Nut Geometry Inspection Using Improved Hough Line and Circle Methods

Abstract

1. Introduction

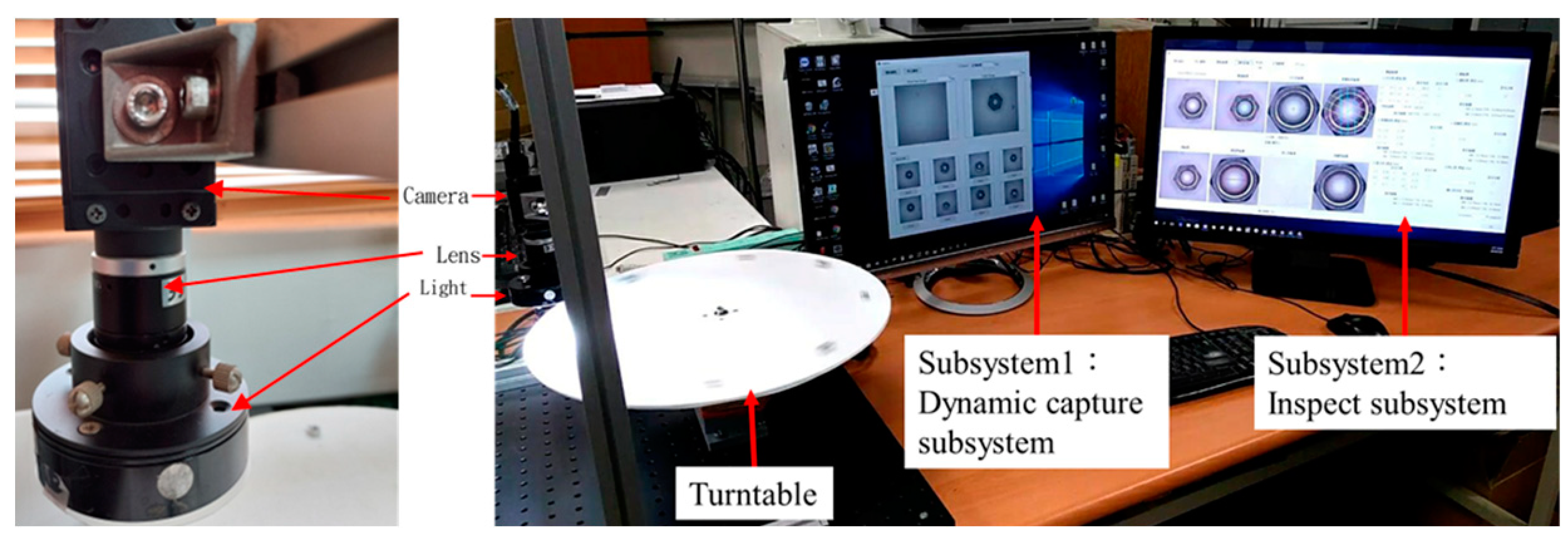

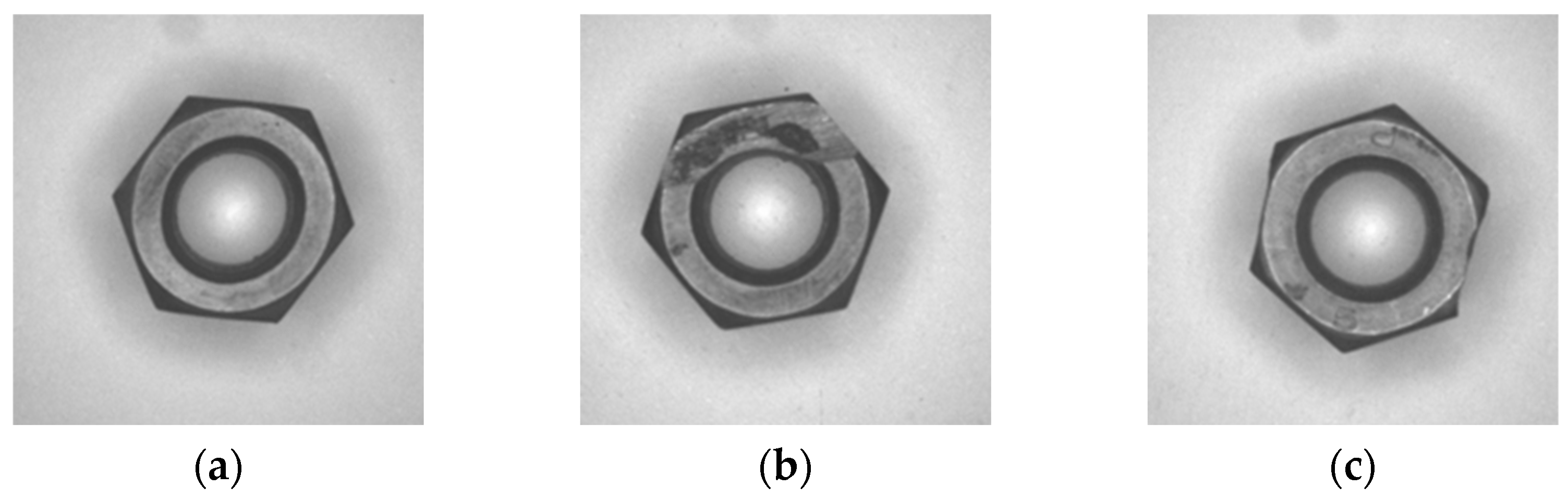

2. System Setup

3. System Framework

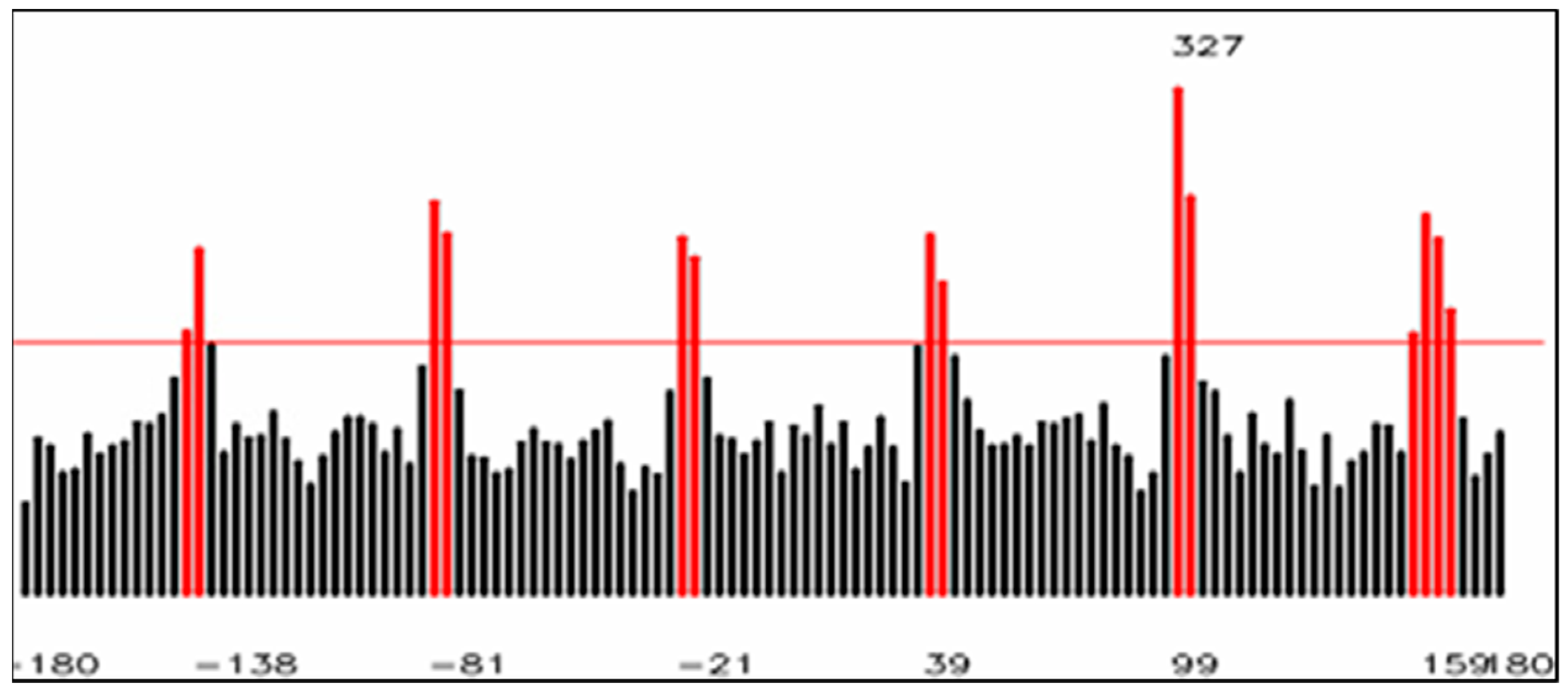

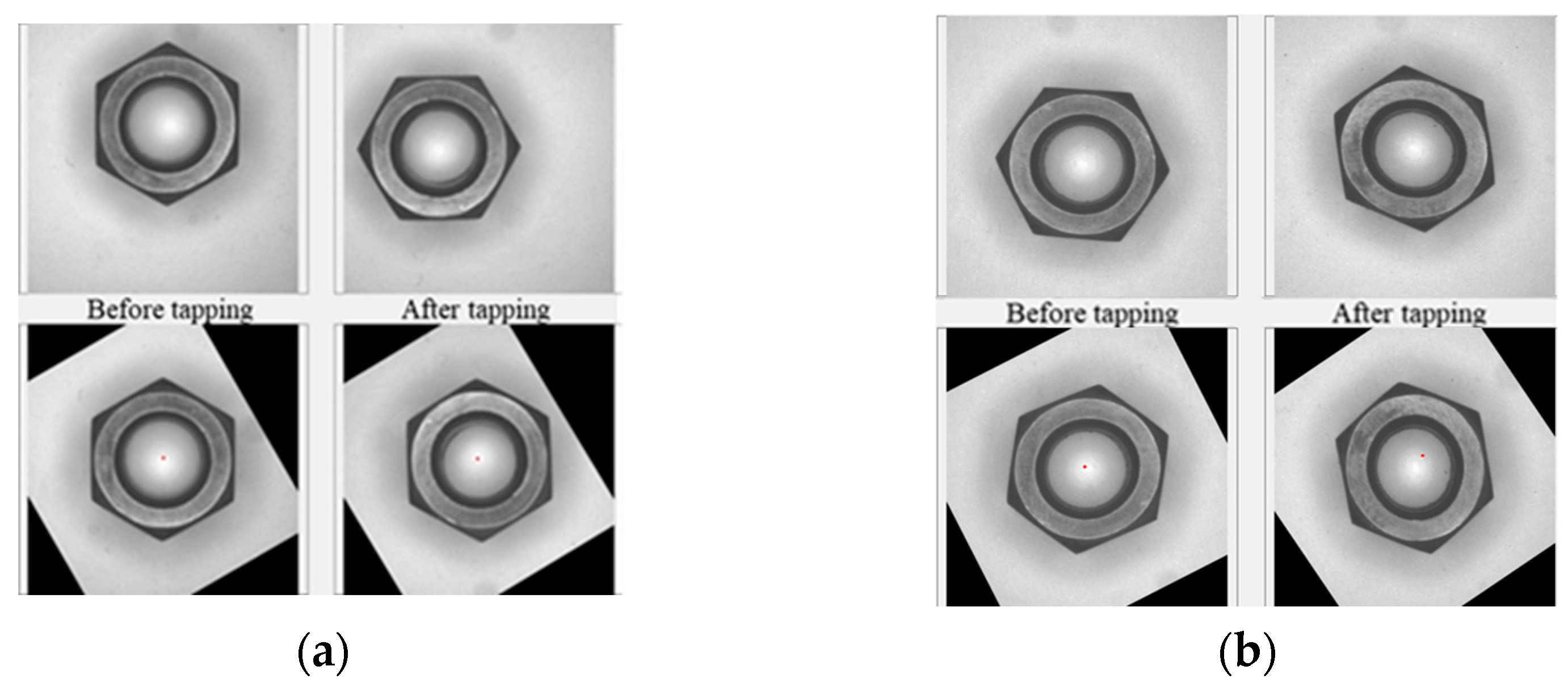

3.1. Dynamic Capture Subsystem

3.2. Inspection Subsystem

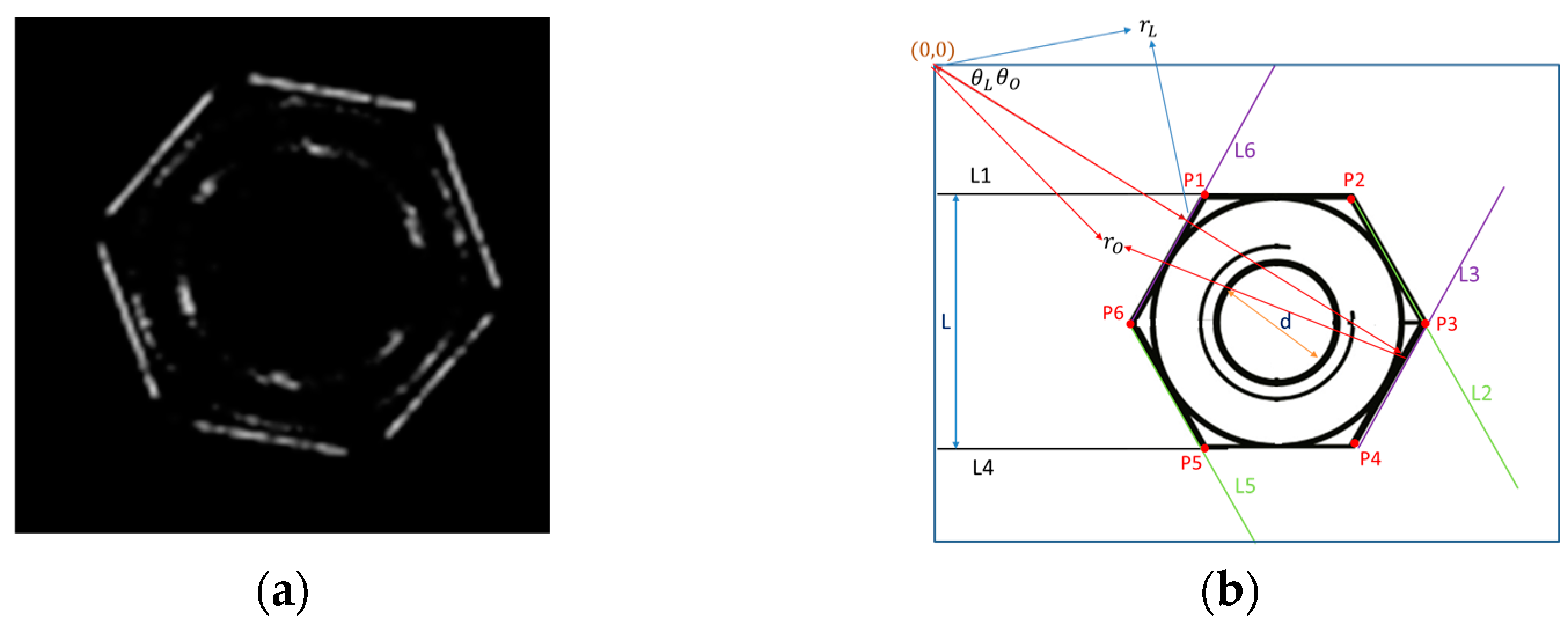

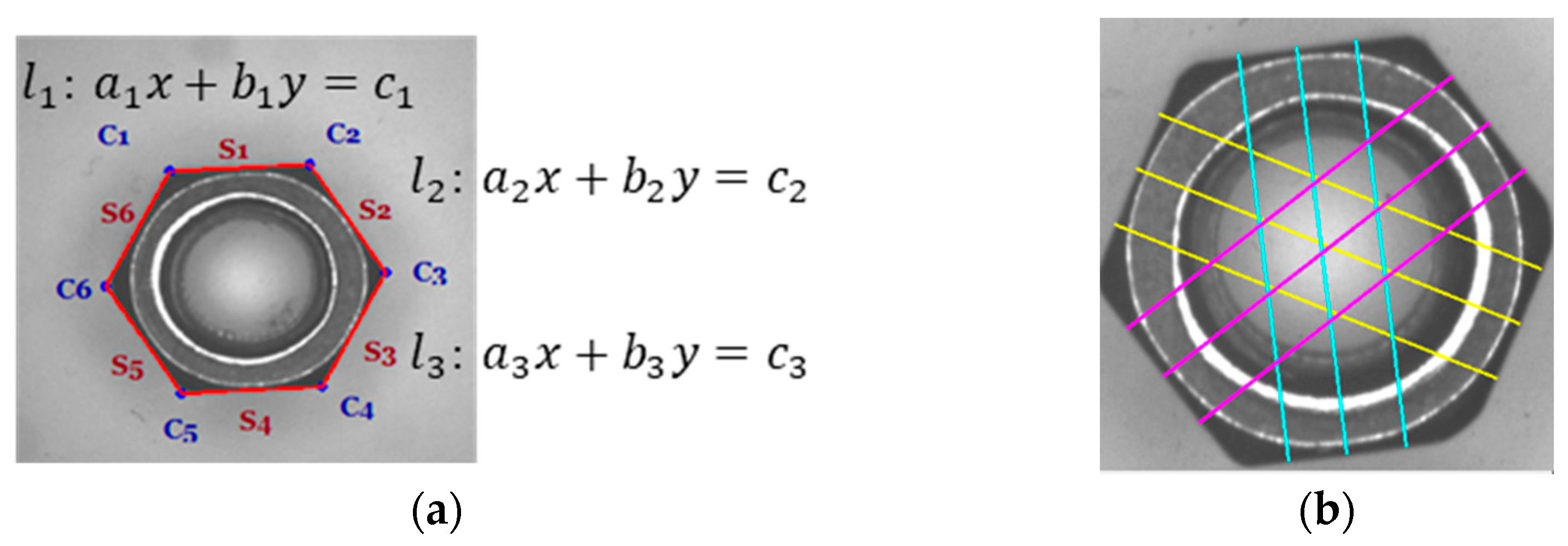

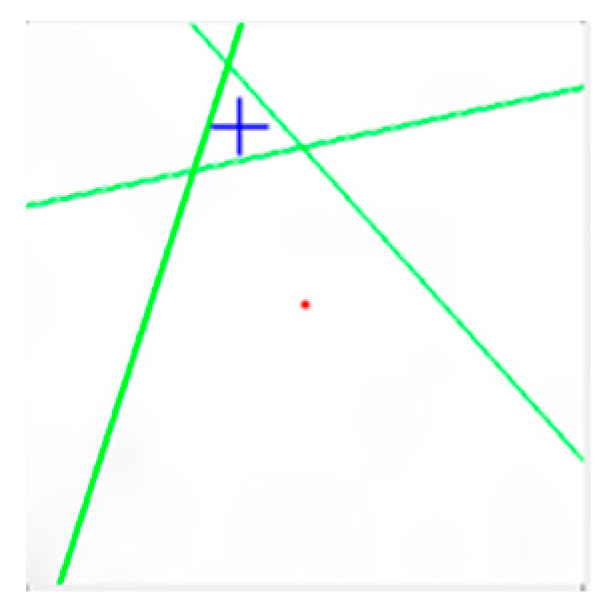

3.2.1. Parallel Line Detection

3.2.2. The Opposite Side Length

3.2.3. Edge Flatness of the Nut

3.2.4. Bore Diameter

3.2.5. Roundness

3.2.6. Concentricity

3.2.7. Eccentricity

4. Experimental Results

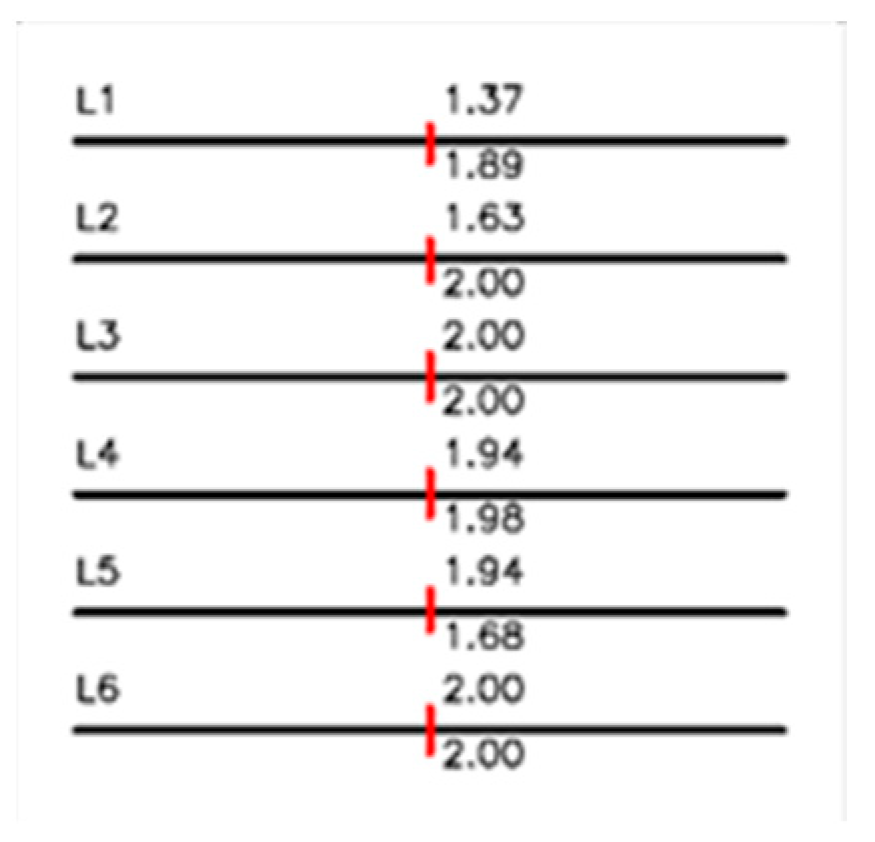

4.1. Line Geometry Inspection Results

4.2. Circle Geometry Inspection Results

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pondech, W.; Saenthon, A.; Konghuayrob, P. The Development of Adaptive Gray Level Mapping Combined Partical Wwarm Optimization for Measuring the Dimeter Size of Automotive Nut. In Proceedings of the 2020 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–21 April 2020; pp. 240–244. [Google Scholar]

- Peng, Z.; Wang, C.; Ma, Z.; Liu, H. A Multifeature Hierarchical Locating Algorithm for Hexagon Nut of Railway Fasteners. IEEE Trans. Instrum. Meas. 2020, 69, 693–699. [Google Scholar] [CrossRef]

- Yao, Z.; Yi, W. Curvature Aided Hough Transform for Circle Detection. Expert Syst. Appl. 2016, 51, 26–33. [Google Scholar] [CrossRef]

- Mu, Z.; Li, Z. A Novel Shi-Tomasi Corner Detection Algorithm Based on Progressive Probabilistic Hough Transform. Chin. Autom. Congr. 2018, 2918–2922. [Google Scholar]

- Ye, H.; Shang, G.; Wang, L.; Zheng, M. A New Method Based on Hough Transform for Quick Line and Circle Detection. In Proceedings of the International Conference on Biomedical Engineering and Informatics, Shenyang, China, 14–16 October 2015. [Google Scholar]

- Nguyen, T.C.; Huynh, T.C.; Ryu, J.Y.; Park, J.H.; Kim, J.T. Bolt-Loosening Identification of Bolt Connections by Vision Image-Based Technique. In Proceedings of the SPIE, Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure, Las Vegas, NV, USA, 8 April 2016. [Google Scholar]

- Huynh, T.-C.; Park, J.-H.; Jung, H.-J.; Kim, J.-T. Quasi-autonomous bolt-loosening detection method using vision-based deep learning and image processing. Autom. Constr. 2019, 105, 102844. [Google Scholar] [CrossRef]

- Ta, Q.-B.; Kim, J.-T. Monitoring of Corroded and Loosened Bolts in Steel tructures via Deep Learning and Hough Transforms. Sensors 2020, 23, 6888. [Google Scholar] [CrossRef] [PubMed]

- Huynh, T.-C. Vision-Based Autonomous Bolt-Looseness Detection Method for Splice Connections: Design, Lab-Scale Evaluation, and Field Application. Autom. Constr. 2021, 124, 103591. [Google Scholar] [CrossRef]

- Wei, S.; Li, X.; Ding, S.; Yang, Q.; Yan, W. Hotspots Infrared Detection of Photovoltaic Modules Based on Hough Line Transformation and Faster-RCNN Approach. In Proceedings of the 2019 6th International Conference on Control, Decision and Information Technologies, Paris, France, 23–26 April 2019. [Google Scholar]

- Zhao, K.; Han, Q.; Zhang, C.-B.; Xu, J.; Cheng, M.-M. Deep Hough Transform for Semantic Line Detection. IEEE Trans. Pattern Anal. Mach. Intell. 2022, 44, 4793–4806. [Google Scholar] [CrossRef] [PubMed]

- Hoang, H.-H.; Nguyen, T.-H.; Tran, V.-H.; Bui, T.-H.; Nguyen, D.-M. Machine Vision System for Automated Nuts Classification and Inspection. In Proceedings of the 2nd Annual International Conference on Material, Machines and Methods for Sustainable Development, Nha Trang, Vietnam, 12–15 November 2020; pp. 755–759. [Google Scholar]

- Li, S.; Luo, C.C. Research on Straightness Detection of Steel Strip Edge Based on Machine Vision. J. Phys. Conf. Ser. 2021, 1820, 012063. [Google Scholar] [CrossRef]

- Zhang, C.; Duan, F.; Fu, X.; Liu, W.; Su, Y.; Li, X. Research of Intelligent Segment-Fitting Algorithm for Increasing the Measurement Accuracy of Quadrant Detector in Straightness Measuring System. Opt. Laser Technol. 2020, 125, 106062. [Google Scholar] [CrossRef]

- Gong, J.; Zhang, G.; Wang, K. Human Iris Localization Combined with Ant Colony and Improved Hough Circle Detection. J. Math. Inform. 2019, 16, 23–39. [Google Scholar] [CrossRef]

- Ma, B.; Liu, H.; Zhang, Q. Hough Circle Detection Method for Shaking Instruments in Drilling Field. In Proceedings of the International Conference on Computer Network, Electronic and Automation, Xi’an, China, 24–26 September 2021. [Google Scholar]

- Le, T.; Duan, Y. Circle Detection on Images by Line Segment and Circle Completeness. In Proceedings of the International Conference on Image Processing, Phoenix, AZ, USA, 25–28 September 2016. [Google Scholar]

- Li, Z.; Liao, L. Bright Field Droplet Image Recognition Based on Fast Hough Circle Detection Algorithm. In Proceedings of the 14th International Conference on Computer Research and Development, Shenzhen, China, 7–9 January 2022. [Google Scholar]

- Zhang, H.; Wiklund, K.; Andersson, M. A Fast and Robust Circle Detection Method Using Isosceles Triangles Sampling. Pattern Recognit. 2016, 54, 218–228. [Google Scholar] [CrossRef]

- Zhou, B. Using Vector Quantization of Hough Transform for Circle Detection. In Proceedings of the 14th International Conference on Machine Learning and Applications, Miami, FL, USA, 9–11 December 2015. [Google Scholar]

- Fachruddin, R.; Buliali, J.L. Circle Detection System Using Image Moments. In Proceedings of the International Conference on Computational Intelligence and Cybernetics, Malang, Indonesia, 16–18 June 2022. [Google Scholar]

- Tiainen, T.; Viitala, R. Effect of positional errors on the accuracy of multi-probe roundness measurement methods. Mech. Syst. Signal Process 2020, 144, 107495–107501. [Google Scholar] [CrossRef]

- Ou, Y.; Deng, H.; Liu, Y.; Zhang, Z.; Ruan, X.; Xu, Q.; Peng, C. A Fast Circle Detection Algorithm Based on Information Compression. Sensors 2022, 22, 7267. [Google Scholar] [CrossRef] [PubMed]

- Fourie, J. Robust Circle Detection Using Harmony Search. J. Optim. 2017, 2017, 9710719. [Google Scholar] [CrossRef]

- Liang, Q.; Long, J.; Nan, Y.; Coppola, G.; Zou, K.; Zhang, D.; Sun, W. Angle aided circle detection based on randomized Hough transform and its application in welding spots detection. Math. Biosci. Eng. 2019, 16, 1244–1257. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wu, M. An Improved Hough Transform for Circle Detection using Circular Inscribed Direct Triangle. In Proceedings of the 2020 13th International Congress on Image and Signal Processing, BioMedical Engineering and Informatics, Chengdu, China, 17–19 October 2020. [Google Scholar]

- Barbosa, W.O.; Vieira, A.W. On the improvement of multiple circles detection from images using hough transform. TEMA 2019, 20, 331–342. [Google Scholar] [CrossRef]

- Oertel, E.; Manske, E. Radius and roundness measurement of micro spheres based on a set of AFM surface scans. Meas. Sci. Technol. 2021, 32, 44005–44016. [Google Scholar] [CrossRef]

- Akrichi, S.; Abbassi, A.; Abid, S.; Ben Yahia, N. Roundness and positioning deviation prediction in single point incremental forming using deep learning approaches. Adv. Mech. Eng. 2019, 11, 1–15. [Google Scholar] [CrossRef]

- Du, B.; Hao, Z.; Wei, X. Roundness Detection of End Face for Shaft Workpiece based on Canny-Zernike Sub Pixel Edge Detection and Improved Hough Transform. In Proceedings of the 11th International Conference on Electronics Information and Emergency Communication, Beijing, China, 18–20 June 2021. [Google Scholar]

- Alzahrani, F.; Hobiny, A.; Abbas, I.; Marin, M. An Eigenvalues Approach for a Two-Dimensional Porous Medium Based Upon Weak, Normal and Strong Thermal Conductivities. Symmetry 2020, 12, 848. [Google Scholar] [CrossRef]

- Scutaru, M.L.; Vlase, S.; Marin, M.; Modrea, A. New analytical method based on dynamic response of planar mechanical elastic systems. Bound. Value Probl. 2020, 2020, 104. [Google Scholar] [CrossRef]

- Sobel, I.; Feldman, G. A 3 × 3 isotropic gradient operator for image processing. The Society for Industrial and Applied Mathematics. Scene. Anal. 1973, 15, 271–272. [Google Scholar]

| Line Detection | Circle Detection | Line + Circle Detection |

|---|---|---|

| (1) Parallel 180° ± 1% | (4) Dimeter 6.78 mm ± 1% | (7) Eccentricity <12.86 mm × 1% |

| (2) Straightness <12.86 mm × 1% | (5) Roundness 6.78 mm × 1% | |

| (3) Opposite side length 12.86 mm ± 1% | (6) Concentricity 6.78 mm × 1% |

| Normal | Abnormal | |

|---|---|---|

| Before tapping | 50 | 24 |

| After tapping | 50 | 20 |

| Parallel | LOS | Flatness | Diameter | Roundness | Concentricity | Eccentricity | |

|---|---|---|---|---|---|---|---|

| BMD | 0.05 mm | 0.01 mm | 0.05 mm | 0.05 mm | 0.06 mm | ||

| BM | 12.81 mm | 0.12 mm | 6.86 mm | 0.29 mm | 0.17 mm | ||

| BSD | 0.06 mm | 0.02 mm | 0.60 mm | 0.07 mm | 0.07 mm | ||

| AMD | 0.06 mm | 0.01 mm | 0.05 mm | 0.04 mm | 0.05 mm | 0.03 mm | |

| AM | 12.76 mm | 0.13 mm | 6.87 mm | 0.22 mm | 0.14 mm | 0.16 mm | |

| ASD | 0.08 mm | 0.01 mm | 0.07 mm | 0.05 mm | 0.06 mm | 0.04 mm |

| Parallel | LOS | Flatness | Diameter | Roundness | Concentricity | Eccentricity | |

|---|---|---|---|---|---|---|---|

| BMD | 0.50 mm | 0.01 mm | 0.02 mm | 0.09 mm | 0.14 mm | ||

| BM | 12.48 mm | 0.12 mm | 6.83 mm | 0.28 mm | 0.23 mm | ||

| BSD | 0.74 mm | 0.02 mm | 0.02 mm | 0.12 mm | 0.20 mm | ||

| AMD | 0.28 mm | 0.01 mm | 0.02 mm | 0.18 mm | 0.13 mm | 0.21 mm | |

| AM | 12.60 mm | 0.13 mm | 6.80 mm | 0.29 mm | 0.30 mm | 0.29 mm | |

| ASD | 0.39 mm | 0.02 mm | 0.03 mm | 0.21 mm | 0.17 mm | 0.24 mm |

| Parallel | LOS | Flatness | Diameter | Roundness | Concentricity | Eccentricity | |

|---|---|---|---|---|---|---|---|

| BMD | 0.13 mm | 0.01 mm | 0.08 mm | 0.21 mm | 0.06 mm | ||

| BM | 12.75 mm | 0.13 mm | 6.89 mm | 0.42 mm | 0.18 mm | ||

| BSD | 0.19 mm | 0.01 mm | 0.13 mm | 0.26 mm | 0.08 mm | ||

| AMD | 0.11 mm | 0.01 mm | 0.05 mm | 0.24 mm | 0.06 mm | 0.91 mm | |

| AM | 12.80 mm | 0.13 mm | 6.84 mm | 0.45 mm | 0.19 mm | 0.90 mm | |

| ASD | 0.17 mm | 0.01 mm | 0.06 mm | 0.27 mm | 0.08 mm | 1.09 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, E.-Y.; Tu, C.-T.; Lien, J.-J.J. Nut Geometry Inspection Using Improved Hough Line and Circle Methods. Sensors 2023, 23, 3961. https://doi.org/10.3390/s23083961

Lin E-Y, Tu C-T, Lien J-JJ. Nut Geometry Inspection Using Improved Hough Line and Circle Methods. Sensors. 2023; 23(8):3961. https://doi.org/10.3390/s23083961

Chicago/Turabian StyleLin, En-Yu, Ching-Ting Tu, and Jenn-Jier James Lien. 2023. "Nut Geometry Inspection Using Improved Hough Line and Circle Methods" Sensors 23, no. 8: 3961. https://doi.org/10.3390/s23083961

APA StyleLin, E.-Y., Tu, C.-T., & Lien, J.-J. J. (2023). Nut Geometry Inspection Using Improved Hough Line and Circle Methods. Sensors, 23(8), 3961. https://doi.org/10.3390/s23083961