A Review of Multiscale Interaction Mechanisms of Wind–Leaf–Droplet Systems in Orchard Spraying

Abstract

1. Introduction

- Elucidating the coupling pathways and physical mechanisms between wind fields, leaf dynamics, and droplet behavior across multiple spatial and temporal scales;

- Identifying the key variables that affect orchard spray performance and droplet deposition efficiency, along with their modes of influence;

- Reviewing the state-of-the-art modeling approaches and visualization techniques currently used for spray system analysis, along with their applicability and limitations;

- Analyzing existing challenges such as insufficient model integration, difficulties in parameter acquisition, and the lack of high-resolution experimental validation;

- Proposing future research directions and potential technological breakthroughs to support the development of responsive, environmentally adaptive, and flexibly deployable intelligent spraying systems.

2. Multiscale Coupling Mechanisms of Wind–Leaf–Droplet Interactions

2.1. Microscale Interactions: Droplet–Leaf Surface Dynamics

2.2. Mesoscale Dynamics: Local Leaf Motion and Coordinated Effects

2.3. Macroscale Structure: Canopy Ventilation and Spray Cloud Distribution

3. Key Factors Influencing Spray Quality in Orchards

3.1. Wind Speed and Turbulence Structure

3.2. Mechanical Properties and Response Patterns of Leaves

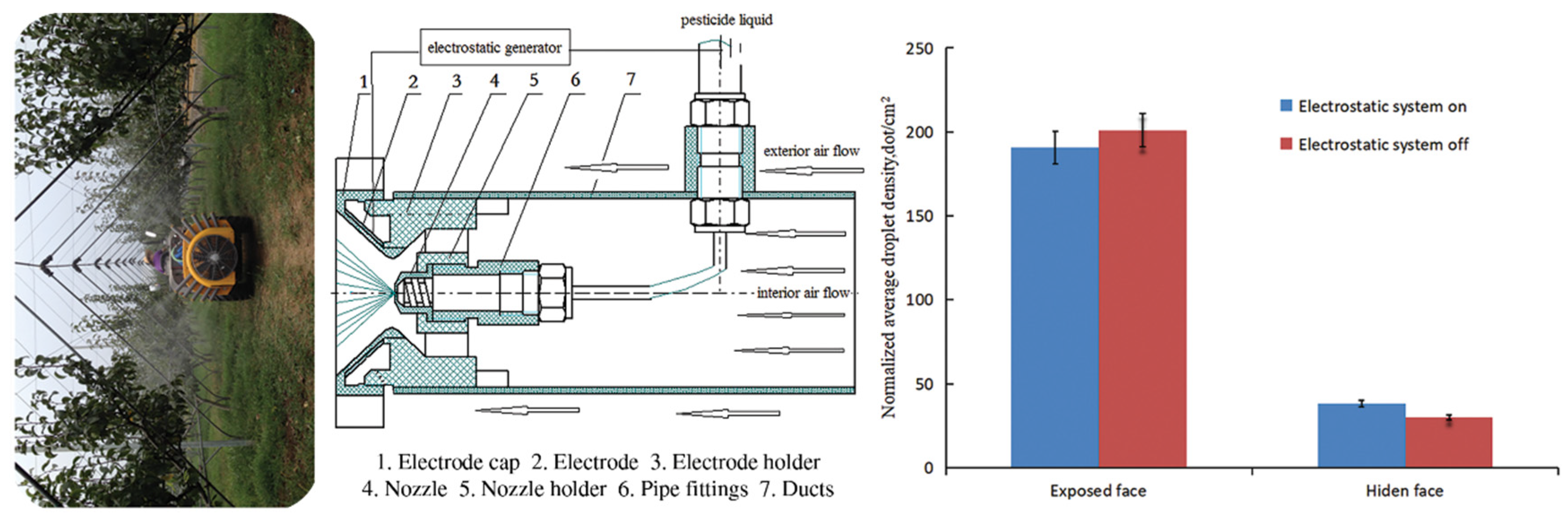

3.3. Physical Properties of Droplets and Deposition Behavior

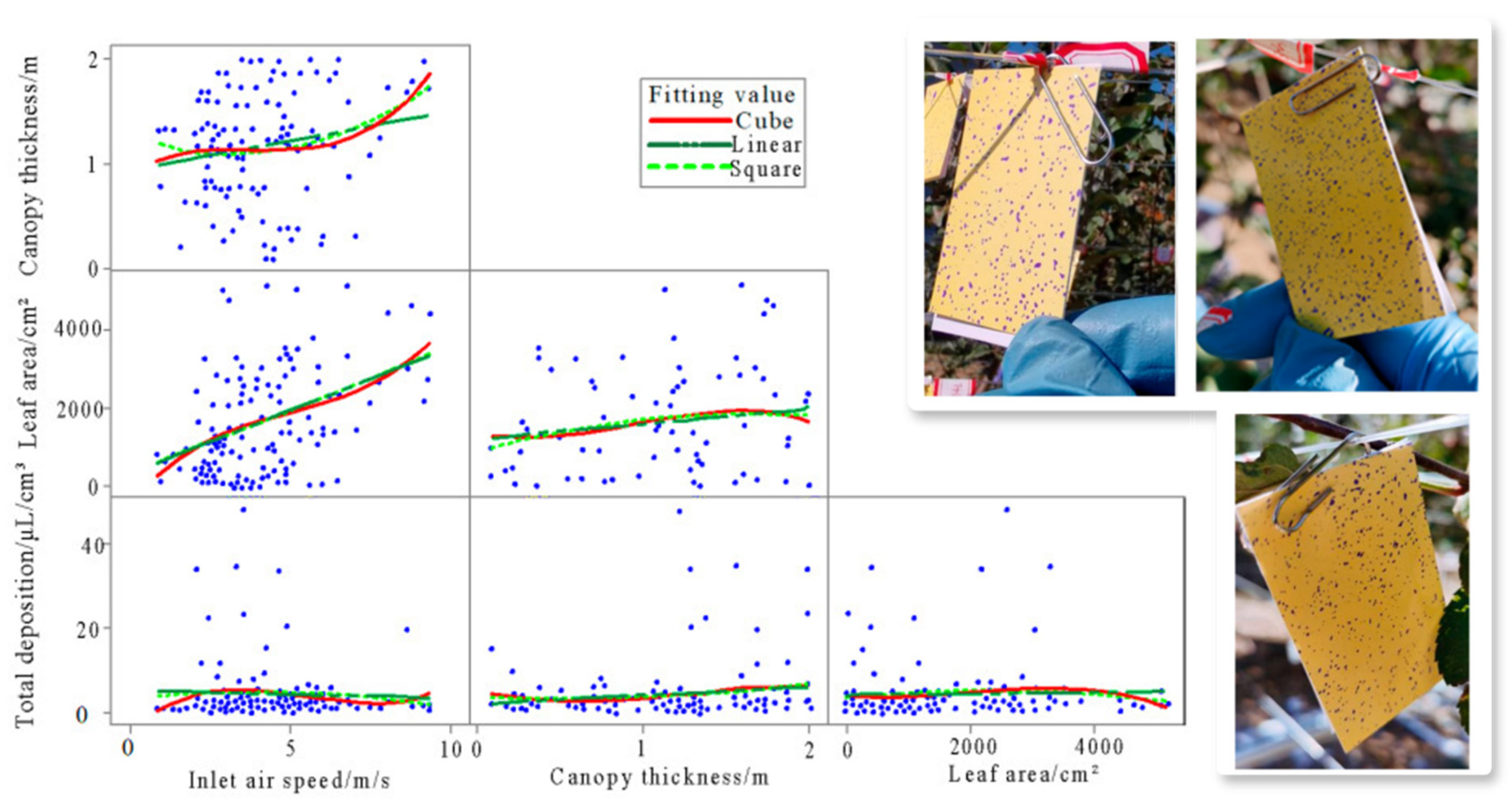

3.4. Canopy Structural Parameters and Penetration Characteristics

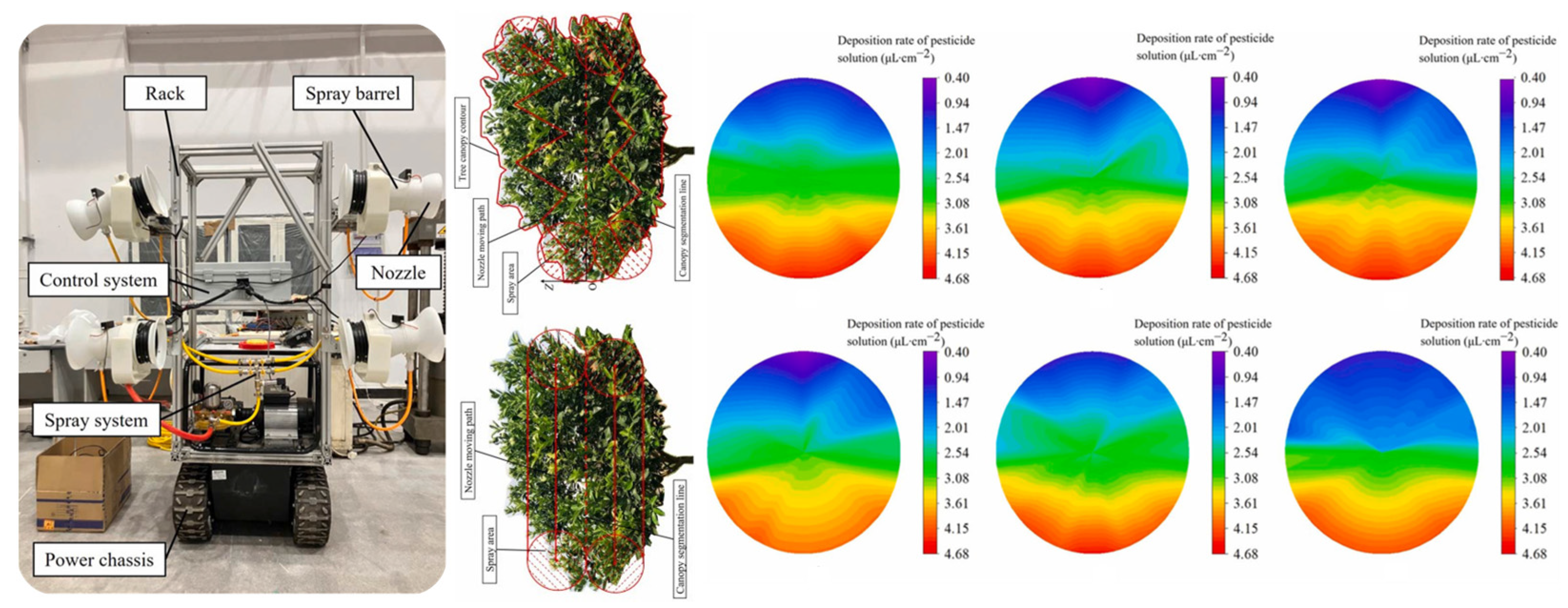

4. Modeling and Experimental Advances

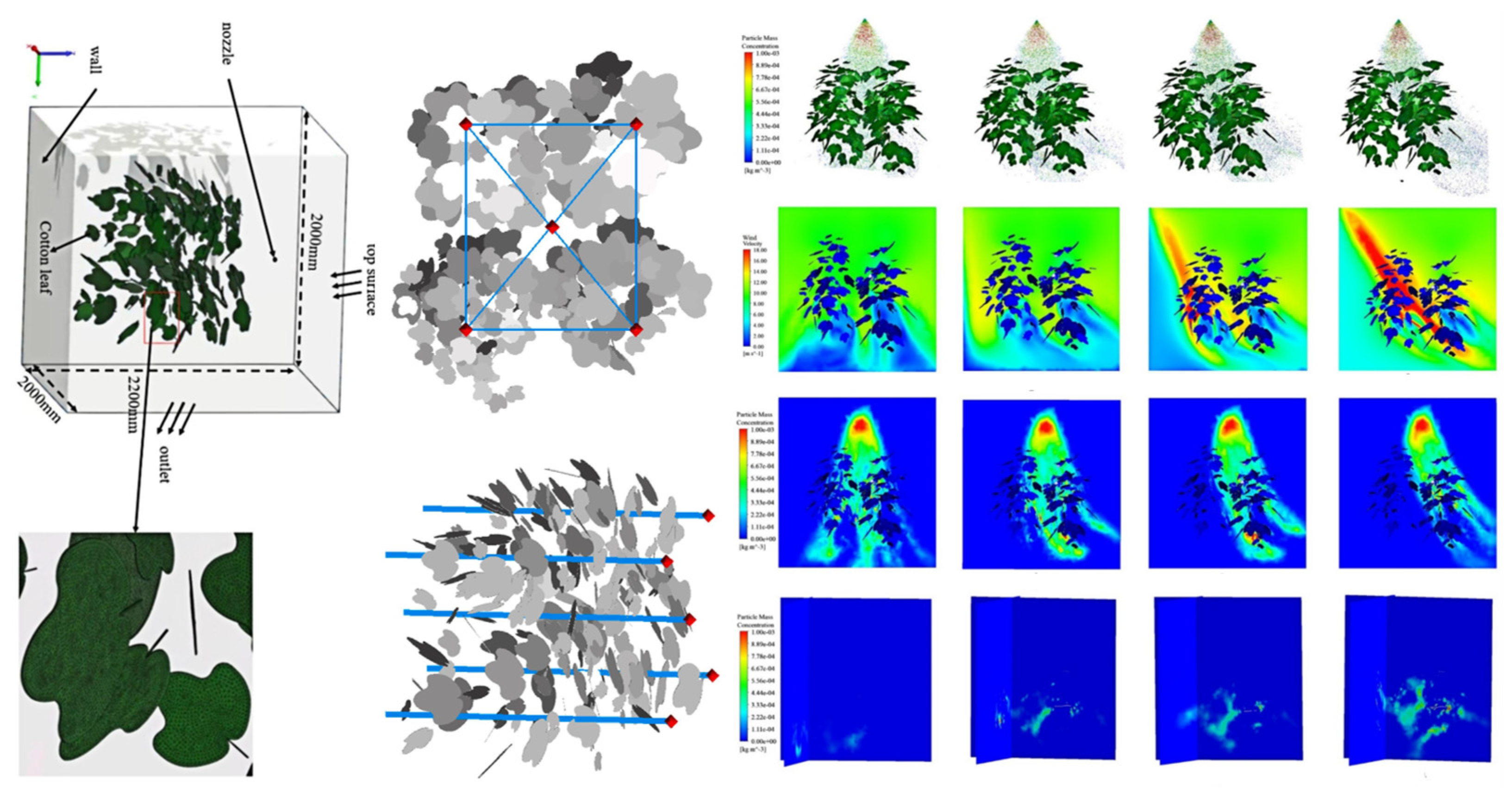

4.1. Multiscale Modeling Approaches: CFD, FSI, and Data-Driven Methods

4.2. Experimental Observation and Visualization Technologies

5. Challenges and Future Research Directions

5.1. Current Research Challenges

5.2. Future Research Directions

- Develop unified cross-scale coupling platforms. Integrate CFD (wind field), FSI (structural response), and droplet transport/wetting models into a chain-based modeling framework, capturing the entire process from external wind disturbance to leaf dynamics and eventual droplet deposition. This enables continuous multiscale representation and response window identification.

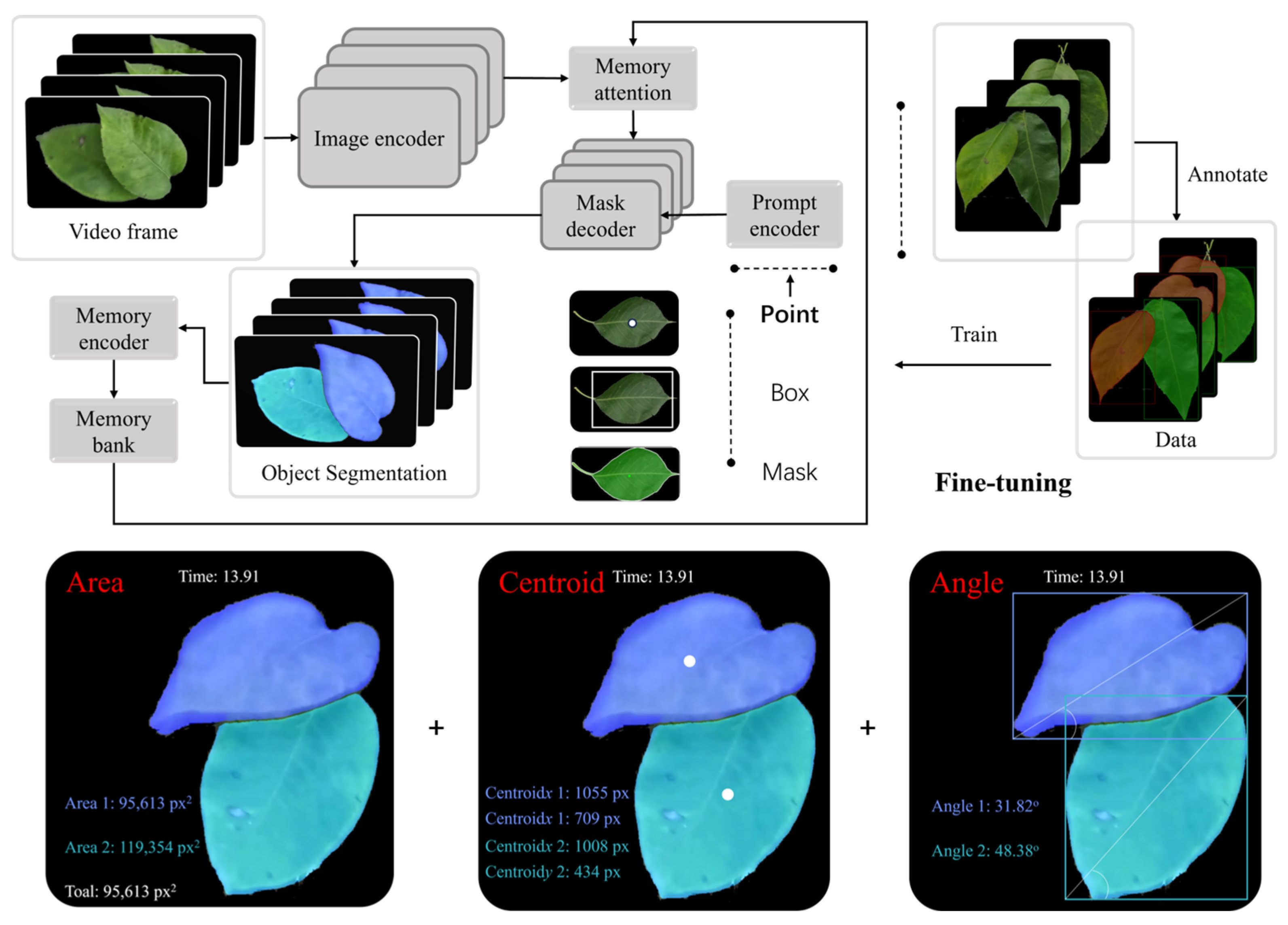

- Establish intelligent observation systems with experimental feedback. Combine high-speed imaging, machine vision, and semantic image recognition techniques with deep learning to structurally decode droplet–leaf interactions—including droplet deformation, contact behavior, spreading, and adhesion dynamics—providing fine-grained calibration data to transition from image recording to mechanistic interpretation.

- Promote integration of physics-based and data-driven models. Develop physics-informed machine learning (PIML) frameworks that embed governing equations, causal logic, and observational data into the training process. This enhances model interpretability, robustness, and adaptability across environmental conditions, addressing the challenges of sparse data, complex physical behavior, and model instability.

- Construct closed-loop systems of sensing, modeling, and control. Integrate multimodal sensors (e.g., RGB, infrared, multispectral, LiDAR point clouds) into orchard operation platforms to support real-time environmental perception for spraying tasks. By incorporating edge computing and reinforcement learning, these systems can achieve intelligent, adaptive control for variable-rate spraying.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, A.; Li, W.; Men, X.; Gao, B.; Xu, Y.; Wei, X. Vegetation detection based on spectral information and development of a low-cost vegetation sensor for selective spraying. Pest Manag. Sci. 2022, 78, 2467–2476. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, B.; Xue, X.; Sun, T.; Peng, B. Parameters optimization of crop protection UAS based on the first industry standard of China. Int. J. Agric. Biol. Eng. 2020, 13, 29–35. [Google Scholar] [CrossRef]

- Wan, L.; Li, H.; Li, C.; Wang, A.; Yang, Y.; Wang, P. Hyperspectral Sensing of Plant Diseases: Principle and Methods. Agronomy 2022, 12, 1451. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, D.; Wei, Y.; Zhang, X.; Li, L. Combining Transfer Learning and Ensemble Algorithms for Improved Citrus Leaf Disease Classification. Agriculture 2024, 14, 1549. [Google Scholar] [CrossRef]

- Poulsen, M.E.; Wenneker, M.; Withagen, J.; Christensen, H.B. Pesticide residues in individual versus composite samples of apples after fine or coarse spray quality application. Crop Prot. 2012, 35, 5–14. [Google Scholar] [CrossRef]

- Mahmud, M.S.; Zahid, A.; He, L.; Martin, P. Opportunities and Possibilities of Developing an Advanced Precision Spraying System for Tree Fruits. Sensor 2021, 21, 3262. [Google Scholar] [CrossRef]

- Zhou, Q.; Xue, X.; Chen, C.; Cai, C.; Jiao, Y. Canopy deposition characteristics of different orchard pesticide dose models. Int. J. Agric. Biol. Eng. 2023, 16, 1–6. [Google Scholar] [CrossRef]

- Xun, L.; Campos, J.; Salas, B.; Fabregas, F.X.; Zhu, H.; Gil, E. Advanced spraying systems to improve pesticide saving and reduce spray drift for apple orchards. Precis. Agric. 2023, 24, 1526–1546. [Google Scholar] [CrossRef]

- Yu, S.; Cui, L.; Cui, H.; Liu, X.; Liu, J.; Xin, Z.; Wang, D. Spray performance of flexible shield canopy opener and rotor wind integrated boom-sprayer application in soybean: Effects on droplet deposition distribution. Pest Manag. Sci. 2024, 80, 3334–3348. [Google Scholar] [CrossRef]

- Wu, S.; Liu, J.; Wang, J.; Hao, D.; Wang, R. The motion of strawberry leaves in an air-assisted spray field and its influence on droplet deposition. Trans. ASABE 2021, 64, 83–93. [Google Scholar] [CrossRef]

- Gao, J.; Tunio, M.H.; Chen, Y.; He, R. Design and experiment of low-frequency ultrasonic nozzle integrating air-assistant system and acoustic levitation mechanism. Int. J. Agric. Biol. Eng. 2020, 13, 25–33. [Google Scholar] [CrossRef]

- Gao, J.; Xu, K.; He, R.; Chen, X.; Tunio, M.H. Development and experiments of low frequency ultrasonic electrostatic atomizing nozzle with double resonators. Int. J. Agric. Biol. Eng. 2022, 15, 39–48. [Google Scholar] [CrossRef]

- Hu, W.; Gao, Z.; Dong, X.; Chen, J.; Qiu, B. Contact Electrification of Liquid Droplets Impacting Living Plant Leaves. Agronomy 2024, 14, 573. [Google Scholar] [CrossRef]

- Guo, J.; Dong, X.; Qiu, B. Analysis of the Factors Affecting the Deposition Coverage of Air-Assisted Electrostatic Spray on Tomato Leaves. Agronomy 2024, 14, 1108. [Google Scholar] [CrossRef]

- Xi, T.; Li, C.; Qiu, W.; Wang, H.; Lv, X.; Han, C.; Ahmad, F. Droplet deposition behavior on a pear leaf surface under wind-induced vibration. Appl. Eng. Agric. 2020, 36, 913–926. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, J.; Guo, J.; Qiu, B. Numerical Simulation and Validation of Droplet Deposition on Tomato Leaf Surface under Air-Assisted Spraying. Agronomy 2024, 14, 1661. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, Y.; Wang, H.; Wang, J.; Yang, Y.; Zhang, Q.; Zhou, G. Wind-induced response of rapeseed seedling stage and lodging prediction based on UAV imagery and machine learning methods. Comput. Electron. Agric. 2024, 217, 108637. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, C.; An, Y.; Chen, Y.; Qiu, W. Droplet deposition behavior on the surface of wheat leaves with wind-induced vibration. Crop Prot. 2024, 181, 106699. [Google Scholar] [CrossRef]

- Gong, C.; Li, D.; Kang, C. Visualization of the evolution of bubbles in the spray sheet discharged from the air-induction nozzle. Pest Manag. Sci. 2022, 78, 1850–1860. [Google Scholar] [CrossRef]

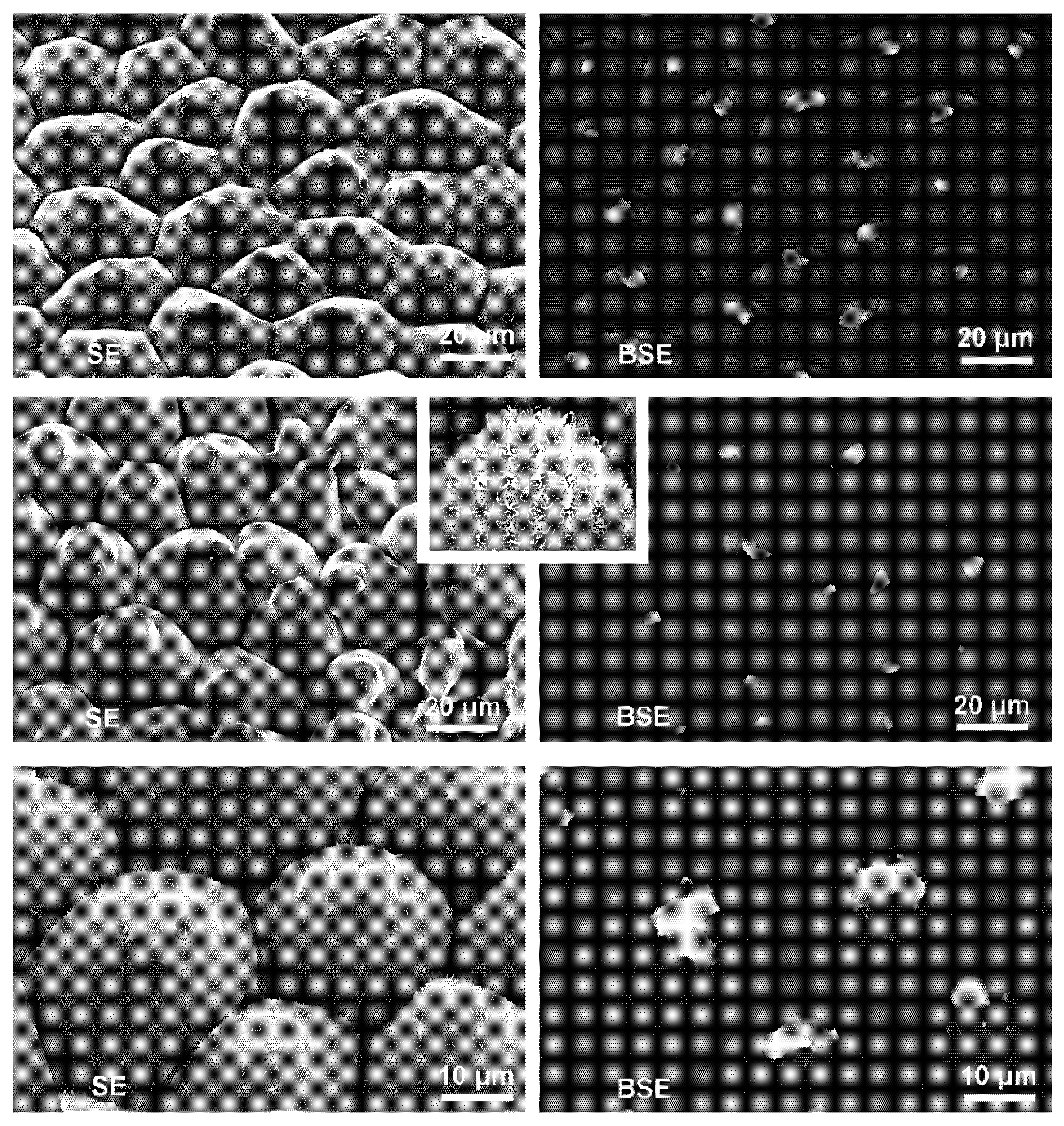

- Ma, J.; Liu, K.; Dong, X.; Chen, C.; Qiu, B.; Zhang, S. Effects of Leaf Surface Roughness and Contact Angle on In Vivo Measurement of Droplet Retention. Agronomy 2022, 12, 2228. [Google Scholar] [CrossRef]

- Wang, H.; Shi, H.; Li, Y.; Wang, Y. The effects of leaf roughness, surface free energy and work of adhesion on leaf water drop adhesion. PLoS ONE 2014, 9, e107062. [Google Scholar] [CrossRef]

- Jiang, H.; Xin, D.; Zhang, H. Wind-tunnel study of the aerodynamic characteristics and mechanical response of the leaves of betula platyphylla sukaczev. Biosyst. Eng. 2021, 207, 162–176. [Google Scholar] [CrossRef]

- Li, J.; Shi, Y.; Lan, Y.; Guo, S. Vertical distribution and vortex structure of rotor wind field under the influence of rice canopy. Comput. Electron. Agric. 2019, 159, 140–146. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; Zhu, X.; Yuan, S. Droplet characterisation of a complete fluidic sprinkler with different nozzle dimensions. Biosyst. Eng. 2016, 148, 90–100. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, X.; Xiao, J. Breakup behavior of a shear-thinning droplet on randomly rough surfaces: A numerical study. Chem. Eng. Sci. 2022, 247, 117071. [Google Scholar] [CrossRef]

- Yue, J.; Chao, C.; Hong, L.; Qingjiang, X. Influences of nozzle parameters and low-pressure on jet breakup and droplet characteristics. Int. J. Agric. Biol. Eng. 2016, 9, 22–32. [Google Scholar]

- Pan, X.; Jiang, Y.; Li, H.; Hui, X.; Xing, S.; Chauhdary, J.N. Numerical simulation and experimental study of jet breakup using a water dispersal needle in irrigation sprinklers. Biosyst. Eng. 2024, 239, 49–67. [Google Scholar] [CrossRef]

- Jiang, Y.; Yang, Z.; Xu, X.; Ma, L.; Li, Y.; Yu, J.; Duan, J. Surface physicochemical characteristics and wettability regulation mechanism of mango leaves at different growth stages. Sci. Hortic. 2025, 345, 114146. [Google Scholar] [CrossRef]

- Dorr, G.J.; Wang, S.; Mayo, L.C.; McCue, S.W.; Forster, W.A.; Hanan, J.; He, X. Impaction of spray droplets on leaves: Influence of formulation and leaf character on shatter, bounce and adhesion. Exp. Fluids 2015, 56, 143. [Google Scholar] [CrossRef]

- Burton, Z.; Bhushan, B. Surface characterization and adhesion and friction properties of hydrophobic leaf surfaces. Ultramicroscopy 2006, 106, 709–719. [Google Scholar] [CrossRef]

- Ensikat, H.J.; Mayser, M.; Barthlott, W. Superhydrophobic and adhesive properties of surfaces: Testing the quality by an elaborated scanning electron microscopy method. Langmuir 2012, 28, 14338–14346. [Google Scholar] [CrossRef]

- Li, J.; Cui, H.; Ma, Y.; Xun, L.; Li, Z.; Yang, Z.; Lu, H. Orchard Spray Study: A Prediction Model of Droplet Deposition States on Leaf Surfaces. Agronomy 2020, 10, 747. [Google Scholar] [CrossRef]

- Jiang, Y.; Yang, Z.; Xu, X.; Shen, D.; Jiang, T.; Xie, B.; Duan, J. Wetting and deposition characteristics of air-assisted spray droplet on large broad-leaved crop canopy. Front. Plant Sci. 2023, 14, 1079703. [Google Scholar] [CrossRef]

- Wu, S.; Liu, J.; Zhen, J.; Lei, X.; Chen, Y. Resistance characteristics of broad-leaf crop canopy in air-assisted spray field and their effects on droplet deposition. Front. Plant Sci. 2022, 13, 924749. [Google Scholar] [CrossRef]

- Huang, S.; Yan, H.; Zhang, C.; Wang, G.; Acquah, S.J.; Yu, J.; Darko, R.O. Modeling evapotranspiration for cucumber plants based on the Shuttleworth-Wallace model in a Venlo-type greenhouse. Agric. Water Manag. 2020, 228, 105861. [Google Scholar] [CrossRef]

- Zhao, B.; An, D.; Yan, C.; Yan, H.; Kong, R.; Su, J. Spatiotemporal Variations of Reference Evapotranspiration and Its Climatic Driving Factors in Guangdong, a Humid Subtropical Province of South China. Agronomy 2023, 13, 1446. [Google Scholar] [CrossRef]

- Yan, H.; Zhao, S.; Zhang, C.; Zhang, J.; Wang, G.; Li, M.; Jiang, J. Calibration and assessment of evapotranspiration methods for cucumber plants in a Venlo-type greenhouse. Irrig. Drain. 2024, 73, 119–135. [Google Scholar] [CrossRef]

- Yan, H.; Acquah, S.J.; Zhang, C.; Wang, G.; Huang, S.; Zhang, H.; Wu, H. Energy partitioning of greenhouse cucumber based on the application of Penman-Monteith and Bulk Transfer models. Agric. Water Manag. 2019, 217, 201–211. [Google Scholar] [CrossRef]

- Gong, C.; Li, D.; Kang, C. Effect of oil-based emulsion on air bubbles in the spray sheet produced through the air-induction nozzle. Pest Manag. Sci. 2022, 78, 5347–5357. [Google Scholar] [CrossRef] [PubMed]

- Gong, C.; Jia, F.; Kang, C. Deposition of water and emulsion hollow droplets on hydrophilic and hydrophobic surfaces. Agriculture 2024, 14, 960. [Google Scholar] [CrossRef]

- Li, H.; Travlos, I.; Qi, L.; Kanatas, P.; Wang, P. Optimization of Herbicide Use: Study on Spreading and Evaporation Characteristics of Glyphosate-Organic Silicone Mixture Droplets on Weed Leaves. Agronomy 2019, 9, 547. [Google Scholar] [CrossRef]

- Zhou, Z.; Cao, C.; Cao, L.; Zheng, L.; Xu, J.; Li, F.; Huang, Q. Effect of surfactant concentration on the evaporation of droplets on cotton (Gossypium hirsutum L.) leaves. Colloids Surf. B Biointerfaces 2018, 167, 206–212. [Google Scholar] [CrossRef]

- Liu, D.; Pan, B.; Wang, B.; Lin, Y.; Jiang, L. Strategy for the Selection of Tank-Mix Adjuvants to Improve the Wettability of Unmanned Aerial Vehicle-Sprayed Liquids on Citrus Leaf Surfaces. Langmuir 2025, 41, 7517–7524. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Wang, D.; Jiang, Z.; Li, X.; Chen, G. Effect of Adjuvants on the Wetting Behaviors of Bifenthrin Droplets on Tea Leaves. Appl. Sci. 2022, 12, 4217. [Google Scholar] [CrossRef]

- Arand, K.; Asmus, E.; Popp, C.; Schneider, D.; Riederer, M. The mode of action of adjuvants—Relevance of physicochemical properties for effects on the foliar application, cuticular permeability, and greenhouse performance of pinoxaden. J. Agric. Food Chem. 2018, 66, 5770–5777. [Google Scholar] [CrossRef]

- Meng, Y.; Wu, Q.; Zhou, H.; Hu, H. How tank-mix adjuvant type and concentration influence the contact angle on wheat leaf surface. PeerJ 2023, 11, e16464. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, H.; Sun, W.; Sun, Y.; Xing, R.; Zhang, K.; Fang, X.; Sui, B.; Xu, J. The Effect of Airflow-Assisted Parameters on Droplet Deposition on Soybean Leaves at the V7 Growth Stage. Agronomy 2025, 15, 141. [Google Scholar] [CrossRef]

- Shao, C.P.; Chen, Y.J.; Lin, J.Z. Wind induced deformation and vibration of a Platanus acerifolia leaf. Acta Mech. Sin. 2012, 28, 583–594. [Google Scholar] [CrossRef]

- Tang, J.; Wang, Y.; Wang, N.; Ning, X.; Lyu, K.; Sui, L.; Shi, Z. Swaying Tree Simulation by Slicing Partition. Chin. J. Electron. 2020, 29, 826–832. [Google Scholar] [CrossRef]

- Ma, Z.; Han, M.; Li, Y.; Yu, S.; Chandio, F.A. Comparing kernel damage of different threshing components using high-speed cameras. Int. J. Agric. Biol. Eng. 2020, 13, 215–219. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, X.; Liang, R.; Li, J.; Wang, X.; Meng, H.; Kan, Z. Cotton stalk restitution coefficient determination tests based on the binocular high-speed camera technology. Int. J. Agric. Biol. Eng. 2022, 15, 181–189. [Google Scholar] [CrossRef]

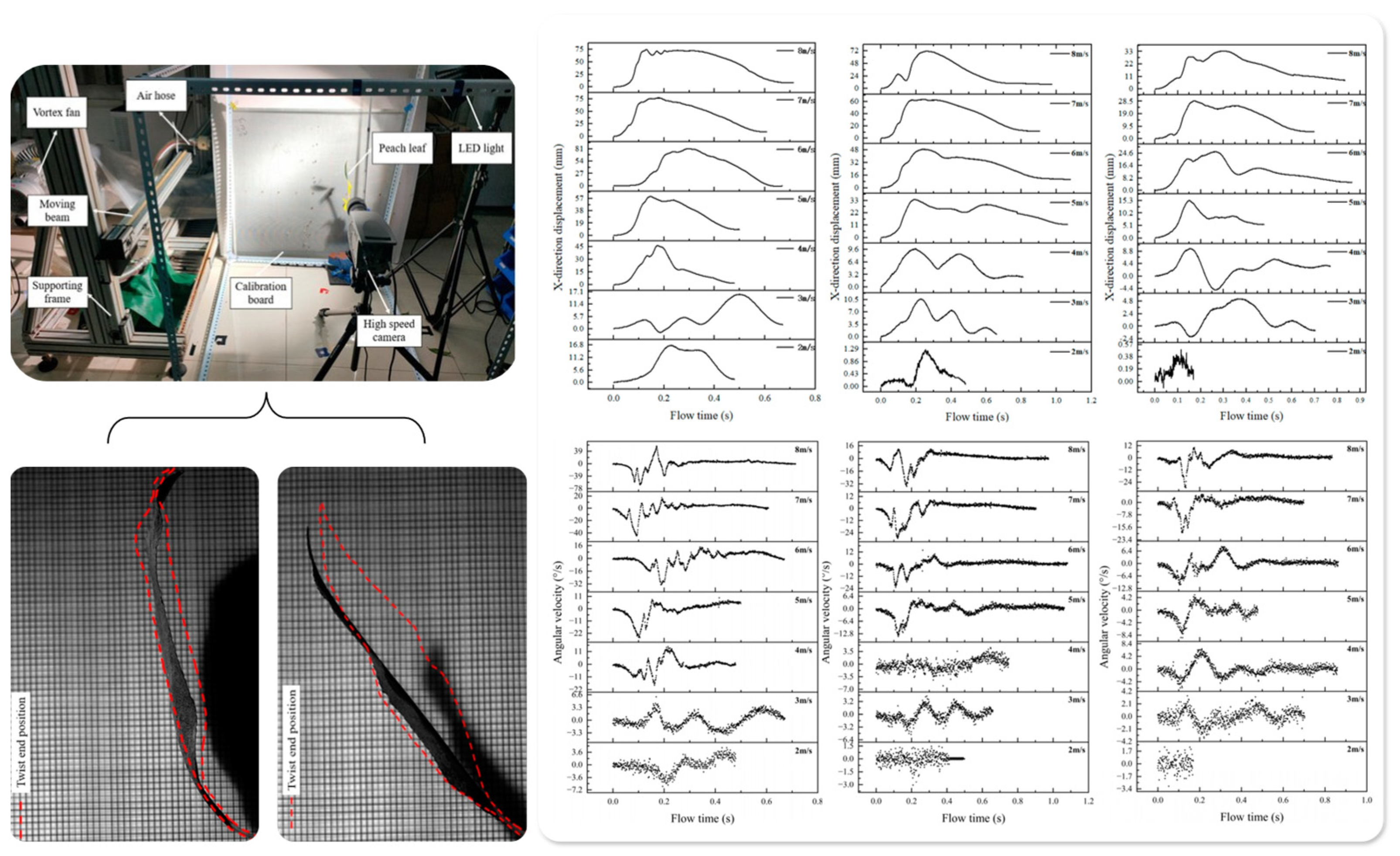

- Wang, G.; Dong, X.; Jia, W.; Ou, M.; Yu, P.; Wu, M.; Zhang, Z.; Hu, X.; Huang, Y.; Lu, F. Influence of Wind Speed on the Motion Characteristics of Peach Leaves (Prunus persica). Agriculture 2024, 14, 2307. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, H.; Xu, L.; Ru, Y.; Ju, H.; Chen, Q. Measurement of morphological changes of pear leaves in airflow based on high-speed photography. Front. Plant Sci. 2022, 13, 900427. [Google Scholar] [CrossRef]

- Yan, C.; Niu, C.; Ma, S.; Tan, H.; Xu, L. CFD models as a tool to analyze the deformation behavior of grape leaves under an air-assisted sprayer. Comput. Electron. Agric. 2022, 198, 107112. [Google Scholar] [CrossRef]

- Cao, Y.; Xi, T.; Xu, L.; Qiu, W.; Guo, H.; Lv, X.; Li, C. Computational fluid dynamics simulation experimental verification and analysis of droplets deposition behaviour on vibrating pear leaves. Plant Methods 2022, 18, 80. [Google Scholar] [CrossRef]

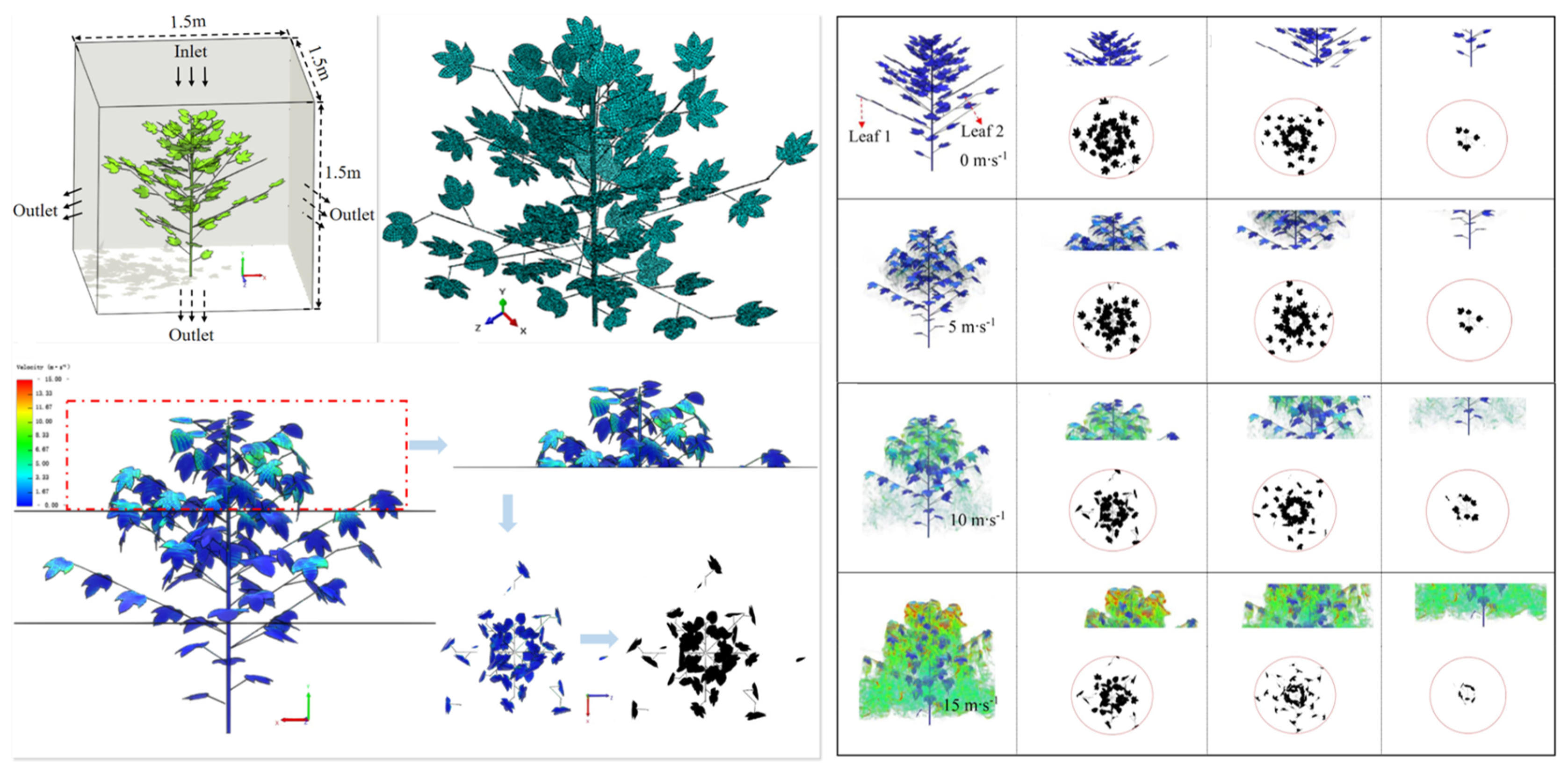

- Cui, H.; Wang, C.; Liu, X.; Yuan, J.; Liu, Y. Dynamic simulation of fluid-structure interactions between leaves and airflow during air-assisted spraying: A case study of cotton. Comput. Electron. Agric. 2023, 209, 107817. [Google Scholar] [CrossRef]

- Yazbeck, T.; Bohrer, G.; De Roo, F.; Mauder, M.; Bakshi, B. Effects of spatial heterogeneity of leaf density and crown spacing of canopy patches on dry deposition rates. Agric. For. Meteorol. 2021, 306, 108440. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Gu, R. Research Status and Prospects on Plant Canopy Structure Measurement Using Visual Sensors Based on Three-Dimensional Reconstruction. Agriculture 2020, 10, 462. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, H. Evaluation of a laser scanning sensor in detection of complex-shaped targets for variable-rate sprayer development. Trans. ASABE 2016, 59, 1181–1192. [Google Scholar]

- Hamed, A.M.; Sadowski, M.J.; Nepf, H.M.; Chamorro, L.P. Impact of height heterogeneity on canopy turbulence. J. Fluid Mech. 2017, 813, 1176–1196. [Google Scholar] [CrossRef]

- Niu, Z.; Huang, T.; Xu, C.; Sun, X.; Taha, M.F.; He, Y.; Qiu, Z. A Novel Approach to Optimize Key Limitations of Azure Kinect DK for Efficient and Precise Leaf Area Measurement. Agricultrue 2025, 15, 173. [Google Scholar] [CrossRef]

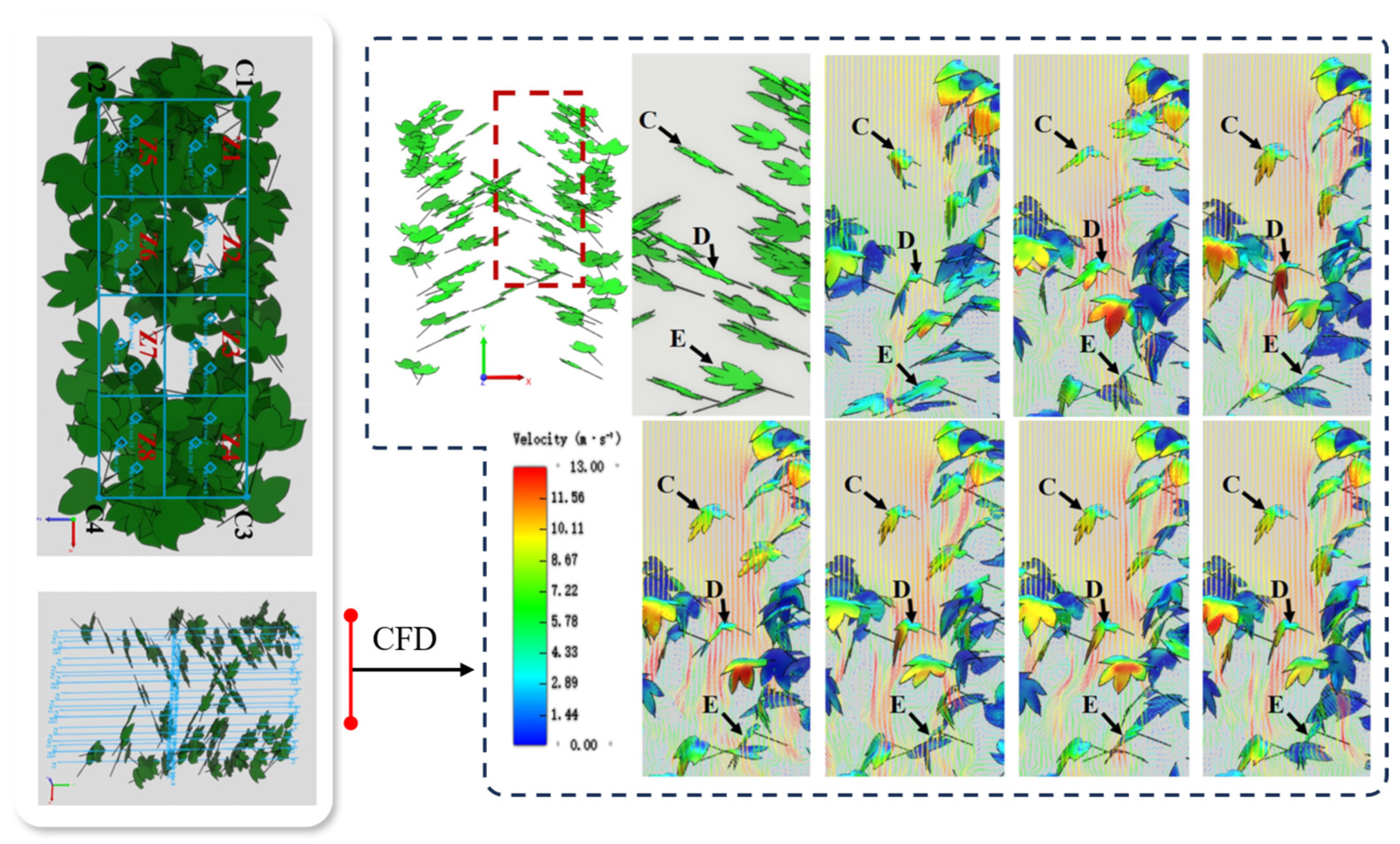

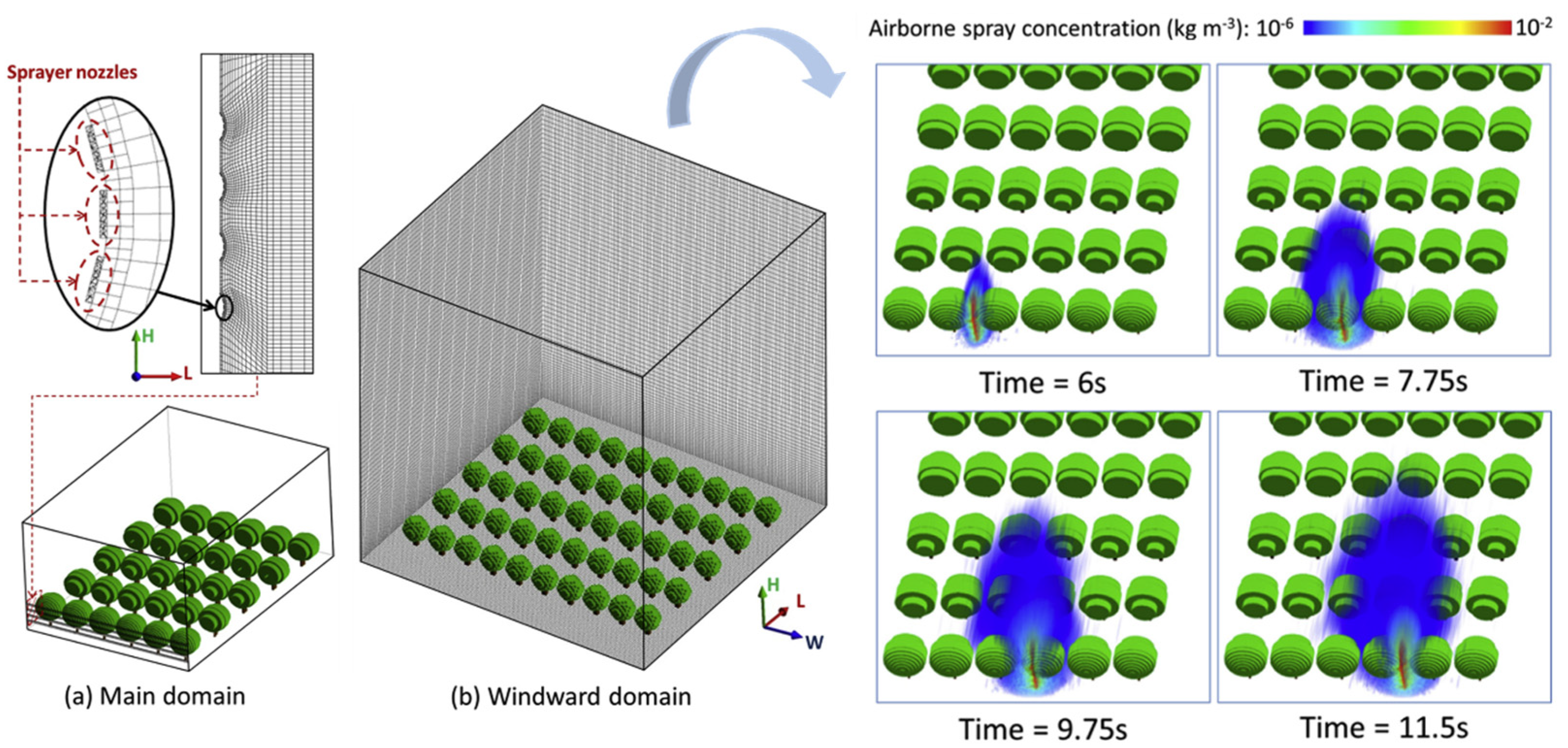

- Endalew, A.M.; Debaer, C.; Rutten, N.; Vercammen, J.; Delele, M.A.; Ramon, H.; Verboven, P. Modelling pesticide flow and deposition from air-assisted orchard spraying in orchards: A new integrated CFD approach. Agric. For. Meteorol. 2010, 150, 1383–1392. [Google Scholar] [CrossRef]

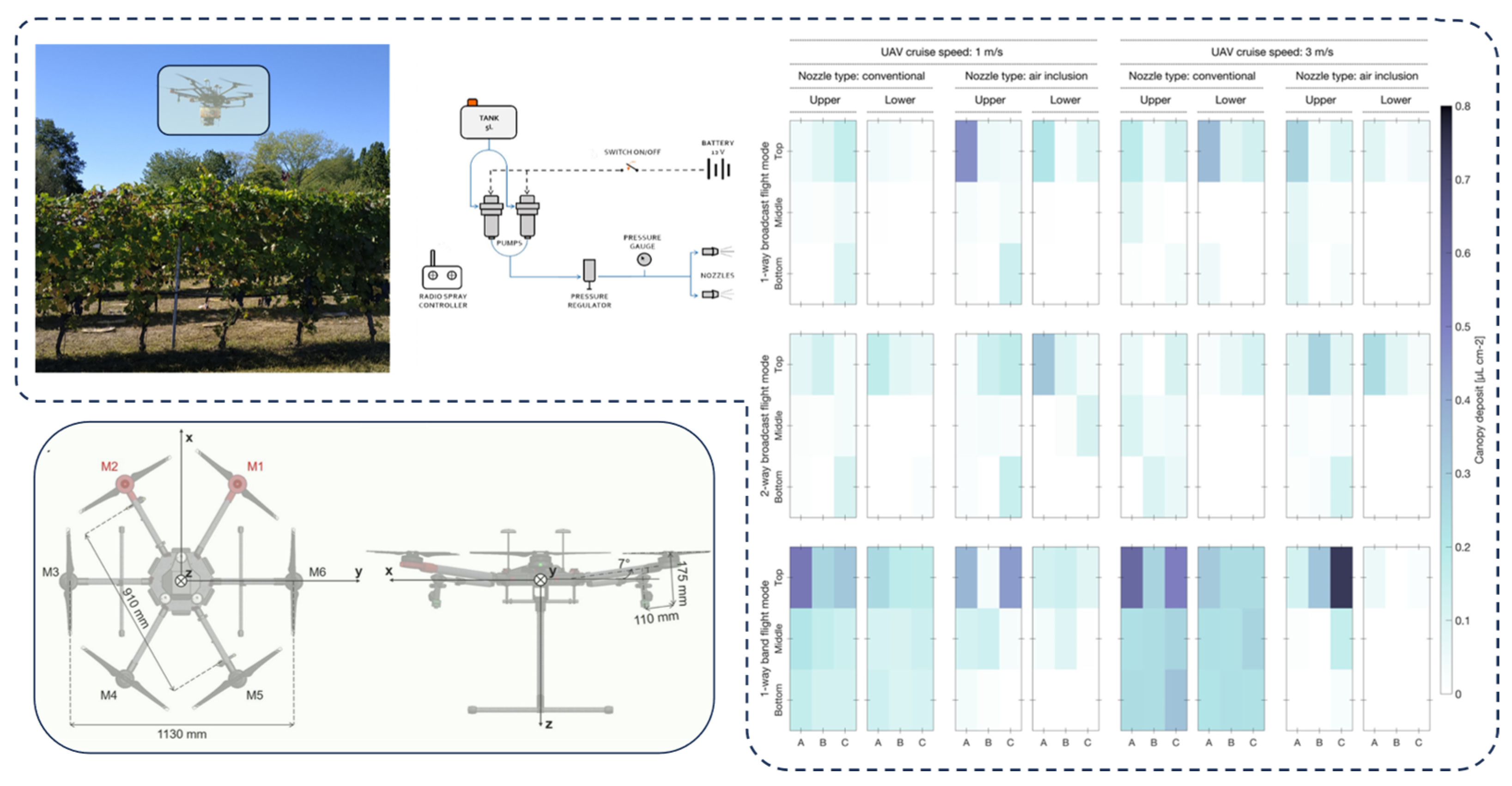

- Guo, S.; Li, J.; Yao, W.; Zhan, Y.; Li, Y.; Shi, Y. Distribution characteristics on droplet deposition of wind field vortex formed by multi-rotor UAV. PLoS ONE 2019, 14, e0220024. [Google Scholar] [CrossRef]

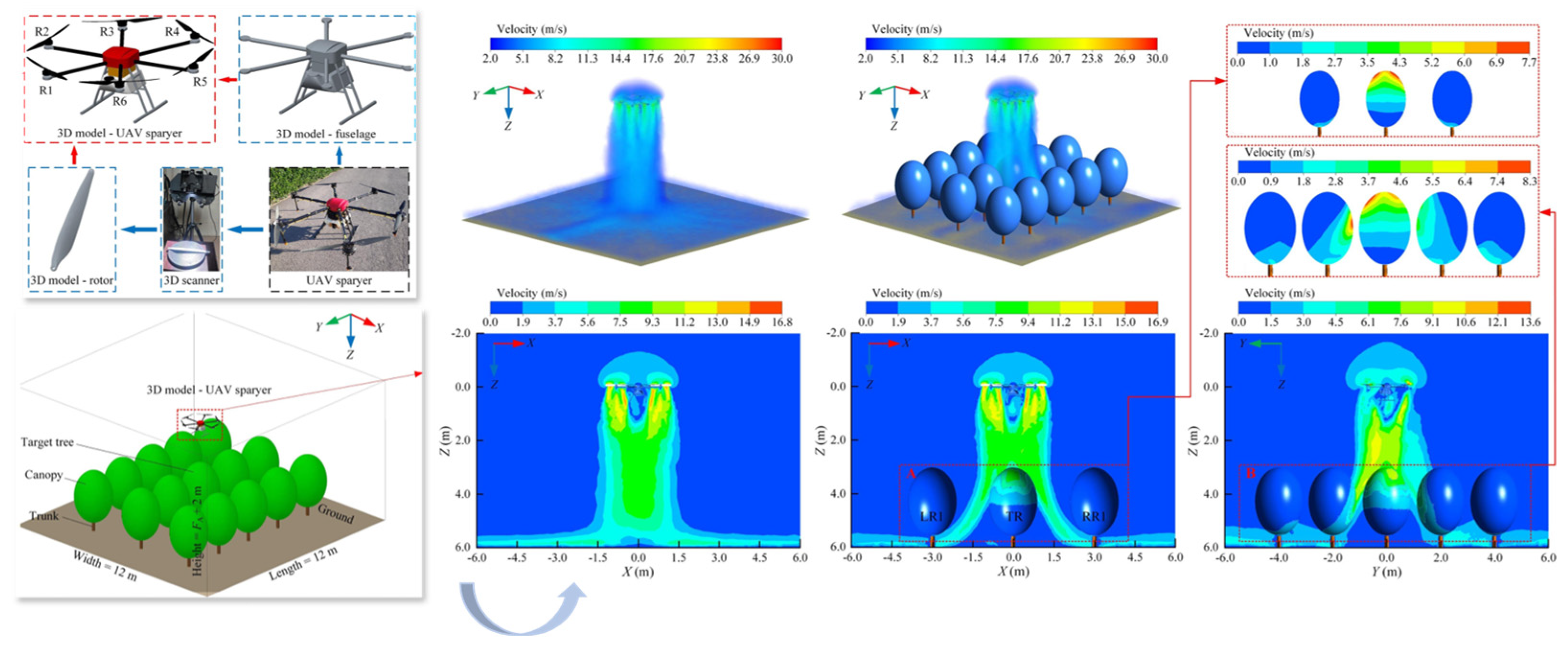

- Zhang, H.; Qi, L.; Wan, J.; Musiu, E.M.; Zhou, J.; Lu, Z.; Wang, P. Numerical simulation of downwash airflow distribution inside tree canopies of an apple orchard from a multirotor unmanned aerial vehicle (UAV) sprayer. Comput. Electron. Agric. 2022, 195, 106817. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, Y.; Zhao, Y.; Pan, Q.; Jin, K.; Xu, G.; Hu, Y. Ts-yolo: An all-day and lightweight tea canopy shoots detection model. Agronomy 2023, 13, 1411. [Google Scholar] [CrossRef]

- Zuo, Z.; Gao, S.; Peng, H.; Xue, Y.; Han, L.; Ma, G.; Mao, H. Lightweight Detection of Broccoli Heads in Complex Field Environments Based on LBDC-YOLO. Agronomy 2024, 14, 2359. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Sun, J.; Yu, T.; Cai, Z.; Zhang, Z.; Mao, H. Low-Cost Lettuce Height Measurement Based on Depth Vision and Lightweight Instance Segmentation Model. Agriculture 2024, 14, 1596. [Google Scholar] [CrossRef]

- Zhu, C.; Hao, S.; Liu, C.; Wang, Y.; Jia, X.; Xu, J.; Guo, S.; Huo, J.; Wang, W. An Efficient Computer Vision-Based Dual-Face Target Precision Variable Spraying Robotic System for Foliar Fertilisers. Agronomy 2024, 14, 2770. [Google Scholar] [CrossRef]

- Fujimoto, A.; Satow, T.; Kishimoto, T. Simulation of spray distribution with boom sprayer considering effect of wind for agricultural cloud computing analysis. Eng. Agric. Environ. Food 2016, 9, 305–310. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Zhou, Z.; Ouyang, F.; Wang, G.; Huang, X.; Deng, X.; Cheng, S. Effect of Droplet Size Parameters on Droplet Deposition and Drift of Aerial Spraying by Using Plant Protection UAV. Agronomy 2020, 10, 195. [Google Scholar] [CrossRef]

- Liu, J.; Yuan, S.; Darko, R.O. Characteristics of water and droplet size distribution from fluidic sprinklers. Irrig. Drain. 2016, 65, 522–529. [Google Scholar] [CrossRef]

- Liao, J.; Hewitt, A.J.; Wang, P.; Luo, X.; Zang, Y.; Zhou, Z.; O’Donnell, C. Development of droplet characteristics prediction models for air induction nozzles based on wind tunnel tests. Int. J. Agric. Biol. Eng. 2019, 12, 1–6. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Q.; Zhou, H.; Liu, C.; Han, R.; Lv, X. Morphological changes and spray coverage of pear leaves and canopy at different phenological periods during air-assisted spraying. Crop Prot. 2025, 197, 107324. [Google Scholar] [CrossRef]

- Jiang, S.; Yang, S.; Xu, J.; Li, W.; Zheng, Y.; Liu, X.; Tan, Y. Wind field and droplet coverage characteristics of air-assisted sprayer in mango-tree canopies. Pest Manag. Sci. 2022, 78, 4892–4904. [Google Scholar] [CrossRef]

- Meyers, T.; Tha Paw U, K. Testing of a higher-order closure model for modeling airflow within and above plant canopies. Bound.-Layer Meteorol. 1986, 37, 297–311. [Google Scholar] [CrossRef]

- Hong, S.W.; Zhao, L.; Zhu, H. CFD simulation of pesticide spray from air-assisted sprayers in an apple orchard: Tree deposition and off-target losses. Atmos. Environ. 2018, 175, 109–119. [Google Scholar] [CrossRef]

- Wang, S.; Ren, L.; Liu, Y.; Han, Z.; Yang, Y. Mechanical characteristics of typical plant leaves. J. Bionic Eng. 2010, 7, 294–300. [Google Scholar] [CrossRef]

- Gibson, L.J. The hierarchical structure and mechanics of plant materials. J. R. Soc. Interface 2012, 9, 2749–2766. [Google Scholar] [CrossRef]

- Xing, D.; Chen, X.; Wu, Y.; Li, Z.; Khan, S. Changes in elastic modulus, leaf tensity and leaf density during dehydration of detached leaves in two plant species of Moraceae. Chil. J. Agric. Res. 2021, 81, 434–447. [Google Scholar] [CrossRef]

- Okonkwo, E.G.; Daniel-Mkpume, C.C.; Ude, S.N.; Onah, C.C.; Ijomah, A.I.; Omah, A.D. Chicken feather fiber—African star apple leaves bio-composite: Empirical study of mechanical and morphological properties. Mater. Res. Express 2019, 6, 105361. [Google Scholar] [CrossRef]

- Cui, H.; Wang, C.; Lu, F.; Liu, X.; Yuan, J. Dynamic stratified porosity computation from canopy interaction simulation between airflow and leaves. Front. Plant Sci. 2023, 14, 1238360. [Google Scholar] [CrossRef]

- Hua, L.; Jiang, Y.; Li, H.; Qin, L. Effects of Different Nozzle Orifice Shapes on Water Droplet Characteristics for Sprinkler Irrigation. Horticulturae 2022, 8, 538. [Google Scholar] [CrossRef]

- Knight, R.M.; Li, X.; Hocter, J.S.; Zhang, B.; Zhao, L.; Zhu, H. Optimization of Induction Charging of Water Droplets to Develop an Electrostatic Spray Scrubber Intended for Poultry Particulate Matter Mitigation. J. ASABE 2022, 65, 815–824. [Google Scholar] [CrossRef]

- Junping, L.; Xingye, Z.; Shouqi, Y.; Xingfa, L. Droplet motion model and simulation of a complete fluidic sprinkler. Trans. ASABE 2018, 61, 1297–1306. [Google Scholar] [CrossRef]

- Liao, J.; Luo, X.; Wang, P.; Zhou, Z.; O’Donnell, C.C.; Zang, Y.; Hewitt, A.J. Analysis of the influence of different parameters on droplet characteristics and droplet size classification categories for air induction nozzle. Agronomy 2020, 10, 256. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, J.; Li, H.; Hua, L.; Yong, Y. Droplet distribution characteristics of impact sprinklers with circular and noncircular nozzles: Effect of nozzle aspect ratios and equivalent diameters. Biosyst. Eng. 2021, 212, 200–214. [Google Scholar] [CrossRef]

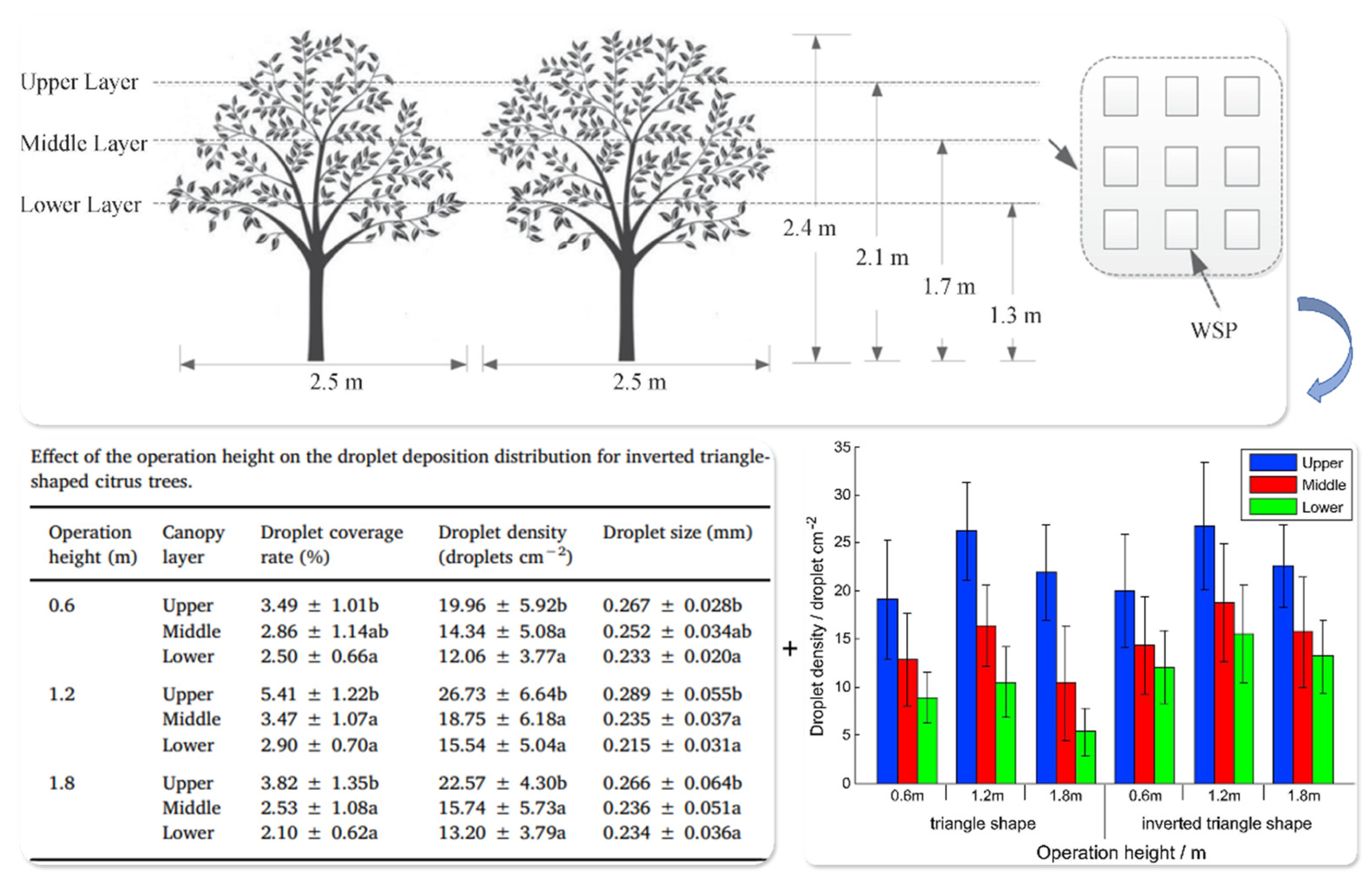

- Tang, Y.; Hou, C.J.; Luo, S.M.; Lin, J.T.; Yang, Z.; Huang, W.F. Effects of operation height and tree shape on droplet deposition in citrus trees using an unmanned aerial vehicle. Comput. Electron. Agric. 2018, 148, 1–7. [Google Scholar] [CrossRef]

- Chen, R.; Li, H.; Wang, J.; Guo, X. Analysis of droplet characteristics and kinetic energy distribution for fixed spray plate sprinkler at low working pressure. Trans. ASABE 2021, 64, 447–460. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, Y.; Liu, J.; Li, H.; Li, H. Experimental Study on Water Distribution and Droplet Kinetic Energy Intensity from Non-Circular Nozzles with Different Aspect Ratios. Agriculture 2022, 12, 2133. [Google Scholar] [CrossRef]

- Gao, J.; Guo, Y.; Tunio, M.H.; Chen, X.; Chen, Z. Design of a high-voltage electrostatic ultrasonic atomization nozzle and its droplet adhesion effects on aeroponically cultivated plant roots. Int. J. Agric. Biol. Eng. 2023, 16, 30–37. [Google Scholar] [CrossRef]

- Koc, C.; Duran, H.; Gerdan Koc, D. Orchard sprayer design for precision pesticide application. Erwerbs-Obstbau 2023, 65, 1819–1828. [Google Scholar] [CrossRef]

- Yang, Q.; Hu, Y.; Wang, Y.; Xu, B.; Zhou, C.; Adhikari, B.; Wang, B. Atmosphere-controlled high-voltage electrospray for improving conductivity, flexibility, and antibacterial properties of chitosan films. Food Res. Int. 2025, 200, 115450. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Zhou, B. Research on Deposition Characteristics of a New Air-Assisted Electrostatic Sprayer. Eur. J. Agric. Food Sci. 2024, 6, 37–43. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, J.; Chen, L.; Wang, Z.; Wang, H.; Wang, X. Study on Deposition Characteristics of the Electrostatic Sprayer for Pesticide Application in Greenhouse Tomato Crops. Agriculture 2024, 14, 1981. [Google Scholar] [CrossRef]

- Liu, C.; Kang, S.; Li, F.; Li, S.; Du, T. Canopy leaf area index for apple tree using hemispherical photography in arid region. Sci. Hortic. 2013, 164, 610–615. [Google Scholar] [CrossRef]

- Zarate-Valdez, J.L.; Whiting, M.L.; Lampinen, B.D.; Metcalf, S.; Ustin, S.L.; Brown, P.H. Prediction of leaf area index in almonds by vegetation indexes. Comput. Electron. Agric. 2012, 85, 24–32. [Google Scholar] [CrossRef]

- Gu, C.; Sun, J.; Li, S.; Yang, S.; Zou, W.; Zhai, C. Deposition Characteristics of Air-Assisted Sprayer Based on Canopy Volume and Leaf Area of Orchard Trees. Plants 2025, 14, 220. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Chen, L.; Tai, S.; Li, Y.; Xu, C. Model and experiment of target-specific variable spraying based on canopy volume perception. Crop Prot. 2025, 194, 107215. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, Y.; Zhang, Q.; Xu, L.; Wang, L.; Zhang, P. Estimation of Crop Height Distribution for Mature Rice Based on a Moving Surface and 3D Point Cloud Elevation. Agronomy 2022, 12, 836. [Google Scholar] [CrossRef]

- Zhao, J.; Li, H.; Chen, C.; Pang, Y.; Zhu, X. Detection of Water Content in Lettuce Canopies Based on Hyperspectral Imaging Technology under Outdoor Conditions. Agriculture 2022, 12, 1796. [Google Scholar] [CrossRef]

- Hong, S.W.; Zhao, L.; Zhu, H. CFD simulation of airflow inside tree canopies discharged from air-assisted sprayers. Comput. Electron. Agric. 2018, 149, 121–132. [Google Scholar] [CrossRef]

- Sun, H.; Zheng, H.; Yu, H.; Qiu, W.; Cao, Y.; Lv, X.; Zhang, Z. CFD simulation of circulating-airflow distribution inside canopy from novel air-assisted sprayer in orchard. J. ASABE 2023, 66, 533–547. [Google Scholar] [CrossRef]

- Cui, H.; Wang, C.; Liu, X.; Yuan, J.; Liu, Y.; Song, L. Cotton canopy airflow simulation and velocity attenuation model based upon 3D phenotype and stratified sub-regional porous medium. Comput. Electron. Agric. 2022, 201, 107282. [Google Scholar] [CrossRef]

- Cui, H.; Wang, C.; Yu, S.; Xin, Z.; Liu, X.; Yuan, J. Two-stage CFD simulation of droplet deposition on deformed leaves of cotton canopy in air-assisted spraying. Comput. Electron. Agric. 2024, 224, 109228. [Google Scholar] [CrossRef]

- Dietsche, L.J.; Neubauer, A.C. Computational fluid dynamics model of viscous droplet breakup. Chem. Eng. Sci. 2009, 64, 4543–4552. [Google Scholar] [CrossRef]

- Tavangar, S.; Hashemabadi, S.H.; Saberimoghadam, A. CFD simulation for secondary breakup of coal–water slurry drops using OpenFOAM. Fuel Process. Technol. 2015, 132, 153–163. [Google Scholar] [CrossRef]

- Zhu, W.; Zhao, N.; Jia, X.; Chen, X.; Zheng, H. Effect of airflow pressure on the droplet breakup in the shear breakup regime. Phys. Fluids 2021, 33, 053309. [Google Scholar] [CrossRef]

- He, Y.; Wu, J.; Fu, H.; Sun, Z.; Fang, H.; Wang, W. Quantitative Analysis of Droplet Size Distribution in Plant Protection Spray Based on Machine Learning Method. Water 2022, 14, 175. [Google Scholar] [CrossRef]

- Paturi, U.M.R.; Reddy, N.S.; Cheruku, S.; Narala, S.K.R.; Cho, K.K.; Reddy, M.M. Estimation of coating thickness in electrostatic spray deposition by machine learning and response surface methodology. Surf. Coat. Technol. 2021, 422, 127559. [Google Scholar] [CrossRef]

- Acharya, P.; Burgers, T.; Nguyen, K.D. A deep-learning framework for spray pattern segmentation and estimation in agricultural spraying systems. Sci. Rep. 2023, 13, 7545. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Hua, L.; Zhang, D. Three-dimensional flow breakup characteristics of a circular jet with different nozzle geometries. Biosyst. Eng. 2020, 193, 216–231. [Google Scholar] [CrossRef]

- Zhao, F.; Zhou, Z.; Hung, D.; Li, X.; Xu, M. Flow field reconstruction from spray imaging: A hybrid physics-based and machine learning approach based on two-phase fluorescence particle image velocimetry measurements. Phys. Fluids 2024, 36, 043316. [Google Scholar] [CrossRef]

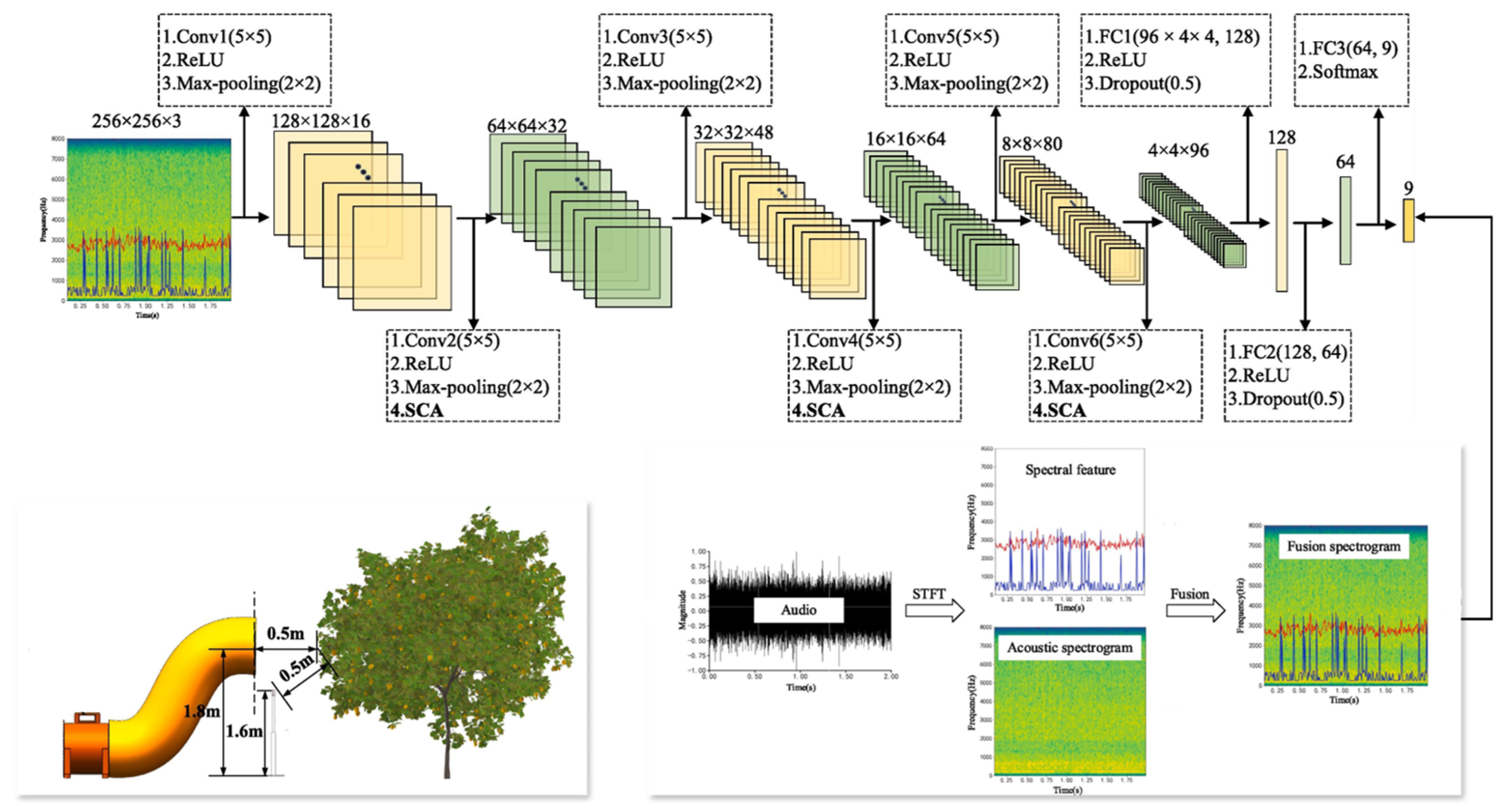

- Li, W.; Yang, S.; Zhao, H.; Jiang, S.; Zheng, Y.; Liu, X.; Tan, Y. Deep learning method for leaf-density estimation based on wind-excited audio of fruit-tree canopies. Comput. Electron. Agric. 2024, 222, 109062. [Google Scholar] [CrossRef]

- Violato, D.; Moore, P.; Scarano, F. Lagrangian and Eulerian pressure field evaluation of rod-airfoil flow from time-resolved tomographic PIV. Exp. Fluids 2011, 50, 1057–1070. [Google Scholar] [CrossRef]

- Czyż, Z.; Karpiński, P.; Stryczniewicz, W. Measurement of the Flow Field Generated by Multicopter Propellers. Sensors 2020, 20, 5537. [Google Scholar] [CrossRef]

- Xun, L.; Gil, E. A novel methodology for water-sensitive papers analysis focusing on the segmentation of overlapping droplets to better characterize deposition pattern. Crop Prot. 2024, 176, 106492. [Google Scholar] [CrossRef]

- Ahmad, F.; Zhang, S.; Qiu, B.; Ma, J.; Xin, H.; Qiu, W.; Ahmed, S.; Chandio, F.A.; Khaliq, A. Comparison of Water Sensitive Paper and Glass Strip Sampling Approaches to Access Spray Deposit by UAV Sprayers. Agronomy 2022, 12, 1302. [Google Scholar] [CrossRef]

- Berrocal, E.; Kristensson, E.; Zigan, L. Light sheet fluorescence microscopic imaging for high-resolution visualization of spray dynamics. Int. J. Spray Combust. Dyn. 2018, 10, 86–98. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, W.; Dai, S.; Ou, M.; Dong, X.; Wang, G.; Gao, B.; Tu, D. Analytical Methods for Wind-Driven Dynamic Behavior of Pear Leaves (Pyrus pyrifolia). Agriculture 2025, 15, 886. [Google Scholar] [CrossRef]

- Hua, L.; Li, H.; Jiang, Y. Axis-switching behavior of liquid jets issued from non-circular nozzles under low-intermediate pressure. Appl. Eng. Agric. 2021, 37, 367–378. [Google Scholar] [CrossRef]

- Tang, P.; Chen, C. An Investigation of the Frequency and Duration of a Drive Spoon–Dispersed Water Jet and Its Influence on the Hydraulic Performance of a Large-Volume Irrigation Sprinkler. Agronomy 2022, 12, 2233. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, Z.; Li, H.; Wang, L. Optimising the hydraulic performance of a jet impingement sprinkler by varying elevation angle: A Comparative study with a non-impingement sprinkler. Biosyst. Eng. 2024, 245, 24–35. [Google Scholar] [CrossRef]

- Ma, J.; Liu, K.; Dong, X.; Huang, X.; Ahmad, F.; Qiu, B. Force and motion behaviour of crop leaves during spraying. Biosyst. Eng. 2023, 235, 83–99. [Google Scholar] [CrossRef]

| Researcher | Plant Type | Main Methodology | Key Findings | Ref. |

|---|---|---|---|---|

| Zhou et al. | Cotton leaves and droplets | Measurement of droplet volume, height, and contact angle evolution | Reduced droplet slippage and improved pesticide retention | [42] |

| Liu et al. | Citrus leaves and droplets | Contact angle and surface tension analysis | Significantly reduced surface tension and contact angle; enhanced wettability | [43] |

| Gao et al. | Tea leaves and droplets | Contact angle measurement and SEM (Scanning Electron Microscopy) analysis | Lowered contact angle and accelerated droplet spreading | [44] |

| Arand et al. | Weed leaves and droplets | Evaluation of droplet retention, hydration, and cuticle penetration | Improved efficacy by enhancing droplet retention and penetration | [45] |

| Meng et al. | Wheat leaves and droplets | Dynamic contact angle and wetting velocity testing | Reduced contact angle and increased wetting efficiency | [46] |

| Category | Representative Parameter | Physical Significance/Role | Potential Influence |

|---|---|---|---|

| Geometric Parameters | Leaf length | Determines overall flexibility and inertial response | Longer leaves tend to have lower stiffness and are more prone to large deformations |

| Leaf thickness | Affects bending stiffness and total mass | Greater thickness increases stiffness, resulting in slower dynamic response | |

| Petiole length | Governs flexibility of the connecting segment | Longer petioles may reduce system damping | |

| Material Properties | Young’s modulus | Indicates material rigidity | Higher modulus corresponds to greater stiffness and smaller deformation |

| Density | Determines leaf mass and inertial characteristics | Higher density may lower the natural response frequency | |

| Dynamic Response Parameters | Natural frequency | Dominant frequency under free vibration | Jointly influenced by mass and stiffness |

| Damping coefficient | Represents the system’s ability to dissipate vibrational energy | Higher damping leads to faster stabilization of the system |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, Z.; Shi, R.; Dai, S.; Jia, W.; Ou, M.; Dong, X.; Yan, M. A Review of Multiscale Interaction Mechanisms of Wind–Leaf–Droplet Systems in Orchard Spraying. Sensors 2025, 25, 4729. https://doi.org/10.3390/s25154729

Wang Y, Zhang Z, Shi R, Dai S, Jia W, Ou M, Dong X, Yan M. A Review of Multiscale Interaction Mechanisms of Wind–Leaf–Droplet Systems in Orchard Spraying. Sensors. 2025; 25(15):4729. https://doi.org/10.3390/s25154729

Chicago/Turabian StyleWang, Yunfei, Zhenlei Zhang, Ruohan Shi, Shiqun Dai, Weidong Jia, Mingxiong Ou, Xiang Dong, and Mingde Yan. 2025. "A Review of Multiscale Interaction Mechanisms of Wind–Leaf–Droplet Systems in Orchard Spraying" Sensors 25, no. 15: 4729. https://doi.org/10.3390/s25154729

APA StyleWang, Y., Zhang, Z., Shi, R., Dai, S., Jia, W., Ou, M., Dong, X., & Yan, M. (2025). A Review of Multiscale Interaction Mechanisms of Wind–Leaf–Droplet Systems in Orchard Spraying. Sensors, 25(15), 4729. https://doi.org/10.3390/s25154729