Photoacoustic Spectroscopy Combined with Integrated Learning to Identify Soybean Oil with Different Frying Durations

Abstract

1. Introduction

2. Experimental Objects and Methods

2.1. Materials

2.2. Experimental Methods

2.2.1. Frying Experiment

2.2.2. Free Fatty Acid Content Testing

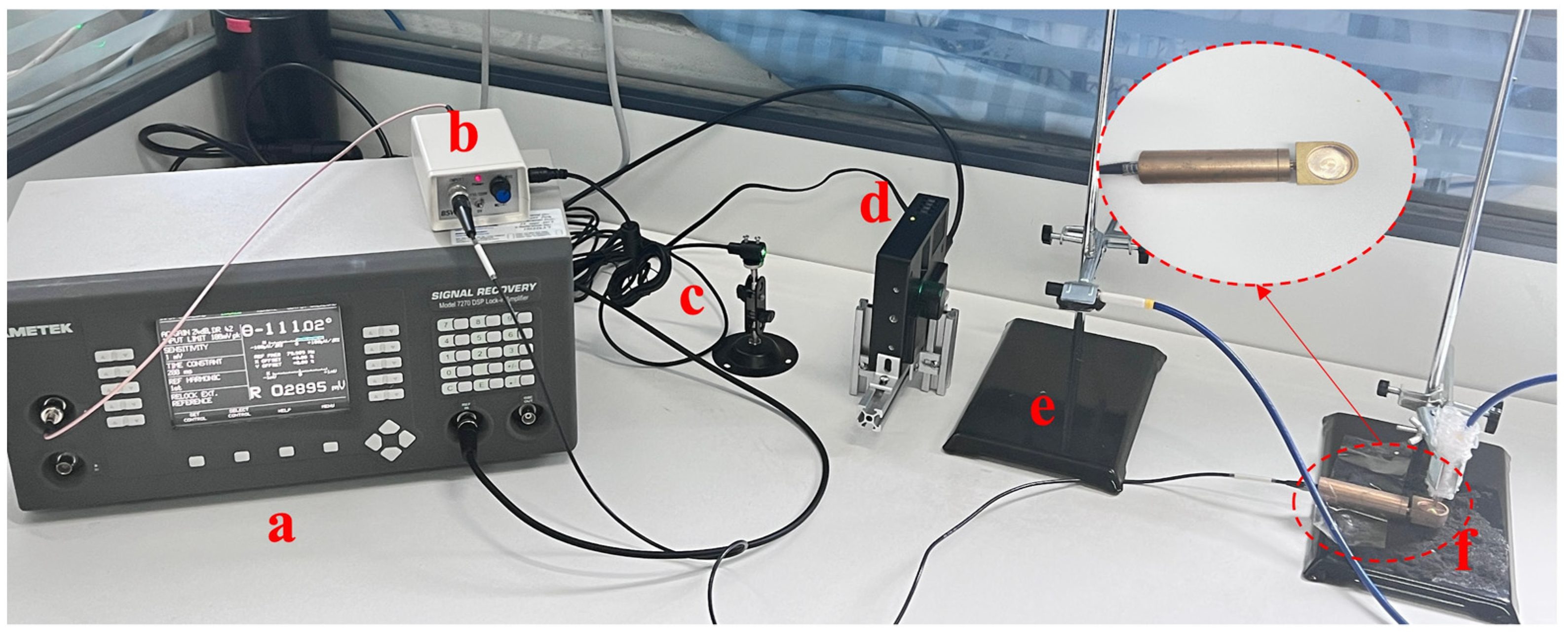

2.3. PAS System

2.4. Spectral Data Preprocessing

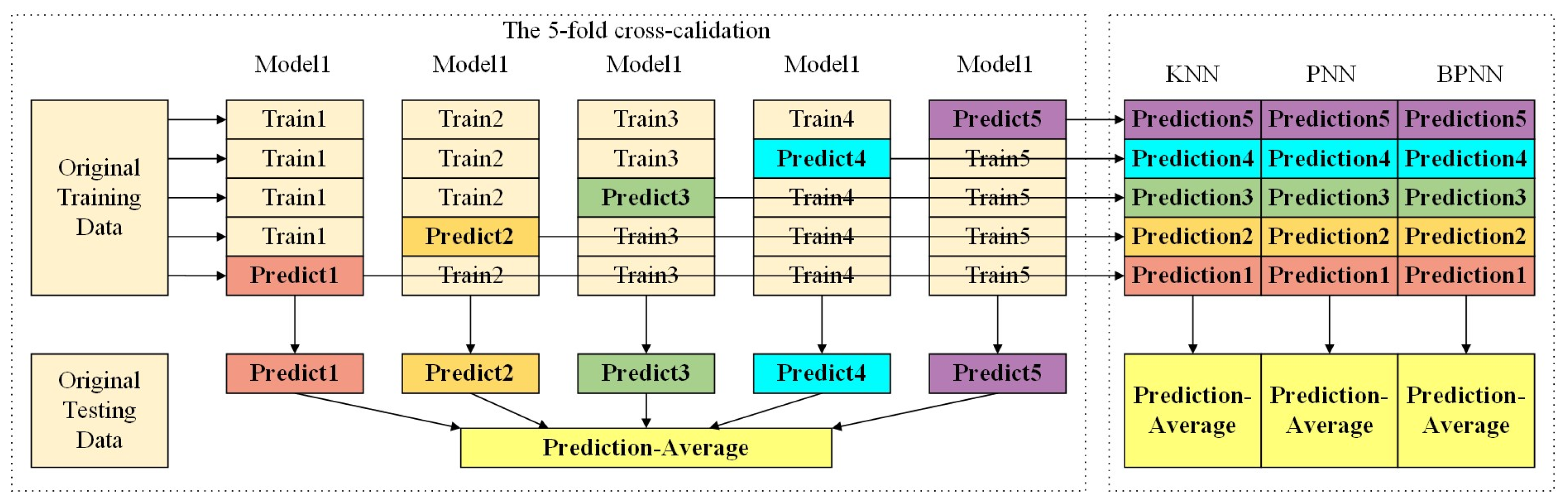

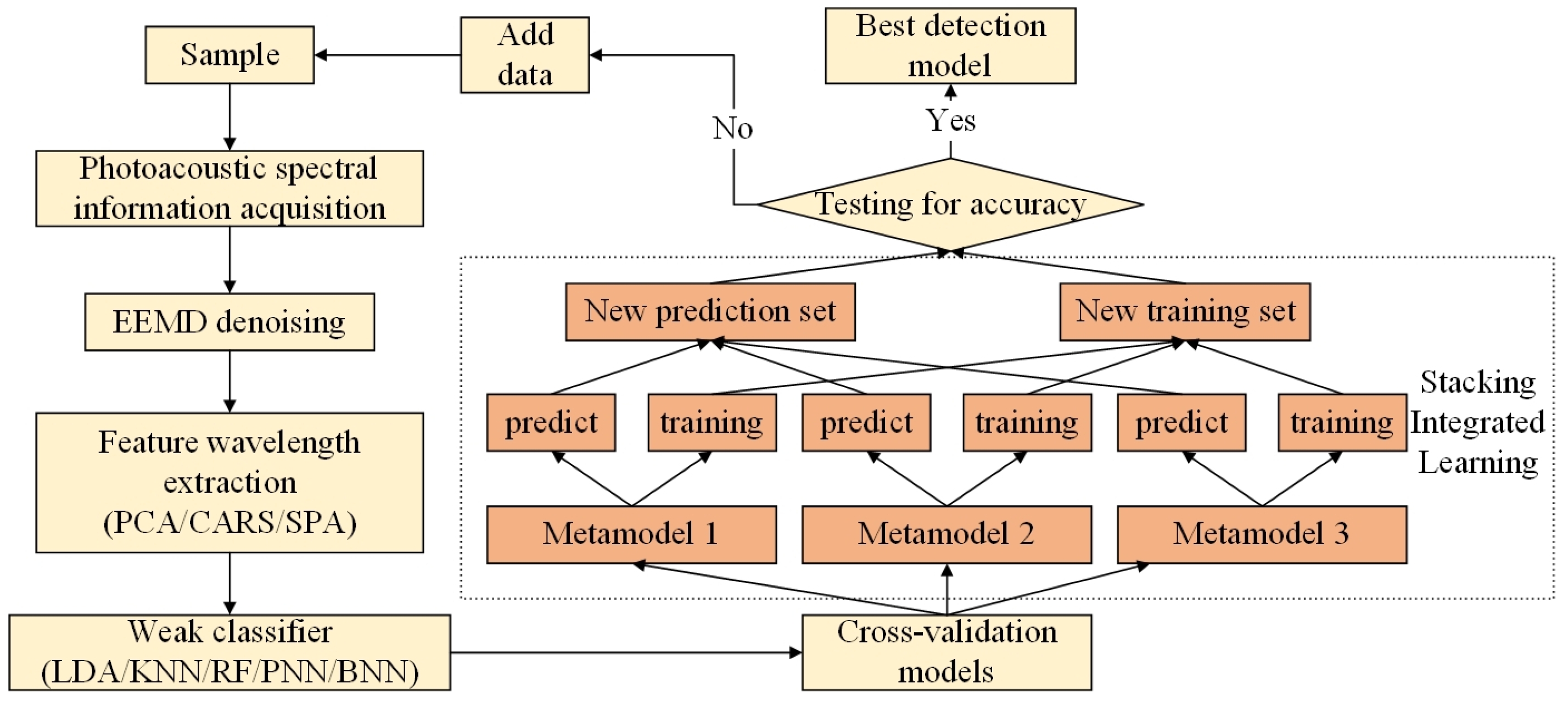

2.5. Modeling of Ensemble Learning Based on Stacking

3. Results and Discussion

3.1. Results of Free Fatty Acid Content Measurements

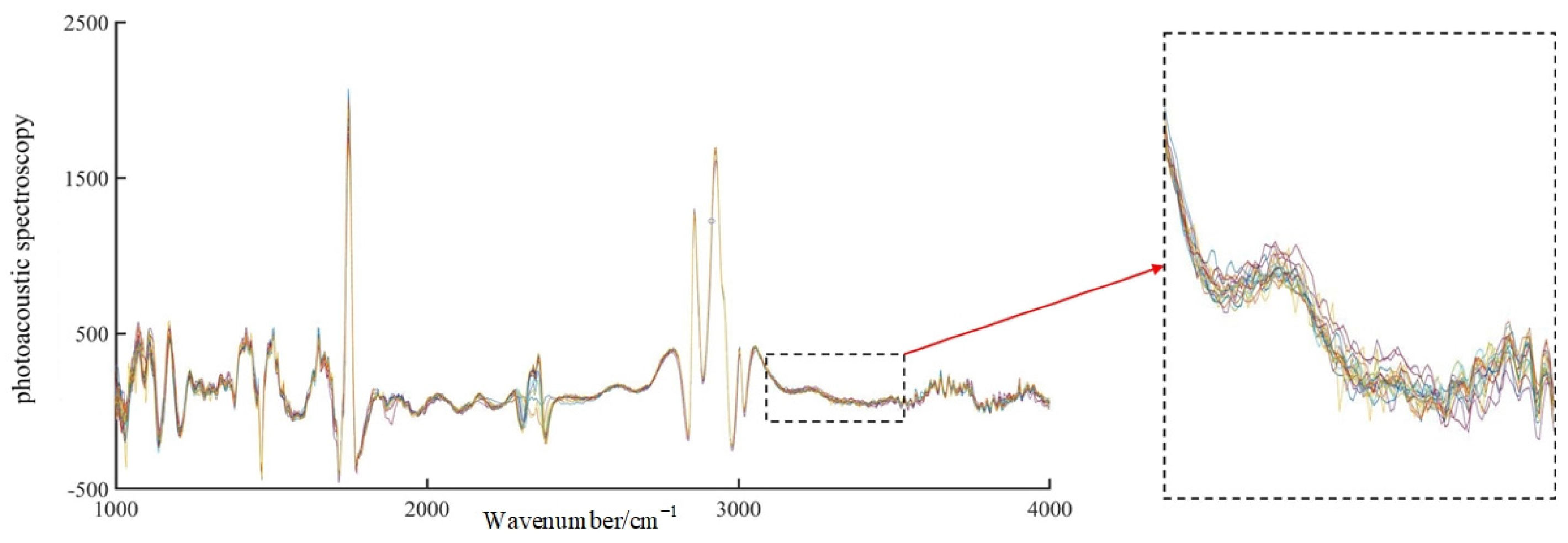

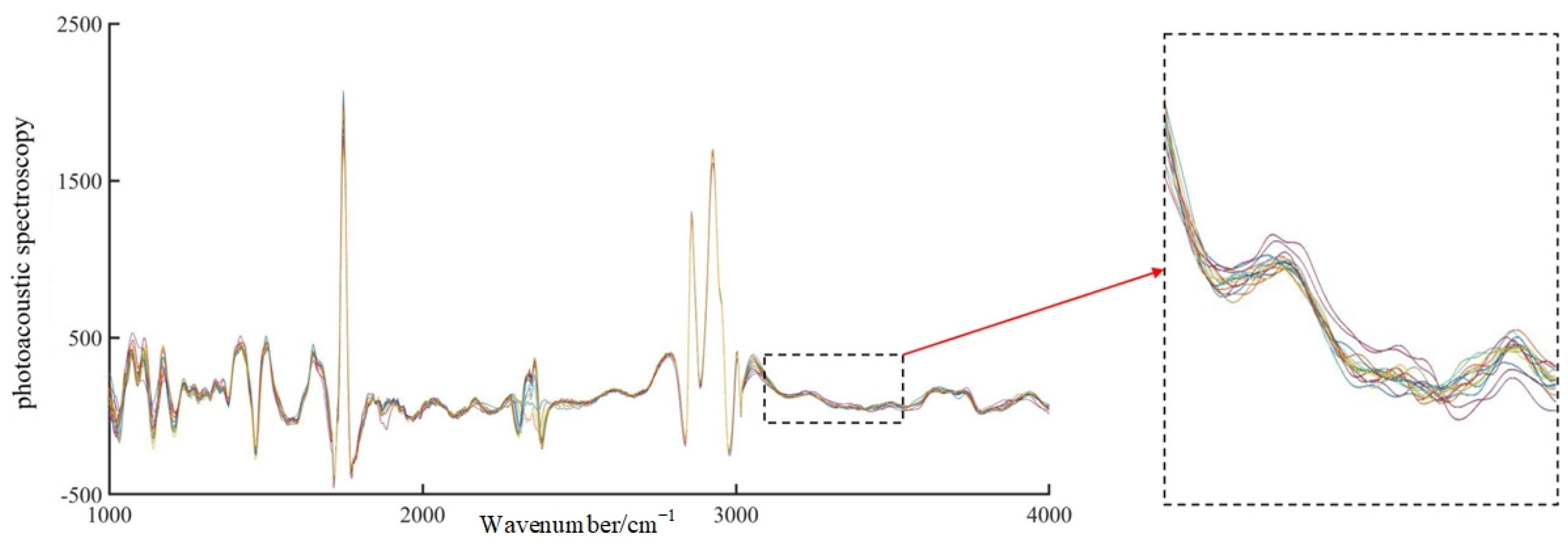

3.2. Spectral Information Preprocessing and Analysis

3.3. Wavelength Extraction of Photoacoustic Spectral Data

3.3.1. PCA Feature Wavelength Extraction

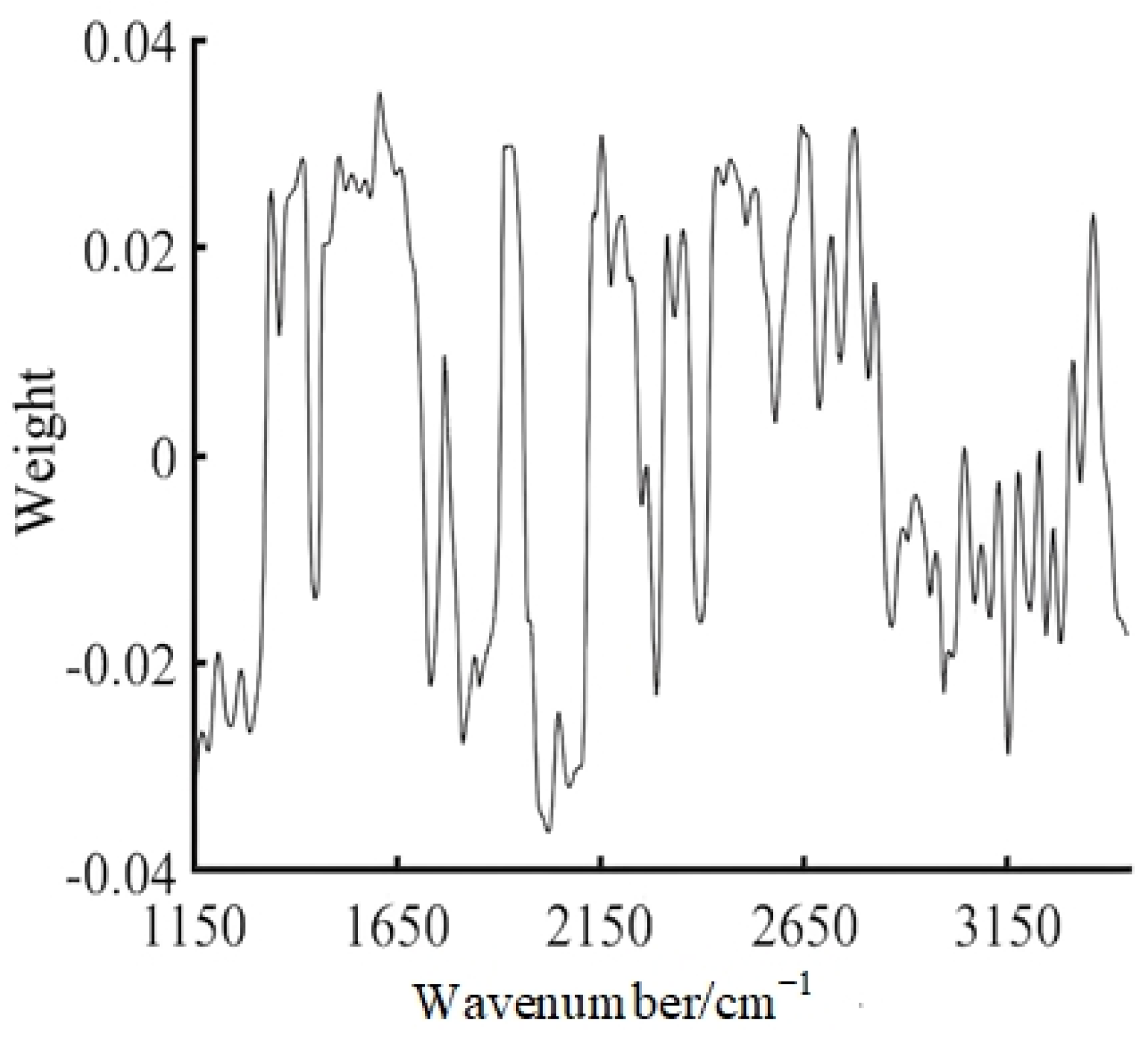

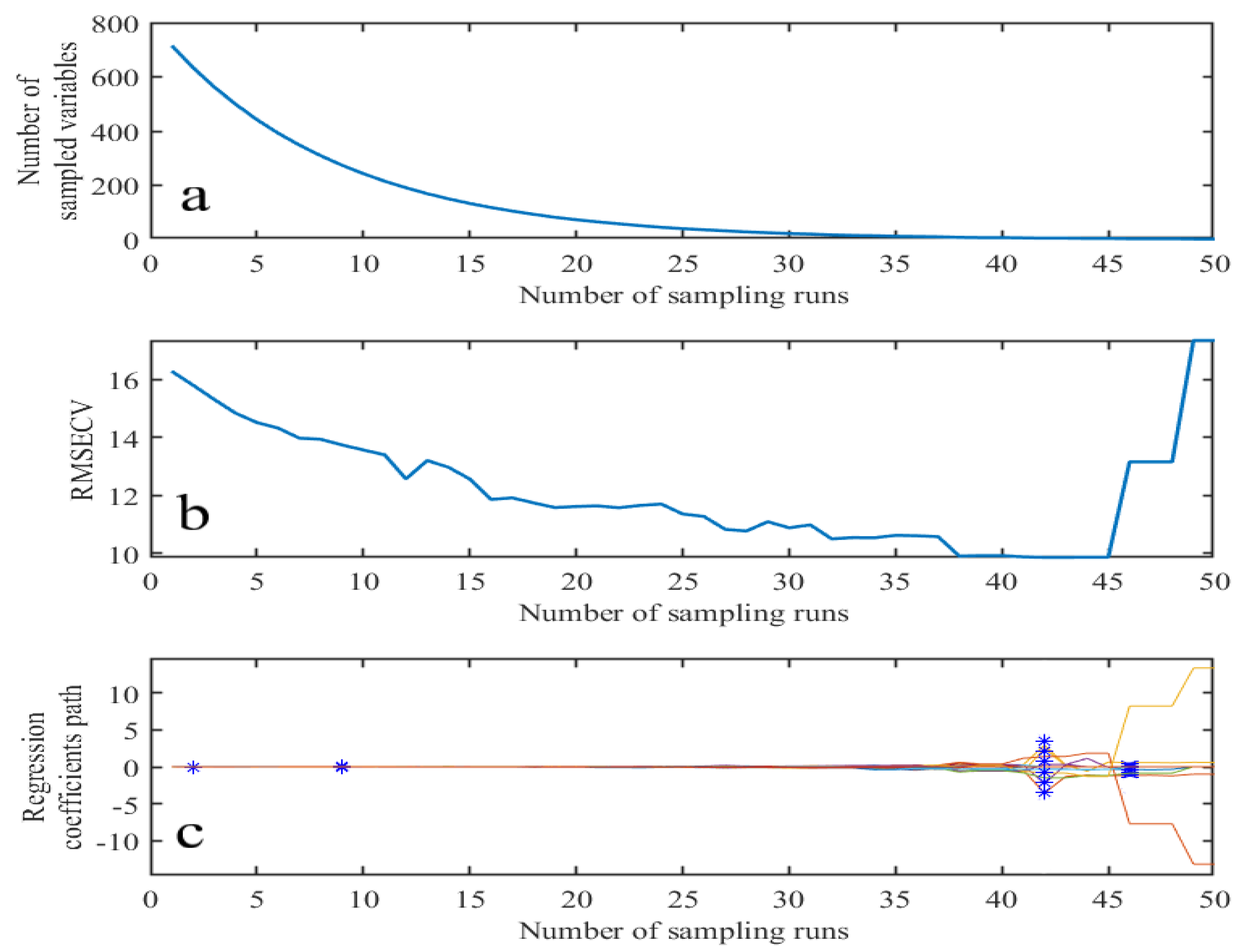

3.3.2. CARS-Based Feature Wavenumber Extraction

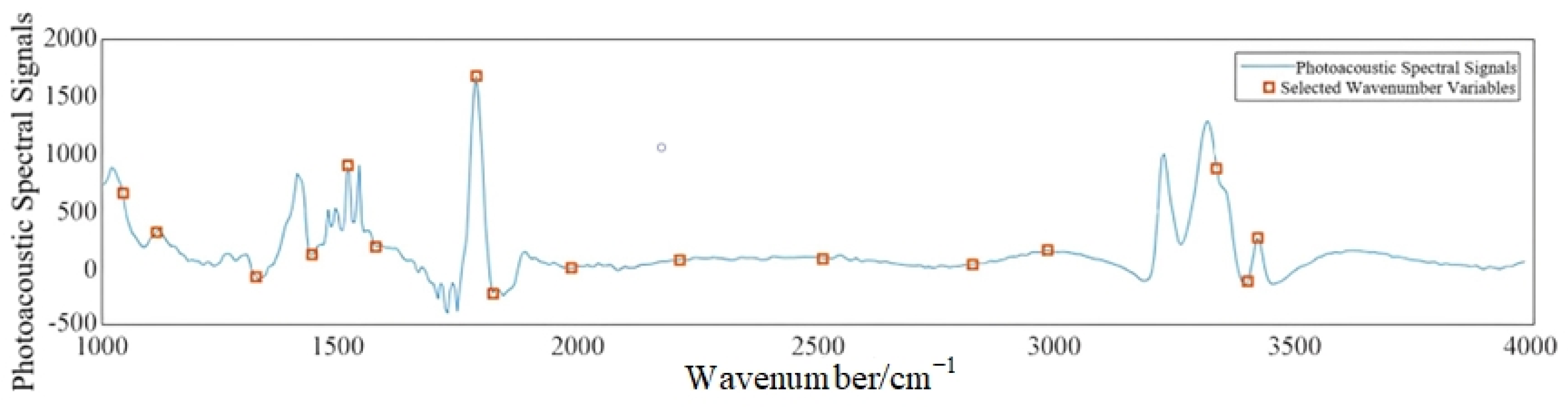

3.3.3. SPA-Based Photoacoustic Feature Extraction

3.4. Model Building and Validation

3.4.1. Classification Results Based on the Weak Classifier

3.4.2. Classification Results Based on Stacking Integration Learning

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Acik, G.; Kamaci, M.; Altinkok, C.; Karabulut, H.R.F.; Tasdelen, M.A. Synthesis and Properties of Soybean Oil-Based Biodegradable Polyurethane Films. Prog. Org. Coat. 2018, 123, 261–266. [Google Scholar] [CrossRef]

- Guit, J.; Tavares, M.B.L.; Hul, J.; Ye, C.; Loos, K.; Jager, J.; Folkersma, R.; Voet, V.S.D. Photopolymer Resins with Biobased Methacrylates Based on Soybean Oil for Stereolithography. ACS Appl. Polym. Mater. 2020, 2, 949–957. [Google Scholar] [CrossRef]

- Savych, A.; Basaraba, R.; Muzyka, N.; Ilashchuk, P. Analysis of Fatty Acid Composition Content in the Plant Components of Antidiabetic Herbal Mixture by GC-MS. Pharmacia 2021, 68, 433–439. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; Liu, O. Development and Validation of a GC–FID Method for Quantitative Analysis of Oleic Acid and Related Fatty Acids. J. Pharm. Anal. 2015, 5, 223–230. [Google Scholar] [CrossRef]

- Akkaya, M.R. Prediction of Fatty Acid Composition of Sunflower Seeds by Near-Infrared Reflectance Spectroscopy. J. Food Sci. Technol. 2018, 55, 2318–2325. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Yu, Q.; Gong, Z.; Guo, M.; Qu, C. Ultra-High Sensitive Fiber-Optic Fabry-Perot Cantilever Enhanced Resonant Photoacoustic Spectroscopy. Sens. Actuators B Chem. 2018, 268, 205–209. [Google Scholar] [CrossRef]

- Larios, G.; Nicolodelli, G.; Ribeiro, M.; Canassa, T.; Reis, A.R.; Oliveira, S.L.; Alves, C.Z.; Marangoni, B.S.; Cena, C. Soybean Seed Vigor Discrimination by Using Infrared Spectroscopy and Machine Learning Algorithms. Anal. Methods 2020, 12, 4303–4309. [Google Scholar] [CrossRef] [PubMed]

- Linhares, F.G.; Lima, M.A.; Mothe, G.A.; De Castro, M.P.P.; Da Silva, M.G.; Sthel, M.S. Photoacoustic Spectroscopy for Detection of N2O Emitted from Combustion of Diesel/Beef Tallow Biodiesel/Sugarcane Diesel and Diesel/Beef Tallow Biodiesel Blends. Biomass Convers. Biorefinery 2019, 9, 577–583. [Google Scholar] [CrossRef]

- Pontes, M.S.; Grillo, R.; Graciano, D.E.; Falco, W.F.; Lima, S.M.; Caires, A.R.L.; Andrade, L.H.C.; Santiago, E.F. How Does Aquatic Macrophyte Salvinia Auriculata Respond to Nanoceria upon an Increased CO2 Source? A Fourier Transform-Infrared Photoacoustic Spectroscopy and Chlorophyll a Fluorescence Study. Ecotoxicol. Environ. Saf. 2019, 180, 526–534. [Google Scholar] [CrossRef] [PubMed]

- Xing, Z.; Tian, K.; Du, C.; Li, C.; Zhou, J.; Chen, Z. Agricultural Soil Characterization by FTIR Spectroscopy at Micrometer Scales: Depth Profiling by Photoacoustic Spectroscopy. Geoderma 2019, 335, 94–103. [Google Scholar] [CrossRef]

- Hughes, T.W.; Minkov, M.; Shi, Y.; Fan, S. Training of Photonic Neural Networks through in Situ Backpropagation and Gradient Measurement. Optica 2018, 5, 864–871. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, Y.; Huang, W.; Tian, X.; Xia, Y.; Xu, L.; Fan, S. Nondestructive Measurement of Soluble Solids Content in Apple Using near Infrared Hyperspectral Imaging Coupled with Wavelength Selection Algorithm. Infrared Phys. Technol. 2019, 98, 297–304. [Google Scholar] [CrossRef]

- Li, Q.; Huang, Y.; Song, X.; Zhang, J.; Min, S. Moving Window Smoothing on the Ensemble of Competitive Adaptive Reweighted Sampling Algorithm. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 214, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Gurcan, F.; Ozyurt, O.; Cagitay, N.E. Investigation of Emerging Trends in the E-Learning Field Using Latent Dirichlet Allocation. Int. Rev. Res. Open Distrib. Learn. 2021, 22, 1–18. [Google Scholar] [CrossRef]

- He, P.; Yang, W.; Ali, S.; Lin, H.; Jiang, H.; Shi, Z.; Li, H.; Chen, Q. A Solid-Phase Porphyrin and Boron-Dipyrromethene Sensing Platform for the Infestation Detection of Two Main Hidden Pests in Rice. Sensors Actuators B Chem. 2022, 364, 131843. [Google Scholar] [CrossRef]

- Cooper, J.S.; Kiiveri, H.; Chow, E.; Hubble, L.J.; Webster, M.S.; Müller, K.-H.; Raguse, B.; Wieczorek, L. Quantifying Mixtures of Hydrocarbons Dissolved in Water with a Partially Selective Sensor Array Using Random Forests Analysis. Sensors Actuators B Chem. 2014, 202, 279–285. [Google Scholar] [CrossRef]

- Li, A.; Chang, J.; Liu, Y.; Wang, Q.; Wang, Z. Research on High Sensitivity of Resonant Enhancement Laser Intracavity Photoacoustic Spectroscopy Technology. Optik 2018, 156, 672–676. [Google Scholar] [CrossRef]

- Alkronz, E.S.; Moghayer, K.A.; Meimeh, M.; Gazzaz, M.; Abu-Nasser, B.S.; Abu-Naser, S.S. Prediction of Whether Mushroom Is Edible or Poisonous Using Back-Propagation Neural Network. Int. J. Corpus Linguist. 2019, 3, 1–8. [Google Scholar]

- Lv, G.; Du, C.; Ma, F.; Shen, Y.; Zhou, J. In Situ Detection of Rice Leaf Cuticle Responses to Nitrogen Supplies by Depth-Profiling Fourier Transform Photoacoustic Spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 228, 117759. [Google Scholar] [CrossRef] [PubMed]

- Bryś, A.; Bryś, J.; Mellado, Á.F.; Głowacki, S.; Tulej, W.; Ostrowska-Ligęza, E.; Koczoń, P. Characterization of Oil from Roasted Hemp Seeds Using the PDSC and FTIR Techniques. J. Therm. Anal. Calorim. 2019, 138, 2781–2786. [Google Scholar] [CrossRef]

| Frying Durations | Acid Price (mg/g) | Free Fatty Acids (%) |

|---|---|---|

| 0 h | 0.15 | 0.08 |

| 8 h | 0.41 | 0.20 |

| 16 h | 0.48 | 0.24 |

| 24 h | 0.63 | 0.32 |

| 32 h | 0.93 | 0.47 |

| 40 h | 1.04 | 0.52 |

| 48 h | 1.35 | 0.68 |

| 56 h | 1.74 | 0.87 |

| 64 h | 2.00 | 1.01 |

| 72 h | 2.30 | 1.16 |

| 80 h | 2.55 | 1.28 |

| Classifier | PCA | SPA | CARS | |||

|---|---|---|---|---|---|---|

| Training Set | Test Set | Training Set | Test Set | Training Set | Test Set | |

| LDA | 0.3733 | 0.3481 | 0.6519 | 0.7493 | 0.7547 | 0.8067 |

| RF | 0.4523 | 0.5739 | 0.9128 | 0.9428 | 0.8767 | 0.8407 |

| KNN | 0.5027 | 0.5198 | 0.7183 | 0.7903 | 0.8231 | 0.9384 |

| PNN | 0.6925 | 0.7003 | 0.6368 | 0.7602 | 0.8602 | 0.9499 |

| BPNN | 0.6163 | 0.6731 | 0.9317 | 0.9474 | 0.8909 | 0.9502 |

| Classifier | CARS | SPA | ||

|---|---|---|---|---|

| Training Set | Test Set | Training Set | Test Set | |

| KNN | 0.8401 | 0.8654 | 0.8967 | 0.9514 |

| BPNN | 0.9137 | 0.9582 | 0.9333 | 0.9454 |

| PNN | 0.8333 | 0.8705 | 0.9701 | 0.9846 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Yang, K.; Ji, L.; Kong, L.; Lu, W. Photoacoustic Spectroscopy Combined with Integrated Learning to Identify Soybean Oil with Different Frying Durations. Sensors 2023, 23, 4247. https://doi.org/10.3390/s23094247

Luo H, Yang K, Ji L, Kong L, Lu W. Photoacoustic Spectroscopy Combined with Integrated Learning to Identify Soybean Oil with Different Frying Durations. Sensors. 2023; 23(9):4247. https://doi.org/10.3390/s23094247

Chicago/Turabian StyleLuo, Hui, Kaiyun Yang, Lili Ji, Lingqi Kong, and Wei Lu. 2023. "Photoacoustic Spectroscopy Combined with Integrated Learning to Identify Soybean Oil with Different Frying Durations" Sensors 23, no. 9: 4247. https://doi.org/10.3390/s23094247

APA StyleLuo, H., Yang, K., Ji, L., Kong, L., & Lu, W. (2023). Photoacoustic Spectroscopy Combined with Integrated Learning to Identify Soybean Oil with Different Frying Durations. Sensors, 23(9), 4247. https://doi.org/10.3390/s23094247