Numerical Simulation and Field Monitoring of Blasting Vibration for Tunnel In-Situ Expansion by a Non-Cut Blast Scheme

Abstract

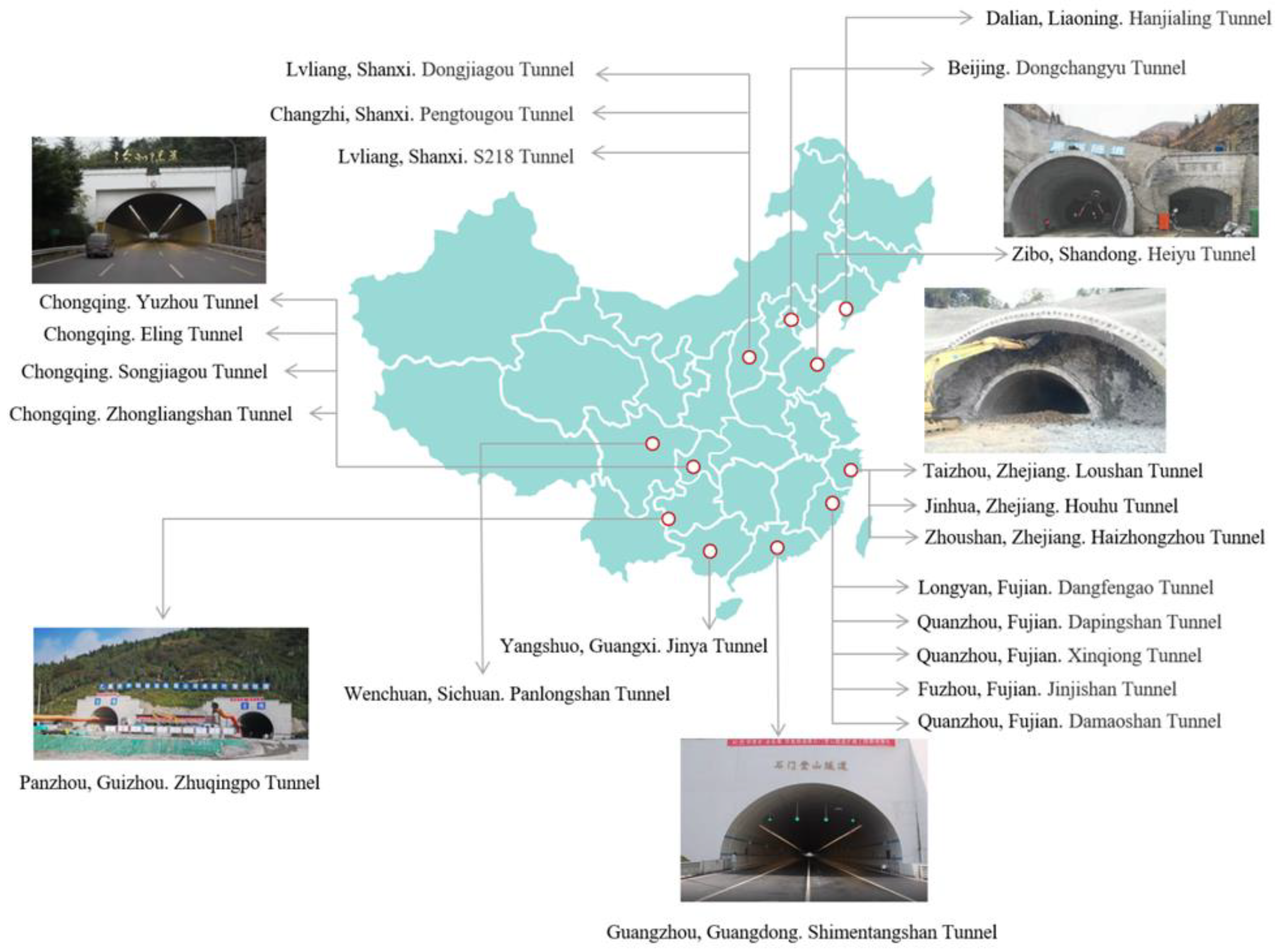

1. Introduction

2. Expansion of the Gushan Tunnel

2.1. General Situation

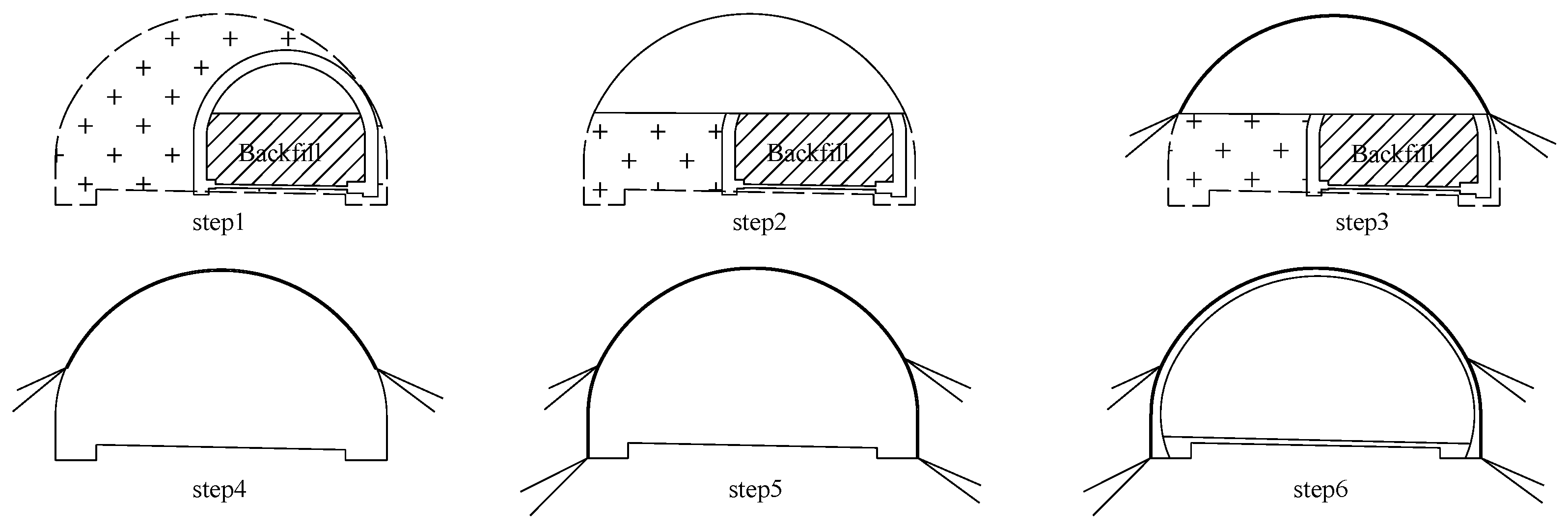

2.2. Traditional Blast Scheme

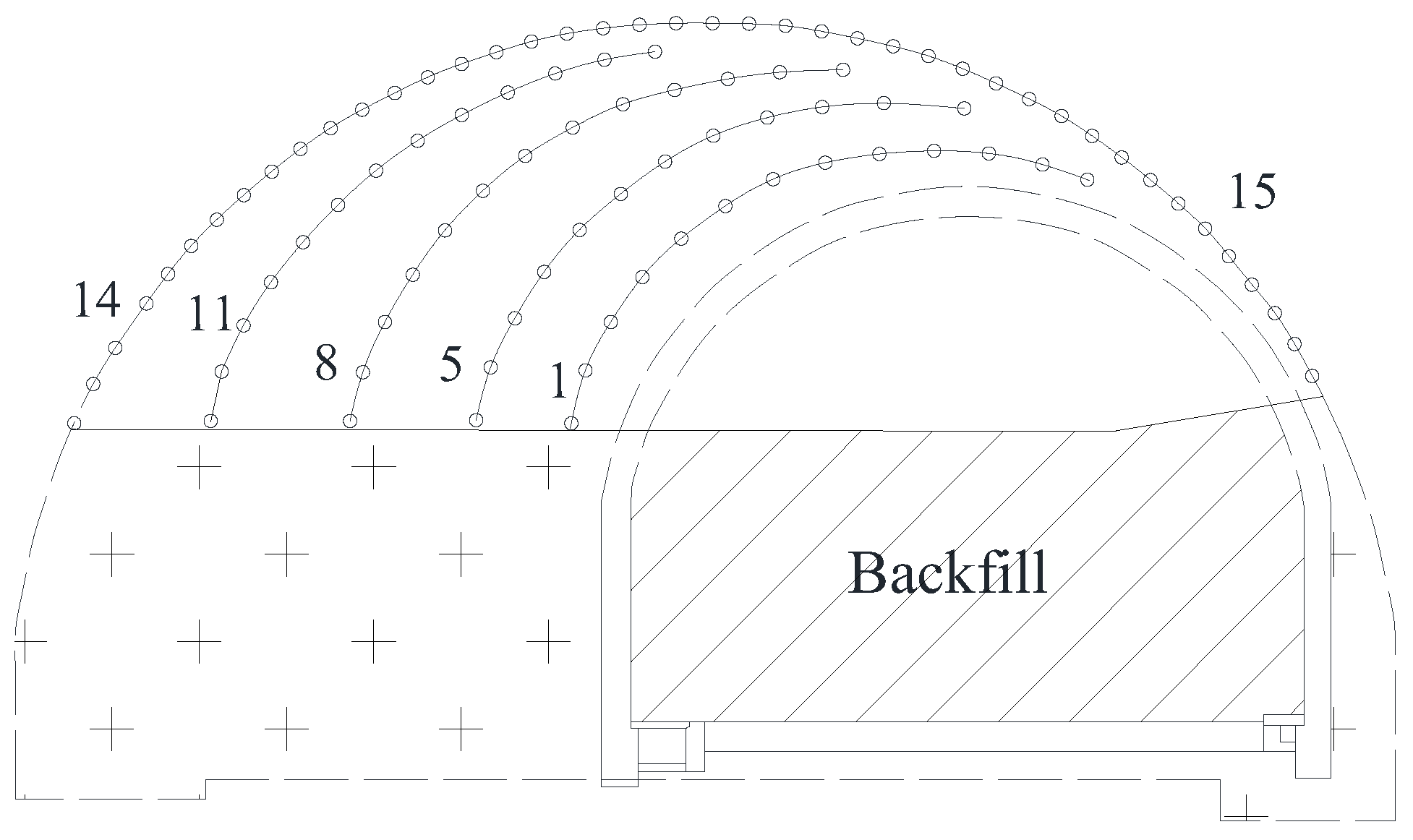

2.3. Non-cut Blast Scheme

3. Numerical Simulation for the Millisecond Blasting of Tunnel Excavation

3.1. Dynamic Calculation in FLAC3D

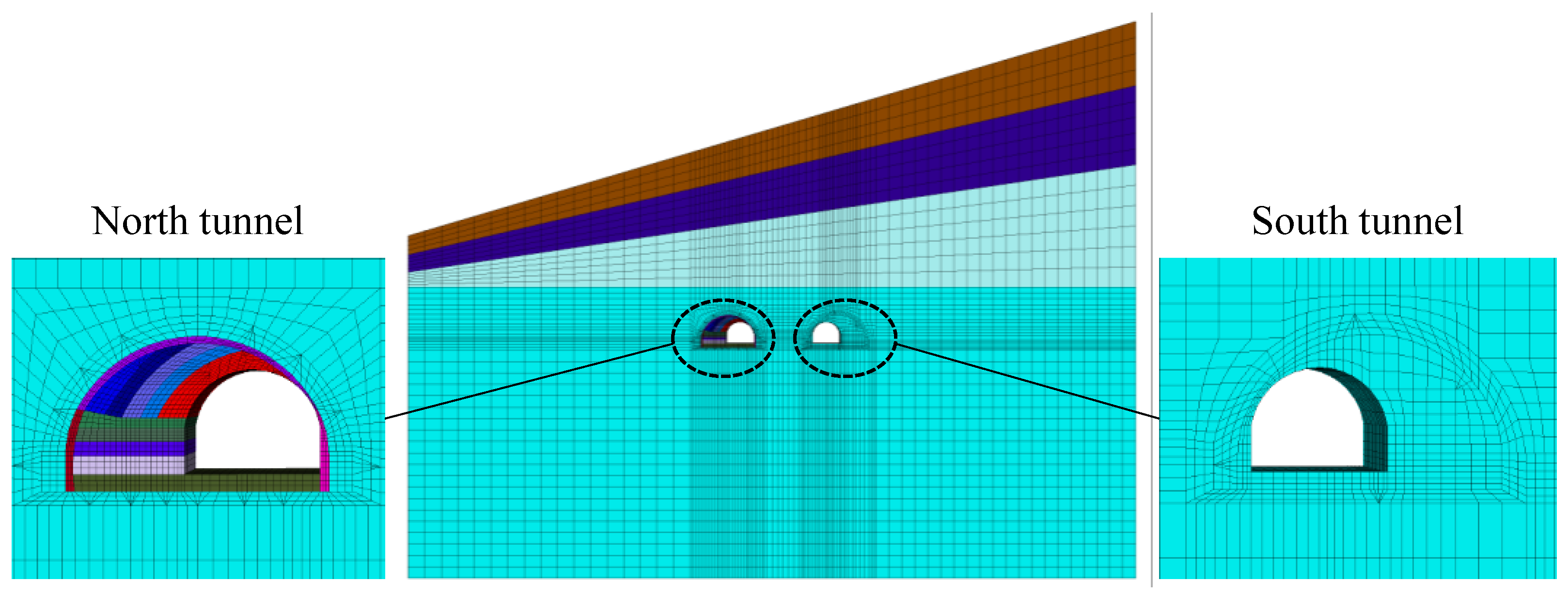

3.2. Numerical Model

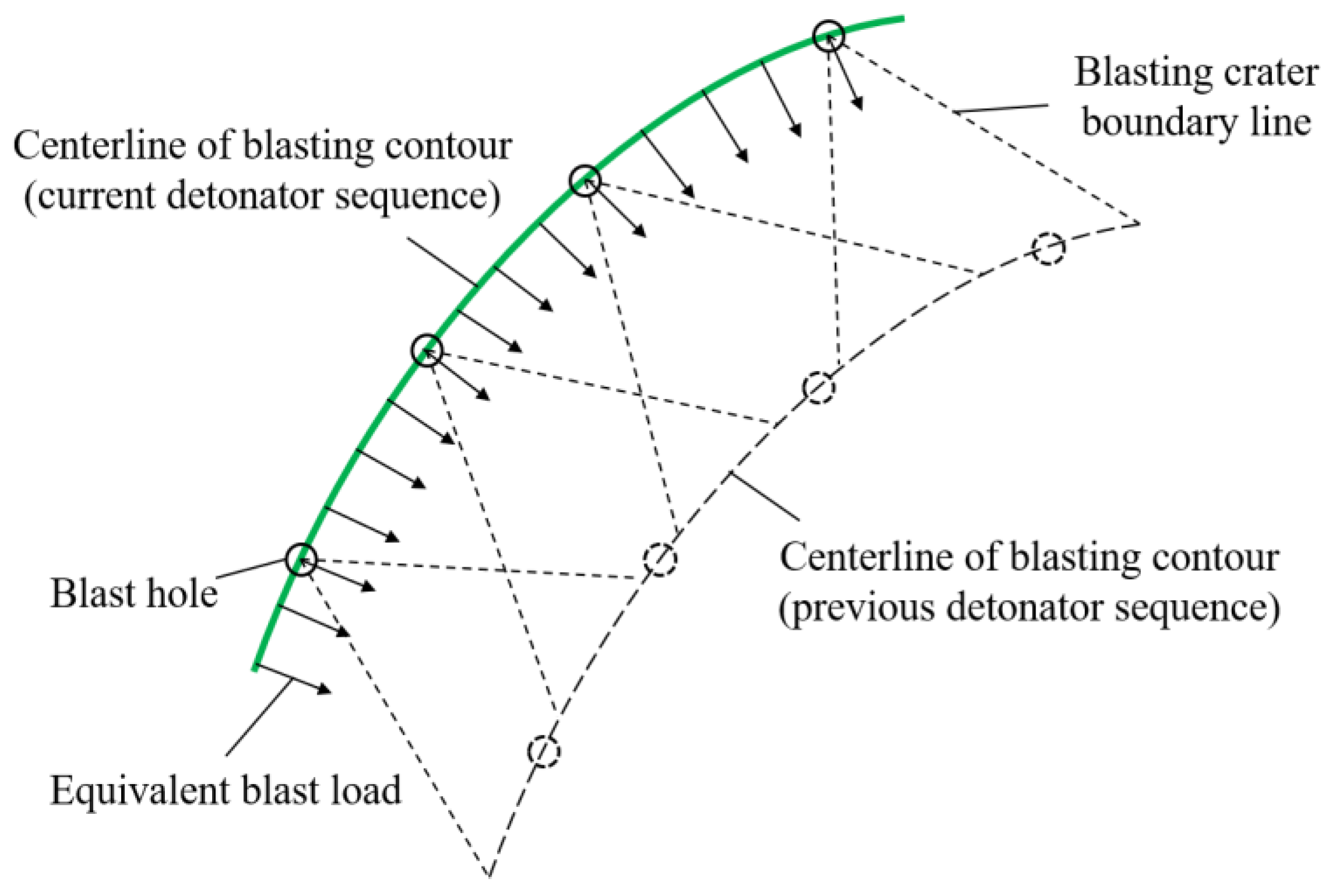

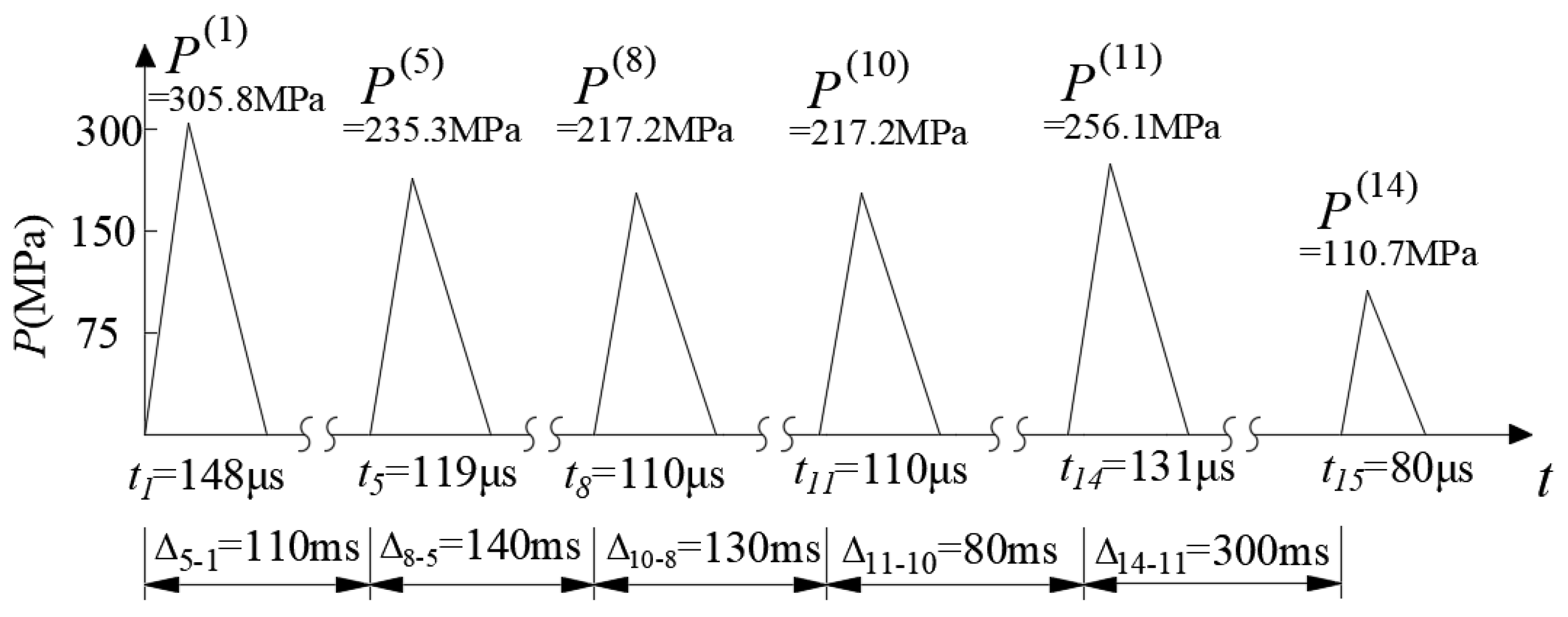

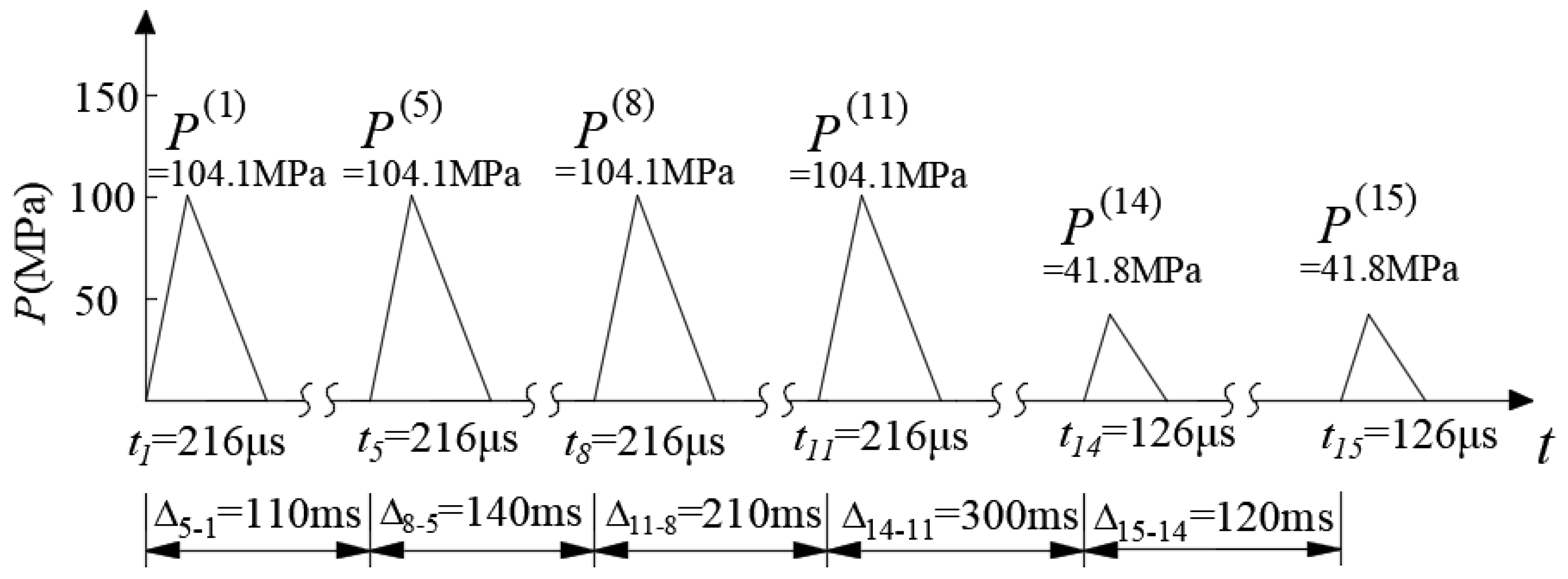

3.3. Equivalent Blasting Load for Two Blast Schemes

3.4. Arrangement of Numerical Monitoring Points

4. Blasting Vibration Analyses Based on Numerical Simulations

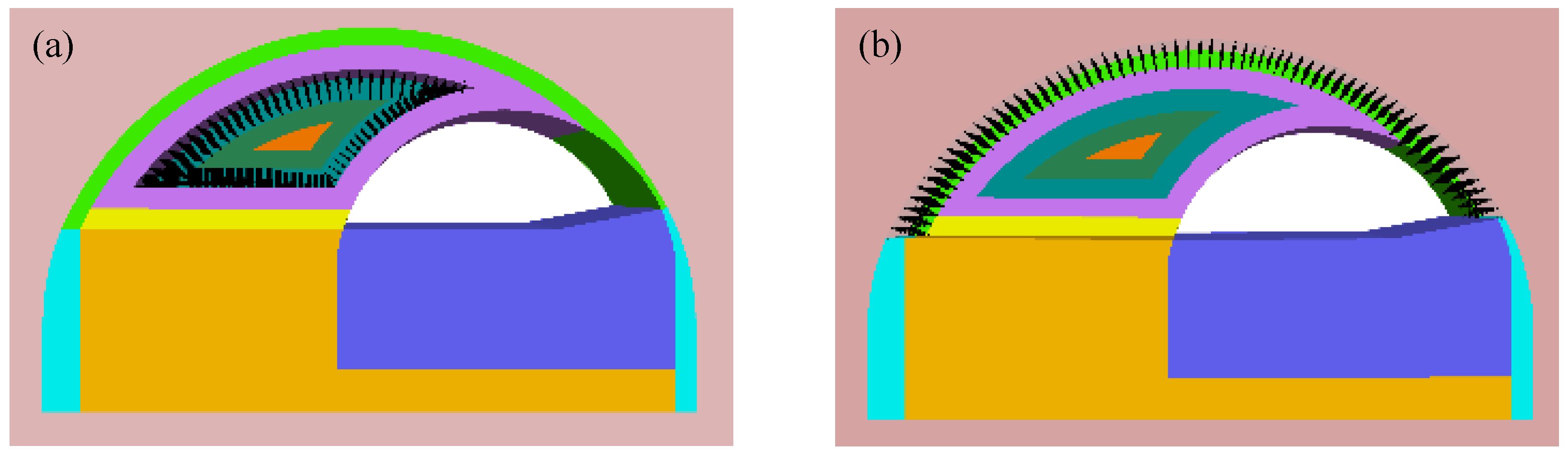

4.1. Vibration Effect on Adjacent Tunnel

4.2. Vibration Effects within Interlaid Rock Mass

4.3. Comparison and Summary of Two Blast Schemes

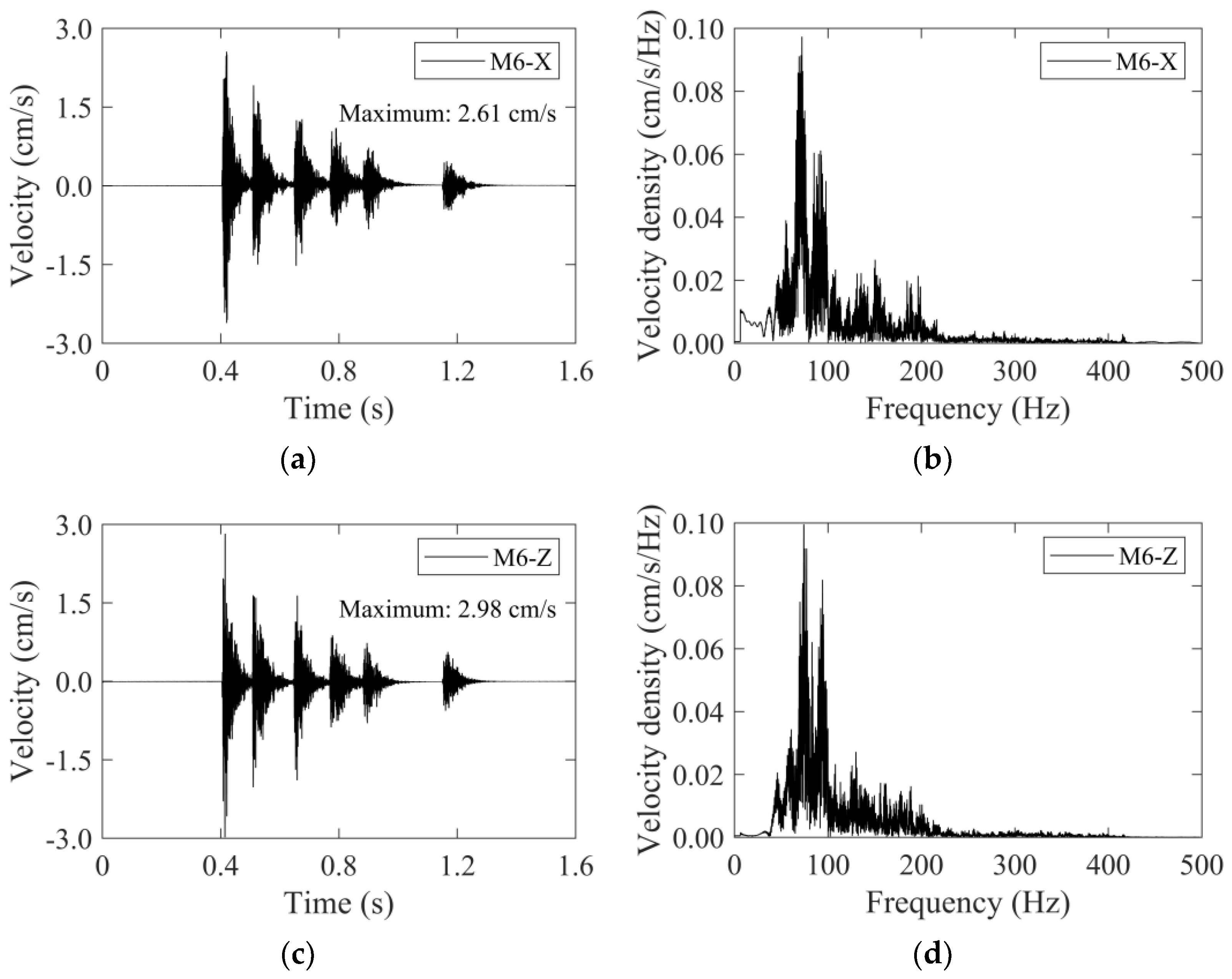

5. Blasting Vibration Analyses Based on Field Monitoring

6. Conclusions

- (1)

- Applying equivalent blasting loads upon the blasting contour by detonator sequences could simulate the whole process of millisecond blasting, which could be used as an effective method for blast scheme optimization and vibration effect prediction.

- (2)

- Both the simulation and the monitoring results showed that the vibration effect on the adjacent tunnel’s back side was much smaller than its counterpart on the blast side. In particular, the presence of a cavity considerably reduced the blasting vibration effect.

- (3)

- The non-cut blast scheme, which effectively utilized the existing free surface, could reduce the explosive consumption and vibration effect significantly, and might be preferred for the tunnel in situ expansion projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, B.; Jamil, S.M.; Jafri, T.H.; Akhtar, K. Effects of different empirical tunnel design approaches on rock mass behaviour during tunnel widening. Heliyon 2019, 5, e02944. [Google Scholar] [CrossRef] [PubMed]

- Andrea, O. Design and excavation for the widening of a railway tunnel: The case of the Castellano tunnel in Italy. In Proceedings of the SEE Tunnel: Promoting Tunneling in SEE Region “ITA WTC 2015 Congress and 41st General Assembly, Dubrovnik, Croatia, 22–28 May 2015. [Google Scholar]

- Bertuzzi, R. Back-analysing rock mass modulus from monitoring data of two tunnels in Sydney, Australia. J. Rock Mech. Geotech. Eng. 2017, 9, 877–891. [Google Scholar] [CrossRef]

- Wu, L.M.; Wang, Z.J.; Chang, Y.Z.; Gao, F.; Zhang, B.; Wu, Y.; Fan, H.X. Vibration Performance of Steel Fiber Concrete Tunnel Lining by Adjacent Tunnel Blasting Construction. Appl. Sci. 2023, 13, 4201. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, J.; Han, D.; Zhao, R.; Ma, Y.; Zhou, T. Experimental study of the dynamic responses of surrounding jointed rock masses and adjacent underground openings and induced ground vibrations subjected to underground explosion. Tunn. Undergr. Space Technol. 2023, 105060. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, S.; Zhang, X.; Zheng, Q.; Cao, B. Numerical analysis of the impact of drill-and-blast tunneling on an overlying landfill. Comput. Geotech. 2024, 170, 106296. [Google Scholar] [CrossRef]

- Ramulu, M.; Chakraborty, A.K.; Sitharam, T.G. Damage assessment of basaltic rock mass due to repeated blasting in a railway tunnelling project—A case study. Tunn. Undergr. Space Technol. 2009, 24, 208–221. [Google Scholar] [CrossRef]

- Mesec, J.; Vrkljan, D.; Ester, Z. Allowed Quantity of Explosive Charge Depending on the Distance from the Blast. Geotech. Geol. Eng. 2009, 27, 431–438. [Google Scholar] [CrossRef]

- Ishchenko, O.; Konoval, V.; Ishchenko, K. Physical and simulation modelling of solid media fracturing by means of explosive charges of different cross-sectional shapes. Min. Miner. Depos. 2022, 16, 122–131. [Google Scholar] [CrossRef]

- Chakraborty, A.K.; Pal Roy, P.; Jethwa, J.L.; Gupta, R.N. Blast performance in small tunnels—A critical evaluation in underground metal mines. Tunn. Undergr. Space Technol. 1998, 13, 331–339. [Google Scholar] [CrossRef]

- Sharafat, A.; Tanoli, W.A.; Raptis, G.; Seo, J.W. Controlled blasting in underground construction: A case study of a tunnel plug demolition in the Neelum Jhelum hydroelectric project. Tunn. Undergr. Space Technol. 2019, 93, 103098. [Google Scholar] [CrossRef]

- Peng, Y.X.; Liu, G.J.; Wu, L.; Zuo, Q.J.; Liu, Y.S.; Zhang, C. Comparative study on tunnel blast-induced vibration for the underground cavern group. Environ. Earth Sci. 2021, 80, 68. [Google Scholar] [CrossRef]

- Jiang, N.; Gao, T.; Zhou, C.B.; Luo, X.D. Effect of excavation blasting vibration on adjacent buried gas pipeline in a metro tunnel. Tunn. Undergr. Space Technol. 2018, 81, 590–601. [Google Scholar] [CrossRef]

- Xia, Y.; Jiang, N.; Zhou, C.; Sun, J.; Luo, X.; Wu, T. Dynamic behaviors of buried reinforced concrete pipelines with gasketed bell-and-spigot joints subjected to tunnel blasting vibration. Tunn. Undergr. Space Technol. 2021, 118, 104172. [Google Scholar] [CrossRef]

- Zhu, B.; Jiang, N.; Zhou, C.; Luo, X.; Li, H.; Chang, X.; Xia, Y. Dynamic interaction of the pipe-soil subject to underground blasting excavation vibration in an urban soil-rock stratum. Tunn. Undergr. Space Technol. 2022, 129, 104700. [Google Scholar] [CrossRef]

- Guan, X.; Zhang, L.; Wang, Y.; Fu, H.; An, J. Velocity and stress response and damage mechanism of three types pipelines subjected to highway tunnel blasting vibration. Eng. Fail. Anal. 2020, 118, 104840. [Google Scholar] [CrossRef]

- Lu, S.; Zhou, C.; Jiang, N.; Xu, X. Effect of Excavation Blasting in an Under-Cross Tunnel on Airport Runway. Geotech. Geol. Eng. 2015, 33, 973–981. [Google Scholar] [CrossRef]

- Fan, H.; Yu, D.; Zhao, D.; Lai, J.; Xie, Y. Experimental and numerical investigation of blasting-induced ground vibration from tunnel undercrossing a village. Civ. Eng. J.-Staveb. Obz. 2017, 26, 404–417. [Google Scholar]

- Shi, H.; Jiang, N.; Zhou, C.; Zhnag, Y.; Yao, Y.; Zhou, W.; Cai, Z. Safety assessment of ancient buddhist pagoda induced by underpass metro tunnel blasting vibration. Eng. Fail. Anal. 2023, 145, 107051. [Google Scholar] [CrossRef]

- Ren, K.; Jiang, A.; Guo, X.; Min, Q. Research on Optimization Design of Tunnel Blasting Scheme Adjacent to Buildings. Appl. Sci. 2023, 13, 11509. [Google Scholar] [CrossRef]

- Dang, V.K.; Dias, D.; Do, N.A.; Vo, T.H. Impact of blasting at tunnel face on an existing adjacent tunnel. Int. J. GEOMATE 2018, 15, 22–31. [Google Scholar] [CrossRef]

- Zhao, H.; Long, Y.; Li, X.; Lu, L. Experimental and numerical investigation of the effect of blast-induced vibration from adjacent tunnel on existing tunnel. KSCE J. Civ. Eng. 2016, 20, 431–439. [Google Scholar] [CrossRef]

- Han, Y.Z.; Liu, H.B. Failure of circular tunnel in saturated soil subjected to internal blast loading. Geomech. Eng. 2016, 11, 421–438. [Google Scholar] [CrossRef]

- Zhang, M. Numerical analysis for dynamic response of in situ blasting expansion of large cross-section tunnel with small net distance. Adv. Civ. Eng. 2021, 2021, 2896782. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Gong, L.J.; An, N.N.; Peng, X.B.; Wang, W.; Wang, Z.F. Field investigation of blasting-induced vibration in concrete linings during expansion of old highway tunnel. Adv. Civ. Eng. 2021, 2021, 8820544. [Google Scholar] [CrossRef]

- Ma, C.Y.; Wu, L.; Sun, M.; Yuan, Q. Time-frequency analysis and application of a vibration signal of tunnel excavation blasting based on CEEMD-MPE-HT. Shock Vib. 2021, 2021, 6672942. [Google Scholar] [CrossRef]

- Zhou, J.; Shu, P.; Zhang, B.; Deng, B.; Wu, Y. A Finite Element Analysis of Tunnel Lining Demolition by Blasting for Subway Tunnel Expansion. Appl. Sci. 2022, 12, 9564. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, H.; Shan, R. Blasting vibration effect and safety evaluation method of railway cross tunnels. Tunn. Undergr. Space Technol. 2024, 145, 105588. [Google Scholar] [CrossRef]

- Zhou, J.; Gao, S.; Luo, P.; Fan, J.; Zhao, C. Optimization of Blasting Parameters Considering Both Vibration Reduction and Profile Control: A Case Study in a Mountain Hard Rock Tunnel. Buildings 2024, 14, 1421. [Google Scholar] [CrossRef]

- An, H.M.; Liu, H.Y.; Han, H.; Zheng, X.; Wang, X.G. Hybrid finite-discrete element modelling of dynamic fracture and resultant fragment casting and muck-piling by rock blast. Comput. Geotech. 2017, 81, 322–345. [Google Scholar] [CrossRef]

- Song, S.G.; Li, S.C.; Li, L.P.; Shi, S.S.; Zhou, Z.Q.; Liu, Z.H.; Shang, C.S.; Sun, H.Z. Model test study on vibration blasting of large cross-section tunnel with small clearance in horizontal stratified surrounding rock. Tunn. Undergr. Space Technol. 2019, 92, 103013. [Google Scholar] [CrossRef]

- Qiu, J.D.; Li, X.B.; Li, D.Y.; Zhao, Y.Z.; Hu, C.W.; Liang, L.S. Physical Model Test on the Deformation Behavior of an Underground Tunnel Under Blasting Disturbance. Rock Mech. Rock Eng. 2021, 54, 91–108. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Zhao, X.; Liang, Y. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 2022, 123, 104416. [Google Scholar] [CrossRef]

- Kang, S.S.; Jang, H.A. case study on tunnel blasting design evaluation considering blast damage zone. Sci. Technol. Energ. Mater 2020, 81, 106–113. [Google Scholar]

- Jia, B.X.; Zhou, L.L.; Cui, J.J.; Chen, H. Attenuation model of tunnel blast vibration velocity based on the influence of free surface. Sci. Rep. 2021, 11, 21077. [Google Scholar] [CrossRef] [PubMed]

- Minh, N.N.; Cao, P.; Liu, Z.Z. Contour blasting parameters by using a tunnel blast design mode. J. Cen. South Univ. 2021, 28, 100–111. [Google Scholar] [CrossRef]

- Iwano, K.; Hashiba, K.; Nagae, J.; Fukui, K. Reduction of tunnel blasting induced ground vibrations using advanced electronic detonators. Tunn. Undergr. Space Technol. 2020, 105, 103556. [Google Scholar] [CrossRef]

- Lysmer, J.; Waas, G. Shear Waves in Plane Infinite Structures. J. Eng. Mech. Div. 1972, 98, 85–105. [Google Scholar] [CrossRef]

- Guan, Z.; Zhu, L.; Yu, B. Fine numerical simulation of row-hole blasting in tunnel excavation. J. Vib. Shock 2021, 40, 154–162. (In Chinese) [Google Scholar]

| Detonator Sequence | Hole Distance | Number of Hole | Delayed Time | Charge Quantity per Hole | Axial Decoupling Coefficient Kl | Charge Quantity per Sequence | |

|---|---|---|---|---|---|---|---|

| Cutting hole | 1 | 0.5 m | 9 | 0 ms | 1.7 kg | 1.3 | 15.5 kg |

| Auxiliary hole | 5 | 0.6 m | 19 | 110 ms | 1.2 kg | 1.8 | 23.2 kg |

| 8 | 0.6 m | 28 | 250 ms | 1.1 kg | 2.0 | 30.8 kg | |

| 10 | 0.6 m | 30 | 380 ms | 1.1 kg | 2.0 | 33 kg | |

| 11 | 0.6 m | 11 | 460 ms | 1.4 kg | 1.6 | 15.1 kg | |

| Peripheral hole | 14 | 0.5 m | 43 | 760 ms | 0.4 kg | 5.5 | 17.2 kg |

| Detonator Sequence | Hole Distance | Number of Hole | Delayed Time | Charge Quantity per Hole | Axial Decoupling Coefficient Kl | Charge Quantity per Sequence | |

|---|---|---|---|---|---|---|---|

| Auxiliary hole | 1 | 0.6 m | 12 | 0 ms | 1.0 kg | 2.2 | 12.0 kg |

| 5 | 0.6 m | 12 | 110 ms | 1.0 kg | 2.2 | 12.0 kg | |

| 8 | 0.7 m | 13 | 250 ms | 1.0 kg | 2.2 | 13.0 kg | |

| 11 | 0.7 m | 14 | 460 ms | 1.0 kg | 2.2 | 14.0 kg | |

| Peripheral hole | 14 | 0.5 m | 20 | 760 ms | 0.4 kg | 5.5 | 8.0 kg |

| 15 | 0.5 m | 20 | 880 ms | 0.4 kg | 5.5 | 8.0 kg |

| Density ρ (g·cm−3) | Young’s Modulus E (GPa) | Poisson Ratio μ | Cohesive Forces c (kPa) | Friction Angle φ (°) | Thickness (m) | |

|---|---|---|---|---|---|---|

| Strongly weathered | 2.2 | 20.5 | 0.33 | 690 | 39.33 | |

| Moderately weathered | 2.5 | 24 | 0.31 | 1620 | 51.45 | |

| Slightly weathered | 2.6 | 26 | 0.3 | 1740 | 51.76 | |

| Existing tunnel lining | 2.7 | 32.2 | 0.2 | 0.35 |

| Propagation Path | Fitting Equations | RMSE (cm·s−1) | R2 | |

|---|---|---|---|---|

| Figure 17a | path A | 0.606 | 0.96 | |

| Figure 17b | path A | 0.553 | 0.97 | |

| Figure 18a | path A | 0.416 | 0.97 | |

| Figure 18b | path A | 0.552 | 0.97 |

| Traditional Scheme | Optimized Scheme | Remark | |

|---|---|---|---|

| Total charge (kg) | 134.8 | 67.0 | 50.2% reduction |

| Maximum charge in single sequence (kg) | 33.0 | 14.0 | 57.6% reduction |

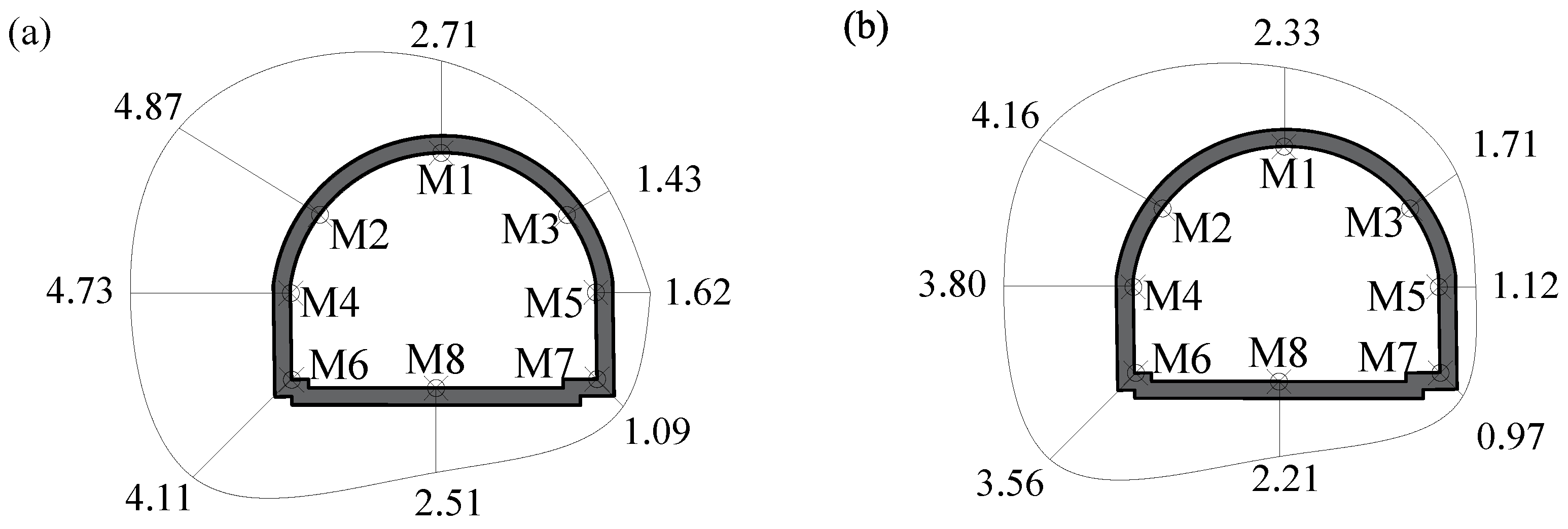

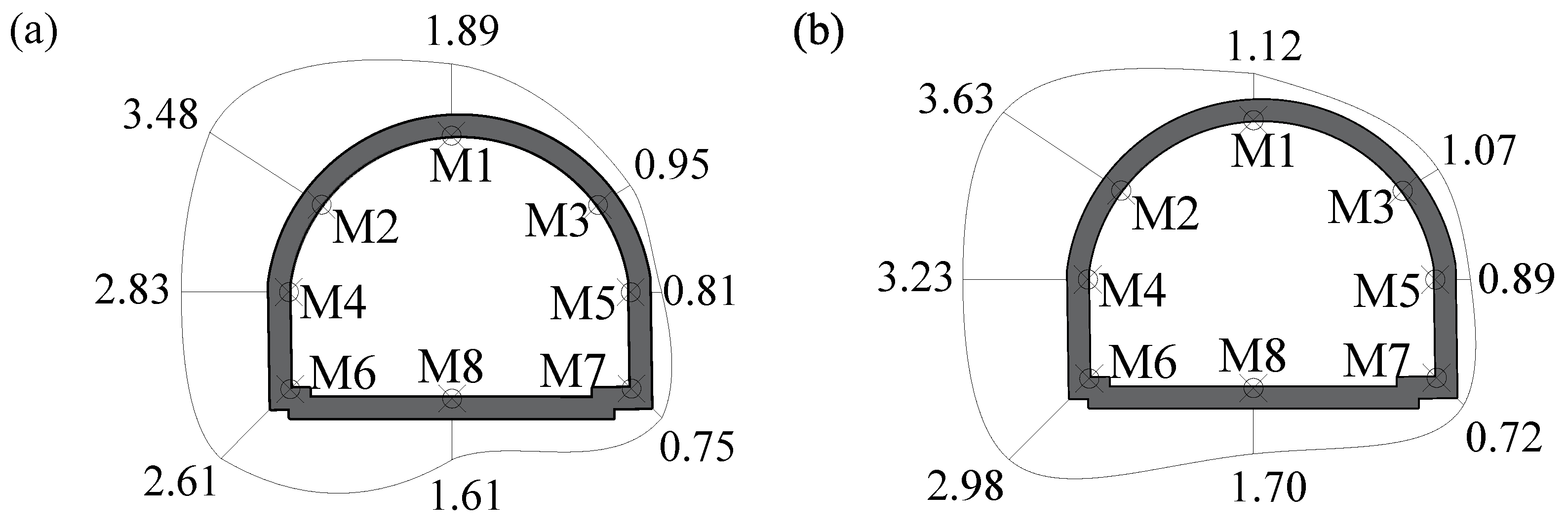

| Maximum vibration velocity of monitoring points of adjacent tunnel lining (X-direction) (cm/s) | 2.71 (M1) 4.87 (M2) 1.43 (M3) 4.73 (M4) 1.62 (M5) 4.11 (M6) 1.09 (M7) 2.51 (M8) | 1.89 (M1) 3.48 (M2) 0.95 (M3) 2.83 (M4) 0.81 (M5) 2.61 (M6) 0.75 (M7) 1.61 (M8) | 35.76% reduction in average |

| Maximum vibration velocity of monitoring points of adjacent tunnel lining (Z-direction) (cm/s) | 2.33 (M1) 4.16 (M2) 1.71 (M3) 3.80 (M4) 1.12 (M5) 3.56 (M6) 0.97 (M7) 2.21 (M8) | 1.12 (M1) 3.63 (M2) 1.07 (M3) 3.23 (M4) 0.89 (M5) 2.98 (M6) 0.72 (M7) 1.70 (M8) | 25.35% reduction in average |

| Average attenuation rate of interlaid rock mass (X-direction) (cm·s−1/m) | (0–5 m): 1.083 (5–20 m): 0.159 (20–29 m): 0.354 | (0–5 m): 0.911 (5–20 m): 0.106 (20–29 m): 0.239 | Basically consistent |

| Average attenuation rate of interlaid rock mass (Z-direction) (cm·s−1/m) | (0–5 m): 1.422 (5–20 m): 0.146 (20–29 m): 0.286 | (0–5 m): 1.305 (5–20 m): 0.149 (20–29 m): 0.271 | Basically consistent |

| Monitoring Point | Mileage | In X-Direction (cm·s−1) | In Z-Direction (cm·s−1) |

|---|---|---|---|

| M6 | NK18+104 | 2.44 | 2.61 |

| NK18+110 | 2.23 | 2.52 | |

| NK18+214 | 2.52 | 2.98 | |

| … | … | … | |

| averaged | 2.44 | 2.51 | |

| M7 | NK18+104 | 0.73 | 0.70 |

| NK18+110 | 0.85 | 0.82 | |

| NK18+214 | 0.75 | 0.54 | |

| … | … | … | |

| averaged | 0.76 | 0.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, Z.; Xie, L.; Chen, D.; Shi, J. Numerical Simulation and Field Monitoring of Blasting Vibration for Tunnel In-Situ Expansion by a Non-Cut Blast Scheme. Sensors 2024, 24, 4546. https://doi.org/10.3390/s24144546

Guan Z, Xie L, Chen D, Shi J. Numerical Simulation and Field Monitoring of Blasting Vibration for Tunnel In-Situ Expansion by a Non-Cut Blast Scheme. Sensors. 2024; 24(14):4546. https://doi.org/10.3390/s24144546

Chicago/Turabian StyleGuan, Zhenchang, Lifu Xie, Dong Chen, and Jingkang Shi. 2024. "Numerical Simulation and Field Monitoring of Blasting Vibration for Tunnel In-Situ Expansion by a Non-Cut Blast Scheme" Sensors 24, no. 14: 4546. https://doi.org/10.3390/s24144546

APA StyleGuan, Z., Xie, L., Chen, D., & Shi, J. (2024). Numerical Simulation and Field Monitoring of Blasting Vibration for Tunnel In-Situ Expansion by a Non-Cut Blast Scheme. Sensors, 24(14), 4546. https://doi.org/10.3390/s24144546