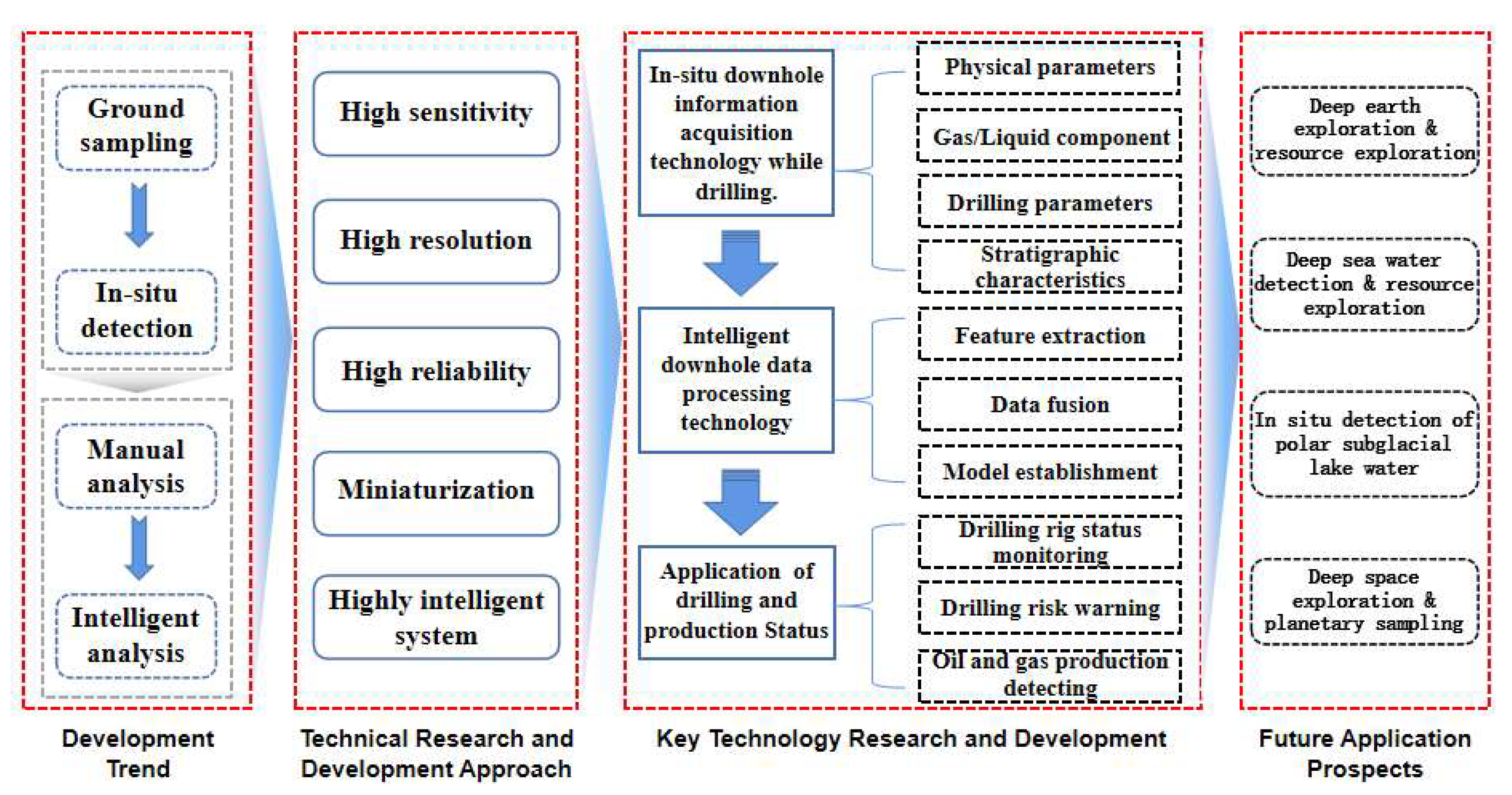

Sensing While Drilling and Intelligent Monitoring Technology: Research Progress and Application Prospects

Abstract

1. Introduction

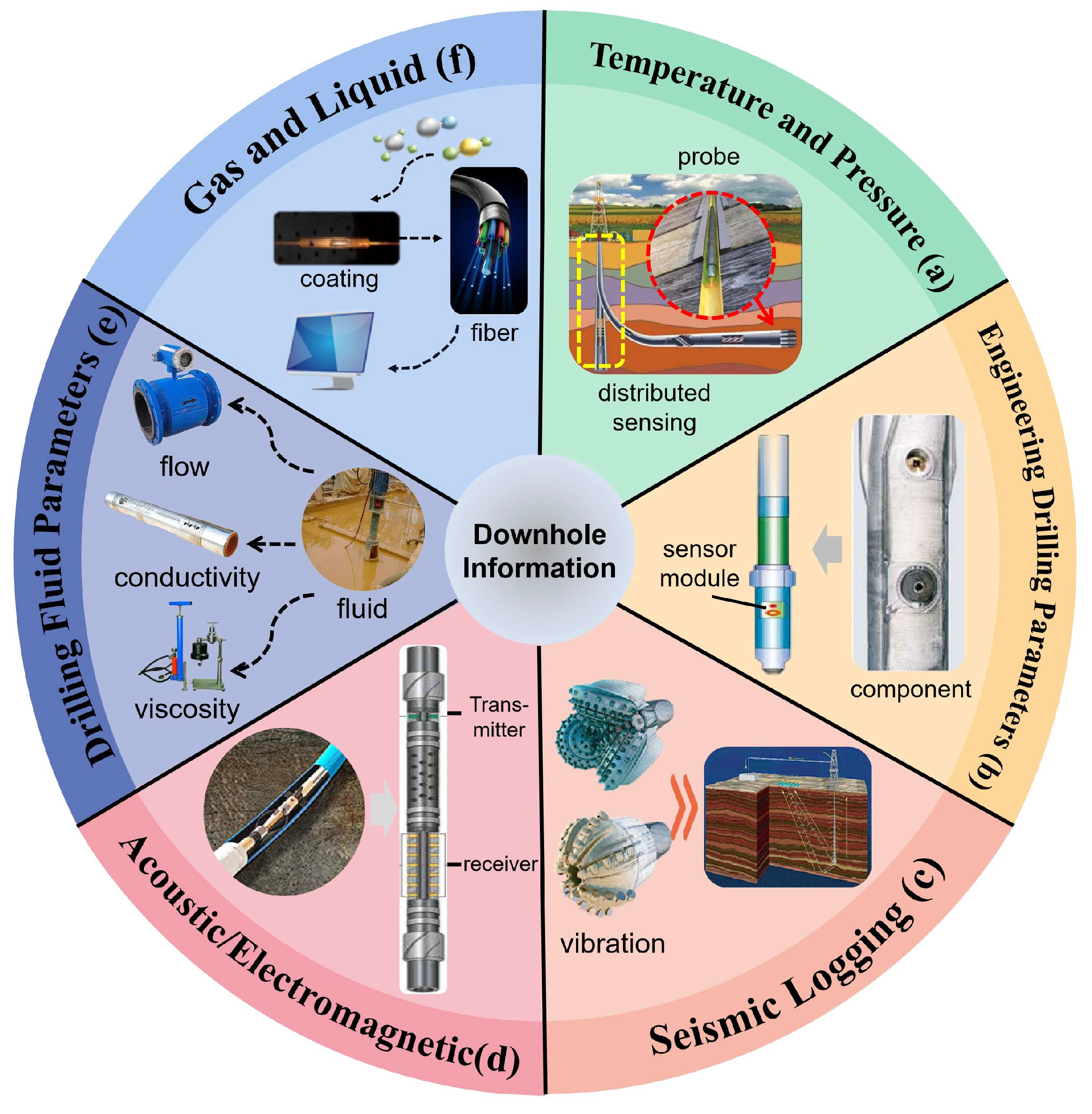

2. In Situ Downhole Information Acquisition Technology While Drilling

2.1. Fiber-Optic Temperature Sensing

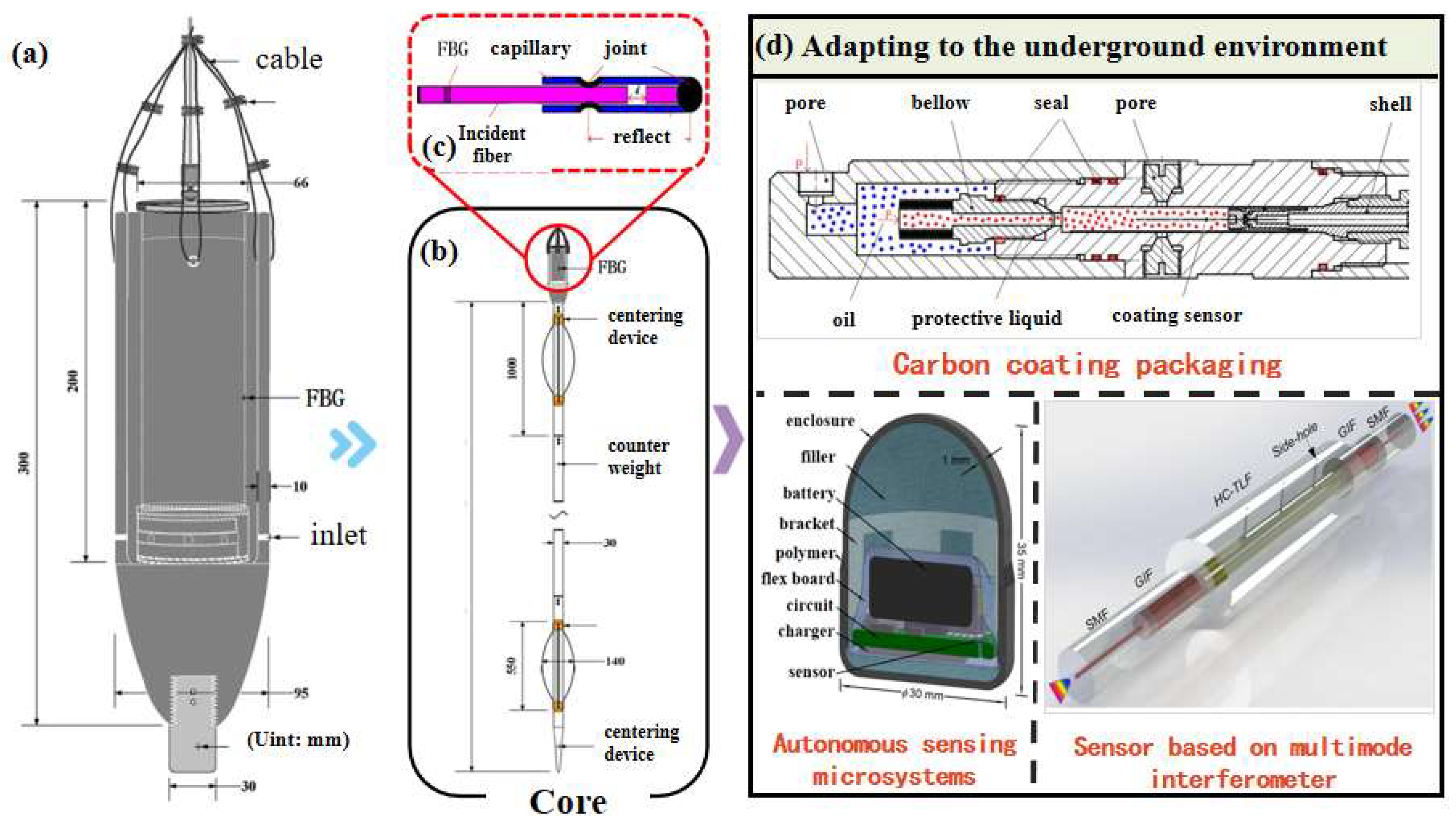

2.1.1. Fiber Bragg Grating Temperature Sensing

2.1.2. Distributed Temperature Sensing

2.2. Fiber-Optic Pressure Sensing

2.3. Fiber-Optic Pipeline Safety Sensing

2.4. Downhole Gas–Liquid Sensing

2.4.1. Bionic Olfaction

2.4.2. Crude Oil/Natural Gas Fiber Optic Sensing

2.5. Engineering Drilling Parameters

2.6. Drilling Fluid Parameters

2.7. Acoustic/Electromagnetic Wave Sensing

2.7.1. Sonic Logging

2.7.2. Electromagnetic Wave Logging

2.8. Seismic Logging

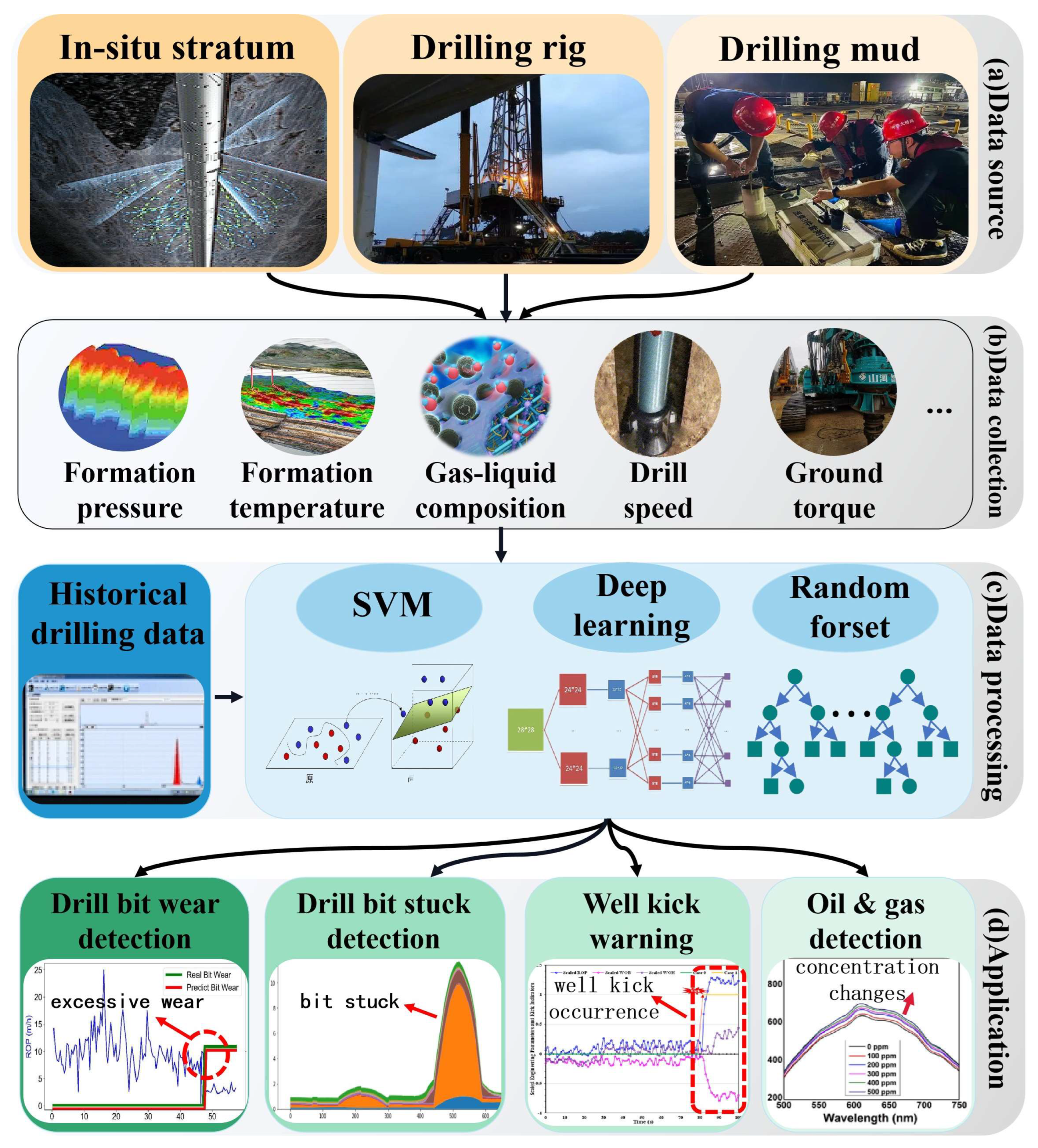

3. Intelligent Downhole Data Processing Technology

3.1. Typical Intelligent Algorithms

3.2. Real-Time Monitoring of Drill Bit Wear

3.3. Drilling Stuck Real-Time Monitoring

3.4. Real-Time Monitoring for Well Kick

3.5. Identification of Favorable Reservoirs and Petroleum Production

4. Application Prospects of Intelligent Monitoring Technology

4.1. Deep and Ultra-Deep Scientific Exploration and Resource Prospecting

4.2. In Situ Exploration of Polar and Deep-Sea Regions

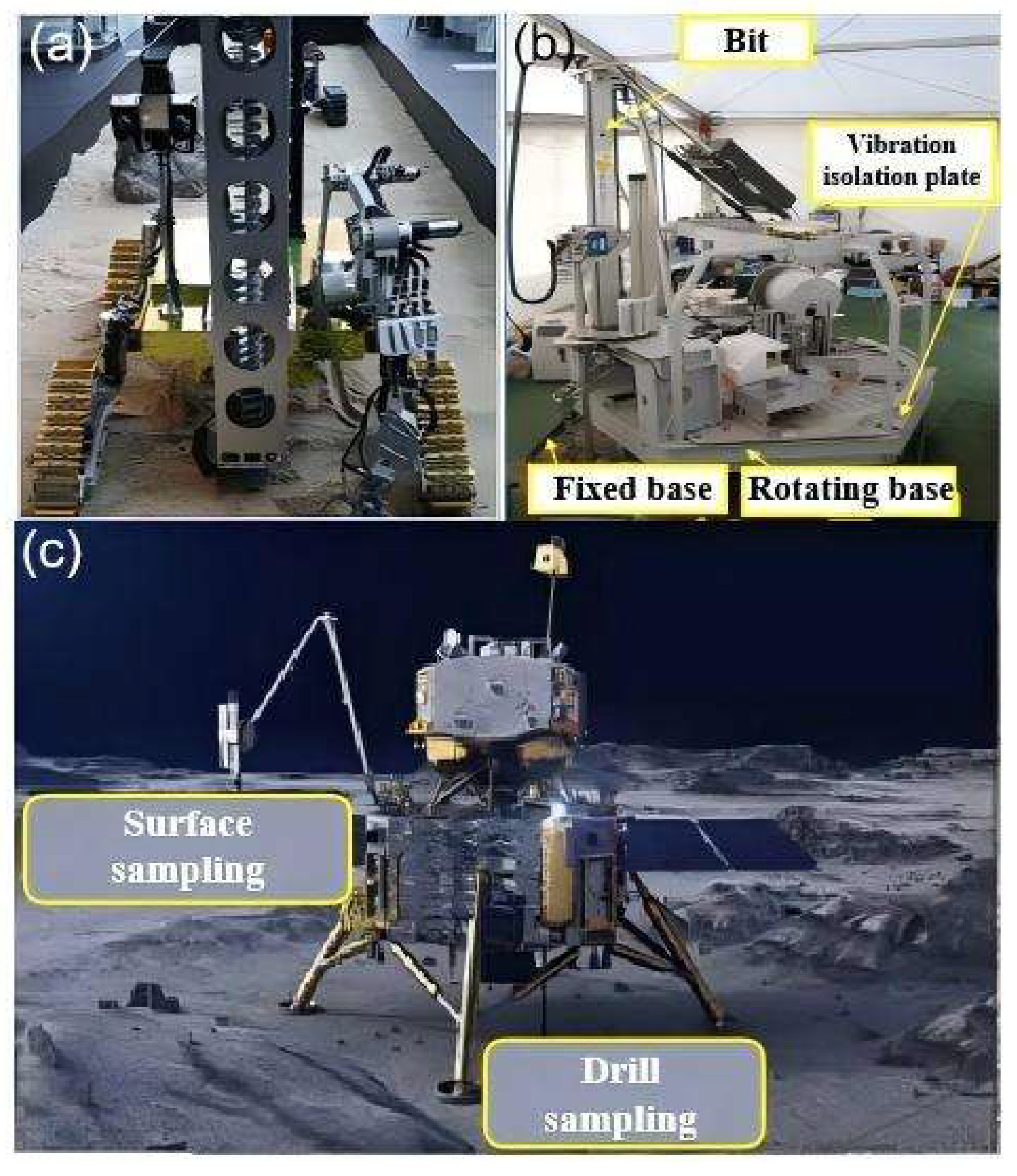

4.3. Extraterrestrial Planetary Sampling

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.; Zou, C.; Chen, J.; Wu, S.; Pan, S.; Ma, F.; Li, J.; Jiang, W.; Wang, X. “Exploring petroleum inside or near the source kitchen”: Innovations in petroleum geology theory and reflections on hydrocarbon exploration in key fields. Acta Pet. Sin. 2021, 42, 1310–1324. [Google Scholar]

- Bao, K.; Xu, W.; Wang, Q. Stratigraphic information extraction from landsat data based on machine learning—A case study pf the Keping area of southwest Tianshan Mountains. Geol. Bull. China 2023, 42, 637–645. [Google Scholar]

- Liu, Q. Development status and application prospect for several intelligent drilling equipment: A case study of shale gas development in Sichuan basin. Drill. Prod. Technol. 2022, 45, 1–10. [Google Scholar]

- Wang, J. Study on liquid surface testing method of oil drilling mud. CIESC J. 2022, 12, 27–30. [Google Scholar]

- Wang, H.; Liu, S.; Ma, L.; Zhu, Y.; Shu, J.; Wang, X. Comprehensive correlation technology of coal and rock layers in mines for intelligent mining. Coal Geol. Explor. 2022, 50, 24–38. [Google Scholar]

- Agwu, O.E.; Akpabio, J.U.; Alabi, S.B.; Dosunmu, A. Artificial intelligence techniques and their applications in drilling fluid engineering: A review. J. Pet. Sci. Eng. 2018, 167, 300–315. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiong, Y.; Gao, Y.; Liu, L.; Wang, M.; Peng, G. Wellbore temperature distribution during circulation stage when well-kick occurs in a continuous formation from the bottom-hole. Energy 2018, 164, 964–977. [Google Scholar] [CrossRef]

- Shang, B.; Ma, Y.; Hu, R.; Yuan, C.; Hu, J.; Luo, X. Passive thermal management system for downhole electronics in harsh thermal environments. Appl. Therm. Eng. 2017, 118, 593–599. [Google Scholar] [CrossRef]

- Hurtig, E.; Growig, S.; Jobmamn, M.; Kuhn, K.; Marschall, P. Fibre-optic temperature measurements in shallow boreholes: Experimental application for fluid logging—ScienceDirect. Geothermics 1994, 23, 355–364. [Google Scholar] [CrossRef]

- Qiao, X.; Shao, Z.; Bao, W.; Rong, Q. Fiber Bragg Grating Sensors for the Oil Industry. Sensors 2017, 17, 429. [Google Scholar] [CrossRef]

- Burhanuddin, W.A.F.W.; Ahmad, H.; Alias, M.A.; Sa’Ad, M.S.M.; Sun, S.; Ismail, M.F. Multiparameter fiber bragg grating (FBG)-based sensor fabricated using 3-d printing technology for precise measurement of vertical earth pore pressure. IEEE Sens. J. 2024, 24, 25793–25801. [Google Scholar]

- Yu, C.W.; Lei, S.C.; Chen, W.S.; Song, S.R. Downhole fiber optic temperature-pressure innovative measuring system used in Sanshing geothermal test site. Geothermics 2018, 74, 190–196. [Google Scholar] [CrossRef]

- He, J.; Xu, X.; Du, B.; Xu, B.; Chen, R.; Wang, Y.; Liao, C.; Guo, J.; Wang, Y.; He, J. Stabilized ultra-high-temperature sensors based on inert gas-sealed sapphire fiber Bragg gratings. ACS Appl. Mater. Interfaces 2022, 14, 12359–12366. [Google Scholar] [CrossRef]

- Ghafoori, Y.; Vidmar, A.; Kryžanowski, A. A dynamic calibration of optical fiber DTS measurements using PEST and reference thermometers. Sensors 2022, 22, 3890. [Google Scholar] [CrossRef]

- Ekechukwu, G.K.; Sharma, J. Well-scale demonstration of distributed pressure sensing using fiber-optic DAS and DTS. Sci. Rep. 2021, 11, 12505. [Google Scholar] [CrossRef]

- Pouladi, B.; Bour, O.; Longuevergne, L.; Jerome, B.; Nataline, S. Modelling borehole flows from Distributed Temperature Sensing data to monitor groundwater dynamics in fractured media. J. Hydrol. 2021, 598, 126450. [Google Scholar] [CrossRef]

- Zheng, H.; Wu, H.; Wang, Y.; Shen, X.; Fang, Z.; Huang, D.; Dash, J.N.; Htein, L.; Cheng, X.; Tam, H.Y.; et al. High-sensitivity distributed optical fiber sensor for simultaneous hydrostatic pressure and temperature measurement based on birefringent frequency-scanning φ-OTDR. Opt. Laser Technol. 2024, 175, 110756. [Google Scholar] [CrossRef]

- Qin, L.; Yang, Q.; Zhang, W.; Yin, Z.; Li, J.; Zhang, M. Design of a wireless remote monitoring system for Raman distributed-optical-fiber sensing. Laser Optoelectron. Prog. 2024, 61, 2106001. [Google Scholar]

- Yang, B.; Zhao, Q.C.; Che, C.R.; An, B.X.; Xu, Z. High-Precision optical fiber temperature and pressure sensor and its application in production wells. Laser Optoelectron. Prog. 2022, 59, 1706006. [Google Scholar] [CrossRef]

- Sun, Y.; Xue, Z.; Hashimoto, T.; Zhang, Y. Optically quantifying spatiotemporal responses of water injection-induced strain via downhole distributed fiber optics sensing. Fuel 2020, 283, 118948. [Google Scholar] [CrossRef]

- Li, Z.; Liao, C.; Yang, Y.; Wang, Y.; Wang, Y. High sensitivity gas pressure sensor based on multimode interferometer using hollow-core tube lattice fiber. Opt. Lett. 2020, 45, 4571–4574. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.Y.; Zhang, F.X.; Zhao, Q.C.; Che, C.R. Real-time monitoring of pressure and temperature of oil well using a carbon-coated and bellow-packaged optical fiber sensor. Opt. Fiber Technol. 2021, 67, 102703. [Google Scholar] [CrossRef]

- Vellaluru, N.; Dutta, P.; Benken, A.; Boero-Rollo, J.G.; Ordonez-Varela, J.R.; Gianchandani, Y. Sensing microsystem with H2S compatible package and enhanced buoyancy for downhole monitoring. SPE J. 2022, 27, 3884–3895. [Google Scholar] [CrossRef]

- Hu, X.; Su, D.; Qiao, X. Diaphragm-Structured Fiber-Optic Pressure Sensors for Oil Downhole Applications. IEEE Sens. J. 2024, 24, 14270–14278. [Google Scholar]

- Xu, L.; Shi, S.; Huang, Y.; Yan, F.; Yang, X.; Bao, Y. Corrosion monitoring and assessment of steel under impact loads using discrete and distributed fiber optic sensors. Opt. Laser Technol. 2024, 174, 110553. [Google Scholar] [CrossRef]

- Gan, W.; Li, X.; Wang, Y.; Wulamu, A.; Zhang, C.; Chen, X. Gas pipeline leakage detection and location by using w-FBG array based micro-strain sensing technology. Meas. Sci. Technol. 2024, 35, 056108. [Google Scholar] [CrossRef]

- Pereira, L.; Sousa, I.; Mesquita, E.; Cabral, A.; Alberto, N.; Diaz, C.; Varum, H.; Antunes, P. FBG-Based Accelerometer for Buried Pipeline Natural Frequency Monitoring and Corrosion Detection. Buildings 2024, 14, 456. [Google Scholar] [CrossRef]

- Gao, K.; Sun, Y.; Gao, R.; Xu, L.; Wang, C.; Li, Y. Application and prospect of bionic non-smooth theory in drilling engineering. Pet. Explor. Dev. 2009, 36, 519–522+540. [Google Scholar] [CrossRef]

- Kong, C.; Zhao, S.; Weng, X.; Liu, C.; Guan, R.; Chang, Z. Weighted summation: Feature extraction of farm pigsty data for electronic nose. IEEE Access 2019, 7, 96732–96742. [Google Scholar] [CrossRef]

- Wang, B.; Li, X.; Chen, D.; Weng, X.; Chang, Z. Development of an electronic nose to characterize water quality parameters and odor concentration of wastewater emitted from different phases in a wastewater treatment plant. Water Res. 2023, 235, 119878. [Google Scholar] [CrossRef]

- Mawardzi, M.F.; Japper-Jaafar, A.; Najib, M.S.; Daud, S.M.; Ya, T.M. Intelligent classification of waxy crude oil odor-profile at different temperature. IOP Conf. Ser. Mater. Sci. Eng. 2019, 469, 012071. [Google Scholar] [CrossRef]

- Aliano-González, M.; Ferreiro-González, M.; Gerardo, B.; Jesus, A.; Jose, A.A.; Miguel, P.; Carmelo, G.B. An electronic nose based method for the discrimination of weathered petroleum-derived products. Sensors 2018, 18, 2180. [Google Scholar] [CrossRef]

- Totland, C.; Thomas, P.J.; Stordal, I.F.; Eek, E. A fully distributed fibre optic sensor for the detection of liquid hydrocarbons. IEEE Sens. J. 2020, 21, 7631–7637. [Google Scholar] [CrossRef]

- Samavati Alireza, S.; Zahra, I.; Ahmad, F.I.; Noorhana, Y.; Mohd, H.D.O.; Mukhlis, A.R. Multi aspect investigation of crude oil concentration detecting via optical fiber sensor coated with ZnO/Ag nano-heterostructure. Measurement 2021, 167, 108171. [Google Scholar] [CrossRef]

- Dabrowski, K.M.; Kuczyński, S.; Barbacki, J.; Wlodek, T.; Smulski, R.; Nagy, S. Downhole measurements and determination of natural gas composition using Raman spectroscopy. J. Nat. Gas Sci. Eng. 2019, 65, 25–31. [Google Scholar] [CrossRef]

- Yang, A.; Wu, M.; Hu, J.; Chen, L.; Lu, C.; Cao, W. Discrimination and correction of abnormal data for condition monitoring of drilling process. Neurocomputing 2021, 433, 275–286. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, G.; Li, J.; Li, L.; Wang, S.; Tan, T. Pressure while drilling system development and field test. Oil Drill. Prod. Technol. 2012, 34, 20–22. [Google Scholar]

- Dong, H.; Chen, L.; Wu, J.; Liu, H. Research and application of low-density drilling fluid for complex formation. Coal Geol. Explor. 2017, 45, 168–172. [Google Scholar]

- Zhang, H.; Wang, M.; Gao, Y.; Nie, W.; Wang, X.; Li, S. Technical system for mud loss analysis and diagnosis in drilling engineering to prevent reservoir damage. Energy Sci. Eng. 2024, 12, 1337–1355. [Google Scholar] [CrossRef]

- Haghgouei, H.; Lavrov, A.; Nermoen, A. Effect of drill string lateral vibrations on wellbore stability and optimal mud pressure determination. Geoenergy Sci. Eng. 2025, 247, 213691. [Google Scholar] [CrossRef]

- Mahmoudian, M.S.; Shiri, Y.; Vaezian, A. Estimating the safe mud weight window for drilling operations through pre-stack seismic inversion, a case study in one of the Southwestern Iran oil fields. J. Pet. Explor. Prod. Technol. 2025, 15, 24. [Google Scholar] [CrossRef]

- Chen, M.; Sun, D.; Xie, X.; Gao, Y.; Wang, F.; Liu, J. Progress and prospect of acoustic logging while drilling technologies. Geol. Explor. 2023, 30, 32–41. [Google Scholar]

- Market, J.; Bilby, C. Introducing the first LWD crossed-dipole sonic imaging service. Petrophysics 2012, 53, 208–221. [Google Scholar]

- Zhang, P.; Deng, S.; Hu, X.; Wang, L.; Wang, Z.; Yuan, X.; Cai, L. Detection performance and sensitivity of logging-while-drilling extra-deep azimuthal resistivity measurement. Chin. J. Geophys. 2021, 64, 2210–2219. [Google Scholar]

- Zhao, K.; Wu, S.; Hong, D. A Robust Forward Modeling for Ultradeep Azimuthal Resistivity Logging in 3D Well Trajectory. IEEE Trans. Geosci. Remote Sens. 2025, 63, 4501212. [Google Scholar]

- Zhang, M.; Zhao, Q.; Luo, B.; Liu, Y. Review of the drill bit seismic while drilling technology. Prog. Geophys. 2022, 37, 1677–1688. [Google Scholar]

- Lee, G.; Pyun, S.; Chung, Y.; Shin, J.; Nam, M.J.; Choi, W.; Yu, Y.C.; Hwang, S. 3D Near-surface Velocity Model Building by Integrating Surface, Borehole Seismic, and Well-logging Data in a Small-scale Testbed. J. Environ. Eng. Geophys. 2024, 28, 12–27. [Google Scholar] [CrossRef]

- Wang, P.; Fan, E.; Wang, P. Comparative analysis of image classification algorithms based on traditional machine learning and deep learning. Pattern Recognit. Lett. 2021, 141, 61–67. [Google Scholar] [CrossRef]

- Asaye, L.; Le, C.; Huang, Y.; Le, T.Q.; Yadav, O.P.; Le, T. Predicting and Understanding Emergency Shutdown Durations Level of Pipeline Incidents Using Machine Learning Models and Explainable AI. Processes 2025, 13, 445. [Google Scholar] [CrossRef]

- Dong, S.; Wang, P.; Abbas, K. A survey on deep learning and its applications. Comput. Sci. Rev. 2021, 40, 100379. [Google Scholar] [CrossRef]

- Agostini, C.E.; Sampaio, M.A. Probabilistic neural network with Bayesian-based, spectral torque imaging and deep convolutional autoencoder for PDC bit wear monitoring. J. Pet. Sci. Eng. 2020, 193, 107434. [Google Scholar] [CrossRef]

- Lin, L.; Guo, H.; Guo, F.; Lv, Y.; Liu, J.; Tong, C. A novel domain adversarial time-varying conditions intervened neural network for drill bit wear monitoring of the jumbo drill under variable working conditions. Measurement 2023, 208, 112474. [Google Scholar] [CrossRef]

- Alsaihati, A.; Elkatatny, S.; Mahmoud, A.A.; Abdulraheem, A. Use of machine learning and data analytics to detect downhole abnormalities while drilling horizontal wells, with real case study. J. Energy Resour. Technol. 2021, 143, 043201. [Google Scholar] [CrossRef]

- Zhu, S.; Song, X.; Zhu, Z.; Yao, X.; Liu, M. Intelligent Prediction of stuck pipe using combined data-driven and knowledge-driven model. Appl. Sci. 2022, 12, 5282. [Google Scholar]

- Wu, H.; Wang, Z.; Si, L.; Zou, X. Drill tools sticking prediction based on adaptive long short-term memory. Meas. Sci. Technol. 2024, 35, 086134. [Google Scholar] [CrossRef]

- Osarogiagbon, A.; Muojeke, S.; Venkatesan, R.; Khan, F.; Gillard, P. A new methodology for kick detection during petroleum drilling using long short-term memory recurrent neural network. Process Saf. Environ. Prot. 2020, 142, 126–137. [Google Scholar] [CrossRef]

- Yin, Q.; Yang, J.; Tyagi, M.; Zhou, X.; Hou, X.; Cao, B. Field data analysis and risk assessment of gas kick during industrial deepwater drilling process based on supervised learning algorithm. Process Saf. Environ. Prot. 2020, 146, 312–328. [Google Scholar] [CrossRef]

- Zhang, Z.; Lai, X.; Wu, M.; Chen, L.; Lu, C.; Du, S. Fault diagnosis based on feature clustering of time series data for loss and kick of drilling process. J. Process Control 2021, 102, 24–33. [Google Scholar] [CrossRef]

- Roshani, M.; Phan, G.; Faraj, R.H.; Phan, N.H.; Roshani, G.H.; Nazemi, B.; Corniani, E.; Nazemi, E. Proposing a gamma radiation based intelligent system for simultaneous analyzing and detecting type and amount of petroleum by-products. Nucl. Eng. Technol. 2020, 53, 1277–1283. [Google Scholar] [CrossRef]

- Alizadeh, S.; Khodabakhshi, A.; Hassani, P.A.; Vaferi, B. Smart Identification of Petroleum Reservoir Well Testing Models Using Deep Convolutional Neural Networks (GoogleNet). J. Energy Resour. Technol. 2021, 143, 073008. [Google Scholar] [CrossRef]

- Tadjer, A.; Hong, A.; Bratvold, R.B. Machine learning based decline curve analysis for short-term oil production forecast. Energy Explor. Exploit. 2021, 39, 1747–1769. [Google Scholar] [CrossRef]

- Kaczmarczyk-Kuszpit, W.; Sowizdzal, K. Integration of Well Logging and Seismic Data for the Prognosis of Reservoir Properties of Carbonates. Energies 2024, 17, 355. [Google Scholar] [CrossRef]

- Chang, Z.; Sun, Y.; Zhang, Y.; Gao, Y.; Weng, X.; Chen, D.; David, L.; Xie, J. Bionic optimization design of electronic nose chamber for oil and gas Detection. J. Bionic Eng. 2018, 15, 533–544. [Google Scholar] [CrossRef]

- Zhou, H.; Jiao, P.; Lin, Y. Emerging deep-sea smart composites: Advent, performance, and future trends. Materials 2022, 15, 6469. [Google Scholar] [CrossRef]

- Sun, Y.; Deng, S.; Wang, H. Advances in the exploitation technologies and researches of oil shale in the world: Report on 33rd oil shale symposium in US. J. Jilin Univ. (Earth Sci. Ed.) 2015, 45, 1052–1059. [Google Scholar]

- Gao, M.; Wang, X.; Zhang, G.; Li, M.; Liu, T.; Hao, H.; Li, C.; Xie, H. The novel idea and technical progress of lunar in-situ condition preserved coring. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 46. [Google Scholar] [CrossRef]

- Bai, F.; Sun, Y.; Liu, Y.; Guo, M. Evaluation of the porous structure of Huadian oil shale during pyrolysis using multiple approaches. Fuel 2017, 187, 1–8. [Google Scholar] [CrossRef]

- Sun, Y.H.; Guo, W.; Deng, S.H. The status and development trend of in-situ conversion and drilling exploitation technology for oil shale. Drill. Eng. 2021, 48, 57–67. [Google Scholar]

- He, W.; Sun, Y.; Guo, W.; Shan, X. Controlling the in-situ conversion process of oil shale via geochemical methods: A case study on the Fuyu oil shale, China. Fuel Process. Technol. 2021, 219, 106876. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Z.; Li, Q.; Deng, S.; Guo, W. Controlling groundwater infiltration by gas flooding for oil shale in situ pyrolysis exploitation. J. Pet. Sci. Eng. 2019, 179, 444–454. [Google Scholar] [CrossRef]

- Oszczepalski, S.; Speczik, S. Maturity assessment by rock-eval pyrolysis as an exploration tool, Kupferschiefer, Poland. In Proceedings of the 10th Biennial SGA Meeting of the Society-for-Geology-Applied-to-Mineral-Deposits, Townsville, Australia, 17–20 August 2009. [Google Scholar]

- Weng, X.; Sun, Y.; Xie, J.; Deng, S.; Chang, Z. Bionic layout optimization of sensor array in electronic nose for oil shale pyrolysis process detection. J. Bionic Eng. 2021, 18, 441–452. [Google Scholar] [CrossRef]

- Sun, Y.; Li, B.; Fan, X.; Li, Y.; Li, G.; Yu, H.; Li, H.; Wang, D.; Zhang, N.; Gong, D.; et al. Brief communication: New sonde to unravel the mystery of polar subglacial lakes. Cryosphere 2023, 17, 1089–1095. [Google Scholar] [CrossRef]

- Fang, Y.; Bao, G.; Jin, X. Prospects for the development and utilization of deep sea resources in the 21st century. Mar. Sci. Bull. 2000, 19, 73–78. [Google Scholar]

- Yao, Y.; Li, H.; Sun, Y.; Chang, Z. A Bionic Degassing Device Inspired by Gills: Application on Underwater Oil and Gas Detection. J. Bionic Eng. 2022, 20, 253–266. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, B.; Wei, H.; Zhang, Y.; Chao, C.; Xu, K.; Ding, X.; Hou, X.; Zhao, Z. Review on planetary regolith-sampling technology. Prog. Aerosp. Sci. 2021, 127, 100760. [Google Scholar] [CrossRef]

- Kawamoto, H.; Kubo, K.; Kikumiya, R. Vertical transportation of lunar regolith and ice particles using vibrating tube. J. Aerosp. Eng. 2021, 34, 04021097. [Google Scholar] [CrossRef]

- Cannon, H.N.; Stoker, C.R.; Dunagan, S.E.; Dunagan, K.D.; Javier, G.E.; Brian, J.G.; Lawrence, G.L.; David, M.; Rosalba, B.; Mark, B.; et al. MARTE: Technology development and lessons learned from a Mars drilling mission simulation. J. Field Robot. 2010, 24, 877–905. [Google Scholar]

- Liu, C.; Li, J.; Zhang, T.; Liu, Q.; Huang, Z.; Zhang, J.; Gao, Y.; Yu, T.; Zhang, K.; Chang, T.; et al. Key technologies in the teleoperation of the Chang’e-5 lunar sampling. Sci. Sin. Technol. 2022, 52, 473–488. [Google Scholar]

- Li, P.; Cheng, J. Digital twin technology of geological information in mining and excavation working face. Coal Geol. Explor. 2022, 50, 19. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Yao, Z.; Zhang, T.; Chang, Z. Sensing While Drilling and Intelligent Monitoring Technology: Research Progress and Application Prospects. Sensors 2025, 25, 6368. https://doi.org/10.3390/s25206368

Li X, Yao Z, Zhang T, Chang Z. Sensing While Drilling and Intelligent Monitoring Technology: Research Progress and Application Prospects. Sensors. 2025; 25(20):6368. https://doi.org/10.3390/s25206368

Chicago/Turabian StyleLi, Xiaoyu, Zongwei Yao, Tao Zhang, and Zhiyong Chang. 2025. "Sensing While Drilling and Intelligent Monitoring Technology: Research Progress and Application Prospects" Sensors 25, no. 20: 6368. https://doi.org/10.3390/s25206368

APA StyleLi, X., Yao, Z., Zhang, T., & Chang, Z. (2025). Sensing While Drilling and Intelligent Monitoring Technology: Research Progress and Application Prospects. Sensors, 25(20), 6368. https://doi.org/10.3390/s25206368