Optimizing 3D Laser Scanning Parameters for Early-Stage Defect Detectability in Subgrade Condition Monitoring

Abstract

1. Introduction

2. Methodology

2.1. Three-Dimensional Laser Scanning Technology

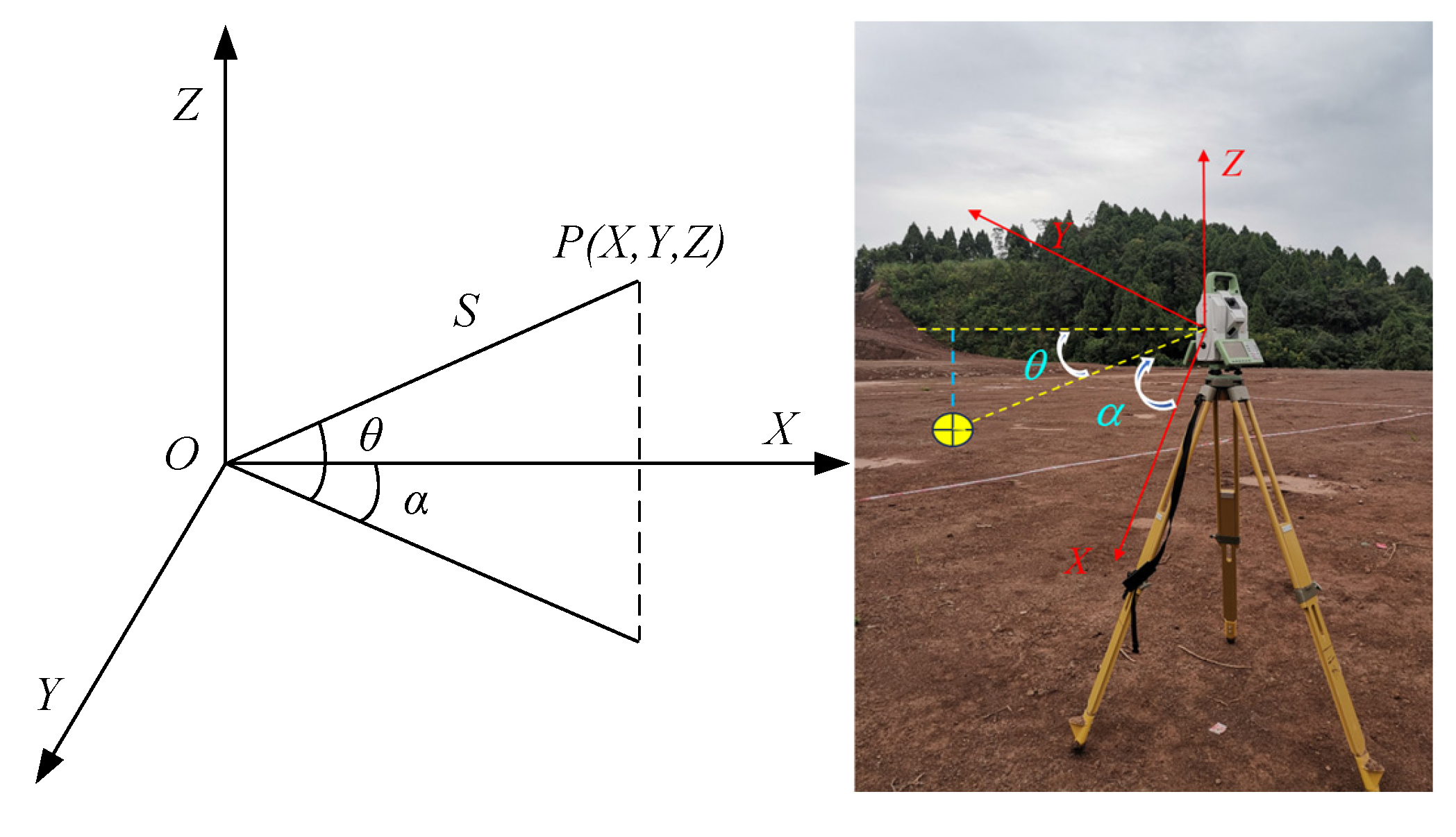

2.1.1. Point Cloud Coordinate Acquisition

2.1.2. Factors Affecting Scanning Accuracy

- (1)

- Point cloud density

- (2)

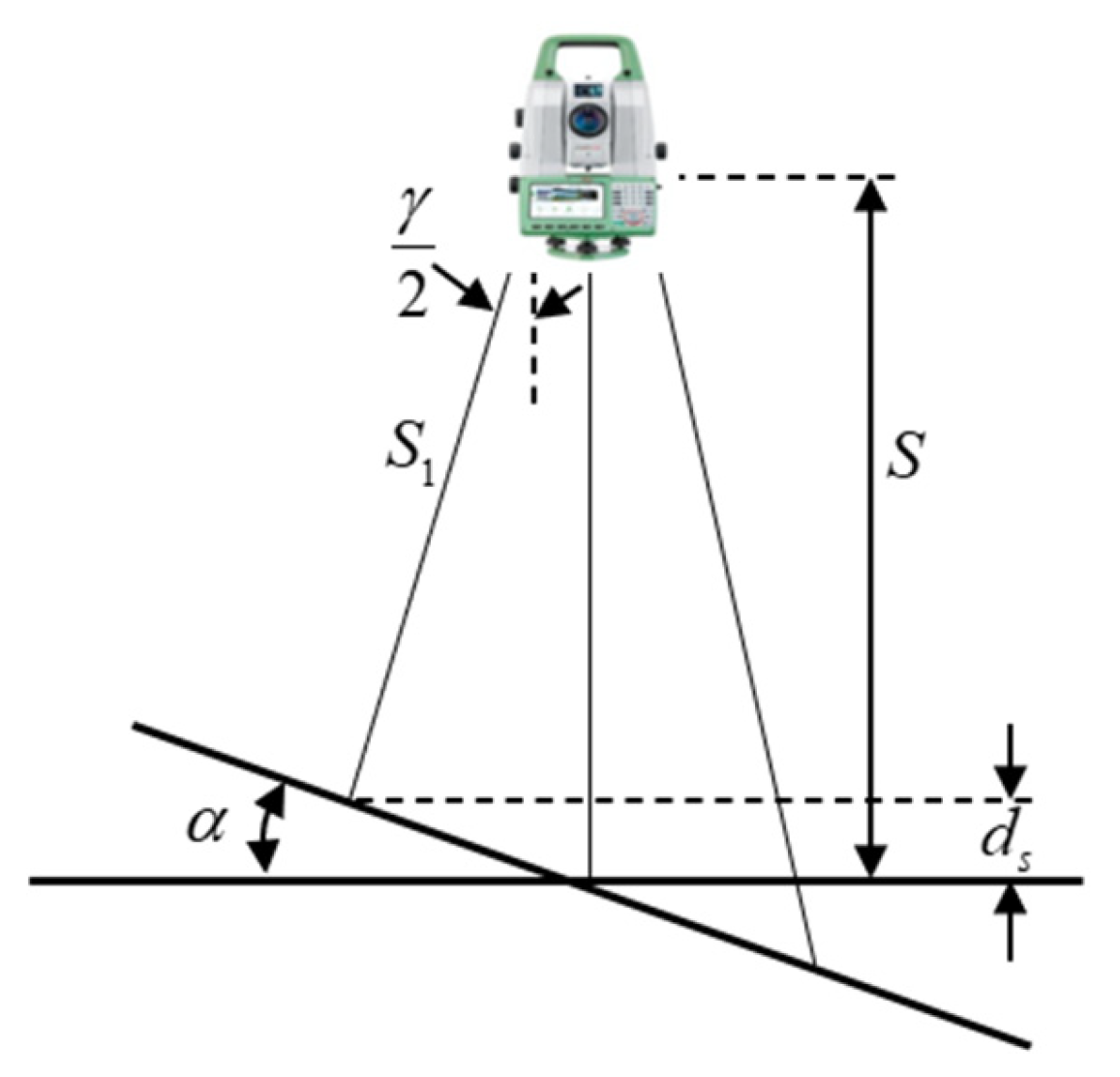

- Reflective surface tilt

- (3)

- Target surface roughness

- (4)

- Incidence angle

- (5)

- Soil Type

- (6)

- Moisture Content

- (7)

- Lighting Conditions

- (8)

- Atmospheric Effects

2.2. Experimental Procedures

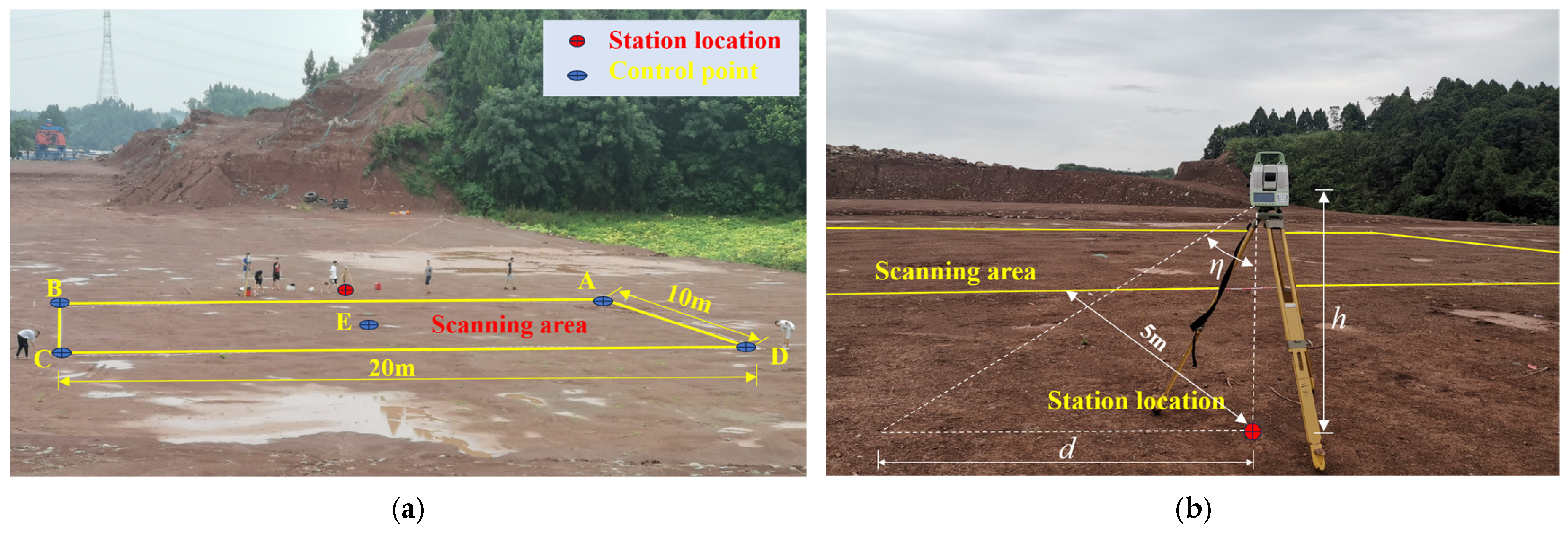

2.2.1. Testing Site

2.2.2. Instruments

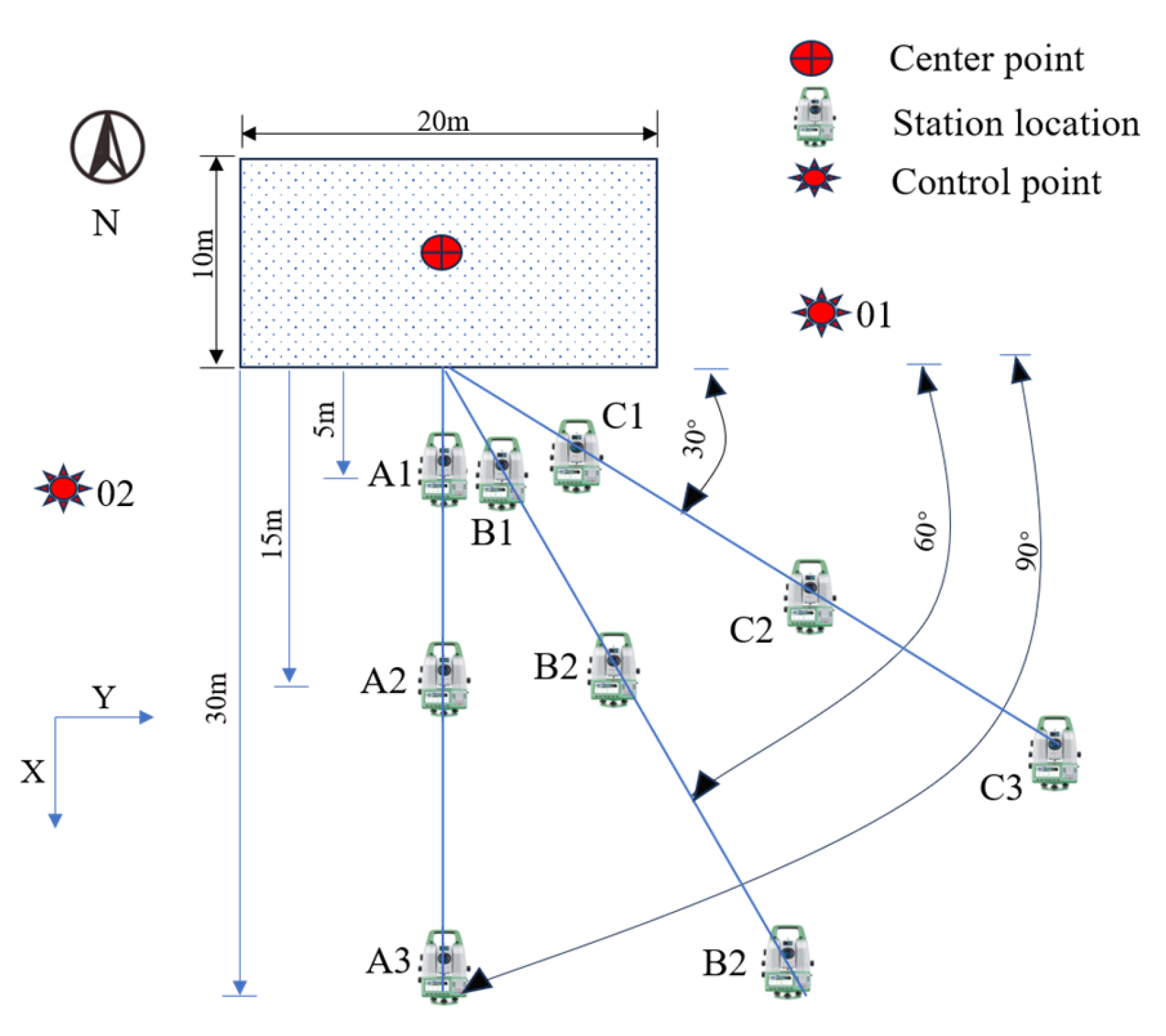

2.2.3. Test Procedure

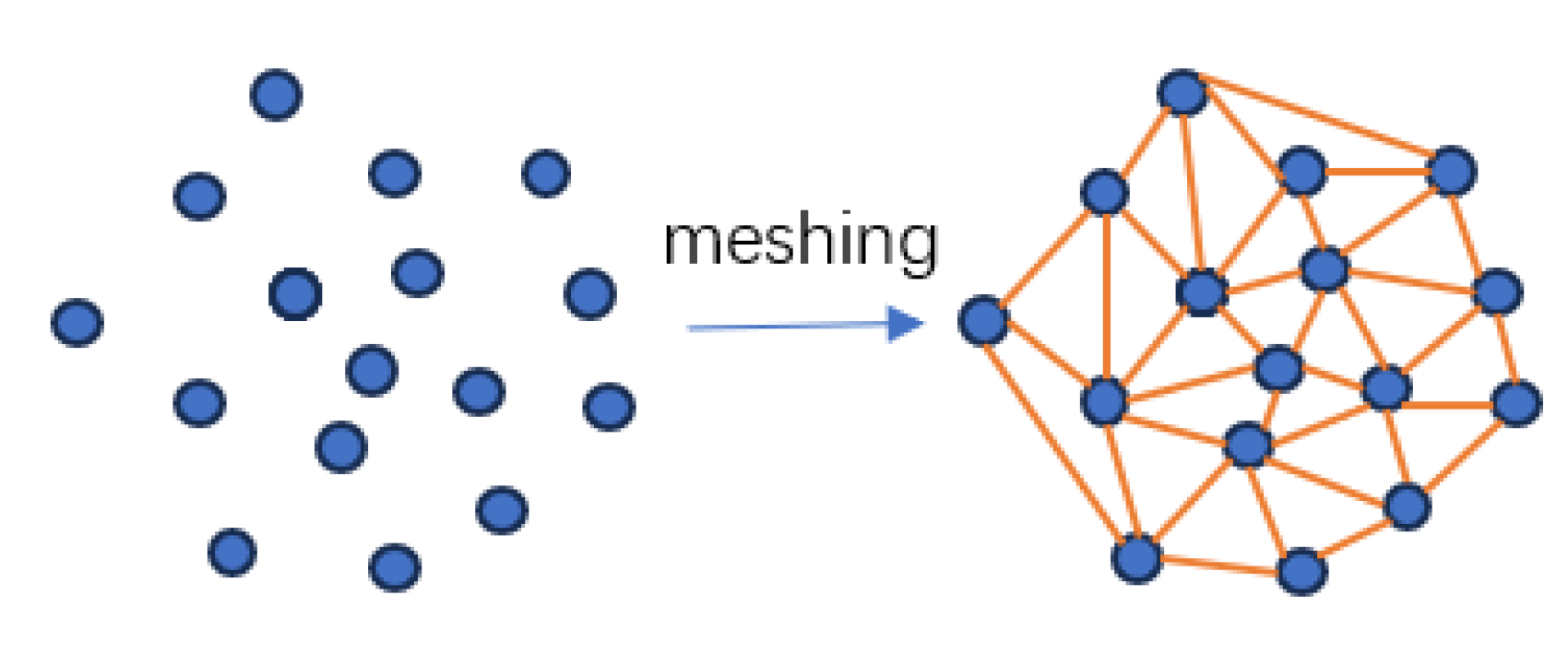

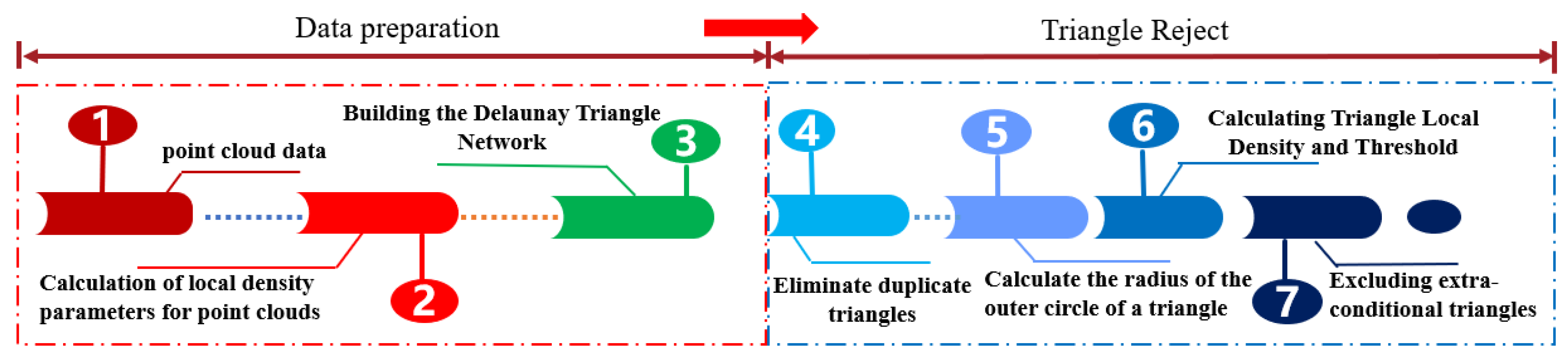

2.3. Model Reconstruction Methods

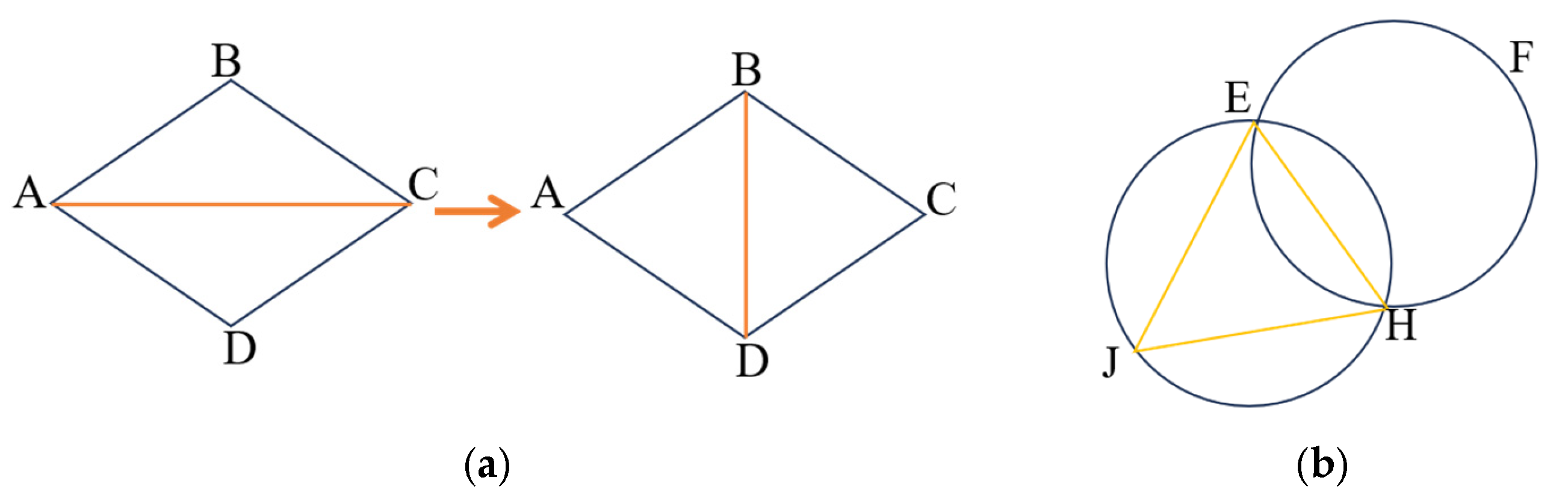

2.3.1. Delaunay Triangulation Principle

2.3.2. Delaunay Triangulation Algorithm

3. Results and Discussion

3.1. Scanning Data Results and Discussion

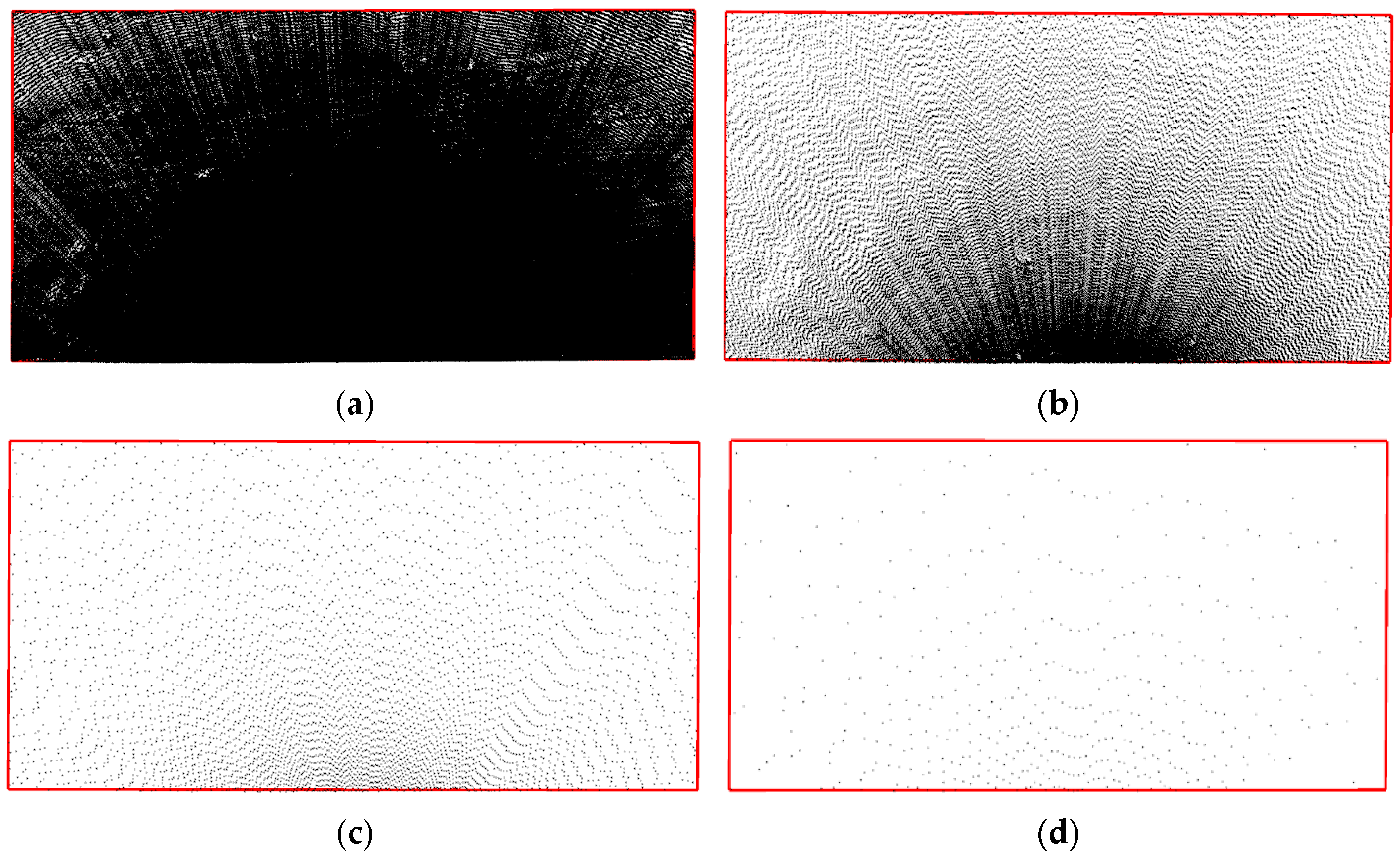

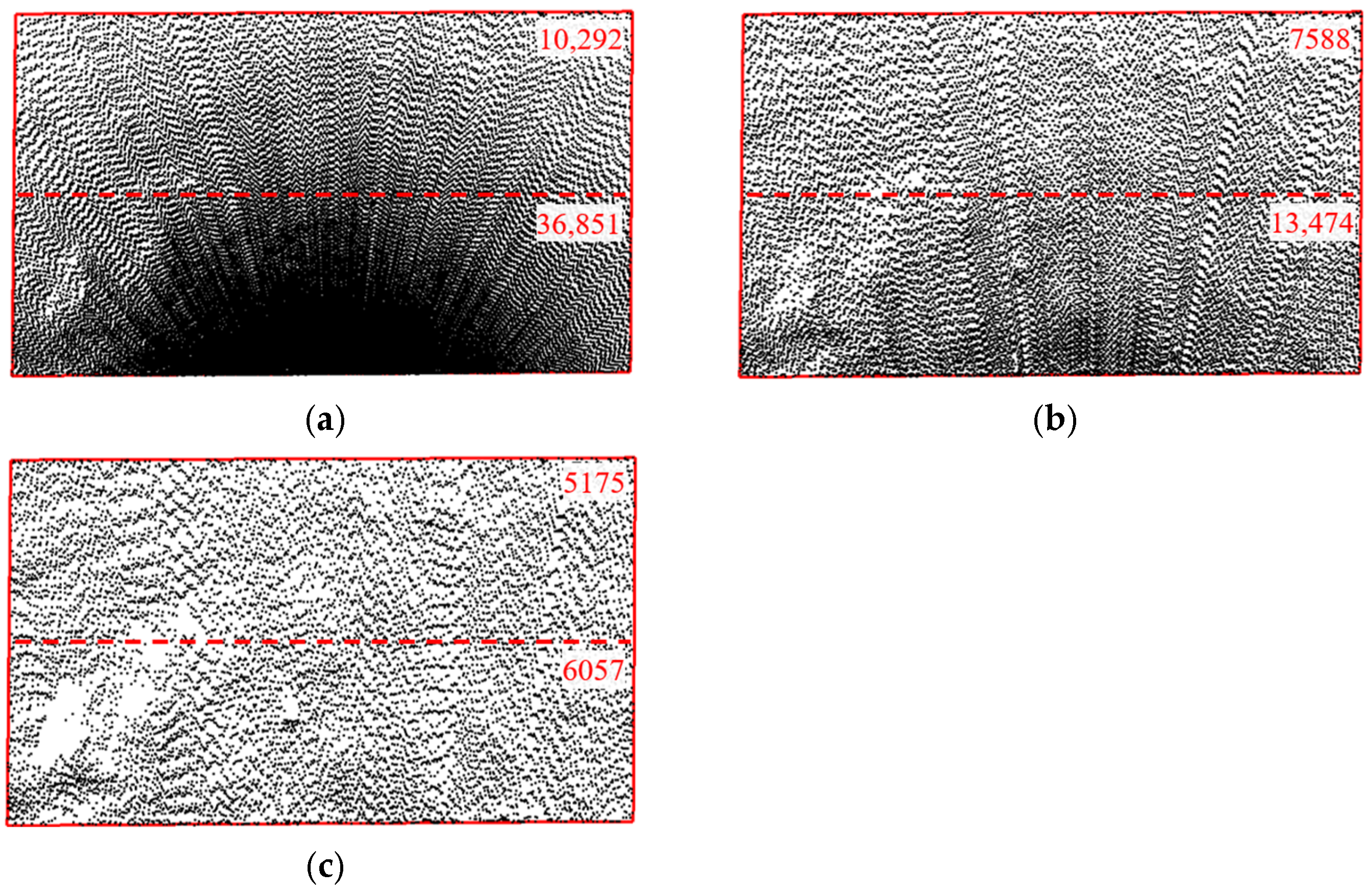

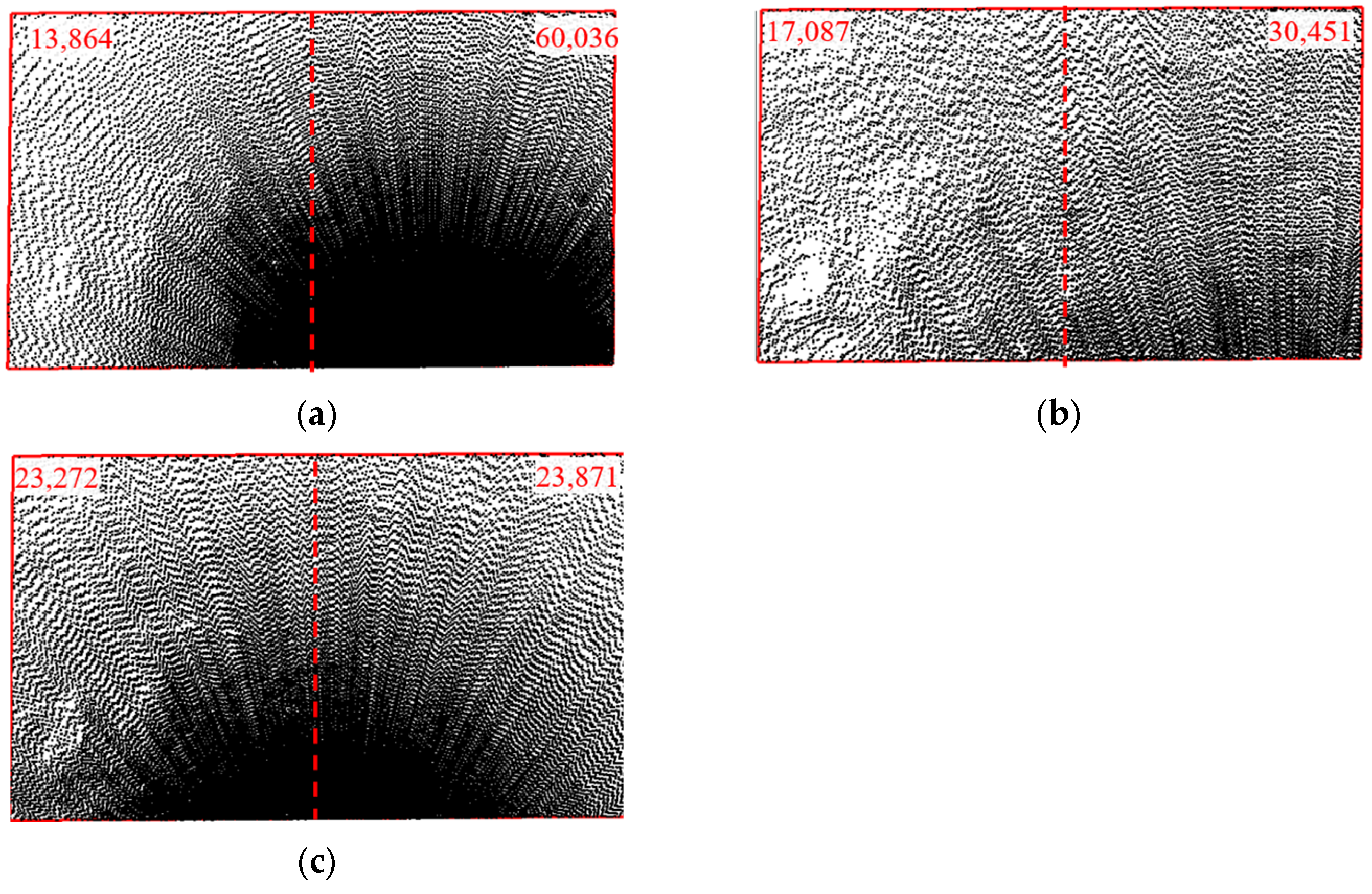

3.1.1. Distribution Patterns of Point Clouds

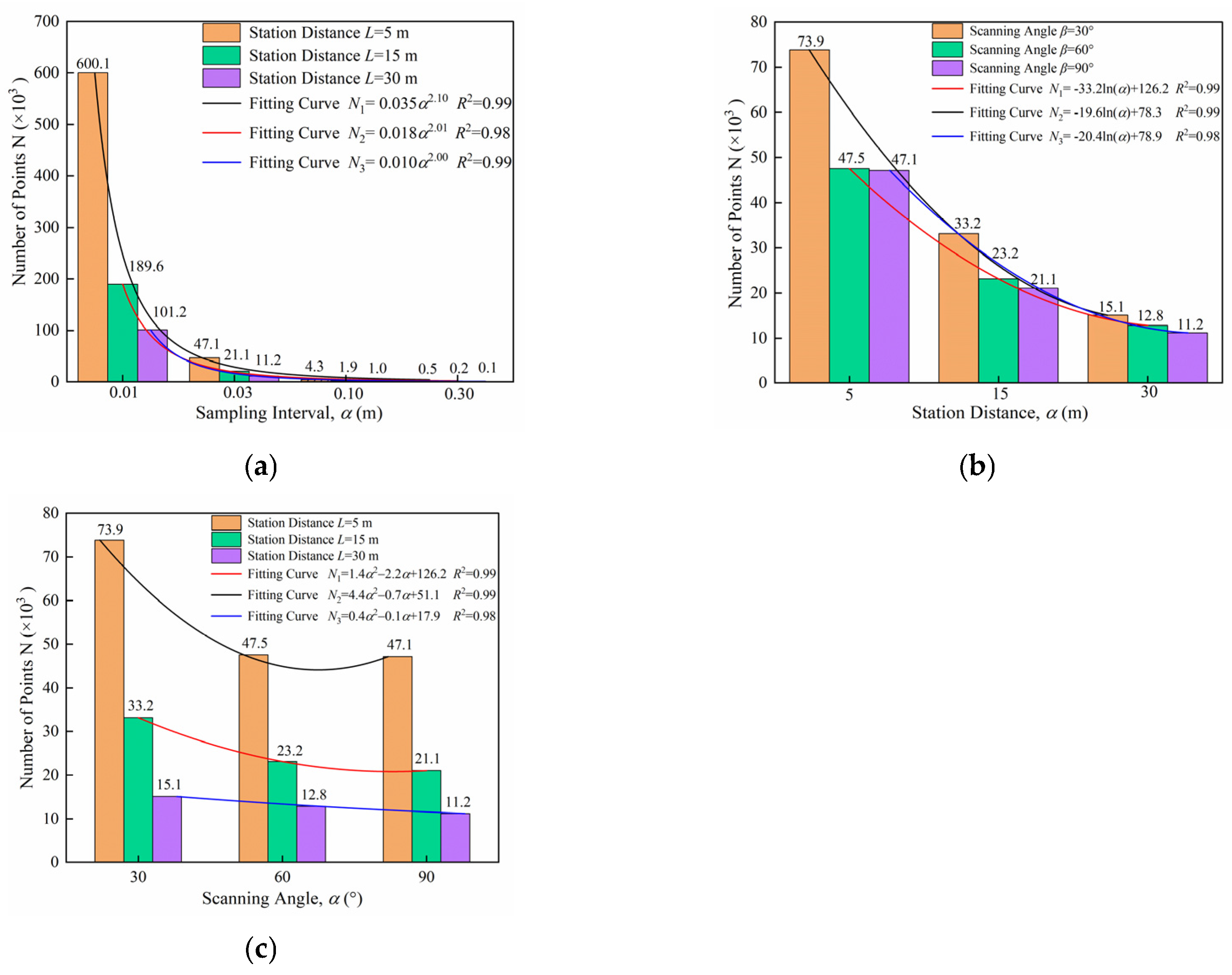

3.1.2. Statistical Analysis of Point Cloud Quantity

3.1.3. Discussion of Scanning Parameter Settings

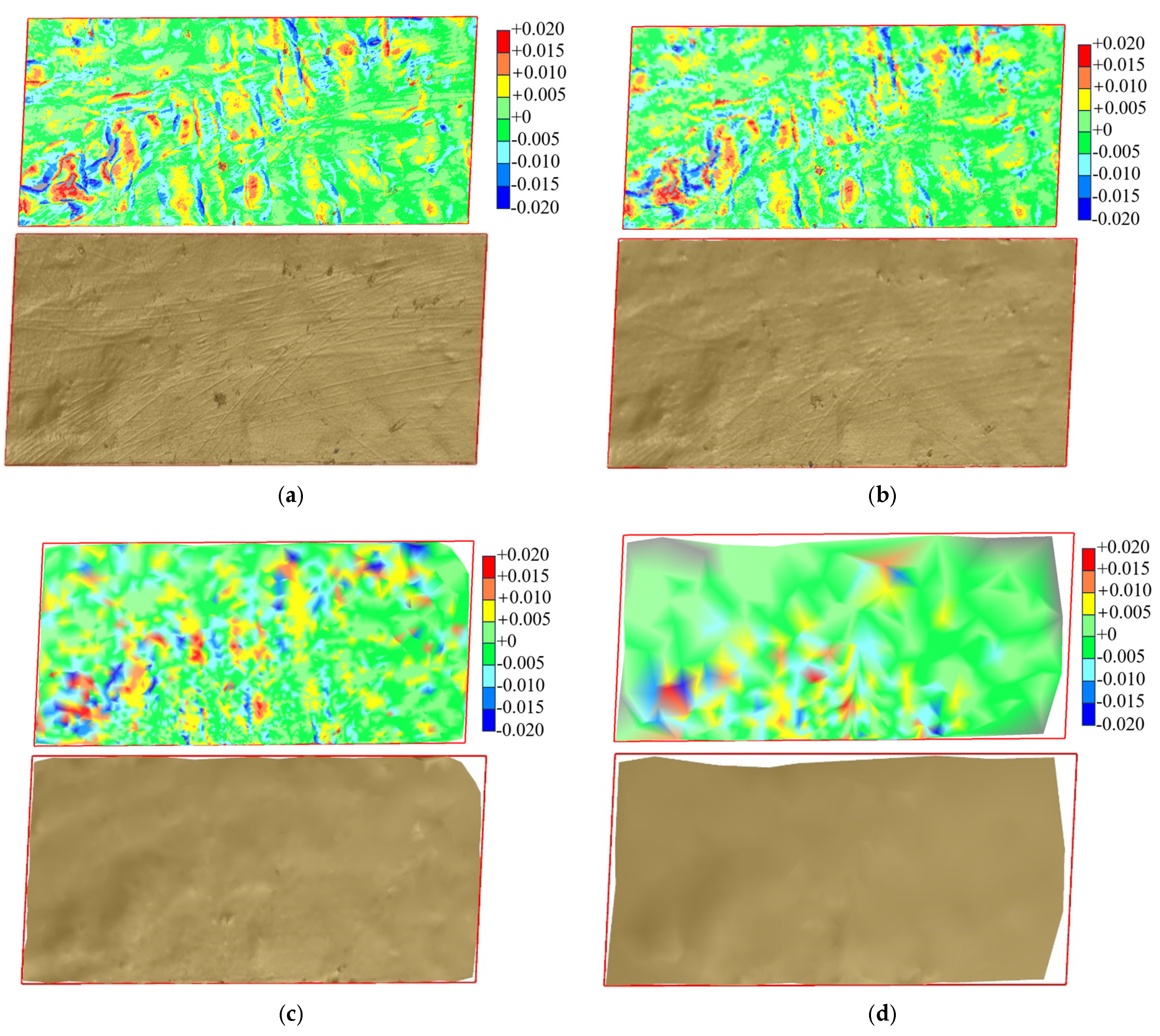

3.2. Model Reconstruction Analysis and Discussion

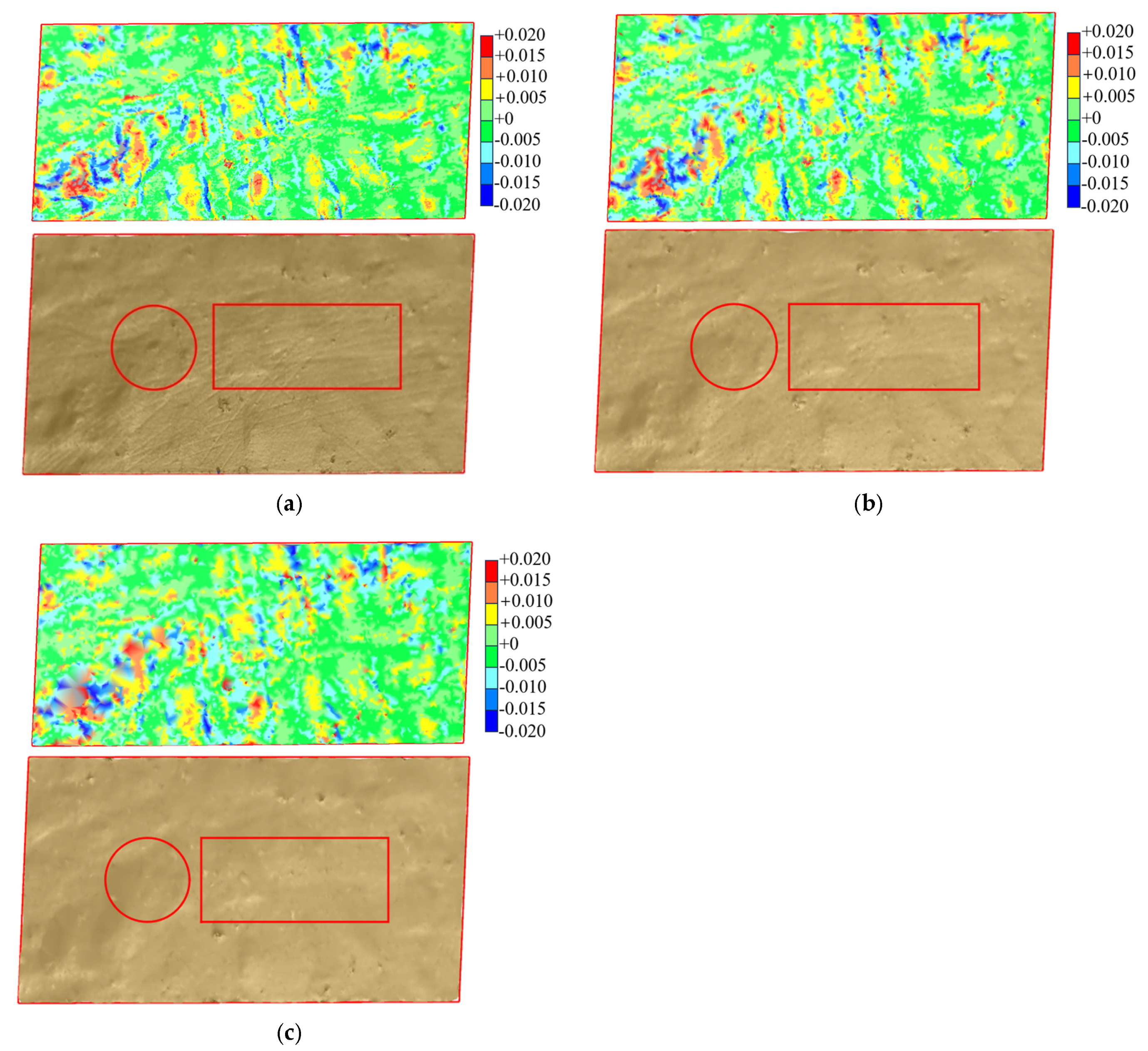

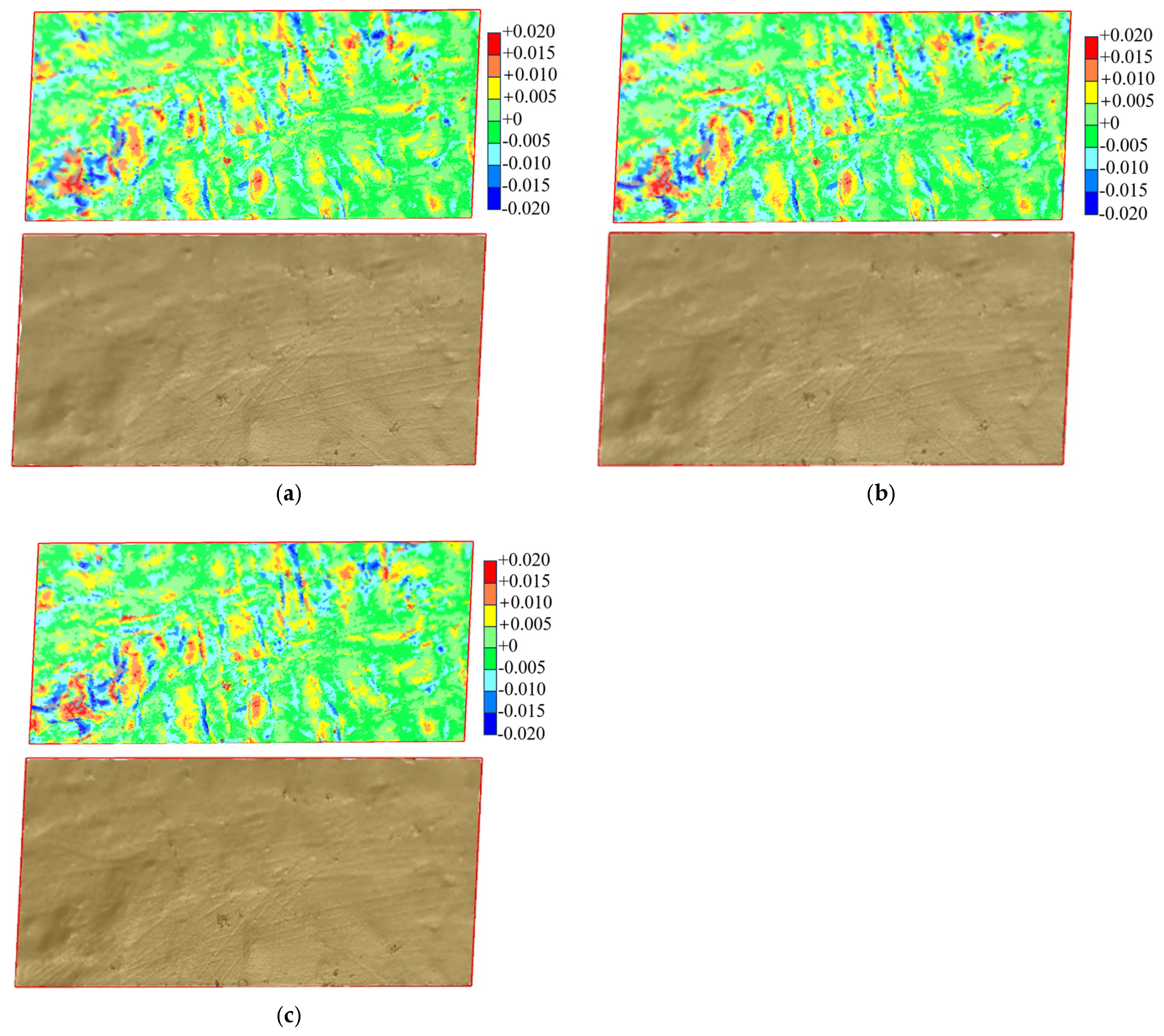

3.2.1. Reconstruction of Fill Surface Model

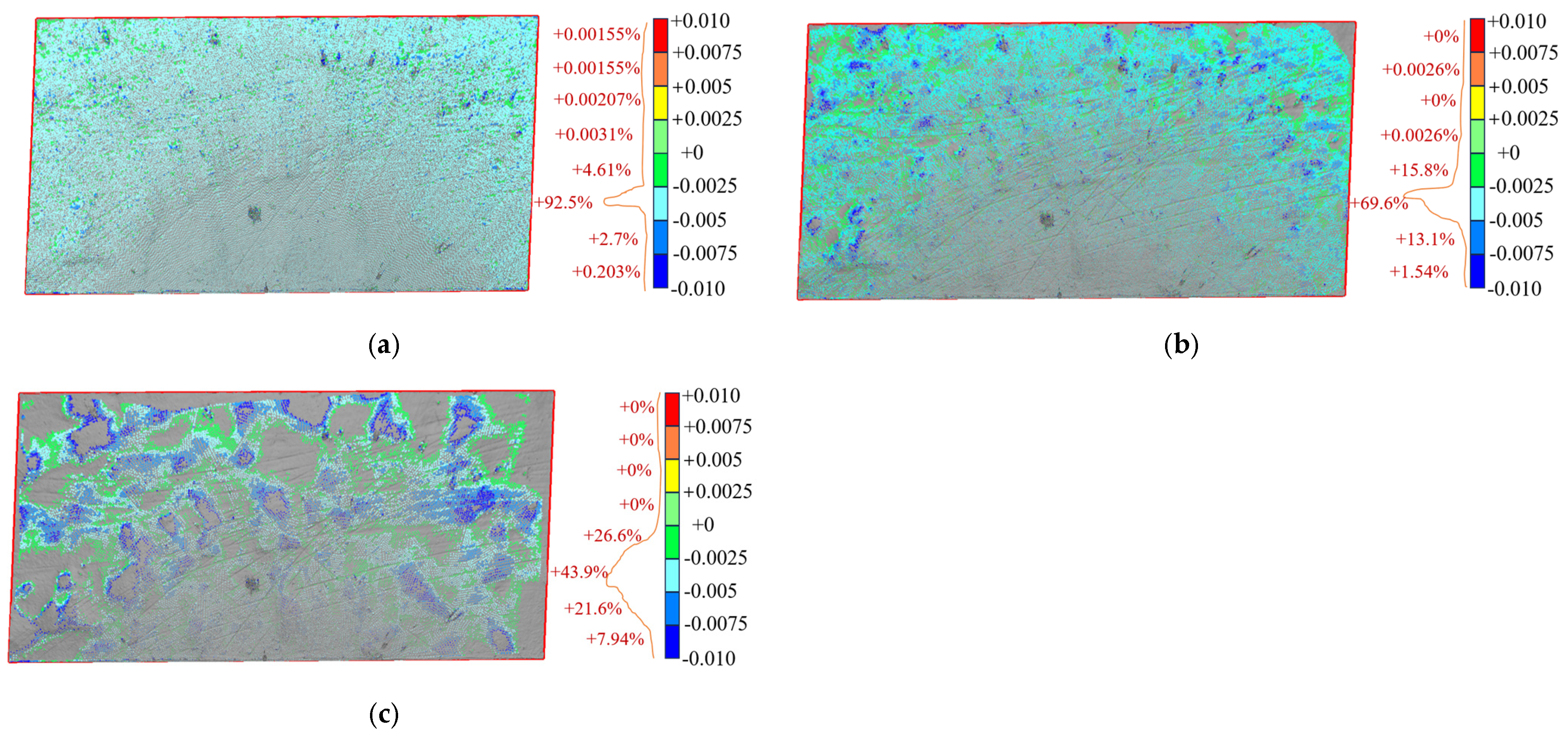

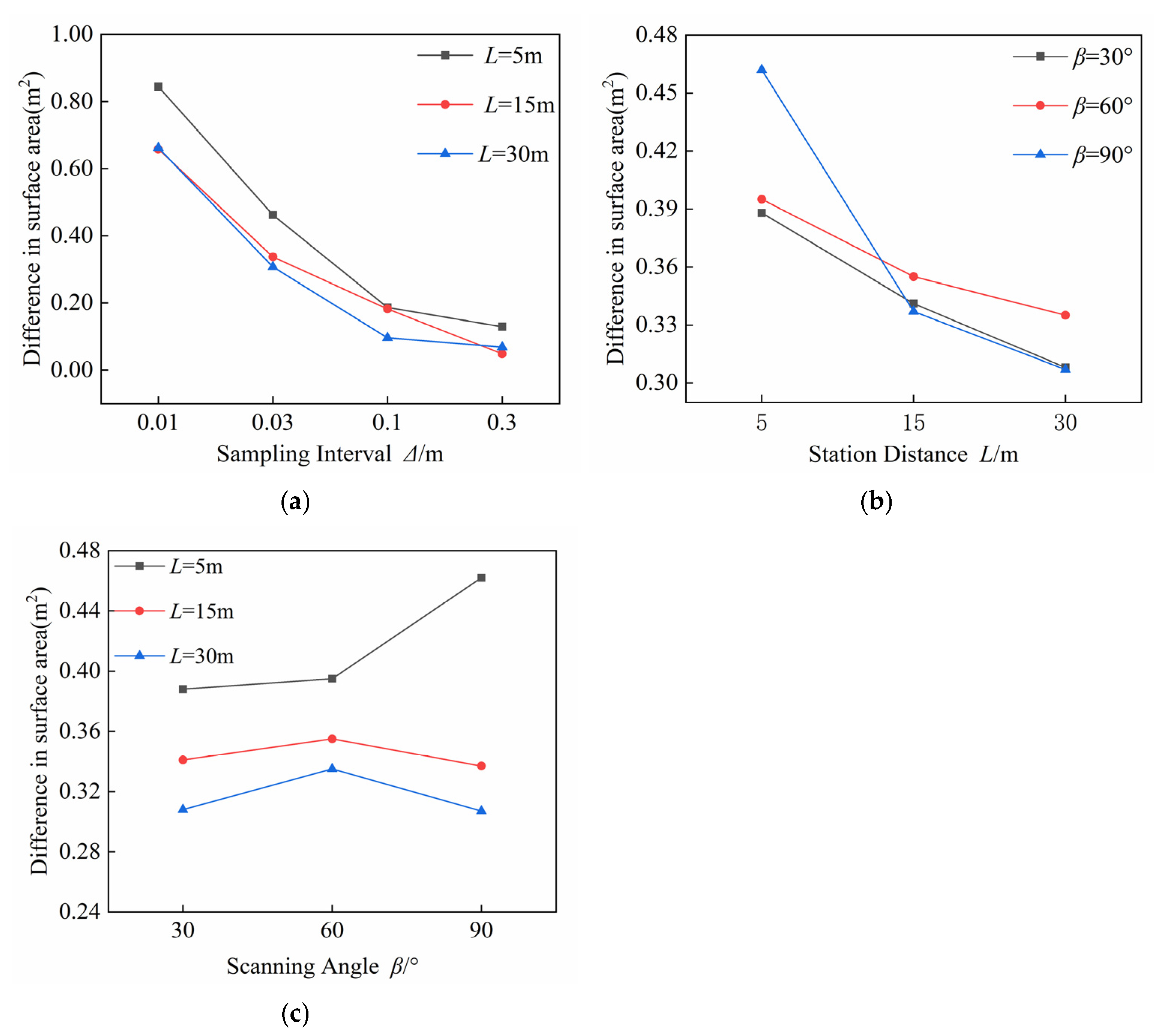

3.2.2. Surface Area Analysis of Reconstructed Models

4. Conclusions

- (1)

- In three-dimensional laser scanning of fill surfaces, the point cloud exhibits high density near the setup station, gradually becoming sparser with distance. At a scanning angle of 90°, the point cloud also shows left-right symmetry. Statistical analysis reveals that the number of points in the target area decreases exponentially with the sampling interval and logarithmically with increasing station distance. The sampling interval exerts a more pronounced influence on point cloud density compared to station distance and scanning angle. The number of points at β = 30° increases by approximately 40% compared to β = 90°, with β = 60° and 90° showing similar numbers.

- (2)

- The three-dimensional model of the fill surface was reconstructed using the Delaunay triangulation algorithm based on point cloud data. Results indicate that both sampling interval and station distance affect the resolution of the reconstructed surface model and its ability to accurately capture bumps and undulations, with resolution decreasing as sampling interval and station distance increase. A larger sampling interval can lead to missing edges in the reconstructed model. The accuracy of the reconstructed surface model shows minimal sensitivity to changes in scanning angle.

- (3)

- When conducting three-dimensional laser scanning of fill surfaces with a total station, the setup station should ideally be positioned as close as possible to the target area while meeting minimum scanning distance requirements. If site constraints necessitate a greater station distance, reducing the sampling interval can enhance scanning accuracy. Ideally, the setup station should align with the symmetry line along the longer side of the target area. However, if site conditions prevent this alignment, a moderate deviation from the symmetry line has a negligible impact on scanning outcomes. A sampling interval of 0.03 m is recommended to achieve a balance between scanning accuracy and efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anttila, K.; Kaasalainen, S.; Krooks, A.; Kaartinen, H.; Kukko, A.; Manninen, T.; Lahtinen, P.; Siljamo, N. Radiometric Calibration of TLS Intensity: Application to Snow Cover Change Detection. ISPRS—Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, 3812, 175–179. [Google Scholar] [CrossRef]

- Azam, A.; Alshehri, A.H.; Alharthai, M.; El-Banna, M.M.; Yosri, A.M.; Beshr, A.A.A. Applications of Terrestrial Laser Scanner in Detecting Pavement Surface Defects. Processes 2023, 11, 1370. [Google Scholar] [CrossRef]

- Bae, J.; Lee, J.; Jang, A.; Ju, Y.K.; Park, M.J. SMART SKY EYE System for Preliminary Structural Safety Assessment of Buildings Using Unmanned Aerial Vehicles. Sensors 2022, 22, 2762. [Google Scholar] [CrossRef]

- Bai, J.; Niu, Z.; Gao, S.; Bi, K.; Wang, J.; Huang, Y.; Sun, G. An exploration, analysis, and correction of the distance effect on terrestrial hyperspectral LiDAR data. ISPRS J. Photogramm. Remote Sens. 2023, 198, 60–83. [Google Scholar] [CrossRef]

- Będkowski, J. Benchmark of multi-view Terrestrial Laser Scanning Point Cloud data registration algorithms. Measurement 2023, 219, 113199. [Google Scholar] [CrossRef]

- Shen, Y.; Fan, X.; Chen, Z.; Huang, J.; Lu, R.; Wang, G.; Cao, Z.; Liu, Y. Design a common optical path system for near-and far-field detection of optical phased array chips. Opt. Eng. 2024, 63, 025106. [Google Scholar] [CrossRef]

- Coenen, T.B.J.; Golroo, A. A review on automated pavement distress detection methods. Cogent Eng. 2017, 4, 1374822. [Google Scholar] [CrossRef]

- Barbarella, M.; De Blasiis, M.R.; Fiani, M. Terrestrial laser scanner for the analysis of airport pavement geometry. Int. J. Pavement Eng. 2019, 20, 466–480. [Google Scholar] [CrossRef]

- Barbarella, M.; D’Amico, F.; De Blasiis, M.R.; Di Benedetto, A.; Fiani, M. Use of Terrestrial Laser Scanner for Rigid Airport Pavement Management. Sensors 2018, 18, 44. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y.; Kaya, O.; Ceylan, H.; Kim, S. Investigation of Longitudinal Cracking in Widened Concrete Pavements. Balt. J. Road Bridge Eng. 2020, 15, 211–231. [Google Scholar] [CrossRef]

- De Blasiis, M.R.; Di Benedetto, A.; Fiani, M. Mobile Laser Scanning Data for the Evaluation of Pavement Surface Distress. Remote Sens. 2020, 12, 942. [Google Scholar] [CrossRef]

- Beshr, A.A.A.; Heneash, O.G.; Fawzy, H.E.-D.; El-Banna, M.M. Condition assessment of rigid pavement using terrestrial laser scanner observations. Int. J. Pavement Eng. 2022, 23, 4248–4259. [Google Scholar] [CrossRef]

- Bolkas, D. Terrestrial laser scanner intensity correction for the incidence angle effect on surfaces with different colours and sheens. Int. J. Remote Sens. 2019, 40, 7169–7189. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Zhang, X.; Zhang, W. Effect of laser incidence angle on the femtosecond laser ablation characteristics of silicon carbide ceramics. Opt. Lasers Eng. 2024, 172, 107849. [Google Scholar] [CrossRef]

- Collins, M.J.; Ma, M.; Dabboor, M. On the Effect of Polarization and Incidence Angle on the Estimation of Significant Wave Height From SAR Data. IEEE Trans. Geosci. Remote Sens. 2019, 57, 4529–4543. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, W.; Mou, Y.; Li, Y.; Yin, L. Microscopic 3D reconstruction based on point cloud data generated using defocused images. Meas. Control 2021, 54, 1309–1318. [Google Scholar] [CrossRef]

- Tan, K.; Cheng, X. Correction of Incidence Angle and Distance Effects on TLS Intensity Data Based on Reference Targets. Remote Sens. 2016, 8, 251. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Xu, Q. Research on 3D laser scanning technology based on point cloud data acquisition. In Proceedings of the 2014 International Conference on Audio, Language and Image Processing, Shanghai, China, 7–9 July 2014; pp. 631–634. [Google Scholar]

- Kedzierski, M.; Fryskowska, A. Methods of laser scanning point clouds integration in precise 3D building modelling. Measurement 2015, 74, 221–232. [Google Scholar] [CrossRef]

- Bolkas, D.; Martinez, A. Effect of target color and scanning geometry on terrestrial LiDAR point-cloud noise and plane fitting. J. Appl. Geod. 2018, 12, 109–127. [Google Scholar] [CrossRef]

- Yang, Y.; Cheng, Q.; Zhu, Y.; Wang, L.; Jin, R. Feasibility Study of Tractor-Test Vehicle Technique for Practical Structural Condition Assessment of Beam-Like Bridge Deck. Remote Sens. 2020, 12, 114. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, H.; Tan, X.; Chai, H.K.; Wang, R.; Zhang, Y. Fundamental mode shape estimation and element stiffness evaluation of girder bridges by using passing tractor-trailers. Mech. Syst. Signal Process. 2022, 169, 108746. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Tan, X. Review on Vibration-Based Structural Health Monitoring Techniques and Technical Codes. Symmetry 2021, 13, 1998. [Google Scholar] [CrossRef]

- Zhang, H.X.; Zhu, W.B. Theory and Application of 3D Laser Scanning Data Processing; Electronic Industry Press: Beijing, China, 2012. [Google Scholar]

- Zhang, Z. A new measurement method of three-dimensional laser scanning for the volume of railway tank car (container). Measurement 2021, 170, 108454. [Google Scholar] [CrossRef]

- Zhao, G.; Deng, Z.; Shen, J.; Qiu, Z.; Huang, J. Three-Dimensional Reconstruction of Wood Carving Cultural Relics Based on CT Tomography Data. In Proceedings of the Data Science, Changsha, China, 22–24 September 2017; pp. 462–471. [Google Scholar]

- Zhao, Y.; Zhu, Z.; Liu, W.; Zhan, J.; Wu, D. Application of 3D laser scanning on NATM tunnel deformation measurement during construction. Acta Geotech. 2023, 18, 483–494. [Google Scholar] [CrossRef]

- Zhang, W. Research on the Application of Three-Dimensional Laser Scanning in Roadbed Deformation Detection of Qinghai-Tibet Highway. Master’s Thesis, Chang’an University, Xi’an, China, 2017. [Google Scholar]

- Zhang, H.; Zhu, W. Three-Dimensional Laser Scanning Data Processing Theory and Application; Electronic Industry Press: Beijing, China, 2012. [Google Scholar]

- Farahani, B.V.; Barros, F.; Sousa, P.J.; Cacciari, P.P.; Tavares, P.J.; Futai, M.M.; Moreira, P. A coupled 3D laser scanning and digital image correlation system for geometry acquisition and deformation monitoring of a railway tunnel. Tunn. Undergr. Space Technol. 2019, 91, 102995. [Google Scholar] [CrossRef]

- Han, Y.; Sun, H.; Zhong, R. Three-Dimensional Linear Restoration of a Tunnel Based on Measured Track and Uncontrolled Mobile Laser Scanning. Sensors 2021, 21, 3815. [Google Scholar] [CrossRef]

- Ji, H.; Luo, X. 3D scene reconstruction of landslide topography based on data fusion between laser point cloud and UAV image. Environ. Earth Sci. 2019, 78, 534. [Google Scholar] [CrossRef]

- Chen, S.; Verbeeck, H.; Terryn, L.; Liu, C.; Disney, M.; Origo, N.; Calders, K. Quantifying Forest Dynamics with Terrestrial Laser Scanning Data. In Proceedings of the IGARSS 2024–2024 IEEE International Geoscience and Remote Sensing Symposium, Athens, Greece, 7–12 July 2024; pp. 1130–1133. [Google Scholar] [CrossRef]

- Jin, C.; Li, L.; Han, X.; Wu, J.; Sun, Z.; Yang, X. Macroscopic and mesoscopic characterization of asphalt pavement texture for their correlation analysis based on 3-D laser scanning technology. Measurement 2024, 235, 114946. [Google Scholar] [CrossRef]

- Kaya, O.; Zhang, Y.; Ceylan, H.; Kim, S.; Yang, S.; Taylor, P.C.; Gopalakrishnan, K. Numerical analysis of longitudinal cracking in widened jointed plain concrete pavement systems. Int. J. Pavement Res. Technol. 2019, 12, 277–287. [Google Scholar] [CrossRef]

- Li, P.; Qiu, W.; Cheng, Y.; Lu, F. Application of 3D Laser Scanning in Underground Station Cavity Clusters. Adv. Civ. Eng. 2021, 2021, 8896363. [Google Scholar] [CrossRef]

- Mirzaei, K.; Arashpour, M.; Asadi, E.; Masoumi, H.; Bai, Y.; Behnood, A. 3D point cloud data processing with machine learning for construction and infrastructure applications: A comprehensive review. Adv. Eng. Inform. 2022, 51, 101501. [Google Scholar] [CrossRef]

- Qiao, J.; Medic, T.; Baumann-Ouyang, A. Automatic calibration of terrestrial laser scanners using intensity features. Photogramm. Rec. 2023, 38, 320–338. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Y.; Chen, Y.; Zhao, C.; Qiu, J.; Wu, D.; Liu, T.; Fan, H.; Qin, Y.; Tang, K. A State-of-the-Practice Review of Three-Dimensional Laser Scanning Technology for Tunnel Distress Monitoring. J. Perform. Constr. Facil. 2023, 37, 03123001. [Google Scholar] [CrossRef]

- Yunlan, G. Study on the Data Processing of Terrestrial Laser Seanner. Master’s Thesis, Tongji University, Shanghai, China, 2008. [Google Scholar]

- Wanhua, L. Research on Triangular Mesh Surface Reconstruction Method for 3D Discrete Point Cloud. Master’s Thesis, Guizhou University, Guizhou, China, 2021. [Google Scholar]

- Shen, N.; Wang, B.; Ma, H.; Zhao, X.; Zhou, Y.; Zhang, Z.; Xu, J. A review of terrestrial laser scanning (TLS)-based technologies for deformation monitoring in engineering. Measurement 2023, 223, 113684. [Google Scholar] [CrossRef]

- Tan, D.; Tao, Y.; Ji, B.; Gan, Q.; Guo, T. Full-Section Deformation Monitoring of High-Altitude Fault Tunnels Based on Three-Dimensional Laser Scanning Technology. Sensors 2024, 24, 2499. [Google Scholar] [CrossRef]

- Vain, A.; Kaasalainen, S.; Hyyppä, J.; Ahokas, E. Calibration of laser scanning intensity data using brightness targets. The method developed by the Finnish Geodetic Institute. Geod. Cartogr. 2012, 35, 77–81. [Google Scholar] [CrossRef]

- Verma, M.K.; Yadav, M. Estimation of plant’s morphological parameters using terrestrial laser scanning-based three-dimensional point cloud data. Remote Sens. Appl. Soc. Environ. 2024, 33, 101137. [Google Scholar] [CrossRef]

- Wang, J.-F.; Li, X.-X.; Wang, Y.-W.; Ni, Y.-Q. Automatic detection and evaluation of multitype surface defects in metro tunnels based on mobile laser scanning. Struct. Health Monit. 2025, 14759217251344171. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, H.-Y. Effects of scanning orientation on outlier formation in 3D laser scanning of reflective surfaces. Opt. Lasers Eng. 2016, 81, 35–45. [Google Scholar] [CrossRef]

| References | Laser-Based Scanning Device | Application Scenarios |

|---|---|---|

| [5] | N/A | The deformation of highway and railway embankments |

| [6,7] | N/A | The detection of road surface damage |

| [8] | FARO | Extracting concrete runway irregularities, identifying road surface irregularities. |

| [9] | Leica TC2002 | Calculated fault values between concrete slabs using TLS data to assess horizontal plane differences |

| [10] | Riegl LMS Z-420i | Measure longitudinal cracks in jointed concrete pavements |

| [11] | MLS | Identify hazards on road surfaces and classify each full-size pavement |

| [12] | FARO | Scan large concrete areas and assess rigid pavement slab defects |

| References | Laser-Based Scanning Device | Research Object |

|---|---|---|

| [13,14,15,16] | FARO | Color, roughness, incident angle, and distance on point cloud data quality |

| [17,18] | Leica ScanStation2 | Surface roughness, color, shape, and scanning conditions |

| [19] | N/A | Incident angle, laser range, sampling interval, and station height |

| [20] | Leica ScanStation P40 and Topcon GLS-1500 | Plane residuals, scanning distance, and incident angle. |

| Station Location | Β (°) | L (m) | Δ (m) |

|---|---|---|---|

| A1 | 90 | 5 | 0.01, 0.03, 0.10, 0.30 |

| A2 | 15 | ||

| A3 | 30 | ||

| B1 | 60 | 5 | 0.03 |

| B2 | 15 | ||

| B3 | 30 | ||

| C1 | 30 | 5 | 0.03 |

| C2 | 15 | ||

| C3 | 30 |

| Station Location | L (m) | Δ (m) | Number of Points | Scanning Time |

|---|---|---|---|---|

| A1 | 5 | 0.01 | 600,033 | 21′21″ |

| 0.03 | 47,143 | 4′35″ | ||

| 0.10 | 4250 | 1′20″ | ||

| 0.30 | 461 | 0′36″ | ||

| A2 | 15 | 0.01 | 189,623 | 12′51″ |

| 0.03 | 21,062 | 2′43″ | ||

| 0.10 | 1882 | 0′55″ | ||

| 0.30 | 205 | 0′32″ | ||

| A3 | 30 | 0.01 | 101,227 | 8′20″ |

| 0.03 | 11,232 | 2′31″ | ||

| 0.10 | 1002 | 0′43″ | ||

| 0.30 | 114 | 0′16″ |

| Δ (m) | A | B | C | D | E | RMSE |

|---|---|---|---|---|---|---|

| 0.01 | 0.006 | 0.005 | 0.008 | 0.006 | 0.005 | 0.0136 |

| 0.03 | 0.007 | 0.006 | 0.008 | 0.008 | 0.006 | 0.0149 |

| 0.1 | 0.019 | 0.018 | 0.022 | 0.025 | 0.015 | 0.0449 |

| 0.3 | 0.024 | 0.022 | 0.026 | 0.022 | 0.019 | 0.0508 |

| L (m) | A | B | C | D | E | RMSE |

|---|---|---|---|---|---|---|

| 5 | 0.007 | 0.008 | 0.013 | 0.012 | 0.002 | 0.0207 |

| 15 | 0.011 | 0.012 | 0.02 | 0.019 | 0.008 | 0.0331 |

| 30 | 0.019 | 0.017 | 0.024 | 0.022 | 0.011 | 0.0428 |

| Β (°) | A | B | C | D | E | RMSE |

|---|---|---|---|---|---|---|

| 30 | 0.018 | 0.007 | 0.012 | 0.021 | 0.007 | 0.0317 |

| 60 | 0.014 | 0.009 | 0.017 | 0.018 | 0.006 | 0.0304 |

| 90 | 0.007 | 0.008 | 0.013 | 0.012 | 0.002 | 0.0207 |

| Factor | Type III Sum of Squares | Degrees of Freedom for Statistical Variables (Vdf) | Mean Square | Analysis of Variance Statistic (F) | Significance (p) |

|---|---|---|---|---|---|

| Sampling Interval | 0.744 | 3 | 0.248 | 212.411 | 0.002 |

| Station Distance | 0.048 | 2 | 0.024 | 20.654 | 0.003 |

| Scanning Angle | 0.001 | 2 | 0.001 | 0.453 | 0.645 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Liu, G.; Zhao, M.; Zhang, X.; Yang, K.; Chen, Y. Optimizing 3D Laser Scanning Parameters for Early-Stage Defect Detectability in Subgrade Condition Monitoring. Sensors 2025, 25, 7174. https://doi.org/10.3390/s25237174

Liu M, Liu G, Zhao M, Zhang X, Yang K, Chen Y. Optimizing 3D Laser Scanning Parameters for Early-Stage Defect Detectability in Subgrade Condition Monitoring. Sensors. 2025; 25(23):7174. https://doi.org/10.3390/s25237174

Chicago/Turabian StyleLiu, Mengmeng, Gang Liu, Mingzhi Zhao, Xin Zhang, Kai Yang, and Yang Chen. 2025. "Optimizing 3D Laser Scanning Parameters for Early-Stage Defect Detectability in Subgrade Condition Monitoring" Sensors 25, no. 23: 7174. https://doi.org/10.3390/s25237174

APA StyleLiu, M., Liu, G., Zhao, M., Zhang, X., Yang, K., & Chen, Y. (2025). Optimizing 3D Laser Scanning Parameters for Early-Stage Defect Detectability in Subgrade Condition Monitoring. Sensors, 25(23), 7174. https://doi.org/10.3390/s25237174