Cost-Effectiveness of Structural Health Monitoring in Aviation: A Literature Review

Abstract

1. Introduction

- What types of cost-benefit evaluations have been performed for SHMSs in aerospace structures, and which economic variables are most commonly considered?

- How do SHMS technologies differ in terms of their application contexts (e.g., structural materials, aircraft types, lifecycle stages), and how does this affect their assessed economic impact?

- What are the major gaps and limitations in the existing economic studies, and where should future research focus to improve the realism and relevance of SHMS cost models?

2. Methodology of Literature Selection

2.1. Search Strategy

2.2. Inclusion Criteria

- Studies must explicitly evaluate the economic impacts of SHMSs, either through cost-benefit analysis, lifecycle cost modeling, or direct operating cost comparisons.

- The SHMS must be applied to aircraft structural elements (e.g., fuselage, wing, and rotor blade).

- Studies must involve either civil or military aircraft, including fixed-wing, rotorcraft, or uncrewed aerial vehicles (UAVs).

- Peer-reviewed journal articles, conference papers, and reputable institutional reports were included.

2.3. Exclusion Criteria

- Studies focused solely on system-level monitoring (e.g., engines, avionics, hydraulic systems) were excluded.

- Technical papers describing SHMS technologies without any economic analysis were excluded.

- Studies lacking sufficient information to reconstruct or understand the cost assumptions were also excluded.

2.4. Selection Process

2.5. Rationale for Classification Dimensions

- Inductive derivation: During the full-text analysis of the 17 selected studies, recurring themes and analytical parameters were identified. For example, several papers made distinctions between Scheduled-SHM and Online-SHM strategies, or assessed the impact of SHMS on operational life extension. These patterns informed the development of key categorical variables (e.g., SHMS integration type, life cycle stage, performance assumptions).

- Established frameworks and domain knowledge: Other dimensions were grounded in prior literature and aerospace industry practices. For instance:

- –

- –

- –

- Classifying cost drivers (e.g., maintenance labor, fuel, downtime) aligns with standard direct operating cost structures in aviation economics [33].

3. Current Maintenance Procedures in Aviation and Integration of SHMSs

- A-check: A light inspection, performed every 2–4 weeks. It includes checks of fluids, filters, and basic lubrication.

- B-check: Often incorporated into A-checks and thus rarely performed separately.

- C-check: Conducted every 12–20 months. It involves a more thorough inspection of systems and limited structural elements.

- D-check: The most extensive, performed every 6 to 12 years. The aircraft is taken out of service for several weeks. Paint and external panels are removed to allow deep structural inspection and component replacement, including internal parts.

4. Overview of Economic Studies Presented in the Literature

5. Literature Analysis and Classification of Economic Studies

5.1. Main Features of the Economic Case Studies

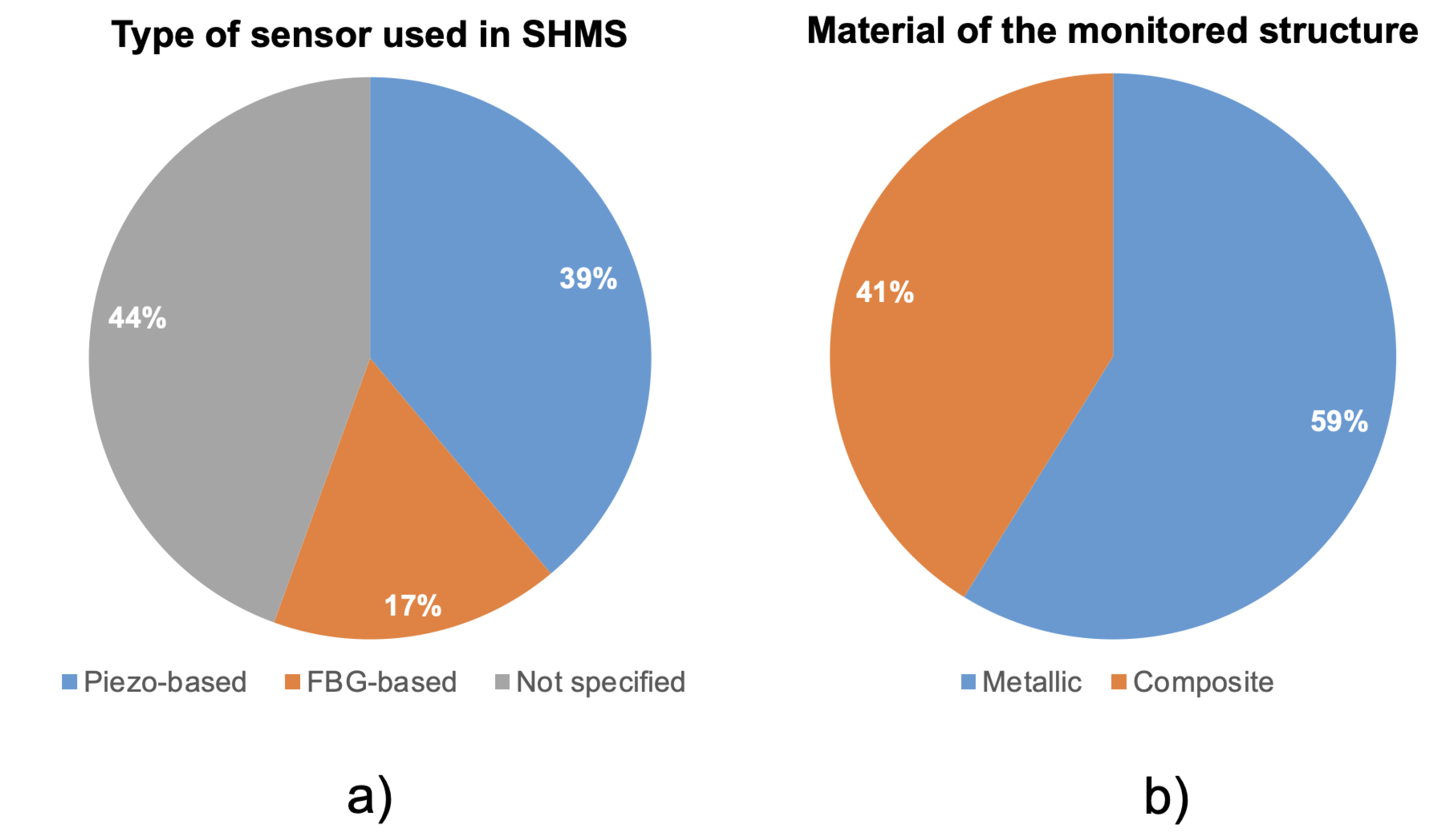

- Type of sensor used in the SHMS: Various sensor types are employed to monitor structural integrity. The most common are piezoelectric sensors [27,70,71,72], FBG sensors [28,73,74,75], and Comparative Vacuum (CV) sensors [76,77,78]. However, due to the absence of case studies involving CV sensors, they were excluded. For some studies, the sensor type was unspecified. Thus, SHMS sensors classification was organized into: Piezo-based, FBG-based, and Not specified. However, most of the unspecified cases involved metallic structures, suggesting an implicit reliance on piezoelectric technology, which is standard in such applications. Thus, the actual prevalence of piezo-based SHMSs may be underreported. The study in [62] evaluated both Piezo and FBG-based SHMS; therefore, it is listed under both categories. In Figure 1a, the partition about the type of sensors adopted by the SHMS can be observed. It can be seen that the majority of the studies do not explicitly mention the type of SHMS taken into consideration. While 39% of them consider an SHMS based on piezo, the remaining 17% of the studies consider an FBG-based SHMS. One of the most striking observations is the widespread inconsistency in technical specificity. For example, although sensor technology is central to SHMS costs and capabilities, nearly half of the studies do not specify the type of sensor used. This raises questions about the robustness of the underlying cost models: how can a study justify an economic outcome without anchoring performance and integration cost to a known sensor type? It suggests that in many cases, economic modeling may be driven by high-level assumptions rather than grounded technical parameters.

- Material of the monitored structure: Given the increasing use of composites in aerospace, SHMS applications in such materials—typically governed by no-growth or slow-growth damage philosophies—warrant special attention. Hence, the studies were classified as involving either metallic or composite materials. In Figure 1b, the classification of the material of the monitored structure can be observed. It can be noted that the majority of the studies, 59% focused on metallic structures, while the remaining focused on composite structures. Although composite materials represent the future of aviation, it is notable that only a small portion of the studies focus on them. This may be due to the fact that studies on metallic structures tend to be older, whereas those addressing composites have been published more recently.

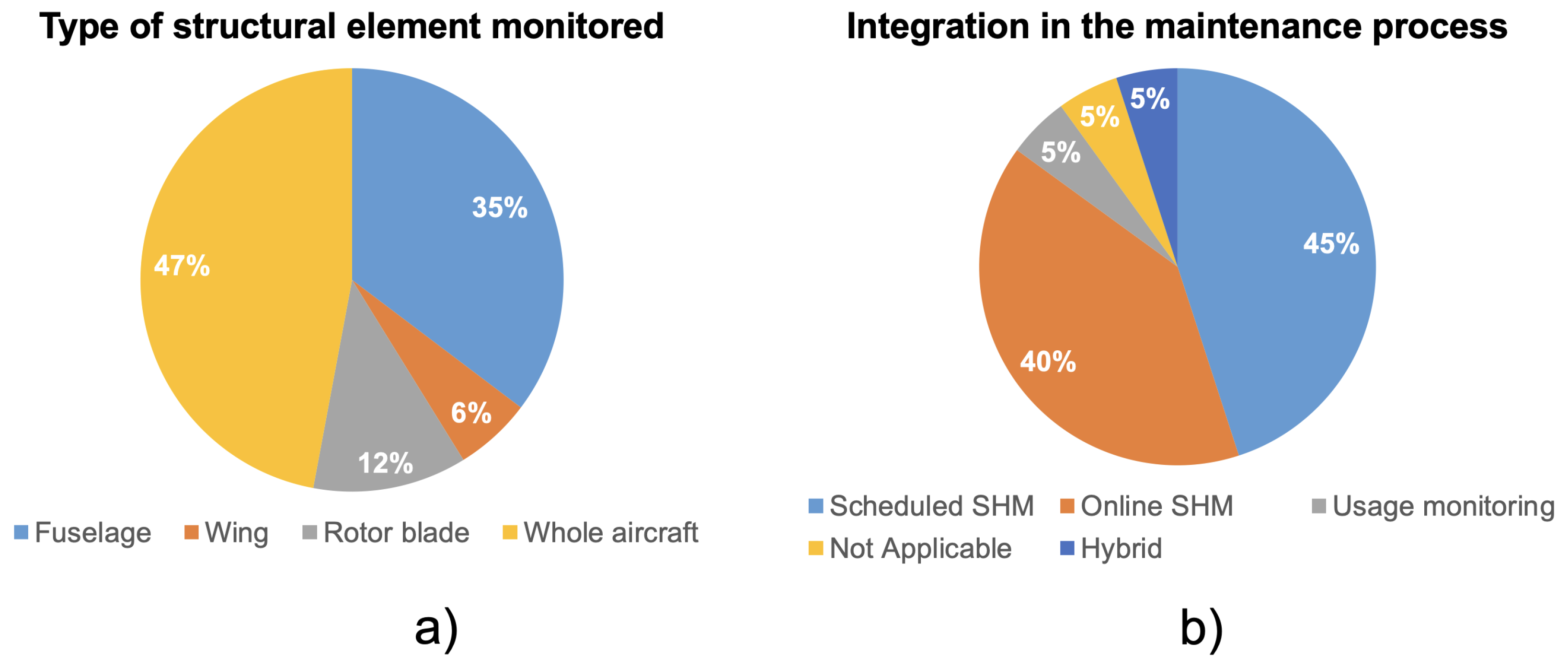

- Type of vehicle monitored: While the majority of the reviewed literature focuses on fixed-wing aircraft, only a small fraction (12%) addresses rotary-wing aircraft (Figure 2a). This imbalance is not merely descriptive—it suggests a potential research gap. Rotary-wing aircraft, such as helicopters, often operate under severe dynamic loads and are subject to higher vibration levels, which make them strong candidates for SHMS implementation. Moreover, differently from fixed-wing aircraft, their mission profile may change significantly from one helicopter to another, thus further motivating the adoption of SHMS. Their underrepresentation in the economic literature may indicate challenges related to data availability, complexity of modeling, or lower commercial prioritization. This trend reveals that the current body of economic evaluations may be disproportionately shaped by platform accessibility rather than operational criticality—an insight that should inform future research targeting high-need segments.

- Lifecycle stage on which the economic impact was assessed: The lifecycle of an aircraft is commonly divided into three main phases: BOL, Middle of Life (MOL), and End of Life (EOL) [79,80,81]. BOL encompasses manufacturing and delivery; MOL covers operational use and maintenance; EOL relates to decommissioning. Since SHMSs primarily influence the design, operation, and maintenance of the aircraft, the literature reviewed here focuses on the BOL and MOL phases.As shown in Figure 2b, a large majority of studies (approximately 80%) focus exclusively on the MOL, while only 20% explicitly address BOL considerations. This strong imbalance highlights a reactive trend in current SHMS economic modeling: the systems are often evaluated for their impact on existing maintenance procedures rather than as part of a broader design strategy. Only a few studies—e.g., [18,41,58]—attempt to assess SHMS across both stages. The underrepresentation of BOL-phase analysis reveals a significant missed opportunity. Early lifecycle integration is essential for realizing many of SHMS’s long-term benefits, such as structural weight optimization, wiring simplification, and platform-wide monitoring capability. By neglecting BOL, many studies may underestimate the total value or overlook critical trade-offs relevant to aircraft designers. This suggests a need for more holistic approaches that evaluate SHMSs not just as an operational enhancement, but as a strategic design investment.

- Type of structural element monitored: The scope of SHMS application varies significantly across studies. While some focus on individual structural components—such as the fuselage, wing, or rotor blade—others evaluate SHMS at the level of the entire aircraft. As shown in Figure 3a, the majority of studies take a whole-aircraft approach, while 35% focus on the fuselage, and only 6% consider the wing in isolation. This distribution reveals important trends. The prevalence of whole-aircraft modeling suggests an ambition to evaluate SHMS at a fleet or system level, potentially capturing broader operational benefits such as maintenance scheduling and aircraft availability. However, this approach may also reflect modeling simplifications, where detailed structural behaviors are abstracted into high-level assumptions. In contrast, component-specific studies—particularly those focused on the fuselage—tend to adopt more granular modeling, often incorporating material-specific damage mechanisms or localized inspection strategies. The underrepresentation of wing-focused studies is notable, given that wings are critical load-bearing structures and frequent sites of fatigue-related damage. Their relative absence in the economic literature may be due to the complexity of wing SHMS integration, aerodynamic sensitivities, or limited access for sensor installation. This imbalance suggests that current economic evaluations may be driven more by modeling feasibility than by structural criticality, and that future work should more systematically align SHMS scope with real-world failure distribution data.

- Integration in the maintenance process: The way SHMSs are integrated into the maintenance process significantly affects both their technical utility and economic impact. Systems may offer real-time (Online) monitoring, enabling continuous structural assessment during flight, or they may rely on scheduled interrogation, where data is extracted periodically during ground inspections. A hybrid approach combining the traditional inspections with the Online SHMS monitoring was also considered. A fourth category, usage monitoring, refers to SHMSs designed primarily to track operational loads throughout the aircraft’s life, rather than detect specific damage. For studies focused exclusively on early design stages (BOL), a Not Applicable category is included, as maintenance integration is not yet relevant. Some studies—such as [56,67]—consider multiple integration strategies and are thus represented in more than one category. As shown in Figure 3b, 45% of the reviewed studies evaluate Scheduled SHM, while 40% consider Online SHM, and only 5% investigate load monitoring capabilities and the combination of different maintenance strategies (hybrid approach). This distribution highlights a near-even split between the two dominant strategies, but the underutilization of usage monitoring is striking, especially given its relevance to fatigue tracking and mission-specific maintenance planning. The prominence of Scheduled SHM may reflect its compatibility with existing maintenance frameworks, making it easier to integrate without disrupting current operations. In contrast, Online SHM requires more substantial architectural integration (e.g., onboard processing, real-time data handling), but offers the greatest potential for cost savings through early anomaly detection and reduced downtime. Interestingly, preliminary analysis suggests that studies evaluating Online SHM are more likely to report positive economic outcomes, while Scheduled SHM results are more mixed. This could indicate that continuous monitoring better supports predictive maintenance strategies, or that economic models assume more aggressive benefits from online systems. However, without standardized evaluation frameworks, such conclusions remain tentative. Still, the data suggest a strategic shift toward online architectures, reflecting the broader aerospace trend toward condition-based and predictive maintenance paradigms.

- Impact of SHMS performance: Given the safety-critical role of SHMS, assumptions regarding their detection performance are central to any economic or operational analysis [38]. Key performance indicators include the POD and PFA [30,82], which directly influence maintenance decisions, inspection deferrals, and ultimately, lifecycle costs.In the reviewed literature, studies diverge significantly in how they model SHMS performance. Some adopt idealized assumptions, treating SHMS as having 100% POD and 0% PFA, thus enabling perfect damage detection and no false positives. Others incorporate realistic POD curves, acknowledging that detection is probabilistic and may vary based on damage size, sensor type, or location. In our classification, studies that model a realistic POD—regardless of whether they assume a nonzero PFA—are grouped under “realistic SHMS.”As shown in Figure 4a, 47% of the studies incorporate realistic performance assumptions, while the majority assume perfect SHMS behavior. This pattern reveals a tendency in the field to prioritize model simplicity over realism—potentially overestimating the value and reliability of SHMS. Assuming perfect detection capabilities removes the need to address false alarms, maintenance delays, or conditional inspection strategies, all of which are critical for actual implementation.Notably, this modeling choice can significantly influence economic outcomes. Several studies that incorporate realistic POD models still report positive cost-effectiveness, suggesting that SHMS can be economically viable even with imperfect detection. This underscores the robustness of certain system configurations, but also highlights a methodological inconsistency: there is no standardized threshold or benchmark for what constitutes “acceptable” SHMS performance in economic terms.The widespread use of perfect-performance assumptions likely stems from either lack of validated sensor performance data or an intent to establish best-case upper bounds. However, for SHMS to be integrated into safety-critical environments like commercial aviation, future studies must move beyond idealization and evaluate how performance uncertainty affects decision-making, maintenance intervals, and risk profiles.

- Impact of SHMS weight: The additional weight introduced by SHMS—whether from sensors, wiring, data acquisition units, or power sources—can have a substantial impact on aircraft performance. When MTOW limits are fixed, any added mass can either reduce payload capacity or increase fuel consumption over the aircraft’s lifecycle, thus directly influencing economic viability.In our review, studies were classified based on whether they explicitly included SHMS weight in their economic evaluation. As shown in Figure 4b, 53% of the studies accounted for the effects of added mass, while the remaining 47% omitted this factor altogether. This nearly even split highlights a key inconsistency in cost modeling practices: while over half of the studies attempt to reflect real-world integration constraints, a significant portion still rely on massless or abstract SHMS models.The omission of weight considerations can bias economic conclusions, as it disregards one of the most tangible trade-offs in SHMS adoption. Even modest increases in structural weight can result in meaningful lifecycle fuel penalties, especially in fuel-sensitive missions such as long-haul commercial flights or high-frequency regional operations. Interestingly, some of the studies that do model SHMS weight still report positive economic outcomes, suggesting that weight penalties can be mitigated or outweighed by benefits such as inspection cost reduction, increased aircraft availability, or reduced unscheduled maintenance. However, this finding also raises questions about how weight-related costs are calculated—and whether all studies use consistent assumptions regarding fuel burn sensitivity, mission profiles, or integration architectures.Overall, the treatment of SHMS weight in the literature remains fragmented, revealing a need for standardized modeling approaches that transparently incorporate mass-related penalties. Without this, comparisons between studies—and reliable conclusions about the cost-effectiveness of SHMS—remain difficult to make.

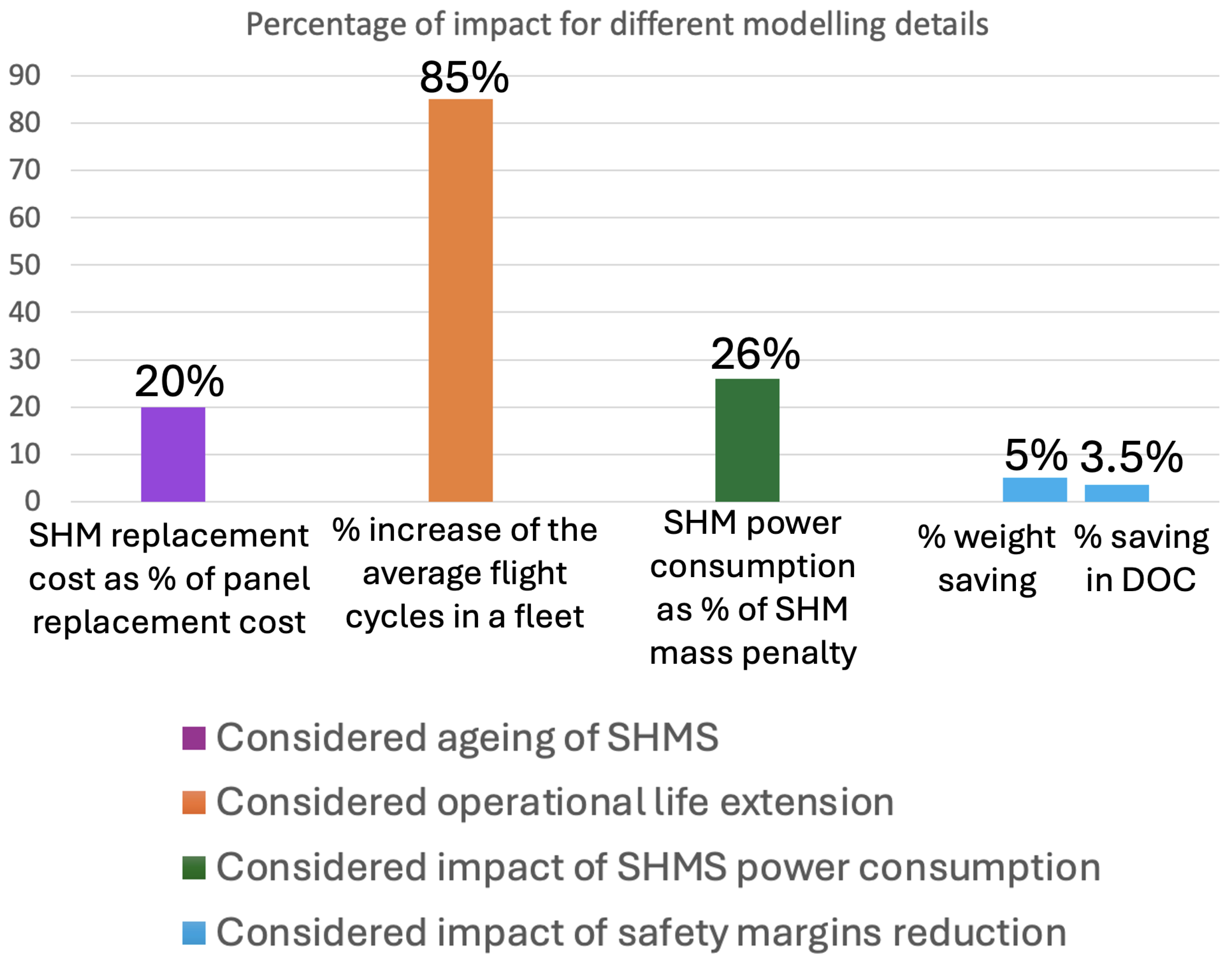

5.2. Modeling Details Considered by Few Studies

- Impact of SHMS aging: Like all onboard systems, SHMSs are subject to aging-related degradation, which may affect their reliability, performance, and maintenance requirements over time. Components such as sensors, adhesives, and connectors can experience environmentally induced deterioration (e.g., thermal cycling, humidity exposure, vibration fatigue), potentially leading to increased false alarms, signal drift, or outright system failure. For example, studies such as [83,84] have shown that fiber FBG sensors may suffer from moisture-induced wavelength shifts, which compromise long-term measurement accuracy.Despite the relevance of this phenomenon, only one study in the reviewed literature explicitly considers SHMS aging, and the cost to substitute the monitoring system was estimated to be 20% of the cost to replace the entire aircraft’s panel, as can be see in Figure 5. The fact that only one study considers this aspect suggests that the durability and lifecycle reliability of SHMS remain underexplored dimensions in economic impact assessments. Most models appear to assume time-invariant system performance, thereby overlooking costs associated with recalibration, replacement, or performance degradation over time.This omission is concerning, as it implies that some positive economic conclusions may be overly optimistic—particularly for systems expected to operate over long service intervals or across high-cycle aircraft. Ignoring aging effects could underestimate maintenance costs or overstate availability improvements, especially in harsh operational environments (e.g., maritime patrol, tropical climates, or high-altitude operations).Moreover, the failure to model SHMS aging stands in contrast to the broader trend in aircraft lifecycle modeling, where component aging and degradation are routinely included for engines, avionics, and other critical systems. Extending such treatment to SHMSs would improve model realism and support more robust cost-benefit conclusions. As SHMS adoption scales toward full-aircraft coverage and long-duration platforms (e.g., commercial airliners, military transports), integrating aging behavior into economic models will become essential.In short, the lack of attention to SHMS aging represents a clear methodological gap in the literature and an opportunity for future work to provide more grounded, lifecycle-aware assessments of SHMS value.

- Impact of operational life extension: In conventional aircraft design, structural components are retired conservatively, based on worst-case assumptions about loading and fatigue accumulation. This approach ensures safety but often results in components being withdrawn well before their true end-of-life. One of the key promises of SHMSs is the ability to enable operational life extension by providing real-time or cumulative insights into structural health, allowing operators to defer replacement or inspection without compromising safety [69,85].Despite this potentially high-value benefit, our review reveals that only one study explicitly incorporates life extension into its economic evaluation, and the authors estimated a potential extension of 85% of the average flight, as reported in Figure 5. This omission is striking, especially considering that extended usage of structural elements could offer substantial cost savings in military, cargo, or legacy fleet applications—where extending airframe life is a strategic priority.The underrepresentation of this factor suggests that most existing cost models are conservatively framed, perhaps due to the difficulty of quantifying life extension benefits or a lack of long-term field data. Alternatively, it may reflect the risk-averse culture of aviation certification, where structural design lives are tightly regulated and changes to life limits require substantial validation.Nonetheless, failing to consider operational life extension understates the full economic potential of SHMS. Accurate structural tracking—especially through fatigue-prone areas—can allow for condition-based retirement, reducing unnecessary maintenance, deferrals, and parts replacement. For airlines and operators with high utilization rates, even modest life extensions could translate into millions in cost avoidance over a fleet’s operational horizon.Future cost-effectiveness models would benefit from explicitly incorporating probabilistic life extension scenarios, grounded in validated sensor data, to more fully capture SHMS’s potential value. This is particularly relevant as the industry moves toward digital twin frameworks and predictive maintenance ecosystems, where aircraft-specific structural histories can support tailored life management strategies.

- Impact of SHMS power consumption: Beyond structural weight, an SHMS imposes an electrical power demand that can subtly but meaningfully impact aircraft efficiency. Since onboard electricity is typically generated by the engines—either directly or via auxiliary power units—any additional power draw translates into increased fuel burn, particularly on long-haul flights or for aircraft operating in power-sensitive environments.As shown in Figure 5, only one of the reviewed studies considered this factor, and estimated a contribution of the cost related to the SHMS energy supply to be more or less 26% of the cost induced by the mass of the SHMS. This omission suggests that energy use is largely neglected in current cost-benefit frameworks, despite being an essential contributor to operational cost—especially as SHMS architectures become more complex and sensor-dense.This trend may stem from the relatively small magnitude of SHMS power draw per flight, leading some researchers to treat it as negligible. However, when considered across thousands of flight hours, the cumulative energy cost—especially for continuously operating systems such as Online SHM—can become non-trivial. Moreover, aircraft with more electric architectures will be even more sensitive to power distribution trade-offs, making this an increasingly relevant variable.The failure to consider power consumption also raises methodological concerns, as it introduces an optimistic bias in systems that offer real-time monitoring but at a continuous energy cost. Without accounting for this dimension, economic evaluations may overestimate the net benefit of such systems—particularly in marginal cases where lifecycle savings are small.Moving forward, future SHMS economic assessments should treat energy demand not as an optional parameter but as an integrated part of the system-level trade-off analysis, especially as aviation moves toward electrified and hybrid propulsion systems, where electrical efficiency becomes mission-critical.

- Impact of safety margins reduction: One of the most transformative potentials of SHMS lies in their ability to enable reduced structural safety margins without compromising airworthiness. Traditionally, aircraft structures are designed with conservative safety factors to account for uncertainty in loading, damage accumulation, and inspection intervals. However, with reliable real-time or near-real-time damage detection, SHMS could allow for higher allowable damage tolerance, faster crack growth acceptance, or thinner structures, ultimately reducing structural weight and improving overall efficiency. As shown in Figure 5, only two studies considered this potential: one estimates a potential weight saving of 5%, while the other estimates a potential saving in the direct operational costs of 3.5%. This under-representation suggests a significant missed opportunity: while safety margin reduction could deliver some of the greatest lifecycle cost savings through structural mass reduction and fuel efficiency gains, it remains largely unquantified in current models.The omission may be due to several factors. First, certification frameworks are currently built around conservative structural design assumptions, and reducing margins would require substantial regulatory changes and validation of SHMS reliability. Second, many economic evaluations focus on retrofitting SHMS into existing platforms, where redesign is not feasible, rather than on new aircraft programs where SHMS-informed structural optimization could be realistically pursued.Nonetheless, studies that do consider safety margin reduction demonstrate its potential to amplify the economic value of SHMS beyond inspection or maintenance savings alone. Incorporating this factor can shift the role of SHMS from a reactive maintenance tool to a design enabler, justifying more integrated, lightweight, and mission-tailored structures.As the industry evolves toward digital design, digital twins, and certification by simulation, SHMS has the potential to become a key enabler of more agile and efficient aircraft design. Future economic models should aim to integrate this dimension, not just as an assumption, but as a scenario-based variable, to better capture the full design-space benefits of SHMS adoption.

5.3. Evaluation of SHMS Cost-Effectiveness

- Positive, indicating a favorable cost-benefit outcome,

- Negative, indicating that an SHMS increases lifecycle costs, and

- Parametric, where the study presents a sensitivity-based model without committing to a definitive conclusion (e.g., outcomes depend on system parameters or mission profiles).

5.4. Cost Models Adopted in the Economic Assessment

- Cost of maintenance manpower,

- Cost of sensors,

- Cost of manpower for sensor integration,

- Cost of fuel,

- Cost of downtime,

- Cost of charges (e.g., airport or airspace fees),

- Cost of crew,

- Cost of passenger tickets,

- Cost of spare parts.

5.5. Cross-Comparison Insights

6. Discussion

6.1. Analysis of the Literature

6.1.1. Overemphasis on Maintenance Phase

6.1.2. The Weight Paradox

6.1.3. Unrealistic Performance Assumptions

6.1.4. Sensor Type, Aircraft Type, and Structural Focus

6.1.5. Whole-Aircraft vs. Component-Level Monitoring

6.1.6. Unaddressed System-Level Impacts

6.1.7. Underexplored Benefits

6.1.8. Cost Modeling Variability

6.1.9. Broader Implications

6.2. Future Directions

- Quantifying SHMS performance and reliability.SHMS adoption depends on trust in detection performance (POD, PFA), yet economic models often assume perfect performance. Furthermore, none of the studies considered the reliability of the SHMS, which instead may be subjected to faults during the lifecycle. For instance, considering the case study presented in [18], a fuselage equipped with piezoelectric sensors was assumed, each with a failure rate over the entire life cycle. The cost to replace failed sensors can be expressed as:where is the labor rate, is the loss of revenue, is the sensors’ installation time during the production of the aircraft, and is the cost of one sensor. The factor of 2 accounts for both removal and installation, assuming equal time requirements. According to [66], unscheduled maintenance activities can cost up to five times more than scheduled ones; therefore, a factor was introduced. Furthermore, a factor accounts for the additional time needed to remove surrounding structural elements when replacing sensors during service, as reflects only installation during manufacturing. Based on this model, a sensor failure rate of results in an estimated increase in SHMS implementation costs, underscoring the relevance of incorporating reliability effects into future economic assessments. Future works should be aimed at developing probabilistic cost–benefit models that integrate actual or estimated POD/PFA curves, including SHMS failure probability. Studies should simulate outcomes under variable SHMS reliability using Monte Carlo simulations, capturing both false negatives (missed damage) and false positives (unnecessary inspections).

- Lifecycle Cost Modeling with Integrated Design Phase Consideration.Current studies mostly assess SHMSs during the maintenance phase (MOL), neglecting integration costs and benefits at the design and manufacturing stages (BOL). Researchers should create bottom-up cost models for SHMS integration into airframe design, incorporating manufacturing disruptions, sensor protection needs, and certification costs. Models should include discounted cash flow, net present value, and real-options analysis to evaluate long-term return on investment.

- Economic Studies for Emerging Aircraft Types.Electrically powered and urban mobility aircraft have distinctive lifecycle profiles that offer opportunities to integrate SHMSs from the outset. As noted by [90], fully exploiting the potential of SHMSs requires its inclusion at the aircraft design stage. In the authors’ view, this presents a particularly valuable opportunity for e-VTOLs, whose architectures are still in development. Future research should therefore focus on conceptual design studies that embed SHMSs early in the e-VTOL and other novel platform architectures, employing multidisciplinary design optimization to account for SHMS-related trade-offs (e.g., weight, power, cost, inspection intervals). A logical first step would be the development of life cycle cost models tailored to e-VTOLs operating under representative mission profiles. Within this context, battery monitoring has received particular attention [91], as lithium-based energy storage systems present fire-related safety risks from thermal runaway, making their health and structural integrity a critical focus of SHMSs.

- Addressing Operational Costs of False Alarms.False positives drive unnecessary inspections, increasing downtime and labor costs—yet these are rarely modeled. Future works should develop operational simulation models, for instance, discrete-event, that simulate maintenance operations and the economic impact of SHMS-triggered false alarms across a fleet.

- SHMSs in Probabilistic Design and Safety Margin Reduction.SHMSs may justify reduced structural margins, lowering weight and cost—but few studies quantify this. Research studies should apply probabilistic damage tolerance analysis to evaluate how SHMSs can support the reduction in safety factors without compromising reliability: for instance, assuming a slow growth approach for composite structures could help to consider a safety margin reduction.

6.3. Limitations

- Small sample size: The review includes only 17 studies, reflecting the relative novelty and limited number of publications offering quantitative economic evaluations of SHMSs applied to structural components. This restricts the breadth of comparative analysis and may bias findings toward more frequently studied systems (e.g., piezo-based SHMS on metallic airframes).

- Scope exclusions: This review intentionally excludes SHMSs applied to systems-level components (e.g., engines, avionics, hydraulics), despite their significant role in operational failures and maintenance costs. As discussed earlier, our structural focus addresses a specific research gap in economic evaluation, but it does not provide a full picture of SHM applicability across the aircraft lifecycle.

- Heterogeneity of economic models: The reviewed studies employ diverse modeling approaches, often with simplified or unreported assumptions. Important factors such as discount rates, sensitivity to failure probabilities, and treatment of uncertainty were not consistently addressed, reducing the ability to generalize findings.

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Giurgiutiu, V. Structural Health Monitoring of Aerospace Composites; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.C.P. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- European Union Aviation Safety Agency. Acceptable Means of Compliance and Guidance Material to Part 25 (CS-25)—Large Aeroplanes; EASA: Cologne, Germany, 2023. [Google Scholar]

- Airoldi, A.; Boiocchi, M.; Natali, M.; Mirani, C.; Di Pancrazio, L.; Consiglio, G.; Ballarin, P.; Riva, M. Feasibility of a morphing rocket nozzle for thrust vector control based on corrugated composite laminates. Appl. Compos. Mater. 2023, 30, 399–429. [Google Scholar] [CrossRef]

- Riva, M.; Airoldi, A.; Turconi, T.; Ballarin, P.; Boiocchi, M.; Bottasso, L. Development and manufacturing of flexible joints based on corrugated composite laminates. Compos. Struct. 2023, 308, 116683. [Google Scholar] [CrossRef]

- Lightfoot, J.S.; Wisnom, M.R.; Potter, K. A new mechanism for the formation of ply wrinkles due to shear between plies. Compos. Part A Appl. Sci. Manuf. 2013, 49, 139–147. [Google Scholar] [CrossRef]

- Belnoue, J.P.H.; Mesogitis, T.; Nixon-Pearson, O.J.; Kratz, J.; Ivanov, D.S.; Partridge, I.K.; Potter, K.D.; Hallett, S.R. Understanding and predicting defect formation in automated fibre placement pre-preg laminates. Compos. Part A Appl. Sci. Manuf. 2017, 102, 196–206. [Google Scholar] [CrossRef]

- Tang, Z.; Hang, C.; Suo, T.; Wang, Y.; Dai, L.; Zhang, Y.; Li, Y. Numerical and experimental investigation on hail impact on composite panels. Int. J. Impact Eng. 2017, 105, 102–108. [Google Scholar] [CrossRef]

- Juntikka, R.; Olsson, R. Experimental and modelling study of hail impact on composite plates. In Proceedings of the 17th International Conference of Composite Materials, Edinburgh, UK, 27–31 July 2009; pp. 27–31. [Google Scholar]

- Zhang, Y.; Zhou, Y. Investigation of bird-strike resistance of composite sandwich curved plates with lattice/foam cores. Thin-Walled Struct. 2023, 182, 110203. [Google Scholar] [CrossRef]

- Georgiadis, S.; Gunnion, A.J.; Thomson, R.S.; Cartwright, B.K. Bird-strike simulation for certification of the Boeing 787 composite moveable trailing edge. Compos. Struct. 2008, 86, 258–268. [Google Scholar] [CrossRef]

- Van den Bergh, J.; De Bruecker, P.; Beliën, J.; Peeters, J. Aircraft maintenance operations: State of the art. HUB Res. Pap. 2013, 9, 2013. [Google Scholar]

- Cho, P.Y. Optimal Scheduling of Fighter Aircraft Maintenance. Ph.D. Thesis, Massachusetts Institute of Technology, Boston, MA, USA, 2011. [Google Scholar]

- Steiner, A. A heuristic method for aircraft maintenance scheduling under various constraints. In Proceedings of the 6th Swiss Transport Research Conference, Ascona, Switzerland, 15–17 March 2006. [Google Scholar]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef]

- Bossi, R.H.; Giurgiutiu, V. Nondestructive testing of damage in aerospace composites. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 413–448. [Google Scholar] [CrossRef]

- Oliveira, T.L.L.; Hadded, M.; Mimouni, S.; Schaan, R.B. The Role of Non-Destructive Testing of Composite Materials for Aerospace Applications. NDT 2025, 3, 3. [Google Scholar] [CrossRef]

- Dong, T.; Kim, N.H. Cost-effectiveness of structural health monitoring in fuselage maintenance of the civil aviation industry. Aerospace 2018, 5, 87. [Google Scholar] [CrossRef]

- Yuan, F.G. Structural Health Monitoring (SHM) in Aerospace Structures; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar] [CrossRef]

- Land, J.E. HUMS-the benefits-past, present and future. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 10–17 March 2001; IEEE: Piscataway, NJ, USA, 2001; Volume 6, pp. 3083–3094. [Google Scholar] [CrossRef]

- Güemes, A.; Fernandez-Lopez, A.; Pozo, A.R.; Sierra-Pérez, J. Structural health monitoring for advanced composite structures: A review. J. Compos. Sci. 2020, 4, 13. [Google Scholar] [CrossRef]

- Diamanti, K.; Soutis, C. Structural health monitoring techniques for aircraft composite structures. Prog. Aerosp. Sci. 2010, 46, 342–352. [Google Scholar] [CrossRef]

- Ballarin, P.; Sala, G.; Macchi, M.; Roda, I.; Baldi, A.; Airoldi, A. Application of Artificial Neural Networks to a Model of a Helicopter Rotor Blade for Damage Identification in Realistic Load Conditions. Sensors 2024, 24, 5411. [Google Scholar] [CrossRef] [PubMed]

- Airoldi, A.; Ballarin, P.; Di Mauro, S.; Rigamonti, D.; Reinert, F.; Dadras, M.M.; Zabihzadeh, S.; De Nicolò, E.; Bettini, P.; Cartabia, L. Development of an additive manufactured fitting sensorized with optical fibres for load recognition. In Proceedings of the AIAA Scitech 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 2079. [Google Scholar] [CrossRef]

- Staszewski, W.; Boller, C.; Tomlinson, G.R. Health Monitoring of Aerospace Structures: Smart Sensor Technologies and Signal Processing; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; Xiong, T.; Huang, Y.; Qiu, L. Recent progress in aircraft smart skin for structural health monitoring. Struct. Health Monit. 2022, 21, 2453–2480. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Structural Health Monitoring (SHM) of Aerospace Composites. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 491–558. [Google Scholar] [CrossRef]

- Di Sante, R. Fibre optic sensors for structural health monitoring of aircraft composite structures: Recent advances and applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, Q.b.; Zhao, H.t.; Chen, J.a.; Wang, Y.y. Review on composite structural health monitoring based on fiber Bragg grating sensing principle. J. Shanghai Jiaotong Univ. (Sci.) 2013, 18, 129–139. [Google Scholar] [CrossRef]

- Falcetelli, F.; Yue, N.; Di Sante, R.; Zarouchas, D. Probability of detection, localization, and sizing: The evolution of reliability metrics in Structural Health Monitoring. Struct. Health Monit. 2022, 21, 2990–3017. [Google Scholar] [CrossRef]

- Wensveen, J.G. Air Transportation: A Management Perspective; Routledge: London, UK, 2016. [Google Scholar] [CrossRef]

- Shaw, S. Airline Marketing and Management; Routledge: London, UK, 2016. [Google Scholar] [CrossRef]

- Cusati, V.; Corcione, S.; Memmolo, V. Impact of structural health monitoring on aircraft operating costs by multidisciplinary analysis. Sensors 2021, 21, 6938. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Kosova, F.; Altay, Ö.; Ünver, H.Ö. Structural health monitoring in aviation: A comprehensive review and future directions for machine learning. Nondestruct. Test. Eval. 2025, 40, 1–60. [Google Scholar] [CrossRef]

- Hassani, S.; Mousavi, M.; Gandomi, A.H. Structural health monitoring in composite structures: A comprehensive review. Sensors 2021, 22, 153. [Google Scholar] [CrossRef] [PubMed]

- Reveley, M.S.; Briggs, J.L.; Evans, J.K.; Jones, S.M.; Kurtoglu, T.; Leone, K.M.; Sandifer, C.E. Causal Factors and Adverse Events of Aviation Accidents and Incidents Related to Integrated Vehicle Health Management; Technical Report NASA/TM—2011-216967; NASA: Washington, DC, USA, 2011. [Google Scholar]

- Sbarufatti, C.; Manes, A.; Giglio, M. Performance optimization of a diagnostic system based upon a simulated strain field for fatigue damage characterization. Mech. Syst. Signal Process. 2013, 40, 667–690. [Google Scholar] [CrossRef]

- Sala, G.; Di Landro, L.; Airoldi, A.; Bettini, P. Fibre optics health monitoring for aeronautical applications. Meccanica 2015, 50, 2547–2567. [Google Scholar] [CrossRef]

- Verhagen, W.J.; Santos, B.F.; Freeman, F.; van Kessel, P.; Zarouchas, D.; Loutas, T.; Yeun, R.C.; Heiets, I. Condition-Based Maintenance in Aviation: Challenges and Opportunities. Aerospace 2023, 10, 762. [Google Scholar] [CrossRef]

- Pattabhiraman, S.; Kim, N.H.; Haftka, R. Effects of uncertainty reduction measures by structural health monitoring on safety and lifecycle costs of aircrafts. In Proceedings of the 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 18th, Orlando, FL, USA, 12–15 April 2010; p. 2677. [Google Scholar] [CrossRef]

- Air Transport Association of America. ATA MSG-3: Operator/Manufacturer Scheduled Maintenance Development; Air Transport Association of America: Washington, DC, USA, 2007. [Google Scholar]

- Ahmadi, A.; Söderholm, P.; Kumar, U. On aircraft scheduled maintenance program development. J. Qual. Maint. Eng. 2010, 16, 229–255. [Google Scholar] [CrossRef]

- Rajamani, R. Condition-Based Maintenance in Aviation: The History, the Business and the Technology; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Janapati, V.; Kopsaftopoulos, F.; Li, F.; Lee, S.J.; Chang, F.K. Damage detection sensitivity characterization of acousto-ultrasound-based structural health monitoring techniques. Struct. Health Monit. 2016, 15, 143–161. [Google Scholar] [CrossRef]

- Kaplan, M.P.; Lincoln, J.W. The US Air Force approach to aircraft damage tolerant design. In Fatigue and Fracture; ASM International: Almere, The Netherlands, 1996; pp. 577–588. [Google Scholar]

- Garg, A.C. Delamination—A damage mode in composite structures. Eng. Fract. Mech. 1988, 29, 557–584. [Google Scholar] [CrossRef]

- Wang, S. Fracture mechanics for delamination problems in composite materials. J. Compos. Mater. 1983, 17, 210–223. [Google Scholar] [CrossRef]

- Federal Aviation Administration. AC 20-107B: Composite Aircraft Structure; Advisory Circular AC 20-107B; U.S. Department of Transportation, Federal Aviation Administration: Washington, DC, USA, 2009. [Google Scholar]

- Andrade, P.; Silva, C.; Ribeiro, B.; Santos, B.F. Aircraft maintenance check scheduling using reinforcement learning. Aerospace 2021, 8, 113. [Google Scholar] [CrossRef]

- Deng, Q.; Santos, B.F. Lookahead approximate dynamic programming for stochastic aircraft maintenance check scheduling optimization. Eur. J. Oper. Res. 2022, 299, 814–833. [Google Scholar] [CrossRef]

- Galanopoulos, G.; Eleftheroglou, N.; Milanoski, D.; Broer, A.; Zarouchas, D.; Loutas, T. A novel strain-based health indicator for the remaining useful life estimation of degrading composite structures. Compos. Struct. 2023, 306, 116579. [Google Scholar] [CrossRef]

- Galanopoulos, G.; Milanoski, D.; Broer, A.A.; Zarouchas, D.; Loutas, T. Health indicators for diagnostics and prognostics of composite aerospace structures. In Proceedings of the 2021 IEEE 8th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Naples, Italy, 23–25 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 541–546. [Google Scholar] [CrossRef]

- Cristiani, D.; Sbarufatti, C.; Cadini, F.; Giglio, M. Fatigue damage diagnosis and prognosis of an aeronautical structure based on surrogate modelling and particle filter. Struct. Health Monit. 2021, 20, 2726–2746. [Google Scholar] [CrossRef]

- Sprong, J.P.; Jiang, X.; Polinder, H. Deployment of Prognostics to Optimize Aircraft Maintenance—A Literature Review. J. Int. Bus. Res. Mark. 2020, 5, 26–37. [Google Scholar] [CrossRef]

- Pattabhiraman, S.; Gogu, C.; Kim, N.H.; Haftka, R.T.; Bes, C. Skipping unnecessary structural airframe maintenance using an on-board structural health monitoring system. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2012, 226, 549–560. [Google Scholar] [CrossRef]

- Pattabhiraman, S.; Kim, N.H.; Haftka, R. Effect of inspection strategies on the weight and lifecycle cost of airplanes. In Proceedings of the 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Denver, CO, USA, 4–7 April 2011; p. 1763. [Google Scholar] [CrossRef]

- Giannakeas, I.N.; Khodaei, Z.S.; Aliabadi, M.F. Structural health monitoring cost estimation of a piezosensorized aircraft fuselage. Sensors 2022, 22, 1771. [Google Scholar] [CrossRef]

- Cusati, V.; Corcione, S.; Memmolo, V. Potential benefit of structural health monitoring system on civil jet aircraft. Sensors 2022, 22, 7316. [Google Scholar] [CrossRef]

- Fitzwater, L.; Davis, C.; Torng, T.; Poblete, J. Cost/benefit analysis for intergration of non-deterministic analysis and in-situ monitoring for structural integrity. In Proceedings of the 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Denver, CO, USA, 4–7 April 2011; p. 1700. [Google Scholar] [CrossRef]

- Dienel, C.P.; Meyer, H.; Werwer, M.; Willberg, C. Estimation of airframe weight reduction by integration of piezoelectric and guided wave–based structural health monitoring. Struct. Health Monit. 2019, 18, 1778–1788. [Google Scholar] [CrossRef]

- Büchter, K.D.; Sebastia Saez, C.; Steinweg, D. Modeling of an aircraft structural health monitoring sensor network for operational impact assessment. Struct. Health Monit. 2022, 21, 208–224. [Google Scholar] [CrossRef]

- Ballarin, P.; Macchi, M.; Roda, I.; Sala, G.; Baldi, A.; Airoldi, A. Economic Impact Assessment of Structural Health Monitoring Systems on Helicopter Blade Beginning of Life. Struct. Control Health Monit. 2024, 2024, 2865576. [Google Scholar] [CrossRef]

- Ballarin, P.; Macchi, M.; Roda, I.; Sala, G.; Baldi, A.; Airoldi, A. Economic Impact Assessment of Structural Health Monitoring Systems on the Lifecycle of a Helicopter Blade. e-J. Nondestruct. Test. 2024, 29, 1–8. [Google Scholar] [CrossRef]

- Kapoor, H.; Braun, C.; Boller, C. Modelling and optimisation of maintenance intervals to realise Structural Health Monitoring applications on aircraft. In Proceedings of the 5th European Workshop on Structural Health Monitoring, Naples, Italy, 28 June–4 July 2010. [Google Scholar]

- Sun, J.; Chen, D.; Li, C.; Yan, H. Integration of scheduled structural health monitoring with airline maintenance program based on risk analysis. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2018, 232, 92–104. [Google Scholar] [CrossRef]

- Chen, X.; Bil, C.; Ren, H. Influence of SHM techniques on scheduled maintenance for aircraft composite structures. In Proceedings of the 14th AIAA Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 16–20 June 2014; p. 3264. [Google Scholar]

- Cottone, G.; Gollwitzer, S.; Heckenberger, U.; Straub, D. Reliability-oriented optimization of replacement strategies for monitored composite panels for aircraft structures. In Proceedings of the 9th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 10–12 September 2013. [Google Scholar]

- Pfingstl, S.; Steinweg, D.; Zimmermann, M.; Hornung, M. On the potential of extending aircraft service time using load monitoring. J. Aircr. 2022, 59, 377–385. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Structural Health Monitoring: With Piezoelectric Wafer Active Sensors; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar] [CrossRef]

- Jiao, P.; Egbe, K.J.I.; Xie, Y.; Matin Nazar, A.; Alavi, A.H. Piezoelectric sensing techniques in structural health monitoring: A state-of-the-art review. Sensors 2020, 20, 3730. [Google Scholar] [CrossRef] [PubMed]

- Qing, X.; Li, W.; Wang, Y.; Sun, H. Piezoelectric transducer-based structural health monitoring for aircraft applications. Sensors 2019, 19, 545. [Google Scholar] [CrossRef]

- Takeda, N.; Okabe, Y.; Kuwahara, J.; Kojima, S.; Ogisu, T. Development of smart composite structures with small-diameter fiber Bragg grating sensors for damage detection: Quantitative evaluation of delamination length in CFRP laminates using Lamb wave sensing. Compos. Sci. Technol. 2005, 65, 2575–2587. [Google Scholar] [CrossRef]

- Grattan, K.T.; Sun, T. Fiber optic sensor technology: An overview. Sens. Actuators A Phys. 2000, 82, 40–61. [Google Scholar] [CrossRef]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef]

- Stehmeier, H.; Speckmann, H. Comparative vacuum monitoring (CVM). In Proceedings of the 2nd European Workshop on Structural Health Monitoring, Munich, Germany, 7–9 July 2004; Citeseer: Princeton, NJ, USA, 2004; pp. 7–9. [Google Scholar]

- Roach, D. Real time crack detection using mountable comparative vacuum monitoring sensors. Smart Struct. Syst. 2009, 5, 317–328. [Google Scholar] [CrossRef]

- Blond, K.; O’Brien, T.; Thompson, N.; Piotrowski, D.; Clark, A. Comparative Vacuum Monitoring Solutions to Advance US Air Force KC-46A Condition-Based Maintenance Plus. Aerospace 2023, 10, 587. [Google Scholar] [CrossRef]

- Ouertani, M.Z.; Parlikad, A.K.; McFarlane, D.C. Towards an approach to Select an Asset Information Management Strategy. Int. J. Comput. Sci. Appl. 2008, 5, 25–44. [Google Scholar]

- Badurdeen, F.; Shuaib, M.; Liyanage, J.P. Risk modeling and analysis for sustainable asset management. In Proceedings of the Engineering Asset Management and Infrastructure Sustainability: Proceedings of the 5th World Congress on Engineering Asset Management (WCEAM 2010), Brisbane, Australia, 25–27 October 2010; Springer: London, UK, 2012; pp. 61–75. [Google Scholar] [CrossRef]

- Kiritsis, D.; Nguyen, V.K.; Stark, J. How closed-loop PLM improves Knowledge Management over the complete product lifecycle and enables the factory of the future. Int. J. Prod. Lifecycle Manag. 2008, 3, 54–77. [Google Scholar] [CrossRef]

- Mendler, A.; Döhler, M.; Grosse, C.U. Predictive probability of detection curves based on data from undamaged structures. Struct. Health Monit. 2024, 23, 1725–1741. [Google Scholar] [CrossRef]

- Aceti, P.; Sala, G. Impact of Moisture Absorption on Optical Fiber Sensors: New Bragg Law Formulation for Monitoring Composite Structures. J. Compos. Sci. 2024, 8, 518. [Google Scholar] [CrossRef]

- Aceti, P.; Calervo, L.; Bettini, P.; Sala, G. Measurement and Decoupling of Hygrothermal-Mechanical Effects with Optical Fibers: Development of a New Fiber Bragg Grating Sensor. Sensors 2025, 25, 1037. [Google Scholar] [CrossRef]

- Baker, W.; McKenzie, I.; Jones, R. Development of life extension strategies for Australian military aircraft, using structural health monitoring of composite repairs and joints. Compos. Struct. 2004, 66, 133–143. [Google Scholar] [CrossRef]

- Hölzel, N.B.; Schilling, T.; Gollnick, V. An aircraft lifecycle approach for the cost-benefit analysis of prognostics and condition-based maintenance based on discrete-event simulation. In Proceedings of the Annual Conference of the PHM Society, Fort Worth, TX, USA, 29 September–2 October 2014; Volume 6. [Google Scholar] [CrossRef]

- Vandawaker, R.M.; Jacques, D.R.; Freels, J.K. Impact of prognostic uncertainty in system health monitoring. Int. J. Progn. Health Manag. 2015, 6. [Google Scholar] [CrossRef]

- Vandawaker, R.M.; Jacques, D.R.; Ryan, E.T.; Huscroft, J.R.; Freels, J.K. Health monitoring impact on non-repairable component supply methods. J. Qual. Maint. Eng. 2017, 23, 82–94. [Google Scholar] [CrossRef]

- Omoleye, T.J.; Alabdulkarim, A.A.; Tsui, K.L. Impact of resources and monitoring effectiveness on prognostics enabled condition based maintenance policy. J. Simul. 2019, 13, 254–271. [Google Scholar] [CrossRef]

- Boller, C. Next generation structural health monitoring and its integration into aircraft design. Int. J. Syst. Sci. 2000, 31, 1333–1349. [Google Scholar] [CrossRef]

- Granado, L.; Ben-Marzouk, M.; Saenz, E.S.; Boukal, Y.; Jugé, S. Machine learning predictions of lithium-ion battery state-of-health for eVTOL applications. J. Power Sources 2022, 548, 232051. [Google Scholar] [CrossRef]

| Year | Authors | Title | Focus Area | Citation |

|---|---|---|---|---|

| 2010 | Diamanti & Soutis | Structural health monitoring techniques for aircraft composite structures | Damage detection, composites | [22] |

| 2015 | Giurgiutiu | SHM of aerospace composites | Technologies, sensors | [1] |

| 2016 | Yuan | SHM in aerospace structures | Broad SHM overview | [19] |

| 2020 | Güemes et al. | SHM for advanced composite structures: a review | Composites, sensor integration | [21] |

| 2021 | Hassani et al. | SHM in composite structures: a comprehensive review | ML, composites | [36] |

| 2025 | Kosova et al. | SHM in aviation: future directions for machine learning | ML in SHM | [35] |

| Ref. | Type of Sensor Used in SHMS | Material of the Monitored Structure | Type of Vehicle Monitored | Life Cycle Stages for Economic Assessment | Type of Structural Element Monitored | Integration in Maintenance Process | Impact of SHMS Performance | Impact of SHMS Weight | Impact of SHMS Ageing | Impact of Operational Life Extension | Impact of SHMS Power Consumption | Impact of Safety Margins Reduction | Evaluation of SHMS Cost-Effectiveness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [18] | Piezo | Met. | Fixed Wing | BOL and MOL | Fuselage | Sched. | Perf. | Y | N | N | N | N | Neg. |

| [58] | Piezo | Comp. | Fixed Wing | BOL and MOL | Fuselage | Sched. | Perf. | Y | N | N | N | N | Param. |

| [57] | N.S. | Met. | Fixed Wing | MOL | Fuselage | Sched. | Real. | Y | N | N | N | N | Pos. |

| [56] | N.S. | Met. | Fixed Wing | MOL | Fuselage | Sched., Online, and Hybrid | Real. | Y | N | N | N | N | Pos. |

| [33] | Piezo | Met. | Fixed Wing | MOL | Whole aircraft | Online | Perf. | Y | N | N | N | N | Param. |

| [65] | N.S. | Met. | Fixed Wing | MOL | Whole aircraft | Sched. | Perf. | N | N | N | N | N | Neg. |

| [66] | N.S. | Met. | Fixed Wing | MOL | Whole aircraft | Sched. | Real. | N | N | N | N | N | Pos. |

| [62] | Piezo and FBG | Met. | Fixed Wing | MOL | Whole aircraft | Online | Perf. | Y | N | N | Y | N | Pos. |

| [61] | Piezo | Comp. | Fixed Wing | MOL | Whole aircraft | Online | Perf. | Y | N | N | N | Y | Pos. |

| [67] | N.S. | Comp. | Fixed Wing | MOL | Whole aircraft | Sched. and Online | Real. | N | N | N | N | N | Pos. |

| [60] | Piezo | Met. | Fixed Wing | MOL | Fuselage | Online | Real. | N | N | N | N | N | Pos. |

| [59] | Piezo | Comp. | Fixed Wing | MOL | Whole aircraft | Online | Perf. | Y | N | N | N | Y | Pos. |

| [63] | FBG | Comp. | Rotary Wing | BOL | Rotor blade | N.A. | Perf. | N | N | N | N | N | Param. |

| [64] | FBG | Comp. | Rotary Wing | MOL | Rotor blade | Sched. | Real. | N | N | N | N | N | Neg. |

| [69] | N.S. | Met. | Fixed Wing | MOL | Whole aircraft | Usage mon. | Perf. | N | N | Y | N | N | Pos. |

| [41] | N.S. | Met. | Fixed Wing | BOL and MOL | Fuselage | Sched. | Real. | Y | Y | N | N | N | Pos. |

| [68] | N.S. | Comp. | Fixed Wing | MOL | Wing | Online | Real. | N | N | N | N | N | Param. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ballarin, P.; Sala, G.; Airoldi, A. Cost-Effectiveness of Structural Health Monitoring in Aviation: A Literature Review. Sensors 2025, 25, 6146. https://doi.org/10.3390/s25196146

Ballarin P, Sala G, Airoldi A. Cost-Effectiveness of Structural Health Monitoring in Aviation: A Literature Review. Sensors. 2025; 25(19):6146. https://doi.org/10.3390/s25196146

Chicago/Turabian StyleBallarin, Pietro, Giuseppe Sala, and Alessandro Airoldi. 2025. "Cost-Effectiveness of Structural Health Monitoring in Aviation: A Literature Review" Sensors 25, no. 19: 6146. https://doi.org/10.3390/s25196146

APA StyleBallarin, P., Sala, G., & Airoldi, A. (2025). Cost-Effectiveness of Structural Health Monitoring in Aviation: A Literature Review. Sensors, 25(19), 6146. https://doi.org/10.3390/s25196146