Early Warning of Abnormal Operating Modes via Feature Extraction from Cross-Section Frame at Discharge End for Sintering Process

Abstract

1. Introduction

- (1)

- An early warning method for abnormal operating modes that exploits feature extraction from the cross-section frame at the discharge end;

- (2)

- A labeled, interpretable early warning model that operators can readily accept for control guidance;

- (3)

- An early warning approach that combines Bayesian theory with operator experience, improving the reliability of abnormal mode forecasting.

2. Process Description and Design Method

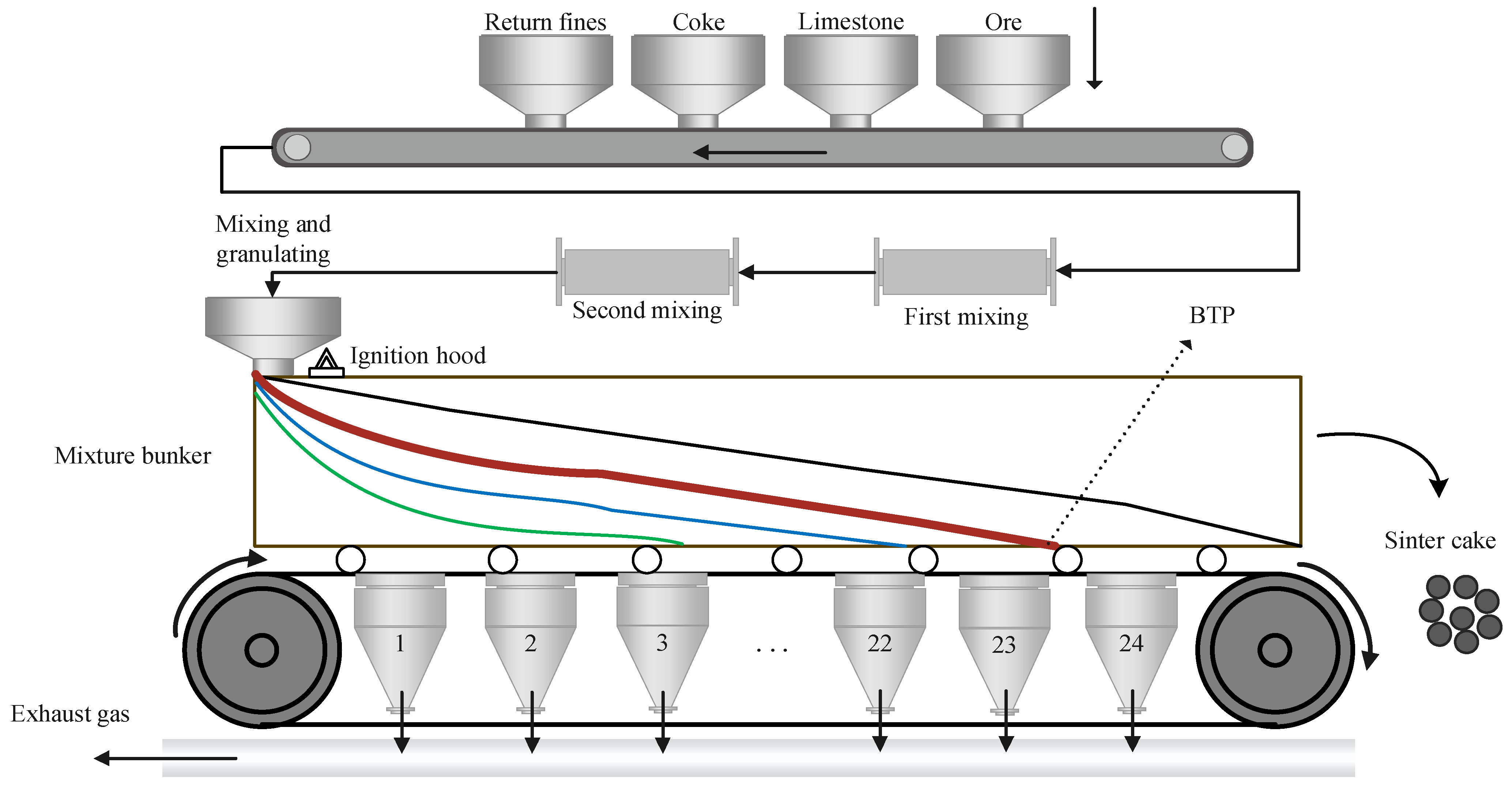

2.1. Description of the Iron Ore Sintering Process

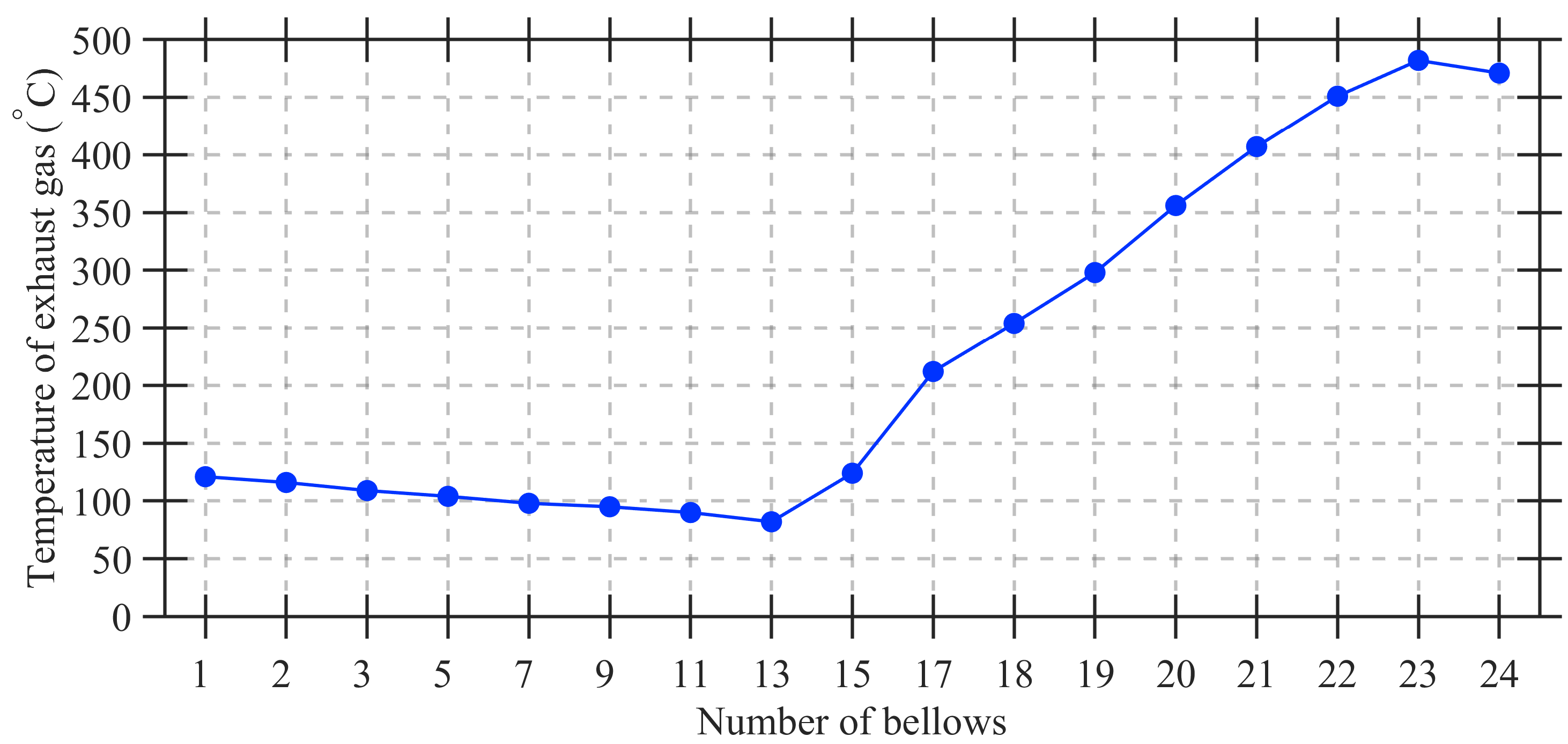

2.2. Characteristic Analysis of Sintering Process

2.3. Burn-Through Point as the Classification Criterion

2.4. Design of the Early Warning Scheme for Abnormal Operating Modes

3. Early Warning Model for Abnormal Operating Modes

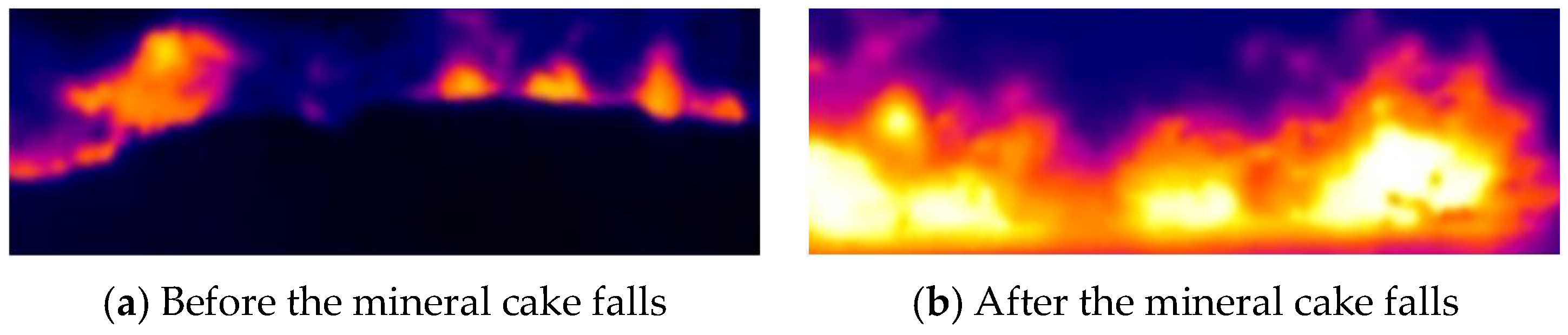

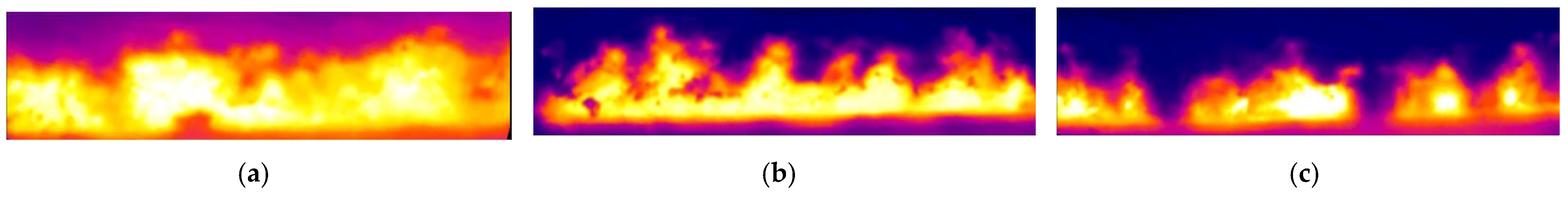

3.1. Feature Extraction from the Cross-Section Frame at the Discharge End

3.2. Input Variable Selection of Early Warning Model

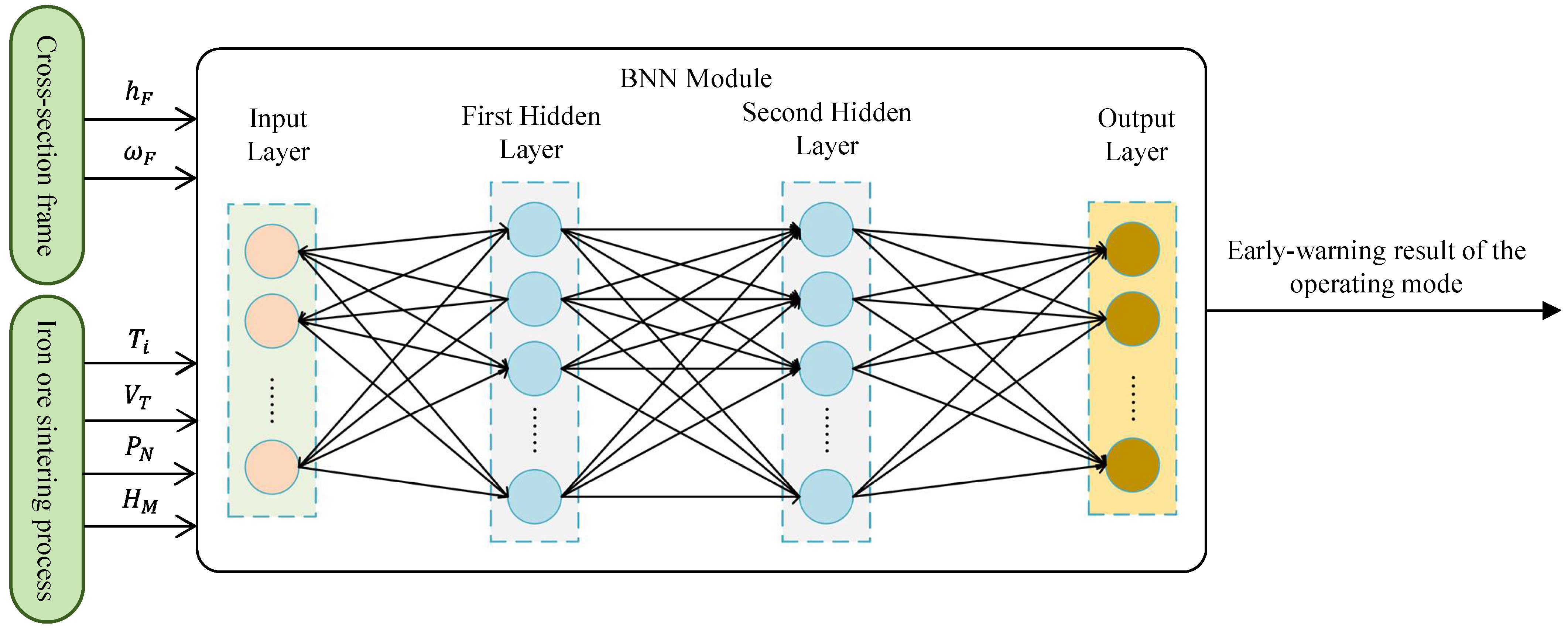

3.3. Structure of Early Warning Model

4. Experimental Study and Analysis

4.1. Experimental Design

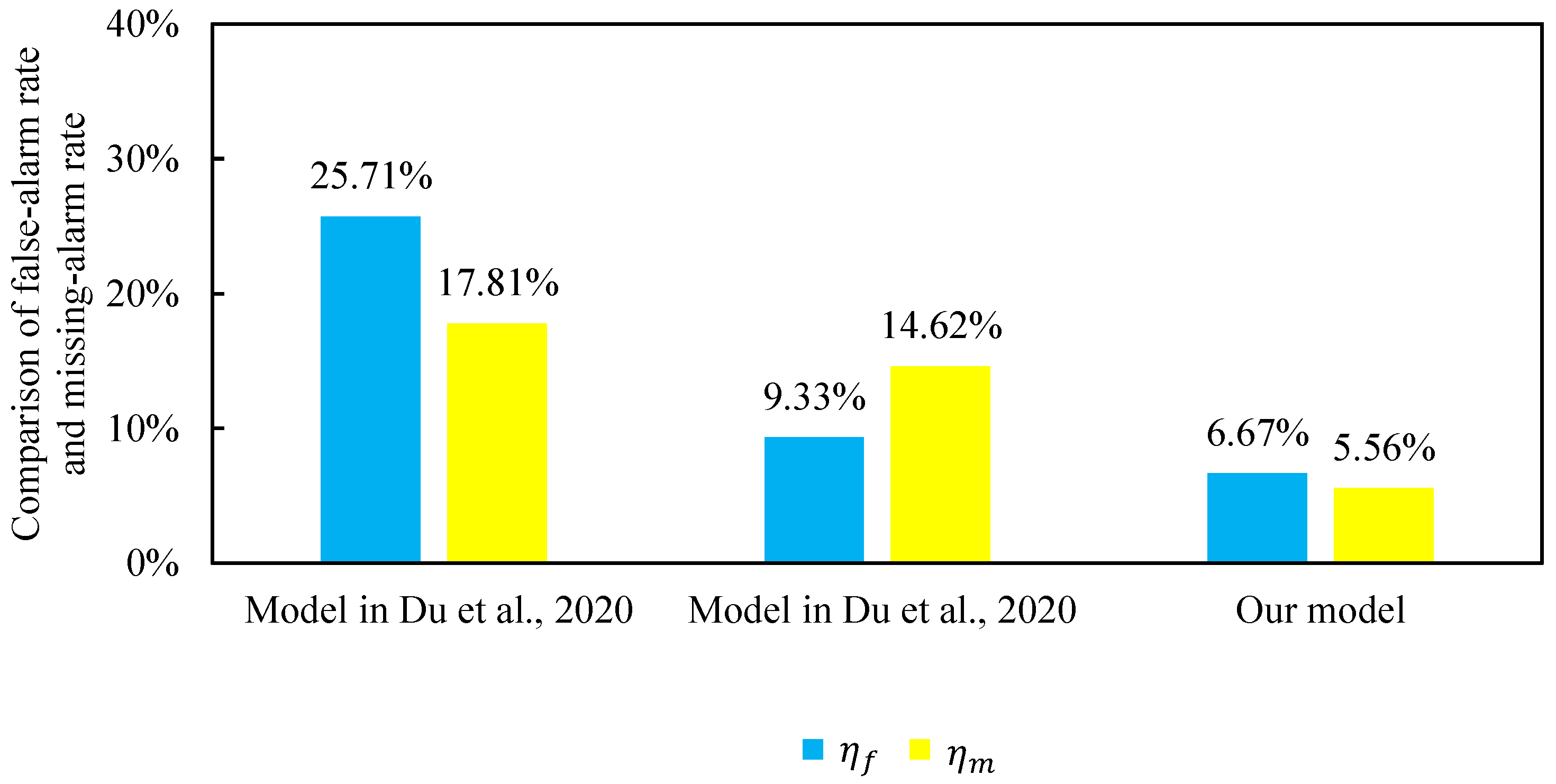

4.2. Experimental Result Analysis

4.3. Significance Test

- Step 1. Hypothesis setting

- Step 2. Test statistic computation

5. Conclusions

- (1)

- It relies on an on-site, high-temperature infrared camera to obtain the key frames required for real-time warnings;

- (2)

- Because of the harsh working environment, discharge end images are sometimes blurred, which can degrade the accuracy of the warning results;

- (3)

- While the model demonstrates high accuracy on a specific sintering strand, its direct applicability to other plants or configurations has not yet been validated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, J.; Li, H.; Li, H.; Wu, M.; Cao, W.; Pedrycz, W. Relevance vector machine with hybrid-kernel soft sensor via data augmentation for incomplete output data in the sintering process. Control Eng. Pract. 2024, 145, 105850. [Google Scholar] [CrossRef]

- World Steel Association. December 2024 Crude-Steel Production and 2024 Global Totals. Available online: https://worldsteel.org/zh-hans/media/press-releases/2025/december-2024-crude-steel-production-and-2024-global-totals/ (accessed on 24 January 2024).

- Fernández-González, D.; Ruiz-Bustinza, I.; Mochón, J.; González-Gasca, C.; Verdeja, L.F. Iron-ore sintering: Process. Miner. Process. Extr. Metall. Rev. 2017, 38, 215–227. [Google Scholar] [CrossRef]

- Bazart, L.; Maquin, D.; Khelassi, A.; Bèle, B.; Ragot, J. Operating-mode recognition: Application in continuous casting. In Proceedings of the IEEE Conference on Control and Fault-Tolerant Systems (SysTol 2013), Nice, France, 9–11 October 2013; pp. 790–795. [Google Scholar] [CrossRef]

- Hwang, D.H.; Han, C. Real-time monitoring for a process with multiple operating modes. Control Eng. Pract. 1999, 7, 891–902. [Google Scholar] [CrossRef]

- Tang, C.; Huang, J.; Xu, M.; Liu, X.; Yang, F.; Feng, W.; He, Z.; Lv, J. Attention-based early warning framework for abnormal operating conditions in fluid catalytic cracking units. Appl. Soft Comput. 2024, 153, 111275. [Google Scholar] [CrossRef]

- Du, S.; Wu, M.; Chen, L.; Cao, W.; Pedrycz, W. Operating-mode recognition based on clustering of time-series data for the iron-ore sintering process. Control Eng. Pract. 2020, 96, 104297. [Google Scholar] [CrossRef]

- Chen, X.; She, J. A hybrid just-in-time soft sensor for carbon efficiency of the iron-ore sintering process based on feature extraction of cross-sectional frames at the discharge end. J. Process Control 2017, 54, 14–24. [Google Scholar] [CrossRef]

- Liang, X.; An, J.; Cao, X.; Zeng, K.; Wang, F.; Liu, H. Classification of combustion state of sintering flame based on a CNN-Transformer dual-stream network. J. Appl. Opt. 2023, 44, 1030–1036. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Chen, Y.; Huang, X.X. Edge detection of images based on an improved Sobel operator and genetic algorithms. In Proceedings of the 2009 International Conference on Image Analysis and Signal Processing (IASP 2009), Linhai, China, 11–12 April 2009; pp. 31–35. [Google Scholar] [CrossRef]

- Wu, M.; Xu, C.; She, J.; Cao, W. Neural-network-based integrated model for predicting the burn-through point in a lead–zinc sintering process. J. Process Control 2012, 22, 925–934. [Google Scholar] [CrossRef]

- Chen, X.; Hu, Y.; Liu, C.; Chen, A.; Chi, Z. Dynamic spatio-temporal graph network based on multi-level feature interaction for sinter TFe prediction. J. Process Control 2025, 148, 103401. [Google Scholar] [CrossRef]

- Du, S.; Wu, M.; Chen, L.; Cao, W.; Pedrycz, W. An intelligent decision-making strategy based on the forecast of abnormal operating mode for the iron-ore sintering process. J. Process Control 2020, 96, 57–66. [Google Scholar] [CrossRef]

- Hu, J.; Wu, M.; Chen, L.; Cao, W.; Pedrycz, W. Real-time dynamic prediction model of carbon efficiency with working-condition identification in the sintering process. J. Process Control 2022, 111, 97–105. [Google Scholar] [CrossRef]

- Li, H.; Wu, M.; Du, S.; Hu, J.; Zhang, W.; Chen, L.; Ma, X.; Li, H. Prediction model of burn-through point with data correction based on feature matching of cross-section frame at the discharge end. J. Process Control 2024, 140, 103265. [Google Scholar] [CrossRef]

- Chen, X.; Liu, C.; Xia, H.; Chi, Z. Burn-through point prediction and control based on multi-cycle dynamic spatio-temporal feature extraction. Control Eng. Pract. 2025, 154, 106165. [Google Scholar] [CrossRef]

- Du, S.; Ma, X.; Fan, H.; Hu, J.; Cao, W.; Wu, M.; Pedrycz, W. Intelligent prediction and soft sensing of comprehensive production indicators for iron-ore sintering: A review. Comput. Ind. 2025, 165, 104215. [Google Scholar] [CrossRef]

- Chen, R.C.; Dewi, C.; Huang, S.W.; Caraka, R.E. Selecting critical features for data classification based on machine-learning methods. J. Big Data 2020, 7, 52. [Google Scholar] [CrossRef]

- Wang, K.; Du, H.; Jia, R.; Jia, H. Performance comparison of a Bayesian deep-learning model and a traditional Bayesian neural network in short-term PV interval prediction. Sustainability 2022, 14, 12683. [Google Scholar] [CrossRef]

| Feature | |||||||

|---|---|---|---|---|---|---|---|

| Gini-based importance | 0.402 | 0.356 | 0.341 | 0.305 | 0.302 | 0.282 | 0.279 |

| Feature | |||||||

| Gini-based importance | 0.233 | 0.198 | 0.153 | 0.149 | 0.098 | 0.071 | 0.032 |

| Operating Mode | Average Height | Continuity Degree |

|---|---|---|

| Over-burning | 0.15 | 0.62 |

| Normal | 0.37 | 0.70 |

| Under-burning | 0.58 | 0.73 |

| Mode | Actual | Accuracy | False Alarm Rate | Missing Alarm Rate | |||

|---|---|---|---|---|---|---|---|

| Early warning | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, X.; Du, S.; Ma, X.; Zhao, M. Early Warning of Abnormal Operating Modes via Feature Extraction from Cross-Section Frame at Discharge End for Sintering Process. Sensors 2025, 25, 4267. https://doi.org/10.3390/s25144267

Hao X, Du S, Ma X, Zhao M. Early Warning of Abnormal Operating Modes via Feature Extraction from Cross-Section Frame at Discharge End for Sintering Process. Sensors. 2025; 25(14):4267. https://doi.org/10.3390/s25144267

Chicago/Turabian StyleHao, Xinzhe, Sheng Du, Xian Ma, and Mengxin Zhao. 2025. "Early Warning of Abnormal Operating Modes via Feature Extraction from Cross-Section Frame at Discharge End for Sintering Process" Sensors 25, no. 14: 4267. https://doi.org/10.3390/s25144267

APA StyleHao, X., Du, S., Ma, X., & Zhao, M. (2025). Early Warning of Abnormal Operating Modes via Feature Extraction from Cross-Section Frame at Discharge End for Sintering Process. Sensors, 25(14), 4267. https://doi.org/10.3390/s25144267