A Simple Method to Manufacture a Force Sensor Array Based on a Single-Material 3D-Printed Piezoresistive Foam and Metal Coating

Abstract

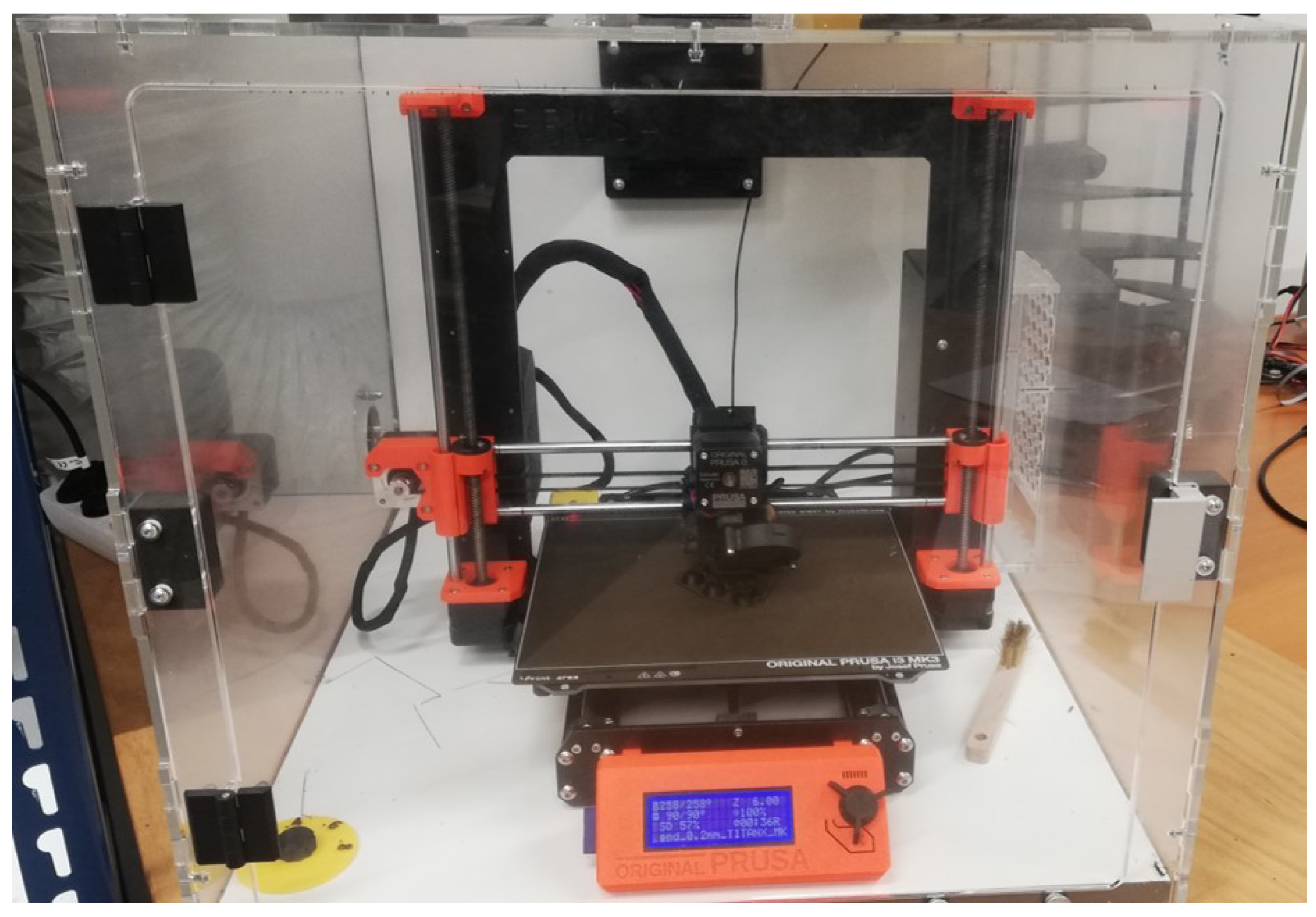

1. Introduction

- Integration of pre-existing sensors into a 3D-printed structure: This method presents notable benefits, such as the utilization of reliable, calibrated, and readily available sensors. Nonetheless, this approach necessitates the adaptation of each design to accommodate the sensor and may even require pausing the printing process to position them, thereby limiting productivity.

- Integration of 3D-printed sensors in a 3D-printed structure: This approach presents the advantage of crafting customized sensors that match specific design requirements [45]. However, similarly to the first method, it involves one fabrication process per design and multiple fabrication steps.

- Fully 3D-printed: This method allows for complete tailoring, offering maximum design flexibility. The sensors can be intricately integrated into the mechanical structure, especially with multimaterial printing [46,47], enhancing the overall customization. The challenge lies in ensuring robust electrical connections (poor connections can impact the overall performance of the integrated sensors). Indeed, metals and polymers cannot be printed together, and conductive polymers often show limitations: their electrical resistivity makes them relatively poor candidates for electrodes, and their mechanical fragility can break the connections.

- By using a single material, the risk of failure due to multimaterial interactions is significantly reduced. This is particularly crucial in applications where electrical connections within the structure are involved.

- This approach eliminates the complexities associated with managing multiple materials during fabrication, resulting in faster and cheaper production cycles.

- The reduced complexity in material usage aligns with sustainable practices. A mono-material system simplifies the recycling processes, contributing to a more environmentally friendly approach to manufacturing.

- Smart Textiles: The integration of such foams into fabrics can create smart textiles capable of sensing pressure or deformation, enabling applications like interactive clothing, posture-monitoring systems, or healthcare garments.

- Biomedical Devices: In biomedical engineering, piezoresistive foams can find application in pressure-sensitive implants or prosthetic limbs to provide feedback about the pressure distribution or movement.

- Robotics: These foams can be utilized in robotic systems for tactile sensing, allowing robots to perceive and respond to the forces applied to their surfaces. This can enhance their ability to interact safely and effectively with the environment.

- Sports Equipment: Incorporating piezoresistive foams into sports equipment such as helmets, pads, or shoes can provide real-time feedback on impact forces, helping athletes to monitor and prevent injuries.

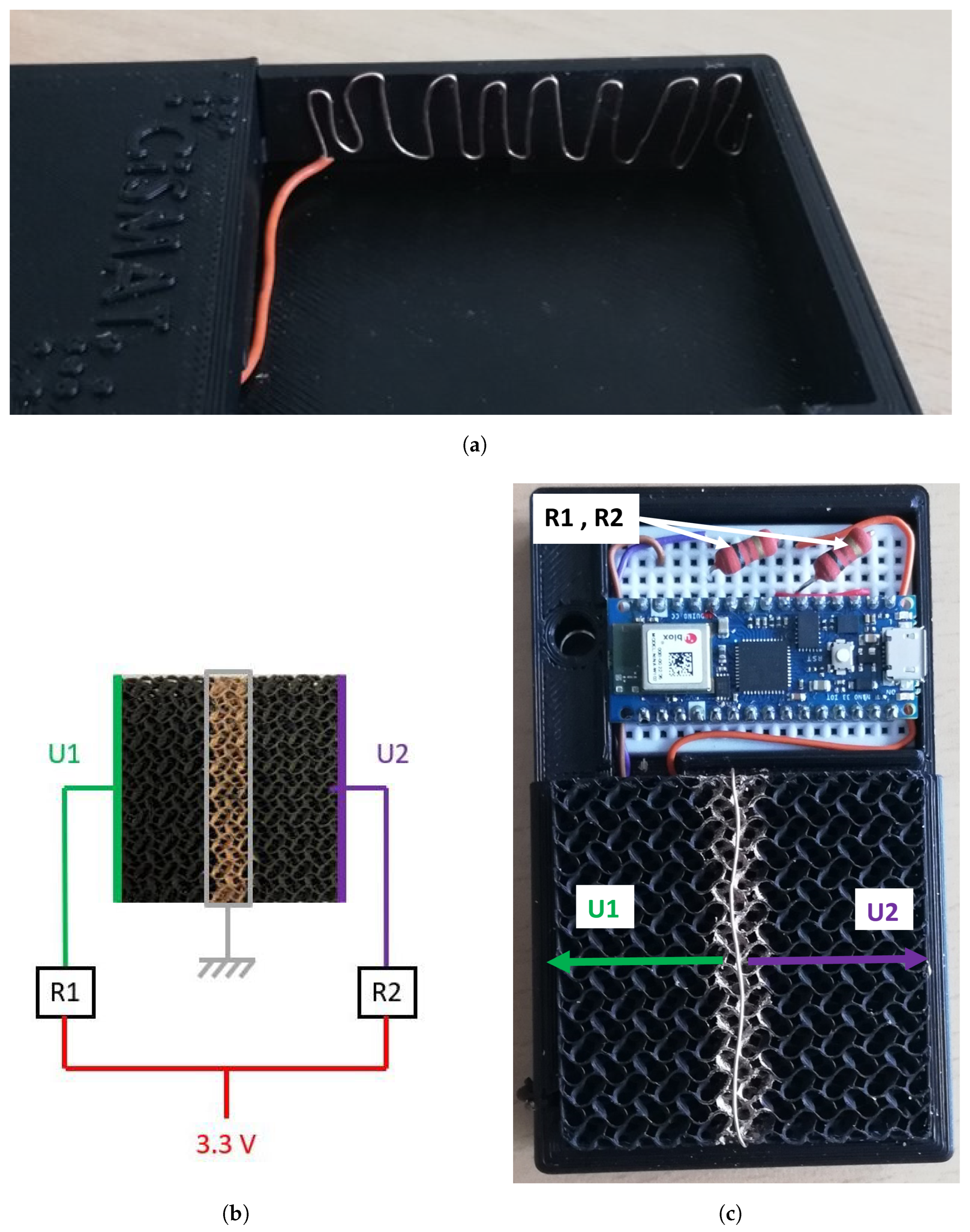

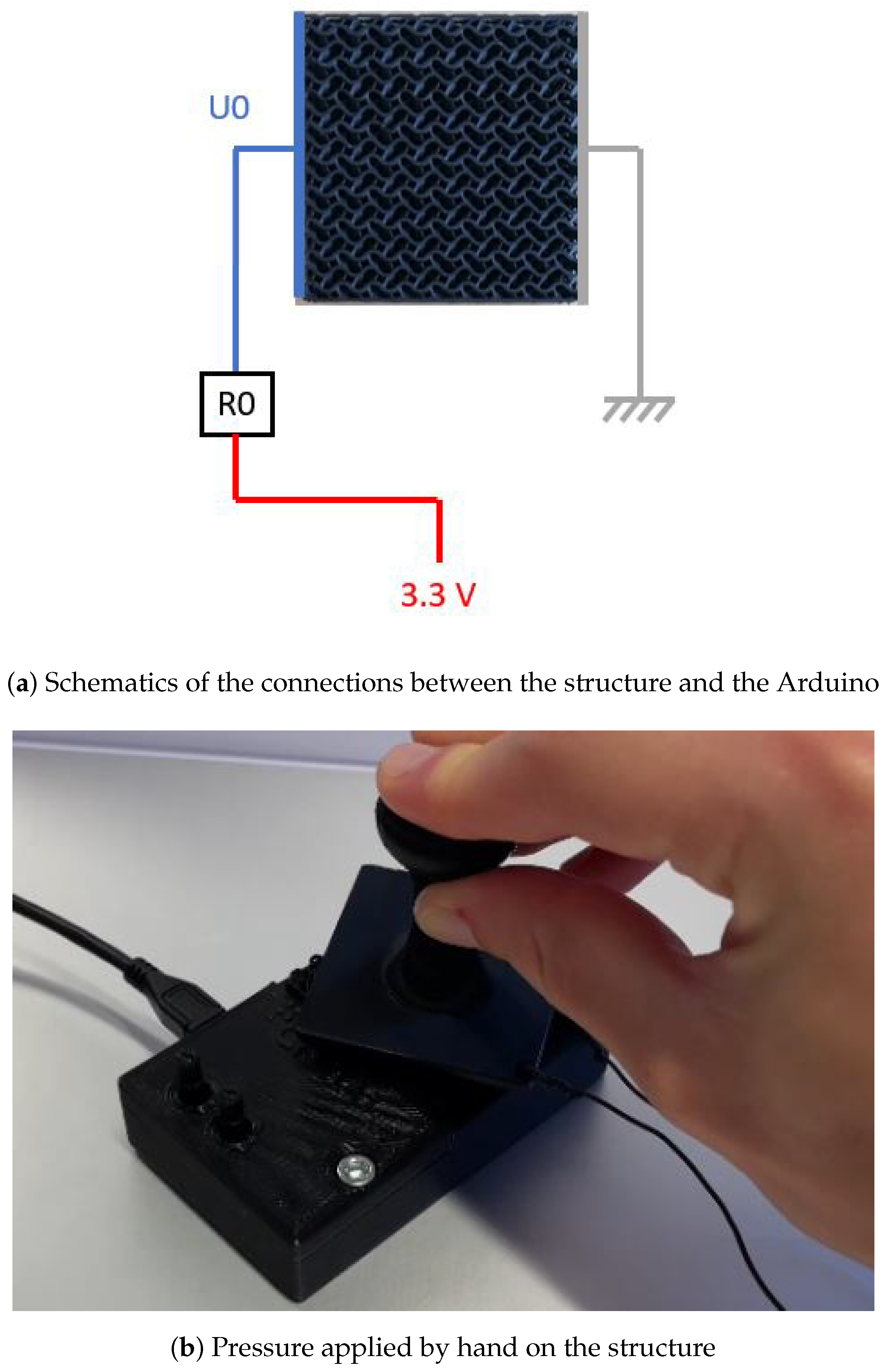

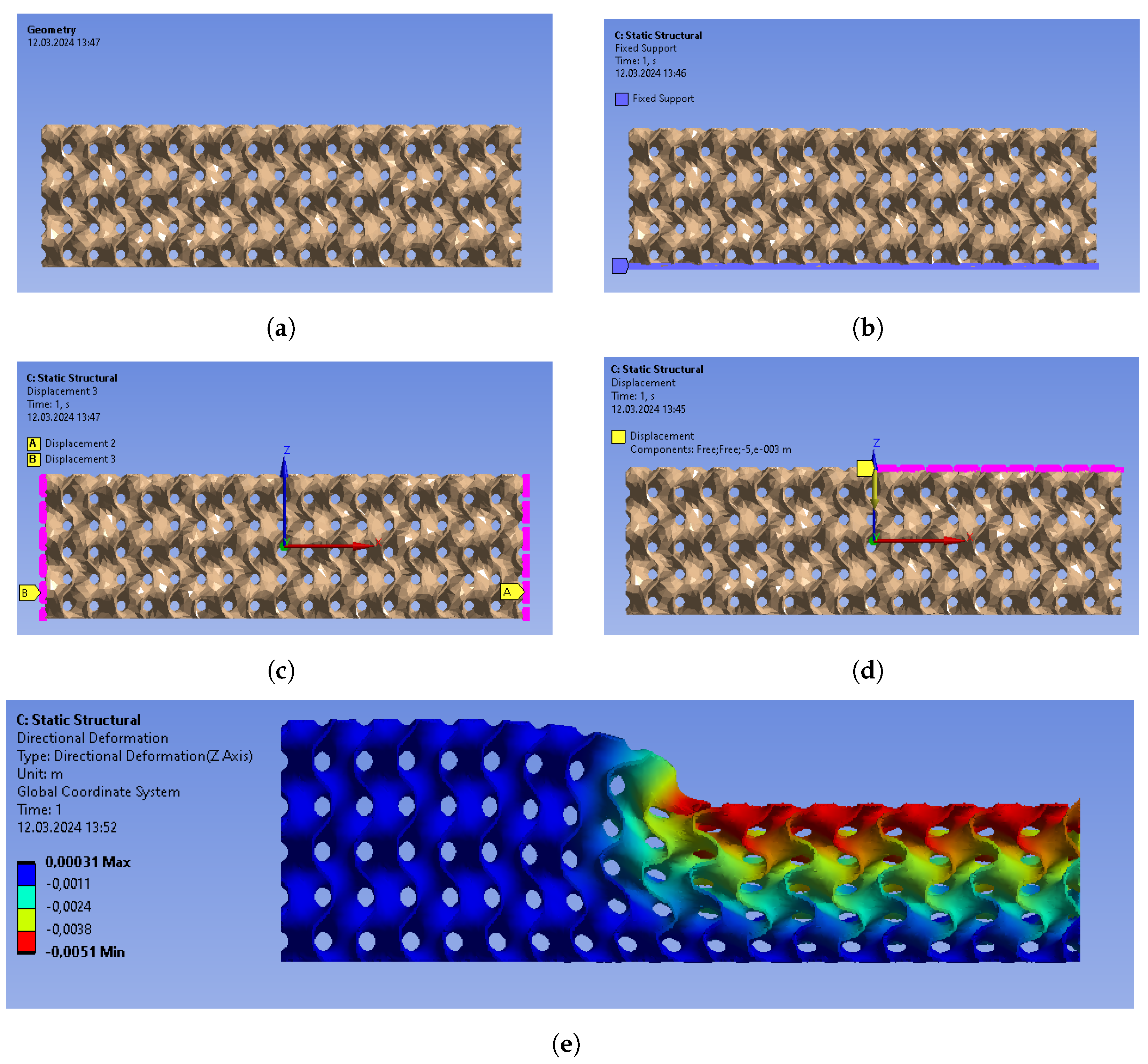

2. Materials and Methods

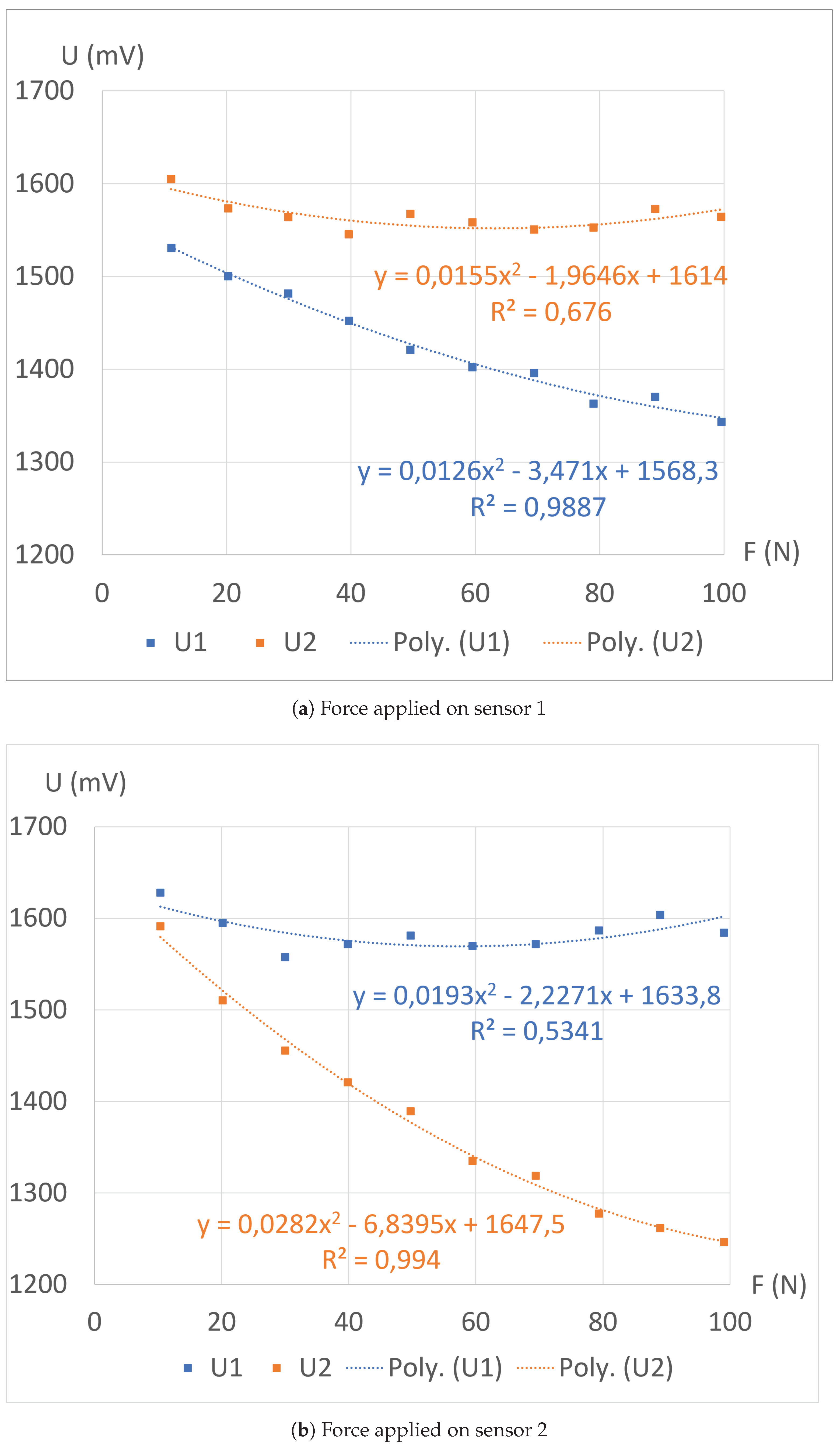

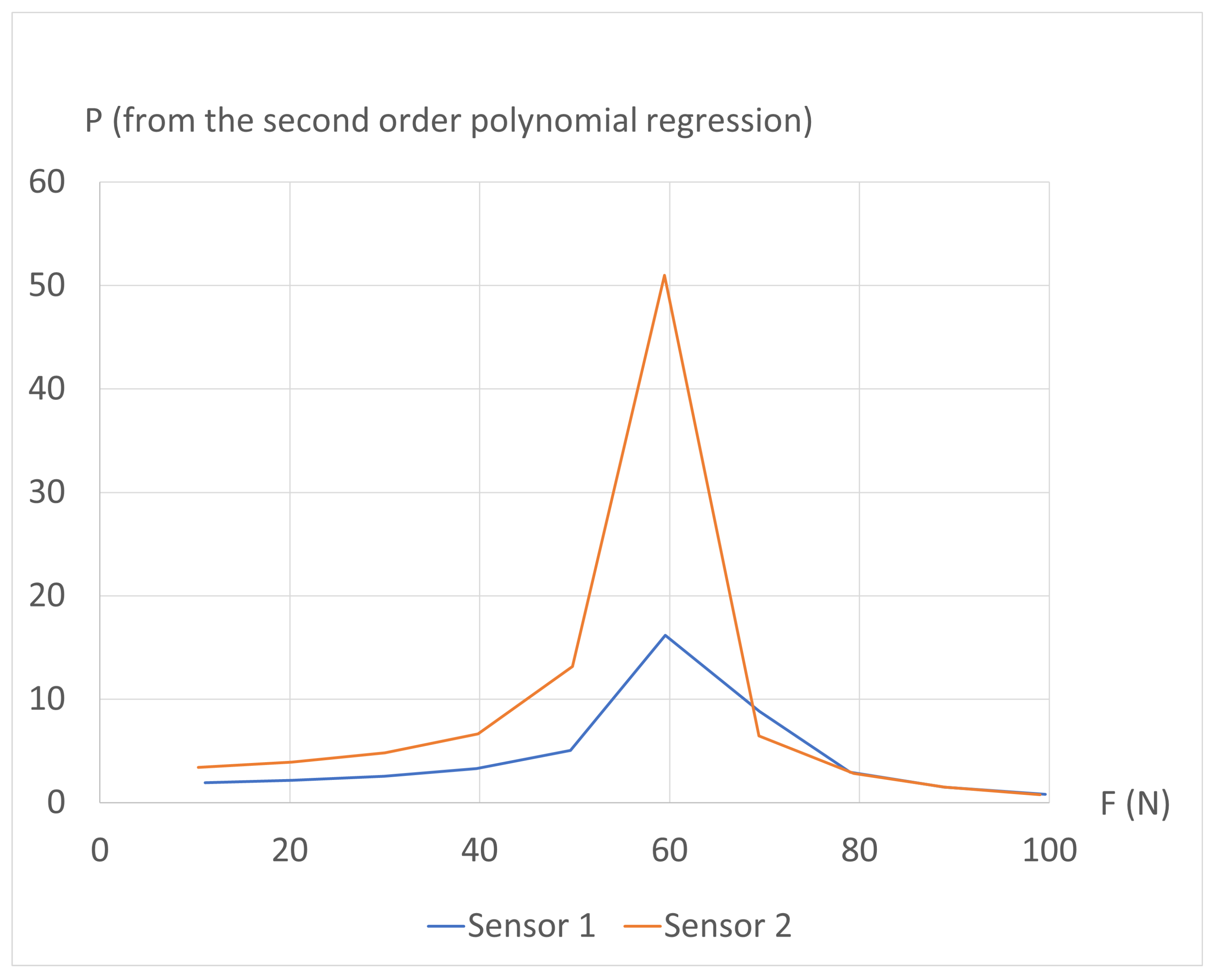

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Salehi, H.; Burgueño, R.; Chakrabartty, S.; Lajnef, N.; Alavi, A.H. A comprehensive review of self-powered sensors in civil infrastructure: State-of-the-art and future research trends. Eng. Struct. 2021, 234, 111963. [Google Scholar] [CrossRef]

- Cuomo, F.; Catarinucci, L.; Klancar, G.; Nardello, M.; Glisic, B. Concise Historic Overview of Strain Sensors Used in the Monitoring of Civil Structures: The First One Hundred Years. Sensors 2022, 22, 2397. [Google Scholar] [CrossRef]

- Nicolay, P.; Schlögl, S.; Thaler, S.M.; Humbert, C.; Filipitsch, B. Smart Materials for Green(er) Cities, a Short Review. Appl. Sci. 2023, 13, 9289. [Google Scholar] [CrossRef]

- Das, S.; Saha, P. A review of some advanced sensors used for health diagnosis of civil engineering structures. Measurement 2018, 129, 68–90. [Google Scholar] [CrossRef]

- Gao, K.; Zhang, Z.; Weng, S.; Zhu, H.; Yu, H.; Peng, T. Review of Flexible Piezoresistive Strain Sensors in Civil Structural Health Monitoring. Appl. Sci. 2022, 12, 9750. [Google Scholar] [CrossRef]

- Gillot, C.; Picoux, B.; Reynaud, P.; da Silva, D.C.; Rakotovao-Ravahatra, N.; Feix, N.; Petit, C. Wireless Strain Gauge for Monitoring Bituminous Pavements. Appl. Sci. 2024, 14, 2245. [Google Scholar] [CrossRef]

- Taher, S.A.; Li, J.; Jeong, J.H.; Laflamme, S.; Jo, H.; Bennett, C.; Collins, W.N.; Downey, A.R. Structural Health Monitoring of Fatigue Cracks for Steel Bridges with Wireless Large-Area Strain Sensors. Sensors 2022, 22, 5076. [Google Scholar] [CrossRef]

- Güemes, A.; Fernandez-Lopez, A.; Pozo, A.R.; Sierra-Pérez, J. Structural health monitoring for advanced composite structures: A review. J. Compos. Sci. 2020, 4, 13. [Google Scholar] [CrossRef]

- Shen, Z.; Zhang, Z.; Zhang, N.; Li, J.; Zhou, P.; Hu, F.; Rong, Y.; Lu, B.; Gu, G. High-Stretchability, Ultralow-Hysteresis ConductingPolymer Hydrogel Strain Sensors for Soft Machines. Adv. Mater. 2022, 34, 2203650. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhou, Y.; Asghar, W.; Liu, Y.; Li, F.; Sun, D.; Hu, C.; Wu, Z.; Shang, J.; Yu, Z.; et al. Liquid Metal-Based Strain Sensor with Ultralow Detection Limit for Human–Machine Interface Applications. Adv. Intell. Syst. 2021, 3, 2000235. [Google Scholar] [CrossRef]

- Wang, D.; Li, X.; Tian, H.; Chen, X.; Nie, B.; Luo, Y.; Shao, J. Flexible strain sensor based on embedded three-dimensional annular cracks with high mechanical robustness and high sensitivity. Appl. Mater. Today 2021, 25, 101247. [Google Scholar] [CrossRef]

- Feng, J.; Wang, X.; Lv, Z.; Qu, J.; Lu, X.; Wei, Q.; Wang, Q. Multifunctional wearable strain sensor made with an elastic interwoven fabric for patients with motor dysfunction. Adv. Mater. Technol. 2020, 5, 2000560. [Google Scholar] [CrossRef]

- Gao, W.C.; Wu, W.; Chen, C.Z.; Zhao, H.; Liu, Y.; Li, Q.; Huang, C.X.; Hu, G.H.; Wang, S.F.; Shi, D.; et al. Design of a Superhydrophobic Strain Sensor with a Multilayer Structure for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2022, 14, 1874–1884. [Google Scholar] [CrossRef]

- Dual, S.A.; Zambrano, B.L.; Sündermann, S.; Cesarovic, N.; Kron, M.; Magkoutas, K.; Hengsteler, J.; Falk, V.; Starck, C.; Meboldt, M.; et al. Continuous Heart Volume Monitoring by Fully Implantable Soft Strain Sensor. Adv. Healthc. Mater. 2020, 9, 2000855. [Google Scholar] [CrossRef]

- Abramson, A.; Chan, C.T.; Khan, Y.; Mermin-Bunnell, A.; Matsuhisa, N.; Fong, R.; Shad, R.; Hiesinger, W.; Mallick, P.; Gambhir, S.S.; et al. A flexible electronic strain sensor for the real-time monitoring of tumor regression. Sci. Adv. 2022, 8, 6550. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, G.; Xue, L.; Dong, G.; Su, W.; Cui, M.J.; Wang, Z.G.; Liu, M.; Zhou, Z.; Zhang, X. Ultrasoft and Biocompatible Magnetic-Hydrogel-Based Strain Sensors for Wireless Passive Biomechanical Monitoring. ACS Nano 2022, 16, 21555–21564. [Google Scholar]

- Yang, Y.; Tang, W.; Wang, J.; Liu, R.; Yang, P.; Chen, S.; Yuan, Y.; Xu, J.; Ren, X.; Yu, S.; et al. Stress-deconcentrated ultrasensitive strain sensor with hydrogen-bonding-tuned fracture resilience for robust biomechanical monitoring. Sci. China Mater. 2022, 65, 2289–2297. [Google Scholar] [CrossRef]

- Qaiser, N.; Al-Modaf, F.; Khan, S.M.; Shaikh, S.F.; El-Atab, N.; Hussain, M.M. A Robust Wearable Point-of-Care CNT-Based Strain Sensor for Wirelessly Monitoring Throat-Related Illnesses. Adv. Funct. Mater. 2021, 31, 2103375. [Google Scholar] [CrossRef]

- Liu, C.X.; Choi, J.W. An embedded PDMS nanocomposite strain sensor toward biomedical applications. In Proceedings of the 31st Annual International Conference of the IEEE Engineering in Medicine and Biology Society: Engineering the Future of Biomedicine, EMBC 2009, Minneapolis, MN, USA, 3–6 September 2009; pp. 6391–6394. [Google Scholar] [CrossRef]

- Roriz, P.; Carvalho, L.; Frazão, O.; Santos, J.L.; Simões, J.A. From conventional sensors to fibre optic sensors for strain and force measurements in biomechanics applications: A review. J. Biomech. 2014, 47, 1251–1261. [Google Scholar] [CrossRef]

- del Bosque, A.; Sánchez-Romate, X.F.; Gómez, A.; Sánchez, M.; Ureña, A. Highly stretchable strain sensors based on graphene nanoplatelet-doped ecoflex for biomedical purposes. Sens. Actuators A Phys. 2023, 353, 114249. [Google Scholar] [CrossRef]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

- Alaimo, F.; Sadeqi, A.; Nejad, H.R.; Jiang, Y.; Wang, W.; Demarchi, D.; Sonkusale, S. Reel-to-reel fabrication of strain sensing threads and realization of smart insole. Sens. Actuators A Phys. 2020, 301, 111741. [Google Scholar] [CrossRef]

- Larimi, S.R.; Nejad, H.R.; Oyatsi, M.; O’Brien, A.; Hoorfar, M.; Najjaran, H. Low-cost ultra-stretchable strain sensors for monitoring human motion and bio-signals. Sens. Actuators A Phys. 2018, 271, 182–191. [Google Scholar] [CrossRef]

- Wang, J.; Lu, C.; Zhang, K. Textile-Based Strain Sensor for Human Motion Detection. Energy Environ. Mater. 2020, 3, 80–100. [Google Scholar] [CrossRef]

- Xiao, T.; Qian, C.; Yin, R.; Wang, K.; Gao, Y.; Xuan, F. 3D printing of flexible strain sensor array based on UV-curable multiwalled carbon nanotube/elastomer composite. Adv. Mater. Technol. 2021, 6, 2000745. [Google Scholar] [CrossRef]

- Pei, Z.; Zhang, Q.; Yang, K.; Yuan, Z.; Zhang, W.; Sang, S. A fully 3D-printed wearable piezoresistive strain and tactile sensing array for robot hand. Adv. Mater. Technol. 2021, 6, 2100038. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. 3D-printed sensors: Current progress and future challenges. Sens. Actuators A Phys. 2020, 305, 111916. [Google Scholar] [CrossRef]

- Zymelka, D.; Togashi, K.; Kobayashi, T. Concentric Array of Printed Strain Sensors for Structural Health Monitoring. Sensors 2020, 20, 1997. [Google Scholar] [CrossRef]

- Herbert, R.; Lim, H.R.; Yeo, W.H.; Yeo, W.H.; Yeo, W.H. Printed, Soft, Nanostructured Strain Sensors for Monitoring of Structural Health and Human Physiology. ACS Appl. Mater. Interfaces 2020, 12, 25020–25030. [Google Scholar] [CrossRef]

- Ali, M.A.; Hu, C.; Yttri, E.A.; Panat, R. Recent advances in 3D printing of biomedical sensing devices. Adv. Funct. Mater. 2022, 32, 2107671. [Google Scholar] [CrossRef]

- Rachim, V.P.; Park, S.M. Review of 3D-printing technologies for wearable and implantable bio-integrated sensors. Essays Biochem. 2021, 65, 491–502. [Google Scholar]

- Guo, B.; Ji, X.; Chen, X.; Li, G.; Lu, Y.; Bai, J. A highly stretchable and intrinsically self-healing strain sensor produced by 3D printing. Virtual Phys. Prototyp. 2020, 15, 520–531. [Google Scholar] [CrossRef]

- Osman, A.; Lu, J. 3D printing of polymer composites to fabricate wearable sensors: A comprehensive review. Mater. Sci. Eng. R Rep. 2023, 154, 100734. [Google Scholar] [CrossRef]

- Votzke, C.; Daalkhaijav, U.; Mengue, Y.; Johnston, M.L. Highly-Stretchable Biomechanical Strain Sensor using Printed Liquid Metal Paste. In Proceedings of the 2018 IEEE Biomedical Circuits and Systems Conference, BioCAS 2018, Cleveland, OH, USA, 17–19 October 2018. [Google Scholar] [CrossRef]

- Giffney, T.; Bejanin, E.; Kurian, A.S.; Travas-Sejdic, J.; Aw, K. Highly stretchable printed strain sensors using multi-walled carbon nanotube/silicone rubber composites. Sens. Actuators A Phys. 2017, 259, 44–49. [Google Scholar] [CrossRef]

- Xia, T.; Yu, R.; Yuan, J.; Yi, C.; Ma, L.; Liu, F.; Cheng, G.J. Ultrahigh Sensitivity Flexible Pressure Sensors Based on 3D-Printed Hollow Microstructures for Electronic Skins. Adv. Mater. Technol. 2021, 6, 2000984. [Google Scholar] [CrossRef]

- Han, T.; Kundu, S.; Nag, A.; Xu, Y. 3D Printed Sensors for Biomedical Applications: A Review. Sensors 2019, 19, 1706. [Google Scholar] [CrossRef] [PubMed]

- Cheng, M.; Zhu, G.; Zhang, F.; Tang, W.; Shi, J.; Yang, J.; Zhu, L. A review of flexible force sensors for human health monitoring. J. Adv. Res. 2020, 26, 53–68. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Miao, J.; Fan, Q.; Zhang, W.; Zuo, X.; Tian, M.; Zhu, S.; Zhang, X.; Qu, L. Recent Progress on Smart Fiber and Textile Based Wearable Strain Sensors: Materials, Fabrications and Applications. Adv. Fiber Mater. 2022, 4, 361–389. [Google Scholar] [CrossRef]

- Kalkal, A.; Kumar, S.; Kumar, P.; Pradhan, R.; Willander, M.; Packirisamy, G.; Kumar, S.; Malhotra, B.D. Recent advances in 3D printing technologies for wearable (bio)sensors. Addit. Manuf. 2021, 46, 102088. [Google Scholar] [CrossRef]

- Han, X.; Xiao, W.; Wen, S.; Lin, J.; He, A.; Jiang, Q.; Nie, H. High-performance stretchable strain sensor based on Ag nanoparticles sandwiched between two 3D-printed polyurethane fibrous textiles. Adv. Electron. Mater. 2021, 7, 2001242. [Google Scholar] [CrossRef]

- Sharafeldin, M.; Jones, A.; Rusling, J.F. 3D-printed biosensor arrays for medical diagnostics. Micromachines 2018, 9, 394. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.S.; Zaman, S.; Dantzler, J.Z.; Leyva, D.H.; Mahmud, M.S.; Ramirez, J.M.; Gomez, S.G.; Lin, Y. 3D Printed Integrated Sensors: From Fabrication to Applications—A Review. Nanomaterials 2023, 13, 3148. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.H.; Wang, K.; Wu, C.; Chen, Y.; Zhang, C.; Wang, B. A facile method for integrating direct-write devices into three-dimensional printed parts. Smart Mater. Struct. 2015, 24, 065008. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef] [PubMed]

- Goh, G.L.; Zhang, H.; Chong, T.H.; Yeong, W.Y. 3D printing of multilayered and multimaterial electronics: A review. Adv. Electron. Mater. 2021, 7, 2100445. [Google Scholar] [CrossRef]

- Xiao, R.; Feng, X.; Fan, R.; Chen, S.; Song, J.; Gao, L.; Lu, Y. 3D printing of titanium-coated gradient composite lattices for lightweight mandibular prosthesis. Compos. Part B Eng. 2020, 193, 108057. [Google Scholar] [CrossRef]

- Juarez, T.; Schroer, A.; Schwaiger, R.; Hodge, A.M. Evaluating sputter deposited metal coatings on 3D printed polymer micro-truss structures. Mater. Des. 2018, 140, 442–450. [Google Scholar] [CrossRef]

- Pesce, N.; Fortunato, M.; Tamburrano, A. 3D Printed Graphene-Based Piezoresistive Foam Mat for Pressure Detection Through Electrical Resistance Tomography and Machine Learning Classification Techniques. IEEE Sens. Lett. 2023, 7, 1–4. [Google Scholar] [CrossRef]

- Lü, X.; Yu, T.; Meng, F.; Bao, W. Wide-Range and High-Stability Flexible Conductive Graphene/Thermoplastic Polyurethane Foam for Piezoresistive Sensor Applications. Adv. Mater. Technol. 2021, 6, 2100248. [Google Scholar] [CrossRef]

- Asghari, N.; Hassanian-Moghaddam, D.; Javadi, A.; Ahmadi, M. Enhanced sensing performance of EVA/LDPE/MWCNT piezoresistive foam sensor for long-term pressure monitoring. Chem. Eng. J. 2023, 472, 145055. [Google Scholar] [CrossRef]

- Li, X.; Cui, S.; Wu, M.; Tang, J.; Zhou, X.; Xu, M.; Gao, P.; Jiao, T.; Wang, L.; Zheng, W. An ultra-lightweight and hydrophobic piezoresistive foam with super-wide strain and pressure detection range. Compos. Part B Eng. 2024, 277, 111412. [Google Scholar] [CrossRef]

- Dusek, J.E.; Triantafyllou, M.S.; Lang, J.H. Piezoresistive foam sensor arrays for marine applications. Sens. Actuators A Phys. 2016, 248, 173–183. [Google Scholar] [CrossRef]

- Kordas, K.; Pitkänen, O. Piezoresistive carbon foams in sensing applications. Front. Mater. 2019, 6, 445836. [Google Scholar] [CrossRef]

- Gu, Y.; Zhang, Z.; Fan, F.; Wei, L.; Wu, T.; Wang, D.; Li, Q. Designable high-performance TPU foam strain sensors towards human-machine interfaces. Compos. Part A Appl. Sci. Manuf. 2024, 182, 108169. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Humbert, C.; Barriol, M.; Varsavas, S.D.; Nicolay, P.; Brandstötter, M. A Simple Method to Manufacture a Force Sensor Array Based on a Single-Material 3D-Printed Piezoresistive Foam and Metal Coating. Sensors 2024, 24, 3854. https://doi.org/10.3390/s24123854

Humbert C, Barriol M, Varsavas SD, Nicolay P, Brandstötter M. A Simple Method to Manufacture a Force Sensor Array Based on a Single-Material 3D-Printed Piezoresistive Foam and Metal Coating. Sensors. 2024; 24(12):3854. https://doi.org/10.3390/s24123854

Chicago/Turabian StyleHumbert, Claude, Mathis Barriol, Sakine Deniz Varsavas, Pascal Nicolay, and Mathias Brandstötter. 2024. "A Simple Method to Manufacture a Force Sensor Array Based on a Single-Material 3D-Printed Piezoresistive Foam and Metal Coating" Sensors 24, no. 12: 3854. https://doi.org/10.3390/s24123854

APA StyleHumbert, C., Barriol, M., Varsavas, S. D., Nicolay, P., & Brandstötter, M. (2024). A Simple Method to Manufacture a Force Sensor Array Based on a Single-Material 3D-Printed Piezoresistive Foam and Metal Coating. Sensors, 24(12), 3854. https://doi.org/10.3390/s24123854