measurements in the extraction gasoline is significantly better than AIC, but as with the water level measurements, there is a systematic error associated with the amplitude threshold, which is approximately 0.10–0.80 μs, which translates into a level measurement error of approximately +0.05 mm for a 10 MHz sensor +0.15 mm for a 4 MHz sensor, and +0.45 mm for a 2 MHz sensor (

Figure 13). The instability of liquid level detection in the tank is mainly due to the influence of liquid surface vibrations (

Figure 12 and

Figure 13). It can be minimized by averaging several to several dozen recorded signals before measuring the level. This will allow for an additional improvement in measurement accuracy.

Analysis of the performance of the AIC method at different levels of SNR shows greater accuracy and noise immunity compared to the T10 method for the three ultrasonic sensors (

Figure 18). Higher frequencies improve the accuracy of both methods, but T10 always overestimates the measured pulse start time values due to the amplitude threshold. The overestimated values measured by the T10 method are independent of the SNR level up to a value slightly above the set amplitude threshold level (in this case, approximately 25 dB), that is, for a given frequency, there is a constant measurement error (

Figure 18). Values measured using the T10 method above SNR ≥ 25 dB are random time values that range from the beginning of the measurement window to the beginning of the pulse (see

Figure 14), regardless of frequency. This is the result of time measurements for noise samples exceeding the amplitude threshold (orange hatched area in

Figure 18). The AIC method performs correct measurements even for very low SNR = 5 dB levels, but the error increases as the SNR decreases. The AIC method shows a weak dependence on the SNR level in the narrow range of 55 to 60 dB for a frequency of 2 MHz, in the range of 40 to 60 dB for 4 MHz, and in the wide range of approximately 5 to 60 dB for 10 MHz. It should be noted that when measuring liquid levels in tanks, the SNR is usually high (more than 40 dB) due to low ultrasonic attenuation, the large surface area of the ultrasonic transducers, and the ultrasonic wave reflection coefficient at the liquid/gas interface being close to 100%.

The computational complexity of the AIC algorithm increases with the length of the signal window to be analyzed. Therefore, a relatively short measurement window should first be defined. This can be done automatically by simple amplitude detection, i.e., by searching for the first absolute maximum of the signal appearing after the transmitted pulse. The measurement window can then be set in terms of the number of samples before and after this maximum, which will ensure that the window covers the samples before and after the start of the measurement pulse. In the case of ultrasonic level measurements of quasi-homogeneous liquids, no echoes or multi-echoes may appear between the transmitted pulse and the pulse reflected from the liquid surface, provided that the repetition frequency of the generated pulses is sufficiently low. The number of mathematical operations required in the AIC algorithm (Equation (7)) for a signal length (measurement window) equal to N is: 2 × N for logarithm, 4 × N for division, N × N + 2 × N for multiplication, 3 × N × N for summation/subtraction. Logarithmic calculations can be accelerated by tabulating logarithm values, if the measurement system has a suitable memory chip. A simple analysis was performed to assess the applicability of the AIC algorithm to measure liquid levels in real-time embedded systems. Calculating the value of the AIC(k) function for N = 1000 signal samples requires approximately 5 million basic operations. A small processor in the form of a 16-bit microcontroller performs 10 MIPS (Million Instructions Per Second), which means calculating the AIC(k) function twice per second. Smaller ARM (Advanced RISC Machine) processors used in mobile devices and embedded systems have a computing power of around 0.5 GFLOPS (Giga Floating-Point Operations Per Second), which means calculating the AIC(k) function 100 times per second. The use of Raspberry Pi 5 SBCs (Small Single-Board Computers) with a computing power of 5 GFLOPS would enable the calculation of the AIC(k) function 1000 times per second.

6. Conclusions

The AIC method is an excellent method for TOF detection in ultrasonic volume measurements in cylindrical tanks. Most false detections occur only between the start of the ultrasonic signal and the first positive zero crossing (

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13). The AIC method provides more accurate results than the commonly used fixed-fractional amplitude threshold method. The development of a more accurate reference method for the direct measurement of liquid volume in a tank could demonstrate even a lower susceptibility of the AIC method to measurement errors in liquid volume using the AIC method. Note that the measurement results are also affected by the accuracy of the ultrasonic wave propagation speed in the liquid used to convert time measurements into distance, which was not considered here.

No influence of the pulse frequency, pulse shape, and above all its rise time was found on the results of pulse start detection using the AIC method.

The AIC method is not sensitive to interference and is capable of detecting the start of a pulse even in noise (

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 18). It should be noted that when measuring liquid levels in tanks, the SNR is usually high (more than 40 dB) due to low ultrasonic attenuation, the large surface area of the ultrasonic transducers, and the ultrasonic wave reflection coefficient at the liquid/gas interface being close to 100%.

The most accurate liquid volume measurements using the AIC method were obtained for the ultrasonic sensor with the highest frequency (fr = 10 MHz); however, due to the additional protective layer on the surface of the transducer, it was necessary to calibrate the measurements by adding a constant time correction value (delay) for the passage of ultrasound through this layer. Such calibration is necessary for every ultrasonic sensor, also due to its design. In these studies, no correlation was found between the results of liquid volume measurements and the diameter of the ultrasonic sensor, but the studies were not strictly conducted in this direction. It should be remembered that the energy and amplitude of the ultrasonic pulse generated in the liquid are higher the larger the active (vibrating) surface area of the piezoelectric transducer. For small diameters and large tanks, the reflected pulse may have a low amplitude, which will not allow an accurate detection of its onset hidden in the noise. In addition, the small diameter and low frequency of the sensor increase the beam divergence angle, and the ultrasonic energy reflected from the liquid surface and returned to the sensor is scattered beyond the sensor surface. Therefore, the selection of an ultrasonic sensor should be carefully carried out, depending on the measurement conditions. Recall that attenuation in a liquid increases with frequency.

The AIC method requires a priori information about the time interval containing the measurement pulse reflected from the liquid surface. Since the SNR level is high in such an application, it is sufficient to search for the maximum signal after the transmission pulse and determine the measurement window on this basis. Since the AIC algorithm selects the arrival time based on the global minimum value for the data window, it should be used in small time intervals that contain a large number of signal samples before the start of the pulse reflected from the liquid surface and a small number of samples after its peak.

The computational complexity of the AIC algorithm has been assessed to be low and it is suitable for real-time liquid level measurement. Information about TOF is carried here by the ultrasonic signal in the current measurement rather than signals in two consecutive measurements. Therefore, the performance of the AIC method is not limited by the waveform similarity between two measurements. The advantages of the AIC method are the high accuracy, versatility, elimination of complex calculations, the ease of implementation, and the suitability for embedded systems.