Total Solution-Processed Zr: HfO2 Flexible Memristor with Tactile Sensitivity: From Material Synthesis to Application in Wearable Electronics

Abstract

1. Introduction

- A flexible Pt/Zr: HfO2 (HZO)/graphene oxide (GO)/mica memristor is proposed via the total solution-processed method.

- The interfacial oxygen competition mechanism between the HZO layer and the GO bottom electrode facilitates the formation of the HZO ferroelectric phase.

- The as-prepared device shows a switching ratio of ~150 and eight stable resistance levels, can effectively simulate neural responses, and exhibits good adaptability to mechanical deformations and temperature variations.

2. Methods

2.1. Materials

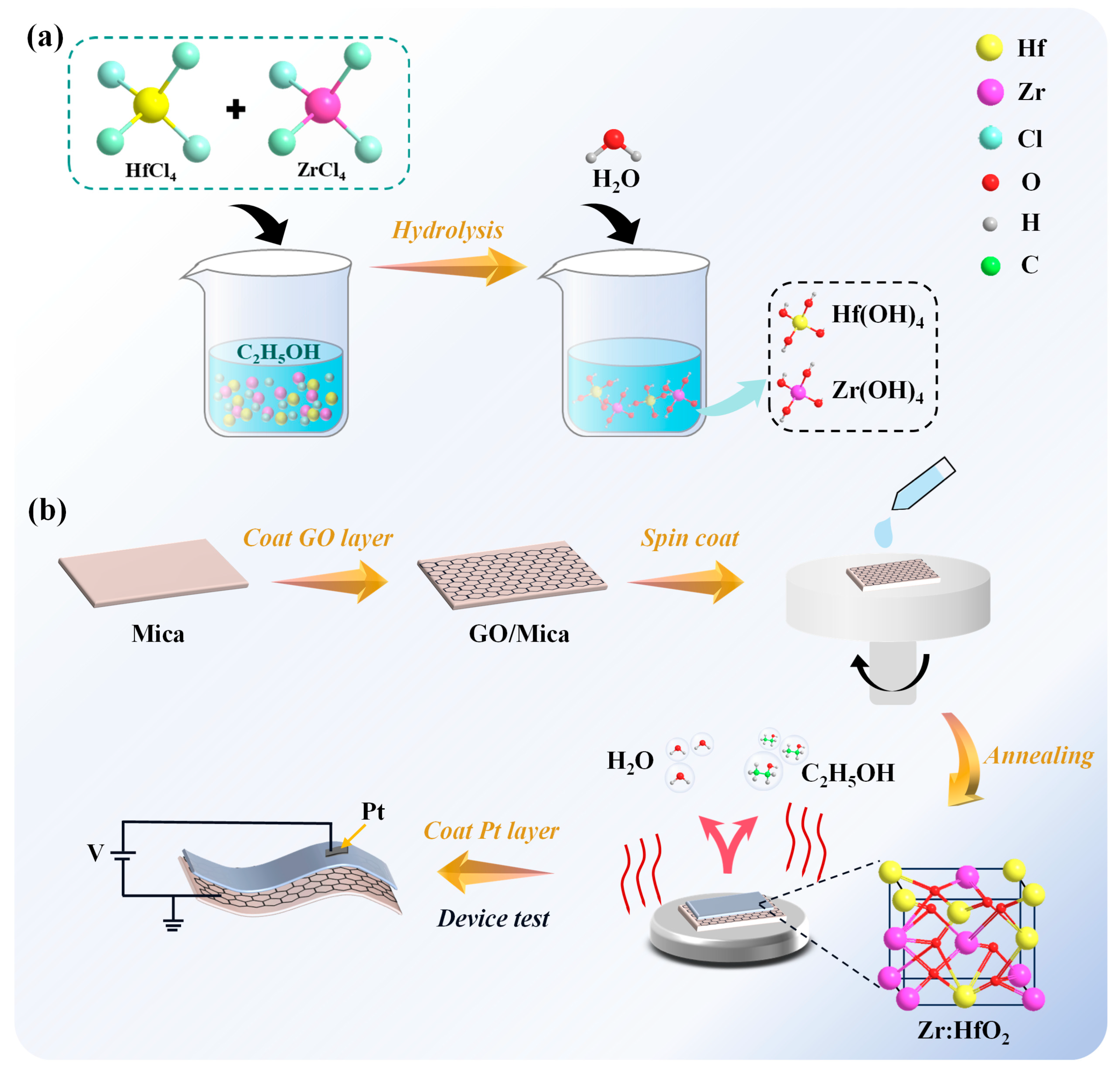

2.2. Preparation of HZO Precursor Solution

2.3. Preparation of Pt/HZO/GO/Mica Devices

2.4. Characterization and Measurement

3. Results and Discussion

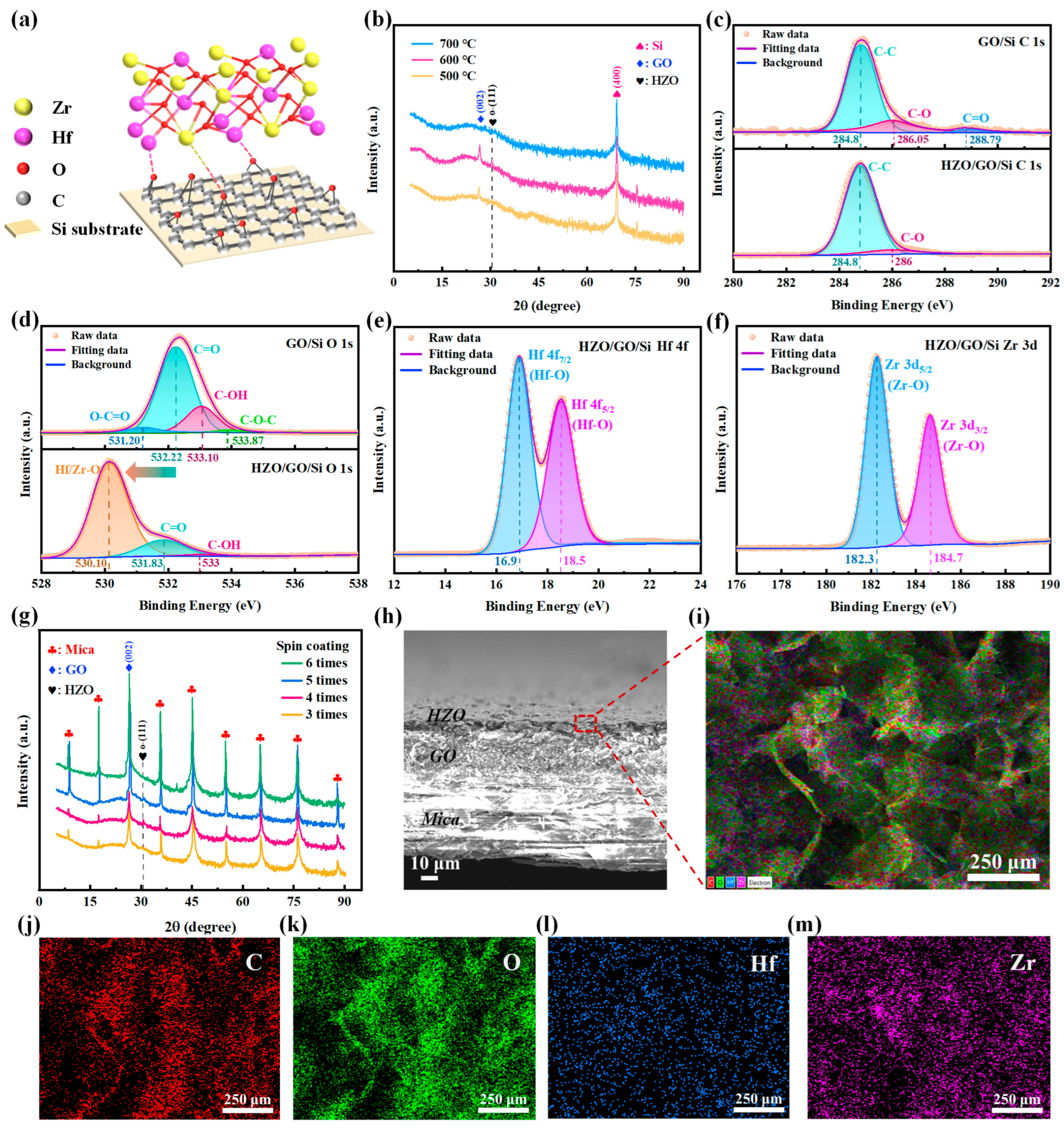

3.1. Characterization of the Solution-Processed HZO Films

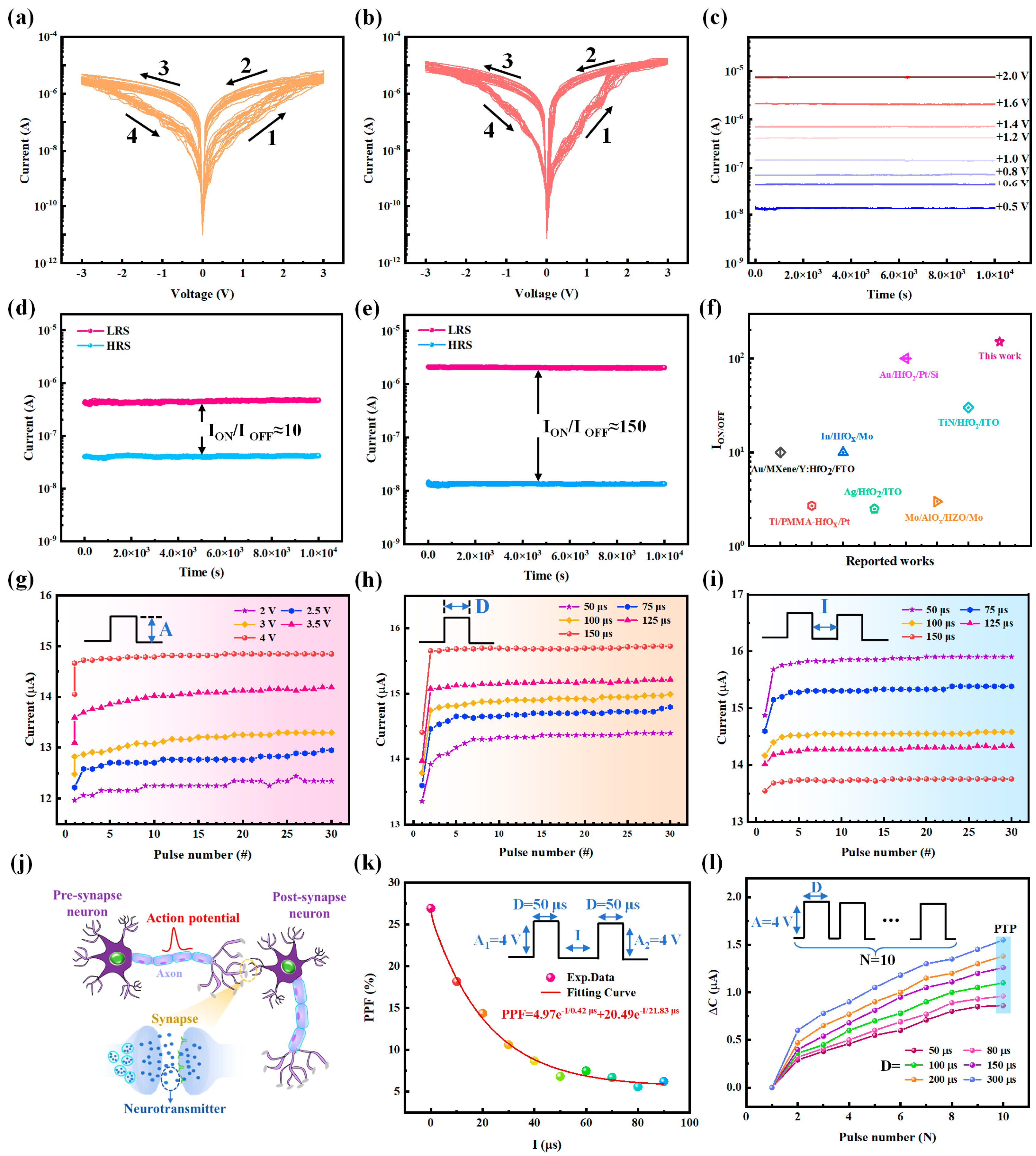

3.2. Basic Electric Features and Simulation of Neuro-Responses

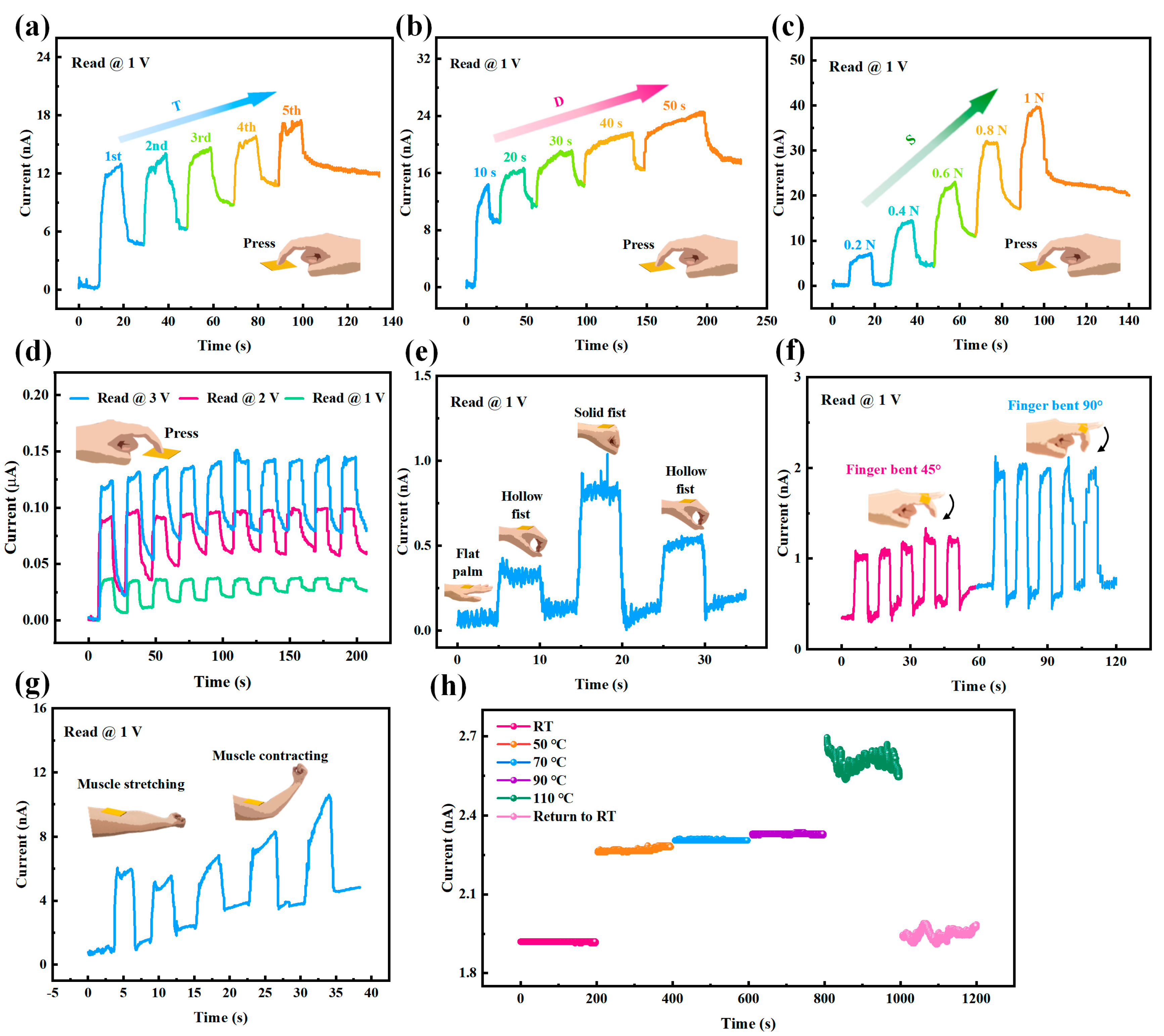

3.3. Mechanical and Thermal Influences

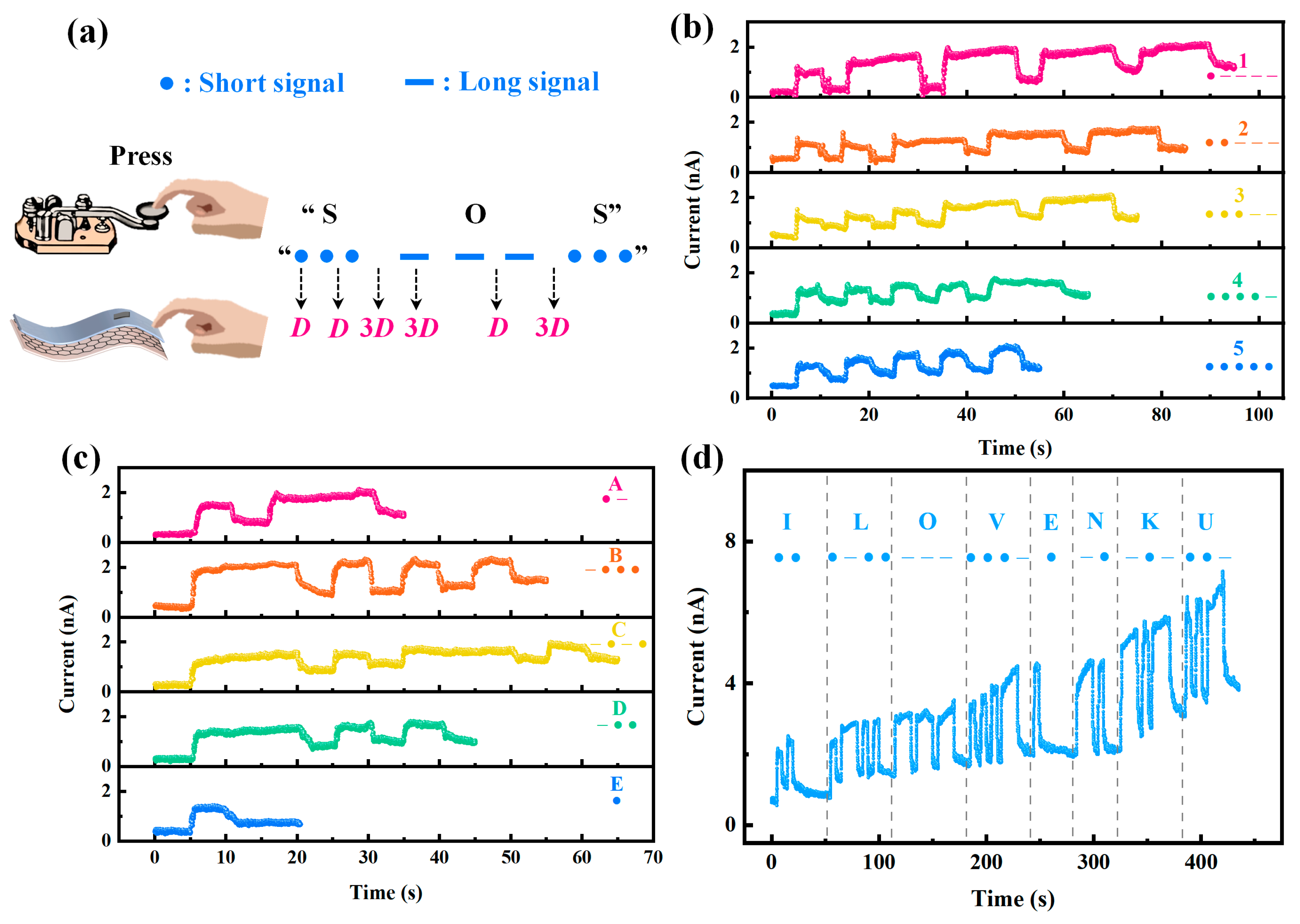

3.4. Application for Morse Code Recognition

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, Z.; Wang, Z.; Guan, Z.; Ma, C.; Zhao, L.; Liu, C.; Sun, H.; Wang, H.; Lin, Y.; Jin, X.; et al. High-precision and linear weight updates by subnanosecond pulses in ferroelectric tunnel junction for neuro-inspired computing. Nat. Commun. 2022, 13, 699. [Google Scholar] [CrossRef]

- Li, J.; Ge, C.; Du, J.; Wang, C.; Yang, G.; Jin, K. Reproducible Ultrathin Ferroelectric Domain Switching for High-Performance Neuromorphic Computing. Adv. Mater. 2020, 32, e1905764. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Luo, Z.; Huang, W.; Zhao, L.; Chen, Q.; Lin, Y.; Liu, X.; Chen, Z.; Liu, C.; Sun, H.; et al. Sub-nanosecond memristor based on ferroelectric tunnel junction. Nat. Commun. 2020, 11, 1439. [Google Scholar] [CrossRef] [PubMed]

- Chanthbouala, A.; Garcia, V.; Cherifi, R.O.; Bouzehouane, K.; Fusil, S.; Moya, X.; Xavier, S.; Yamada, H.; Deranlot, C.; Mathur, N.D.; et al. A ferroelectric memristor. Nat. Mater. 2012, 11, 860–864. [Google Scholar] [CrossRef]

- Yoong, H.Y.; Wu, H.; Zhao, J.; Wang, H.; Guo, R.; Xiao, J.; Zhang, B.; Yang, P.; Pennycook, S.J.; Deng, N. Epitaxial ferroelectric Hf0.5Zr0.5O2 thin films and their implementations in memristors for brain-inspired computing. Adv. Funct. Mater. 2018, 28, 1806037. [Google Scholar] [CrossRef]

- Kim, D.; Jeon, Y.-R.; Ku, B.; Chung, C.; Kim, T.H.; Yang, S.; Won, U.; Jeong, T.; Choi, C. Analog Synaptic Transistor with Al-Doped HfO2 Ferroelectric Thin Film. ACS Appl. Mater. Interfaces 2021, 13, 52743–52753. [Google Scholar] [CrossRef]

- Kim, M.-K.; Lee, J.-S. Ferroelectric Analog Synaptic Transistors. Nano Lett. 2019, 19, 2044–2050. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; He, H.; Liu, G.; Zhao, Z.; Pei, Y.; Liu, P.; Zhao, J.; Zhou, Z.; Wang, K.; Yan, H. A Robust Memristor Based on Epitaxial Vertically Aligned Nanostructured BaTiO3−CeO2 Films on Silicon. Adv. Mater. 2022, 34, 2110343. [Google Scholar] [CrossRef]

- Yan, X.; Sun, J.; Zhang, Y.; Zhao, Z.; Wang, L.; Niu, J.; Jia, X.; Zhang, Z.; Han, X.; Shao, Y.; et al. An artificial synapse based on La:BiFeO3 ferroelectric memristor for pain perceptual nociceptor emulation. Mater. Today Nano 2023, 22, 100343. [Google Scholar] [CrossRef]

- Du, J.; Xie, D.; Zhang, Q.; Zhong, H.; Meng, F.; Fu, X.; Sun, Q.; Ni, H.; Li, T.; Guo, E.-j.; et al. A robust neuromorphic vision sensor with optical control of ferroelectric switching. Nano Energy 2021, 89, 106439. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Z.; Xu, J.; Zhao, P.; Wang, J.; Wang, Y.; Zhang, W.; Li, C.; Cui, H.; Wang, J.; et al. High Photoresponsivity and Fast Response Speed Ferroelectric Photomemristor for Artificial Visual System Application. Adv. Funct. Mater. 2024, 34, 2406666. [Google Scholar] [CrossRef]

- Sun, H.; Luo, Z.; Zhao, L.; Liu, C.; Ma, C.; Lin, Y.; Gao, G.; Chen, Z.; Bao, Z.; Jin, X.; et al. BiFeO3-Based Flexible Ferroelectric Memristors for Neuromorphic Pattern Recognition. ACS Appl. Electron. Mater. 2020, 2, 1081–1089. [Google Scholar] [CrossRef]

- Sun, H.; Luo, Z.; Liu, C.; Ma, C.; Wang, Z.; Yin, Y.; Li, X. A flexible BiFeO3-based ferroelectric tunnel junction memristor for neuromorphic computing. J. Mater. 2022, 8, 144–149. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, H.; Li, J.; Du, X.; Wang, H.; Luo, Z.; Wang, Z.; Lin, Y.; Shen, S.; Yin, Y.; et al. A flexible Hf0.5Zr0.5O2 thin film with highly robust ferroelectricity. J. Mater. 2024, 10, 210–217. [Google Scholar] [CrossRef]

- Wang, T.-Y.; Meng, J.-L.; He, Z.-Y.; Chen, L.; Zhu, H.; Sun, Q.-Q.; Ding, S.-J.; Zhang, D.W. Atomic Layer Deposited Hf0.5Zr0.5O2-based Flexible Memristor with Short/Long-Term Synaptic Plasticity. Nanoscale Res. Lett. 2019, 14, 102. [Google Scholar] [CrossRef]

- Park, M.H.; Lee, Y.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Kim, K.D.; Müller, J.; Kersch, A.; Schroeder, U.; Mikolajick, T.; et al. Ferroelectricity and Antiferroelectricity of Doped Thin HfO2-Based Films. Adv. Mater. 2015, 27, 1811–1831. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, X.; Tang, L.; Chen, Y.; Luo, H.; Yuan, X.; Bowen, C.R.; Zhang, D. HfO2-based ferroelectrics: From enhancing performance, material design, to applications. Appl. Phys. Rev. 2022, 9, 011307. [Google Scholar] [CrossRef]

- Böscke, T.S.; Müller, J.; Bräuhaus, D.; Schröder, U.; Böttger, U. Ferroelectricity in hafnium oxide thin films. Appl. Phys. Lett. 2011, 99, 102903. [Google Scholar] [CrossRef]

- Du, X.; Sun, H.; Wang, H.; Li, J.; Yin, Y.; Li, X. High-Speed Switching and Giant Electroresistance in an Epitaxial Hf0.5Zr0.5O2-Based Ferroelectric Tunnel Junction Memristor. ACS Appl. Mater. Interfaces 2022, 14, 1355–1361. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wei, C.; Zhang, F.; Peng, Y.; Sun, T.; Peng, Y.; Tang, H.; Yang, J.; Ding, M.; Jiang, C.; et al. A Flexible Hf0.5Zr0.5O2 Nonvolatile Memory with High Polarization Based on Mica Substrate. ACS Appl. Electron. Mater. 2024, 6, 6266–6274. [Google Scholar] [CrossRef]

- Estandía, S.; Dix, N.; Chisholm, M.F.; Fina, I.; Sánchez, F. Domain-Matching Epitaxy of Ferroelectric Hf0.5Zr0.5O2 on La2/3Sr1/3MnO3(001). Cryst. Growth Des. 2020, 20, 3801–3806. [Google Scholar] [CrossRef]

- Lyu, J.; Fina, I.; Solanas, R.; Fontcuberta, J.; Sánchez, F. Growth Window of Ferroelectric Epitaxial Hf0.5Zr0.5O2 Thin Films. ACS Appl. Electron. Mater. 2019, 1, 220–228. [Google Scholar] [CrossRef]

- Cho, J.W.; Song, M.S.; Choi, I.H.; Go, K.-J.; Han, J.; Lee, T.Y.; An, C.; Choi, H.-J.; Sohn, C.; Park, M.H.; et al. Atomic Layer Deposition of Epitaxial Ferroelectric Hf0.5Zr0.5O2 Thin Films. Adv. Funct. Mater. 2024, 34, 2314396. [Google Scholar] [CrossRef]

- Kim, B.Y.; Park, H.W.; Hyun, S.D.; Lee, Y.B.; Lee, S.H.; Oh, M.; Ryoo, S.K.; Lee, I.S.; Byun, S.; Shim, D.; et al. Enhanced Ferroelectric Properties in Hf0.5Zr0.5O2 Films Using a HfO0.61N0.72 Interfacial Layer. Adv. Electron. Mater. 2022, 8, 2100042. [Google Scholar] [CrossRef]

- Shimizu, T.; Yokouchi, T.; Shiraishi, T.; Oikawa, T.; Krishnan, P.S.R.; Funakubo, H. Study on the effect of heat treatment conditions on metalorganic-chemical-vapor-deposited ferroelectric Hf0.5Zr0.5O2 thin film on Ir electrode. Jpn. J. Appl. Phys. 2014, 53 (9S), 09PA04. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, Y.; Zhang, L.; Yuan, Q.; Zhang, W.; Li, Y. Excellent HZO ferroelectric thin films on flexible PET substrate. J. Alloys Compd. 2022, 919, 165872. [Google Scholar] [CrossRef]

- Zhong, H.; Li, M.; Zhang, Q.; Yang, L.; He, R.; Liu, F.; Liu, Z.; Li, G.; Sun, Q.; Xie, D.; et al. Large-Scale Hf0.5Zr0.5O2 Membranes with Robust Ferroelectricity. Adv. Mater. 2022, 34, 2109889. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Zhen, H.; Niu, L.; Fang, X.; Zhang, Y.; Guo, R.; Yu, Y.; Yan, F.; Li, H.; Zheng, Z. Full-Solution Processed Flexible Organic Solar Cells Using Low-Cost Printable Copper Electrodes. Adv. Mater. 2014, 26, 7271–7278. [Google Scholar] [CrossRef]

- Song, W.; Fan, X.; Xu, B.; Yan, F.; Cui, H.; Wei, Q.; Peng, R.; Hong, L.; Huang, J.; Ge, Z. All-Solution-Processed Metal-Oxide-Free Flexible Organic Solar Cells with Over 10% Efficiency. Adv. Mater. 2018, 30, 1800075. [Google Scholar] [CrossRef] [PubMed]

- Fukuda, K.; Takeda, Y.; Mizukami, M.; Kumaki, D.; Tokito, S. Fully Solution-Processed Flexible Organic Thin Film Transistor Arrays with High Mobility and Exceptional Uniformity. Sci. Rep. 2014, 4, 3947. [Google Scholar] [CrossRef]

- Kim, C.; Song, J.-M.; Lee, J.-S.; Lee, M.J. All-solution-processed nonvolatile flexible nano-floating gate memory devices. Nanotechnology 2014, 25, 014016. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, D.; Li, S.; Liu, X.; Zhao, P.; Sun, N.; Ali, F.; Wang, J. Ferroelectric yttrium doped hafnium oxide films from all-inorganic aqueous precursor solution. Ceram. Int. 2018, 44, 13867–13872. [Google Scholar] [CrossRef]

- Jeong, B.; Gkoupidenis, P.; Asadi, K. Solution-Processed Perovskite Field-Effect Transistor Artificial Synapses. Adv. Mater. 2021, 33, 2104034. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Wan, Z.; Qi, J.; Wang, M. Ferroelectric photovoltaic properties of perovskite Na0.5Bi0.5FeO3-based solution-processed solar cells. J. Alloys Compd. 2018, 750, 959–964. [Google Scholar] [CrossRef]

- Liu, H.; Zheng, S.; Chen, Q.; Zeng, B.; Jiang, J.; Peng, Q.; Liao, M.; Zhou, Y. Structural and ferroelectric properties of Pr doped HfO2 thin films fabricated by chemical solution method. J. Mater. Sci. Mater. Electron. 2019, 30, 5771–5779. [Google Scholar] [CrossRef]

- Lee, J.Y.; Anoop, G.; Lee, H.J.; Kwak, J.H.; Jo, J.Y. Structural properties of solution-processed Hf0.5Zr0.5O2 thin films. Curr. Appl Phys. 2017, 17, 704–708. [Google Scholar] [CrossRef]

- Pujar, P.; Cho, H.; Gandla, S.; Naqi, M.; Hong, S.; Kim, S. Sub-Thermionic Negative Capacitance Field Effect Transistors with Solution Combustion-Derived Hf0.5Zr0.5O2. Adv. Funct. Mater. 2021, 31, 2103748. [Google Scholar] [CrossRef]

- Hasan, M.M.; Ahn, C.W.; Kim, T.H.; Jang, J. Solution processed high performance ferroelectric Hf0.5Zr0.5O2 thin film transistor on glass substrate. Appl. Phys. Lett. 2021, 118, 152901. [Google Scholar] [CrossRef]

- Zhou, L.; Yang, S.; Ding, G.; Yang, J.-Q.; Ren, Y.; Zhang, S.-R.; Mao, J.-Y.; Yang, Y.; Zhou, Y.; Han, S.-T. Tunable synaptic behavior realized in C3N composite based memristor. Nano Energy 2019, 58, 293–303. [Google Scholar] [CrossRef]

- Yan, X.; Zhao, J.; Liu, S.; Zhou, Z.; Liu, Q.; Chen, J.; Liu, X.Y. Memristor with Ag-Cluster-Doped TiO2 Films as Artificial Synapse for Neuroinspired Computing. Adv. Funct. Mater. 2018, 28, 1705320. [Google Scholar] [CrossRef]

- Alle, H.; Jonas, P.; Geiger, J.R.P. PTP and LTP at a hippocampal mossy fiber-interneuron synapse. Proc. Natl. Acad. Sci. USA 2001, 98, 14708–14713. [Google Scholar] [CrossRef]

- Ilyas, N.; Wang, J.; Li, C.; Fu, H.; Li, D.; Jiang, X.; Gu, D.; Jiang, Y.; Li, W. Controllable resistive switching of STO:Ag/SiO2-based memristor synapse for neuromorphic computing. J. Mater. Sci. Technol. 2022, 97, 254–263. [Google Scholar] [CrossRef]

- Westra, J.M.; Vavruňková, V.; Šutta, P.; van Swaaij, R.A.C.M.M.; Zeman, M. Formation of thin-film crystalline silicon on glass observed by in-situ XRD. Energy Procedia 2010, 2, 235–241. [Google Scholar] [CrossRef]

- Hyuk Park, M.; Joon Kim, H.; Jin Kim, Y.; Lee, W.; Moon, T.; Seong Hwang, C. Evolution of phases and ferroelectric properties of thin Hf0.5Zr0.5O2 films according to the thickness and annealing temperature. Appl. Phys. Lett. 2013, 102, 242905. [Google Scholar] [CrossRef]

- Müller, J.; Böscke, T.S.; Schröder, U.; Mueller, S.; Bräuhaus, D.; Böttger, U.; Frey, L.; Mikolajick, T. Ferroelectricity in Simple Binary ZrO2 and HfO2. Nano Lett. 2012, 12, 4318–4323. [Google Scholar] [CrossRef]

- Gaddam, V.; Das, D.; Jeon, S. Insertion of HfO2 Seed/Dielectric Layer to the Ferroelectric HZO Films for Heightened Remanent Polarization in MFM Capacitors. IEEE Trans. Electron Devices 2020, 67, 745–750. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Malolepszy, A.; Mazurkiewicz, M.; Mierzwa, B.; Zemek, J.; Jiricek, P.; Bieloshapka, I. Graphene oxide and reduced graphene oxide studied by the XRD, TEM and electron spectroscopy methods. J. Electron. Spectrosc. Relat. Phenom. 2014, 195, 145–154. [Google Scholar] [CrossRef]

- Hachemi, M.B.; Salem, B.; Consonni, V.; Roussel, H.; Garraud, A.; Lefevre, G.; Labau, S.; Basrour, S.; Bsiesy, A. Study of structural and electrical properties of ferroelectric HZO films obtained by single-target sputtering. AIP Adv. 2021, 11, 085004. [Google Scholar] [CrossRef]

- Guo, R.; Lin, W.; Yan, X.; Venkatesan, T.; Chen, J. Ferroic tunnel junctions and their application in neuromorphic networks. Appl. Phys. Rev. 2020, 7, 011304. [Google Scholar] [CrossRef]

- Fang, J.; Tang, Z.; Lai, X.-C.; Qiu, F.; Jiang, Y.-P.; Liu, Q.-X.; Tang, X.-G.; Sun, Q.-J.; Zhou, Y.-C.; Fan, J.-M.; et al. New-Style Logic Operation and Neuromorphic Computing Enabled by Optoelectronic Artificial Synapses in an MXene/Y:HfO2 Ferroelectric Memristor. ACS Appl. Mater. Interfaces 2024, 16, 31348–31362. [Google Scholar] [CrossRef]

- Lee, J.-W.; Cho, W.-J. Fabrication of resistive switching memory based on solution processed PMMA-HfOxblended thin films. Semicond. Sci. Technol. 2017, 32, 025009. [Google Scholar] [CrossRef]

- Hsu, C.-C.; Sun, J.-K.; Tsao, C.-C.; Chen, Y.-T. Effects of sol aging on resistive switching behaviors of HfOx resistive memories. Phys. B Condens. Matter 2017, 508, 98–103. [Google Scholar] [CrossRef]

- Ramadoss, A.; Krishnamoorthy, K.; Kim, S.J. Resistive Switching Behaviors of HfO2 Thin Films by Sol–Gel Spin Coating for Nonvolatile Memory Applications. Appl. Phys. Express 2012, 5, 085803. [Google Scholar] [CrossRef]

- Liu, C.-F.; Tang, X.-G.; Wang, L.-Q.; Tang, H.; Jiang, Y.-P.; Liu, Q.-X.; Li, W.-H.; Tang, Z.-H. Resistive Switching Characteristics of HfO2 Thin Films on Mica Substrates Prepared by Sol-Gel Process. Nanomaterials 2019, 9, 1124. [Google Scholar] [CrossRef]

- Ye, C.; Zhan, C.; Tsai, T.-M.; Chang, K.-C.; Chen, M.-C.; Chang, T.-C.; Deng, T.; Wang, H. Low-power bipolar resistive switching TiN/HfO2/ITO memory with self-compliance current phenomenon. Appl. Phys. Express 2014, 7, 034101. [Google Scholar] [CrossRef]

- Goswami, S.; Matula, A.J.; Rath, S.P.; Hedström, S.; Saha, S.; Annamalai, M.; Sengupta, D.; Patra, A.; Ghosh, S.; Jani, H.; et al. Robust resistive memory devices using solution-processable metal-coordinated azo aromatics. Nat. Mater. 2017, 16, 1216–1224. [Google Scholar] [CrossRef]

- Max, B.; Hoffmann, M.; Mulaosmanovic, H.; Slesazeck, S.; Mikolajick, T. Hafnia-Based Double-Layer Ferroelectric Tunnel Junctions as Artificial Synapses for Neuromorphic Computing. ACS Appl. Electron. Mater. 2020, 2, 4023–4033. [Google Scholar] [CrossRef]

- Jung, M.; Kim, S.; Hwang, J.; Kim, C.; Kim, H.J.; Kim, Y.-J.; Jeon, S. Monolithic three-dimensional hafnia-based artificial nerve system. Nano Energy 2024, 126, 109643. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, X.; Ding, Y.; Wang, Y.; Lu, X.; Yuan, G.; Liu, J.-M. Strong piezoelectricity of the nm-thick flexible Hf0.5Zr0.5O2 ferroelectric film. J. Alloys Compd. 2023, 968, 172083. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, L.; Jia, Y. Total Solution-Processed Zr: HfO2 Flexible Memristor with Tactile Sensitivity: From Material Synthesis to Application in Wearable Electronics. Sensors 2025, 25, 6429. https://doi.org/10.3390/s25206429

Yao L, Jia Y. Total Solution-Processed Zr: HfO2 Flexible Memristor with Tactile Sensitivity: From Material Synthesis to Application in Wearable Electronics. Sensors. 2025; 25(20):6429. https://doi.org/10.3390/s25206429

Chicago/Turabian StyleYao, Luqi, and Yunfang Jia. 2025. "Total Solution-Processed Zr: HfO2 Flexible Memristor with Tactile Sensitivity: From Material Synthesis to Application in Wearable Electronics" Sensors 25, no. 20: 6429. https://doi.org/10.3390/s25206429

APA StyleYao, L., & Jia, Y. (2025). Total Solution-Processed Zr: HfO2 Flexible Memristor with Tactile Sensitivity: From Material Synthesis to Application in Wearable Electronics. Sensors, 25(20), 6429. https://doi.org/10.3390/s25206429