Development of Smart Irrigation Equipment for Soilless Crops Based on the Current Most Representative Water-Demand Sensors

Abstract

1. Introduction

2. Materials and Methods

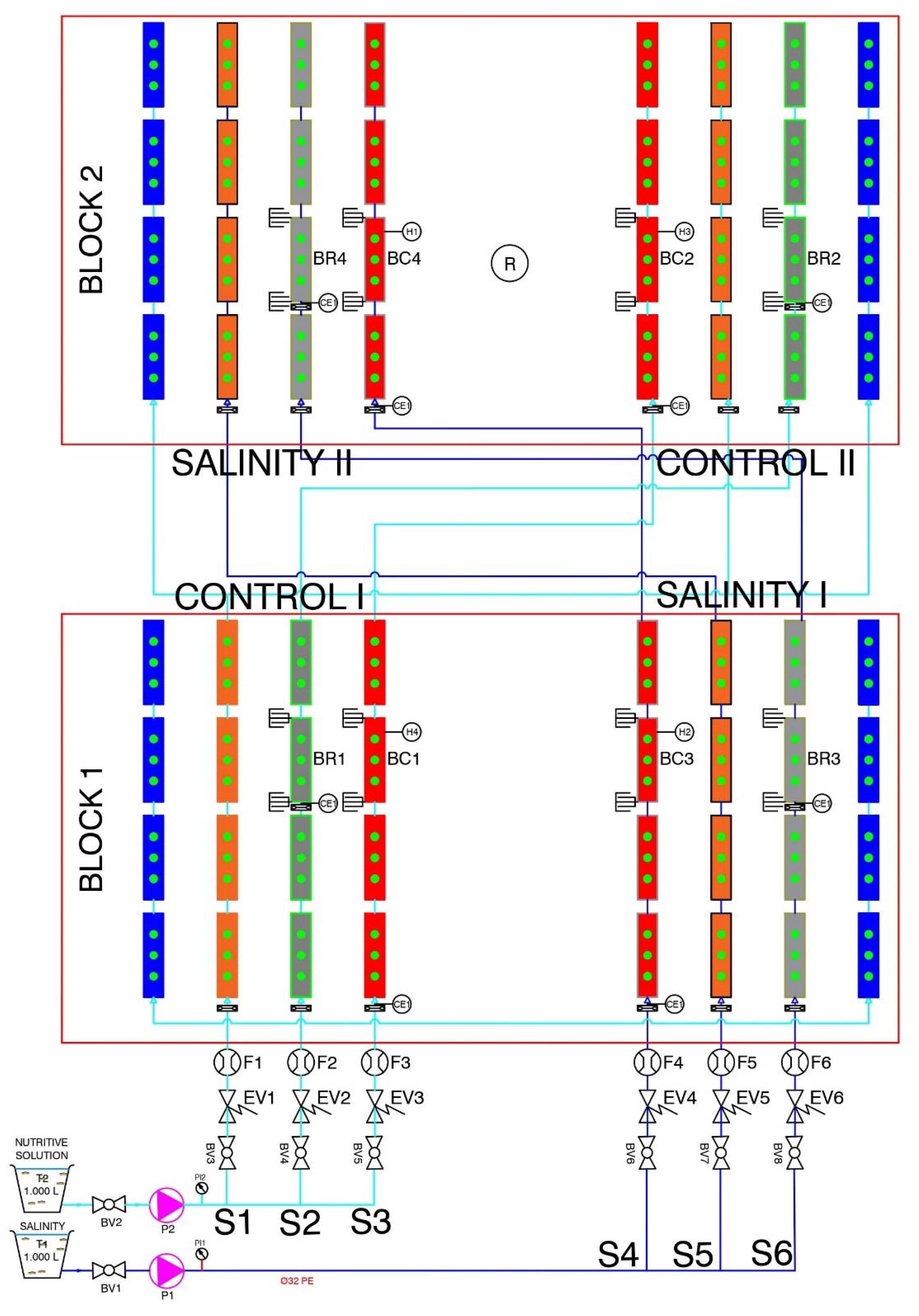

2.1. Agronomic Trials

2.1.1. Analytical Data

2.1.2. Statistical Analysis

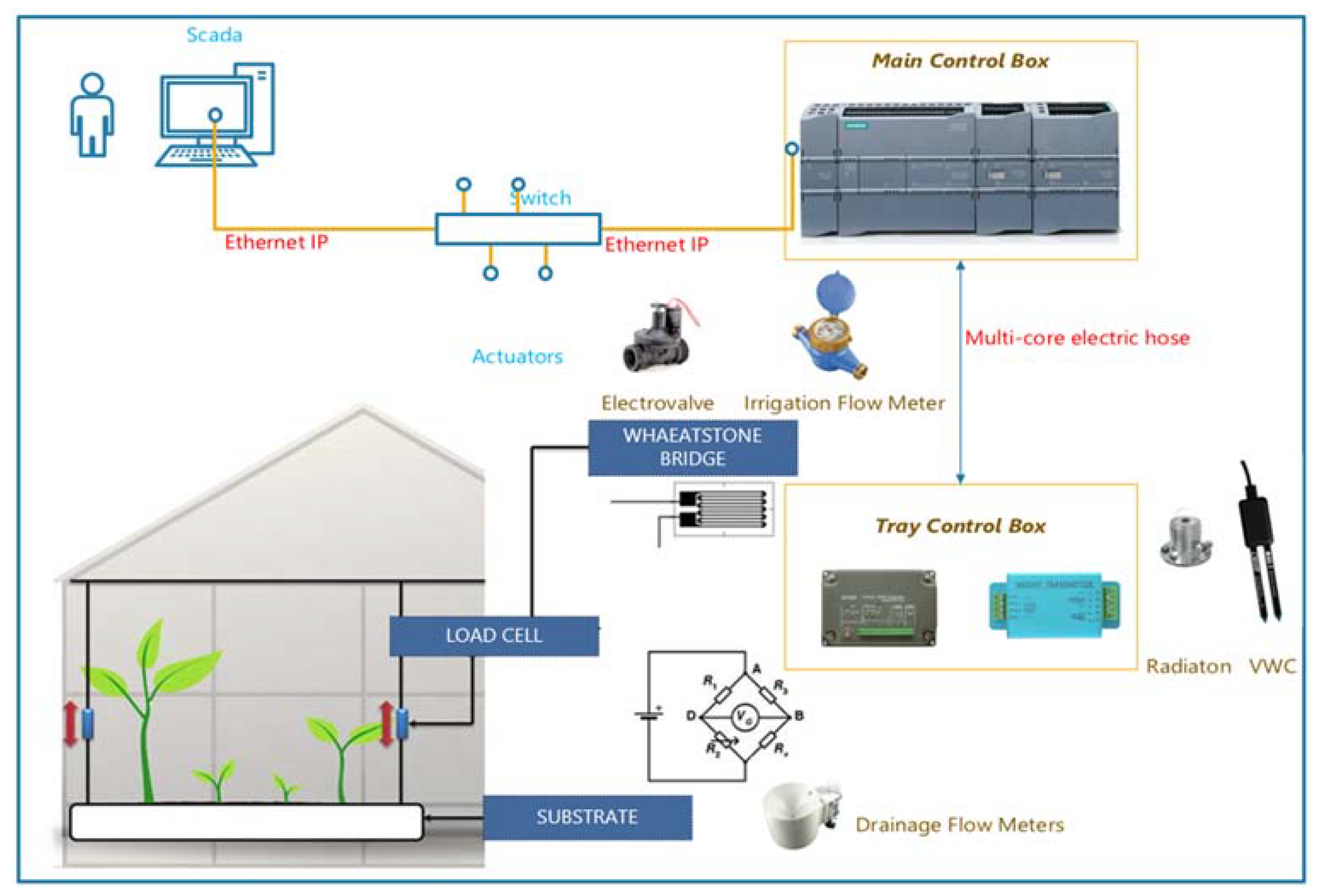

2.2. Irrigation Control Systems: General Architecture of the Test System

2.2.1. Volumetric Water Content (VWC) Control System

2.2.2. Radiation (AR) Control System

2.2.3. Gravimetric Control System

2.2.4. Control Software Development and SCADA

3. Results and Discussion

3.1. Comparative Agronomic Study of Irrigation Control

3.2. Final Development of a Commercial Prototype of Gravimetric Control System

3.2.1. General Architecture of the Gravimetric Control System

- -

- It provides remote access to the program and to data, graphs, and historical data and can download data, which requires a license at a very low cost.

- -

- It can even act as a gateway to access the PLC programming itself and even modify it if necessary.

3.2.2. Improvements in Electronic Instrumentation and Communication

- -

- Polarity reversal protection.

- -

- Linear voltage regulator.

- -

- Self-protected Mosfet output.

- -

- Transistors at the input and output for transient protection.

- Digital input of SDB1, equivalent to PLC’s NPN digital inputs.

- 24 Vdc relay without protective circuit against overvoltage.

- 24 Vdc relay with different RC’s protective circuits.

- 24 Vdc relay without 1N4007 freewheel diode.

- Voltage peaks of hundreds of volts at the 24 Vdc relay without a protective circuit.

- Peaks were reduced when RC protective circuits were used.

- Negligible overvoltage with the 24 Vdc + 1N4007.

- The SCE-CCHR1 with a 24 Vdc + 1N4007 relay load or digital input of the SDB1 gave signals with no overvoltage.

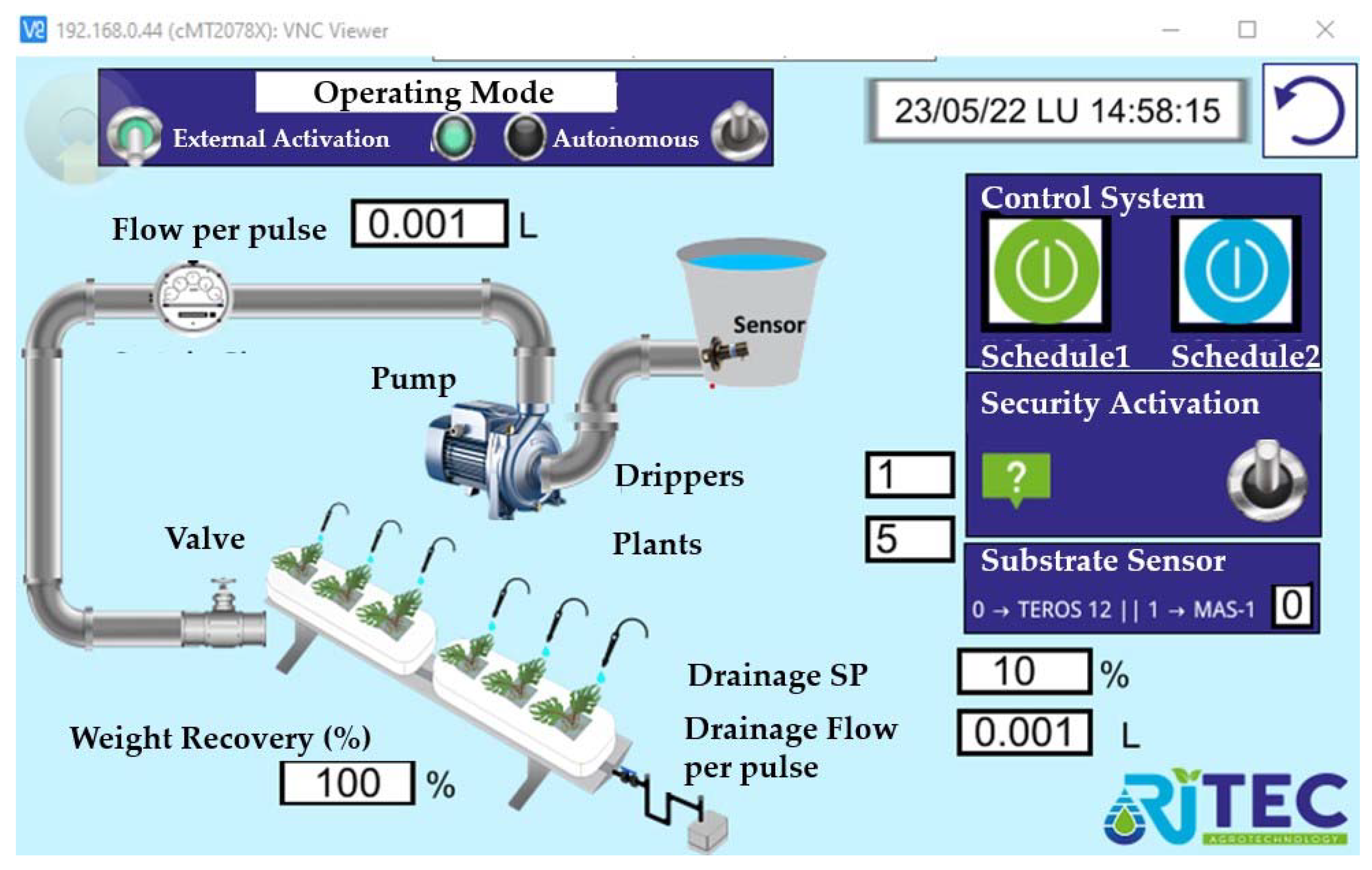

3.2.3. Control System

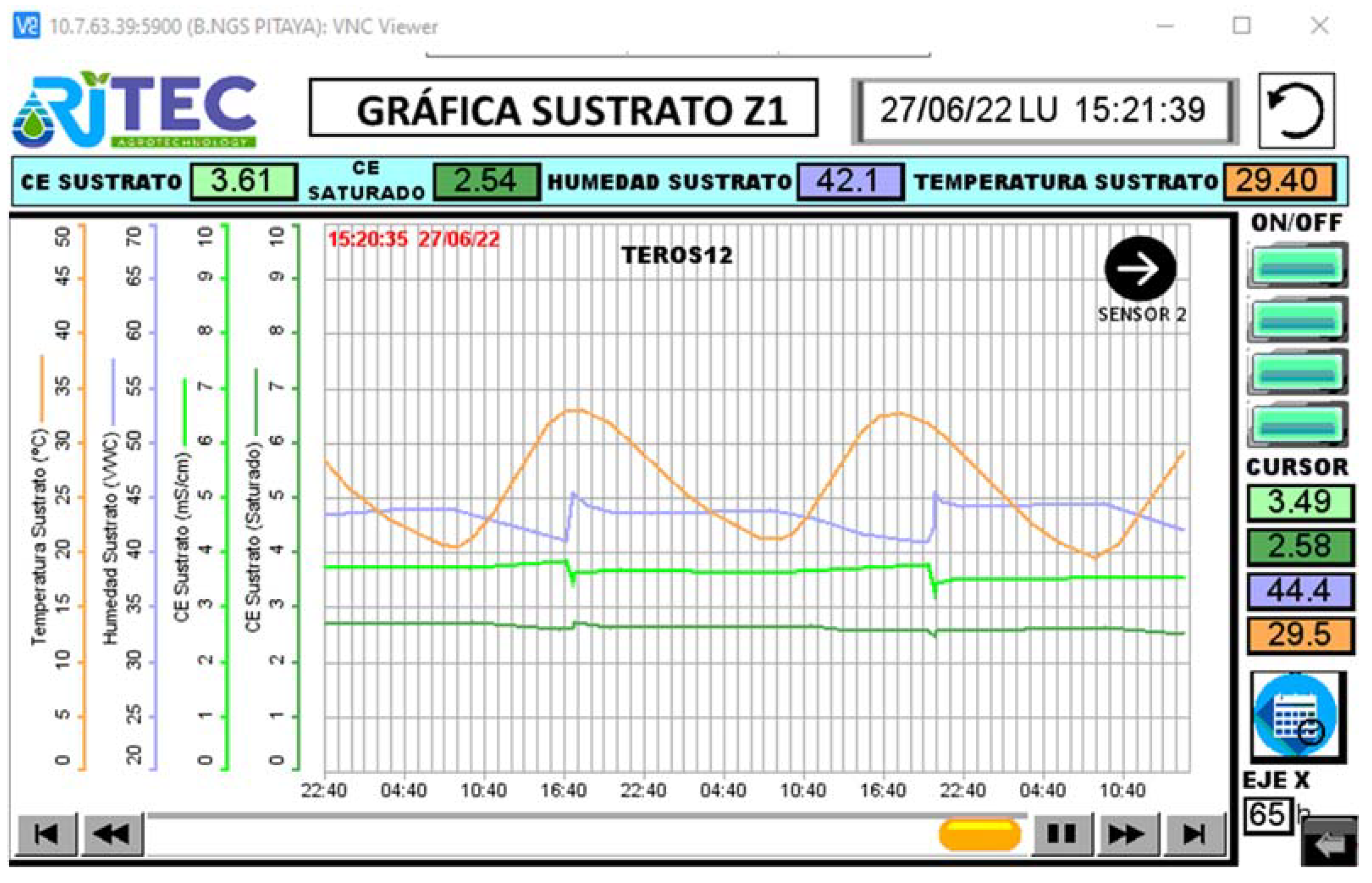

- Visualizing the information and monitoring the processes running in the machine in real-time. As shown in (Figure A4), it is possible to record the values of the irrigation and drainage volumes, the weight of the tray, and its drainage percentage, as well as the irrigation time and the values provided by each of the sensors.

- Entering the information needed to operate, select recipes, display indicators, etc.

- Display and control instruments and mechanisms. In this case, the number of plants and the number of drippers per plant, the drainage command, and the counter volumes per pulse must be entered (Figure 11). It is also necessary to define an active schedule as well as the volume consumed per plant.

- Alarms, permissions, irrigation graphs, and logs (Figure 12). Macros were created to obtain all the information regarding the measured weight magnitudes, EC, pH and drainage temperature, EC, VWC, and substrate temperature and the values of the irrigation and drainage volumes, and other indirectly calculated values such as drainage percentages or plant consumption.

3.3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SDB | Data Acquisition System developed to communicate the smart tray with the PLC |

| FAO | UN’s Food and Agriculture Organization |

| VWC | Volumetric Water Content |

| EC | Electrical Conductivity |

| G | Gravimetry |

| AR | Acumulated Solar Radiation |

| SCS | Soilles Culture System |

| GM | Growing media |

| Etc | Crop Evapotranspiration |

| WUE | Water Use Efficiency |

| CEBAS | Centro de Edafología y Biología Aplicada del Segura |

| PLC | Programmable Logic Controller |

| RTU | Remote Terminal Unit |

| SCADA | Supervisory Control and Data Acquisition |

| SDI-12 | Serial Data Interface at 1200 baud |

| CODESYS | Leading manufacturer-independent IEC 61131-3 automation software for engineering control systems. |

| HMI | Human-Machine Interface |

| DLI | Daily Light Integral |

Appendix A

References

- Zhang, Q. Precision Agriculture Technology for Crop Farming, 1st ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2015; ISBN 9781482251074. [Google Scholar]

- Daccache, A.; Ciurana, J.S.; Rodriguez Diaz, J.A.; Knox, J.W. Water and Energy Footprint of Irrigated Agriculture in the Mediterranean Region. Environ. Res. Lett. 2014, 9, 124014. [Google Scholar] [CrossRef]

- Nikolaou, G.; Neocleous, D.; Christou, A.; Kitta, E.; Katsoulas, N. Implementing sustainable irrigation in water-scarce regions under the impact of climate change. Agronomy 2020, 10, 1120. [Google Scholar] [CrossRef]

- Iglesias, A.; Garrote, L. Adaptation strategies for agricultural water management under climate change in Europe. Agric. Water Manag. 2015, 155, 113–124. [Google Scholar] [CrossRef]

- Frisvold, G.; Bai, T. Irrigation technology choice as adaptation to climate change in the Western United States. J. Contemp. Water Res. Educ. 2016, 158, 62–77. [Google Scholar] [CrossRef]

- Larson, N.; Sekhri, S.; Sidhu, R. Adoption of water-saving technology in agriculture: The case of laser levelers. Water Resour. Econ. 2015, 14, 44–64. [Google Scholar] [CrossRef]

- Bryan, E.; Deressa, T.T.; Gbetibouo, G.A.; Ringler, C. Adaptation to climate change in Ethiopia and South Africa: Options and constraints. Environ. Sci. Policy 2009, 12, 413–426. [Google Scholar] [CrossRef]

- Jiménez-Carvajal, C.; Ruiz-Peñalver, L.; Vera-Repullo, J.; Jiménez-Buendía, M.; Antolino-Merino, A.; Molina-Martínez, J. Weighing lysimetric system for the determination of the water balance during irrigation in potted plants. Agric. Water Manag. 2016, 183, 78–85. [Google Scholar] [CrossRef]

- Blanke, A.; Rozelle, S.; Lohmar, B.; Wang, J.; Huang, J. Water saving technology and saving water in China. Agric. Water Manag. 2007, 87, 139–150. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, J.; Li, Y. Do water saving technologies save water? empirical evidence from North China. J. Environ. Econ. Manag. 2017, 82, 1–16. [Google Scholar] [CrossRef]

- Zachariadis, T. Climate Change in Cyprus, Review of the Impacts and Outline of an Adaptation Strategy. In Springer Briefs in Environmental Science; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Eitzinger, J.; Alexandrou, V.; Utset, A.; Saylan, L.; Marta, A.D.; Nejedlik, R.; Altobelli, F. Factors determining crop water productivity in agricultural crop production-a Review. Ital. J. Agrometeorol. 2015, 3, 15–29. [Google Scholar]

- Tonhati, R.; Mello, S.C.; Momesso, P.; Pedroso, R.M. L-proline alleviates heat stress of tomato plants grown under protected environment. Sci. Hortic. 2020, 268, 109370. [Google Scholar] [CrossRef]

- Chavan, R.F.; Sakhal, B.K. Studies on the effect of exogenous application of salicylic acid on post-harvest quality and shelf life of tomato fruit Cv. Abhinav. Food Res. 2020, 4, 1444–1450. [Google Scholar] [CrossRef] [PubMed]

- FAO. Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#search/tomato%20production (accessed on 17 May 2022).

- López-Cruz, I.L.; Fitz-Rodríguez, E.; Salazar-Moreno, R.; Rojano-Aguilar, A.; Kacira, M. Development and analysis of dynamical mathematical models of greenhouse climate: A review. Eur. J. Hortic. Sci. 2018, 83, 269–279. [Google Scholar] [CrossRef]

- Savvas, D.; Gruda, N. Application of soilless culture technologies in the modern greenhouse industry: A review. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Khan, F.A. A review on hydroponic greenhouse cultivation for sustainable agriculture. Int. J. Agric. Environ. Food Sci. 2018, 2, 59–66. [Google Scholar] [CrossRef]

- Hamdy, A.; Ragab, R.; Scarascia-Mugnozza, E. Coping with water scarcity: Water saving and increasing water productivity. Irrig. Drain. J. Int. Comm. Irrig. Drain. 2003, 52, 3–20. [Google Scholar] [CrossRef]

- Qadir, M.; Oster, J.D. Crop and irrigation management strategies for saline-sodic soils and waters aimed at environmentally sustainable agriculture. Sci. Total Environ. 2004, 323, 1–19. [Google Scholar] [CrossRef]

- Ibrahim, A.; Elfaki, J. Impact of Irrigation with Saline Water on the Production of Tomato (Solanum lycopersicum) under Soilless and Traditional Techniques. Asian Soil Res. J. 2020, 2, 1–14. [Google Scholar] [CrossRef]

- De Pascale, S.; Incrocci, L.; Massa, D.; Rouphael, Y.; Pardossi, A. Advances in Irrigation Management in Greenhouse Cultivation. In Achieving Sustainable Greenhouse Cultivation; Marcelis, L.F.M., Heuvelink, E., Eds.; Burleigh Dodds Science Publishing Limited: Cambridge, UK, 2019; pp. 1–44. [Google Scholar]

- Lieth, J.H.; Oki, L.R. Irrigation in Soilles Production. In Soilless Culture: Theory and Practice Theory and Practice; Raviv, M., Lieth, J., Bar-Tal, A., Eds.; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780444636966. [Google Scholar]

- Anapalli, S.S.; Ahuja, L.R.; Gowda, P.H.; Ma, L.W.; Marek, G.; Evett, S.R.; Howell, T.A. Simulation of crop evapotranspiration and crop coefficients with data in weighing lysimeters. Agric. Water Manag. 2016, 177, 274–283. [Google Scholar] [CrossRef]

- Jiménez-Buendía, M.; Ruiz-Peñalver, L.; Vera-Repullo, J.A.; Intrigliolo-Molina, D.S.; Molina-Martínez, J.M. Development and assessment of a network of water meters and rain gauges for determining the water balance. New SCADA monitoring software. Agric. Water Manag. 2015, 151, 93–102. [Google Scholar] [CrossRef]

- Medrano, E.; Lorenzo, P.; Sánchez, M.C.; Montero, J.I. Evaluation and modelling of greenhouse cucumber-crop transpiration under high and low radiation conditions. Sci. Hortic. 2005, 105, 163–175. [Google Scholar] [CrossRef]

- Nemali, K.S.; Montesano, F.; Dove, S.K.; Van Iersel, M.W. Calibration and performance of moisture sensors in soilless substrates: ECH2O and Theta probes. Sci. Hortic. 2007, 112, 227–234. [Google Scholar] [CrossRef]

- Incrocci, L.; Marzialetti, P.; Incrocci, G.; Di Vita, A.; Balendonck, J.; Bibbiani, C.; Spagnol, S.; Pardossi, A. Sensor-based management of container nursery crops irrigated with fresh or saline water. Agric. Water Manage. 2019, 213, 49–61. [Google Scholar] [CrossRef]

- Gallardo, M.; Thompson, R.B.; Fernandez, M.D. Water Requirements and Irrigation Management in Mediterranean GREENHOUSES: The Case of the Southeast Coast of Spain. In Good Agricultural Practices for Greenhouse Vegetable Crops: Principle for Mediterranean Climate Areas; FAO: Rome, Italy, 2013; pp. 109–136. [Google Scholar]

- Massa, D.; Magan, J.J.; Montesano, F.; Tzortzakis, N. Minimizing water and nutrient losses from soilless cropping in southern Europe. Agric. Water Manag. 2020, 241, 106395. [Google Scholar] [CrossRef]

- Thompson, R.B.; Incrocci, L.; Van Ruijvend, J.; Massa, D. Reducing contamination of water bodies from European vegetable production systems. Agric. Water Manag. 2020, 240, 106258. [Google Scholar] [CrossRef]

- Ray, D.K.; Mueller, N.D.; West, P.C.; Foley, J.A. Yield Trends Are Insufficient to Double Global Crop Production by 2050. PLoS ONE 2013, 8, e66428. [Google Scholar] [CrossRef]

- Rodríguez, F.; Berenguel, M.; Guzmán, J.L.; Ramírez-Arias, A. Modeling and Control of Greenhouse Crop Growth; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 9783319111339. [Google Scholar]

- Ren, R.; Liu, T.; Ma, L.; Fan, B.; Du, Q.; Li, J. Irrigation based on daily weighted evapotranspiration affects yield and quality of oriental melon. Sci. Hortic. 2021, 275, 109714. [Google Scholar] [CrossRef]

- Ruiz-Peñalver, L.; Vera-Repullo, J.A.; Jiménez-Buendía, M.; Guzmán, I.; Molina-Martínez, J.M. Development of an innovative low cost weighing lysimeter for potted plants: Application in lysimetric stations. Agric. Water Manag. 2015, 151, 103–113. [Google Scholar] [CrossRef]

- Liu Id, J.; Hu, T.; Feng, P.; Wang, L.; Yang, S. Tomato yield and water use efficiency change with various soil moisture and potassium levels during different growth stages. PLoS ONE 2019, 14, e0213643. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, Z.J.; Andersen, M.N.; Hu, T.T. Tomato yield and water use efficiency—Coupling effects between growth stage specific soil water deficits. Acta Agric. Scand. Sect. B Soil Plant Sci. 2015, 65, 460–469. [Google Scholar] [CrossRef]

- Kuşçu, H.; Turhan, A.; Demir, A.O. The response of processing tomato to deficit irrigation at various phenological stages in a sub-humid environment. Agric. Water Manag. 2014, 133, 92–103. [Google Scholar] [CrossRef]

- Cantore, V.; Lechkar, O.; Karabulut, E.; Sellami, M.H.; Albrizio, R.; Boari, F.; Stellacci, A.M.; Todorovic, M. Combined effect of deficit irrigation and strobilur in application on yield, fruit quality, and water use efficiency of ‘Cherry’ tomato (Solanum lycopersicum L.). Agric. Water Manag. 2016, 167, 53–61. [Google Scholar] [CrossRef]

- Denaxa, N.; Nomikou, A.; Malamos, N.; Liveri, E.; Roussos, P.A.; Papasotiropoulos, V. Salinity Effect on Plant Growth Parameters and Fruit Bioactive Compounds of Two Strawberry Cultivars, Coupled with Environmental Conditions Monitoring. Agronomy 2022, 12, 2279. [Google Scholar] [CrossRef]

- Miceli, A.; Ikuyinminu, E.; Goñi, O.; O’connell, S. Enhancing Irrigation Salinity Stress Tolerance and Increasing Yield in Tomato Using a Precision Engineered Protein Hydrolysate and Ascophyllum nodosum-Derived Biostimulant. Agronomy 2022, 12, 809. [Google Scholar] [CrossRef]

- El-Mogy, M.M.; Garchery, C.; Stevens, R. Acta Agriculturae Scandinavica, Section B-Soil & Plant Science Irrigation with salt water affects growth, yield, fruit quality, storability and marker-gene expression in cherry tomato Irrigation with salt water affects growth, yield, fruit quality, storability and marker-gene expression in cherry tomato. Acta Agric. Scand. Sect. B Soil Plant Sci. 2018, 68, 727–737. [Google Scholar] [CrossRef]

- Mestre, T.C.; Garcia-Sanchez, F.; Rubio, F.; Martinez, V.; Rivero, R.M. Glutathione homeostasis as an important and novel factor controlling blossom-end rot development in calcium-deficient tomato fruits. J. Plant Physiol. 2012, 169, 1719–1727. [Google Scholar] [CrossRef]

- De Oliveira HF, E.; de Campos, H.M.; Mesquita, M.; Machado, R.L.; Vale, L.S.R.; Siqueira, A.P.S.; Ferrarezi, R.S. Horticultural performance of greenhouse cherry tomatoes irrigated automatically based on soil moisture sensor readings. Water 2021, 13, 2662. [Google Scholar] [CrossRef]

- Shin, J.H.; Son, J.E. Development of a real-time irrigation control system considering transpiration, substrate electrical conductivity, and drainage rate of nutrient solutions in soilless culture of paprika (Capsicum annuum L.). Eur. J. Hortic. Sci. 2015, 80, 271–279. [Google Scholar] [CrossRef]

- Sabeh, N.C. Evaluating and Minimizing Water Use by Greenhouse Evaporative Cooling Systems in a Semi-Arid Climate. Ph.D. Thesis, University of Arizona, Tucson, AZ, USA, 2007. [Google Scholar]

- Nikolaou, G.; Neocleous, D.; Katsoulas, N.; Kittas, C. Irrigation of greenhouse crops. Horticulturae 2019, 5, 7. [Google Scholar] [CrossRef]

| Error | Ascending Measures | Descending Measures |

|---|---|---|

| Ɛ%FS average | 0.231 | 0.318 |

| Near to Zero | Near to Full Scale | |

| Min. detect. weight (gr) | 5 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez Millán, F.; Ortiz, F.J.; Mestre Ortuño, T.C.; Frutos, A.; Martínez, V. Development of Smart Irrigation Equipment for Soilless Crops Based on the Current Most Representative Water-Demand Sensors. Sensors 2023, 23, 3177. https://doi.org/10.3390/s23063177

Sánchez Millán F, Ortiz FJ, Mestre Ortuño TC, Frutos A, Martínez V. Development of Smart Irrigation Equipment for Soilless Crops Based on the Current Most Representative Water-Demand Sensors. Sensors. 2023; 23(6):3177. https://doi.org/10.3390/s23063177

Chicago/Turabian StyleSánchez Millán, Francisco, Francisco J. Ortiz, Teresa C. Mestre Ortuño, Antonio Frutos, and Vicente Martínez. 2023. "Development of Smart Irrigation Equipment for Soilless Crops Based on the Current Most Representative Water-Demand Sensors" Sensors 23, no. 6: 3177. https://doi.org/10.3390/s23063177

APA StyleSánchez Millán, F., Ortiz, F. J., Mestre Ortuño, T. C., Frutos, A., & Martínez, V. (2023). Development of Smart Irrigation Equipment for Soilless Crops Based on the Current Most Representative Water-Demand Sensors. Sensors, 23(6), 3177. https://doi.org/10.3390/s23063177