Design and Experiment of Online Detection System for Water Content of Fresh Tea Leaves after Harvesting Based on Near Infra-Red Spectroscopy

Abstract

1. Introduction

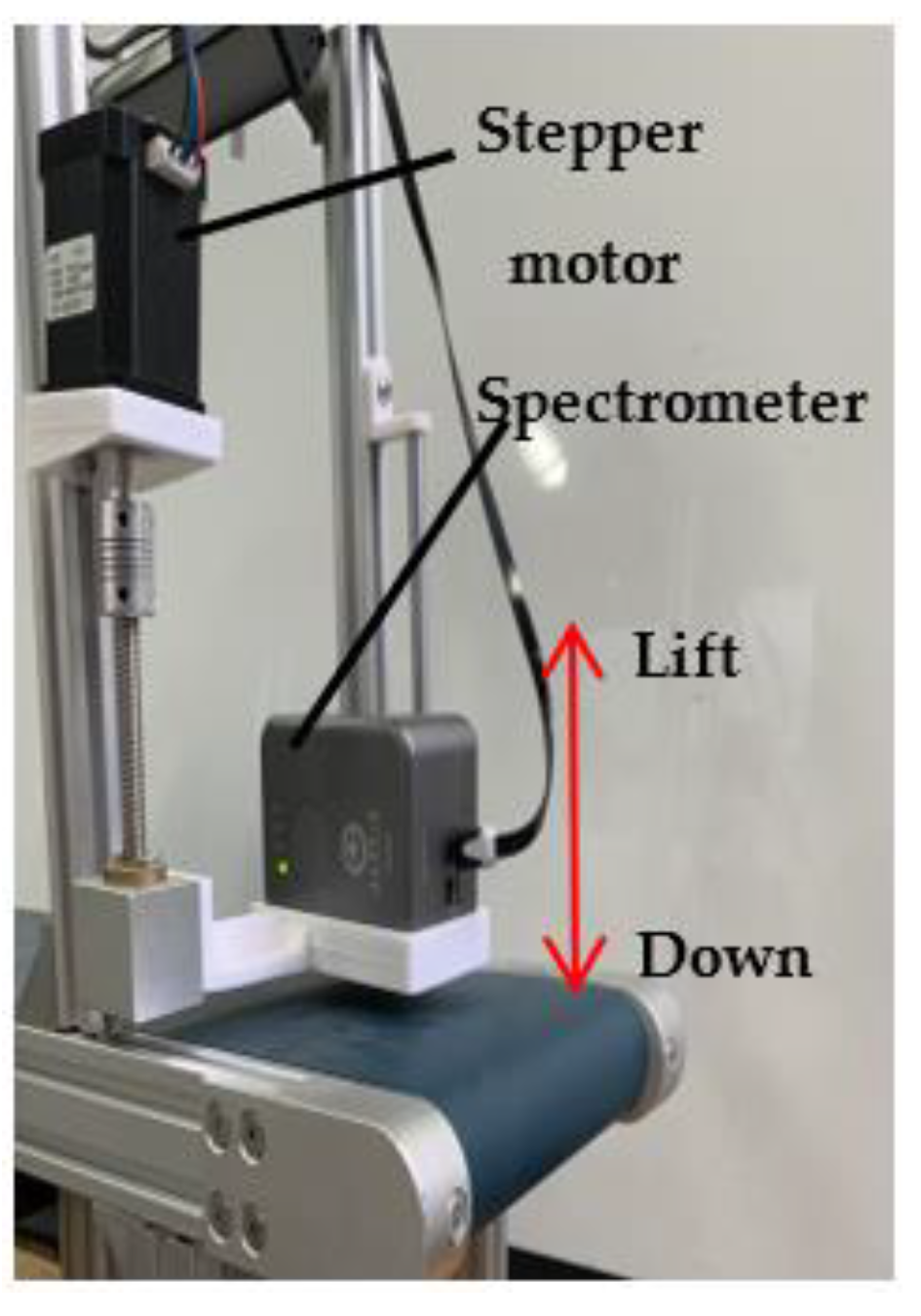

2. Overall Design of Online Detection System

3. Design of Real-Time Detection of Water Content of Tea Fresh Leaves after Harvesting

3.1. Principle of Real-Time Detection of Water Content of Tea Fresh Leaves

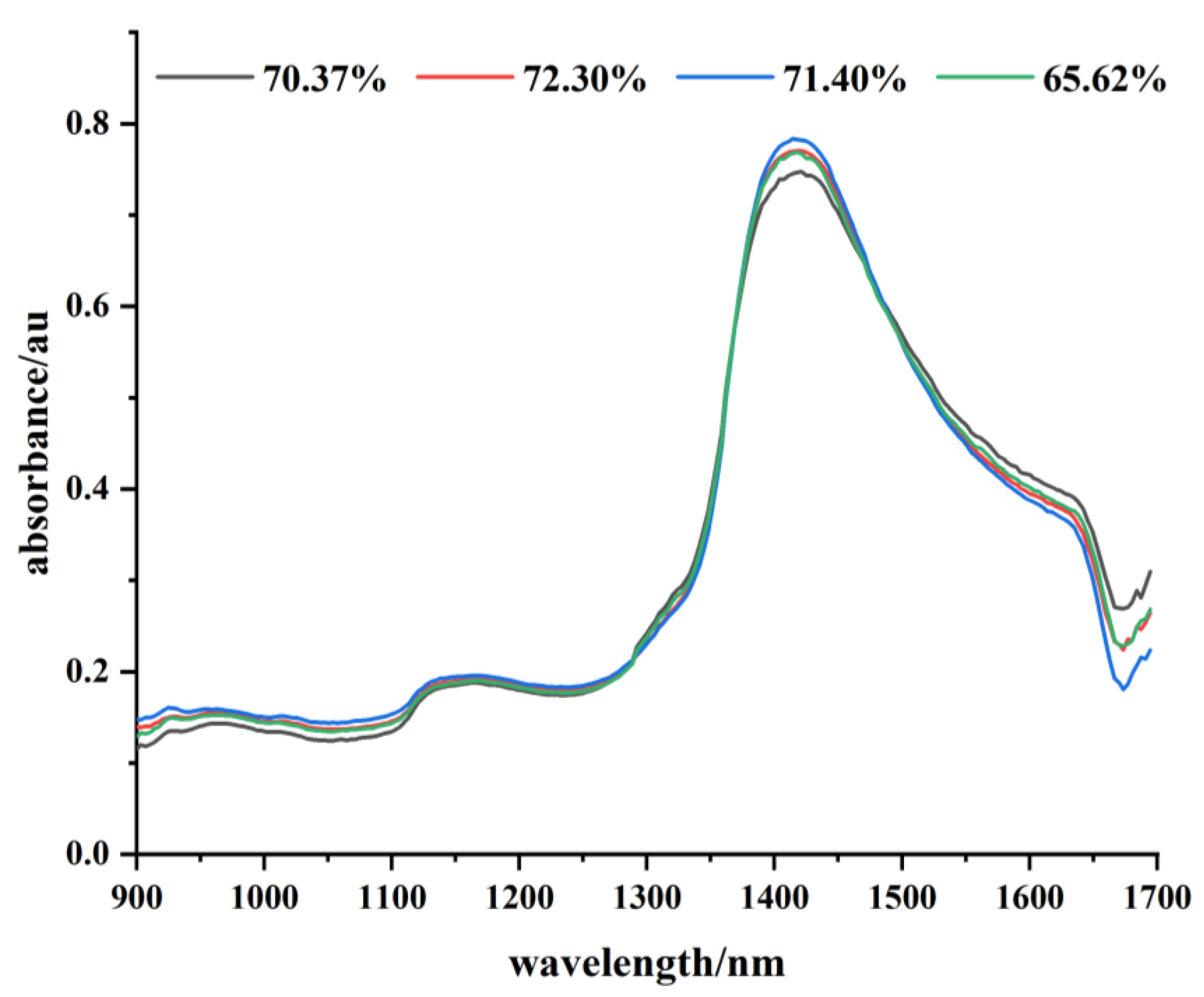

3.2. Spectral Data Acquisition

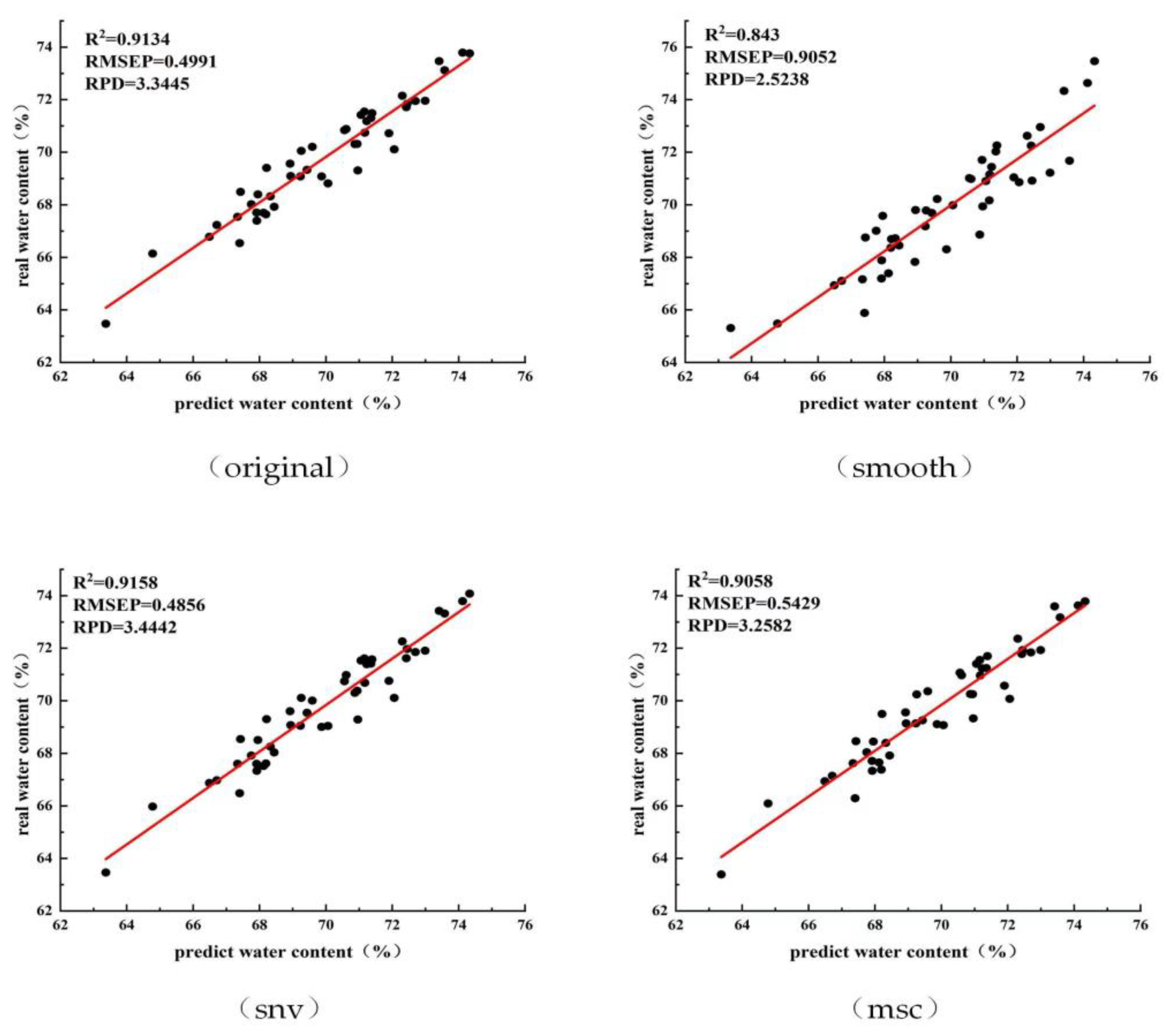

3.3. Establishment of Water Content Prediction Model

3.4. Tea Fresh Leaf Water Content Real-Time Detection Process

3.5. Water Content Testing Platform Temperature and Humidity Parameters Monitoring

4. Online Control of Process Parameters

4.1. Control Method and Hardware Implementation

4.2. Control Method and Software Implementation

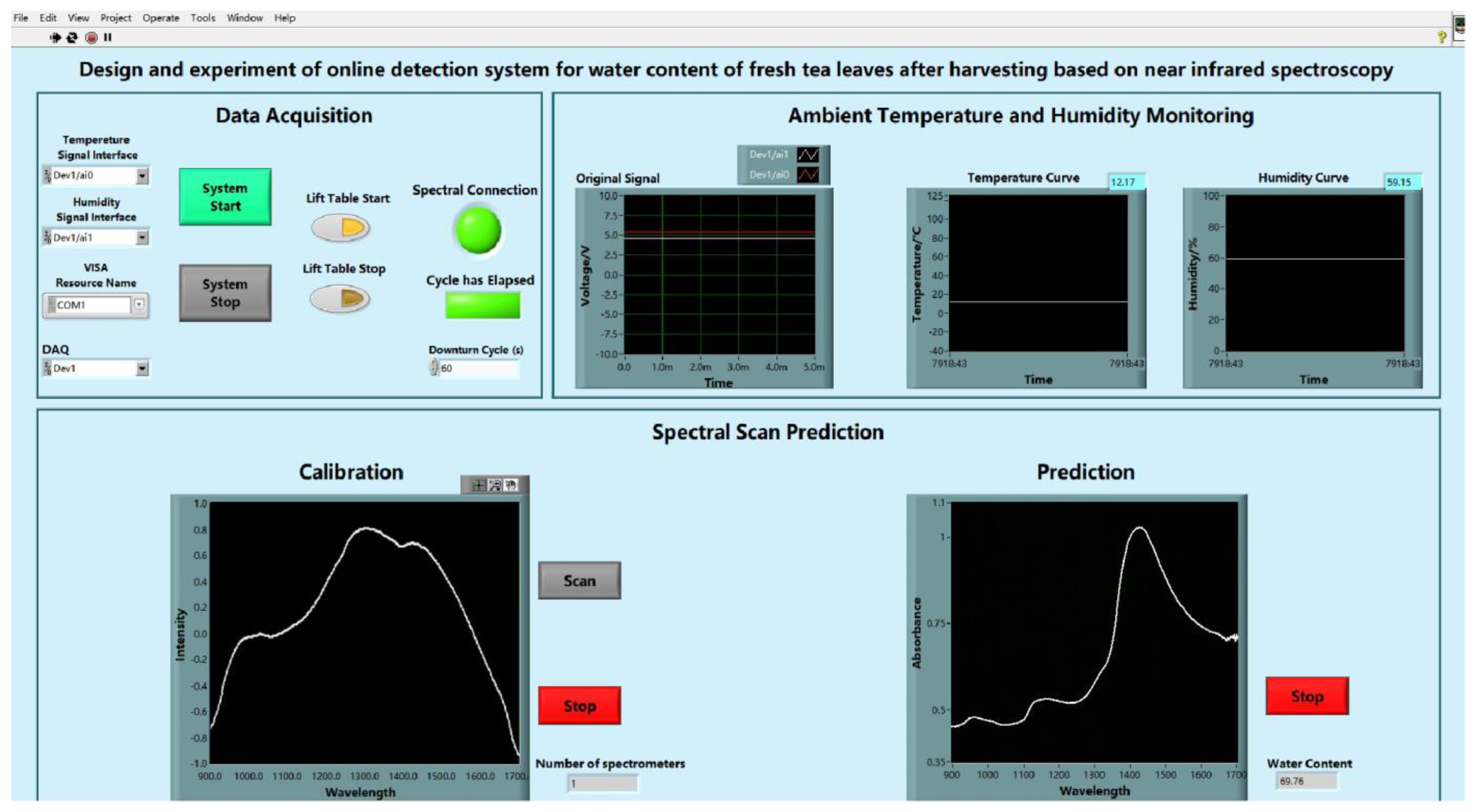

4.2.1. Design and Implementation of the Upper Computer Control Program

4.2.2. Establishment of Communication between the Host Computer and Master Station

5. System Testing

5.1. Control Method and Software Implementation

5.2. Control Method and Software Implementation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xia, T. Manufacture of Tea; China Agriculture Press: Beijing, China, 2016. [Google Scholar]

- Wang, Q.; Deng, X.; Ren, Y.; Ding, Y.; Xiong, L.; Wen, Y.; Wang, S. Egg freshness detection based on digital image technology. Sci. Res. Essays 2009, 4, 1073–1079. [Google Scholar]

- Duan, Y.; Wang, Q.; Li, X.; Tang, Y. Online visual high-throughput detection method for egg size and shape based on convex packet algorithm. J. Agric. Eng. 2016, 32, 282–288. [Google Scholar]

- Wang, Q.; Li, X.; Duan, Y. Online inspection and grading of egg freshness based on CUVE-PLS-DA. Food Sci. 2016, 37, 187–191. [Google Scholar]

- Kemps, B.J.; Bamelis, F.R.; De Ketelaere, B.; Mertens, K.; Tona, K.; Decuypere, E.M.; De Baerdemaeker, J.G. Visible transmission spectroscopy for the the assessment of egg freshness. J. Sci. Food Agric. 2006, 86, 1399–1406. [Google Scholar] [CrossRef]

- Xiang, X.L.; Wang, Y.L.; Yu, Z.H.; Ma, M.H.; Zhu, Z.H.; Jin, Y.G. Non-destructive characterization of egg odor and fertilization status by SPME/GC-MS coupled with electronic nose. J. Sci. Food Agric. 2019, 99, 3264–3275. [Google Scholar] [CrossRef]

- Ji, X.; Zheng, J.; Yang, L.; Zheng, L. Discriminating egg storage time based on electronic nose and random subspace integrated learning method. China Poult. 2018, 40, 39–42. [Google Scholar]

- Soltani, M.; Omid, M.; Alimardani, R. Egg quality prediction using dielectric and visual properties based on artificial neural network. Food Anal. Methods 2015, 8, 710–717. [Google Scholar] [CrossRef]

- Lau, S.K.; Subbiah, J. An automatic system for measuring dielectric properties of foods: Albumen, yolk, and shell of fresh eggs. J. Food Eng. 2018, 223, 79–90. [Google Scholar] [CrossRef]

- Akbarzadeh, N.; Mireei, S.A.; Askari, G.; Mahdavi, A.H. Microwave spectroscopy based on the waveguide technique for the nondestructive freshness evaluation of egg. Food Chem. 2019, 277, 558–565. [Google Scholar] [CrossRef]

- Laghi, L.; Cremonini, M.A.; Placucci, G.; Sykora, S.; Wright, K.; Hills, B. A proton NMR relaxation study of hen egg quality. Magn. Reson. Imaging 2005, 23, 501–510. [Google Scholar] [CrossRef]

- Xu, L.; Jia, F.; Luo, C.; Zhao, F.; Gao, F.; Liu, Y.; Dai, R.; Li, X. Study of moisture changes in egg whites under carbon dioxide gas storage using low-field NMR. Food Ind. Sci. Technol. 2017, 38, 313–318. [Google Scholar]

- Duan, Y.; Zhao, Y.; Chi, Y. Analysis of moisture distribution and quality changes of white hard-boiled eggs under different storage conditions based on low-field nuclear magnetic resonance technique. Food Sci. 2018, 39, 26–32. [Google Scholar]

- Wang, H.; Mao, J.; Zhang, J.; Jiang, H.; Wang, J. Acoustic feature extraction and optimization of crack detection for eggshell. J. Food Eng. 2016, 171, 240–247. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, S.; Li, S. Egg crack detection based on acoustic signal recurrence map. J. Huazhong Agric. Univ. 2019, 38, 102–108. [Google Scholar]

- Yu, H.; Pan, X.; Zhu, X.; Ye, Z.; Zhu, Z.; Liu, J. Detection of water content of Wenzhou mandarin based on transmission spectroscopy. J. Huazhong Agric. Univ. 2021, 40, 86–92. [Google Scholar]

- Zhou, J.; Wu, X.; Chen, Z.; Xiong, S. Rapid prediction of freshness of doughnuthead bream by near-infrared spectroscopy. J. Huazhong Agric. Univ. 2019, 38, 120–126. [Google Scholar]

- Wang, S.; Gao, S.; Teng, J.; Ye, T.; Gui, A.; Zheng, P.; Yang, Q.; Han, H. Research progress of near-infrared spectroscopy in tea. J. Huazhong Agric. Univ. 2021, 40, 226–232. [Google Scholar]

- Ren, D.; Qu, F.; Lu, A.; Wang, J.; Ren, S.; Li, W.; Zhang, C.; Zhang, Z.; Zhang, Y.; Jia, W.; et al. Near-Infrared Spectroscopy Techniques and Applications; Science Press: Beijing, China, 2018. [Google Scholar]

- Wang, Y.; Li, L.; Liu, Y. Enhanced quality monitoring during black tea processing by the fusion of NIRS and computer vision. Food Eng. 2021, 304, 110599. [Google Scholar] [CrossRef]

- Huang, L.; Meng, L.; Zhu, N. A primary study on forecasting the days before decay of peach fruit using near-infrared spectroscopy and electronic nose techniques. Postharvest Biol. Technol. 2017, 133, 104–112. [Google Scholar] [CrossRef]

- Zhang, K.; Xu, Y.; Johnson, L. Development of near-infrared spectroscopy models for quantitative determination of cellulose and hemicellulose contents of big bluestem. Renew. Energy 2017, 109, 101–109. [Google Scholar] [CrossRef]

- Wang, S.; Wan, X.; Lin, M.; Zhang, Z. A near-infrared method for evaluating the quality of fresh tea leaves based on moisture, total nitrogen and crude fiber content. Tea Sci. 2011, 31, 922. [Google Scholar]

- Dong, C.; Liang, G.; An, T.; Wang, J.; Zhu, H. Establishment of a rapid detection model for sensory quality and composition of black tea by near-infrared spectroscopy. J. Agric. Eng. 2018, 34, 306–313. [Google Scholar]

- Chen, Q.; Zhao, J.; Fang, C.H.; Wang, D. Feasibility study on identification of green, black and Oolong teas using near-infrared reflectance spectroscopy based on support vector machine(SVM). Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2007, 66, 568–574. [Google Scholar] [CrossRef]

- Wei, L. Research on the Method of Judging the Quality and Grade of Black Tea Based on Near-Infrared Spectroscopy; Anhui Agricultural University: Hefei, China, 2015; O657. 33; TS272. 52. [Google Scholar]

- Firmani, P.; De Luca, S.; Bucci, R.; Marini, F.; Biancolillo, A. Near Infrared(NIR) spectroscopy-based classification for the authentication of darjeeling black tea. Food Control 2019, 100, 292–299. [Google Scholar] [CrossRef]

- Hall, M.N.; Robertson, A.; Scotter, C.N. Near-infrared reflectance prediction of quality, theaflavin content and moisture content of black tea. Food Chem. 1988, 27, 61–75. [Google Scholar] [CrossRef]

- An, M.; Cao, C.; Wu, Z.; Luo, K. Detection Method for Walnut Shell-Kernel Separation Accuracy Based on Near-Infrared Spectroscopy. Sensors 2022, 22, 8301. [Google Scholar] [CrossRef] [PubMed]

- Lu, W. Modern Near Infrared Spectroscopy Techniques; China Petrochemical Press: Beijing, China, 2010. [Google Scholar]

- Gao, H.; Jin, P.; Zhou, Y.; Shi, Y. Introduction to the principle, detection and calibration techniques of near-infrared spectroscopy. China Sci. Technol. Inf. 2014, Z1, 59–61. [Google Scholar]

- Zhang, X.; He, Y. Rapid estimation of seed yield using hyperspectral images of oilseed rape leaves. Ind. Crops Prod. 2013, 42, 416–420. [Google Scholar] [CrossRef]

- Xie, C.; Li, X.; Nie, P.; He, Y. Application of time series hyperspectral imaging(TS-HSI) for determing water content within tea leaves during drying. Trans. ASABE 2013, 56, 1431–1440. [Google Scholar]

- Matko, V.; Milanovic, M. Temperature-compensated capacitance-frequency converter with high resolution. Sens. Actuators A Phys. 2014, 220, 262–269. [Google Scholar] [CrossRef]

| Testing Times | Average Predicted Value | Average Overall Value | Error Absolute Value |

|---|---|---|---|

| 5 | 69.89% | 71.64% | 1.75% |

| 10 | 69.58% | 70.27% | 0.69% |

| 15 | 70.64% | 70.16% | 0.48% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wu, Z.; Cao, C.; An, M.; Luo, K.; Sun, L.; Wang, X. Design and Experiment of Online Detection System for Water Content of Fresh Tea Leaves after Harvesting Based on Near Infra-Red Spectroscopy. Sensors 2023, 23, 666. https://doi.org/10.3390/s23020666

Wang S, Wu Z, Cao C, An M, Luo K, Sun L, Wang X. Design and Experiment of Online Detection System for Water Content of Fresh Tea Leaves after Harvesting Based on Near Infra-Red Spectroscopy. Sensors. 2023; 23(2):666. https://doi.org/10.3390/s23020666

Chicago/Turabian StyleWang, Shishun, Zhengmin Wu, Chengmao Cao, Minhui An, Kun Luo, Liang Sun, and Xiaoran Wang. 2023. "Design and Experiment of Online Detection System for Water Content of Fresh Tea Leaves after Harvesting Based on Near Infra-Red Spectroscopy" Sensors 23, no. 2: 666. https://doi.org/10.3390/s23020666

APA StyleWang, S., Wu, Z., Cao, C., An, M., Luo, K., Sun, L., & Wang, X. (2023). Design and Experiment of Online Detection System for Water Content of Fresh Tea Leaves after Harvesting Based on Near Infra-Red Spectroscopy. Sensors, 23(2), 666. https://doi.org/10.3390/s23020666