RoboCT: The State and Current Challenges of Industrial Twin Robotic CT Systems

Abstract

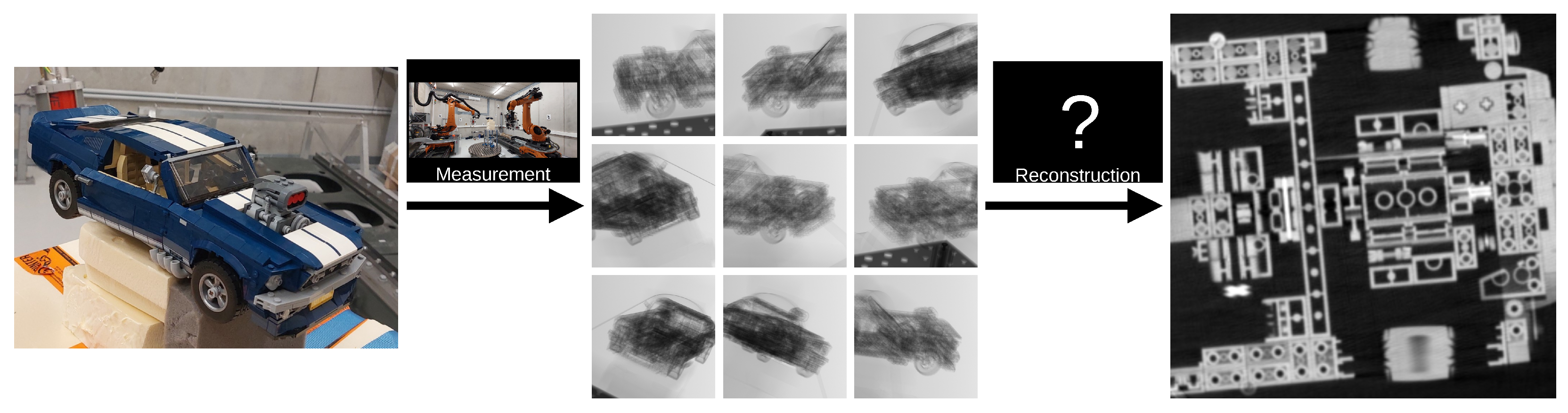

:1. Introduction

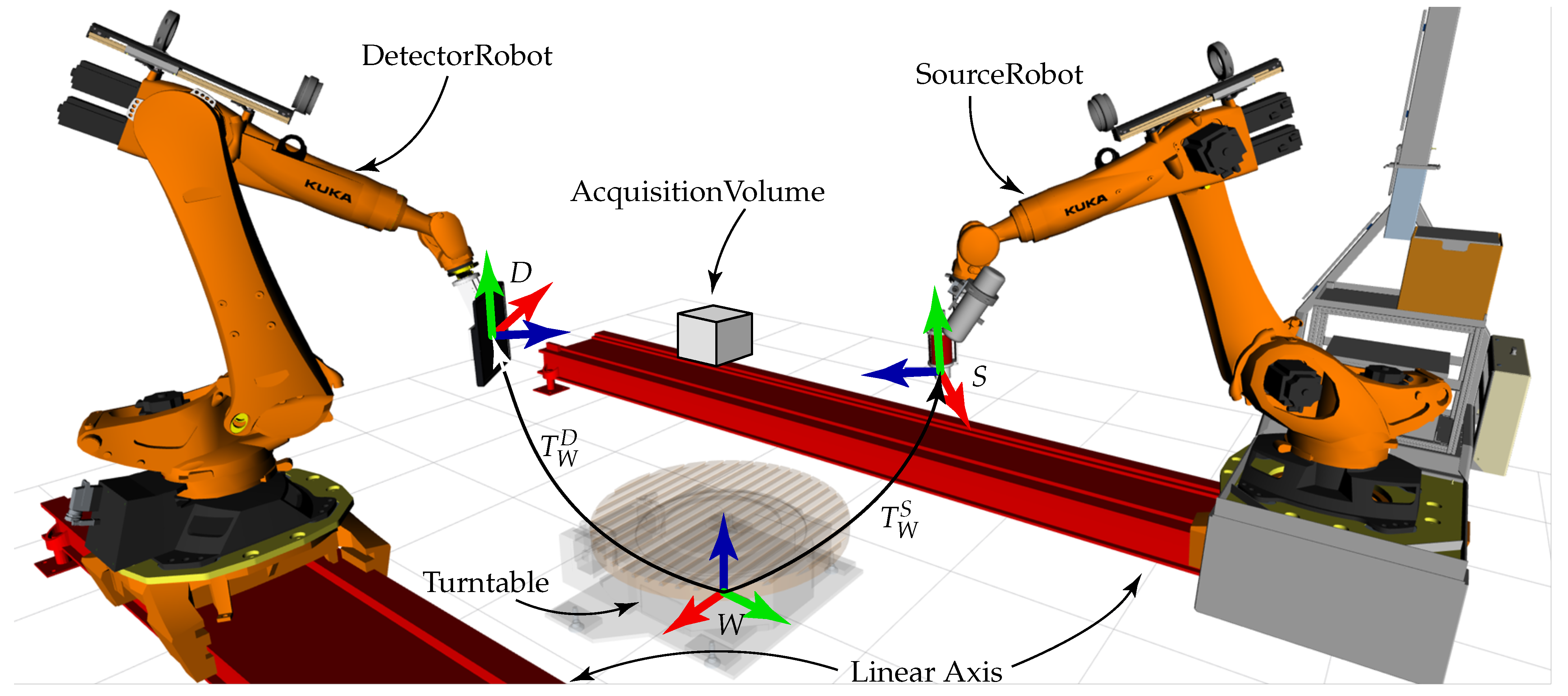

2. Definitions

2.1. Coordinate Systems

- (world): Base coordinate system of the robotic system.

- (object): Base coordinate system of the object or an ROI of the object that should be measured and reconstructed.

- (detector): Coordinate system of the detector; the origin is in the center of the detector.

- (source): Coordinate system of the X-ray source; the origin is in the focal spot of the X-ray source.

2.2. X-Ray Projection Acquisition

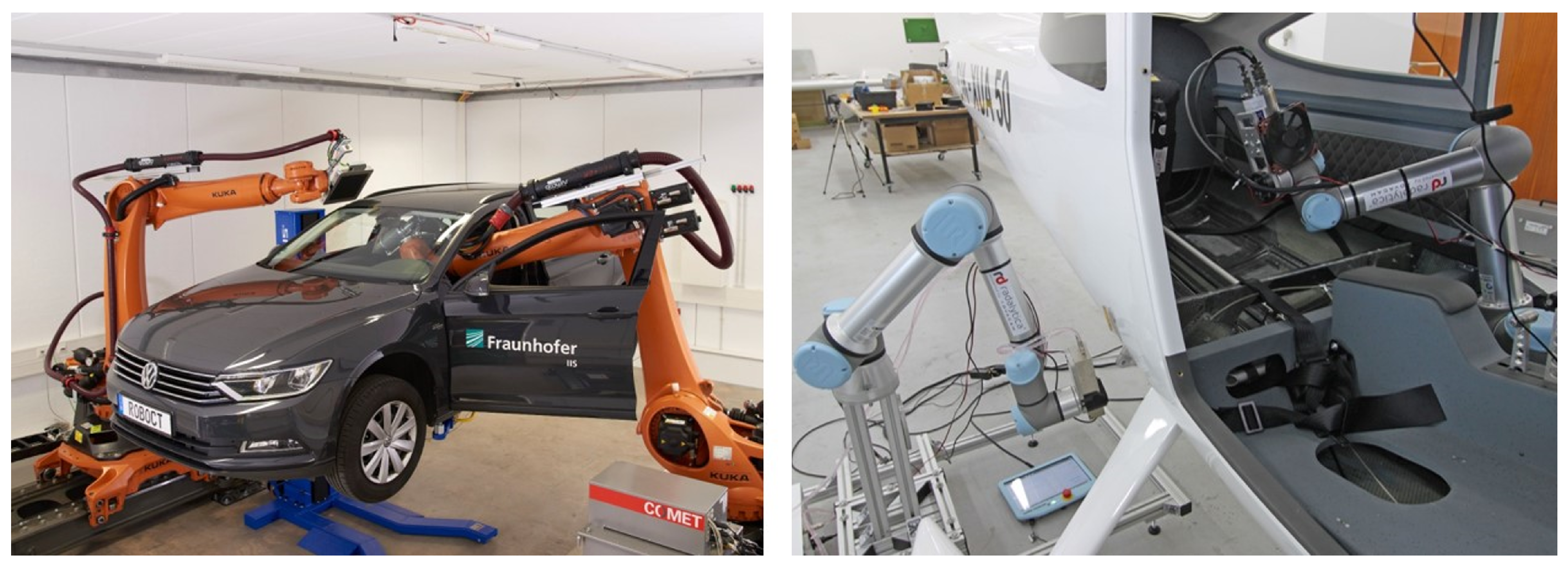

2.3. Robotic Integration

2.4. Reconstruction and Image Quality

3. Challenge: CT Trajectory Optimization

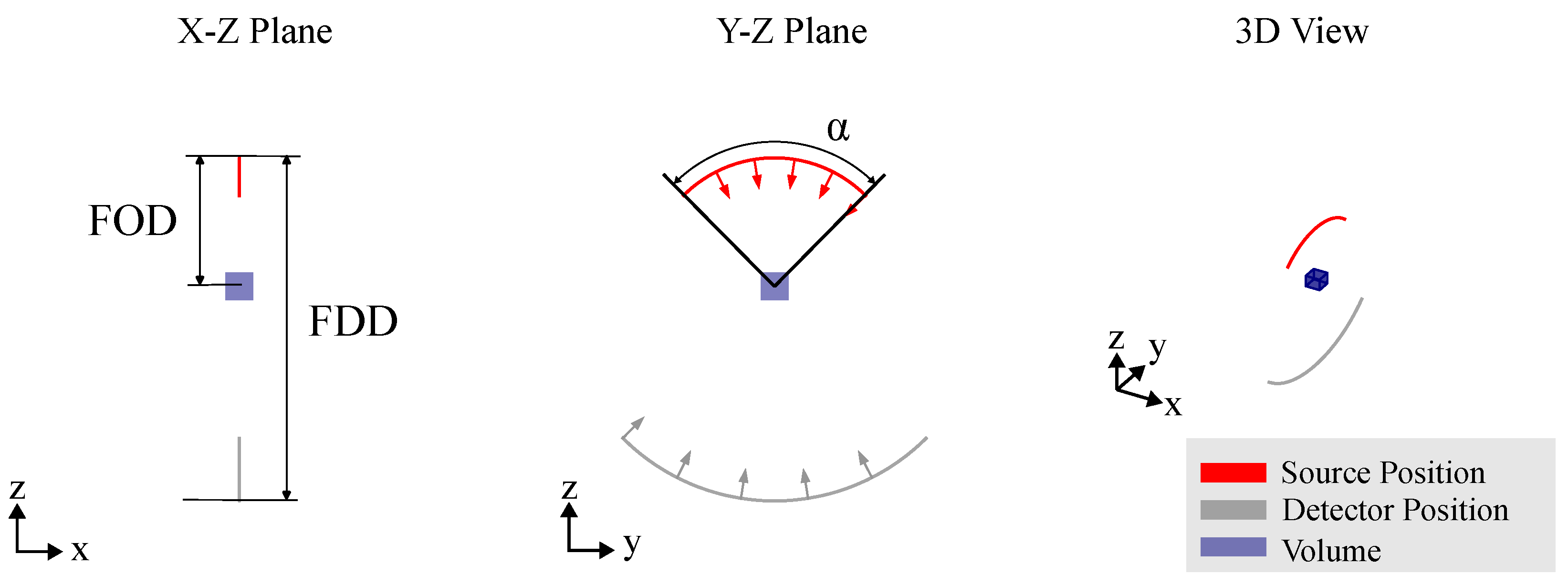

3.1. Circular CT Trajectory

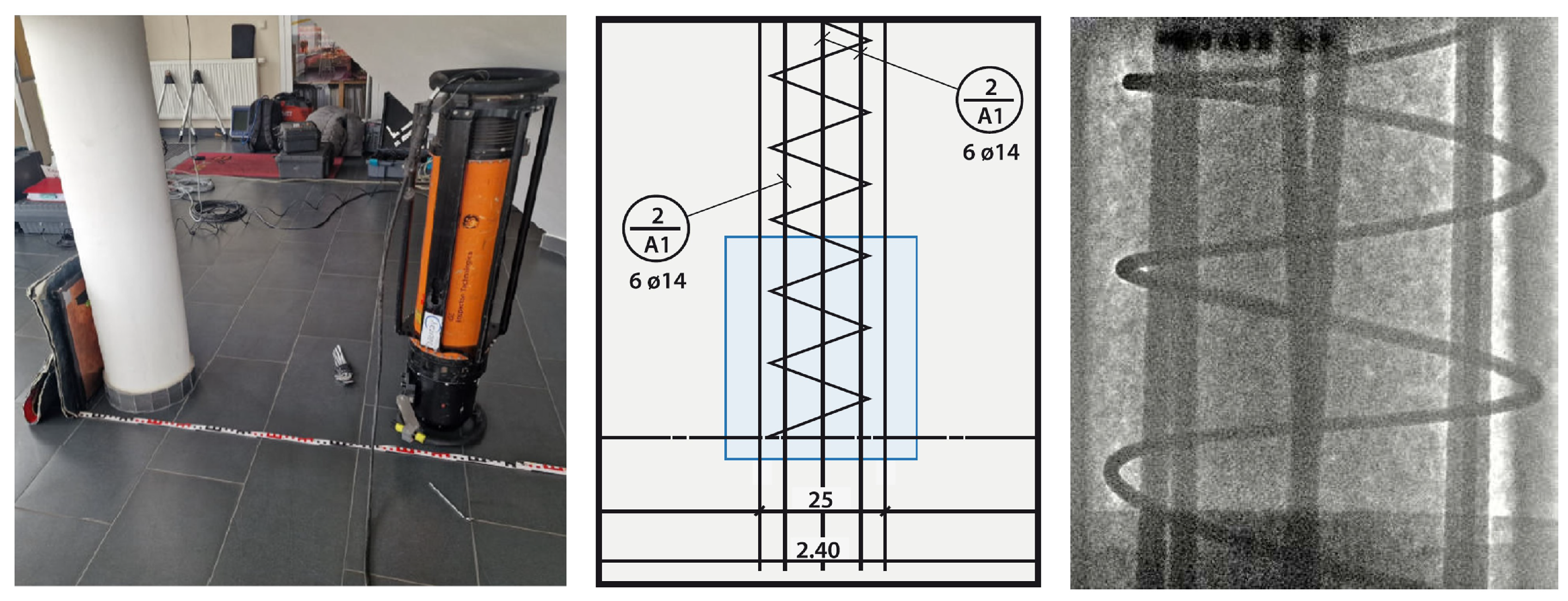

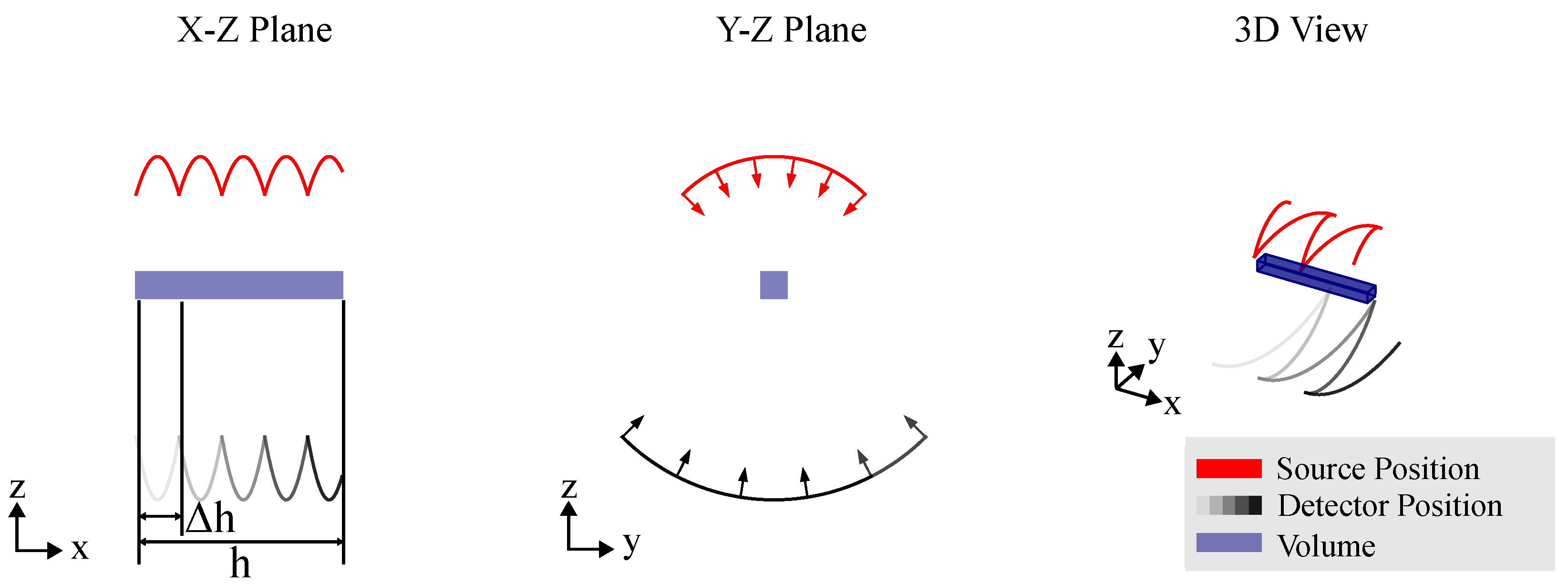

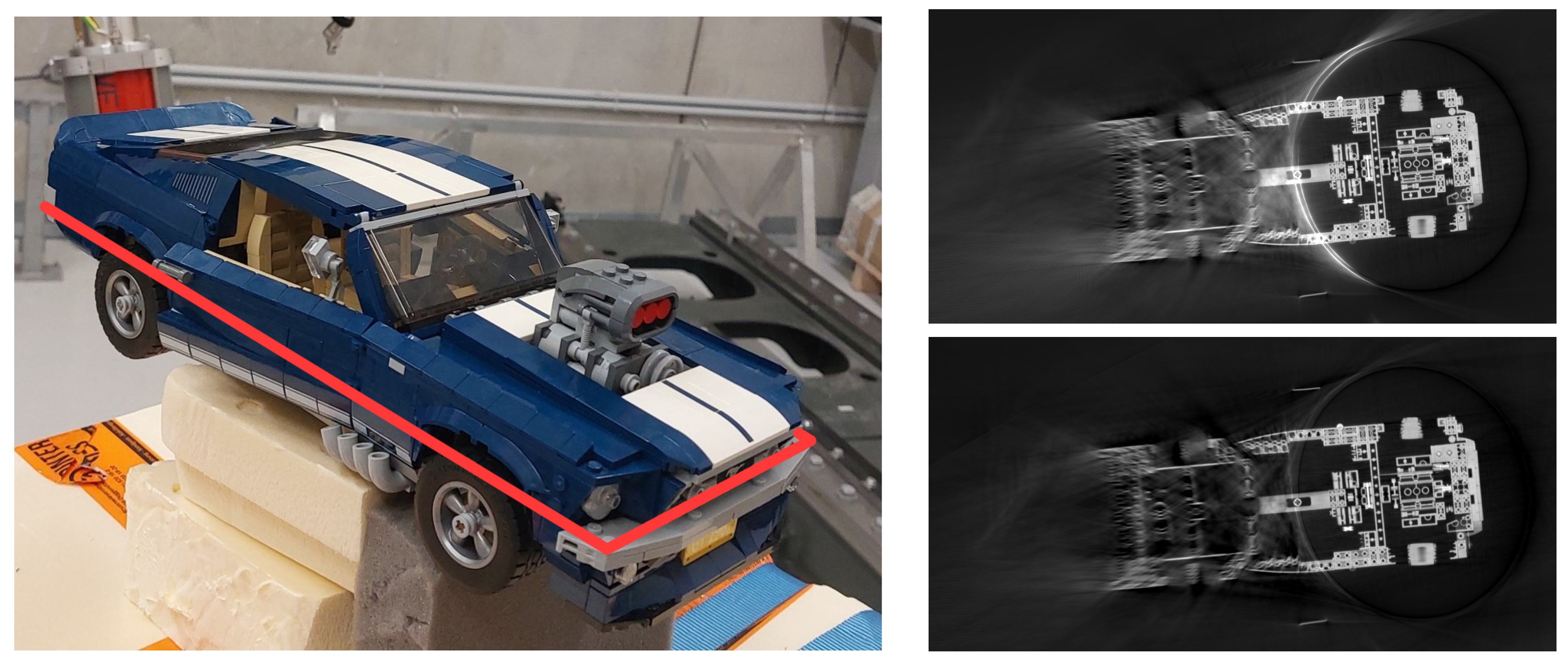

3.2. Computed Laminography

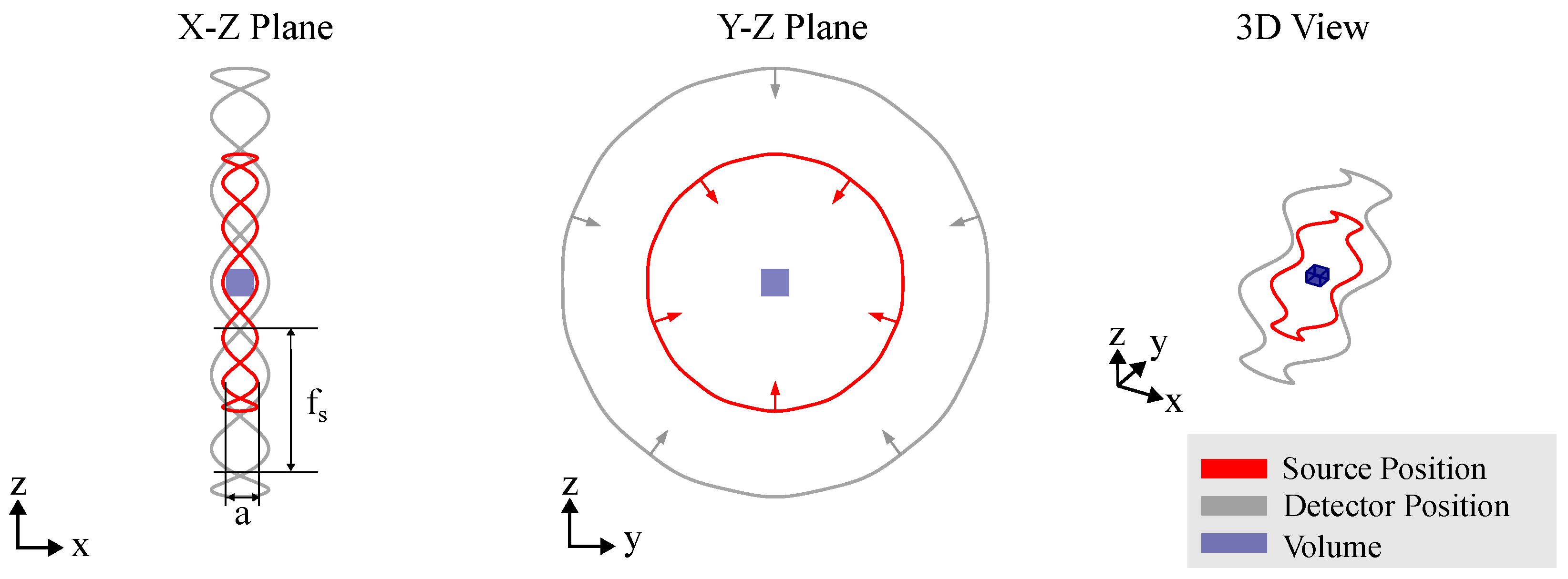

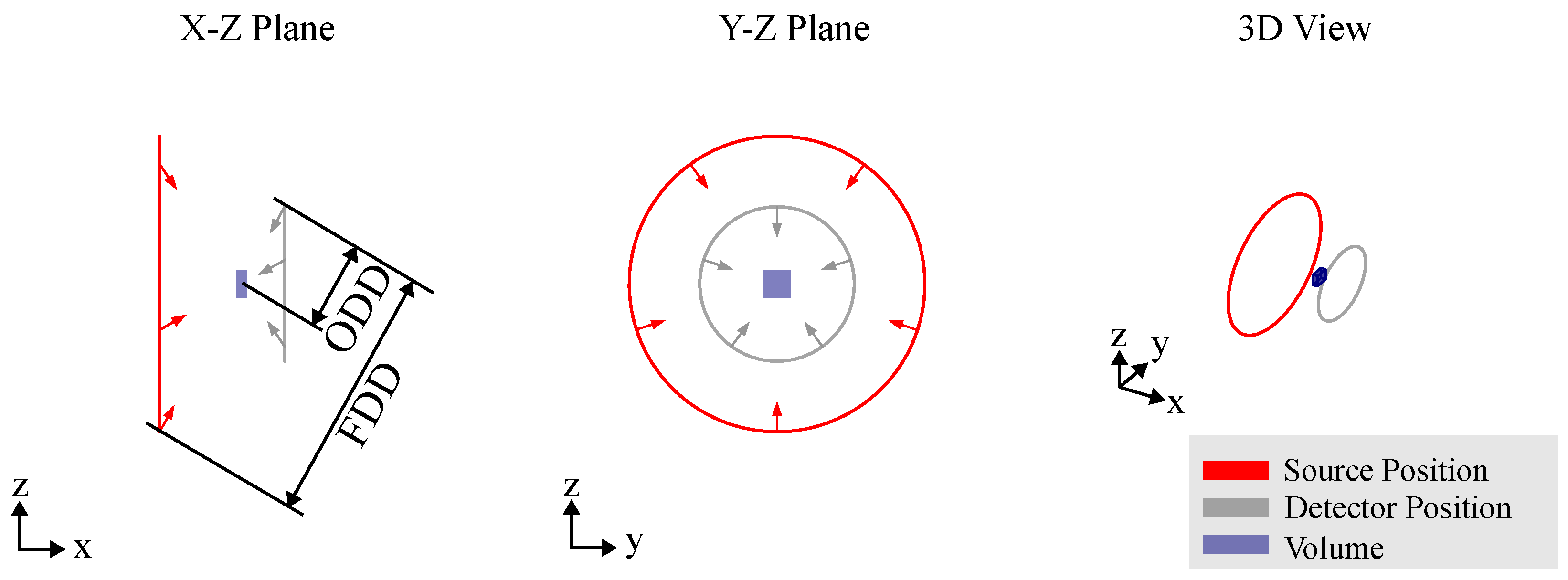

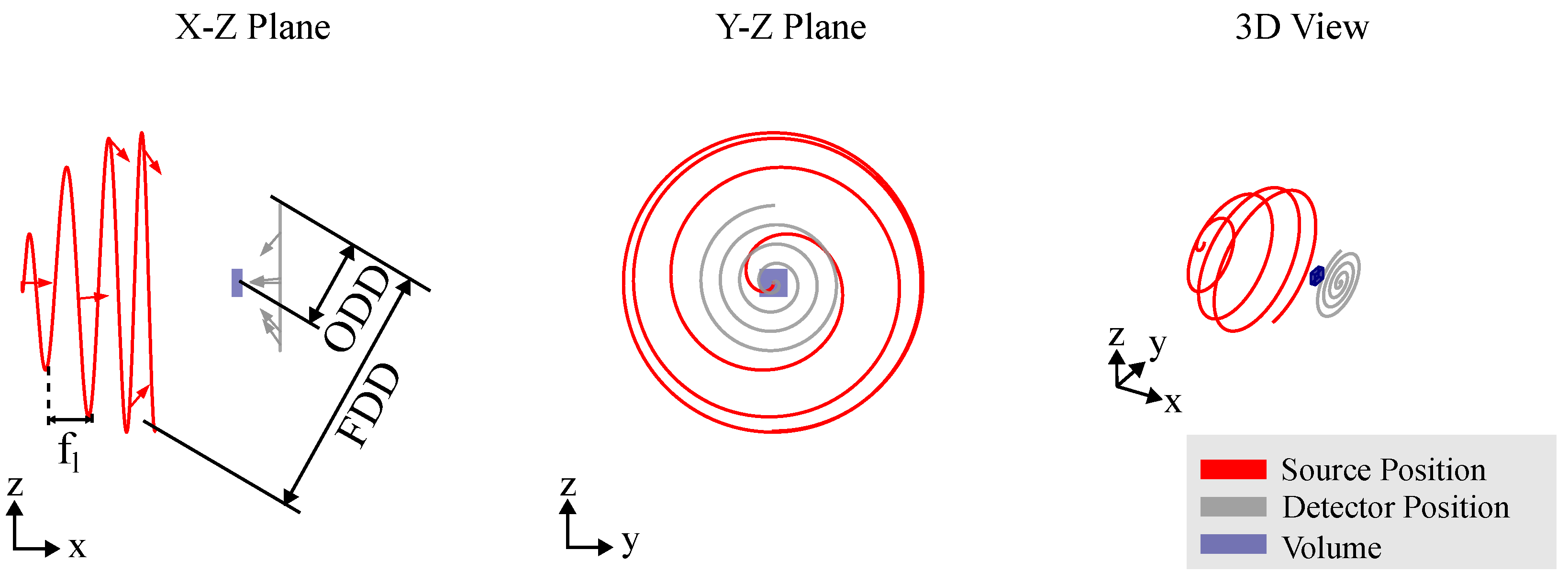

3.3. Field of View Extensions

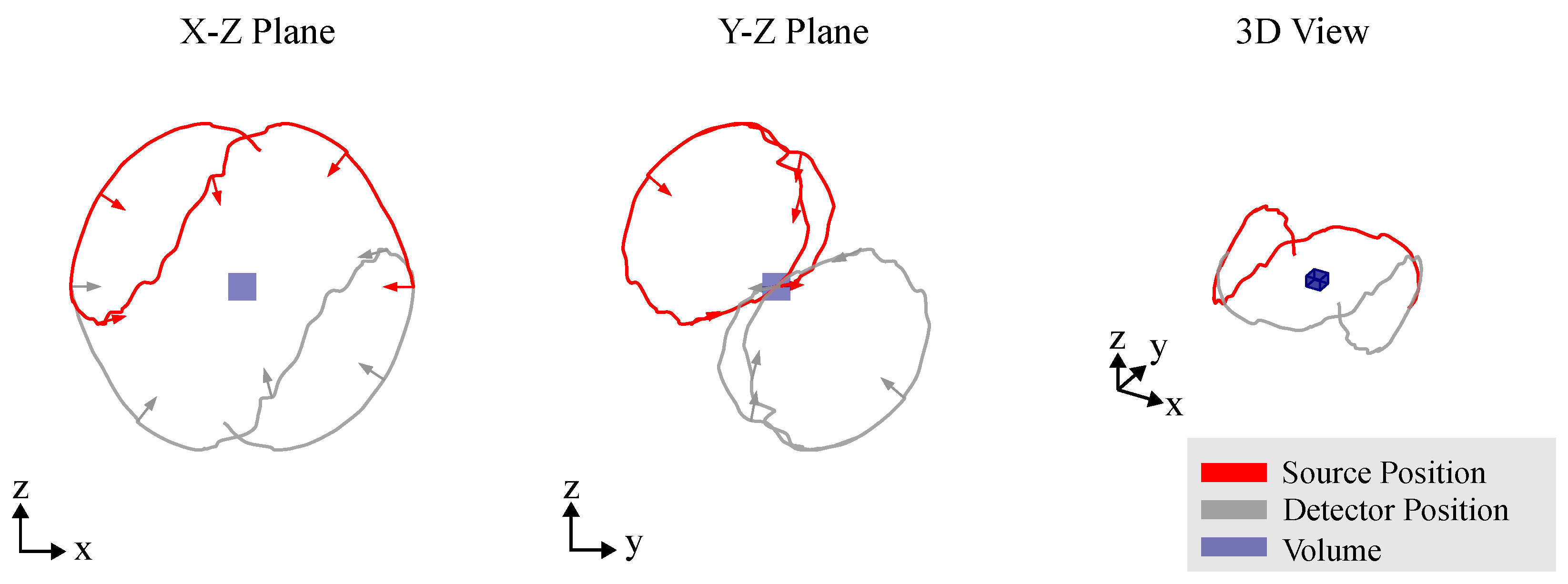

3.4. Arbitrary Views

- Task-independent: Task-independent trajectory optimization aims to improve the overall image quality without focusing on any specific task. This approach seeks to optimize the imaging process to generate the best possible images across the entire scanned area, ensuring that all features, regardless of their relevance to a specific task, are captured with high quality. These methods are beneficial when the imaging goals are broad, and there is no predefined task or feature that needs to be prioritized [19,21,22]. The optimization process in this case is more generalized, seeking to improve factors such as noise reduction, artifact minimization and spatial resolution across the entire image [43].

- Task-dependent: Task-dependent trajectory optimization is designed to improve the detectability of specific features or tasks within a CT scan [44]. The main focus is on optimizing the imaging process for a particular known task, such as identifying a specific region of interest or detecting certain features that correspond to crucial signals in the scan. This approach prioritizes the visibility and clarity of the task-relevant features, potentially at the expense of the overall image quality. For instance, some areas of the image might suffer from lower quality or increased artifacts, but the target task, such as detecting a specific anomaly, will be more easily distinguishable [45]. This method is particularly useful when the exact nature of the task is known beforehand, and the CT scan can be tailored to enhance the detection of those specific features.

3.4.1. Task-Independent CT Trajectory Optimization

3.4.2. Task-Dependent CT Trajectory Optimization

3.5. Conclusion: CT Trajectory Optimization

4. Challenge: Geometric Calibration

4.1. Robot Calibration

4.1.1. Factors Affecting Pose Accuracy—Error Sources

4.1.2. Calibration Data Acquisition

4.1.3. Calibration Procedures

4.1.4. External Prismatic or Revolute Joints

4.1.5. Conclusion to Robot Calibration

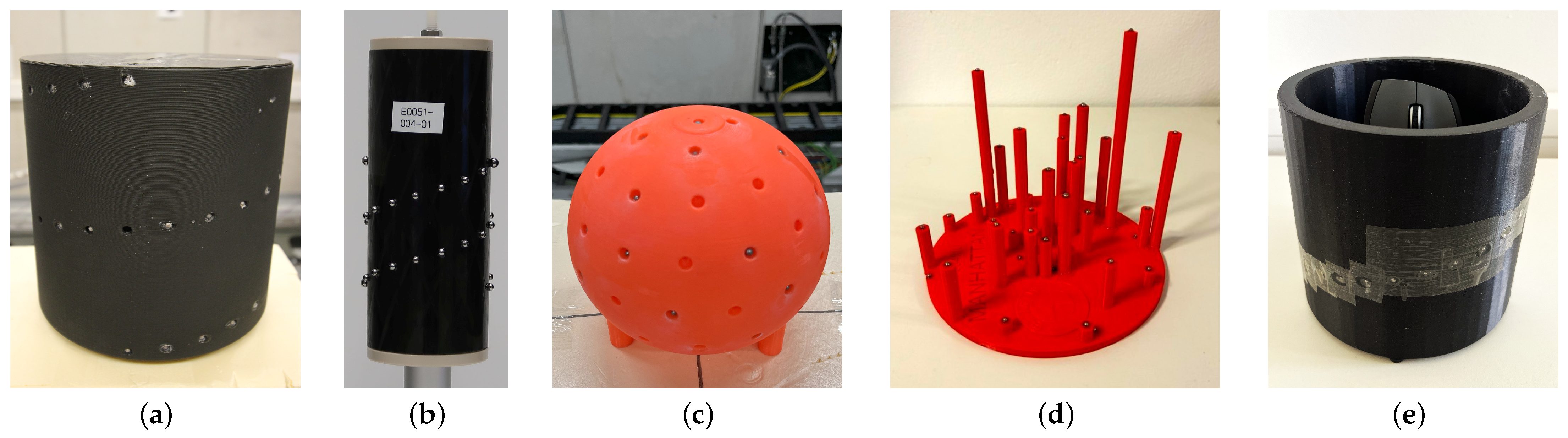

4.2. Image-Based Calibration

4.2.1. Offline Calibration

4.2.2. Online Calibration

4.2.3. Conclusion to Image-Based Geometric Calibration

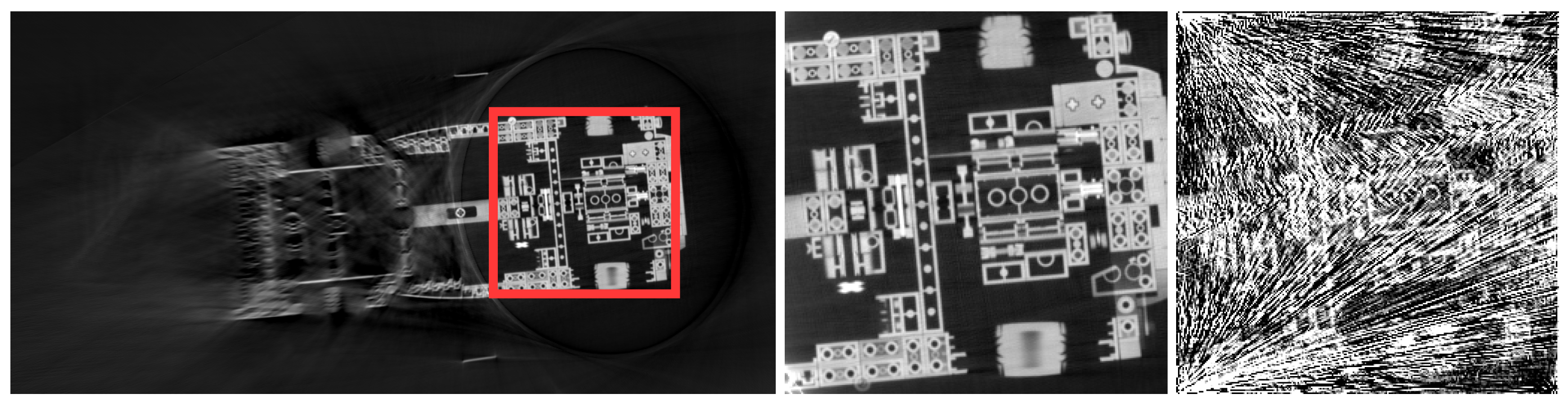

5. Challenge: CT Reconstruction

5.1. Reconstruction Methods

5.1.1. Analytic Reconstruction Methods

5.1.2. Iterative Reconstruction Methods

5.1.3. Deep Learning Reconstruction Methods

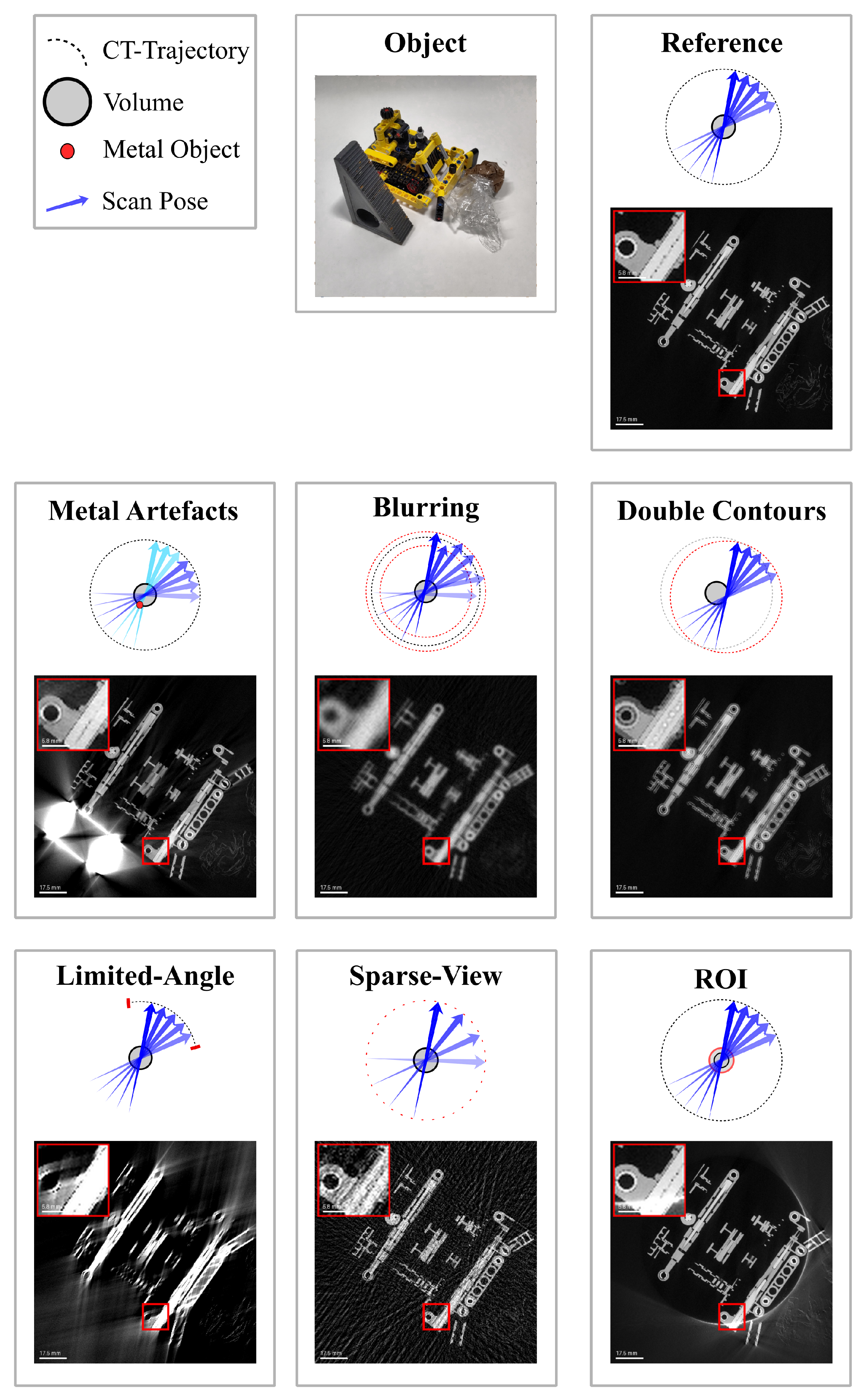

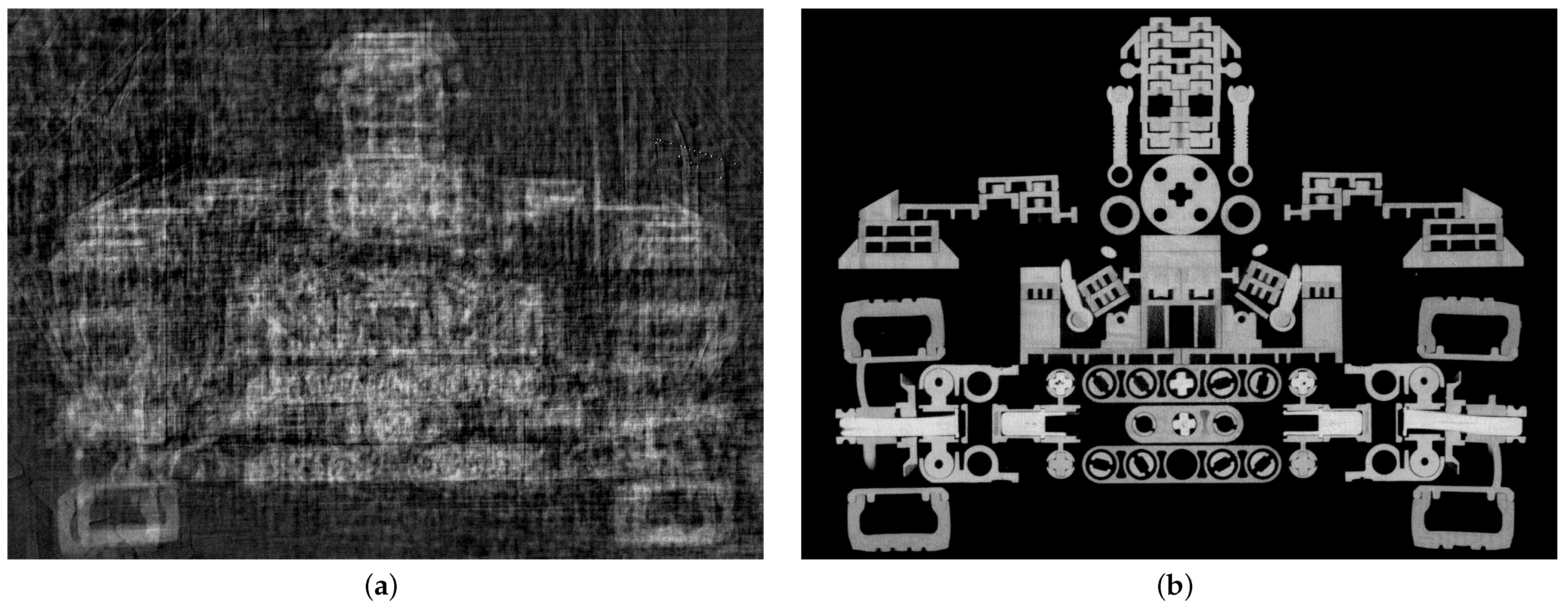

5.2. Challenges Regarding Twin Robotic CT Systems

5.2.1. Arbitrary Trajectories

5.2.2. Region of Interest Reconstruction

5.2.3. Other Challenges

5.3. Conclusion to CT Reconstruction for Robot CT Systems

6. Conclusions

7. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ART | Algebraic Reconstruction Technique |

| CBCT | Cone Beam CT |

| ConvNet | Convolutional Neural Network |

| CNR | Contrast-to-Noise Ratio |

| CT | Computed Tomography |

| DART | Discrete Algebraic Reconstruction Technique |

| DLT | Direct Linear Transformation |

| FBP | Filtered Back Projection |

| FDD | Focus to Detector Distance |

| FDK | Feldkamp, Davis and Kress algorithm |

| FOV | Field of View |

| FOD | Focus to Object Distance |

| MTF | Modulation Transfer Function |

| NPS | Noise Power Spectrum |

| ODD | Object to Detector Distance |

| PSNR | Peak Signal-to-Noise Ratio |

| ROI | Region of Interest |

| SART | Simultaneous Algebraic Reconstruction Technique |

| SIRT | Simultaneous Iterative Reconstruction Technique |

| SNR | Signal-to-Noise Ratio |

| SSIM | Structural Similarity Index |

| TCP | Tool Center Point |

References

- Zabler, S.; Maisl, M.; Hornberger, P.; Hiller, J.; Fella, C.; Hanke, R. X-ray imaging and computed tomography for engineering applications. Tm-Tech. Mess. 2021, 88, 211–226. [Google Scholar] [CrossRef]

- Hounsfield, G.N. Computerized transverse axial scanning (tomography). 1. Description of system. Br. J. Radiol. 1973, 46, 1016–1022. [Google Scholar] [CrossRef] [PubMed]

- Bossi, R.H.; Cooprider, K.K.; Georgeson, G.E. X-ray computed tomography of composites. In Proceedings of the 36th International SAMPE Symposium and Exhibition, San Diego, CA, USA, 15–18 April 1991; pp. 224–238. [Google Scholar]

- Sire, P.; Rizo, P.; Martin, M.; Grangeat, P.; Morisseau, P. Development of an Advanced 3D Cone Beam Tomographic System. In Review of Progress in Quantitative Nondestructive Evaluation; Springer: Boston, MA, USA, 1992; pp. 371–378. [Google Scholar] [CrossRef]

- Waldmann, T.; Gorse, S.; Samtleben, T.; Schneider, G.; Knoblauch, V.; Wohlfahrt-Mehrens, M. A Mechanical Aging Mechanism in Lithium-Ion Batteries. J. Electrochem. Soc. 2014, 161, A1742–A1747. [Google Scholar] [CrossRef]

- Mueller, D.; Fella, C.; Altmann, F.; Graetz, J.; Balles, A.; Ring, M.; Gambino, J. Characterization of electrically stressed power device metallization using nano-CT imaging. Microelectron. Reliab. 2022, 135, 114589. [Google Scholar] [CrossRef]

- Holub, W.; Brunner, F.; Schön, T. RoboCT—Application for in-situ inspection of join technologies of large scale objects. In Proceedings of the International Symposium on Digital Industrial Radiology and Computed Tomography, Fuerth, Germany, 2–4 July 2019. [Google Scholar]

- Maier, A.; Steidl, S.; Christlein, V.; Hornegger, J. (Eds.) Medical Imaging Systems: An Introductory Guide; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Krumm, M.; Sauerwein, C.; Hämmerle, V.; Heile, S. Robotic X-ray computed tomography system for fast automated non-destructive testing of joints in large assemblies and its application in automotive production. In Proceedings of the 12th European Conference on Non-Destructive Testing (ECNDT 2018) Proceedings, Gothenburg, Sweden, 11–15 June 2018. [Google Scholar]

- Pekel, E.; Schaff, F.; Dierolf, M.; Pfeiffer, F.; Lasser, T. X-ray computed tomography with seven degree of freedom robotic sample holder. Eng. Res. Express 2022, 4, 035022. [Google Scholar] [CrossRef]

- Hiller, J.; Landstorfer, P.; Marx, P.; Herbst, M. Evaluation of the impact of faulty scanning trajectories in robot-based x-ray computed tomography. Meas. Sci. Technol. 2021, 32, 015401. [Google Scholar] [CrossRef]

- Holub, W.; Hassler, U.; Schorr, C.; Maisl, M. XXL-Micro-CT Comparative Evaluation of Microscopic Computed Tomography for Macroscopic Objects. In Proceedings of the Digital Industrial Radiology and Computed Tomography (DIR 2015), Ghent, Belgium, 22–25 June 2015. [Google Scholar]

- Vienne, C.; Costin, M. Adapted acquisition trajectory and iterative reconstruction for few-views CT inspection. E-J. Nondestruct. Test. 2018, 23, 88–95. [Google Scholar]

- Weiss, A.; Wittl, S.; Herl, G.; Zabler, S. Simulated and experimental evaluation of the accuracy of twin robotic CT systems. In Proceedings of the 12th Conference on Industrial Computed Tomography (iCT) 2023, Fürth, Germany, 27 February–2 March 2023. [Google Scholar]

- Ziertmann, A.; Jahnke, P.; Kerscher, S.; Koch, M.; Holub, W. Robot guided Computed Tomography. J. Jpn. Soc. Precis. Eng. 2020, 86, 316–322. [Google Scholar] [CrossRef]

- Evangelista, D.; Terreran, M.; Pretto, A.; Moro, M.; Ferrari, C.; Menegatti, E. 3D Mapping of X-Ray Images in Inspections of Aerospace Parts. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 1223–1226. [Google Scholar] [CrossRef]

- Ghita, M.; Uher, J.; Boh’ačov’a, J.; Kadeř’abek, R. Arbitrary Path CT by Multi-Robot Imaging Platform (RadalyX). E-J. Nondestruct. Test. 2022, 27, 45–52. [Google Scholar] [CrossRef]

- Wittl, S.; Weiss, A.; Herl, G.; Zabler, S.; Dewailly, P.; Le Goff, R. Unveiling the Full Picture: Advanced Scanning Procedure for Complete Large Component Scans via Twin Robotic Computed Tomography. E-J. Nondestruct. Test. 2024, 29, 123–130. [Google Scholar] [CrossRef]

- Herl, G.; Hiller, J.; Maier, A. Scanning trajectory optimisation using a quantitative Tuybased local quality estimation for robot-based X-ray computed tomography. Nondestruct. Test. Eval. 2020, 35, 287–303. [Google Scholar] [CrossRef]

- Herl, G.; Hiller, J.; Thies, M.; Zaech, J.N.; Unberath, M.; Maier, A. Task-Specific Trajectory Optimisation for Twin-Robotic X-Ray Tomography. IEEE Trans. Comput. Imaging 2021, 7, 894–907. [Google Scholar] [CrossRef]

- Herl, G. Multipositional X-Ray Tomography for Avoidance and Reduction of Image Artefacts. Ph.D. Thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen, Germany, 2022. [Google Scholar]

- Bauer, F.; Forndran, D.; Schromm, T.; Grosse, C.U. Practical Part-Specific Trajectory Optimization for Robot-Guided Inspection via Computed Tomography. J. Nondestruct. Eval. 2022, 41, 55. [Google Scholar] [CrossRef]

- Hatamikia, S.; Biguri, A.; Herl, G.; Kronreif, G.; Reynolds, T.; Kettenbach, J.; Russ, T.; Tersol, A.; Maier, A.; Figl, M.; et al. Source-detector trajectory optimization in cone-beam computed tomography: A comprehensive review on today’s state-of-the-art. Phys. Med. Biol. 2022, 67, 16TR03. [Google Scholar] [CrossRef]

- Landstorfer, P.; Hiller, J.; Herbst, M. Investigation of positioning accuracy of industrial robots for robotic-based X-ray computed tomography. E-J. Nondestruct. Test. 2019, 24, 102–110. [Google Scholar] [CrossRef]

- Banjak, H.; Costin, M.; Vienne, C.; Kaftandjian, V. X-ray Computed Tomography Reconstruction on Non-Standard Trajectories for Robotized Inspection. In Proceedings of the 19th World Conference on Non-Destructive Testing 2016, Munich, Germany, 13–17 June 2016. [Google Scholar]

- Gallo, E. The SO(3) and SE(3) Lie Algebras of Rigid Body Rotations and Motions and their Application to Discrete Integration, Gradient Descent Optimization, and State Estimation. Available online: https://example.com/so3-se3-lie-algebras (accessed on 8 May 2025).

- Sidky, E.Y.; Kao, C.M.; Pan, X. Accurate image reconstruction from few-views and limited-angle data in divergent-beam CT. J. X-Ray Sci. Technol. 2006, 14, 119–139. [Google Scholar] [CrossRef]

- Frikel, J.; Quinto, E.T. Characterization and reduction of artifacts in limited angle tomography. Inverse Probl. 2013, 29, 125007. [Google Scholar] [CrossRef]

- Chityala, R.; Hoffmann, K.R.; Bednarek, D.R.; Rudin, S. Region of Interest (ROI) Computed Tomography. Proc. SPIE-Int. Soc. Opt. Eng. 2004, 5368, 534–541. [Google Scholar] [CrossRef]

- Lifton, J.J.; Malcolm, A.A.; McBride, J.W. An experimental study on the influence of scatter and beam hardening in x-ray CT for dimensional metrology. Meas. Sci. Technol. 2016, 27, 015007. [Google Scholar] [CrossRef]

- Ferrucci, M.; Leach, R.K.; Giusca, C.; Carmignato, S.; Dewulf, W. Towards geometrical calibration of x-ray computed tomography systems—A review. Meas. Sci. Technol. 2015, 26, 092003. [Google Scholar] [CrossRef]

- Schmitt, R.H.; Buratti, A.; Grozmani, N. Investigating the influence of workpiece placement on the uncertainty of measurements in industrial computed tomography. E-J. Nondestruct. Test. 2019, 24. [Google Scholar] [CrossRef] [PubMed]

- Amirkhanov, A.; Heinzl, C.; Reiter, M.; Gröller, E. Visual optimality and stability analysis of 3DCT scan positions. IEEE Trans. Vis. Comput. Graph. 2010, 16, 1477–1486. [Google Scholar] [CrossRef] [PubMed]

- Linde, M.; Wiest, W.; Trauth, A.; Sause, M.G.R. Selecting Feasible Trajectories for Robot-Based X-ray Tomography by Varying Focus-Detector-Distance in Space Restricted Environments. J. Nondestruct. Eval. 2024, 43, 65. [Google Scholar] [CrossRef]

- Butzhammer, L.; Hausotte, T. Complex 3D scan trajectories for industrial cone-beam computed tomography using a hexapod. Meas. Sci. Technol. 2021, 32, 105402. [Google Scholar] [CrossRef]

- Wei, C.; Albrecht, J.; Rit, S.; Laurendeau, M.; Thummerer, A.; Corradini, S.; Belka, C.; Steininger, P.; Ginzinger, F.; Kurz, C.; et al. Reduction of cone-beam CT artifacts in a robotic CBCT device using saddle trajectories with integrated infrared tracking. Med. Phys. 2024, 51, 1674–1686. [Google Scholar] [CrossRef]

- Rehak, M.; Hassler, U.; Hanke, R. Acquisition Trajectories for X-Ray Tomosynthesis Applied to Planar Samples. In Proceedings of the 2nd International Symposium on NDT in Aerospace, Hamburg, Germany, 22–24 November 2010. [Google Scholar]

- Fischer, A.; Lasser, T.; Schrapp, M.; Stephan, J.; Noël, P.B. Object Specific Trajectory Optimization for Industrial X-ray Computed Tomography. Sci. Rep. 2016, 6, 19135. [Google Scholar] [CrossRef]

- Huynh-Thu, Q.; Ghanbari, M. Scope of validity of PSNR in image/video quality assessment. Electron. Lett. 2008, 44, 800. [Google Scholar] [CrossRef]

- Wang, Z.; Bovik, A.C.; Sheikh, H.R.; Simoncelli, E.P. Image quality assessment: From error visibility to structural similarity. IEEE Trans. Image Process. 2004, 13, 600–612. [Google Scholar] [CrossRef]

- González, R.C.; Woods, R.E.; Masters, B.R. Digital Image Processing, Third Edition. J. Biomed. Opt. 2009, 14, 029901. [Google Scholar] [CrossRef]

- Haacke, E.M.; Xu, Y.; Cheng, Y.C.N.; Reichenbach, J.R. Susceptibility weighted imaging (SWI). Magn. Reson. Med. 2004, 52, 612–618. [Google Scholar] [CrossRef]

- Zeng, G.L. Medical Image Reconstruction; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Gang, G.J.; Stayman, J.W.; Ouadah, S.; Ehtiati, T.; Siewerdsen, J.H. Task-driven imaging in cone-beam computed tomography. Proc. SPIE-Int. Soc. Opt. Eng. 2015, 9412, 941220. [Google Scholar] [CrossRef] [PubMed]

- Zaech, J.N.; Gao, C.; Bier, B.; Taylor, R.; Maier, A.; Navab, N.; Unberath, M. Learning to avoid poor images: Towards task-aware C-arm cone-beam CT trajectories. In Proceedings of the Medical Image Computing and Computer Assisted Intervention–MICCAI 2019: 22nd International Conference, Shenzhen, China, 13–17 October 2019; Proceedings, Part V 22, 2019. pp. 11–19. [Google Scholar]

- Bauer, F.; Goldammer, M.; Grosse, C.U. Scan Time Reduction by Fewer Projections—An Approach for Circular and Spherical Trajectories. E-J. Nondestruct. Test. 2024, 29. [Google Scholar] [CrossRef] [PubMed]

- Gang, G.J.; Siewerdsen, J.H.; Stayman, J.W. Non-circular CT orbit design for elimination of metal artifacts. Proc. SPIE-Int. Soc. Opt. Eng. 2020, 11312, 1131227. [Google Scholar] [CrossRef] [PubMed]

- Tuy, H.K. An Inversion Formula for Cone-Beam Reconstruction. SIAM J. Appl. Math. 1983, 43, 546–552. [Google Scholar] [CrossRef]

- Yuan, Y.; Schneider, L.S.; Maier, A. Application of Gated Recurrent Units for CT Trajectory Optimization. In Proceedings of the CT Meeting, San Francisco, CA, USA, 15–18 March 2024. [Google Scholar]

- Cho, K.; van Merriënboer, B.; Gulcehre, C.; Bahdanau, D.; Bougares, F.; Schwenk, H.; Bengio, Y. Learning phrase representations using RNN encoder-decoder for statistical machine translation. In Proceedings of the Conference on Empirical Methods in Natural Language Processing, Doha, Qatar, 25–29 October 2014. [Google Scholar]

- Bussy, V.; Vienne, C.; Escoda, J.; Kaftandjian, V. Best projections selection algorithm based on constrained QDEIM for sparse-views X-ray Computed Tomography. E-J. Nondestruct. Test. 2023, 28. [Google Scholar] [CrossRef]

- Haque, M.A.; Ahmad, M.O.; Swamy, M.N.S.; Hasan, M.K.; Lee, S.Y. Adaptive projection selection for computed tomography. IEEE Trans. Image Process. 2013, 22, 5085–5095. [Google Scholar] [CrossRef]

- Matz, A.; Holub, W.; Schielein, R. Trajectory Optimization in Computed Tomography Based on Object Geometry. E-J. Nondestruct. Test. 2022, 27. [Google Scholar] [CrossRef]

- Dabravolski, A.; Batenburg, K.J.; Sijbers, J. Adaptive zooming in X-ray computed tomography. J. X-Ray Sci. Technol. 2014, 22, 77–89. [Google Scholar] [CrossRef]

- Schielein, R.; Scholz, G.; Wagner, R.; Kretzer, C.; Fuchs, T.; Kasperl, S.; Bär, F.P.; Kirsch, S.; Zepf, M.; Wolters-Rosbach, M. The MUSICES Project: Simulative automated CT acquisition planning for historical brass instruments improves image quality. In Proceedings of the 6th Conference on Industrial Computed Tomography (iCT Conference 2016), Wels, Austria, 9–12 February 2016. [Google Scholar]

- Shannon, C.E. A Mathematical Theory of Communication. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Brierley, N.; Bellon, C.; Lazaro Toralles, B. Optimized multi-shot imaging inspection design. Proc. Math. Phys. Eng. Sci. 2018, 474, 20170319. [Google Scholar] [CrossRef]

- Schneider, L.S.; Thies, M.; Schielein, R.; Syben, C.; Unberath, M.; Maier, A. Learning-based Trajectory Optimization for a Twin Robotic CT System. E-J. Nondestruct. Test. 2023, 28. [Google Scholar] [CrossRef] [PubMed]

- Linde, M.; Wiest, W.; Trauth, A.; Sause, M.G. Trajectory optimization for few-view robot-based CT: Transitioning from static to object-specific acquisition geometries. Tomogr. Mater. Struct. 2025, 7, 100058. [Google Scholar] [CrossRef]

- DIN Deutsches Institut für Normung, e.V. DIN 1319-1:1995-01, Grundlagen der Meßtechnik—Teil 1: Grundbegriffe. Available online: https://www.dinmedia.de/de/norm/din-1319-1/2440447 (accessed on 8 May 2025).

- Weiss, A.; Wittl, S.; Herl, G.; Zabler, S.; Trauth, A.; Sause, M.G.R. Safeguarding accuracy for CT imaging with industrial robots: Efficient calibration methods for arbitrary trajectories. E-J. Nondestruct. Test. 2025, 30. [Google Scholar] [CrossRef]

- Khaled, T.A.; Akhrif, O.; Bonev, I.A. Dynamic Path Correction of an Industrial Robot Using a Distance Sensor and an ADRC Controller. IEEE/ASME Trans. Mechatron. 2021, 26, 1646–1656. [Google Scholar] [CrossRef]

- Nubiola, A.; Bonev, I.A. Absolute calibration of an ABB IRB 1600 robot using a laser tracker. Robot. Comput.-Integr. Manuf. 2013, 29, 236–245. [Google Scholar] [CrossRef]

- Benjamin, W.; Roth, Z.S.; Driels, M.R. Fundamentals of manipulator calibration. J. Manuf. Syst. 1992, 11, 146. [Google Scholar] [CrossRef]

- Sigron, P.; Aschwanden, I.; Bambach, M. Compensation of Geometric, Backlash, and Thermal Drift Errors Using a Universal Industrial Robot Model. IEEE Trans. Autom. Sci. Eng. 2024, 21, 6615–6627. [Google Scholar] [CrossRef]

- Le Reun, A.; Subrin, K.; Dubois, A.; Garnier, S. Thermal drift and backlash issues for industrial robots positioning performance. Robotica 2022, 40, 2933–2952. [Google Scholar] [CrossRef]

- Klimchik, A.; Wu, Y.; Caro, S.; Furet, B.; Pashkevich, A. Geometric and elastostatic calibration of robotic manipulator using partial pose measurements. Adv. Robot. 2014, 28, 1419–1429. [Google Scholar] [CrossRef]

- Chen, G.; Li, T.; Chu, M.; Jia, Q.X.; Sun, H.X. Review on kinematics calibration technology of serial robots. Int. J. Precis. Eng. Manuf. 2014, 15, 1759–1774. [Google Scholar] [CrossRef]

- Li, Z.; Li, S.; Luo, X. An overview of calibration technology of industrial robots. IEEE/CAA J. Autom. Sin. 2021, 8, 23–36. [Google Scholar] [CrossRef]

- Ginani, L.S.; Motta, J.M.S.T. Theoretical and practical aspects of robot calibration with experimental verification. J. Braz. Soc. Mech. Sci. Eng. 2011, 33, 15–21. [Google Scholar] [CrossRef]

- Messay, T.; Ordóñez, R.; Marcil, E. Computationally efficient and robust kinematic calibration methodologies and their application to industrial robots. Robot. Comput.-Integr. Manuf. 2016, 37, 33–48. [Google Scholar] [CrossRef]

- Deng, K.; Gao, D.; Ma, S.; Zhao, C.; Lu, Y. Elasto-geometrical error and gravity model calibration of an industrial robot using the same optimized configuration set. Robot. Comput.-Integr. Manuf. 2023, 83, 102558. [Google Scholar] [CrossRef]

- AUTOMATED PRECISION EUROPE GMBH. API Radian Laser Tracker—Brochure 2021. Available online: https://apimetrology.com/wp-content/uploads/2021/08/API_Radian_Brochure_2021-Rev_DE_08_081921_web.pdf (accessed on 30 April 2025).

- FARO. FARO® Quantum Max—The Next Generation ScanArm. Available online: https://media.faro.com/-/media/Project/FARO/FARO/FARO/Resources/2021/06/30/22/08/Brochure_QuantumMax_3DM_LTR_ENG.pdf (accessed on 19 July 2024).

- Renishaw plc. Data Sheet—MP250 Touch Probe. 02.2018. Available online: https://www.renishaw.com/media/pdf/de/fbae95a7da0849e99ff0f68c5e091fab.pdf (accessed on 30 April 2025).

- Qualisys. Arqus Camera System—Tech Specs. Available online: https://www.qualisys.com/cameras/arqus/#tech-specs (accessed on 30 April 2025).

- Li, Z.; Li, S.; Luo, X. Data-driven Industrial Robot Arm Calibration: A Machine Learning Perspective. In Proceedings of the 2021 IEEE International Conference on Networking, Sensing and Control (ICNSC), Xiamen, China, 3–5 December 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Dynalog Inc. CompuGauge: Robot Performance Analysis System (ISO-9283); Dynalog Inc.: Bloomfield Hills, MI, USA, 2024. [Google Scholar]

- Liu, Y.; Zhuang, Z.; Li, Y. Closed-Loop Kinematic Calibration of Robots Using a Six-Point Measuring Device. IEEE Trans. Instrum. Meas. 2022, 71, 1–12. [Google Scholar] [CrossRef]

- Yang, X.; Liu, D.; Bai, Y.; Cong, M.; Liao, Z. Kinematics calibration research based on the positioning error of the 6-DOF industrial robot. In Proceedings of the 2015 IEEE International Conference on Cyber Technology in Automation, Control, and Intelligent Systems (CYBER), Shenyang, China, 8–12 June 2015; pp. 913–917. [Google Scholar] [CrossRef]

- Wang, B.; Liu, J.; Wang, C. Measurement and analysis of backlash on harmonic drive. IOP Conf. Ser. Mater. Sci. Eng. 2019, 542, 012005. [Google Scholar] [CrossRef]

- Giovannitti, E.; Nabavi, S.; Squillero, G.; Tonda, A. A virtual sensor for backlash in robotic manipulators. J. Intell. Manuf. 2022, 33, 1921–1937. [Google Scholar] [CrossRef]

- Abele, E.; Weigold, M.; Rothenbücher, S. Modeling and Identification of an Industrial Robot for Machining Applications. CIRP Ann. 2007, 56, 387–390. [Google Scholar] [CrossRef]

- Cai, Y.; Yuan, P.; Chen, D.; Gao, D.; Wu, X.; Xue, L.; Wang, T. A calibration method of industrial robots based on ELM. In Proceedings of the 2017 IEEE International Conference on Advanced Robotics and Mechatronics (ICARM), Hefei & Tai’an, China, 27–31 August 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Li, Z.; Li, S.; Luo, X. A Novel Machine Learning System for Industrial Robot Arm Calibration. IEEE Trans. Circuits Syst. II Express Briefs 2024, 71, 2364–2368. [Google Scholar] [CrossRef]

- Qiao, Y.; Lu, Y.; Hu, H.; Zhuang, C. A Kinematic Calibration Method Based on Residual Network Combining Joint Angles and Robot Pose. In Proceedings of the 2023 5th International Conference on Robotics and Computer Vision (ICRCV), Nanjing, China, 15–17 September 2023; pp. 310–315. [Google Scholar] [CrossRef]

- Borrmann, C.; Wollnack, J. Calibration of external linear robot axes using spline interpolation. In Proceedings of the International Conference on Modelling, Identification & Control, Melbourne, VIC, Australia, 3–5 December 2014; pp. 111–116. [Google Scholar] [CrossRef]

- WEISS GmbH. SCHWERLAST-TISCH CR & TH. Online Resource. Available online: https://asp-gmbh.at/wp-content/uploads/2016/08/rundschalttisch_cr.pdf (accessed on 7 July 2023).

- Lee, J.W.; Park, G.T.; Shin, J.S.; Woo, J.W. Industrial robot calibration method using denavit—Hatenberg parameters. In Proceedings of the 2017 17th International Conference on Control, Automation and Systems: Proceedings, Jeju, Republic of Korea, 18–21 October 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Hartley, R.; Zisserman, A. Multiple View Geometry in Computer Vision; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- Noo, F.; Clackdoyle, R.; Mennessier, C.; White, T.A.; Roney, T.J. Analytic method based on identification of ellipse parameters for scanner calibration in cone-beam tomography. Phys. Med. Biol. 2000, 45, 3489–3508. [Google Scholar] [CrossRef]

- Cho, Y.; Moseley, D.J.; Siewerdsen, J.H.; Jaffray, D.A. Accurate technique for complete geometric calibration of cone-beam computed tomography systems. Med. Phys. 2005, 32, 968–983. [Google Scholar] [CrossRef] [PubMed]

- Jacobson, M.W.; Ketcha, M.D.; Capostagno, S.; Martin, A.; Uneri, A.; Goerres, J.; de Silva, T.; Reaungamornrat, S.; Han, R.; Manbachi, A.; et al. A line fiducial method for geometric calibration of cone-beam CT systems with diverse scan trajectories. Phys. Med. Biol. 2018, 63, 025030. [Google Scholar] [CrossRef] [PubMed]

- Strobel, N.K.; Heigl, B.; Brunner, T.M.; Schuetz, O.; Mitschke, M.M.; Wiesent, K.; Mertelmeier, T. Improving 3D image quality of x-ray C-arm imaging systems by using properly designed pose determination systems for calibrating the projection geometry. In Proceedings of the Medical Imaging 2003: Physics of Medical Imaging, SPIE Proceedings, San Diego, CA, USA, 15–20 February 2003; Yaffe, M.J., Antonuk, L.E., Eds.; SPIE: Bellingham, WA, USA, 2003; p. 943. [Google Scholar] [CrossRef]

- Amr, M.; Schön, T.; Suth, D. A Flexible and Acquisition Geometry-Independent Calibration for Computed Tomography. In Proceedings of the 8th Conference on Industrial Computed Tomography (iCT 2018), Wels, Austria, 6–9 February 2018. [Google Scholar]

- Li, X.; Da, Z.; Liu, B. A generic geometric calibration method for tomographic imaging systems with flat-panel detectors—A detailed implementation guide. Med. Phys. 2010, 37, 3844–3854. [Google Scholar] [CrossRef]

- Mennessier, C.; Clackdoyle, R.; Noo, F. Direct determination of geometric alignment parameters for cone-beam scanners. Phys. Med. Biol. 2009, 54, 1633–1660. [Google Scholar] [CrossRef] [PubMed]

- Butzhammer, L.; Braun, M.R.O.; Hausotte, T. CT scan trajectory calibration based on projected metal spheres: When and how should errors from elliptical distortion be corrected? E-J. Nondestruct. Test. 2023, 28. [Google Scholar] [CrossRef]

- Wittl, S.; Weiss, A.; Herl, G.; Zabler, S. Keeping Attention to the Mapping. In Proceedings of the 12th Conference on Industrial Computed Tomography (iCT) 2023, Fürth, Germany, 27 February–2 March 2023; Volume 27. [Google Scholar]

- Aichert, A.; Bier, B.; Rist, L.; Maier, A.K. Projective invariants for geometric calibration in flat-panel computed tomography. In Proceedings of the CT-Meeting, Salt Lake City, UT, USA, 18–22 June 2018; pp. 69–72. [Google Scholar]

- Klein, P.; Herol, F. Methode zur automatischen Bestimmung der Projektionsgeometrie. Berichtsband DGZfP Jahrestag. 2017, 2017, 1–8. [Google Scholar]

- Kang, R.; Guerrero, P.; Probst, G.; Slaets, P.; Dewulf, W. Reference free method for robot CT imaging geometry estimation. Precis. Eng. 2022, 78, 102–113. [Google Scholar] [CrossRef]

- Hardner, M.; Liebold, F.; Wagner, F.; Maas, H.G. Investigations into the Geometric Calibration and Systematic Effects of a Micro-CT System. Sensors 2024, 24, 5139. [Google Scholar] [CrossRef]

- Li, G.; Luo, S.; You, C.; Getzin, M.; Zheng, L.; Wang, G.; Gu, N. A novel calibration method incorporating nonlinear optimization and ball-bearing markers for cone-beam CT with a parameterized trajectory. Med. Phys. 2019, 46, 152–164. [Google Scholar] [CrossRef]

- von Smekal, L.; Kachelriess, M.; Stepina, E.; Kalender, W.A. Geometric misalignment and calibration in cone-beam tomography. Med. Phys. 2004, 31, 3242–3266. [Google Scholar] [CrossRef]

- Graetz, J. Auto-calibration of cone beam geometries from arbitrary rotating markers using a vector geometry formulation of projection matrices. Phys. Med. Biol. 2021, 66, 075013. [Google Scholar] [CrossRef] [PubMed]

- Gross, D.; Heil, U.; Schulze, R.; Schoemer, E.; Schwanecke, U. Auto calibration of a cone-beam-CT. Med. Phys. 2012, 39, 5959–5970. [Google Scholar] [CrossRef] [PubMed]

- Butzhammer, L.; Müller, A.M.; Hausotte, T. Calibration of 3D scan trajectories for an industrial computed tomography setup with 6-DOF object manipulator system using a single sphere. Meas. Sci. Technol. 2023, 34, 015403. [Google Scholar] [CrossRef]

- Blumensath, T.; O’Brien, N.; Wood, C.E. Calibration of Robotic Manipulator Systems for Cone-Beam Tomography Imaging. IEEE Trans. Nucl. Sci. 2018, 65, 1384–1393. [Google Scholar] [CrossRef]

- Li, G.; Chen, X.; You, C.; Huang, X.; Deng, Z.; Luo, S. A nonconvex model-based combined geometric calibration scheme for micro cone-beam CT with irregular trajectories. Med. Phys. 2023, 50, 2759–2774. [Google Scholar] [CrossRef]

- Li, G.; Huang, X.; Chen, X.; Wang, H.; Zhou, L.; Ji, X.; Chen, Y.; Luo, S. A Self-Contained Calibration Scheme for Micro-CT With Irregular Trajectories Based on Phantom Auto-Measurement. IEEE Trans. Instrum. Meas. 2025, 74, 1–13. [Google Scholar] [CrossRef]

- Butzhammer, L.; Handke, N.; Wittl, S.; Herl, G.; Hausotte, T. Direct assessment of the influence of pose repeatability on the accuracy of dimensional measurements for computed tomography systems with high degrees of freedom. Meas. Sci. Technol. 2025, 36, 025401. [Google Scholar] [CrossRef]

- Ouadah, S.; Stayman, J.W.; Gang, G.; Uneri, A.; Ehtiati, T.; Siewerdsen, J.H. Self-Calibration of Cone-Beam CT Geometry Using 3D-2D Image Registration: Development and Application to Task-Based Imaging with a Robotic C-Arm. Phys. Med. Biol. 2016, 61, 2613. [Google Scholar] [CrossRef]

- Chung, K.; Schad, L.R.; Zöllner, F.G. Tomosynthesis implementation with adaptive online calibration on clinical C-arm systems. Int. J. Comput. Assist. Radiol. Surg. 2018, 13, 1481–1495. [Google Scholar] [CrossRef]

- Tönnes, C.; Russ, T.; Schad, L.R.; Zöllner, F.G. Feature-based CBCT self-calibration for arbitrary trajectories. Int. J. Comput. Assist. Radiol. Surg. 2022, 17, 2151–2159. [Google Scholar] [CrossRef]

- Ji, X.; Lu, Y.; Zhuo, X.; Zhang, Y.; Zhu, S.; Chen, Y. A Geometrical Calibration Method for C-Arm CT Based on a Nonlinear Registration Model. IEEE Trans. Instrum. Meas. 2023, 72, 1–13. [Google Scholar] [CrossRef]

- Bussy, V.; Vienne, C. Robust 3D/2D hybrid registration for integrating a priori CAD model into X-ray Computed Tomography. In Proceedings of the ORASIS 2021, Carry-le-Rouet, France, 1–4 June 2021. [Google Scholar]

- Kyriakou, Y.; Lapp, R.M.; Hillebrand, L.; Ertel, D.; Kalender, W.A. Simultaneous misalignment correction for approximate circular cone-beam computed tomography. Phys. Med. Biol. 2008, 53, 6267–6289. [Google Scholar] [CrossRef]

- Yang, J.; Wang, D.; Fan, B.; Dong, D.; Zhou, W. Online absolute pose compensation and steering control of industrial robot based on six degrees of freedom laser measurement. Opt. Eng. 2017, 56, 034111. [Google Scholar] [CrossRef]

- Presenti, A.; Liang, Z.; Pereira, L.F.A.; Sijbers, J.; de Beenhouwer, J. Fast and accurate pose estimation of additive manufactured objects from few X-ray projections. Expert Syst. Appl. 2023, 213, 118866. [Google Scholar] [CrossRef]

- Bossema, F.G.; Palenstijn, W.J.; Heginbotham, A.; Corona, M.; van Leeuwen, T.; van Liere, R.; Dorscheid, J.; O’Flynn, D.; Dyer, J.; Hermens, E.; et al. (Eds.) Enabling 3D CT-Scanning of Cultural Heritage Objects Using Only In-House 2D X-Ray Equipment in Museums; Nature Communications, Springer Nature: London, UK, 2024; Volume 15. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Reynolds, T.; Ehtiati, T.; Weiss, C.; Hong, K.; Theodore, N.; Gang, G.J.; Stayman, J.W. Fully automatic online geometric calibration for non-circular cone-beam CT orbits using fiducials with unknown placement. Med. Phys. 2024, 51, 3245–3264. [Google Scholar] [CrossRef]

- Meng, Y.; Gong, H.; Yang, X. Online geometric calibration of cone-beam computed tomography for arbitrary imaging objects. IEEE Trans. Med. Imaging 2013, 32, 278–288. [Google Scholar] [CrossRef]

- Debbeler, C.; Maass, N.; Elter, M.; Dennerlein, F.; Buzug, T.M. A New CT Rawdata Redundancy Measure applied to Automated Misalignment Correction. In Proceedings of the Fully Three-Dimensional Image Reconstruction in Radiology and Nuclear Medicine, Lake Tahoe, CA, USA, 16–21 June 2013; Volume 2013. [Google Scholar]

- Defrise, M.; Clack, R. A cone-beam reconstruction algorithm using shift-variant filtering and cone-beam backprojection. IEEE Trans. Med. Imaging 1994, 13, 186–195. [Google Scholar] [CrossRef]

- Maass, N.; Dennerlein, F.; Aichert, A.; Maier, A. Geometrical jitter correction in computed tomography. In Proceedings of the Third International Conference on Image Formation in X-Ray Computed Tomography, Edited by Frederic Noo, Salt Lake City, UT, USA, 22–25 June 2014; pp. 338–342. [Google Scholar]

- Cant, J.; Behiels, G.; Sijbers, J. Automatic geometric calibration of chest tomosynthesis using data consistency conditions—Cant. In Proceedings of the 4th International Conference on Image Formation in X-Ray Computed Tomography, Bamberg, Germany, 18–22 July 2016. [Google Scholar]

- Aichert, A.; Wang, J.; Schaffert, R.; Dörfler, A.; Hornegger, J.; Maier, A.K. Epipolar Consistency in Fluoroscopy for Image-Based Tracking. In Proceedings of the British Machine Vision Conference 2015; Xie, X., Jones, M.W., Tam, G.K.L., Eds.; BMVA Press: Durham, UK, 2015. [Google Scholar]

- Aichert, A.; Berger, M.; Wang, J.; Maass, N.; Doerfler, A.; Hornegger, J.; Maier, A.K. Epipolar Consistency in Transmission Imaging. IEEE Trans. Med. Imaging 2015, 34, 2205–2219. [Google Scholar] [CrossRef]

- Frysch, R.; Pfeiffer, T.; Rose, G. A novel approach to 2D/3D registration of X-ray images using Grangeat’s relation. Med. Image Anal. 2021, 67, 101815. [Google Scholar] [CrossRef]

- Li, M.; Bohacova, J.; Uher, J.; Cong, W.; Rubinstein, J.; Wang, G. Motion correction for robot-based X-ray photon-counting CT at ultrahigh resolution. In Proceedings of the Developments in X-Ray Tomography XIV, San Diego, CA, USA, 22–24 August 2022; Optical Engineering, SPIE: Bellingham, WA, USA, 2022; p. 33. [Google Scholar] [CrossRef]

- Li, M.; Zan, G.; Yun, W.; Uher, J.; Wen, J.; Wang, G. Data-driven imaging geometric recovery of ultrahigh resolution robotic micro-CT for in-vivo and other applications. In Proceedings of the 8th International Conference on Biomedical Engineering and Bioinformatics, Milan, Italy, 13–15 September 2024. [Google Scholar]

- Pedersen, F.H.; Jørgensen, J.S.; Andersen, M.S. A Bayesian approach to CT reconstruction with uncertain geometry. Appl. Math. Sci. Eng. 2023, 31, 2166041. [Google Scholar] [CrossRef]

- Rückert, D.; Wang, Y.; Li, R.; Idoughi, R.; Heidrich, W. NeAT: Neural Adaptive Tomography. ACM Trans. Graph. (TOG) 2022, 41, 1–13. [Google Scholar] [CrossRef]

- Mildenhall, B.; Srinivasan, P.P.; Tancik, M.; Barron, J.T.; Ramamoorthi, R.; Ng, R. NeRF: Representing Scenes as Neural Radiance Fields for View Synthesis. Commun. ACM 2021, 65, 99–106. [Google Scholar] [CrossRef]

- Rückert, D.; Butzhammer, L.; Wittl, S.; Herl, G.; Hausotte, T.; Kurth, P. Uncalibrated CT Reconstruction for One-Shot Scanning of Arbitrary Trajectories. E-J. Nondestruct. Test. 2024, 29. [Google Scholar] [CrossRef]

- Jung, A.; Maier, A.; Herl, G. Towards Efficient Truncation Correction in Arbitrary Geometry: Residual Projections for Region Of Interest Algebraic Reconstruction. In Proceedings of the 8th International Conference on Image Formation in X-Ray Computed Tomography (CT Meeting), Bamberg, Germany, 5–9 August 2024; pp. 122–125. [Google Scholar]

- Hadamard, J. Lectures on the Cauchy Problem in Linear Partial Differential Equations; Yale University Press: New Haven, CT, USA, 1923. [Google Scholar]

- Natterer, F. The Mathematics of Computerized Tomography; John Wiley & Sons: Hoboken, NJ, USA, 1986. [Google Scholar]

- Louis, A.K. Inverse und Schlecht Gestellte Probleme; Teubner: Stuttgart, Germany, 1989. [Google Scholar]

- Rieder, A. Keine Probleme Mit Inversen Problemen: Eine Einführung in Ihre Stabile Lösung; Vieweg: Berlin, Germany, 2003. [Google Scholar]

- Buzug, T.M. Einführung in die Computertomographie; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar] [CrossRef]

- Smith, B.D. Image Reconstruction from Cone-Beam Projections: Necessary and Sufficient Conditions and Reconstruction Methods. IEEE Trans. Med. Imaging 1985, 4, 14–25. [Google Scholar] [CrossRef] [PubMed]

- Grangeat, P. Mathematical framework of cone-beam reconstruction via the first derivative of the radon transform. In Lecture Notes in Mathematics; Herman, G.T., Louis, A.K., Natterer, F., Eds.; Springer: Berlin/Heidelberg, Germany, 1991; Volume 1497, pp. 66–97. [Google Scholar]

- Kudo, H.; Saito, T. Derivation and Implementation of a Cone-Beam Reconstruction Algorithm for Nonplanar Orbits. IEEE Trans. Med. Imaging 1994, 13, 196–211. [Google Scholar] [CrossRef]

- Katsevich, A. A general scheme for constructing inversion algorithms for cone beam CT. Int. J. Math. Math. Sci. 2003, 2003, 1305–1321. [Google Scholar] [CrossRef]

- Louis, A.K. Development of algorithms in computerized tomography. In Proceedings of the Radon Transform, Inverse Problems, and Tomography; Olafsson, G., Quinto, E.T., Eds.; American Mathematical Society: Providence, RI, USA, 2006; pp. 25–42. [Google Scholar]

- Louis, A.K. Approximate inverse for linear and some nonlinear problems. Inverse Probl. 1996, 12, 175–190. [Google Scholar] [CrossRef]

- Oeckl, S. Rekonstruktionsverfahren Mit der Approximativen Inversen und Einer Neuen Formel zur Inversion der Röntgen-Transformation. Ph.D. Thesis, Universität des Saarlandes, Saarbrücken, Germany, 2014. [Google Scholar] [CrossRef]

- Feldkamp, L.A.; Davis, L.C.; Kress, J.W. Practical cone-beam algorithm. J. Opt. Soc. Am. A-Opt. Image Sci. Vis. 1984, 1, 612–619. [Google Scholar] [CrossRef]

- Crawford, C.R.; King, K.F. Computed tomography scanning with simultaneous patient translation. Med. Phys. 1990, 17, 967–982. [Google Scholar] [CrossRef]

- Kalender, W.A.; Seissler, W.; Klotz, E.; Vock, P. Spiral volumetric CT with single-breath-hold technique, continuous transport, and continuous scanner rotation. Radiology 1990, 176, 181–183. [Google Scholar] [CrossRef]

- Des Plantes, B.G.Z. Eine Neue Methode Zur Differenzierung in der Rontgenographie (Planigraphies). Acta Radiol. 1932, 13, 182–192. [Google Scholar] [CrossRef]

- Sechopoulos, I. A review of breast tomosynthesis. Part II. Image reconstruction, processing and analysis, and advanced applications. Med. Phys. 2013, 40, 014302. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarz, S. Angenäherte Auflösung von Systemen linearer Gleichungen. Bull. Int. L’Académie Pol. Sci. Lettres 1937, 35, 355–357. [Google Scholar]

- Gordon, R.; Bender, R.; Herman, G.T. Algebraic reconstruction techniques (ART) for three-dimensional electron microscopy and x-ray photography. J. Theor. Biol. 1970, 29, 471–481. [Google Scholar] [CrossRef]

- Gilbert, P. Iterative methods for the three-dimensional reconstruction of an object from projections. J. Theor. Biol. 1972, 36, 105–117. [Google Scholar] [CrossRef]

- Andersen, A. Simultaneous Algebraic Reconstruction Technique (SART): A superior implementation of the ART algorithm. Ultrason. Imaging 1984, 6, 81–94. [Google Scholar] [CrossRef]

- Jiang, M.; Wang, G. Convergence studies on iterative algorithms for image reconstruction. IEEE Trans. Med. Imaging 2003, 22, 569–579. [Google Scholar] [CrossRef]

- Wang, G.; Jiang, M. Ordered-subset simultaneous algebraic reconstruction techniques (OS-SART). J. X-Ray Sci. Technol. 2003, 12, 169–177. [Google Scholar] [CrossRef]

- Censor, Y.; Elfving, T. Block-Iterative Algorithms with Diagonally Scaled Oblique Projections for the Linear Feasibility Problem. SIAM J. Matrix Anal. Appl. 2002, 24, 40–58. [Google Scholar] [CrossRef]

- Sauer, K.; Bouman, C. A local update strategy for iterative reconstruction from projections. IEEE Trans. Signal Process. 1993, 41, 534–548. [Google Scholar] [CrossRef]

- Wang, G.; Yu, H.; de Man, B. An outlook on X-ray CT research and development. Med. Phys. 2008, 35, 1051–1064. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Ye, J.C.; Mueller, K.; Fessler, J.A. Image Reconstruction is a New Frontier of Machine Learning. IEEE Trans. Med. Imaging 2018, 37, 1289–1296. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.M.; Dong, B. A Review on Deep Learning in Medical Image Reconstruction. J. Oper. Res. Soc. China 2020, 8, 311–340. [Google Scholar] [CrossRef]

- Wang, G.; Ye, J.C.; de Man, B. Deep learning for tomographic image reconstruction. Nat. Mach. Intell. 2020, 2, 737–748. [Google Scholar] [CrossRef]

- Bellens, S.; Guerrero, P.; Vandewalle, P.; Dewulf, W. Machine learning in industrial X-ray computed tomography—A review. CIRP J. Manuf. Sci. Technol. 2024, 51, 324–341. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, J.Z.; Cauley, S.F.; Rosen, B.R.; Rosen, M.S. Image reconstruction by domain-transform manifold learning. Nature 2018, 555, 487–492. [Google Scholar] [CrossRef]

- Syben, C.; Michen, M.; Stimpel, B.; Seitz, S.; Ploner, S.; Maier, A.K. Technical Note: PYRO-NN: Python reconstruction operators in neural networks. Med. Phys. 2019, 46, 5110–5115. [Google Scholar] [CrossRef]

- Lagerwerf, M.J.; Pelt, D.M.; Palenstijn, W.J.; Batenburg, K.J. A Computationally Efficient Reconstruction Algorithm for Circular Cone-Beam Computed Tomography Using Shallow Neural Networks. J. Imaging 2020, 6, 135. [Google Scholar] [CrossRef]

- Fu, L.; de Man, B. Deep learning tomographic reconstruction through hierarchical decomposition of domain transforms. Vis. Comput. Ind. Biomed. Art 2022, 5, 30. [Google Scholar] [CrossRef]

- Ye, C.; Schneider, L.S.; Sun, Y.; Thies, M.; Mei, S.; Maier, A. DRACO: Differentiable Reconstruction for Arbitrary CBCT Orbits. Phys. Med. Biol. 2025, 70, 075005. [Google Scholar] [CrossRef]

- Vienne, C.; Escoda, J.; Touron, A.; Costin, M. Assessing the influence of CT acquisition parameters on flaw detectability through simulation. E-J. Nondestruct. Test. 2022, 27. [Google Scholar] [CrossRef] [PubMed]

- Sukowski, F.; Suth, D.; Waldyra, A.; Grulich, T.; Jung, A. Automated 3D Defect Detectionm based on Simulated Reference. E-J. Nondestruct. Test. 2023, 28. [Google Scholar] [CrossRef] [PubMed]

- Fleßner, M.; Jung, A.; Baldini, M.; Steinberger, N.; Tolle, K. Analyzing image data to detect a CT system’s error state and identify the corresponding root cause. E-J. Nondestruct. Test. 2024, 29. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Zhang, J.; Fitzgerald, P.; Jobin, J.; Reddy, N.; Debnath, A.; Haneda, E.; Fan, Y.; Pack, J.; Lorraine, P.; et al. An overview of the open-source CT simulation environment XCIST. In Proceedings of the 8th International Conference on Image Formation in X-Ray Computed Tomography (CT Meeting), San Diego, CA, USA, 1–4 June 2024; pp. 368–371. [Google Scholar]

- Krumm, M.; Sauerwein, C.; Hämmerle, V.; Heile, S.; Schön, T.; Jung, A.; Sindel, M. Rapid robotic X-ray computed tomography of large assemblies in automotive production. In Proceedings of the 8th Conference on Industrial Computed Tomography (iCT 2018), Wels, Austria, 6–9 February 2018; Volume 23. [Google Scholar]

- Weber, T.; Weber, T. Schnelle Rekonstruktionskernberechnung in der 3D-Computertomographie. Ph.D. Thesis, Universität des Saarlandes, Saarbrücken, Germany, 2008. [Google Scholar] [CrossRef]

- Schön, T.; Dietmayer, K.; Louis, A.K. New n-dimensional reconstruction formula for flat detector geometry. In Proceedings of the The 14th International Meeting on Fully Three-Dimensional Image Reconstruction in Radiology and Nuclear Medicine, Xi’an, China, 18–23 June 2017; pp. 505–509. [Google Scholar]

- Noo, F.; Clack, R.; Defrise, M. Cone-beam reconstruction from general discrete vertex sets using Radon rebinning algorithms. IEEE Trans. Nucl. Sci. 1997, 44, 1309–1316. [Google Scholar] [CrossRef]

- Russ, T.; Ma, Y.Q.; Golla, A.K.; Bauer, D.F.; Reynolds, T.; Tönnes, C.; Hatamikia, S.; Schad, L.R.; Zöllner, F.G.; Gang, G.J.; et al. Fast CBCT Reconstruction using Convolutional Neural Networks for Arbitrary Robotic C-arm Orbits. Proc. SPIE-Int. Soc. Opt. Eng. 2022, 12031, 120311I. [Google Scholar] [CrossRef]

- Clackdoyle, R.; Defrise, M. Tomographic Reconstruction in the 21st Century. IEEE Signal Process. Mag. 2010, 27, 60–80. [Google Scholar] [CrossRef]

- Banjak, H. X-Ray Computed Tomography Reconstruction on Non-Standard Trajectories for Robotized Inspection. Ph.D. Thesis, Universit’e de Lyon, Lyon, France, 2016. [Google Scholar]

- Noo, F.; Clackdoyle, R.; Pack, J.D. A two-step Hilbert transform method for 2D image reconstruction. Phys. Med. Biol. 2004, 49, 3903. [Google Scholar] [CrossRef]

- Xia, Y.; Maier, A.; Dennerlein, F.; Hornegger, J. Truncation Correction using a 3D Filter for Cone-beam CT. In Proceedings of the Fully3D 2013, Lake Tahoe, CA, USA, 16–21 June 2013; pp. 118–121. [Google Scholar]

- Ihrke, I.; Magnor, M. Adaptive grid optical tomography. Graph. Model. 2006, 68, 484–495. [Google Scholar] [CrossRef]

- Marlevi, D.; Kohr, H.; Buurlage, J.W.; Gao, B.; Batenburg, K.J.; Colarieti-Tosti, M. Multigrid Reconstruction in Tomographic Imaging. IEEE Trans. Radiat. Plasma Med. Sci. 2020, 4, 300–310. [Google Scholar] [CrossRef]

- Gregson, J.; Krimerman, M.; Hullin, M.B.; Heidrich, W. Stochastic tomography and its applications in 3D imaging of mixing fluids. ACM Trans. Graph. 2012, 31, 1–10. [Google Scholar] [CrossRef]

- Kopp, F.K.; Nasirudin, R.A.; Mei, K.; Fehringer, A.; Pfeiffer, F.; Rummeny, E.J.; Noël, P.B. Region of interest processing for iterative reconstruction in X-ray computed tomography. In Proceedings of the Medical Imaging 2015: Physics of Medical Imaging, SPIE Proceedings, Orlando, FL, USA, 21–26 February 2015; Hoeschen, C., Kontos, D., Flohr, T.G., Eds.; p. 94122E. [Google Scholar] [CrossRef]

- Danielsson, P.E.; Magnusson, M. A Proposal for Combining FBP and ART in CT-reconstruction. In Proceedings of the Seventh International Conference on Fully Three-Dimensional Reconstruction in Radiology and Nuclear Medicine, Saint Malo, France, 30 June–4 July 2003. [Google Scholar]

- Zeng, G.L.; Gullberg, G.T. Unmatched projector/backprojector pairs in an iterative reconstruction algorithm. IEEE Trans. Med. Imaging 2000, 19, 548–555. [Google Scholar] [CrossRef] [PubMed]

- Guedouar, R.; Zarrad, B. A new reprojection method based on a comparison of popular reprojection models. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2010, 619, 270–275. [Google Scholar] [CrossRef]

- Guedouar, R.; Zarrad, B. A comparative study between matched and mis-matched projection/back projection pairs used with ASIRT reconstruction method. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2010, 619, 225–229. [Google Scholar] [CrossRef]

- Grund, N.; Menzel, N.; Guthe, M. High-Quality Wavelet Compressed Textures for Real-Time Rendering. In WSCG 2010: Communication Papers Proceedings; Vaclav Skala—Union Agency: Plzen, Czech Republic, 2010; pp. 207–212. [Google Scholar]

- Mavridis, P.; Papaioannou, G. Texture Compression using Wavelet Decomposition. Comput. Graph. Forum 2012, 31, 2107–2116. [Google Scholar] [CrossRef]

- Essakine, A.; Cheng, Y.; Cheng, C.W.; Zhang, L.; Deng, Z.; Zhu, L.; Schönlieb, C.B.; Aviles-Rivero, A.I. Where Do We Stand with Implicit Neural Representations? A Technical and Performance Survey. Available online: https://arxiv.org/abs/2411.03688 (accessed on 30 April 2025).

- Herl, G.; Hiller, J.; Sauer, T. Artifact reduction in X-ray computed tomography by multipositional data fusion using local image quality measures. E-J. Nondestruct. Test. 2019, 24. [Google Scholar] [CrossRef]

- Rockmore, A.J.; Macovski, A. A Maximum Likelihood Approach to Transmission Image Reconstruction from Projections. IEEE Trans. Nucl. Sci. 1977, 24, 1929–1935. [Google Scholar] [CrossRef]

- Fessler, J.A. Penalized weighted least-squares image reconstruction for positron emission tomography. IEEE Trans. Med. Imaging 1994, 13, 290–300. [Google Scholar] [CrossRef]

- Fessler, J.A.; Rogers, W.L. Spatial resolution properties of penalized-likelihood image reconstruction: Space-invariant tomographs. IEEE Trans. Image Process. 1996, 5, 1346–1358. [Google Scholar] [CrossRef]

- Elbakri, I.A.; Fessler, J.A. Statistical image reconstruction for polyenergetic X-ray computed tomography. IEEE Trans. Med. Imaging 2002, 21, 89–99. [Google Scholar] [CrossRef]

- Yu, Z.; Thibault, J.B.; Bouman, C.A.; Sauer, K.D.; Hsieh, J. Fast model-based X-ray CT reconstruction using spatially nonhomogeneous ICD optimization. IEEE Trans. Image Process. 2011, 20, 161–175. [Google Scholar] [CrossRef]

- Syben, C.; Stimpel, B.; Breininger, K.; Würfl, T.; Fahrig, R.; Dörfler, A.; Maier, A. Precision Learning: Reconstruction Filter Kernel Discretization. Available online: https://arxiv.org/abs/1710.06287 (accessed on 30 April 2025).

- Hendriksen, A.A.; Pelt, D.M.; Batenburg, K.J. Noise2Inverse: Self-supervised deep convolutional denoising for tomography. IEEE Trans. Comput. Imaging 2020, 6, 1320–1335. [Google Scholar] [CrossRef]

- Pelt, D.M.; Batenburg, K.J.; Sethian, J.A. Improving Tomographic Reconstruction from Limited Data Using Mixed-Scale Dense Convolutional Neural Networks. J. Imaging 2018, 4, 128. [Google Scholar] [CrossRef]

- Candes, E.J.; Tao, T. Near-Optimal Signal Recovery From Random Projections: Universal Encoding Strategies? IEEE Trans. Inf. Theory 2006, 52, 5406–5425. [Google Scholar] [CrossRef]

- Defrise, M.; Vanhove, C.; Liu, X. An algorithm for total variation regularization in high-dimensional linear problems. Inverse Probl. 2011, 27, 065002. [Google Scholar] [CrossRef]

- Zhang, L.; Vandenberghe, S.; Staelens, S.; Lemahieu, I. A penalized Algebraic Reconstruction Technique (pART) for PET image reconstruction. In Proceedings of the 2007 IEEE Nuclear Science Symposium Conference Record, Honolulu, HI, USA, 26 October–3 November 2007; pp. 3859–3864. [Google Scholar] [CrossRef]

- Schön, T.; Römer, F.; Oeckl, S.; Großmann, M.; Gruber, R.; Jung, A.; Del Galdo, G. Cycle Time Reduction in Process Integrated Computed Tomography using Compressed Sensing. In Proceedings of the 13th International Meeting on Fully Three-Dimensional Image Reconstruction in Radiology and Nuclear Medicine (Fully 3D), Newport, RI, USA, 31 May–4 June 2015. [Google Scholar]

- Roemer, F.; Grosmann, M.; Schoen, T.; Gruber, R.; Jung, A.; Oeckl, S.; Del Galdo, G. Differential SART for sub-Nyquist tomographic reconstruction in presence of misalignments. In Proceedings of the 2017 25th European Signal Processing Conference (EUSIPCO), Kos, Greece, 28 August–2 September 2017; pp. 2354–2358. [Google Scholar] [CrossRef]

- Lin, Y.; Samei, E. An efficient polyenergetic SART (pSART) reconstruction algorithm for quantitative myocardial CT perfusion. Med. Phys. 2014, 41, 021911. [Google Scholar] [CrossRef]

- Herman, G.T.; Kuba, A. Discrete Tomography; Birkhäuser Boston: Boston, MA, USA, 1999. [Google Scholar] [CrossRef]

- Benedetto, J.J.; Herman, G.T.; Kuba, A. Advances in Discrete Tomography and Its Applications; Birkhäuser Boston: Boston, MA, USA, 2007. [Google Scholar] [CrossRef]

- Batenburg, K.J.; Sijbers, J. Dart: A Fast Heuristic Algebraic Reconstruction Algorithm for Discrete Tomography. In Proceedings of the 2007 IEEE International Conference on Image Processing, San Antonio, TX, USA, 16 September–19 October 2007; pp. IV-133–IV-136. [Google Scholar] [CrossRef]

- van Gompel, G.; Joost Batenburg, K.; van de Casteele, E.; van Aarle, W.; Sijbers, J. A discrete tomography approach for superresolution micro-CT images: Application to bone. In Proceedings of the 2010 IEEE International Symposium on Biomedical Imaging: From Nano to Macro, Rotterdam, The Netherlands, 14–17 April 2010; pp. 816–819. [Google Scholar] [CrossRef]

- Vlasov, V.V.; Konovalov, A.B.; Uglov, A.S. An a priori information based algorithm for artifact preventive reconstruction in few-view computed tomography. In Proceedings of the 2012 5th International Symposium on Communications, Control and Signal Processing, Rome, Italy, 2–4 May 2012; pp. 1–5. [Google Scholar] [CrossRef]

- Banjak, H.; Costin, M.; Vienne, C.; Guillamet, R.; Kaftandjian, V. Iterative CT reconstruction on limited angle trajectories applied to robotic inspection. AIP Conf. Proc. 2017, 1806, 020009. [Google Scholar] [CrossRef]

- Six, N.; de Beenhouwer, J.; Sijbers, J. poly-DART: A discrete algebraic reconstruction technique for polychromatic X-ray CT. Opt. Express 2019, 27, 33670–33682. [Google Scholar] [CrossRef]

- Frenkel, D.; Six, N.; de Beenhouwer, J.; Sijbers, J. Tabu-DART: A dynamic update strategy for efficient discrete algebraic reconstruction. Vis. Comput. 2023, 39, 4671–4683. [Google Scholar] [CrossRef]

- Bussy, V. Integration of a Priori Data to Optimise Industrial X-Ray Tomographic Reconstruction. Ph.D. Thesis, INSA de Lyon, Villeurbanne, France, 2024. [Google Scholar]

- Laurentini, A. The visual hull concept for silhouette-based image understanding. IEEE Trans. Pattern Anal. Mach. Intell. 1994, 16, 150–162. [Google Scholar] [CrossRef]

- Schrapp, M.; Scharrer, T.; Goldammer, M.; Rupitsch, S.J.; Sutor, A.; Ermert, H.; Lerch, R. Artifact reduction in non-destructive testing by means of complementary data fusion of x-ray computed tomography and ultrasonic pulse-echo testing. Meas. Sci. Technol. 2013, 24, 125403. [Google Scholar] [CrossRef]

- Stayman, J.W.; Otake, Y.; Prince, J.L.; Khanna, A.J.; Siewerdsen, J.H. Model-based tomographic reconstruction of objects containing known components. IEEE Trans. Med. Imaging 2012, 31, 1837–1848. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Yu, H.; Mou, X.; Zhang, L.; Hsieh, J.; Wang, G. Low-dose X-ray CT reconstruction via dictionary learning. IEEE Trans. Med. Imaging 2012, 31, 1682–1697. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Ravishankar, S.; Long, Y.; Fessler, J.A. PWLS-ULTRA: An Efficient Clustering and Learning-Based Approach for Low-Dose 3D CT Image Reconstruction. IEEE Trans. Med. Imaging 2018, 37, 1498–1510. [Google Scholar] [CrossRef]

- Schulze, S. Radiographie im Bauwesen—Einsatzmöglichkeiten in der Praxis im Rahmen der ZfPBau. Beton- Stahlbetonbau 2022, 117, 1008–1017. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herl, G.; Wittl, S.; Jung, A.; Handke, N.; Weiss, A.; Eberhorn, M.; Oeckl, S.; Zabler, S. RoboCT: The State and Current Challenges of Industrial Twin Robotic CT Systems. Sensors 2025, 25, 3076. https://doi.org/10.3390/s25103076

Herl G, Wittl S, Jung A, Handke N, Weiss A, Eberhorn M, Oeckl S, Zabler S. RoboCT: The State and Current Challenges of Industrial Twin Robotic CT Systems. Sensors. 2025; 25(10):3076. https://doi.org/10.3390/s25103076

Chicago/Turabian StyleHerl, Gabriel, Simon Wittl, Alexander Jung, Niklas Handke, Anton Weiss, Markus Eberhorn, Steven Oeckl, and Simon Zabler. 2025. "RoboCT: The State and Current Challenges of Industrial Twin Robotic CT Systems" Sensors 25, no. 10: 3076. https://doi.org/10.3390/s25103076

APA StyleHerl, G., Wittl, S., Jung, A., Handke, N., Weiss, A., Eberhorn, M., Oeckl, S., & Zabler, S. (2025). RoboCT: The State and Current Challenges of Industrial Twin Robotic CT Systems. Sensors, 25(10), 3076. https://doi.org/10.3390/s25103076