1. Introduction

Tilapia farming is a significant economic activity for Thai farmers, particularly in the northern and central regions, where natural water resources support aquaculture. Tilapia is valued for its tolerance to diverse environments, rapid growth, and strong market demand. However, water quality remains a major constraint that affects survival and growth. Seasonal and climatic fluctuations can reduce dissolved oxygen (DO), particularly during rainy or cloudy periods; sometimes, DO falls below critical thresholds and causes stress, hypoxia, or even fish mortality through surfacing behavior (“air gulping”) [

1]. Sudden shifts in pH and temperature from heavy rainfall further disrupt homeostasis, impairing ion regulation and ammonia excretion and increasing vulnerability to disease [

2].

Studies have shown that DO concentrations below 5 mg/L impair tilapia growth and increase mortality risk, particularly in high-density systems without proper aeration [

2]. Climate variability, including heavy rainfall and drought, can further destabilize pond ecosystems, leading to ammonia or organic pollutant buildup that is toxic to fish [

3]. These conditions threaten long-term growth and reproduction, underscoring the need for effective water quality management through continuous monitoring of DO, pH, temperature, and ammonia, together with adaptive planning based on seasonal and meteorological conditions.

In recent years, the Internet of Things (IoT) has become a transformative tool in aquaculture, enabling real-time monitoring of water quality, a key factor for fish health and growth. Flores-Iwasaki et al. reviewed IoT-based systems in Biofloc, RASs, and aquaponics, showing that pH, temperature, and DO sensors were most common, effectively reducing mortality and improving growth [

4]. Olanubi et al. demonstrated a smart water quality control system using ESP32 with pH, temperature, and turbidity sensors, transmitting data to the cloud and providing real-time alerts via mobile apps [

5]. While these advances support responsive and semi-autonomous control, Bonfante Rodríguez et al. noted persistent challenges in rural or small-scale farms, including unstable connectivity, hardware unsuited for harsh conditions, and limited sensor precision—barriers that hinder full adoption of autonomous IoT systems [

6].

To address the limitations of IoT systems focused mainly on sensing and visualization, recent studies have integrated Artificial Intelligence (AI) and Machine Learning (ML) into aquaculture. These technologies improve predictive capabilities for key parameters such as DO, pH, temperature, and ammonia, directly affecting fish health and survival. Baena-Navarro et al. developed a hybrid system combining ML models, IoT sensors, and the Quantum Approximate Optimization Algorithm (QAOA), which cut training time by up to 50% while maintaining survival rates above 90% under volatile tropical conditions [

7]. A major advantage of this approach is its dual capability for both local and cloud-based processing, making it suitable for large-scale as well as resource-limited farms.

Roy and Kumari reviewed the application of AI in Recirculating Aquaculture Systems (RASs) and aquaponics, emphasizing predictive analytics for optimizing DO, pH, and nutrient levels. These AI-driven systems enhance resource efficiency and promote sustainable production [

8]. Most, however, remain cloud-dependent, requiring high deployment costs and stable internet connectivity, which are often inaccessible to smallholder farmers. To overcome these limitations, Esty et al. introduced EcoGuard, an IoT platform leveraging edge computing and federated learning for distributed processing. This system enables timely water quality predictions and mobile alerts while ensuring data privacy and reducing costs, making it more accessible and scalable for small- and medium-scale farms [

9].

From the literature reviewed [

1,

2,

3,

4,

5,

6,

7,

8], it appears that most Smart Aquaculture systems remain largely passive, collecting sensor data and transmitting it to the cloud with minimal or no deployment of predictive ML models on microcontrollers. Existing studies rarely consider endpoint constraints—such as limited processing power, memory, energy, and intermittent connectivity—that restrict timely responses and hinder effective real-time water quality control. Furthermore, many reported models and thresholds are derived from nonlocal contexts, making them difficult to adapt for site-specific decision-making and insufficient to capture heterogeneity in geomorphology, hydrochemistry, and climate across ponds.

Accordingly, the key research gap lies in the absence of practical demonstrations that deploy predictive ML models directly on ultra-low-cost edge devices, such as the ESP32, for aquaculture water quality management. To address this gap, the present study develops and validates an Edge AIoT system for tilapia aquaculture in Northern Thailand (Doi Lo District, Chiang Mai Province). The system integrates IoT sensing with ML deployed locally on the ESP32 to predict dissolved oxygen (DO) and pH without continuous cloud dependency. As one of the first Edge AI applications in aquaculture, we introduce an explicit “accuracy–feasibility” trade-off framework for model selection under edge constraints. Also, we provide field evidence that lightweight Multiple Linear Regression (MLR) running on ESP32 can maintain DO and pH within biologically optimal ranges at a low energy cost. The edge models are further coupled with actuators (e.g., aeration pumps, localized heaters) and a user alerting mechanism for pH adjustment, enabling autonomous, real-time water quality regulation, reducing production risks, and advancing the sustainability of tilapia aquaculture. This study’s novelty lies in it being among the first studies to demonstrate predictive ML deployment on ultra-low-cost microcontrollers for aquaculture, as well as advancing the shift from cloud-dependent monitoring to useful, independent, and scalable Edge AIoT systems by presenting a realistic accuracy–feasibility architecture and verifying its performance in the actual world.

2. Literature Review

Recent studies have increasingly emphasized the convergence of Internet of Things (IoT) and Machine Learning (ML) for water quality monitoring. Advances in Machine Learning and IoT for Water Quality Monitoring [

10] provided a broad overview, highlighting how IoT enables continuous environmental sensing while ML enhances pattern recognition and forecasting accuracy of critical parameters. The review also examined wireless communication technologies such as LPWAN, Wi-Fi, and ZigBee, concluding that IoT–ML integration represents a promising direction for intelligent monitoring. In practice, An IoT Real-Time Potable Water Quality Monitoring Model [

11] implemented Arduino and NB-IoT for real-time water quality monitoring, achieving high classification accuracy and user alerts; however, it lacked automated feedback or control.

Efforts to improve system responsiveness have further explored distributed computation. Intelligent Edge–Cloud Framework for Water Quality Monitoring [

12] demonstrated that edge processing substantially reduces latency and energy consumption compared to cloud-only approaches, while hybrid architectures enhance accuracy. These findings confirm the growing interest in computational designs that move analytics closer to the data source.

Parallel advances have also been made in predictive modeling of dissolved oxygen (DO). The Development of Dissolved Oxygen Forecast Model Using Hybrid ML [

13] integrated hydro-meteorological variables with advanced algorithms, achieving high precision, while Using Machine Learning Models for Short-Term Prediction of DO in a Microtidal Estuary [

14] demonstrated that temporal sequence models such as RNN and LSTM are highly effective for multi-week predictions. Despite their accuracy, these studies were based on meteorological or laboratory data rather than IoT-enabled real-time deployment, limiting direct application to aquaculture ponds.

Within aquaculture contexts, IoT-enabled platforms have begun to emerge.

AquaBot [

15] employed ESP32-based sensing combined with ML classifiers to recommend fish species based on prevailing conditions. While innovative, this system focused on recommendations rather than direct control of water parameters. Likewise, Random Forest-Based Framework for Water Quality Prediction [

16] applied ML to inland and coastal waters using in situ and satellite data, but it operated entirely on server-based computation and lacked real-time aquaculture applicability. A systematic review of 217 studies [

17] further confirmed that IoT applications in aquaculture are dominated by monitoring pH, temperature, and DO but face persistent challenges in automated control, sensor maintenance, and local ML deployment.

As summarized in

Table 1, these representative studies highlight three clear patterns:

IoT systems are often limited to data collection with minimal local intelligence [

11,

12,

15].

ML prediction models achieve high accuracy [

13,

14] yet remain disconnected from real-time aquaculture operations.

Although edge computing frameworks reduce latency and energy use [

12], small-scale aquaculture ponds have not yet benefited from their deployment.

Taken together, the literature [

10,

11,

12,

13,

14,

15,

16,

17] demonstrates substantial progress in IoT–ML integration for water quality management. However, most implementations remain cloud-dependent, incur high costs, or fail to account for endpoint resource constraints such as limited processing power, energy, and intermittent connectivity. Importantly, none of the reviewed works show predictive ML deployment directly on ultra-low-cost microcontrollers such as ESP32 for aquaculture. This persistent gap motivates the present study, which develops and validates an Edge AIoT system for real-time prediction and autonomous control of dissolved oxygen and pH under field conditions. To address this, the following section details the system design, data acquisition, and model evaluation protocols.

3. Materials and Methods

To develop a real-time, automated water quality control system for tilapia farming using a low-cost platform, this study designed and deployed a prototype system in a real-world aquaculture setting. The system integrates environmental and water quality sensors with machine learning-based prediction algorithms and automatic control mechanisms. Emphasis was placed on ensuring that the system can operate effectively under limited infrastructure and intermittent internet connectivity. The details of the implementation are as follows:

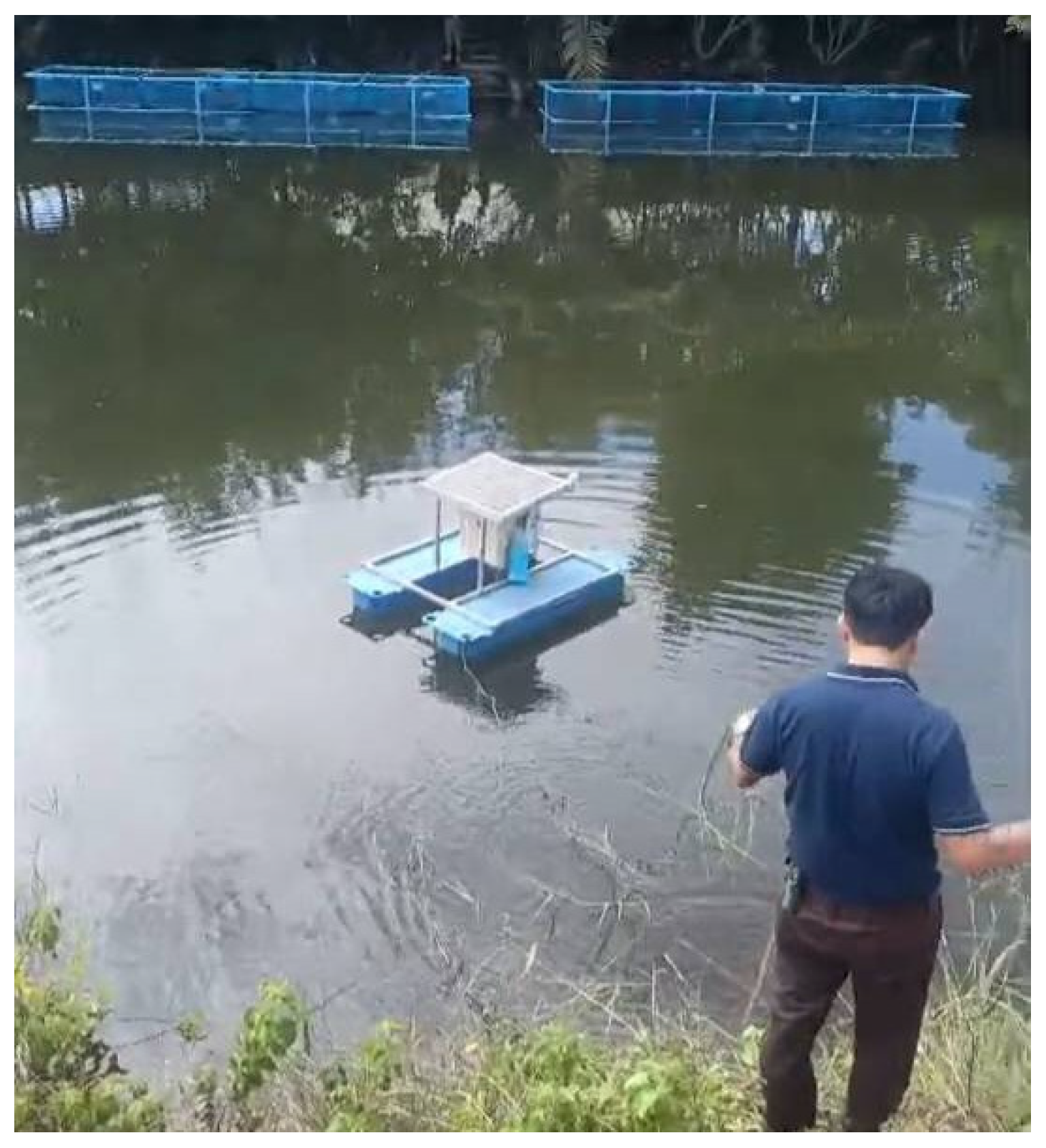

3.1. Experimental Area and Data Collection

This study was conducted in a real-world field setting at the Agricultural Learning and Productivity Enhancement Center in Doi Lo District, Chiang Mai Province, Thailand. The site is located within a mixed-agriculture zone characterized by favorable climatic and environmental conditions for integrated aquaculture. The geographic coordinates of the study location are 18.4947° N, 98.7771° E, as shown in

Figure 1.

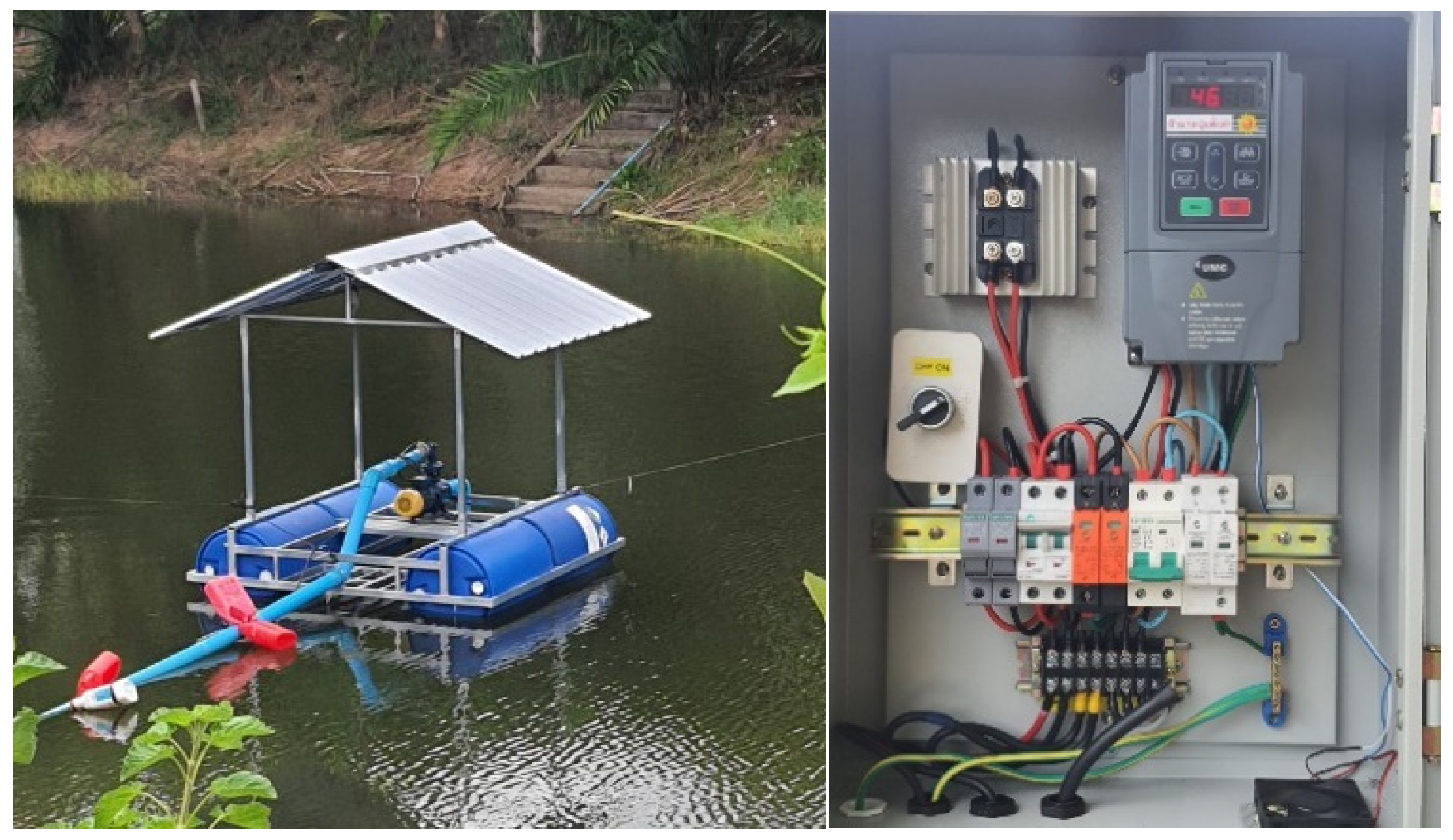

The experimental site consists of a 1000-square-meter open-air tilapia pond equipped with a custom-designed floating platform. This platform hosts solar panels for a renewable power supply and supports the deployment of various water and environmental sensors. An ESP32-based microcontroller serves as the central processing unit, offering integrated Wi-Fi and Bluetooth connectivity.

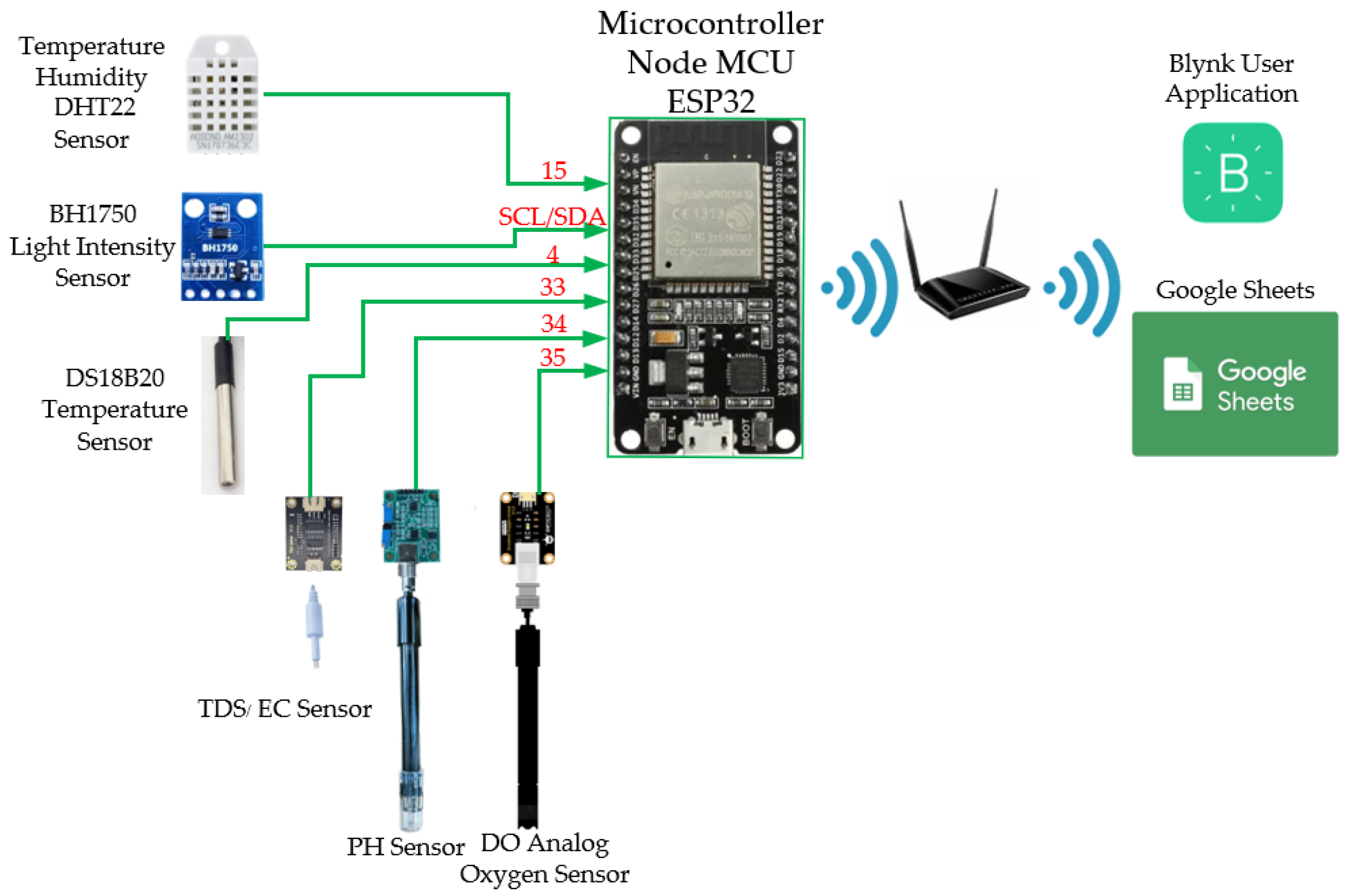

A suite of sensors was installed on platform [

18], including air and water temperature sensors, a relative humidity sensor, a light intensity sensor (BH1750), and probes for electrical conductivity/total dissolved solids (EC/TDS), as well as dedicated sensors for dissolved oxygen (DO) and pH levels. The ESP32 microcontroller—powered by a dual-core Xtensa LX6 processor running at up to 240 MHz with 4 MB of flash memory and 512 kB of RAM—enables on-device data processing and supports lightweight machine learning inference without reliance on external servers, as shown in

Figure 2.

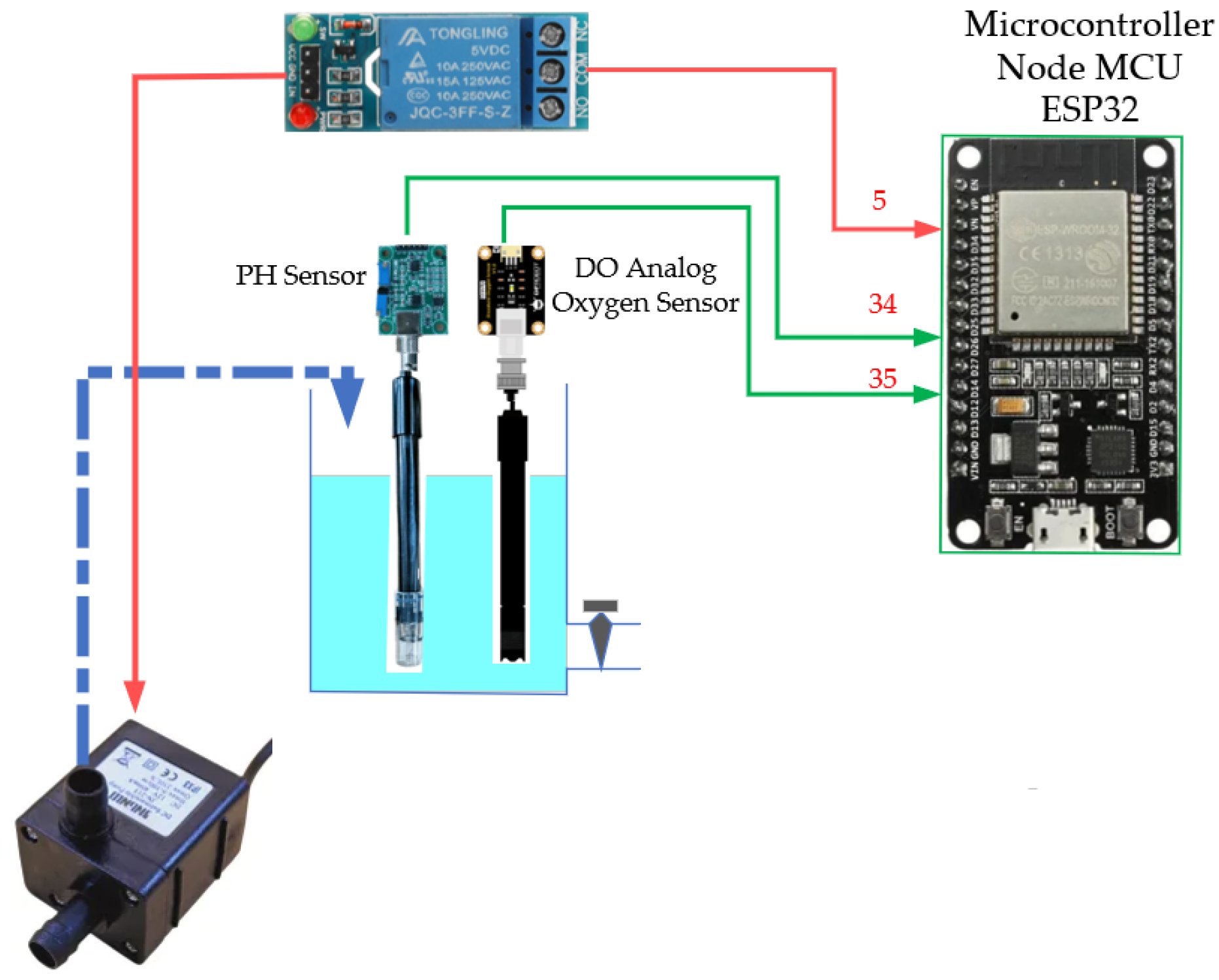

The DO and pH sensing system was designed to sample every hour, balancing data resolution and sensor longevity. Water is pumped into a 900 mL chamber via a submersible pump and relay control to minimize air bubble interference with the electrochemical DO probe. A 5 min stabilization delay ensures accurate readings, followed by drainage within 45 min to prevent sediment buildup. A 1 cm water level is retained to maintain sensor hydration, as recommended by the manufacturer [

18]. To further ensure data reliability, both sensors were factory-calibrated before deployment and recalibrated in the field at two-week intervals. The pH sensor was adjusted using three standard buffer solutions (pH 4.0, 7.0, and 10.0), while the DO sensor employed a two-point method with air-saturated water and sodium sulfite solution for zero-oxygen reference, as shown in

Figure 3.

To reduce system complexity and improve data accuracy, the water quality monitoring system is designed to operate in hourly cycles. An ESP32 board controls the water intake into the sampling chamber and then waits for probe stabilization before measuring dissolved oxygen (DO), pH, and electrical conductivity/total dissolved solids (EC/TDS). Other parameters, including air temperature, relative humidity, light intensity, and water temperature, are directly measured using environmental sensors connected to the ESP32. All collected data are transmitted to a dashboard and cloud server for real-time visualization. The core system logic is summarized in the following pseudocode:

every 1 h:

pump water into chamber (12 s), wait to stabilize (5 min)

read sensors: air temp/RH, light, water temp, EC

read ADC: pH → voltage → pH value

read ADC: DO → mV → ppb → mg/L with correction

read rolling ADC buffer: TDS → voltage → nonlinear calc

send all values to Blynk and Google Sheets

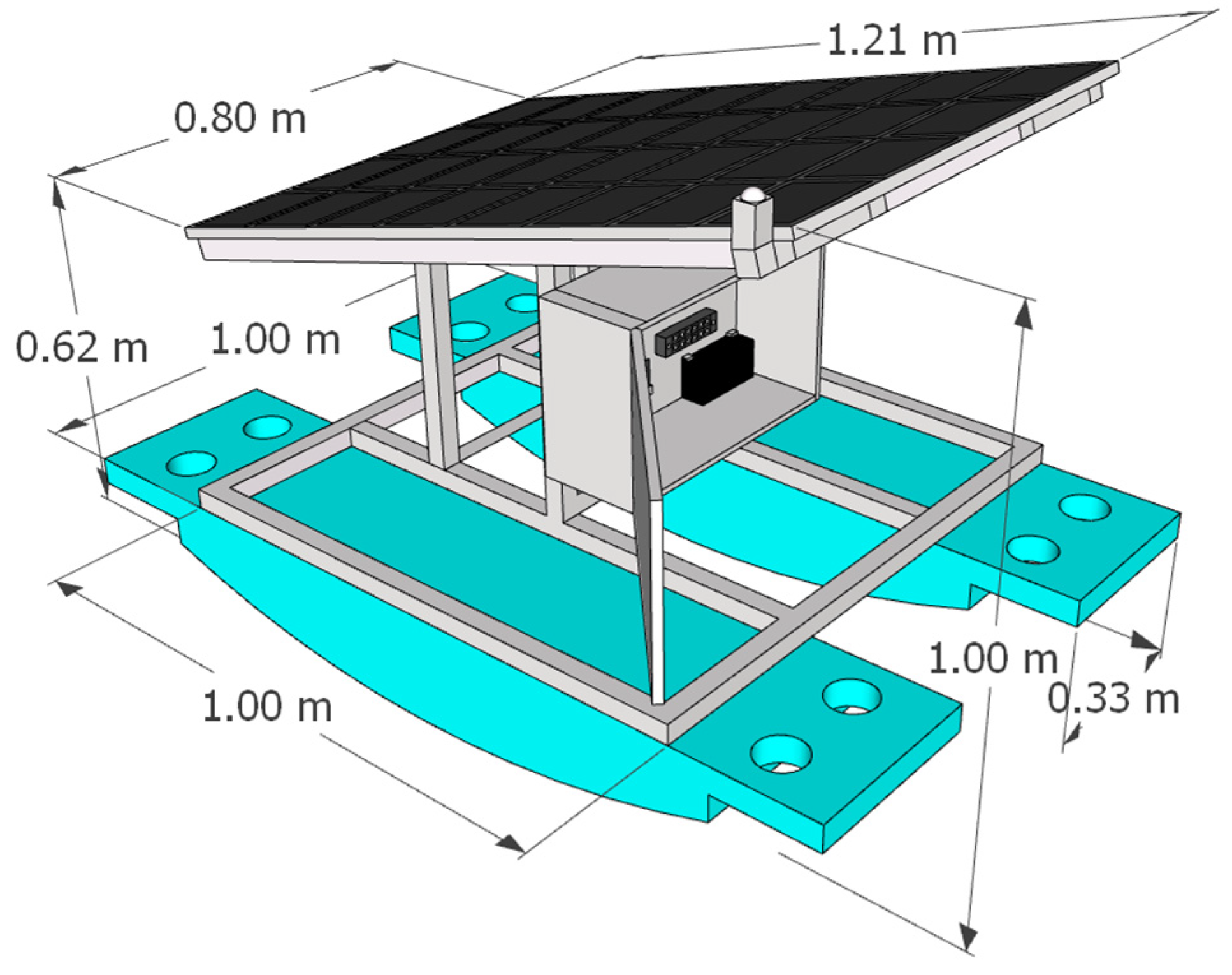

continuously:

The water quality monitoring system is built on a 1 × 1 m floating platform, featuring a control box, solar panel, and sensor chamber placed in a still-water channel to minimize wave interference. The structure is made of galvanized steel or aluminum and mounted on two pontoons, anchored by rope and concrete blocks. A 12 V solar panel and battery supply power via an IP65 control box. The system includes grounding to prevent signal noise, especially for pH and DO probes, ensuring long-term operation in tilapia aquaculture settings. The floating platform structure is shown in

Figure 4.

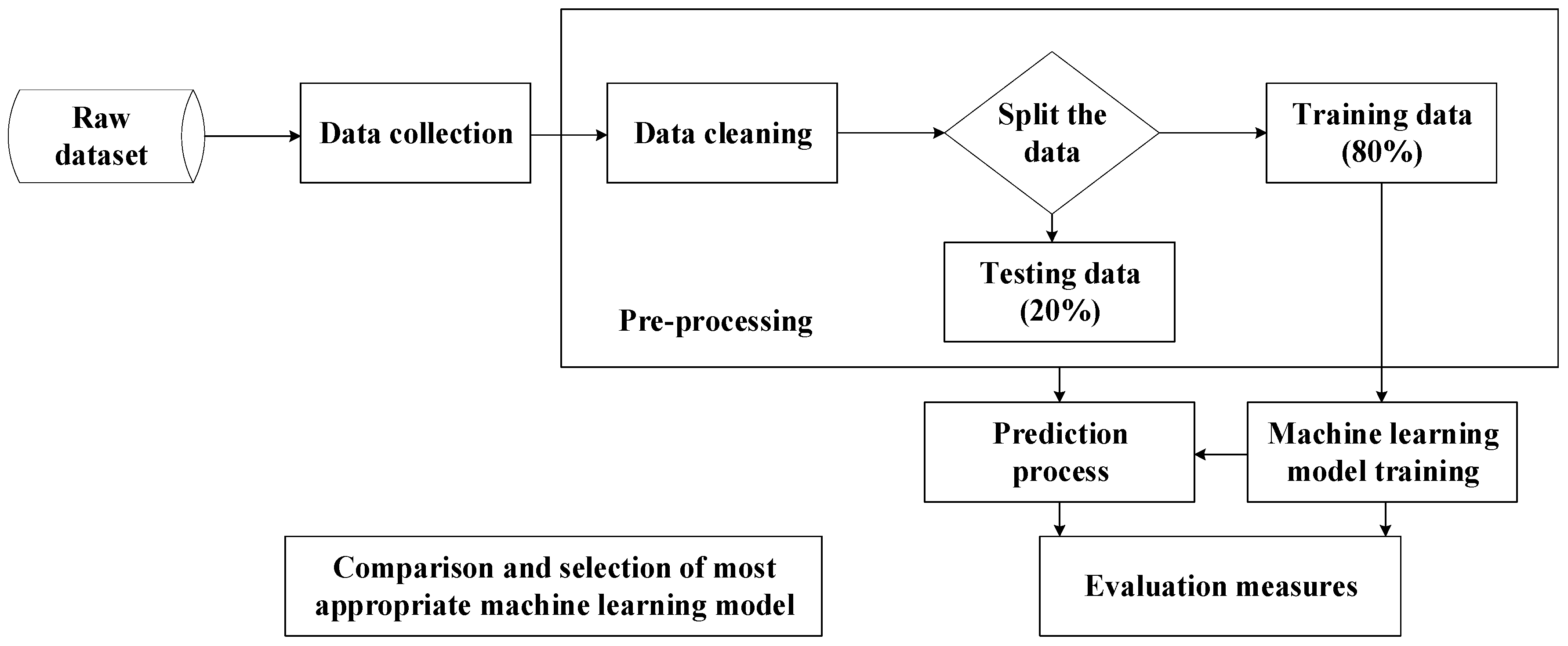

3.2. Machine Learning Model Development

The development process of the environmental control algorithm for tilapia farming using machine learning is illustrated in

Figure 5. It began with collecting raw data from sensors and other sources, followed by organizing and cleaning the dataset. During preprocessing, outliers were detected using the interquartile range (IQR) method (values outside [Q1 − 1.5 IQR, Q3 + 1.5 IQR]) and removed. Missing values representing less than 5% of the dataset were imputed using linear interpolation, while larger gaps were excluded. Sensor calibration procedures were applied prior to data integration, as described in

Section 3.1, to ensure the reliability of input variables.

The processed dataset was then divided into training (80%) and testing (20%) subsets to develop ML models, including Multiple Linear Regression (MLR), Decision Tree Regression (DTR), and Random Forest Regression (RFR). For DTR and RFR, hyperparameter tuning was conducted using grid search with five-fold cross-validation to improve robustness and avoid overfitting. Key parameters such as maximum depth, minimum samples per split, and the number of estimators were optimized based on validation performance. Model performance was evaluated using RMSE, MAE, and R

2 [

19].

The most suitable model was subsequently deployed on an ESP32 microcontroller by converting its parameters into C/C++ code. The embedded system included on-device normalization and real-time prediction of DO and pH values to control actuators such as aeration pumps, acid dosing systems, and water heaters.

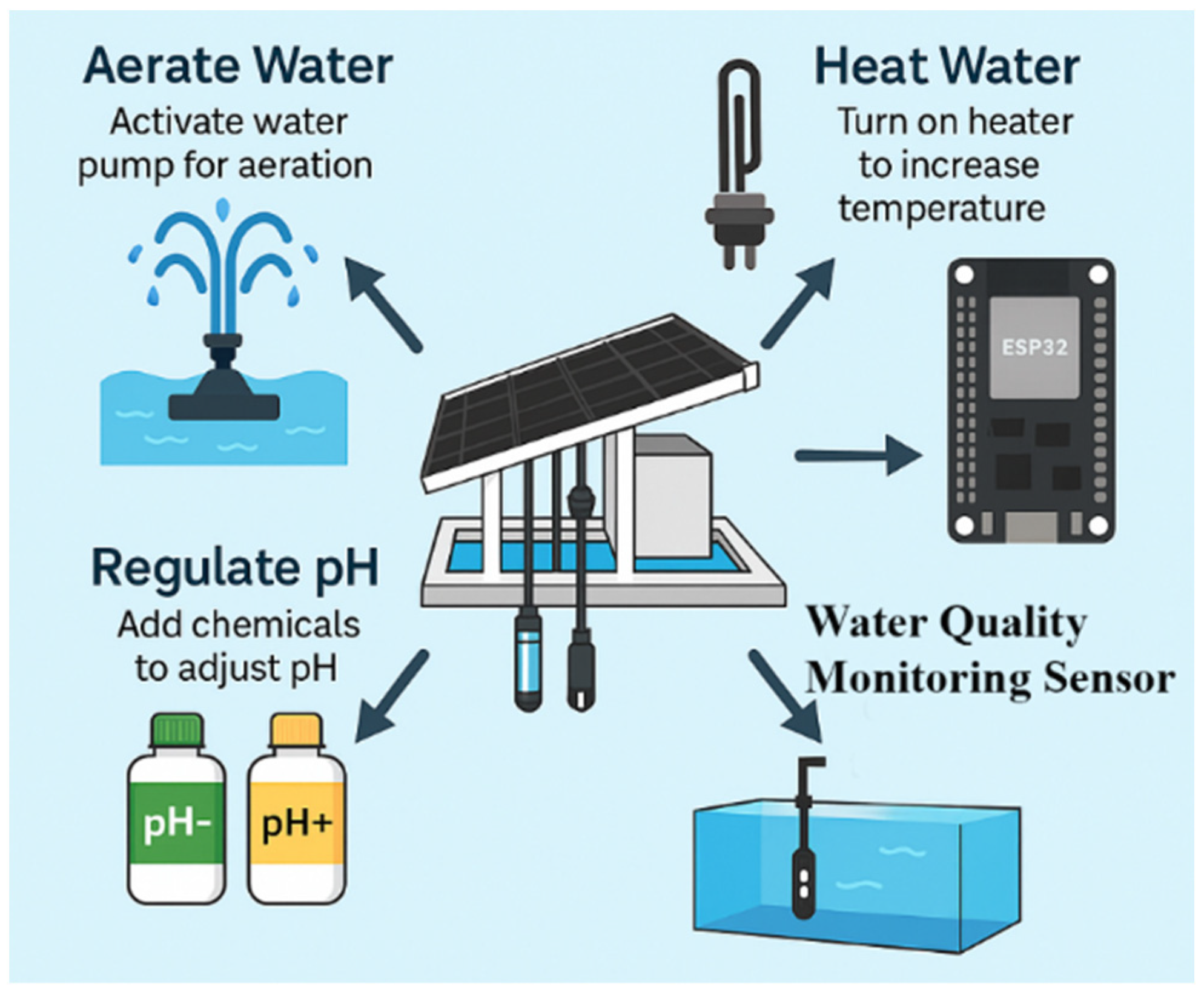

3.3. Automatic Control System

The water quality control system, as illustrated in

Figure 6, was designed to respond proactively to environmental changes in the aquaculture pond. The control process begins with dissolved oxygen (DO) regulation: when DO drops below 6 mg/L, an adjustable aerator is automatically activated until levels rise to the optimal range of 6.2–6.4 mg/L. For pH control, if the measured value exceeds 8.0, a weak acid dosing pump operates in a stepwise manner to gradually bring the pH into the safe range of 7.0–8.0, with overshoot protection in place. Additionally, a 500-watt heater powered by a solar inverter is used to raise the water temperature locally near the floating platform by 1–2 °C, helping to stimulate schooling behavior in tilapia during cooler early morning hours [

20].

5. Discussion

This study presents the design, development, and testing of an integrated water quality forecasting and control system for semi-intensive tilapia aquaculture in Northern Thailand. By combining IoT-based environmental sensing, edge computing, and statistical analysis, the research aimed to enhance real-time water quality management and provide insights into the interactions between environmental conditions and fish behavior. The key findings are organized into three main areas: environmental monitoring, data analysis, and the development of predictive models and automated control mechanisms.

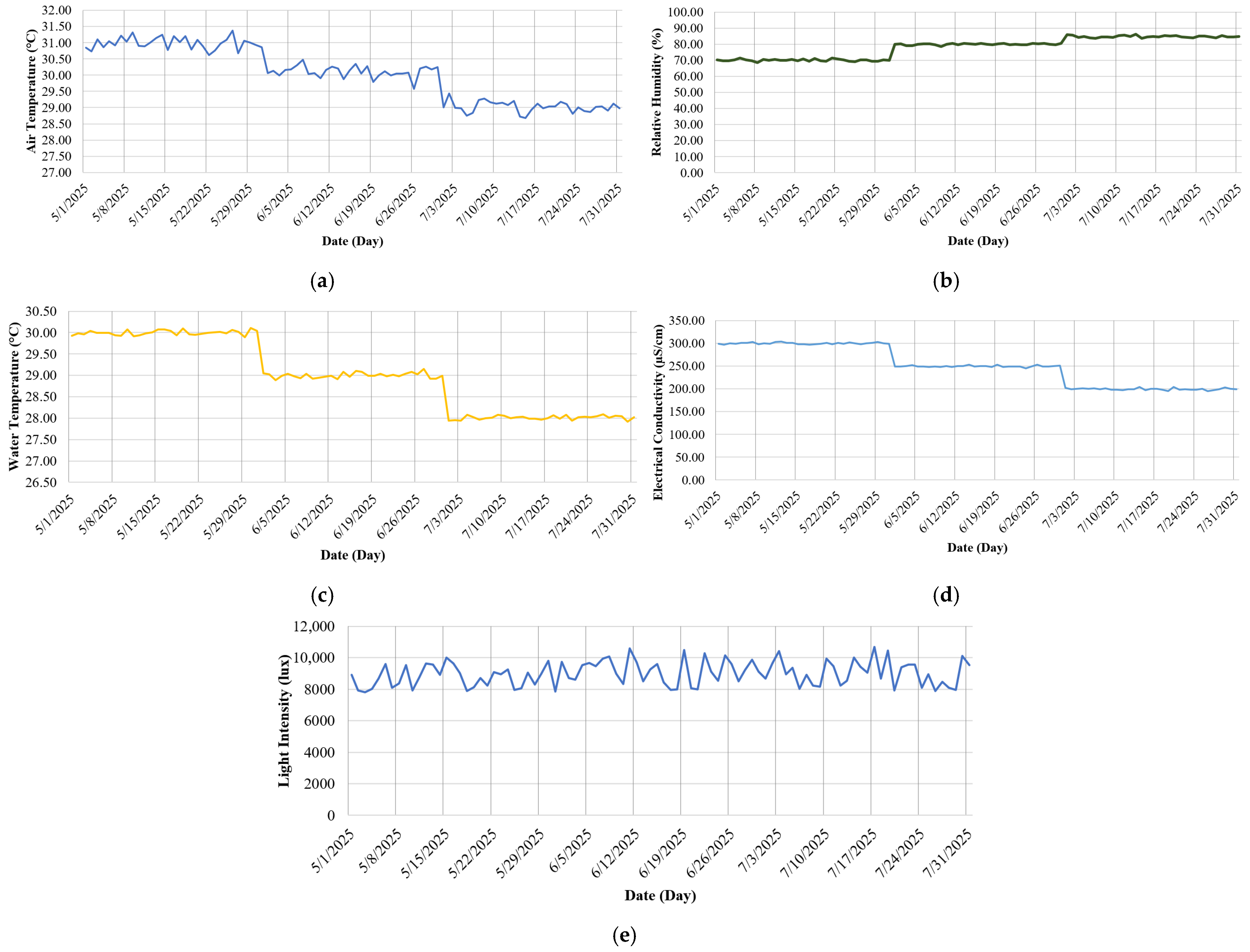

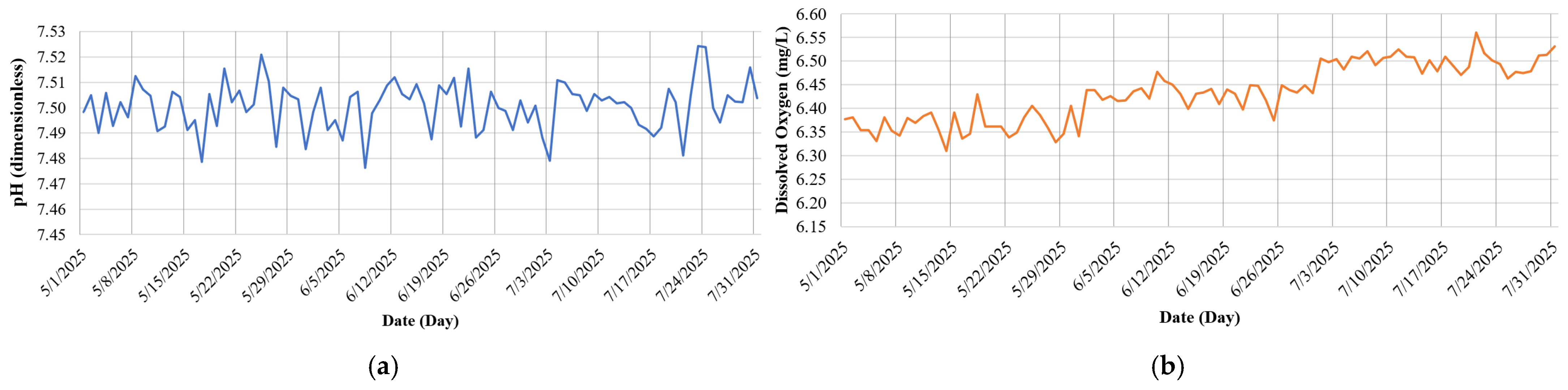

5.1. Environmental Monitoring and Water Quality Assessment

Continuous monitoring of water quality parameters over three months (May–July 2025) revealed distinct seasonal patterns affecting pond ecology. A gradual decline in air temperature (from 31.5 °C to ~29 °C) aligned with increased rainfall, which concurrently lowered water temperature—impacting tilapia behavior, particularly their morning aggregation [

30]. The rise in relative humidity (from 68–72% to 80–85%) during the rainy season corresponded with a drop in electrical conductivity (EC) from 300 to 200 µS/cm, indicating ion dilution from rainwater inflow [

31]. These changes are ecologically significant as they alter the mineral balance essential for fish health.

The pH remained stable between 7.48 and 7.52, while dissolved oxygen (DO) levels increased from 6.30 to 6.55 mg/L, supporting favorable conditions for tilapia growth. These trends aligned with consistent light intensity (8000–11,000 lux) and increased photosynthetic activity toward the end of July [

32]. The sensor network demonstrated reliable performance, providing a valuable dataset for subsequent machine learning applications aimed at predictive water quality control [

33,

34].

5.2. Data Analysis and Environmental Correlations

Effective data preprocessing, particularly the handling of missing and outlier values, proved essential for accurate analysis. The cleaned data reflected natural pond dynamics, with average values indicating optimal conditions for tilapia: water temperature ≈ 29 °C, EC ≈ 249.74 µS/cm, pH ≈ 7.5, and DO ≈ 6.43 mg/L. DO levels above 5 mg/L are critical for tilapia survival and growth [

35].

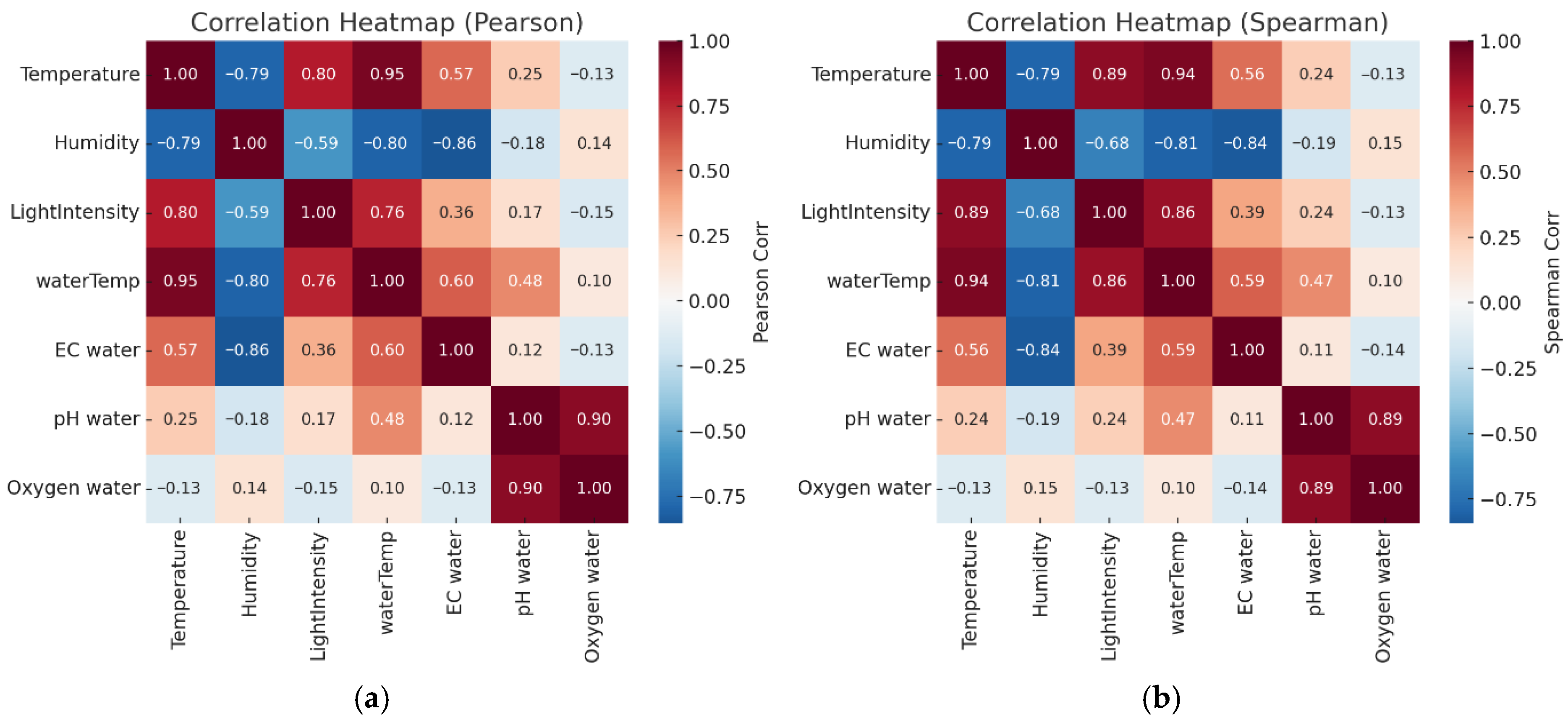

Correlation analysis revealed strong positive relationships between air temperature and water temperature (r = 0.94) and light intensity (r = 0.89), consistent with solar energy transfer dynamics. Relative humidity negatively correlated with temperature (r ≈ −0.80), as expected from meteorological principles. A notable correlation between DO and pH (r = 0.89) likely reflects phytoplankton photosynthesis, which increases both oxygen levels and pH during daylight hours [

36].

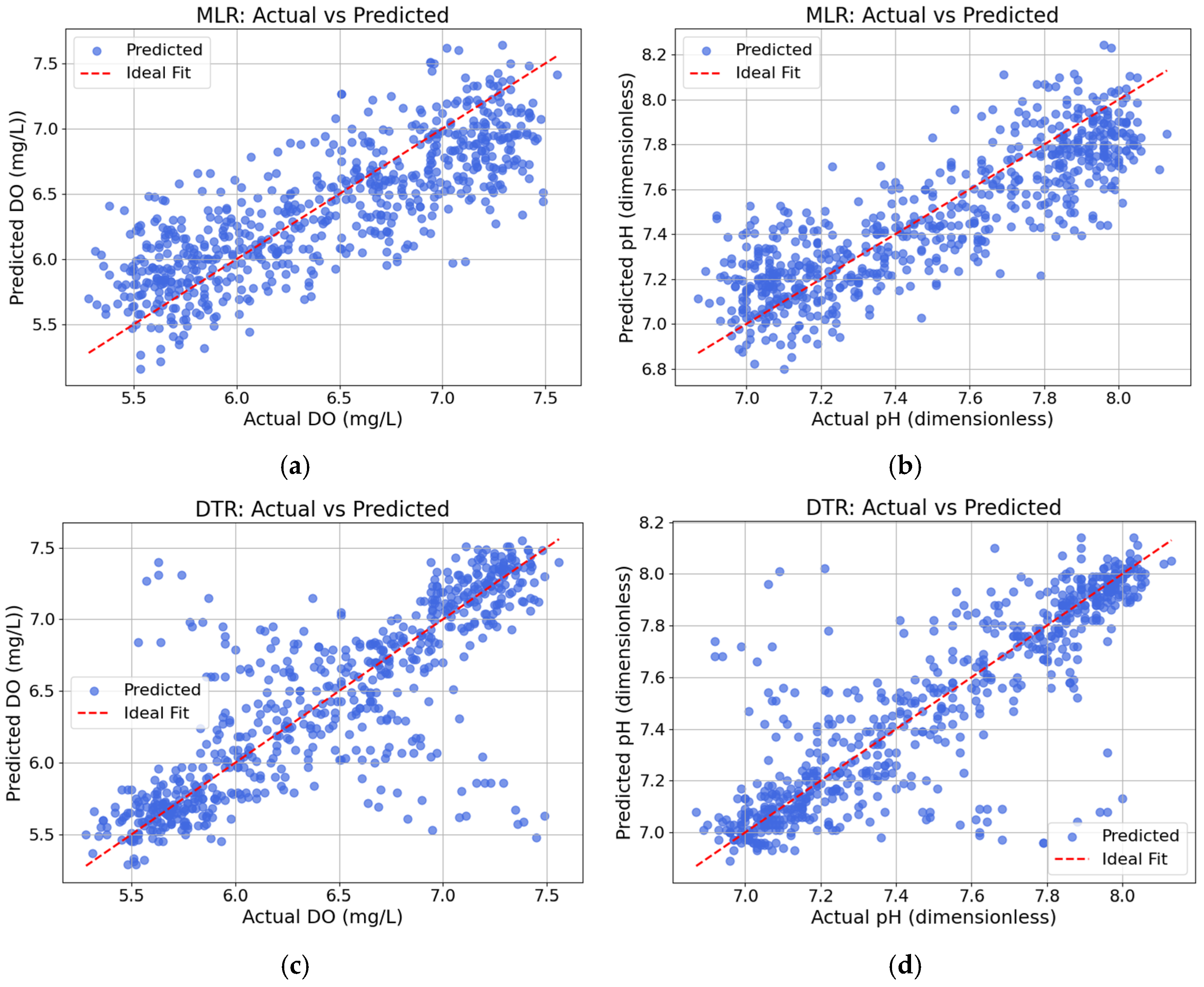

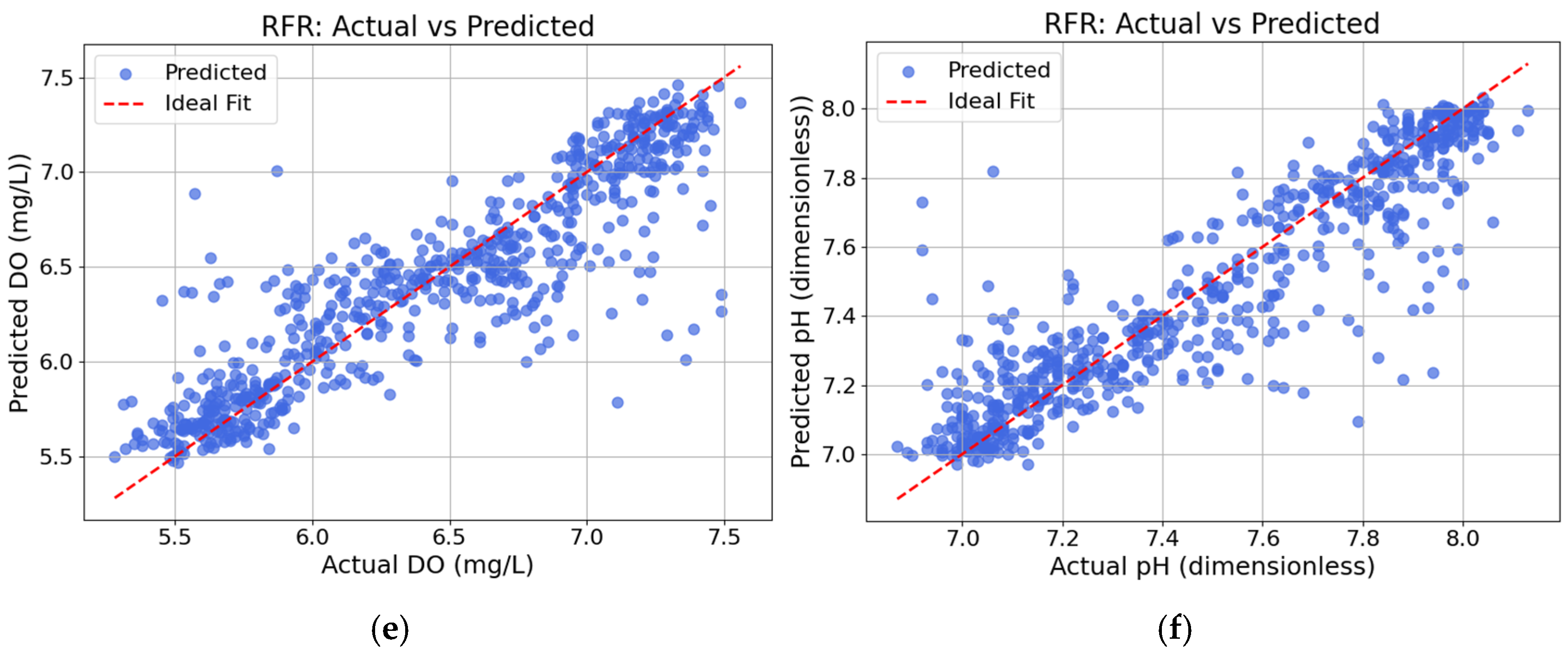

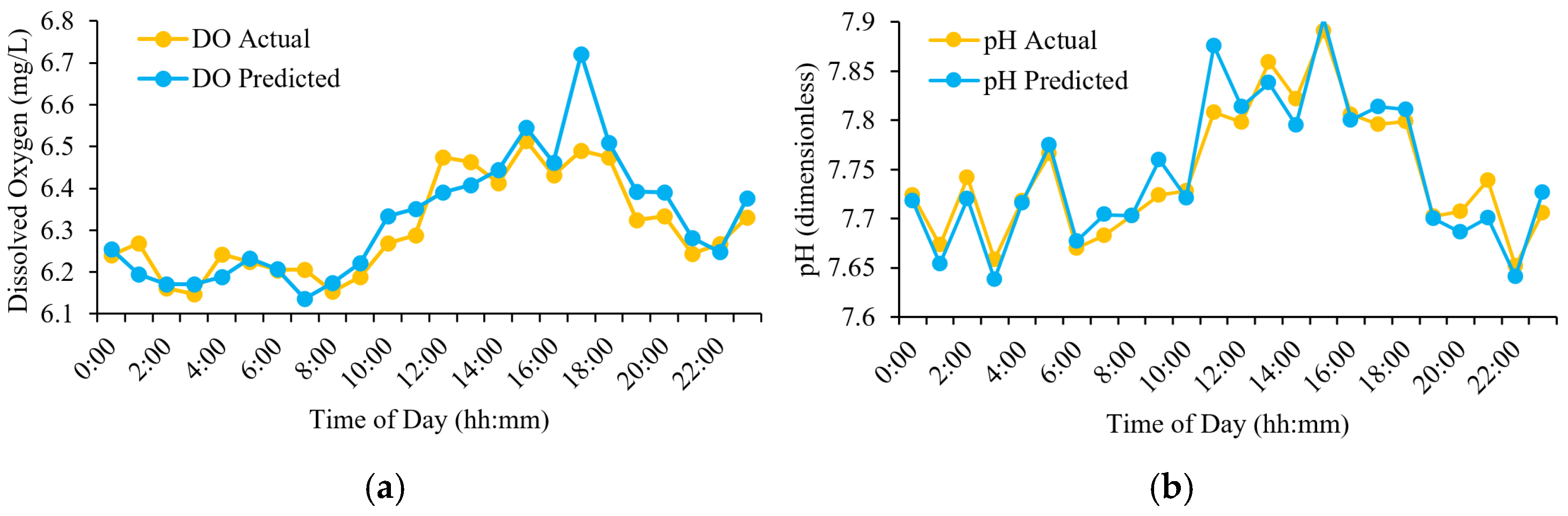

In developing machine learning models for water quality forecasting, MLR offered transparency and low computational cost, ideal for IoT devices like the ESP32. However, its linear nature limits its ability to model complex relationships. While DTR provided better nonlinearity handling, it was prone to overfitting without proper tuning. RFR emerged as the most accurate and stable model, with R

2 > 0.80 and the lowest RMSE and MAE values for both DO and pH [

37,

38]. These results underscore the need to balance model accuracy with hardware constraints—favoring RFR for cloud/server deployment, and MLR for resource-constrained, edge-level applications.

Recent related studies using hybrid or deep learning models have achieved even higher accuracy. For example, Hu et al. [

39] developed an RBF neural network optimized via Grey Relational Analysis (GRA) and demonstrated R

2 ≈ 0.96 for aquatic production forecasting, outperforming BP, GA-BP, and LSTM models in the same study. These methods highlight the potential of advanced models for capturing nonlinear and regional temporal patterns, but their computational and connectivity demands make them less practical for smallholder aquaculture. In contrast, the present ESP32-based system prioritizes feasibility and offline functionality, providing a trade-off between predictive power and real-world applicability.

5.3. Predictive Control and System Performance

Experimental validation of the integrated prediction control system using MLR on ESP32 showed that even resource-limited devices can effectively compute linear models for real-time DO and pH prediction, eliminating the need for expensive sensors and reducing installation and maintenance costs [

40]. This approach aligns with Sharafi et al., who proposed low-cost, resilient IoT forecasting systems using lightweight models for remote aquaculture [

40]. The present results validate this concept for practical farm-level deployment.

Automated control mechanisms responded accurately to predicted values. The aeration system maintained DO levels between 6.2 and 6.4 mg/L using only 0.32 kWh per cycle, demonstrating high energy efficiency. These findings are consistent with recent work by Mao et al. [

41], who highlighted the importance of accurate DO monitoring for sustainable aquaculture management, using satellite-based machine learning to retrieve DO concentrations in fishponds. The pH control system successfully stabilized levels within a safe range (7.9–7.98) using minimal acid addition, preventing overshoots. Meanwhile, the localized heating system stimulated fish aggregation behavior by 35–50%, facilitating efficient feeding and health monitoring. In this prototype, the heating experiment was intended primarily as a proof-of-concept to demonstrate the feasibility of localized thermal control rather than to provide a comprehensive energy cost–benefit analysis. While the behavioral benefits were evident, we recognize that under limited solar or battery supply, trade-offs between additional energy consumption and aggregation outcomes must be carefully considered. This issue has therefore been explicitly noted as a direction for future work.

The threshold-based on/off logic used in this prototype shares conceptual similarities with finite state machine (FSM) control strategies, which explicitly incorporate thresholds and hysteresis in a structured manner [

42]. Although our implementation was intentionally simplified to reduce computational burden on the ESP32, recognizing this connection strengthens the theoretical foundation of the control approach. Future work may further formalize this logic by integrating FSM-based design principles or by adopting explicit hysteresis bands or PID-style controllers to enhance stability and prolong actuator lifespan.

These outcomes not only confirm the technical feasibility but also highlight potential economic benefits for farmers. Energy-efficient aeration and targeted pH dosing reduce operational costs through lower electricity and chemical use, while improved fish aggregation and survival rates enhance productivity and income stability. The adoption of low-cost ESP32 devices further supports accessibility for smallholder farmers, linking technological innovation with long-term economic sustainability.

In the long term, the proposed framework envisions reducing dependency on continuous DO and pH sensing by using predictive models as the primary source of water quality estimation. Physical DO/pH probes would be retained only as backup instruments for periodic validation, thereby extending sensor lifespan and lowering operational expenses.

In summary, this study demonstrates the potential of combining IoT sensing, machine learning, and automation to achieve low-cost, sustainable water quality management in aquaculture. The MLR-on-Edge approach proves viable for small-scale farms, while higher-accuracy models like RFR are suited for centralized cloud processing. The proposed system supports environmental, economic, and energy efficiency goals, aligning with the FAO’s vision of “Smart Aquaculture,” which advocates for AIoT adoption to enhance long-term sustainability in aquaculture systems [

43]. Several limitations, however, should be acknowledged. The present dataset only spans May–July 2025 (rainy season), restricting the generalizability of predictions to dry or cold seasons. Differences in pond types, hydrochemical profiles, and regional climatic conditions were also not addressed, which may affect transferability. In addition, aquaculture environments are inherently dynamic, raising the issue of model drift. To overcome these challenges, future work will extend data collection across multiple seasons and sites, while exploring transfer learning and federated learning approaches to improve scalability and adaptability. Model retraining will be pursued through a hybrid edge–cloud strategy, where updated models are periodically refined offline and redeployed to the ESP32. Moreover, more advanced control strategies, such as explicit hysteresis bands, FSM-based designs, or PID-style controllers, will be investigated to enhance long-term stability and actuator lifespan. Furthermore, while regression- and ensemble-based machine learning models were the main focus of this study, nonlinear Kalman filtering and other state-estimation techniques might also produce reliable and computationally effective forecasts on embedded devices. Future research will incorporate comparative evaluations to assess their trade-offs in accuracy, complexity, and resource requirements.

6. Conclusions

This research presented the development and deployment of an Edge AI system for water quality monitoring and control in small-scale tilapia aquaculture, utilizing the low-cost ESP32 microcontroller. The system was designed to perform real-time environmental sensing, parameter prediction (DO and pH), and control, all without the need for constant cloud connectivity. It successfully collected and analyzed key environmental variables such as air temperature, humidity, EC, and light intensity with clear seasonal patterns, including decreasing temperatures and rising humidity during the rainy season, which affected water temperature and ion concentration. Correlation analysis revealed meaningful biological relationships, such as the positive association between pH and DO driven by phytoplankton photosynthesis during daylight hours.

Although the RFR model showed higher predictive accuracy, the MLR model demonstrated practical advantages for embedded deployment on ESP32, with low resource consumption and offline operability. Field experiments confirmed that the system could reliably maintain DO levels within safe ranges, adjust pH effectively, and even influence fish behavior through localized heating. The system also exhibited energy efficiency and environmental friendliness, aligning with sustainable aquaculture goals.

In summary, the proposed Edge AI system fulfills technical requirements for real-time water quality monitoring and control. Also, it shows strong practical significance for rural aquaculture by reducing operational costs, minimizing risks, and enabling adoption in areas with unstable connectivity. Despite current constraints such as limited seasonal coverage and the linear nature of the deployed model, future expansions involving multi-season data, federated learning approaches, and economic performance analysis could enhance the system’s robustness and scalability for broader commercial and community use. Specifically, the present study covered only three months (May–July), corresponding to part of the rainy season in Northern Thailand. Therefore, seasonal variations in dry and cold periods were not captured, which may reduce generalizability. Future work will extend data collection across multiple seasons to ensure that the system remains robust under diverse environmental conditions. In addition, future studies will consider more advanced control strategies, such as introducing explicit hysteresis bands or PID-style control, to further improve system stability and extend actuator lifespan.