1. Introduction

Waste management, a crucial pillar of our global environmental infrastructure, has undergone remarkable evolution and enhancement over time [

1,

2]. One area commanding attention focuses on the optimization of waste sorting facilities. Various emerging technologies, like robotics, sensor technology, and AI-driven optimization, have begun to contribute to the automation and streamlining of sorting processes [

1,

3].

In waste sorting facilities, materials are separated and typically stored in dedicated bunkers. These bunkers are connected via conveyor belts to mechanical presses, which compress the sorted materials into uniform bales. These compressed bales become valuable raw materials for various industries, fostering a circular economy by supporting the production of new goods. Standardizing their size turns out crucial for efficient storage and transportation logistics. A critical aspect of waste sorting facilities revolves around accurately monitoring and quantifying the volume of waste within the storage compartments after the sorting process is completed.

Using ultrasonic sensors for distance measurement as a precursor to volume determination offers a cost-effective alternative to employing large-scale weighing, being hardly practicable in dynamic systems with multiple large bunkers [

4,

5]. These sensors function by emitting ultrasonic waves and measuring the time taken for the emitted wave to rebound after hitting the object’s surface [

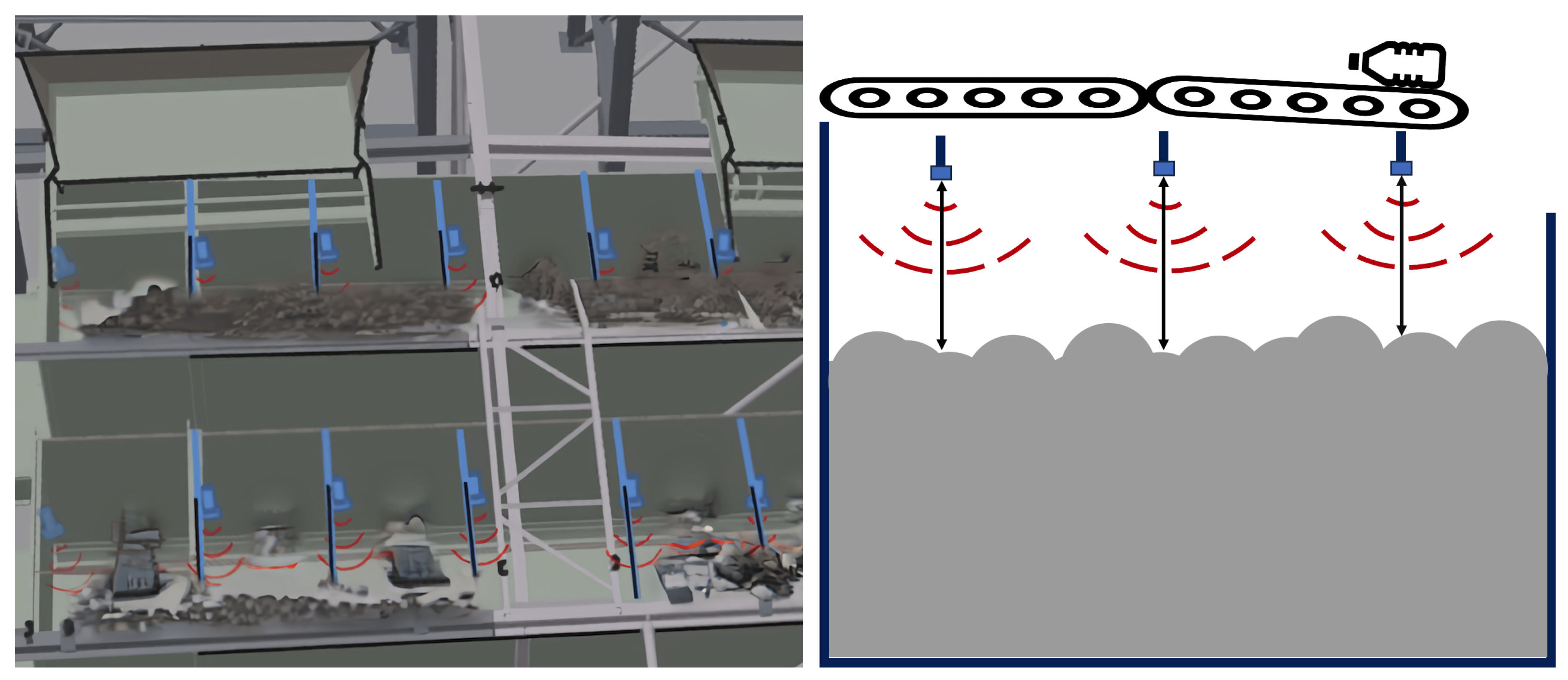

6]. Given the known speed of sound in the air, the calculation of distance to the object becomes possible. In a more complex setup, using multiple sensors in a row-like arrangement allows for a rudimentary representation of the waste pile, thus providing an estimate of its volume (see

Figure 1).

Despite the utility of ultrasonic sensors, they introduce a unique set of challenges. Various factors such as (1) the irregular shapes of waste piles, (2) variability in waste material composition affecting the propagation of ultrasonic waves, (3) differing densities of waste material, and (4) inherent or external noise all can impact the accuracy of volume measurements [

7,

8]. Waste piles within bunkers are inherently dynamic, constantly evolving in both size and shape due to ongoing waste inflow, shifting, and removal. This dynamic nature poses significant challenges when attempting to precisely and consistently measure the volume using point-distance measurements. The distance measurements only give limited information about the total volume distribution. When motion occurs inside the bunker, for example during pile shifting under the input area or emptying, it may lead to temporarily unreliable volume estimates. Regarding the effect of inherent noise on sensors, it has been stated that even distinct sensors of the same model may show unique qualities [

7]. Further, functioning within a dynamic and noisy environment filled with auditory disturbances can substantially distort the sensor readings. These disturbances could stem from the roar of heavy machinery to the impact noise of waste material dumped into the bunker, or even changes in temperature and humidity [

8]. The volume estimates are calculated by an algorithm, taking into account all current sensor readings from the row per bunker. To mitigate the negative effect of outlier values caused by sensor malfunctions, the use of advanced signal processing techniques becomes necessary, aiming to filter out noise and outliers to extract true distance measurements [

7,

8,

9]. Furthermore, material-specific characteristics of the consistency between input and output volume are examined.

In this paper, we aim to explore some challenges in detail and suggest some approaches to enhance the efficiency and accuracy of waste volume determination and handling. This article covers related research in this field, presents typical data structures relevant to this context, addresses specific challenges, and considers potential solutions while outlining future directions for the field. We investigate in detail whether and to what extent the shortcomings of ultrasonic sensors can be compensated by elaborate data post-processing using machine learning methods.

In this paper, we delve into specific challenges associated with improving efficiency and accuracy in waste volume determination and handling. We present related research in this field, typical data structures relevant to this context, specific challenges, and potential solutions, while outlining future directions for the field. Our research identifies a critical need for better measurement techniques amidst noise and material variability, while also showing that accurate bale length estimation remains elusive, despite precise volume and weight data. We investigate in detail whether and to what extent the shortcomings of ultrasonic sensors can be compensated by an elaborate data post-processing using machine learning methods.

Our work thus underscores the need for ongoing development in waste sorting technologies to overcome these limitations.

2. Related Research

Research in sensor technology and machine learning algorithms lays the groundwork for diverse applications, including waste management. This section reviews key literature with a connection to waste sorting in three areas: sensor usage, machine learning algorithms, and computer vision techniques.

2.1. Usage of Sensors

To obtain an estimate of the volume, distance measurements can be utilized, commonly implemented through the use of low-cost ultrasonic (US) and optical sensors [

10]. Ultrasonic sensors emit sound waves to precisely measure distances, while laser sensors rely on light and the reflection principle for distance calculation. Studies have demonstrated that laser sensors are more accurate and exhibit lower error rates in distance measurements across various surface types [

11,

12]. During comparative testing of both optical and ultrasonic sensors, each sensor type manifested distinctive accuracy profiles contingent upon specific material under scrutiny [

10]. Numerous research efforts address the advancement of IoT (“Internet of Things”)-enabled smart waste management systems, aiming to address the issue of overflowing garbage bins and its associated environmental pollution [

13]. This research involves augmenting traditional waste containers with a combination of ultrasonic, laser, and weight sensors, facilitating the real-time monitoring of waste levels [

14]. Thakker et al. [

2] described a system named “Smart Garbage Bin”, which notifies when it nears full capacity, facilitating timely waste collection and mitigating garbage overflow, thus addressing environmental and health concerns. Additionally, the authors propose a method employing Near-Infrared (NIR) spectroscopy to differentiate between five types of non-biodegradable plastic resins. This separation process allows for the extraction of biodegradable waste, which can subsequently be utilized for biogas production [

2].

Another proposed system by Aguila et al. incorporates ultrasonic sensors for volume measurement, load cells for weight monitoring, and an Arduino Uno microcontroller for system control. The researchers in this study further optimized the placement of ultrasonic sensors to achieve the highest data accuracy [

14].

2.2. Usage of Algorithms and Machine Learning

Characterizing the volume of bulky materials commonly found in waste poses a challenging task addressed by multiple approaches, including formulating mathematical models that describe the volume and shape of large granular piles of bulk materials in bunkers [

15].

The exploration of machine learning applications currently emerges as another relevant theme in the literature, offering alternative innovative approaches to traditional solid waste management built upon mechanistic models and rigid algorithms. These conventional approaches often fall short, especially when dealing with limited data. In such situations, AI-powered models may yield more promising and effective solutions [

16].

Rutqvist et al. [

1] offer a compelling instance of this approach. In their work, the authors successfully utilize automated machine learning to detect when recycling containers are emptied, based solely on sensor readings. This implementation significantly improves accuracy and recall rates. Their highest-performing solution leverages a Random Forest classifier, resulting in enhanced predictions for the emptying times of recycling containers.

Bae et al. [

9] introduce a unique data processing algorithm for the smoothing and outlier removal of water level data gathered by ultrasonic sensors. This approach effectively addresses the issue of random errors, such as those caused by water waves, often found in data collected from dynamic environments like waste management sites. The introduced algorithm demonstrates promising outcomes, effectively handling outliers and substantial random error, which contributes to improved accuracy and usability.

Sahoo et al. [

8] tackle the challenge of enhancing sensor measurement precision. Their novel approach employs a modified neural network architecture, the Levenberg–Marquardt backpropagation artificial neural network (LMBP-ANN), to mitigate the impacts of environmental conditions and noise on distance measurements made with low-cost ultrasonic sensors. The proposed model reduces measurement error to within ±1 cm for distances ranging from 2 cm to 500 cm and extends the maximum standard operating range of the ultrasonic sensor from 400 cm to 500 cm. This significant enhancement in measurement accuracy and range demonstrates its applicability in contexts where manual and contact-based distance measurements remain challenging.

In the industrial context, Bowler et al. [

7] stress the importance of ultrasonic sensors in optimizing manufacturing processes during the fourth industrial revolution. Using supervised machine learning models, they aim to connect ultrasonic sensor data with valuable manufacturing insights. However, this requires labeled data, which can often be challenging to obtain in factory settings. To address this, they explore two domain adaptation methods that enable model transfer without labeled data. Their research demonstrates the effectiveness of these methods in monitoring industrial processes, highlighting the potential of combining ultrasonic measurements with transfer learning techniques.

2.3. Usage of Computer Vision and Related Methods

An alternative to distance measurements includes the utilization of stereo camera vision systems coupled with computer vision. The latter has attracted growing attention in the realm of waste sorting, capitalizing on advancements in computational power and algorithms [

17].

One noteworthy application of computer vision is its combination with hierarchical deep learning to enhance waste detection and classification [

18]. However, a possible limitation of CV lies in differentiating materials that share similar appearances [

17].

Stereo cameras may, in turn, exhibit suboptimal performance under specific conditions such as “plain walls, glass surfaces, or poor lighting” [

19]. Integrating optical and ultrasonic sensors could therefore enhance the overall capabilities of the vision system.

Other cutting-edge technologies, such as LIDAR (“Light Detecting and Ranging”) and 3D Laser scanners, are currently under development by various companies. For example, LIDAR scanners have been employed to monitor the vegetative growth in strawberry plants, including volume estimates from 3D point clouds [

20]. These technologies may be applied to accurately determine the volume of different materials within industrial bunkers and conveyor belts. However, it is worth noting that these new scanners are significantly more expensive than US sensors, preventing them from being a comprehensive alternative for many applications.

In sum, these studies spotlight strategies and techniques that harness sensor technology in optimizing volume determination for industrial processes. The overlapping themes of machine learning applications, advanced data processing techniques, and improvements to sensor-based measurement accuracy signal the potential for substantial innovation in this field. Future research can further fine-tune these methods for specific applications and contexts, building upon the ideas and discoveries showcased in these studies.

3. US-based Volume Determination

To understand the challenges associated with volume determination based on measurements from ultrasonic sensors, one must first delve into the underlying available data and its characteristics. The data repository analyzed in this study encompassed details from three distinct European facilities. This data pertained to components such as bunkers, conveyor belts, and presses and included categories like sensor measurements, activity status, energy consumption, and calculated volumes, each paired with a timestamp (refer to

Appendix A,

Table A1 and

Table A2 for exemplary categories).

In those waste management facilities, multiple bunker dimensions (e.g., 10 m × 2 m × 1.8 m) and filling positions (left, middle, right), which determine the entry point of the sorted waste into the bunker, were observed. To monitor these bunkers effectively, multiple ultrasonic (US) sensors of the model microsonic mic + 340 were strategically installed. These devices utilize the principle of echo propagation time measurement to determine distances, featuring an operational range of up to 3400 mm. The sensors demonstrate a resolution between 0.18 mm and 1.5 mm and operate at a transducer frequency of 120 kHz [

21]. They were positioned centrally above each bunker in regular intervals at a height of approximately 200 cm. This arrangement ensured minimal interference between sensors, optimizing their performance for accurate data collection. The number of sensors per bunker varied, depending on the size of the bunker, with an average allocation of approximately ten sensors per bunker.

The data structure was largely constituted of metrics related to waste material processing. A critical aspect was the calculation of bunker volume, derived from multiple readings from ultrasonic sensors. An algorithm designed to manage partial sensor outages was used to estimate volume based on sensor readings, thus enhancing estimates’ accuracy and reliability (see

Appendix A, Algorithm A1). To calculate the average material height, it integrates valid sensor readings and, in case of an invalid reading, the algorithm deduces plausible values using data from neighboring sensors. After calculating the mean height, multiplication by the bunker’s width and length yields the volume estimate. Ensuring accurate volume estimates is pivotal. It helps in determining the optimal time to empty the bunker, guaranteeing that both the conveyor belt and press are available and that an integer number of bales can be produced.

We were particularly interested in three specific relationships: bunker-to-belt volume, bunker-to-bale volume, and belt-to-bale volume. These relationships are defined as follows:

Observations indicate that the volume measured on the belt using lasers tends to be a more accurate predictor for operating the press than the volume measured in the bunker. However, this belt volume data is available only after the bunker volume has already initiated the emptying process. For earlier estimates of , we can derive the factor for each bunker and material type from previous emptying events. This prediction method relies on the median of the last 10 values of recorded for the same material.

The volume inside the bunker (

) is notably larger than that of a bale (

). The pressing process compacts the loose material from the bunker, effectively removing air. For example, 10 m

3 of material in the bunker might compress down to a 1.4 m

3 bale, or in some cases like films, 30 m

3 may be compressed to the same bale volume. After the pressing process, measurements were taken to determine both the length and weight of the current bale. The focus of this study was to address the raw sensory data from bunkers filled with various waste materials (see

Appendix A,

Table A3).

The datasets examined in this study did not contain missing values, except specific periods during which the automatic bunker management system was deactivated and hence no data was logged. However, it is important to acknowledge that several sensors exhibited extreme unreliability, generating substantial outliers. These outliers should be treated as missing values. This adds complexity to the analysis as these implausible values must be identified. Timestamps were consistently maintained, enhancing the temporal coherence of the dataset. The data ranged from 2022 to 2023, with each dataset encompassing approximately 4 to 6 months. Nevertheless, certain metrics, especially energy data, remained unrecorded in the dataset used for our analysis. Moreover, distinct recorded values among all material types exhibited significant deviations from the anticipated ranges.

4. Challenges

Determining volume in waste sorting facilities is faced with numerous challenges, each requiring in-depth analysis and distinct solutions.

4.1. Volume Ratio Is Highly Unstable

Insights into the volume flow dynamics are given by a specific bunker storing PET from a waste sorting facility with two presses over approximately six months (a few hundred emptying cycles), shown in

Figure 2. We observed distinct differences between the volume measured inside the storage bunker using ultrasonic sensor technology, and the volume measured on the conveyor belt with laser sensors, of which the latter mostly measured lower volumes (see

Figure 2a). The figure further illustrates the frequency of press changes, revealing that one press consistently exhibited higher usage than the other. However, this pattern was not uniform across all bunkers (see

Figure 2b). We could observe fluctuations around the average ratio of volume between the bunker and belt. Pronounced spikes in the data were observed (see

Figure 2c).

The number of bales produced during each baling event typically ranged between 2 and 4 (see

Figure 2d).

4.2. US Sensors Show Serious Fluctuation

A primary challenge involves precisely gauging the bunker volume to determine the optimal time of withdrawal.

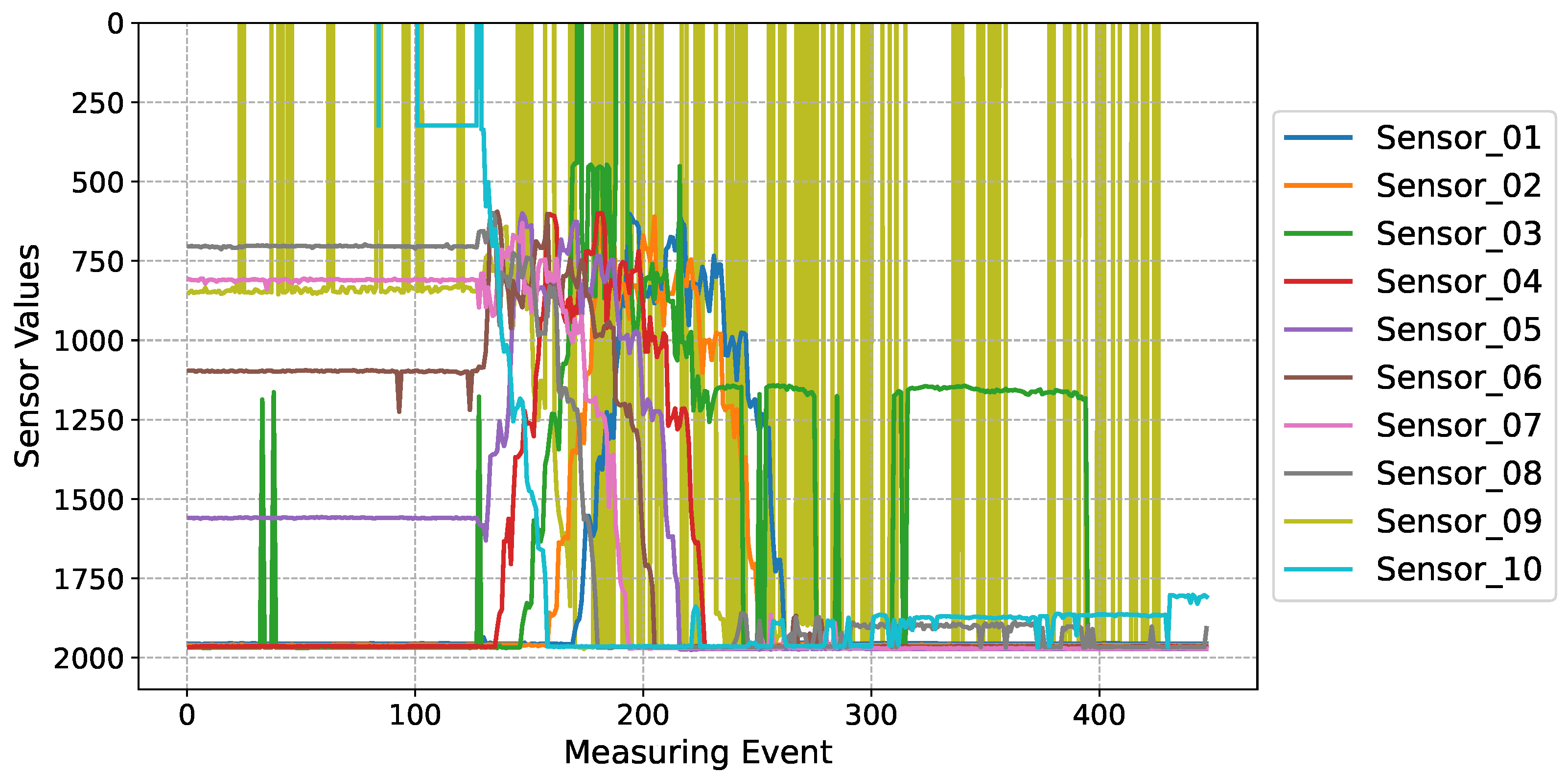

Figure 3,

Figure 4 and

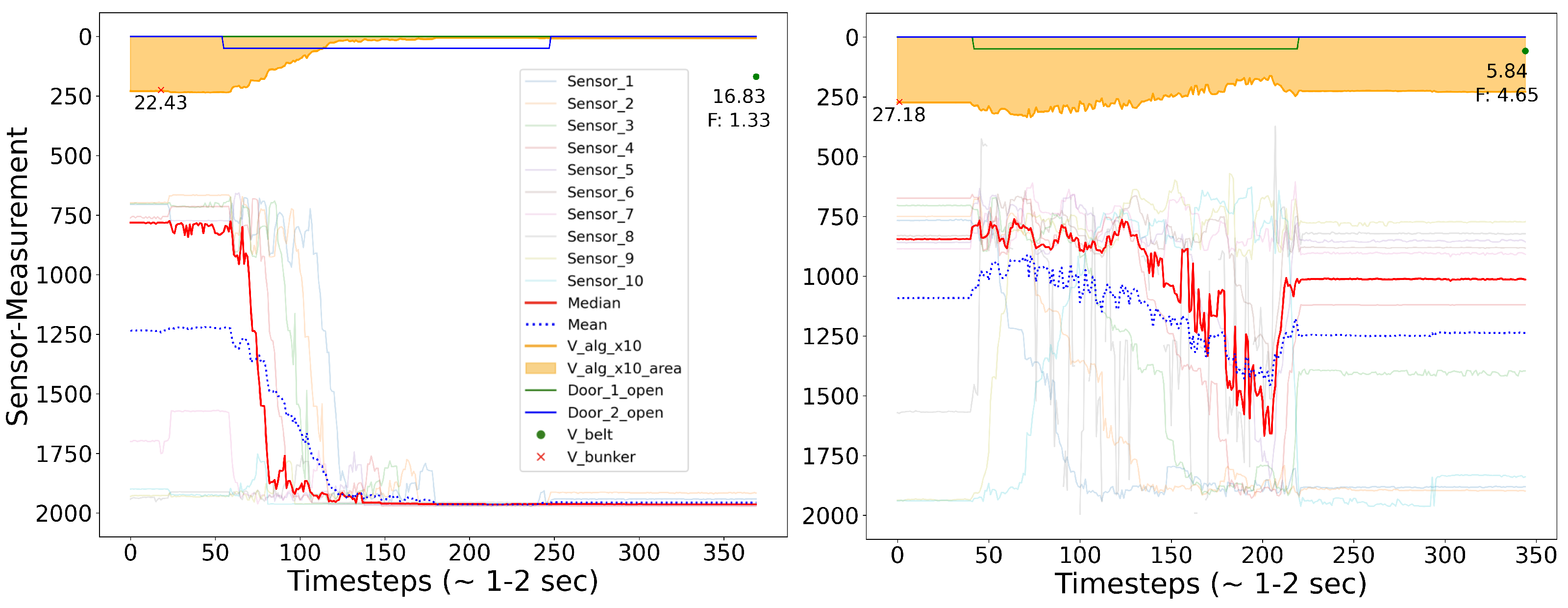

Figure 5 augment our grasp of the problems related to bunker occupancy by offering a detailed picture of sensor readings. The continuous filling of the bunker with regular shifting of the material inside the bunker by moving the bunker belt can be seen in

Figure 3, also showing the spikes of a particular sensor during such movements inside the bunker. Frequent values above or below the given range by certain sensors were regularly observed, as e.g., seen for Sensor 9 in

Figure 4. For some materials, multiple sensor malfunctions were observed in parallel. The variance in reading quality increases the complexity and unpredictability of sensor measurements, complicating the task of maintaining consistency.

Figure 5 depicts the sensor behavior during the bunker emptying process. When the bunker volume exceeded a certain threshold, a door opened for emptying. However, even after the emptying process, some cases were observed (lower plot in

Figure 5) where sensors still indicated a large amount of material remaining inside the bunker. It is important to note that material is continuously added to the bunker, even during the emptying process, thus preventing it from becoming empty. These malfunctions may play a crucial role in understanding deviations in the volume ratio.

Another challenge arose when emptying bunkers with two presses and corresponding doors. By continuously adding additional waste into the bunker, when opening the door closer to the waste entry point, new waste was automatically added on top of the volume being transported to the press. However, opening the opposite door could lead to trailing waste crowding the bunker’s bottom, resulting in a reduced maximum filling level.

4.3. Effect of Multiple Factors (Material, Bale Number)

Multiple factors, including the number of bales pressed per baling cycle and the material type, are important for understanding volume ratios. The distribution of the number of bales produced per emptying cycle per material is illustrated in

Figure 6. Despite some materials having a limited number of data points, a consistent trend emerged, showing that most withdrawals result in an average of 1 to 2 compressed bales.

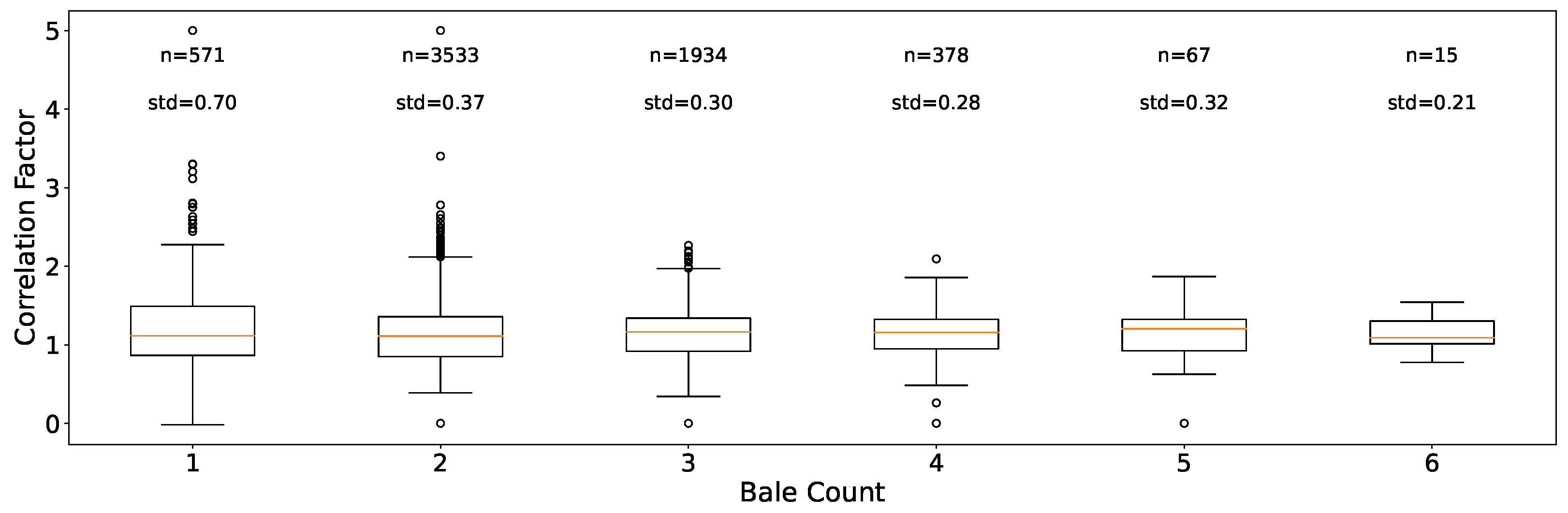

The relationship between the volume ratio and the number of bales pressed at a waste sorting facility is presented in

Figure 7. We observed a tendency in the standard deviation to decrease as the number of bales pressed increased.

This finding gains significance when comparing it with information from

Figure 6, which reveals that often lower bale numbers (e.g., 1 or 2) are pressed, resulting in greater variability in the volume ratio.

In

Figure 8, we observe the volume ratio in relation to material type at our waste sorting facility. Certain materials exhibited more significant variations in their volume ratios, which may be attributed to physical properties unique to each material. Distinct groups, like PE, exhibit similar tendencies.

4.4. Previous Material Influences Current Pressing

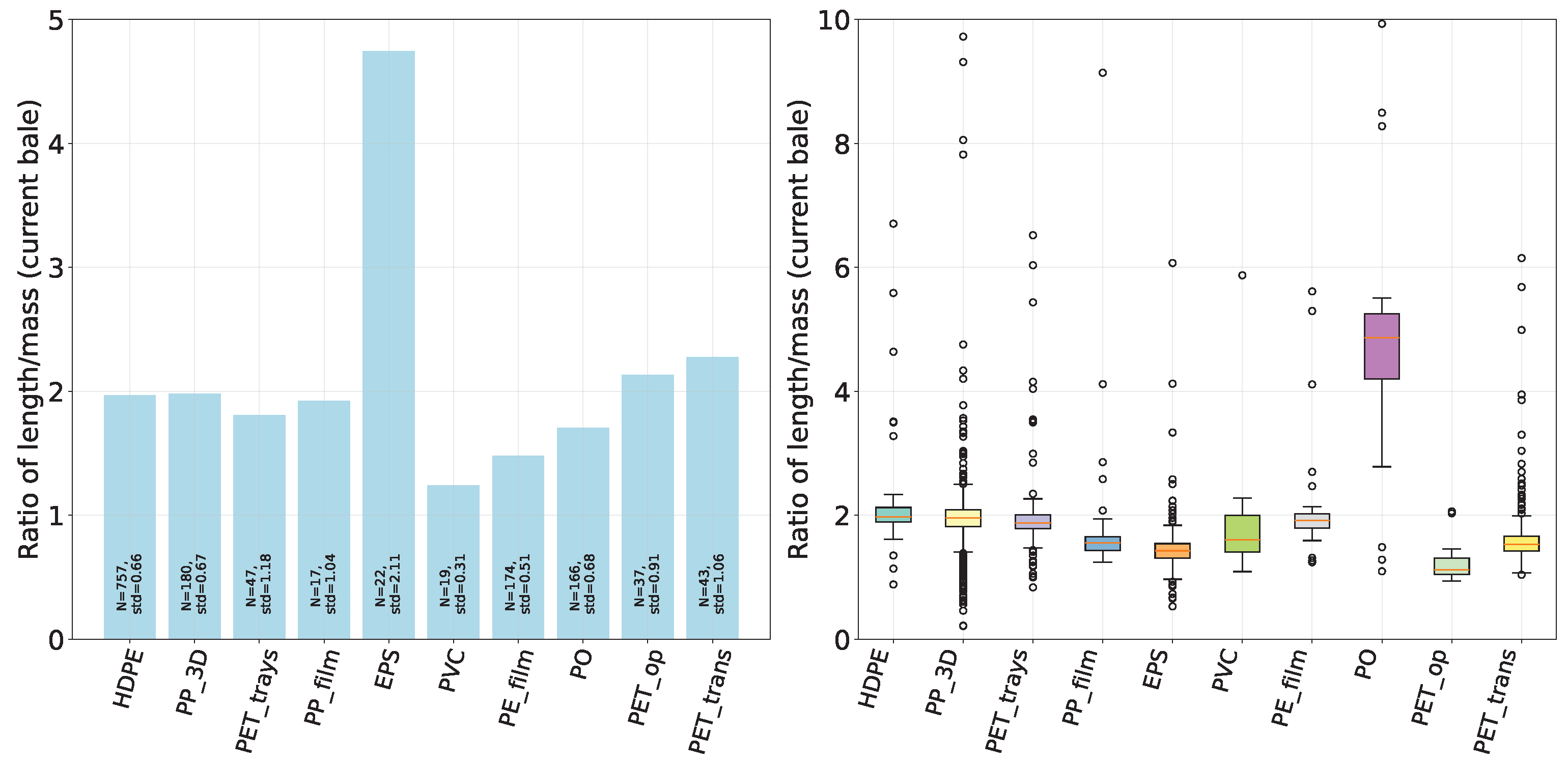

To further analyze the effect of material type on the final volume, we focus on pressed bales. In a setting where the current bale is pressed against the previous bale, the material type of the predecessor may have an impact on the density of the current bale. A comprehensive visualization of the impact of this previous bale material on the Length-to-Mass Ratio of the newly pressed bale (here of type HDPE) can be found in

Figure 9. The subfigure on the right suggests that outliers can manifest even when the material is pressed against its same kind. In the shown case, some materials (e.g., EPS) appear to exhibit a more pronounced influence on the resulting length-to-mass ratio than others. This trend has been observed in other materials as well and highlights the challenges in achieving consistent outcomes with variable material inputs.

The impact of the previous bale material type on subsequent bale density becomes evident in

Figure 10. Specifically, harder materials (e.g., HDPE) from preceding bales appear to result in more compressed bales than soft materials (e.g., foil), as indicated by the pronounced mean ratio of length to mass on the left side. However, the subfigure on the right reveals a large number of outliers within a broad range, highlighting data variability.

An analytical evaluation of volume ratio predictions derived from the median of the last ten actual ratios can be found in

Figure 11. We observed material-specific variances in predictive accuracy, with PET manifesting the most pronounced error. When using this approach, we found that each material showed a distinct time-window size for maximal prediction fidelity. Employing the median consistently yielded superior results compared to the mean. Grouping baling events by identical bale numbers was notably less efficacious than grouping events by the same press, in a bi-press setup.

4.5. Inconsistent Ratio between Mass and Length

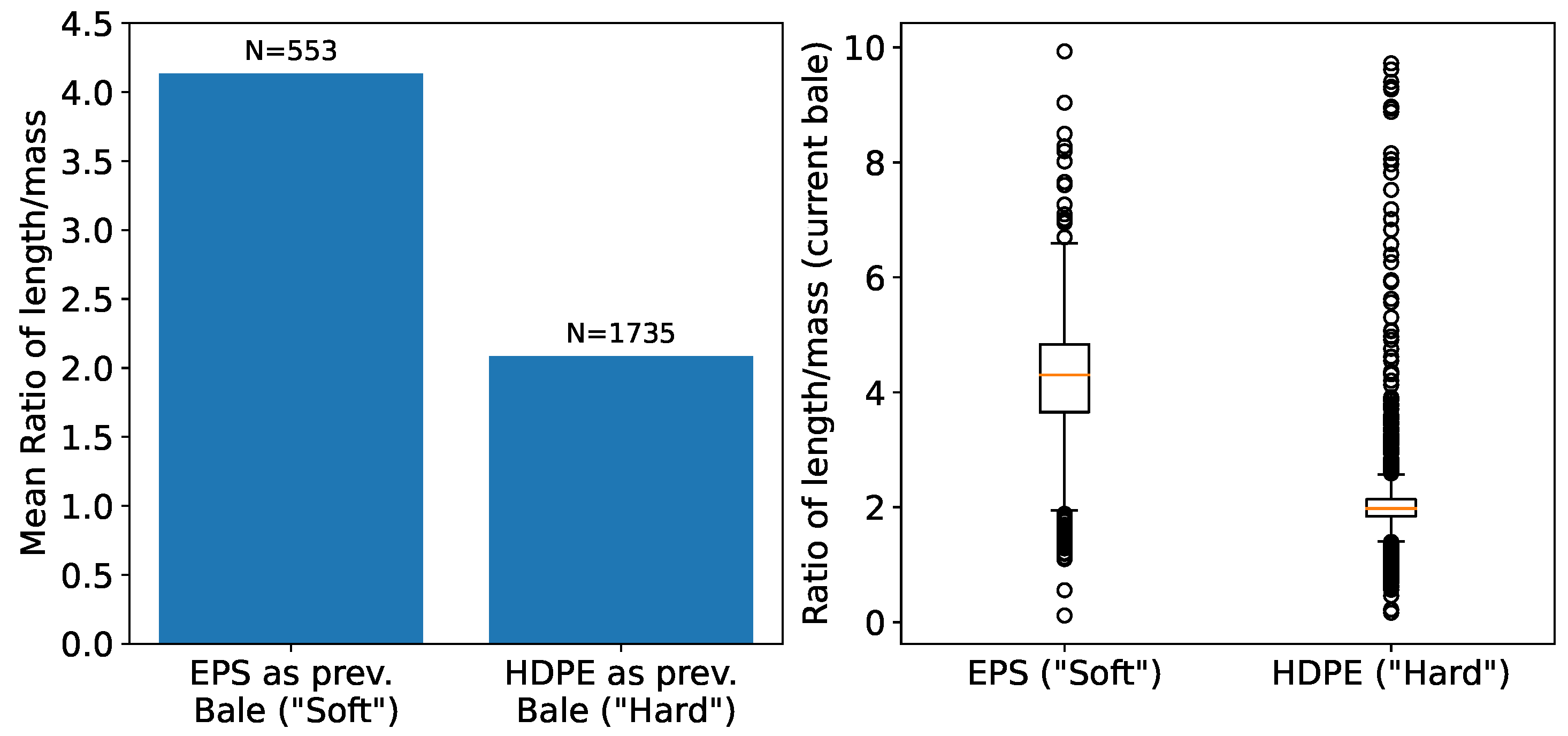

To reliably achieve a bale length near the configured optimum implies that a specific volume of a particular material type yields a predictable bale length. However, upon analyzing the ratio between the final mass and the weight of individual bales within a combination of all given material types, we have noticed deviations from the estimated regression line. This phenomenon has been consistently observed across multiple distinct facilities, as depicted in

Figure 12A,B. When we examined this ratio for individual materials, we encountered a similar level of uncertainty in the data (

Figure 12C,D). Reviewing the residual plots, one notices the uncertainty most prominently, as illustrated in the middle of

Figure 12C,D. Considering these aspects collectively, it becomes apparent that although relevant data is generally accessible, its quality falls short in several key areas, preventing effective and meaningful control.

5. Machine Learning Approach

5.1. Volume Ratio Prediction

We perceive a predictive tool for the upcoming volume ratio as a potential solution for part of the problems at hand. Our objective was to emulate the original distribution of the actual volume ratio using a machine learning model.

We employed the Extreme Gradient Boosting (XGBoost) algorithm [

22] to evaluate the significance of various predictive features across different materials. These features encompassed both present and historical data points, including current metrics such as “bunker volume” and “estimated bale count”, as well as temporal aspects like the “median of the last ten ratios” and the “time difference to the last baling of the same material”.

The preparation of our dataset involved the selection of pertinent columns to avoid data leakage, the generation of temporal additional features from the time-series data, and the exclusion of rows holding missing values. We partitioned the data into an 80% training set and a 20% testing set, following which the hyperparameters for each model were meticulously tuned through the Optuna framework [

23], conducting 100 trials per model with variations in booster type, learning rate, and the number of estimators. Validation was conducted via Rolling Mean Cross-Validation with five groups, utilizing the “TimeSeriesSplit” function from the Scikit-Learn package (version 1.4.1, [

24]), with mean absolute error (MAE) serving as the evaluation metric. The predictive performance was assessed by comparing the MAE between the actual volume ratio

and the predictions from both the optimally tuned machine learning model and a baseline “Median_10” approach.

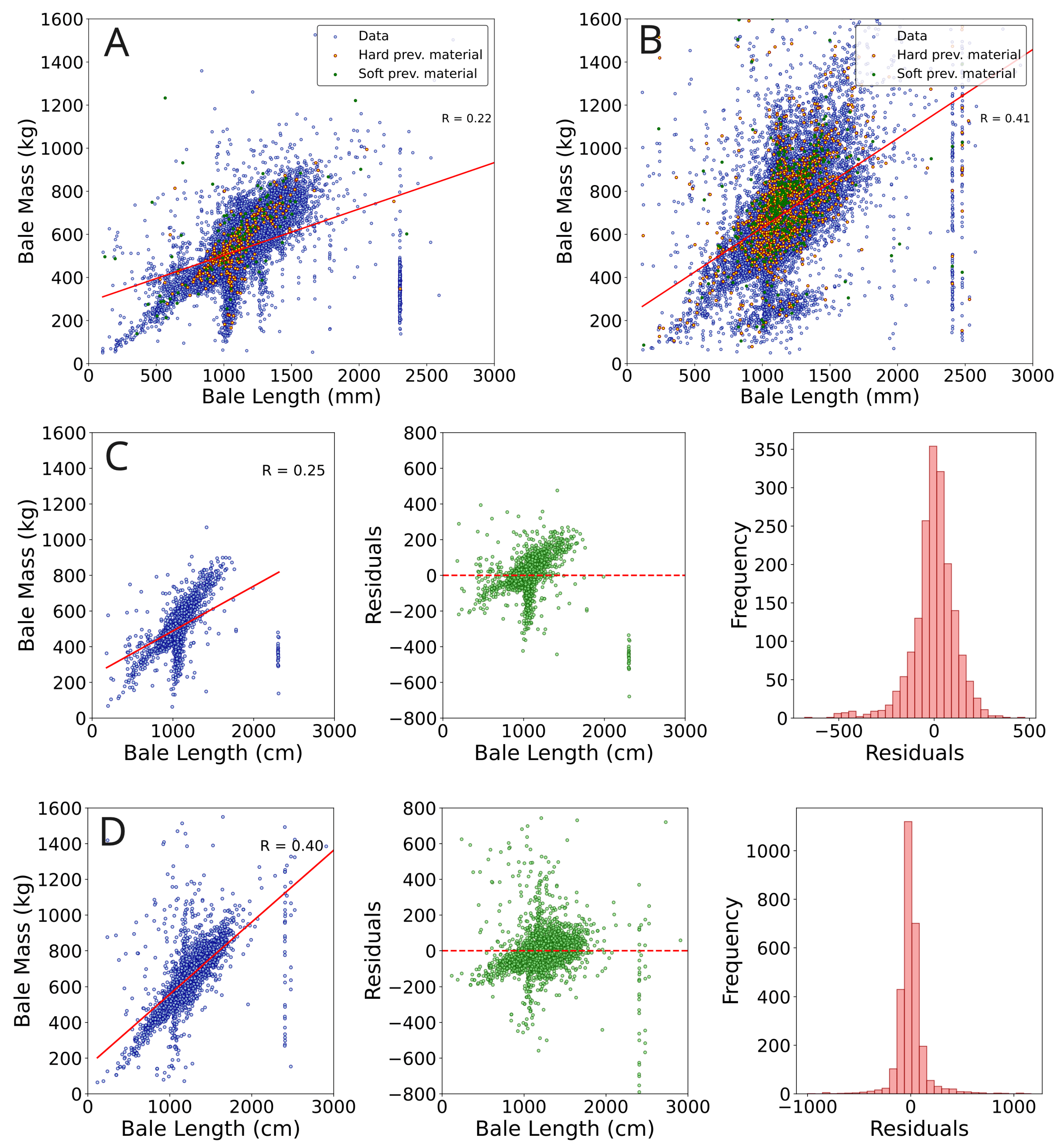

The comparative outcomes of all per-material models developed to forecast the current ratio factor are illustrated in

Figure 13. Interestingly, our predictive models scarcely outperformed the simple median of the ten most recent ratios, indicating the complexity and variability inherent in the data. The analysis revealed considerable variation in the ranking of feature importance across different materials, underscoring the volatile nature of the patterns observed.

Although neither the machine learning models nor the median approach perfectly captured the distribution of real volume ratio values, the latter consistently demonstrated superior performance in modeling accuracy compared to the XGBoost model, as detailed in

Appendix A,

Table A4. Subsequent testing with alternative models, including Linear Regression [

25] and Random Forest Regression [

26], yielded analogous results, further emphasizing the challenge of accurately predicting volume ratios in complex material handling environments.

5.2. Bale Length Prediction

To evaluate the inconsistency in the ratio between final bale mass and length (see

Figure 12, we employed a Random Forest model [

26] to predict the aggregated bale length per emptying and identify the most important features.

The model integrated various features including volume metrics (bunker and belt volumes), baling process specifics (total number of bales and total mass of bales), and time-series data (median ratio of bunker to belt volume from the ten latest measurements, and the elapsed time since the last baling process for the specific material). Before the model training phase, we conducted a data cleaning process to eliminate erroneous data and remove datasets with missing entries or insufficient size. The dataset was divided into an 80% segment for training and a 20% segment for testing without shuffling. The model’s performance was evaluated using the mean absolute error (MAE) metric, comparing the predicted bale length to the actual measured values. The Random Forest Regressor [

26] yielded more accurate predictions than the XGBoost algorithm [

22] in this case. The two most relevant features averaged across all models were the “total mass of bales” and the “number of bales”.

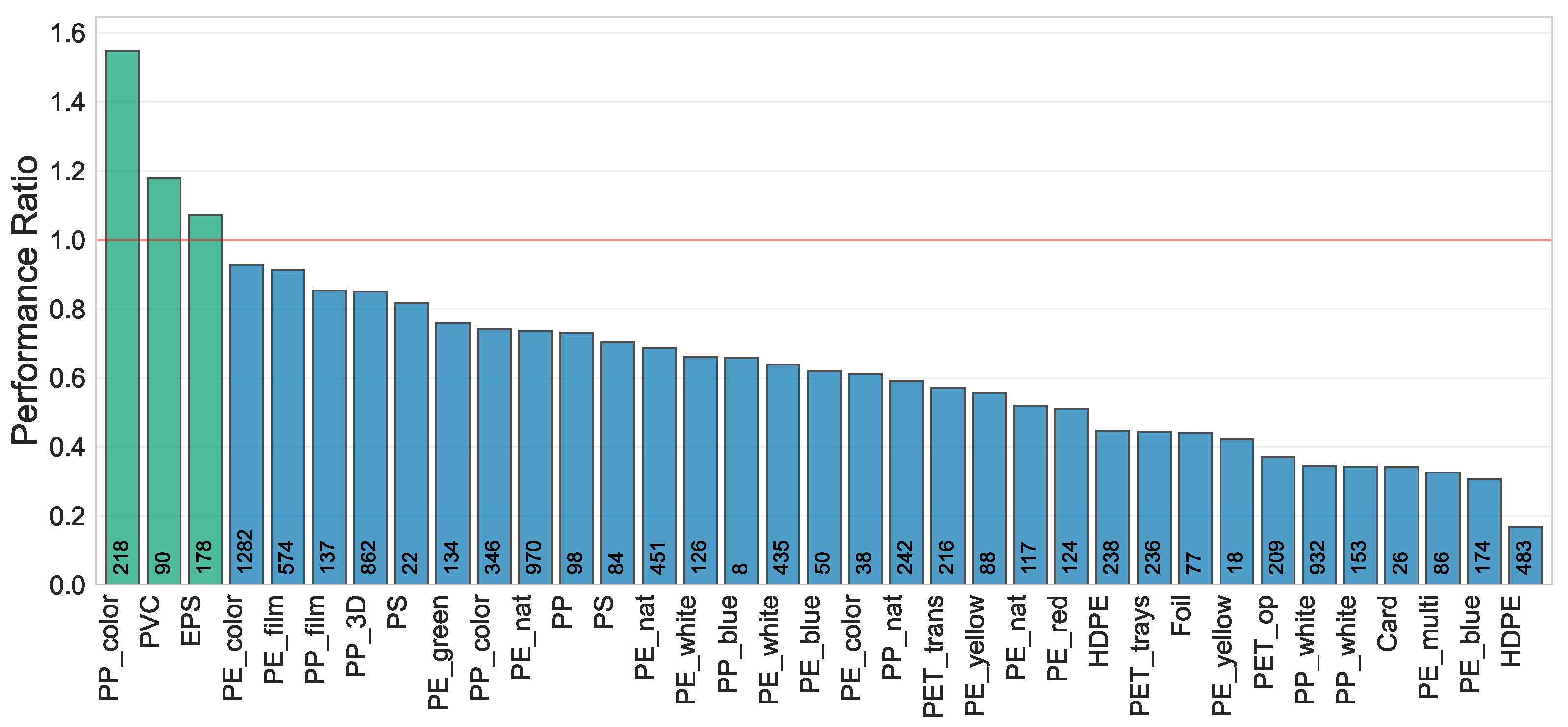

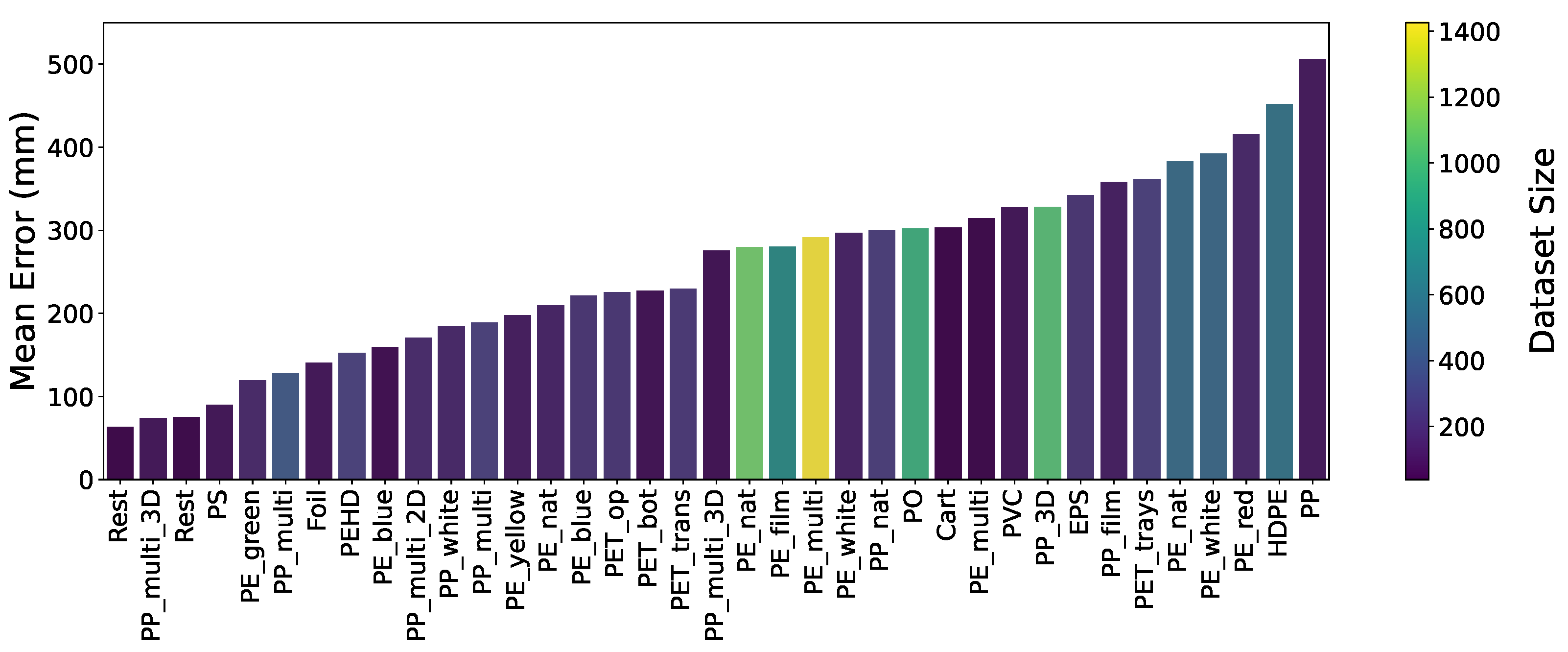

The findings, illustrated in

Figure 14, highlight the Random Forest models’ MAEs for various materials. The data aggregation pertains to baling processes that resulted in anywhere from one to five bales. It is important to note that the available data for most combinations was severely limited. The analysis revealed that the model could predict bale lengths with a mean error of approximately 24.6 cm (with a standard deviation of about 10 cm) across different materials. We further observed that the level of MAE tended to increase with an increasing number of bales. The ability of the model to predict with this insufficient level of accuracy, despite being trained on features not available at the critical decision-making point of emptying the bunker, underscores the complexity of the system under study and the need to search for material-specific solutions.

6. Future Work

The results of this examination underline the necessity for further exploring strategies to enhance measurement technology in waste sorting facilities.

6.1. Sophisticated Sensor Technology

To ensure high-quality bale output from the sorting process, an in-depth analysis of output material volumes becomes essential. Incorporating more accurate level measurements within the bunker by diversifying the sensor suite, albeit potentially higher in cost, could deliver more precise information about current material quantities. The ultrasonic sensors referenced in this study focused on the highest point, while other models may provide more comprehensive data on the 3D surface [

20]. Another idea to overcome the challenge of measuring uneven surfaces may involve the installation of sensors before waste entry, above each bunker’s input conveyor belt.

When dealing with different material types, evaluating customized sensors for specific materials may be necessary. This process involves setting up potential analysis devices and confirming data from practical plants. To identify and address substantial deviations from current volume predictions, one may consider installing cameras on selected bunkers and conveyor belts. These cameras can be mapped to the data, capture critical situations, and provide valuable insights for refining the pipeline. An experimental study found that image analysis effectively determined waste composition, showing a strong correlation with physical sorting [

27]. Using information about the waste composition may be a promising feature for predicting the volume and length of the bale.

6.2. Algorithms and Machine Learning

The current algorithm used for estimating the volume based on distance measurements from US sensors (see

Appendix A, Algorithm A1) may be optimized by considering past sensor readings when detecting erroneous values, given that the belt inside the bunker did not move since and the profile of the waste remains the same. Another approach might include the application of Kalman filters for obtaining a volume estimate from several noisy sensor readings. As a recursive algorithm, Kalman filters continuously measure the state of a dynamic system, where all variables change over time [

28]. This method, in conjunction with ultrasonic sensors, could potentially address the issue of noise and other uncertainties in the measurement system [

29]. Key considerations for this approach include sensor accuracy, system model accuracy, initial state estimation, noise characterization, sampling rate, limited data, and potential nonlinearities in the relationship between measurements and volume.

Time series forecasting methods could also offer a valuable approach for predicting future waste volume based on historical data. Techniques such as auto-regressive integrated moving average (ARIMA) or Long Short-Term Memory (LSTM) neural networks could provide viable solutions, given their efficacy in understanding, modeling, and forecasting temporal data [

30,

31]. Some further conclusions about controlling the complex system of bunkers to presses may involve training an RL agent to learn the hidden dynamics of the systems and find the best points in time for emptying the bunker at an optimal volume, given the current sensory data and historical data as input. A recent study proposed an RL-based environment for regulating this specific part of a waste sorting facility [

32]. To address the possible effect of data scarcity, investigating whether limited data acts as a constraint by further reducing data amounts and analyzing the resultant impact might prove insightful.

7. Discussion

Waste sorting facilities serve as pivotal components in the recycling industry, playing an integral role in processing and preparing waste for future use, with volume determination of waste being essential for producing standardized bales. These bales must exhibit uniformity in length to streamline both the storage and transport processes. In this context, our study delved into the viability of implementing ultrasonic sensors to measure waste volume and explored potential challenges that may arise while striving to produce bales of consistent length.

Distance sensors, including ultrasonic variants, can offer data that feed into algorithms designed for estimating waste volume. These sensors typically facilitate volume calculation and, subsequently, aid in the production of quality bales. However, our investigation revealed that several factors often undermine the efficiency of ultrasonic sensors. The findings from our research are discussed in the following.

7.1. Volume Ratio and Measurement Discrepancies

While ultrasonic sensors provide valuable data for volume determination, the complexities of waste pile characteristics and environmental disruptions may limit their efficiency. Our analysis reveals that reliance solely on ultrasonic sensors can yield imprecise outcomes. Factors such as varying waste material compositions, the ever-changing state of waste piles, and external noise interference play a significant role in these discrepancies. However, identifying the primary source of inaccuracies requires further investigation. The evolution of ultrasonic sensor technology should be closely monitored, as recent advancements might mitigate some of these challenges.

7.2. Effects and Challenges

Investigations into the factors affecting the volume ratio between bunker and belt have been conducted, with material type and the total number of bales per emptying being relevant variables. We found that a larger volume of waste, which results in a greater number of bales pressed, tends to provide a more stable and consistent volume ratio. Consequently, a strategy that emphasizes processing more bales per emptying likely enhances the predictability of these ratios.

The study revealed that volume ratios for some materials exhibited more substantial variations compared to others. The differences in spreading behavior on the conveyor belt and levels of compression that materials underwent possibly contributed to these variations. In systems where a current bale is pressed against the previous one, the material of a previously pressed bale can impact the subsequent bale’s quality and metrics. The physical properties of materials, such as their compressibility and elasticity, were proposed as potential sources of pronounced variations in quality. Recognizing the effect of these properties, especially the impact of using softer or harder materials on the compression of subsequent materials, becomes crucial when developing a machine learning model intended for bale size prediction.

Initial volume ratio estimates, based on the median of the last ten ratios, were refined through material-specific best time windows and data grouping by press type, resulting in a 12% MAE reduction for all materials together. Importantly, our findings indicate that precise bale length cannot be determined solely based on the total final mass. This raises pivotal questions regarding the potential benefits of enhancing volume estimation through the enhancement of sensors in the system. Lastly, materials such as boxes displayed significant discrepancies between their measured volume and actual density. These discrepancies, which are not captured individually, contribute to a stochastic composition of waste, representing inherent noise in the system that is currently challenging to accurately quantify.

7.3. Predictive Machine Learning

We see great potential in leveraging machine learning techniques, e.g., time-series forecasting, to refine volume determination in waste management. The overarching goal is to achieve higher efficiency, accuracy, and sustainability in waste management practices. However, our current efforts to employ machine learning techniques have yielded suboptimal results, underscoring the necessity of refining our approaches.

Our predictive tool for upcoming volume ratio using the XGBoost algorithm underperformed across different materials, compared to a simpler method that employs the median of the last ten volume ratios. This suggests that models capable of adaptive learning, based on shorter timeframes, may need to be explored. Similarly, a Random Forest model designed to predict bale length from various features failed to generate practical results, indicating that optimizing volume measurements alone is insufficient for accurate bale size prediction. These findings underscore the presence of missing features and temporal variations in the data, which obstruct the discernment of clear patterns by the machine learning algorithms. The fragmentation of existing datasets further compromises the reliability of these models, with scant data available for individual materials often subdivided into small segments, each associated with different material types. It necessitates the expansion and consolidation of data for each material, allowing for more effective training of predictive models.

However, variations in waste compositions and machine settings over time limit the usefulness of historical data, rendering past data sometimes less applicable to current waste volume predictions. Addressing waste management challenges requires urgent innovation, including the development of target functions and the identification of key factors such as the relationship between bale length and energy consumption in bale presses. As studies suggest, the integration of advanced machine learning techniques can significantly enhance waste sorting processes, optimize routing efficiency, and improve predictive maintenance, thereby offering substantial benefits over the long term [

33].

7.4. Limitations

This study acknowledges several limitations that impact the generalizability and applicability of our findings. Firstly, the research was conducted under the constraint of limited data availability, due to changes in machine settings and database. Secondly, due to the operational constraints within the waste sorting facilities, there was no opportunity to modify existing technological setups or introduce innovations (e.g., LIDAR sensors) that could potentially enhance the accuracy of volume determination by providing a full height profile. The models we developed were trained based on the configurations of three European waste sorting facilities, suggesting our findings are most applicable to facilities with similar setups. Facilities with different configurations may necessitate the development and training of new models to achieve comparable findings. Future research efforts are encouraged to address these constraints.

8. Conclusions

This study revealed marked discrepancies in volume measurements between storage bunkers and conveyor belts, underscoring the need for a multi-faceted approach to waste volume determination to enhance the production of standardized, quality bales. Although ultrasonic sensors provide valuable insights, they cannot be solely relied upon due to the inherent challenges associated with varying waste compositions, the unstable state of waste piles, external interference, and variations in material-specific densities.

Multiple aspects make this setting a challenging field for Machine Learning. The reliability of predictions is hampered by limited datasets, undocumented changes in machine configurations, and sensor malfunctions. Our findings imply that poor data quality caused by sensory limitations cannot be compensated by processing the data with current machine learning methods. Major improvements are anticipated from two distinct areas, enhancing the system of sensors and developing adequate algorithms to efficiently handle the sensory data and make adequate predictions.

Testing some of the proposed approaches may allow for a more accurate waste volume determination, promoting sustainability that is beneficial to both the environment and society.

Author Contributions

Conceptualization, T.M., N.Z., D.S. and T.G.; Data curation, T.M.; Formal analysis, T.M. and N.Z.; Funding acquisition, D.S. and T.G.; Investigation, T.M.; Methodology, T.M.; Project administration, D.S. and T.G.; Resources, D.S. and T.G.; Software, T.M. and D.S.; Supervision, T.G.; Validation, T.M. and N.Z.; Visualization, T.M.; Writing—original draft, T.M. and N.Z.; Writing—review and editing, T.M., N.Z., D.S. and T.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received external funding from the German Federal Ministry for Economic Affairs and Climate Action through the grant “EnSort”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

In compliance with confidentiality agreements, the raw data used in this study are not publicly available. However, we are committed to promoting transparency and reproducibility in research. The data processing scripts used in this study are available upon request to the first author.

Conflicts of Interest

Author Dorothee Sänger was employed by the company Sutco RecyclingTechnik GmbH. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Appendix A

| Algorithm A1 Calculating Bunker Volume from Sensor Data |

- 1:

procedure BunkerVolume() - 2:

- 3:

- 4:

- 5:

for in do - 6:

if then - 7:

- 8:

- 9:

- 10:

- 11:

else if then - 12:

- 13:

- 14:

- 15:

- 16:

else - 17:

- 18:

- 19:

- 20:

- 21:

end if - 22:

if then - 23:

- 24:

- 25:

else if and then - 26:

- 27:

- 28:

- 29:

- 30:

else if then - 31:

- 32:

- 33:

else if then - 34:

- 35:

- 36:

end if - 37:

end for - 38:

if then - 39:

- 40:

- 41:

else - 42:

- 43:

end if - 44:

return - 45:

end procedure

|

Table A1.

List of abbreviations related to parameters and measurements used in the waste sorting process. Each abbreviation is followed by its description and examples. These parameters serve as the foundation for several figures presented in this document.

Table A1.

List of abbreviations related to parameters and measurements used in the waste sorting process. Each abbreviation is followed by its description and examples. These parameters serve as the foundation for several figures presented in this document.

| Abbreviations | Description | Examples |

|---|

| _unix_dt | Unix timestamp in date format | 1628000000, 1635001200, … |

| _dt | Date | 2023-07-31, 2023-08-01, … |

| TargetName | Target name | Press_1, … |

| BaleID | Bale ID | 001, 002, 003, … |

| Impulse | Impulse | 25, 30, … |

| BunkerName | Bunker name | Bunker A, Bunker B, … |

| BunkerVolume | Bunker volume right before emptying (US) | 17, … |

| BeltVolume | Belt volume of full flow batch (laser) | 15, … |

| RecipeNumber | Recipe number | 3, 4, … |

| MaterialNumber | Material number | 001, 002, 003, … |

| MaterialName | Material name | PET, PE, … |

| CorrelationFactor | BunkerVolume/BeltVolume | 0.95, 0.98, 1.00, … |

| ImpulseVolume | Impulse volume | 0.7, … |

| Regular | Regular | −1, 1 |

| External | External | −1, 1 |

| BaleVolumeTarget | Bale volume (target) | 9.5, … m3 |

| BaleVolumeCalculated | Bunkervolume/Number of produced bales | 10.5, … m3 |

| BaleVolumeActual | BaleVolumeCalculated × CorrelationFactor | 8.5, … m3 |

| ActiveEnergy | Active energy | 2850, … |

| ReactiveEnergy | Reactive energy | 0, … |

| ApparentEnergy | Apparent energy | 0, … |

| BindingImpulses | Binding impulses | 5, 6, 7, … |

| ActualLength | Actual length | 1205, … |

| ActualMass | Actual mass | 625, … |

| TargetImpulsesConfig | Target impulses configuration | Company’s requirements |

| TargetImpulses | Target impulses | Company’s requirements |

| TargetLength | Target length | Company’s requirements |

| TargetMass | Target mass | Company’s requirements |

Table A2.

Abbreviations and Descriptions from Ultrasonic Sensors.

Table A2.

Abbreviations and Descriptions from Ultrasonic Sensors.

| Abbreviations | Description | Examples |

|---|

| _unix_dt | Unix timestamp in date format | 1628000000, 1635001200, … |

| _dt | Date and time | 2023-08-01 12:30:00, 2023-08-01 12:35:00, … |

| h_US_0 | Ultrasonic sensor 0 height measurement | 865, 1783, … [mm] |

| h_US_1 | Ultrasonic sensor 1 height measurement | 865, 1783, … [mm] |

| h_US_2 | Ultrasonic sensor 2 height measurement | 865, 1783, … [mm] |

| h_US_3 | Ultrasonic sensor 3 height measurement | 865, 1783, … [mm] |

| h_US_4 | Ultrasonic sensor 4 height measurement | 865, 1783, … [mm] |

| h_US_5 | Ultrasonic sensor 5 height measurement | 865, 1783, … [mm] |

| MountingHeight_US_0 | Mounting height of sensor 0 | 1953, 2035, … [mm] |

| MountingHeight_US_1 | Mounting height of sensor 1 | 1953, 2035, … [mm] |

| MountingHeight_US_2 | Mounting height of sensor 2 | 1953, 2035, … [mm] |

| MountingHeight_US_3 | Mounting height of sensor 3 | 1953, 2035, … [mm] |

| MountingHeight_US_4 | Mounting height of sensor 4 | 1953, 2035, … [mm] |

| MountingHeight_US_5 | Mounting height of sensor 5 | 1953, 2035, … [mm] |

| Volume | Volume measurement | 6.5, … |

| Active | Activity status | Yes, No |

| Read_Door_Left_Open | Read status of left door (open) | 0, 1 |

| Read_Door_Left_Closed | Read status of left door (closed) | 0, 1 |

| Read_Door_Right_Open | Read status of right door (open) | 0, 1 |

| Read_Door_Right_Closed | Read status of right door (closed) | 0, 1 |

| Read_Bunker_Belt_Left | Read status of left bunker band | 0, 1 |

| Read_Bunker_Belt_Right | Read status of right bunker band | 0, 1 |

Table A3.

This table provides the material abbreviations, their corresponding full descriptions (Description), and examples for each material. These materials are processed in the examined waste sorting facilities and form the basis for all other figures in this document.

Table A3.

This table provides the material abbreviations, their corresponding full descriptions (Description), and examples for each material. These materials are processed in the examined waste sorting facilities and form the basis for all other figures in this document.

| Abbreviations | Description | Examples |

|---|

| Card | Cardboard | Boxes, packaging materials |

| Cardboard | Cardboard Packaging | Cardboard boxes, food packaging |

| Cart | Cartridges | Cartridges for printing, etc. |

| Cont | Contaminants | Non-recyclable materials mixed in with the recyclables |

| EPS | Expanded Polystyrene (Styrofoam) | Coffee cups, packaging peanuts |

| Foil | Foil | foil packaging |

| HDPE | High Density Polyethylene | Sturdy containers, corrosion-resistant piping |

| Label_Foil | Label Foil | Foil used in labels, often with an adhesive on one side |

| PCC | Paper Cardboard Carton | Copy paper, boxes, etc. |

| PE | Polyethylene | Plastic bags, plastic films, containers |

| PE_blue | Polyethylene Blue | Blue plastic containers |

| PE_color | Polyethylene Colored | Colored plastic containers |

| PE_color | Polyethylene Colored | Colored plastic containers |

| PE_film | Polyethylene Film Type 1 | Shrink wrap, plastic food wrap |

| PE_green | Polyethylene Green | Green plastic containers |

| PE_multi | Polyethylene Multi-Colored | Multi-colored plastic products |

| PE_nat | Polyethylene Natural | Plastic bags, bottles |

| PE_red | Polyethylene Red | Red plastic containers |

| PE_white | Polyethylene White | White plastic containers |

| PE_yellow | Polyethylene Yellow | Yellow plastic containers |

| PET_bot | Polyethylene Terephthalate Bottles | Beverage bottles, like water or soda bottles |

| PET_op | Polyethylene Terephthalate Opaque Bottles | Certain types of beverage bottles |

| PET_trans | Polyethylene Terephthalate Clear Bottles | Water bottles |

| PET_brown | Polyethylene Terephthalate Brown | Brown PET products, like bottles |

| PET_clear | Polyethylene Terephthalate Clear | Clear PET products, like beverage bottles |

| PET_green | Polyethylene Terephthalate Green | Green PET products, like bottles |

| PET_multi | Polyethylene Terephthalate Multi-Colored | Multi-colored PET products |

| PET_opaq | Polyethylene Terephthalate Opaque | Non-transparent PET products |

| PET_tray | Polyethylene Terephthalate Tray | Trays made from PET, often for food packaging |

| PET_trays | Polyethylene Terephthalate Trays | Food packaging trays |

| PO | Polyolefin | Various types of packaging films |

| PP | Polypropylene | Bottle caps, yogurt containers, toys |

| PP_3D | Polypropylene 3D | 3D printed objects |

| PP_blue | Polypropylene Blue | Blue plastic containers made from polypropylene |

| PP_color | Polypropylene Colored | Colored polypropylene products |

| PP_color_2D | Polypropylene Colored 2D | Colored polypropylene products |

| PP_color_3D | Polypropylene Colored 3D | Colored polypropylene products |

| PP_film | Polypropylene Film | Snack packaging |

| PP_green | Polypropylene Green | Green plastic containers made from polypropylene |

| PP_nat | Polypropylene Natural | Non-dyed polypropylene products |

| PP_red | Polypropylene Red | Red plastic containers made from polypropylene |

| PP_white | Polypropylene White | White plastic containers made from polypropylene |

| PP_yellow | Polypropylene Yellow | Yellow plastic containers made from polypropylene |

| PS | Polystyrene | Disposable cutlery, CD cases |

| PVC | Polyvinyl Chloride | PVC pipes, vinyl flooring |

| Rest | Residual Waste | Waste that cannot be recycled or composted |

| Tetra | Tetra Pak | carton packaging for beverages |

Table A4.

Results of the volume ratio prediction (5.1), comparing the mean absolute error (MAE) between the bunker–belt volume ratio and the predictions of both an XGBoost-model (“MAE (model)”) and the median of its last ten values (“MAE (median 10)”). The performance ratio is calculated by dividing the column “MAE (median 10)” by “MAE (model)”.

Table A4.

Results of the volume ratio prediction (5.1), comparing the mean absolute error (MAE) between the bunker–belt volume ratio and the predictions of both an XGBoost-model (“MAE (model)”) and the median of its last ten values (“MAE (median 10)”). The performance ratio is calculated by dividing the column “MAE (median 10)” by “MAE (model)”.

| Material | Datapoints (n) | MAE (Median 10) | MAE (Model) | Performance Ratio |

|---|

| PP_color | 218 | 0.1135 | 0.0734 | 154.72 |

| PVC | 90 | 0.127 | 0.1078 | 117.86 |

| EPS | 178 | 0.1184 | 0.1105 | 107.16 |

| PE_film_2 | 562 | 1.1075 | 1.1165 | 99.19 |

| PE_color | 1282 | 0.0859 | 0.0925 | 92.92 |

| PE_film_1 | 574 | 0.0387 | 0.0424 | 91.34 |

| PP_film | 137 | 0.0837 | 0.098 | 85.35 |

| PP_3D | 862 | 0.1387 | 0.163 | 85.06 |

| PS | 22 | 0.1221 | 0.1497 | 81.56 |

| PE_green | 134 | 0.077 | 0.1015 | 75.89 |

| PP_color | 346 | 0.089 | 0.12 | 74.15 |

| PE_nat | 970 | 0.0861 | 0.117 | 73.65 |

| PP | 98 | 0.074 | 0.1012 | 73.12 |

| PS | 84 | 0.0884 | 0.1258 | 70.26 |

| PE_nat | 451 | 0.0686 | 0.0997 | 68.75 |

| PE_white | 126 | 0.108 | 0.1637 | 65.98 |

| PP_blue | 8 | 0.1332 | 0.2023 | 65.82 |

| PE_white | 435 | 0.0526 | 0.0825 | 63.81 |

| PE_blue | 50 | 0.0864 | 0.1395 | 61.91 |

| PE_color | 38 | 0.132 | 0.2157 | 61.17 |

| PP_nat | 242 | 0.073 | 0.1237 | 59.01 |

| PET_trans | 216 | 0.0805 | 0.1409 | 57.11 |

| PE_yellow | 88 | 0.0834 | 0.1499 | 55.65 |

| PE_nat | 117 | 0.0784 | 0.1508 | 51.96 |

| PE_red | 124 | 0.0951 | 0.186 | 51.15 |

| HDPE | 238 | 0.0733 | 0.164 | 44.70 |

| PET_trays | 236 | 0.0771 | 0.1737 | 44.39 |

| Foil | 77 | 0.0841 | 0.1909 | 44.07 |

| PE_yellow | 18 | 0.102 | 0.2422 | 42.11 |

| PET_op | 209 | 0.0694 | 0.1872 | 37.09 |

| PP_white | 932 | 0.0452 | 0.1316 | 34.35 |

| PP_white | 153 | 0.0655 | 0.1918 | 34.17 |

| Card | 26 | 0.1174 | 0.3452 | 34.01 |

| PE_multi | 86 | 0.0416 | 0.1278 | 32.56 |

| PE_blue | 174 | 0.0685 | 0.2242 | 30.57 |

| HDPE | 483 | 0.0927 | 0.5479 | 16.91 |

References

- Rutqvist, D.; Kleyko, D.; Blomstedt, F. An Automated Machine Learning Approach for Smart Waste Management Systems. IEEE Trans. Ind. Inform. 2020, 16, 384–392. [Google Scholar] [CrossRef]

- Thakker, S.; Narayanamoorthi, R. Smart and wireless waste management. In Proceedings of the 2015 International Conference on Innovations in Information, Embedded and Communication Systems (ICIIECS), Coimbatore, India, 19–20 March 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Chen, X.; Huang, H.; Liu, Y.; Li, J.; Liu, M. Robot for automatic waste sorting on construction sites. Autom. Constr. 2022, 141, 104387. [Google Scholar] [CrossRef]

- Kanade, P.; Alva, P.; Prasad, J.P.; Kanade, S. Smart Garbage Monitoring System using Internet of Things(IoT). In Proceedings of the 2021 5th International Conference on Computing Methodologies and Communication (ICCMC), Erode, India, 8–10 April 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 330–335. [Google Scholar] [CrossRef]

- Vicentini, F.; Giusti, A.; Rovetta, A.; Fan, X.; He, Q.; Zhu, M.; Liu, B. Sensorized waste collection container for content estimation and collection optimization. Waste Manag. 2009, 29, 1467–1472. [Google Scholar] [CrossRef] [PubMed]

- Kelemen, M.; Virgala, I.; Kelemenová, T.; Miková, L.; Frankovský, P.; Lipták, T.; Lörinc, M. Distance Measurement via Using of Ultrasonic Sensor. J. Autom. Control 2015, 3, 71–74. [Google Scholar]

- Bowler, A.L.; Watson, N.J. Transfer learning for process monitoring using reflection-mode ultrasonic sensing. Ultrasonics 2021, 115, 106468. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, A.K.; Udgata, S.K. A Novel ANN-Based Adaptive Ultrasonic Measurement System for Accurate Water Level Monitoring. IEEE Trans. Instrum. Meas. 2020, 69, 3359–3369. [Google Scholar] [CrossRef]

- Bae, I.; Ji, U. Outlier Detection and Smoothing Process for Water Level Data Measured by Ultrasonic Sensor in Stream Flows. Water 2019, 11, 951. [Google Scholar] [CrossRef]

- Adarsh, S.; Kaleemuddin, S.M.; Bose, D.; Ramachandran, K.I. Performance comparison of Infrared and Ultrasonic sensors for obstacles of different materials in vehicle/robot navigation applications. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012141. [Google Scholar] [CrossRef]

- Tumbo, S.D.; Salyani, M.; Whitney, J.D.; Wheaton, T.A.; Miller, W.M. Investigation of Laser and Ultrasonic Ranging Sensors for Measurements of Citrus Canopy Volume. Appl. Eng. Agric. 2002, 18, 367–372. [Google Scholar] [CrossRef]

- Ezhov, Y.; Zub, I.; Zhuravlev, A.; Schemelev, V. Ultrasonic and Laser Sensors Measurement Errors Detection. In Proceedings of the Second International Scientific Conference on Advances in Science, Engineering and Digital Education: (ASEDU-II 2021), Krasnoyarsk, Russia, 28 October 2022; p. 060013. [Google Scholar] [CrossRef]

- Gomathy, G.; Kalaiselvi, P.; Selvaraj, D.; Dhinakaran, D.; Anish, T.P.; Arul Kumar, D. Automatic Waste Management based on IoT using a Wireless Sensor Network. In Proceedings of the 2022 International Conference on Edge Computing and Applications (ICECAA), Tamilnadu, India, 13–15 October 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 629–634. [Google Scholar] [CrossRef]

- Aguila, J.M.U.; Dimayuga, H.S.; Pineda, K.O.F.; Magwili, G.V. Development of Smart Waste Bin with Integrated Volume and Weight Sensor. In Proceedings of the 2019 IEEE 11th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Laoag, Philippines, 29 November–1 December 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Buckingham, R.; Gremaud, P.A.; Hauck, C.D.; Kuster, C.M.; Prodanovic, M.; Royal, T.A.; Silantyev, V. Volume determination for bulk materials in bunkers. Int. J. Numer. Methods Eng. 2004, 61, 2239–2249. [Google Scholar] [CrossRef]

- Andeobu, L.; Wibowo, S.; Grandhi, S. Artificial intelligence applications for sustainable solid waste management practices in Australia: A systematic review. Sci. Total Environ. 2022, 834, 155389. [Google Scholar] [CrossRef]

- Lu, W.; Chen, J. Computer vision for solid waste sorting: A critical review of academic research. Waste Manag. 2022, 142, 29–43. [Google Scholar] [CrossRef]

- Sousa, J.; Rebelo, A.; Cardoso, J.S. Automation of Waste Sorting with Deep Learning. In Proceedings of the 2019 XV Workshop de Visão Computacional (WVC), São Bernardo do Campo, Brazil, 9–11 September 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 43–48. [Google Scholar] [CrossRef]

- Mohammad, T. Using Ultrasonic and Infrared Sensors for Distance Measurement. World Acad. Sci. Eng. Technol. 2009, 51, 293–299. [Google Scholar]

- Saha, K.K.; Tsoulias, N.; Weltzien, C.; Zude-Sasse, M. Estimation of Vegetative Growth in Strawberry Plants Using Mobile LiDAR Laser Scanner. Horticulturae 2022, 8, 90. [Google Scholar] [CrossRef]

- MIC+340/IU/TC—Standard Sensors. Available online: https://www.microsonic.de/en/distance-sensors/cylindrical/micplus/standard-sensors/standard-sensors/micplus340iutc.htm (accessed on 5 March 2024).

- Chen, T.; He, T.; Benesty, M.; Khotilovich, V.; Tang, Y.; Cho, H.; Chen, K.; Mitchell, R.; Cano, I.; Zhou, T.; et al. Xgboost: Extreme gradient boosting. R Package Version 0.4-2 2015, 1, 1–4. [Google Scholar]

- Akiba, T.; Sano, S.; Yanase, T.; Ohta, T.; Koyama, M. Optuna: A Next-generation Hyperparameter Optimization Framework. arXiv 2019, arXiv:1907.10902. [Google Scholar]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Galton, F. Regression Towards Mediocrity in Hereditary Stature. J. Anthropol. Inst. Great Br. Irel. 1886, 15, 246–263. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Wagland, S.; Veltre, F.; Longhurst, P. Development of an image-based analysis method to determine the physical composition of a mixed waste material. Waste Manag. 2012, 32, 245–248. [Google Scholar] [CrossRef]

- Li, Q.; Li, R.; Ji, K.; Dai, W. Kalman Filter and Its Application. In Proceedings of the 2015 8th International Conference on Intelligent Networks and Intelligent Systems (ICINIS), Tianjin, China, 1–3 November 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 74–77. [Google Scholar] [CrossRef]

- Al Tahtawi, A.R. Kalman Filter Algorithm Design for HC-SR04 Ultrasonic Sensor Data Acquisition System. IJITEE (Int. J. Inf. Technol. Electr. Eng.) 2018, 2, 15–19. [Google Scholar] [CrossRef]

- Huang, L.; Cai, T.; Zhu, Y.; Zhu, Y.; Wang, W.; Sun, K. LSTM-Based Forecasting for Urban Construction Waste Generation. Sustainability 2020, 12, 8555. [Google Scholar] [CrossRef]

- Marandi, F.; Fatemi Ghomi, S. Time series forecasting and analysis of municipal solid waste generation in Tehran city. In Proceedings of the 2016 12th International Conference on Industrial Engineering (ICIE), Tehran, Iran, 25–26 January 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 14–18. [Google Scholar] [CrossRef]

- Pendyala, A.; Dettmer, J.; Glasmachers, T.; Atamna, A. ContainerGym: A Real-World Reinforcement Learning Benchmark for Resource Allocation. arXiv 2023, arXiv:2307.02991. [Google Scholar] [CrossRef]

- Munir, M.T.; Li, B.; Naqvi, M. Revolutionizing municipal solid waste management (MSWM) with machine learning as a clean resource: Opportunities, challenges and solutions. Fuel 2023, 348, 128548. [Google Scholar] [CrossRef]

Figure 1.

An exemplary illustration of the discussed setting. On the left, two bunkers with rows of multiple ultrasonic sensors are shown from above. On the right, a cross-section through one bunker demonstrates how multiple sensors scan the distance to the waste piles to estimate the volume.

Figure 1.

An exemplary illustration of the discussed setting. On the left, two bunkers with rows of multiple ultrasonic sensors are shown from above. On the right, a cross-section through one bunker demonstrates how multiple sensors scan the distance to the waste piles to estimate the volume.

Figure 2.

This figure offers an analysis of volume flows in a waste sorting facility with two presses. It juxtaposes the volume measured in the bunker (red) and belt (blue) (a), shows the selection of press 1 (blue) or press 2 (red) based on baling event frequency (b), presents the variation (trimmed) in the bunker/belt ratio around its mean (c), and quantifies bales pressed per baling event (d).

Figure 2.

This figure offers an analysis of volume flows in a waste sorting facility with two presses. It juxtaposes the volume measured in the bunker (red) and belt (blue) (a), shows the selection of press 1 (blue) or press 2 (red) based on baling event frequency (b), presents the variation (trimmed) in the bunker/belt ratio around its mean (c), and quantifies bales pressed per baling event (d).

Figure 3.

Graphical representation of raw sensor outputs from a designated bunker during the emptying phase, captured over intervals of 1–2 s. A discernible malfunction is evident in e.g., Sensor_03 and Sensor_09.

Figure 3.

Graphical representation of raw sensor outputs from a designated bunker during the emptying phase, captured over intervals of 1–2 s. A discernible malfunction is evident in e.g., Sensor_03 and Sensor_09.

Figure 4.

The Figure presents a detailed analysis of sensor readings obtained from a specific bunker (“PP_nat”). The bold orange line represents the trend of volume, calculated using Algorithm A1 (see

Appendix A) and scaled for better visibility as explained in the the legend. Opening of the bunker doors marks the specific time designated for bunker emptying, highlighted at the top of the figure. The movement of the belt inside the bunker is further displayed, aiding in understanding the shifting distance measurements. Notably, Sensor 6 (brown) exhibits values outside the plausible range (0–2036 mm). The visual representation utilizes an inverted y-axis for clarity, indicating that at the bottom, the bunker is empty and sensors measure down to the ground of the bunker while decreasing values indicate the filling of the bunker (opaque lines).

Figure 4.

The Figure presents a detailed analysis of sensor readings obtained from a specific bunker (“PP_nat”). The bold orange line represents the trend of volume, calculated using Algorithm A1 (see

Appendix A) and scaled for better visibility as explained in the the legend. Opening of the bunker doors marks the specific time designated for bunker emptying, highlighted at the top of the figure. The movement of the belt inside the bunker is further displayed, aiding in understanding the shifting distance measurements. Notably, Sensor 6 (brown) exhibits values outside the plausible range (0–2036 mm). The visual representation utilizes an inverted y-axis for clarity, indicating that at the bottom, the bunker is empty and sensors measure down to the ground of the bunker while decreasing values indicate the filling of the bunker (opaque lines).

Figure 5.

These graphs illustrate both a successful (upper) and unsuccessful (lower) emptying process. It shows that once the computed volume exceeds a certain threshold (red cross), a door opens (indicated by a shifted line at the top) and the bunker empties. The raw sensor values (translucent, in mm), their mean (red), and median (blue) are compared to the volume calculated by the algorithm (see

Appendix A, Algorithm A1), magnified by factor 10× for visual purposes (yellow area and curve, in m

3). The measurement from the laser sensors on the conveyor belt and the resulting ratio between this value and the previously measured Bunker Volume is shown as F.

Figure 5.

These graphs illustrate both a successful (upper) and unsuccessful (lower) emptying process. It shows that once the computed volume exceeds a certain threshold (red cross), a door opens (indicated by a shifted line at the top) and the bunker empties. The raw sensor values (translucent, in mm), their mean (red), and median (blue) are compared to the volume calculated by the algorithm (see

Appendix A, Algorithm A1), magnified by factor 10× for visual purposes (yellow area and curve, in m

3). The measurement from the laser sensors on the conveyor belt and the resulting ratio between this value and the previously measured Bunker Volume is shown as F.

Figure 6.

Boxplots displaying the distribution of the number of bales produced per emptying cycle per material in a selected waste sorting facility over a period of approximately 5 months.

Figure 6.

Boxplots displaying the distribution of the number of bales produced per emptying cycle per material in a selected waste sorting facility over a period of approximately 5 months.

Figure 7.

Boxplots illustrating the volume ratio F as a function of the number of bales pressed at a selected waste sorting facility. They display the distribution of data points, while the number of samples and the standard deviation are provided for additional context.

Figure 7.

Boxplots illustrating the volume ratio F as a function of the number of bales pressed at a selected waste sorting facility. They display the distribution of data points, while the number of samples and the standard deviation are provided for additional context.

Figure 8.

Volume ratio variation (belt volume/bunker volume) per material type (varying sample sizes) at a waste sorting facility over 5 months. The numbers indicate the available data points per material (n).

Figure 8.

Volume ratio variation (belt volume/bunker volume) per material type (varying sample sizes) at a waste sorting facility over 5 months. The numbers indicate the available data points per material (n).

Figure 9.

Influence of previous bale material on length-to-mass ratio of newly pressed HDPE Bale. Mean ratios are shown on the left, while the right side displays a boxplot representation, including minimum, maximum, and median values, variances, and outliers. Materials with less than 5 data points were excluded from the plot.

Figure 9.

Influence of previous bale material on length-to-mass ratio of newly pressed HDPE Bale. Mean ratios are shown on the left, while the right side displays a boxplot representation, including minimum, maximum, and median values, variances, and outliers. Materials with less than 5 data points were excluded from the plot.

Figure 10.

Comparative analysis of (inverse) bale density influenced by properties of previous bale materials. The left plot visualizes the impact of soft (“EPS”) and hard (“HDPE”) materials from preceding bales on the density of the current bale. The right boxplots highlight the variance in the distributions of these effects.

Figure 10.

Comparative analysis of (inverse) bale density influenced by properties of previous bale materials. The left plot visualizes the impact of soft (“EPS”) and hard (“HDPE”) materials from preceding bales on the density of the current bale. The right boxplots highlight the variance in the distributions of these effects.

Figure 11.

On the left, the graph depicts the MAE for predicted volume ratios (belt volume/bunker volume), calculated using the median of the last ten actual ratios for various materials at a waste sorting facility with two presses. The red line indicates the overall mean MAE. On the right, the subplot compares various median window sizes for predictions against actual ratios. Insufficient data for “Buckets” prevented testing across all time windows.

Figure 11.

On the left, the graph depicts the MAE for predicted volume ratios (belt volume/bunker volume), calculated using the median of the last ten actual ratios for various materials at a waste sorting facility with two presses. The red line indicates the overall mean MAE. On the right, the subplot compares various median window sizes for predictions against actual ratios. Insufficient data for “Buckets” prevented testing across all time windows.

Figure 12.

In (A,B), we present regression analyses between the measured mass (kg) and length (mm) of pressed bales from two distinct facilities, covering all materials. The quality of the previous material—categorized as “soft” or “hard”—is also indicated. For (A), soft materials include “Foil”, “Label-Foil”, and “Cardboard”, for (B), soft materials refer to “EPS”. In both cases, hard material refers to “HDPE”. We highlighted only the data where the current material differed from the previous one to emphasize the effect on different materials. (C,D) show data from these facilities for specific materials. (C) focuses on ’PP_White’, and (D) on ’PP_3D’. Both figures present (1) regression of mass vs. length for the material, (2) residual plots detailing the discrepancies between observed and predicted regression values, and (3) bar plots emphasizing the frequency distribution of residuals.

Figure 12.

In (A,B), we present regression analyses between the measured mass (kg) and length (mm) of pressed bales from two distinct facilities, covering all materials. The quality of the previous material—categorized as “soft” or “hard”—is also indicated. For (A), soft materials include “Foil”, “Label-Foil”, and “Cardboard”, for (B), soft materials refer to “EPS”. In both cases, hard material refers to “HDPE”. We highlighted only the data where the current material differed from the previous one to emphasize the effect on different materials. (C,D) show data from these facilities for specific materials. (C) focuses on ’PP_White’, and (D) on ’PP_3D’. Both figures present (1) regression of mass vs. length for the material, (2) residual plots detailing the discrepancies between observed and predicted regression values, and (3) bar plots emphasizing the frequency distribution of residuals.

Figure 13.

Comparison of the XGBoost model trained individually for each material against the “Median10” method in predicting the volume ratio factor, F. The performance of each model was computed with the ratio of the XGBoost model’s MAE to Median10’s MAE. A red line and color shift indicate which model had closer predictions to the actual volume ratio. The number of data points per material appears above the X-axis. The overview was generated based on the data from two waste sorting facilities.

Figure 13.

Comparison of the XGBoost model trained individually for each material against the “Median10” method in predicting the volume ratio factor, F. The performance of each model was computed with the ratio of the XGBoost model’s MAE to Median10’s MAE. A red line and color shift indicate which model had closer predictions to the actual volume ratio. The number of data points per material appears above the X-axis. The overview was generated based on the data from two waste sorting facilities.

Figure 14.

Mean prediction errors of a Random Forest model predicting the length of the total baling product, covering a range from 1 to 5 bales. The data originates from two separate waste sorting facilities, each handling different materials. The color of the bars corresponds to the dataset size.

Figure 14.

Mean prediction errors of a Random Forest model predicting the length of the total baling product, covering a range from 1 to 5 bales. The data originates from two separate waste sorting facilities, each handling different materials. The color of the bars corresponds to the dataset size.

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).