Digitalization of an Industrial Process for Bearing Production

Abstract

1. Introduction

2. Materials and Methods

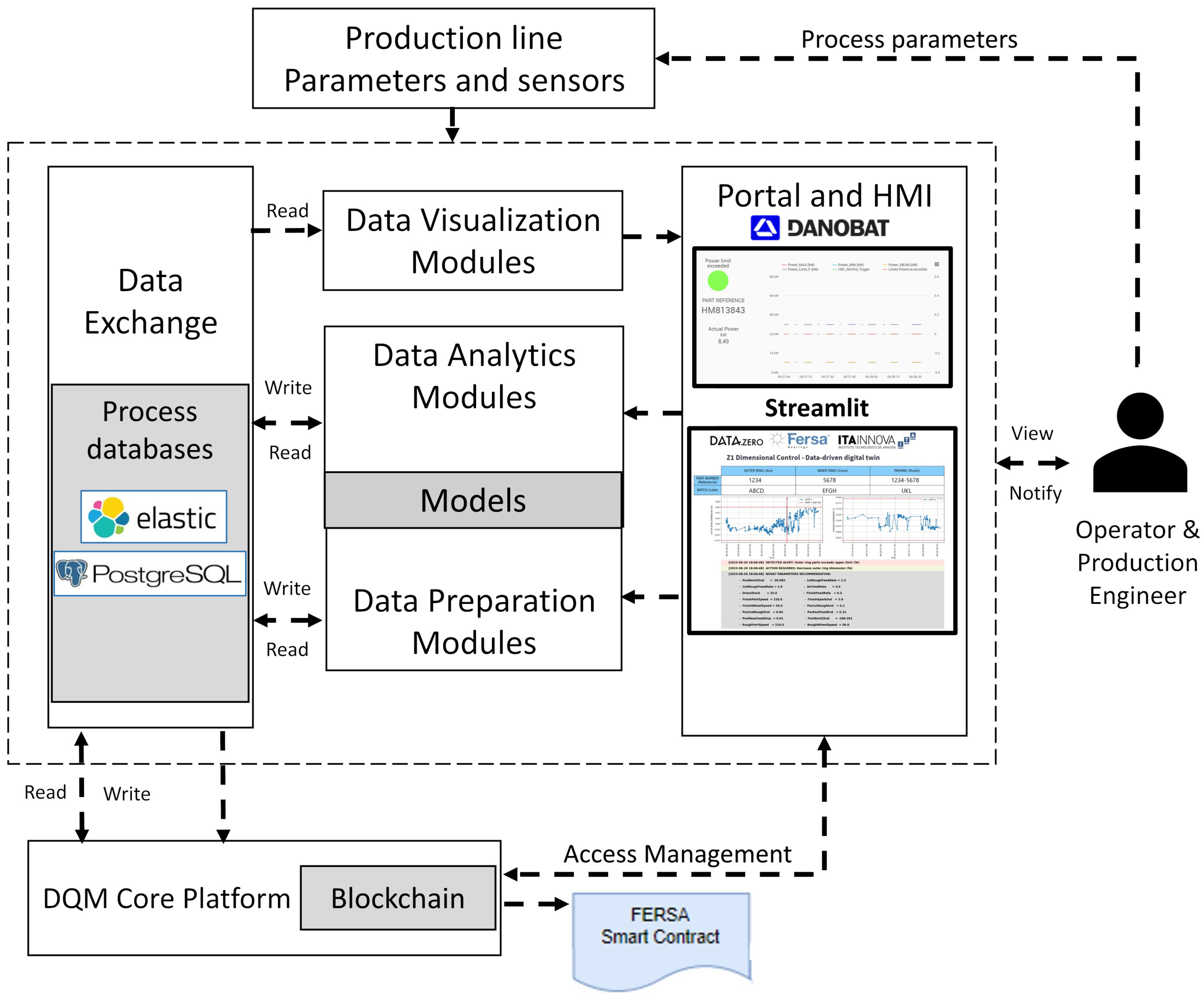

2.1. Description of the Process Line Digitalization

2.1.1. New Sensors

2.1.2. Communication Hardware

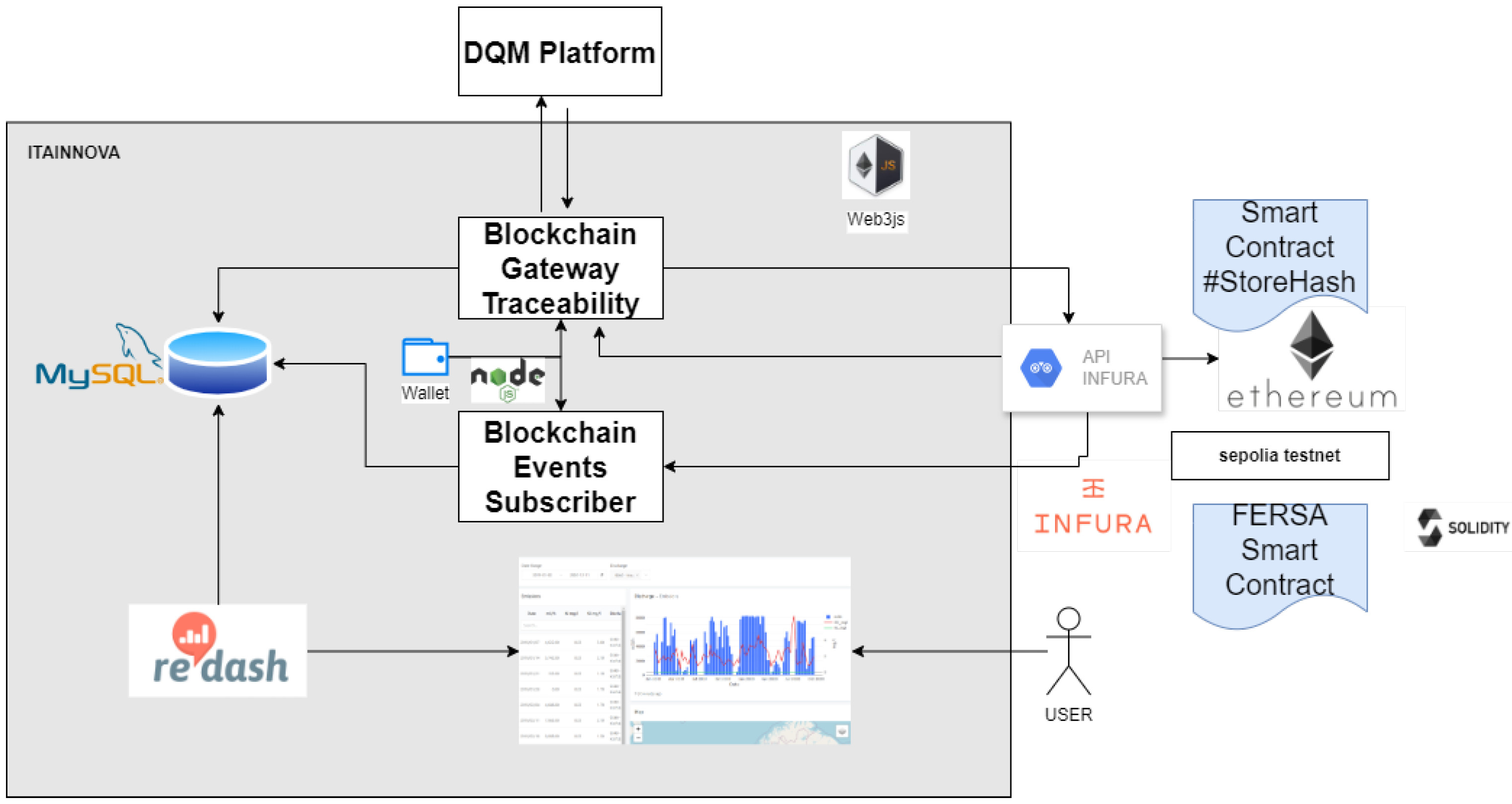

2.1.3. Blockchain

2.2. Description of the Grinding Quality Prediction Algorithms

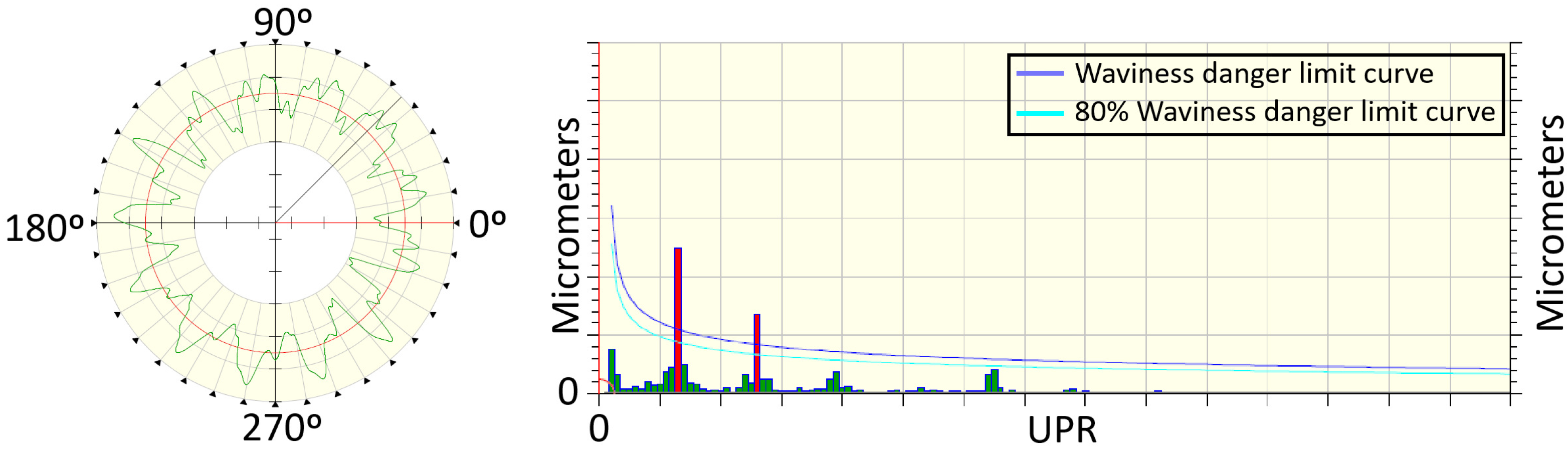

2.2.1. Waviness Prediction Algorithm

2.2.2. Thermal Damage Prediction Algorithm

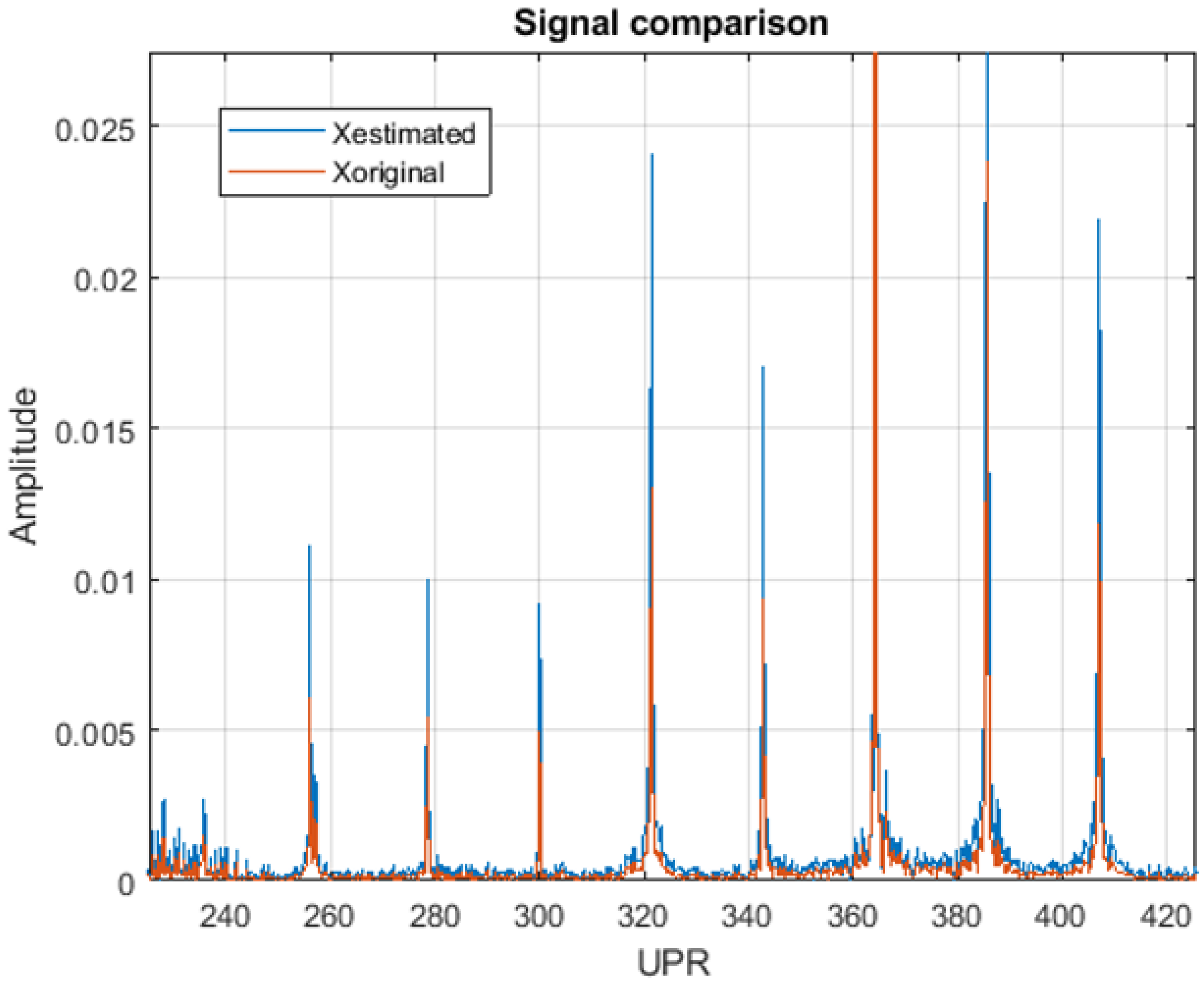

2.2.3. Tool State Identification Algorithm

2.3. Assembly Quality Prediction

2.3.1. Feature Extraction & Feature Engineering

- CNC: Manufacturing configuration parameters comprising 79 variables with a sampling frequency of 5–8 s. These parameters are measurement once per part.

- IC2: 39 accelerometer variables sampled at 1 Hz.

- IC3: 4 power consumption measurements sampled at 1 Hz.

2.3.2. Feature Selection

2.3.3. Data Preparation

2.3.4. Modeling

- Five types of machine learning models were trained: Multi-Layer Perceptron, Decision Tree, Random Forest, SVM, and Gradient Boosting;

- For each model, a hyper-parameter-tuning process was conducted using Bayesian optimization methods;

- Model evaluation was performed using cross-validation techniques, using the metric as the selection criterion.

3. Results

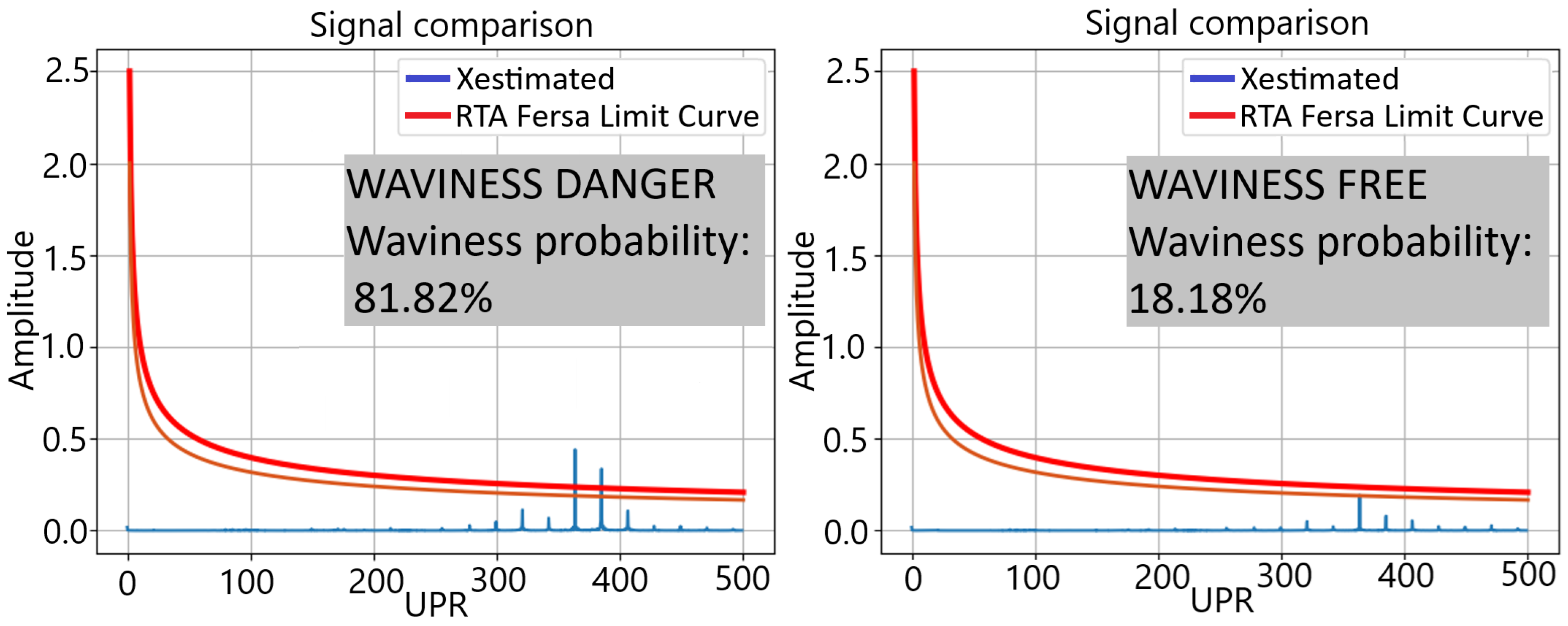

3.1. Waviness

3.2. Burns

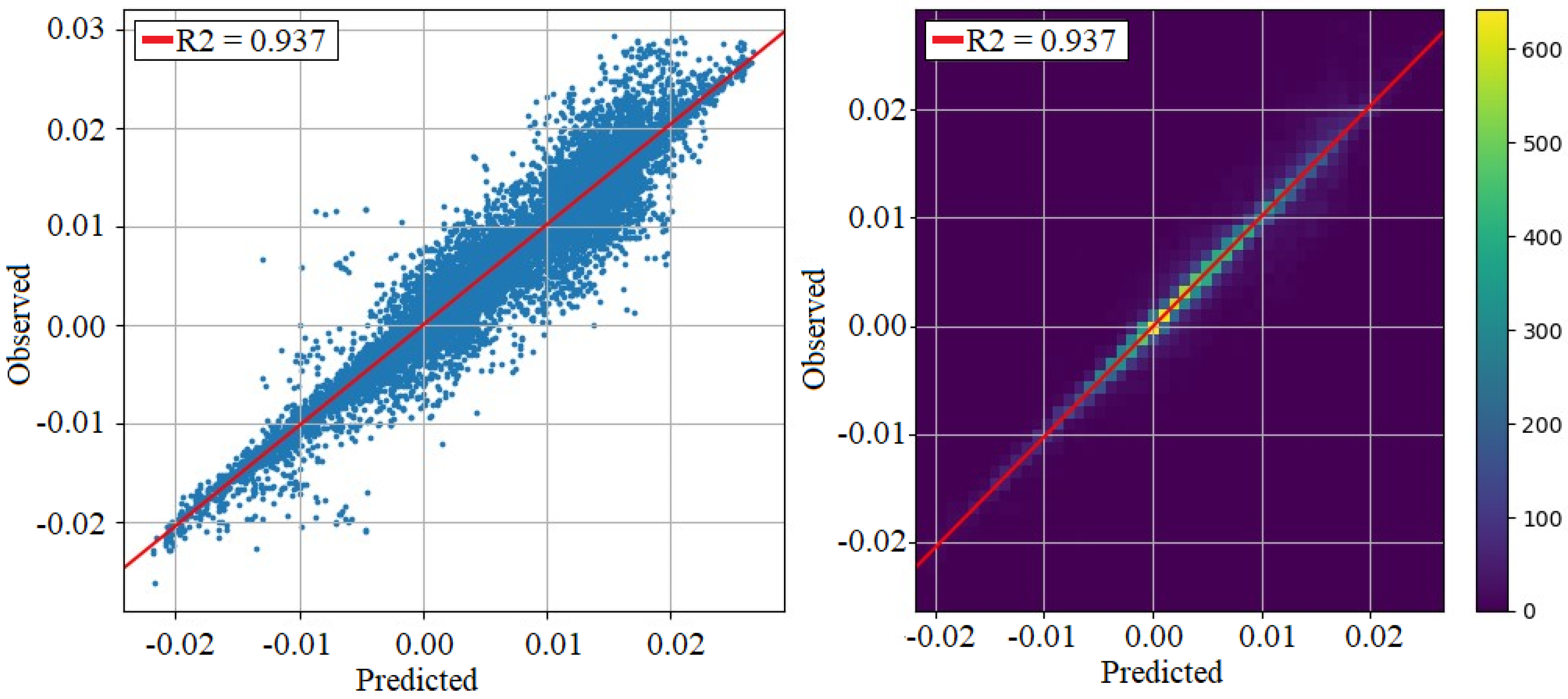

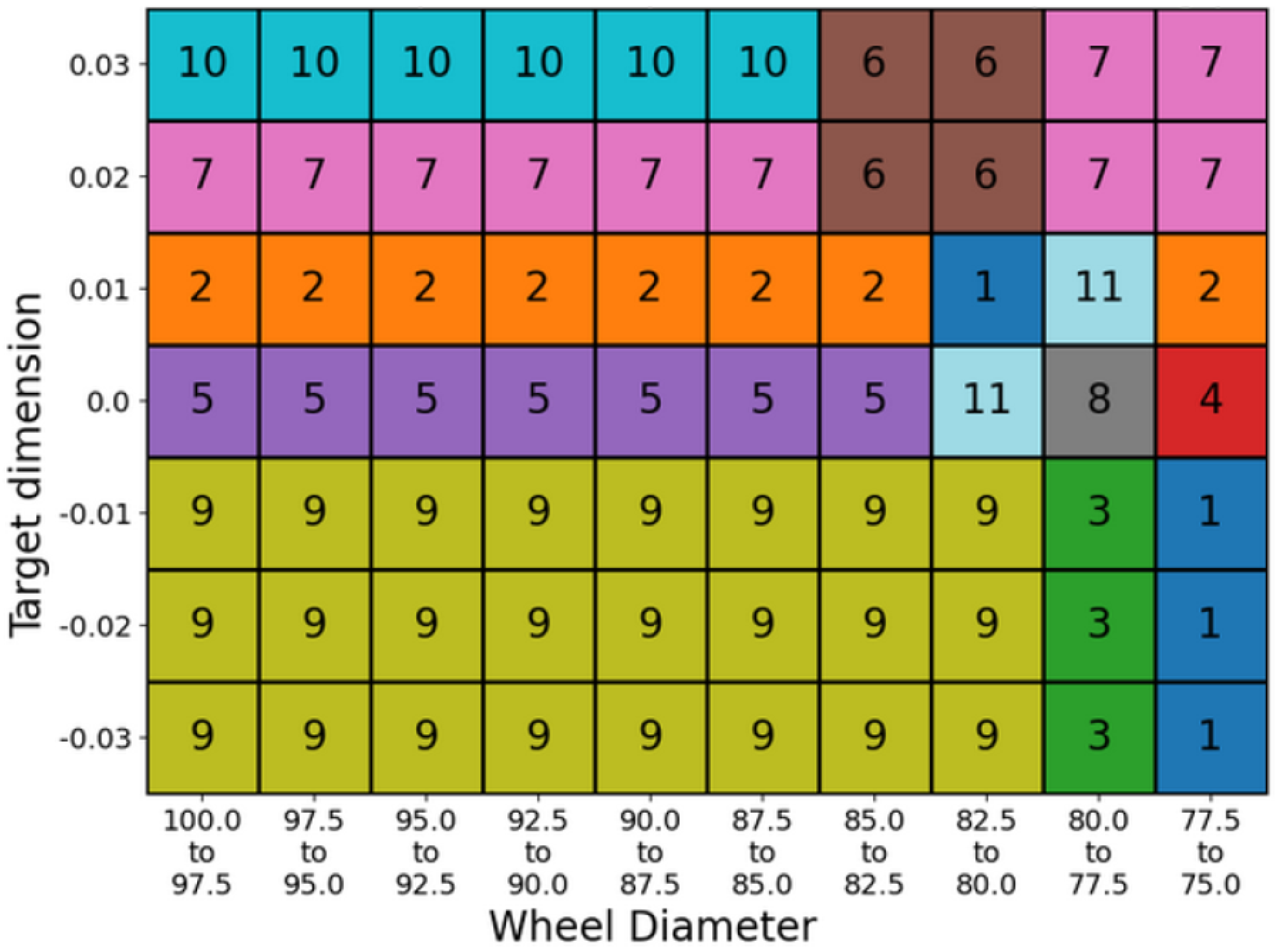

3.3. Line Dimensional Control

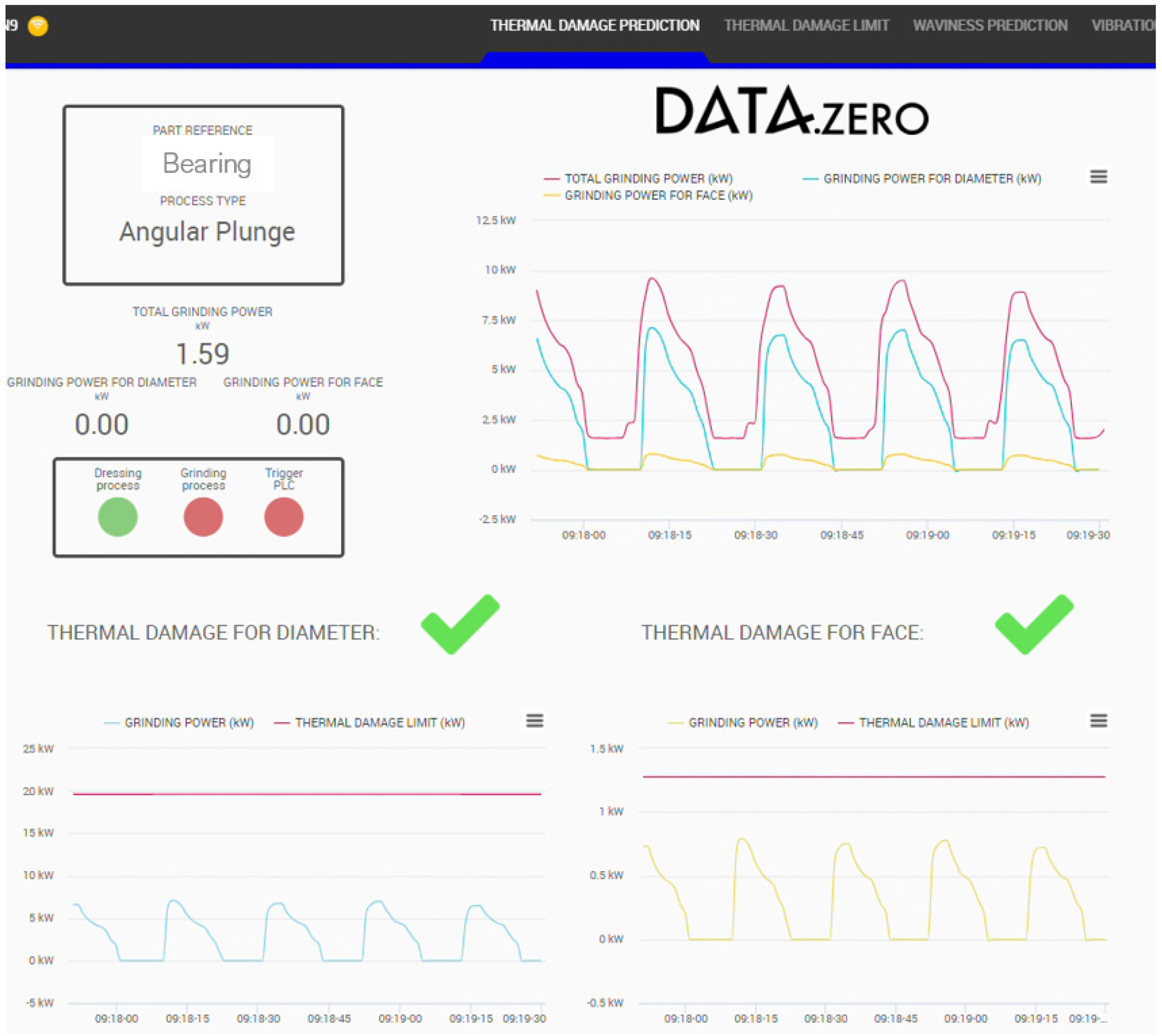

3.4. Data Visualization

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raval, M.B.; Joshi, H. Categorical framework for implementation of industry 4.0 techniques in medium-scale bearing manufacturing industries. Mater. Today Proc. 2022, 65, 3531–3537. [Google Scholar] [CrossRef]

- Patkar, K.S.; Panchpor, J.U.; Vaidya, S.M.; Nadgire, A.R. Industry 4.0: Implementation in Bearing Manufacturing. Int. J. Res. Eng. Appl. Manag. 2018, 9, 45–48. [Google Scholar]

- Xiao, G.; Malkin, S.; Danai, K. Autonomous system for multi-stage cylindrical grinding. ASME J. Dyn. Syst. Meas. Control. 1993, 115, 667–672. [Google Scholar] [CrossRef]

- Cai, R.; Rowe, W.B.; Moruzzi, J.L.; Morgan, M. Intelligent grinding assistant (IGA (©))-system development part I intelligent grinding database. Int. J. Adv. Manuf. Technol. 2007, 35, 75–85. [Google Scholar] [CrossRef]

- Barrenetxea, D.; Alvarez, J.; Marquinez, J.; Gallego, I.; Perello, I.; Krajnik, P. Stability analysis and optimization algorithms for the set-up of infeed centerless grinding. Int. J. Mach. Tools Manuf. 2014, 84, 17–32. [Google Scholar] [CrossRef]

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Sauter, E.; Sarikaya, E.; Winter, M.; Wegener, K. In-process detection of grinding burn using machine learning. Int. J. Adv. Manuf. Technol. 2021, 115, 2281–2297. [Google Scholar] [CrossRef]

- Ahrens, M.; Fischer, R.; Dagen, M.; Denkena, B.; Ortmaier, T. Abrasion Monitoring and Automatic Chatter Detection in Cylindrical Plunge Grinding. Procedia CIRP 2013, 8, 374–378. [Google Scholar] [CrossRef]

- Nelwamondo, F.V.; Marwala, T.; Mahola, U. Early classifications of bearing faults using hidden Markov models, Gaussian mixture models, Mel-frequency cepstral coefficients and fractals. Int. J. Innov. Comput. Inf. Control. 2006, 2, 1281–1299. [Google Scholar]

- Dotto, F.; Aguiar, P.; Carlos, B.; Flauzino, R.A.; Oliveira, C.; Pansanato, L. Automatic detection of thermal damage in grinding process by artificial neural network. Rev. Esc. Minas 2003, 56, 295–300. [Google Scholar] [CrossRef]

- Neto, R.F.G.; Marchi, M.; Martins, C.H.R.; Aguiar, P.; Bianchi, E.C. Monitoring of grinding burn by AE and vibration signals. In Proceedings of the 6th International Conference on Agents and Artificial Intelligenc, Angers, France, 6–8 March 2014; pp. 272–279. [Google Scholar]

- Guo, W.; Li, B.; Shen, S.; Zhou, Q. An intelligent grinding burn detection system based on two-stage feature selection and stacked sparse autoencoder. Int. J. Adv. Manuf. Technol. 2019, 103, 2837–2847. [Google Scholar] [CrossRef]

- Warke, V.; Kumar, S.; Bongale, A.; Kamat, P.; Kotecha, K.; Selvachandran, G.; Abraham, A. Improving the useful life of tools using active vibration control through data-driven approaches: A systematic literature review. Eng. Appl. Artif. Intell. 2024, 128, 107367. [Google Scholar] [CrossRef]

- Yang, Z.; Yu, Z. Grinding wheel wear monitoring based on wavelet analysis and support vector machine. Int. J. Adv. Manuf. Technol. 2012, 62, 107–121. [Google Scholar] [CrossRef]

- Liao, T.W.; Hua, G.G.; Qu, J.; Blau, P.J. Grinding wheel condition monitoring with hidden Markov model-based clustering methods. Mach. Sci. Technol. 2010, 10, 511–538. [Google Scholar] [CrossRef]

- Lu, C.; Li, T.; Liu, H. Online milling tool condition monitoring with a single continuous hidden Markov models approach. J. Vibroeng. 2014, 6, 2448–2457. [Google Scholar]

- Krishnan, P.S.; Rameshkumar, K. Grinding wheel condition prediction with discrete hidden Markov model using acoustic emission signature. Mater. Today Proc. 2021, 46, 9168–9175. [Google Scholar] [CrossRef]

- de Oliveira, J.; Dornfeld, D.A. Dimensional Characterization of Grinding Wheel Surface through Acoustic Emission. CIRP Ann. 1994, 43, 291–294. [Google Scholar] [CrossRef]

- de Oliveira, J.G.; Dornfeld, D. Application of AE Contact Sensing in Reliable Grinding Monitoring. CIRP Ann. 2001, 50, 217–220. [Google Scholar] [CrossRef]

- Lee, D.E.; Hwang, I.; Valente, C.M.O.; Oliveira, J.; Dornfeld, D.A. Precision Manufacturing Process Monitoring with Acoustic Emission; Springer: London, UK, 2006. [Google Scholar]

- Chen, T.; Sampath, V.; May, M.C.; Shan, S.; Jorg, O.J.; Martín, J.; Stamer, F.; Fantoni, G.; Tosello, G.; Calaon, M. Machine Learning in Manufacturing towards Industry 4.0: From ‘For Now’ to ‘Four-Know’. Appl. Sci. 2023, 13, 1903. [Google Scholar] [CrossRef]

- Schmitt, J.; Bönig, J.; Borggräfe, T.; Beitinger, G.; Deuse, J. Predictive model-based quality inspection using Machine Learning and Edge Cloud Computing. Adv. Eng. Inform. 2020, 45, 101101. [Google Scholar] [CrossRef]

- Wang, L.C.; Chen, C.; Hsu, C.C. Applying machine learning and GA for process parameter optimization in car steering wheel manufacturing. Int. J. Adv. Manuf. Technol. 2022, 122, 4389–4403. [Google Scholar] [CrossRef]

- Badger, J.; Murphy, S.; O’Donnell, G. The effect of wheel eccentricity and run-out on grinding forces, waviness, wheel wear and chatter. Int. J. Mach. Tools Manuf. 2011, 51, 766–774. [Google Scholar] [CrossRef]

- Gligoric, N.; Escuín, D.; Polo, L.; Amditis, A.; Georgakopoulos, T.; Fraile, A. IOTA-Based Distributed Ledger in the Mining Industry: Efficiency, Sustainability and Transparency. Sensors 2024, 24, 923. [Google Scholar] [CrossRef] [PubMed]

- Malkin, S.; Guo, C. Thermal analysis of grinding. CIRP Ann. 2007, 56, 760–782. [Google Scholar] [CrossRef]

- Urgoiti, L.; Barrenetxea, D.; Sánchez, J.; Lanzagorta, J. Detailed Thermo-Kinematic Analysis of Face Grinding Operations with Straight Wheels. Metals 2020, 10, 524. [Google Scholar] [CrossRef]

- Urgoiti, L.; Barrenetxea, D.; Sánchez, J.; Godino, L. Experimental study of thermal behaviour of face grinding with alumina angular wheels considering the effect of wheel wear. CIRP J. Manuf. Sci. Technol. 2021, 35, 691–700. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez-Fortun, J.-M.; Alvarez, J.; Monzon, L.; Salillas, R.; Noriega, S.; Escuin, D.; Abadia, D.; Barrutia, A.; Gaspar, V.; Romeo, J.A.; et al. Digitalization of an Industrial Process for Bearing Production. Sensors 2024, 24, 7783. https://doi.org/10.3390/s24237783

Rodriguez-Fortun J-M, Alvarez J, Monzon L, Salillas R, Noriega S, Escuin D, Abadia D, Barrutia A, Gaspar V, Romeo JA, et al. Digitalization of an Industrial Process for Bearing Production. Sensors. 2024; 24(23):7783. https://doi.org/10.3390/s24237783

Chicago/Turabian StyleRodriguez-Fortun, Jose-Manuel, Jorge Alvarez, Luis Monzon, Ricardo Salillas, Sergio Noriega, David Escuin, David Abadia, Aitor Barrutia, Victor Gaspar, Jose Antonio Romeo, and et al. 2024. "Digitalization of an Industrial Process for Bearing Production" Sensors 24, no. 23: 7783. https://doi.org/10.3390/s24237783

APA StyleRodriguez-Fortun, J.-M., Alvarez, J., Monzon, L., Salillas, R., Noriega, S., Escuin, D., Abadia, D., Barrutia, A., Gaspar, V., Romeo, J. A., Cebrian, F., & del-Hoyo-Alonso, R. (2024). Digitalization of an Industrial Process for Bearing Production. Sensors, 24(23), 7783. https://doi.org/10.3390/s24237783