Corrosion Monitoring in Automotive Lap Joints Based on Imaging Methods of Lamb Waves

Abstract

1. Introduction

2. Methodologies

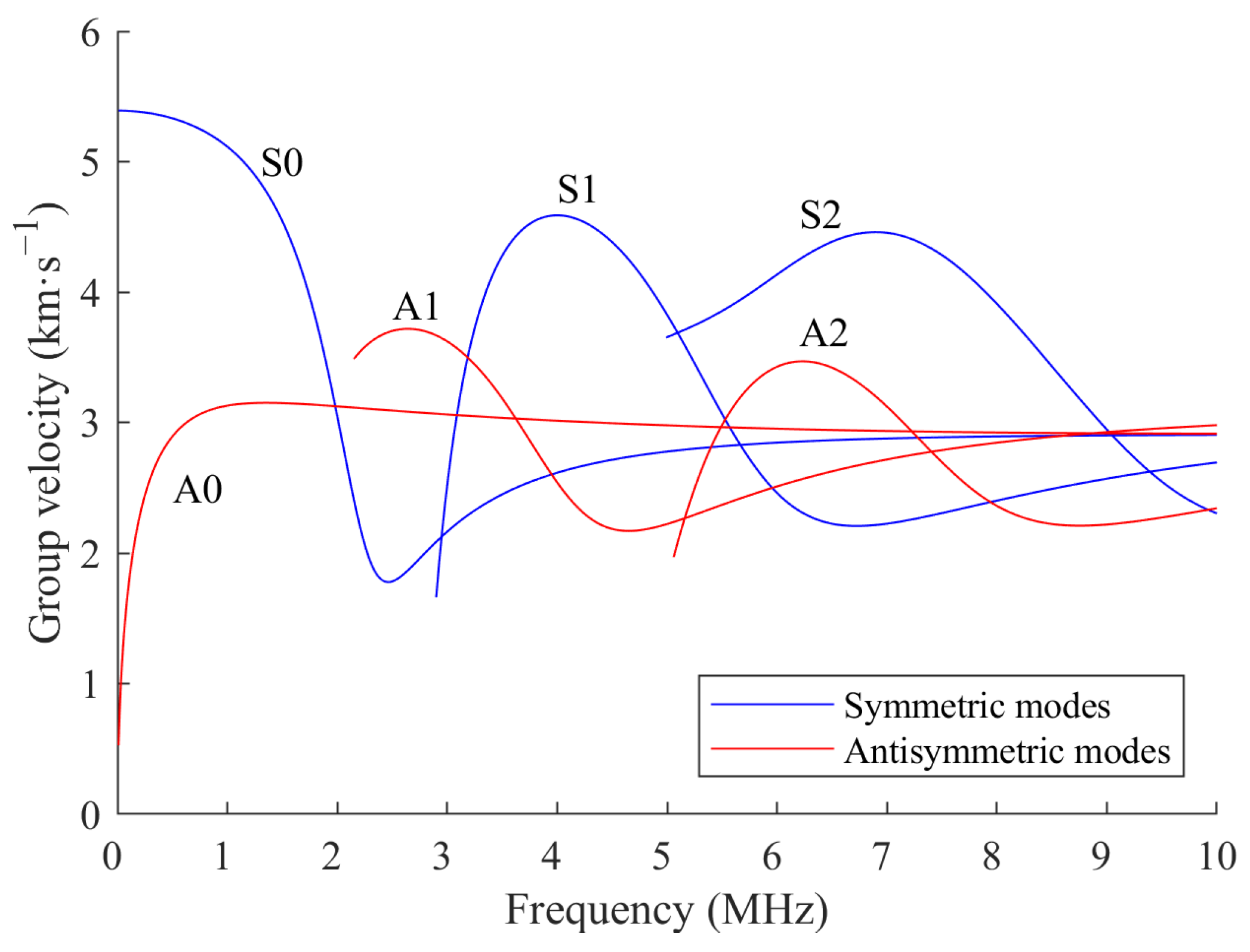

2.1. Dispersion of Lamb Wave

2.2. MVDR Imaging Method

2.3. Weighted RAPID Imaging Method

2.4. Weighted Fusion Bolt Corrosion Imaging Algorithm

- Step 1: Set the experimental equipment and collect the signals before and after tightening bolts.

- Step 2: Conduct the corrosion experiment and collect the signals before and after corrosion.

- Step 3: Use the MVDR algorithm and the signals from Step 1 to image the bolt localization.

- Step 4: Calculate the weighting coefficients based on the bolt imaging and use the weighted RAPID algorithm along with the signals from Step 2 to perform corroded bolts imaging.

3. Experiments of the Bolted Lap Joints

3.1. Experimental Equipment

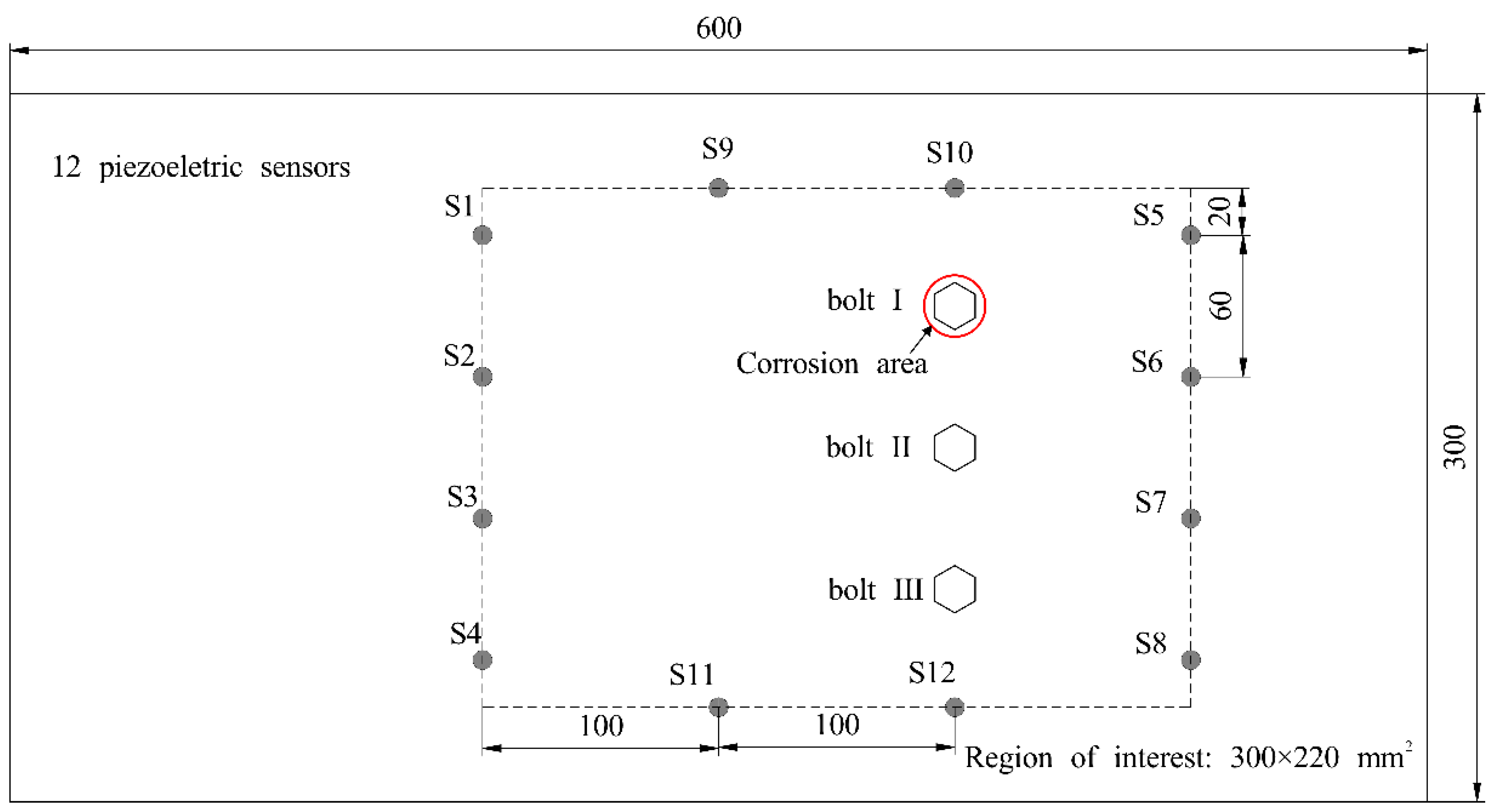

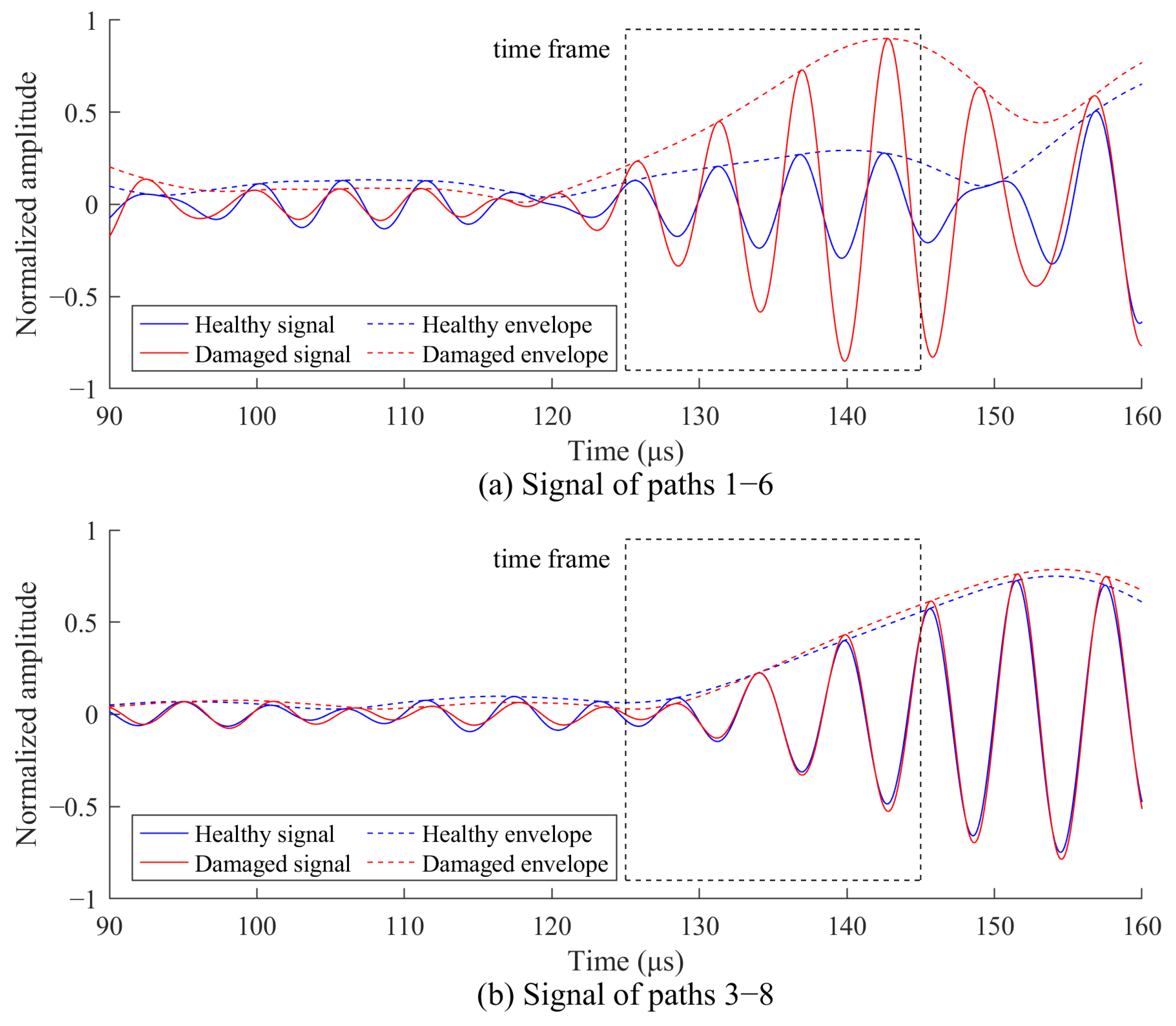

3.2. Case I: Bolted Lap Joint with Single Corrosion

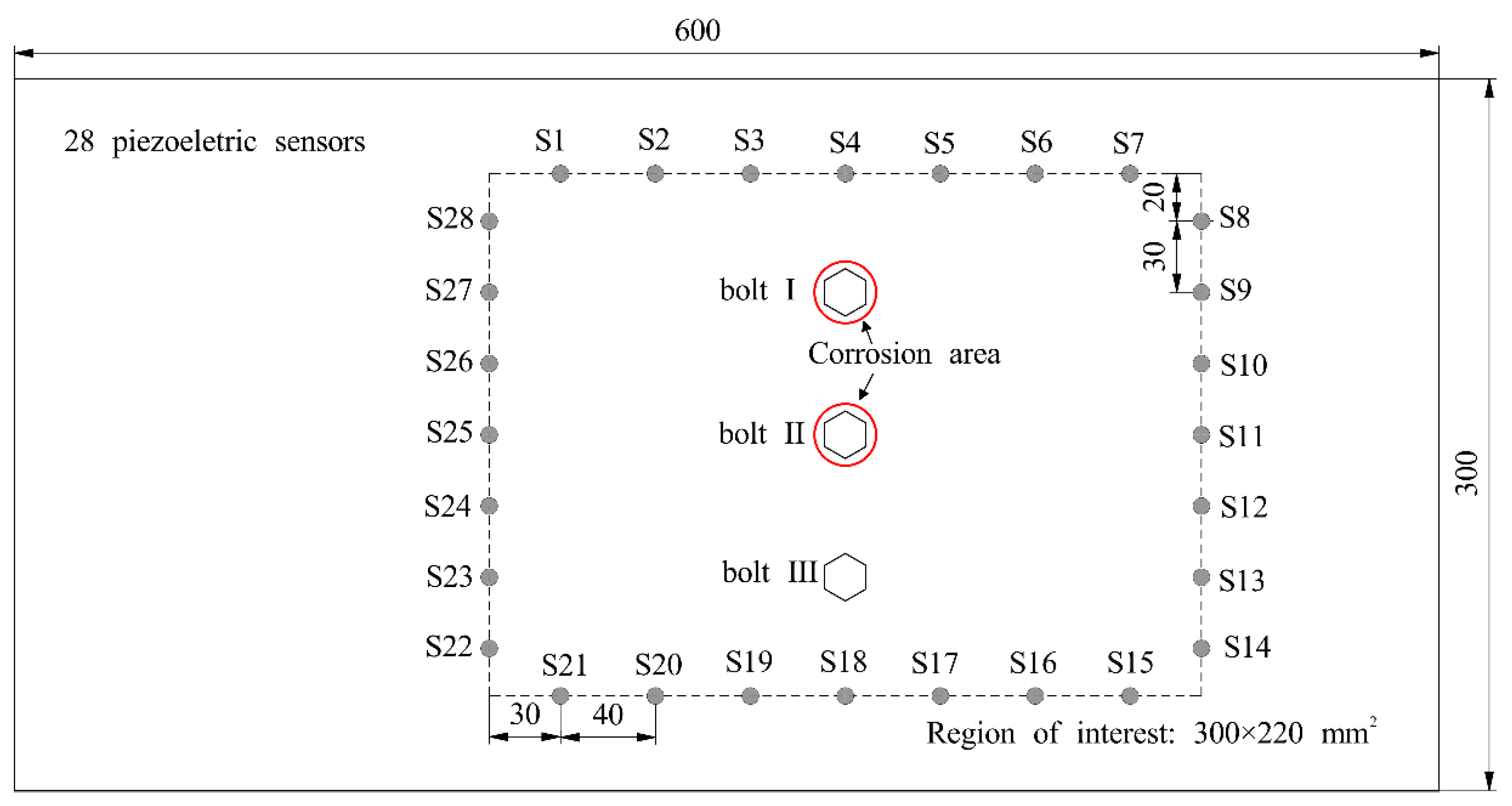

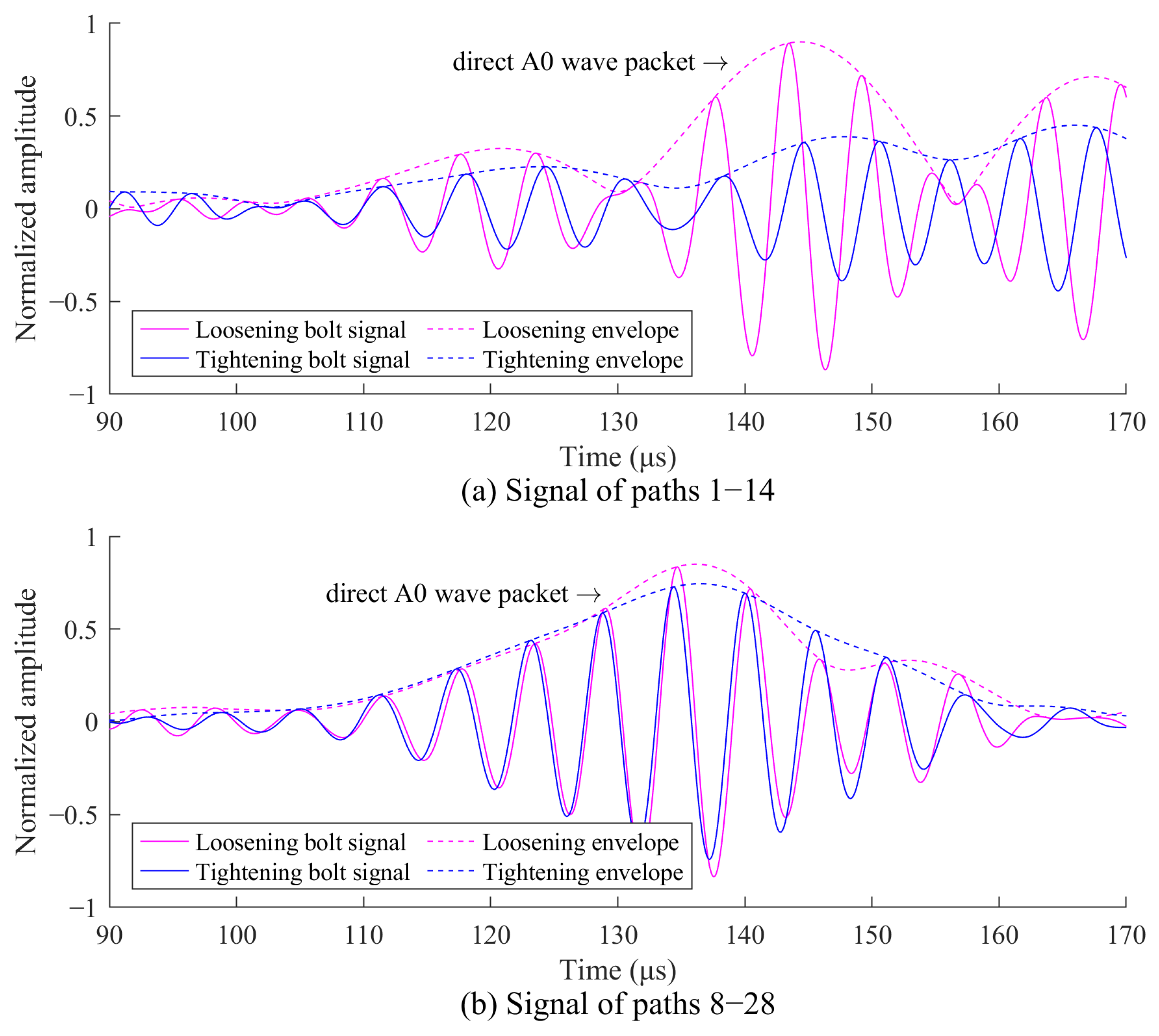

3.3. Case II: Bolted Lap Joint with Two Corrosions

4. Discussion

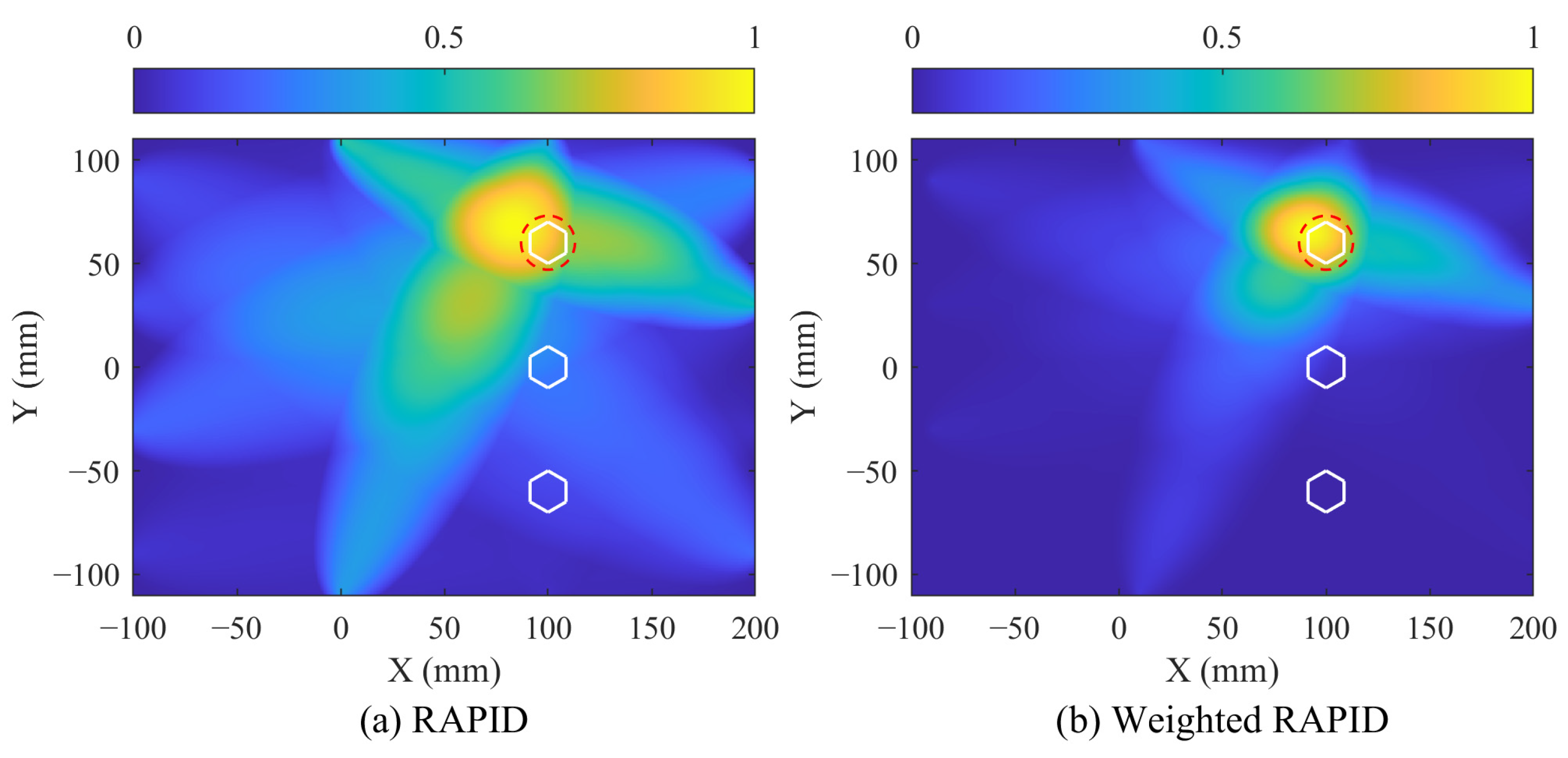

4.1. Imaging Results of Single Corrosion

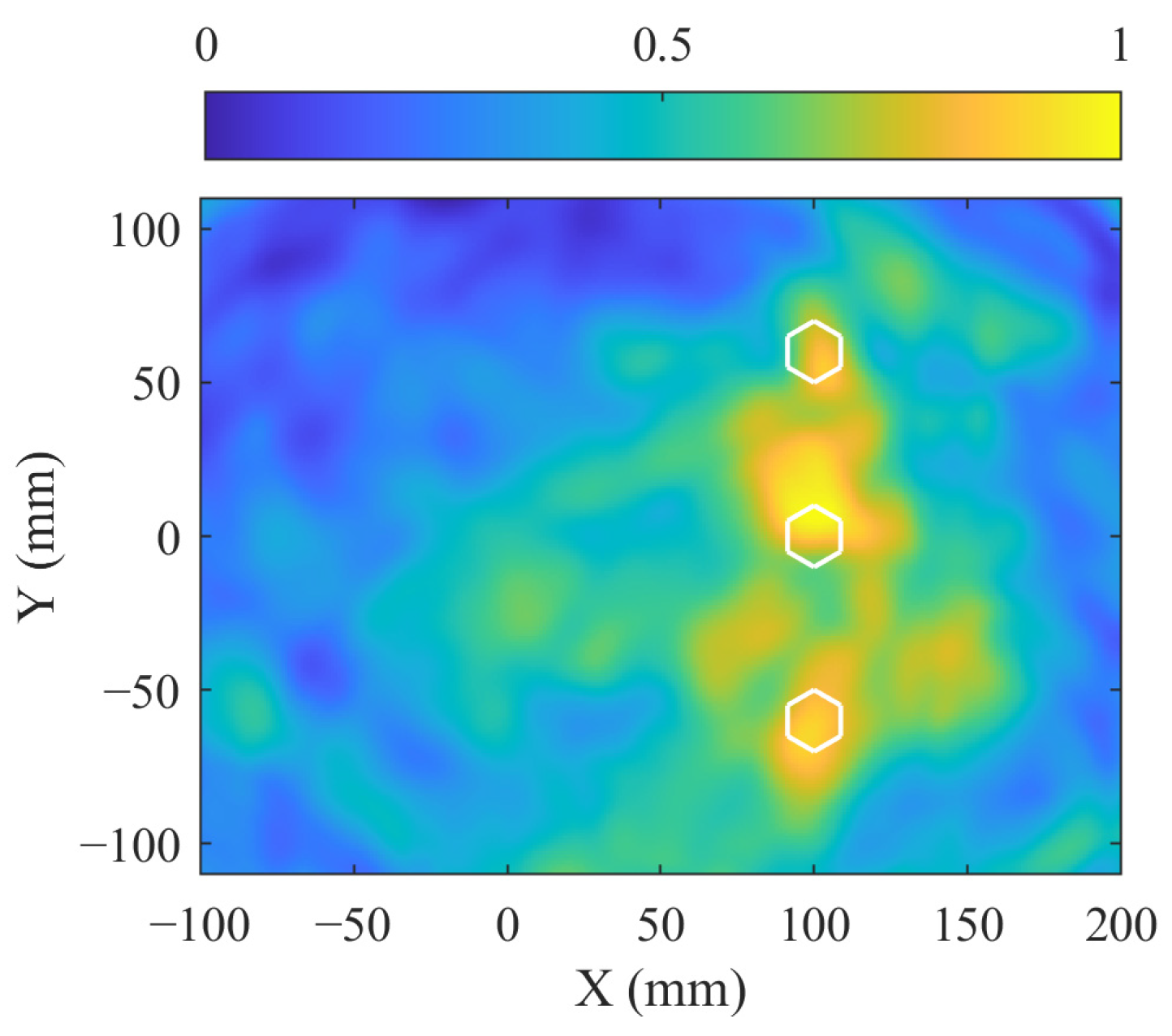

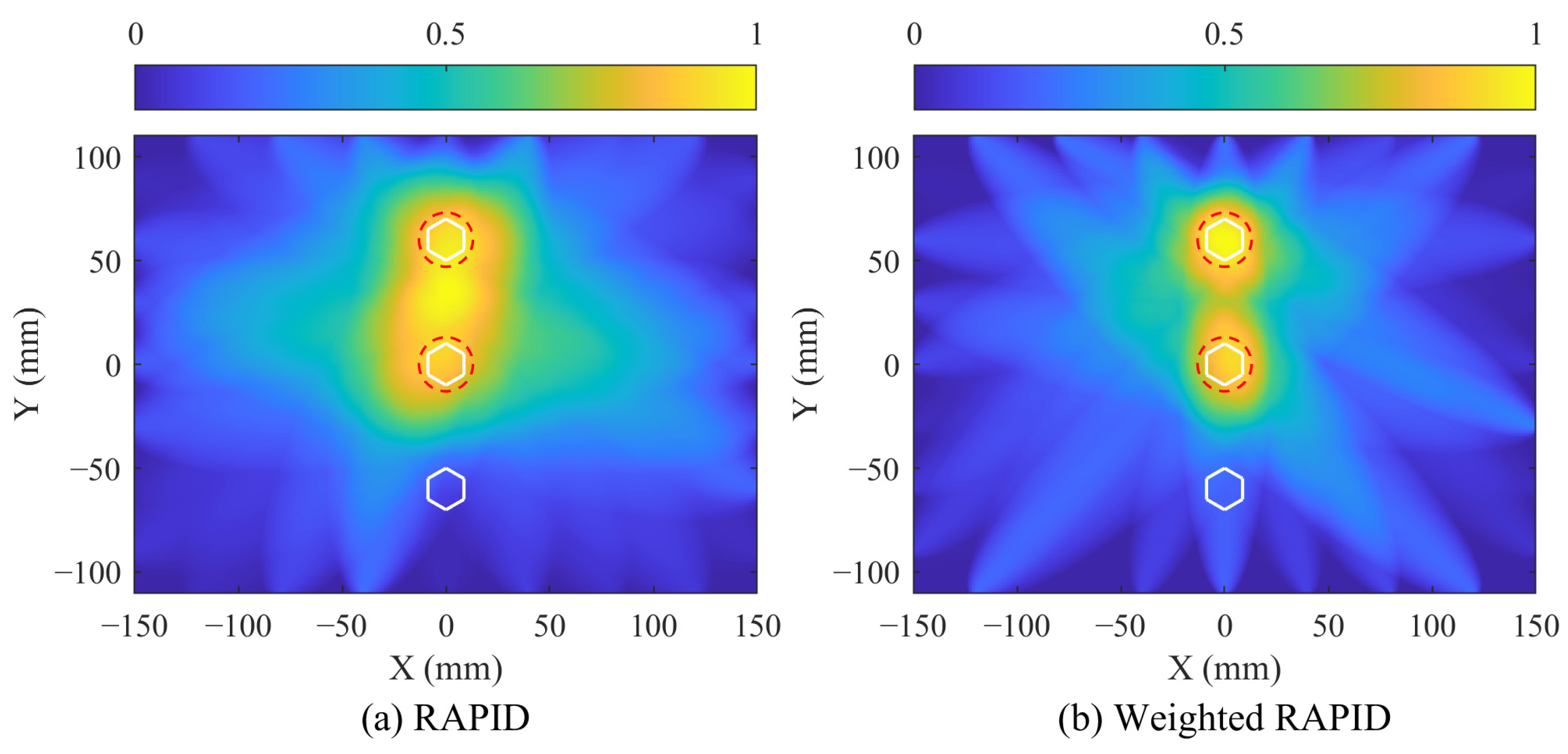

4.2. Imaging of the Two Corrosions

5. Conclusions

- The weighted fusion imaging method integrates the advantages of the MVDR algorithm for identifying bolt loosening and tightening states, along with the RAPID algorithm for damage imaging. It utilizes the MVDR-based bolt localization results as prior information to weight the sensing paths and employs a weighted RAPID method for accurate damage imaging and localization of corroded bolts.

- The proposed weighted RAPID method enables accurate imaging and localization, outperforming the traditional RAPID method. In single-corrosion imaging, this method achieves a location deviation of 6.52 mm. In two-corrosion imaging, leveraging data from a greater number of sensing paths, this method demonstrates higher localization accuracy with a maximum location deviation of 7.43 mm. These results indicate that the weighted RAPID method is suitable for the visual assessment of multi-damage issues in complex structures.

- To enhance the application potential of the proposed method, future research could focus on investigating the impact of noise on the imaging algorithm by introducing noise into the excitation signals. Additionally, the feasibility of applying this algorithm to other types of sensors and the reliability of long-term monitoring could be explored. The findings of this study are also expected to be integrated with V2X communication technology, enabling the incorporation of the algorithm into automotive structural health monitoring systems for remote damage diagnosis in complex structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ragunath, S.; Velmurugan, C.; Kannan, T. Experimental Investigation on Corrosive behavior of Boiler Material Using Polarization Technique. Procedia Mater. Sci. 2014, 5, 1274–1280. [Google Scholar] [CrossRef][Green Version]

- Ahn, J.-H.; Lee, J.M.; Cheung, J.-H.; Kim, I.-T. Clamping force loss of high-strength bolts as a result of bolt head corrosion damage: Experimental research A. Eng. Fail. Anal. 2016, 59, 509–525. [Google Scholar] [CrossRef]

- Li, M.; Yao, L.; Zhang, S.; Wang, D.; He, Z.; Sun, G. Study on bolt head corrosion influence on the clamping force loss of high strength bolt. Eng. Fail. Anal. 2021, 129, 105660. [Google Scholar] [CrossRef]

- Dai, W.; Wang, X.; Zhang, M.; Zhang, W.; Wang, R. Corrosion Monitoring Method of Porous Aluminum Alloy Plate Hole Edges Based on Piezoelectric Sensors. Sensors 2019, 19, 1106. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Dai, W.; Xu, D.; Zhang, W.; Ran, Y.; Wang, R. Hole-Edge Corrosion Expansion Monitoring Based on Lamb Wave. Metals 2020, 10, 1469. [Google Scholar] [CrossRef]

- Watanabe, T.; Trang, H.T.H.; Harada, K.; Hashimoto, C. Evaluation of corrosion-induced crack and rebar corrosion by ultrasonic testing. Constr. Build. Mater. 2014, 67, 197–201. [Google Scholar] [CrossRef]

- Seale, M.D.; Smith, B.T.; Prosser, W.H. Lamb wave assessment of fatigue and thermal damage in composites. J. Acoust. Soc. Am. 1998, 103, 2416–2424. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L.; Lu, Y. Guided Lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Abbas, M.; Shafiee, M. Structural Health Monitoring (SHM) and Determination of Surface Defects in Large Metallic Structures using Ultrasonic Guided Waves. Sensors 2018, 18, 3958. [Google Scholar] [CrossRef] [PubMed]

- Nagy, P.B.; Simonetti, F.; Instanes, G. Corrosion and erosion monitoring in plates and pipes using constant group velocity Lamb wave inspection. Ultrasonics 2014, 54, 1832–1841. [Google Scholar] [CrossRef]

- Huang, L.; Ding, J.; Lin, J.; Luo, Z. Detection and localization of corrosion using identical-group- velocity Lamb wave modes. Nondestruct. Test. Eval. 2024, 39, 594–613. [Google Scholar] [CrossRef]

- Luo, Z.; Zeng, L.; Lin, J. A hidden corrosion detection method based on robust multimodal Lamb waves. Meas. Sci. Technol. 2020, 31, 044002. [Google Scholar] [CrossRef]

- Ding, X.; Xu, C.; Deng, M.; Zhao, Y.; Bi, X.; Hu, N. Experimental investigation of the surface corrosion damage in plates based on nonlinear Lamb wave methods. NDT E Int. 2021, 121, 102466. [Google Scholar] [CrossRef]

- Mandel, M.; Fritzsche, M.; Henschel, S.; Krüger, L. Lamb wave-based corrosion source location on a plate of magnesium alloy WZ73 using the acoustic emission technique. Corros. Commun. 2024, 13, 60–67. [Google Scholar] [CrossRef]

- Wang, F. Identification of multi-bolt head corrosion using linear and nonlinear shapelet-based acousto-ultrasonic methods. Smart Mater. Struct. 2021, 30, 085031. [Google Scholar] [CrossRef]

- Hu, M.; Yue, N.; Groves, R.M. Damage Classification of a Bolted Connection using Guided Waves and Explainable Artificial Intelligence. Procedia Struct. Integr. 2024, 52, 224–233. [Google Scholar] [CrossRef]

- Gazkooh, H.K.; Yousefi-Koma, A. Enhancing the understanding of bolt loosening and wave transmission in bolted lap-joint connections: A numerical and experimental study using guided Lamb waves. Struct. Health Monit. 2024, 23, 3446–3464. [Google Scholar] [CrossRef]

- Huang, L.; Luo, Z.; Zeng, L.; Lin, J. Detection and localization of corrosion using the combination information of multiple Lamb wave modes. Ultrasonics 2024, 138, 107246. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Shao, W.; Song, J.; Yang, X.; Wang, Y.; Qing, X. Corrosion quantification of plate-type structures using Lamb wavefield and monogenic signal processing. Ultrasonics 2023, 130, 106935. [Google Scholar] [CrossRef] [PubMed]

- Tong, T.; Hua, J.; Gao, F.; Lin, J. Identification of bolt state in lap joint based on propagation model and imaging methods of Lamb waves. Mech. Syst. Signal Process. 2023, 200, 110569. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, W.; Wang, X.; Sun, B. Lamb-Wave-Based Tomographic Imaging Techniques for Hole-Edge Corrosion Monitoring in Plate Structures. Materials 2016, 9, 916. [Google Scholar] [CrossRef]

- Hua, J.; Cao, X.; Yi, Y.; Lin, J. Time-frequency damage index of Broadband Lamb wave for corrosion inspection. J. Sound Vib. 2020, 464, 114985. [Google Scholar] [CrossRef]

- Rathod, V.T.; Roy Mahapatra, D. Ultrasonic Lamb wave based monitoring of corrosion type of damage in plate using a circular array of piezoelectric transducers. NDT E Int. 2011, 44, 628–636. [Google Scholar] [CrossRef]

- Lin, M.; Liu, Y. Accurate Thickness Inversion of Corrosion Using A1 Lamb Wave. In Proceedings of the 2021 48th Annual Review of Progress in Quantitative Nondestructive Evaluation, Online, 28–30 July 2021. [Google Scholar]

- Zimmermann, A.A.E.; Huthwaite, P.; Pavlakovic, B. High-resolution thickness maps of corrosion using SH1 guided wave tomography. Proc. Math. Phys. Eng. Sci. 2021, 477, 20200380. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Kim, P.; Lee, J.; Kim, S.; Park, S.; Choi, S.H.; Hwang, J.; Lee, J.H.; Lee, H.; Wijesinghe, R.E.; et al. Non-Destructive Identification of Weld-Boundary and Porosity Formation During Laser Transmission Welding by Using Optical Coherence Tomography. IEEE Access 2018, 6, 76768–76775. [Google Scholar] [CrossRef]

- Knight, S.P.; Salagaras, M.; Trueman, A.R. The study of intergranular corrosion in aircraft aluminium alloys using X-ray tomography. Corros. Sci. 2011, 53, 727–734. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Liu, Y.; Dong, P.; Zhang, J.; Xing, F.; Hong, S. Monitoring reinforcement corrosion and corrosion-induced cracking by X-ray microcomputed tomography method. Cem. Concr. Res. 2017, 100, 311–321. [Google Scholar] [CrossRef]

- Zhang, D.; Cui, C.; Zhang, X.; Jiang, Z.; Zhang, X.; Bao, Y. Monitoring fatigue cracks in rib-to-deck joints of orthotropic steel deck using ultrasonic Lamb waves. Thin-Walled Struct. 2023, 189, 110922. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Chapter 6—Guided Waves. In Structural Health Monitoring with Piezoelectric Wafer Active Sensors, 2nd ed.; Giurgiutiu, V., Ed.; Academic Press: Oxford, UK, 2014; pp. 293–355. [Google Scholar]

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Hua, J.; Zhang, H.; Miao, Y.; Lin, J. Modified minimum variance imaging of Lamb waves for damage localization in aluminum plates and composite laminates. NDT E Int. 2022, 125, 102574. [Google Scholar] [CrossRef]

- Hall, J.; Michaels, J. Minimum Variance Ultrasonic Imaging Applied to an In Situ Sparse Guided Wave Array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 2311–2323. [Google Scholar] [CrossRef]

- Carlson, B.D. Covariance matrix estimation errors and diagonal loading in adaptive arrays. IEEE Trans. Aerosp. Electron. Syst. 1988, 24, 397–401. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L. Identification of Damage Using Lamb Waves: From Fundamentals to Applications; Springer Science and Business Media: New York, NY, USA, 2009; Volume 48. [Google Scholar]

- Xu, D.; Zhang, W.; Han, L.; Liu, X.; Hu, W. Application of Sensor Path Weighting RAPID Algorithm on Pitting Corrosion Monitoring of Aluminum Plate. Materials 2022, 15, 3887. [Google Scholar] [CrossRef]

- Zhao, X.; Gao, H.; Zhang, G.; Ayhan, B.; Yan, F.; Kwan, C.; Rose, J.L. Active health monitoring of an aircraft wing with embedded piezoelectric sensor/actuator network: I. Defect detection, localization and growth monitoring. Smart Mater. Struct. 2007, 16, 1208–1217. [Google Scholar] [CrossRef]

- Wang, D.; Ye, L.; Lu, Y.; Su, Z. Probability of the presence of damage estimated from an active sensor network in a composite panel of multiple stiffeners. Compos. Sci. Technol. 2009, 69, 2054–2063. [Google Scholar] [CrossRef]

- Lee, J.; Sheen, B.; Cho, Y. Quantitative tomographic visualization for irregular shape defects by guided wave long range inspection. Int. J. Precis. Eng. Manuf. 2015, 16, 1949–1954. [Google Scholar] [CrossRef]

- Ling, F.; Chen, H.; Lang, Y.; Yang, Z.; Xu, K.; Ta, D. Lamb wave tomography for defect localization using wideband dispersion reversal method. Measurement 2023, 216, 112965. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Tuned Lamb Wave Excitation and Detection with Piezoelectric Wafer Active Sensors for Structural Health Monitoring. J. Intell. Mater. Syst. Struct. 2005, 16, 291–305. [Google Scholar] [CrossRef]

| Material | Young’s Modulus (GPa) | Poisson’s Ratio | Density (kg·m−3) |

|---|---|---|---|

| 2024-T3 Aluminum alloy | 72 | 0.33 | 2780 |

| Product number | SMD07T05R412WL |

| Material | SM412 |

| Geometry | Diameter: 7 mm, thickness: 0.5 mm |

| Resonant frequency | 4.25 MHz ± 5% |

| Electrostatic capacitance | 2.5 nF ± 30% |

| Test Condition | 25 ± 3 °C 40~70% R.H. (Relative Humidity) |

| Methods | Traditional RAPID | Weighted RAPID |

|---|---|---|

| Deviations (mm) | 18.56 | 6.52 |

| Location | Bolt I | Bolt II |

|---|---|---|

| Deviations (mm) | 4.5 | 7.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, Y.; Qian, C.; Wang, X.; Zhang, W.; Wang, R. Corrosion Monitoring in Automotive Lap Joints Based on Imaging Methods of Lamb Waves. Sensors 2024, 24, 8092. https://doi.org/10.3390/s24248092

Ran Y, Qian C, Wang X, Zhang W, Wang R. Corrosion Monitoring in Automotive Lap Joints Based on Imaging Methods of Lamb Waves. Sensors. 2024; 24(24):8092. https://doi.org/10.3390/s24248092

Chicago/Turabian StyleRan, Yunmeng, Cheng Qian, Xiangfen Wang, Weifang Zhang, and Rongqiao Wang. 2024. "Corrosion Monitoring in Automotive Lap Joints Based on Imaging Methods of Lamb Waves" Sensors 24, no. 24: 8092. https://doi.org/10.3390/s24248092

APA StyleRan, Y., Qian, C., Wang, X., Zhang, W., & Wang, R. (2024). Corrosion Monitoring in Automotive Lap Joints Based on Imaging Methods of Lamb Waves. Sensors, 24(24), 8092. https://doi.org/10.3390/s24248092