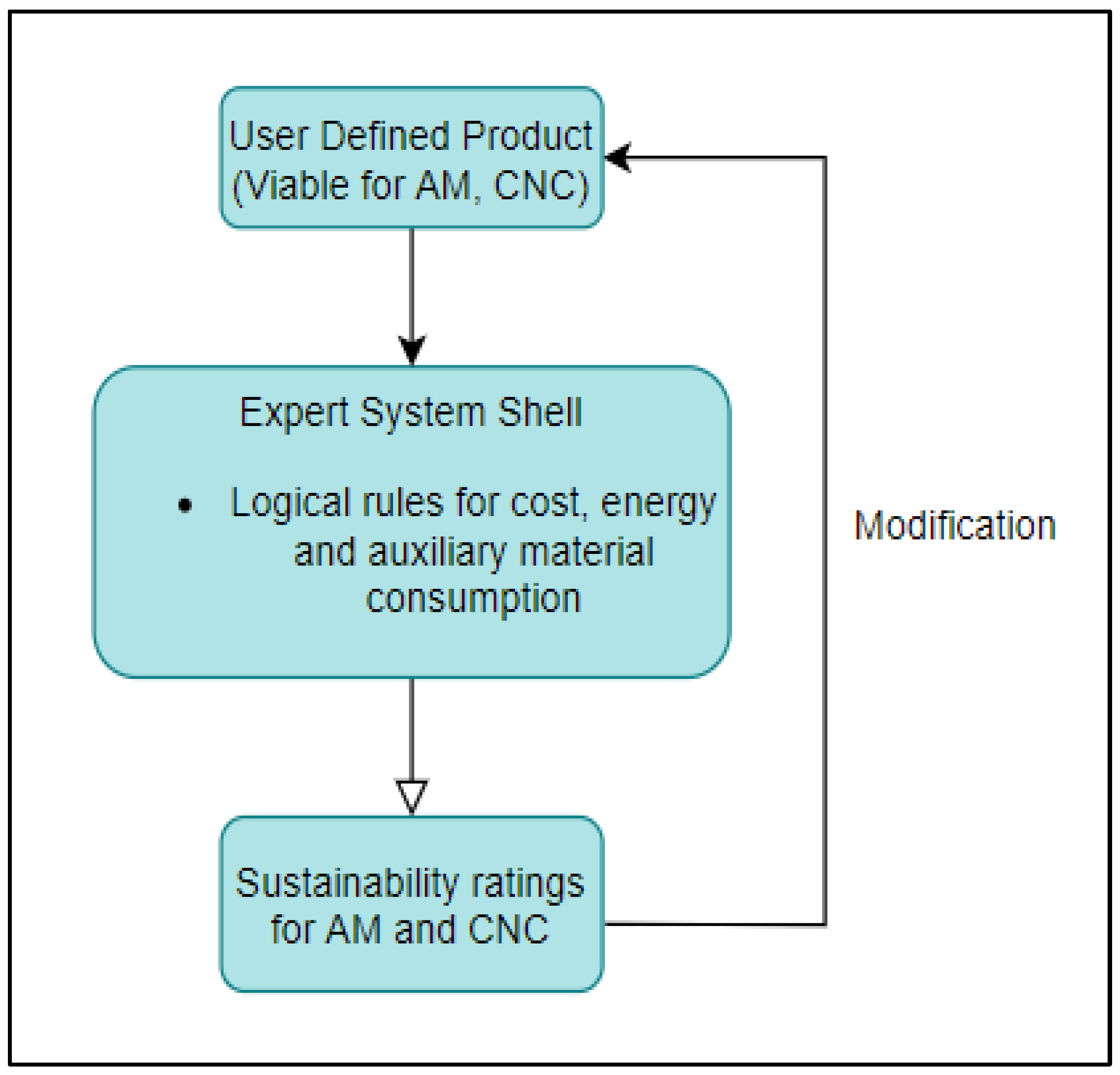

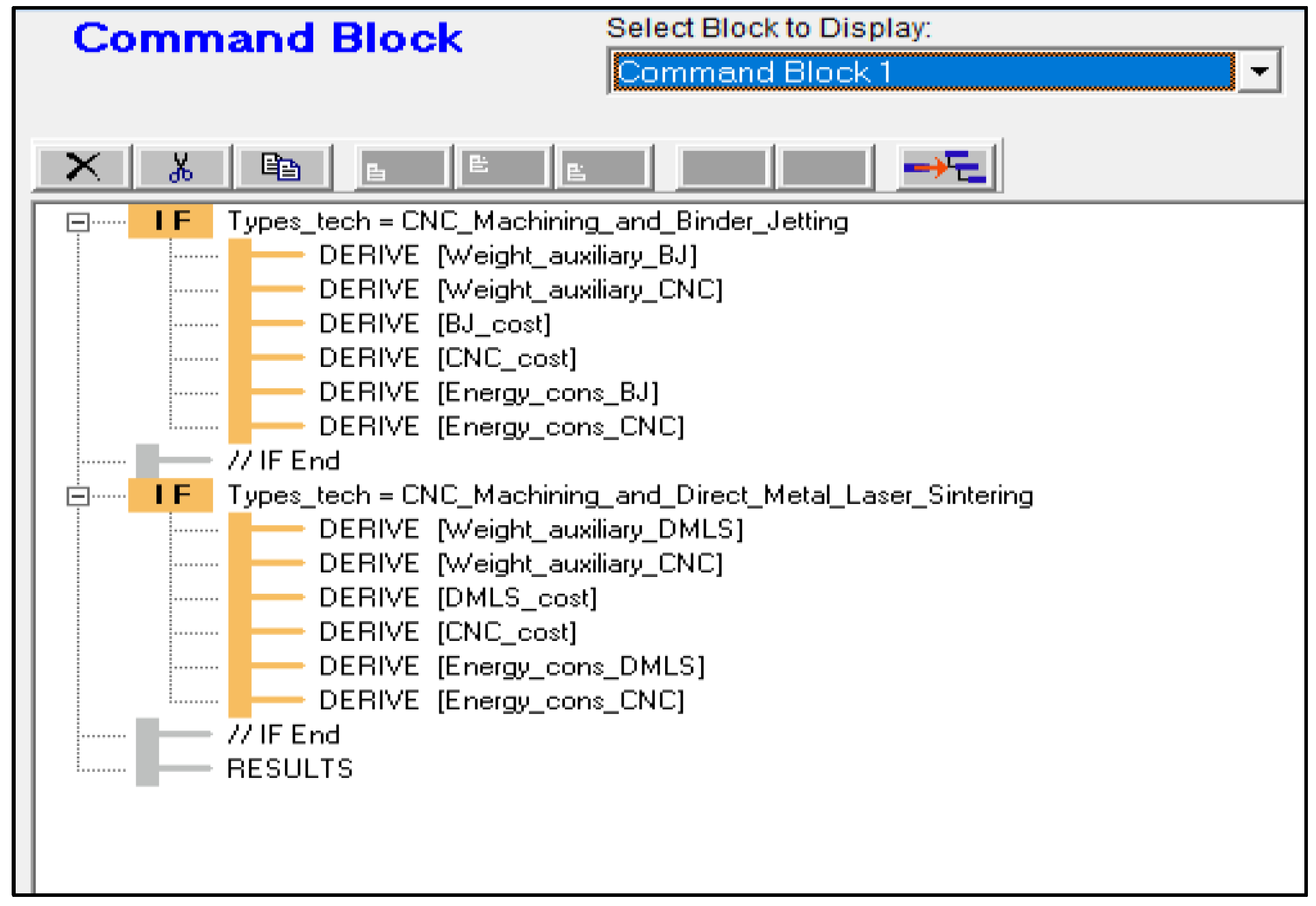

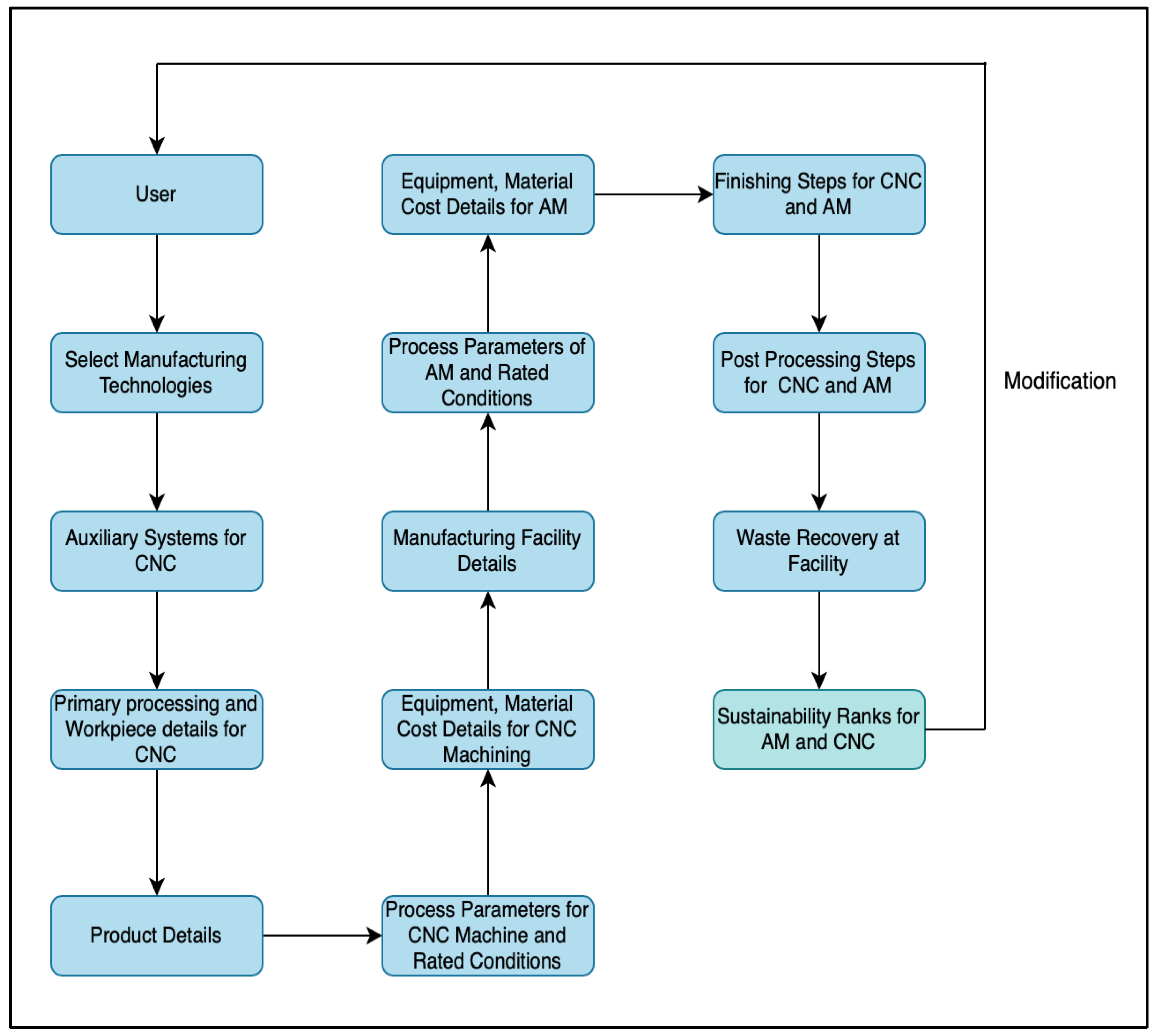

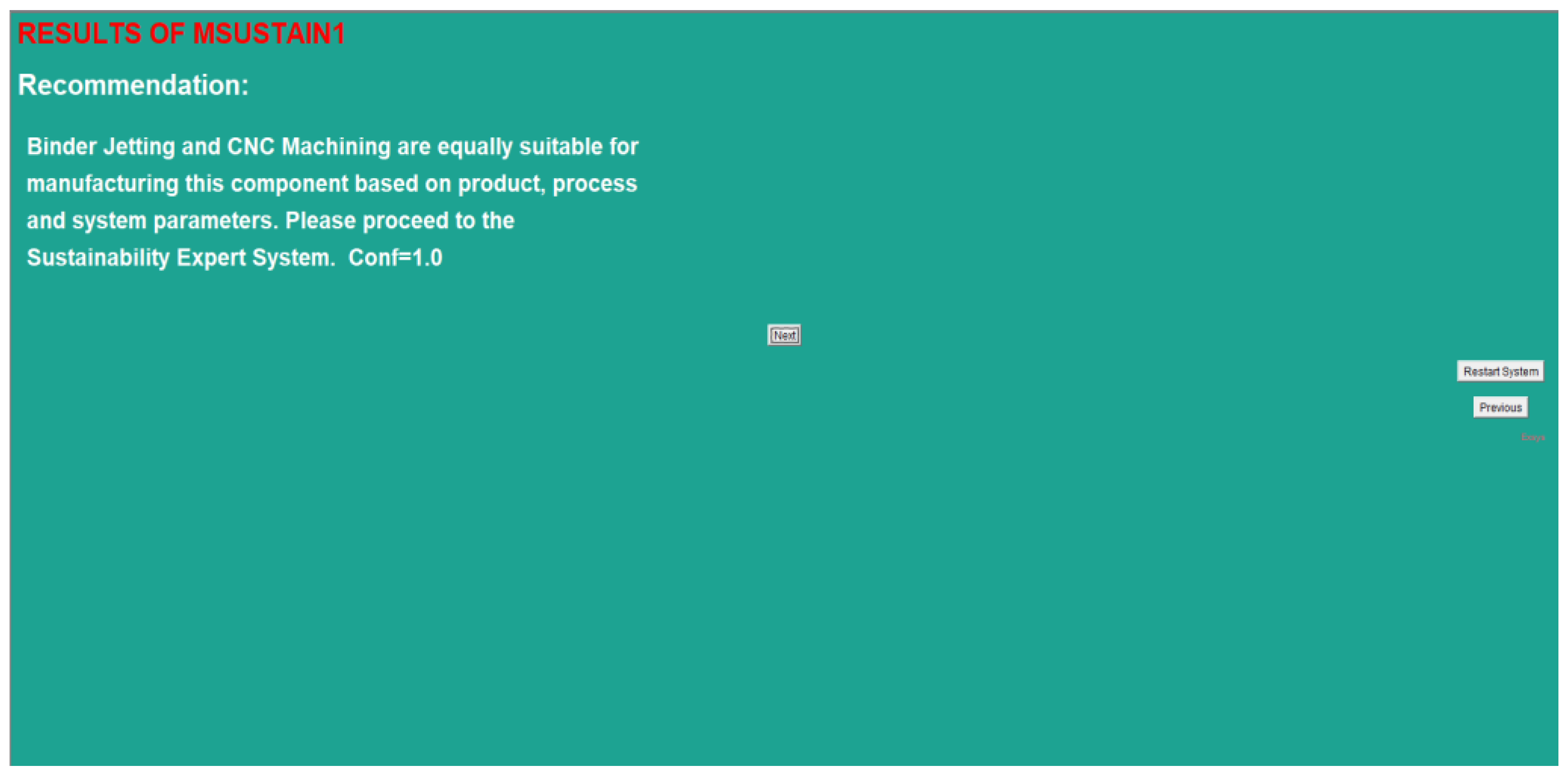

As per the requirements of this research study, the knowledge base was generated by obtaining qualitative/quantitative data through literature reviews and expert opinions. The developed database consists of knowledge related to the feasibility regions of product/process/system parameters, energy consumption during manufacturing and material processing, costs resulting from fabrication, and the impact of auxiliary material consumption on the sustainability of metal 3D printing and CNC machining.

4.1.1. Viable Product, Process, and System Parameters

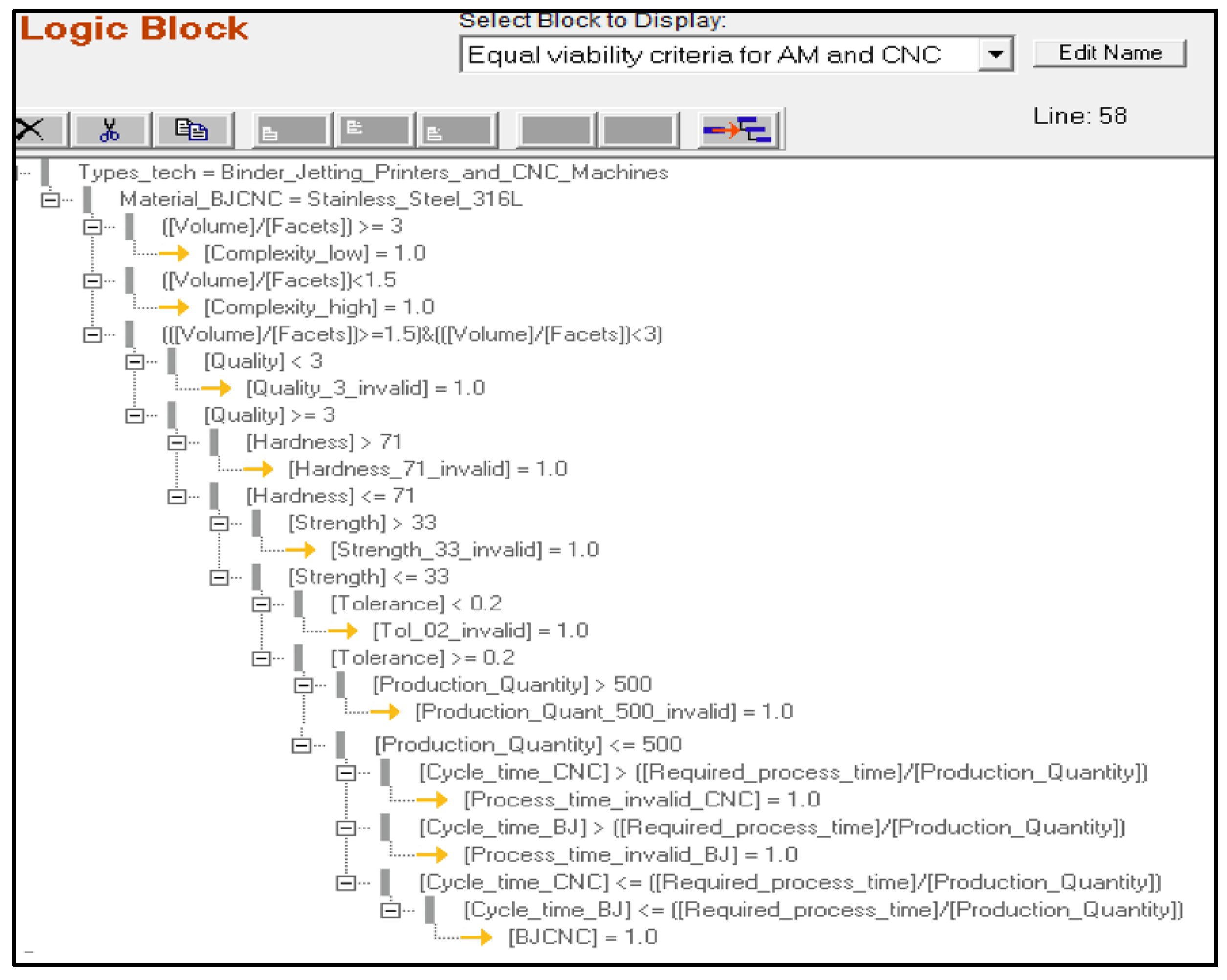

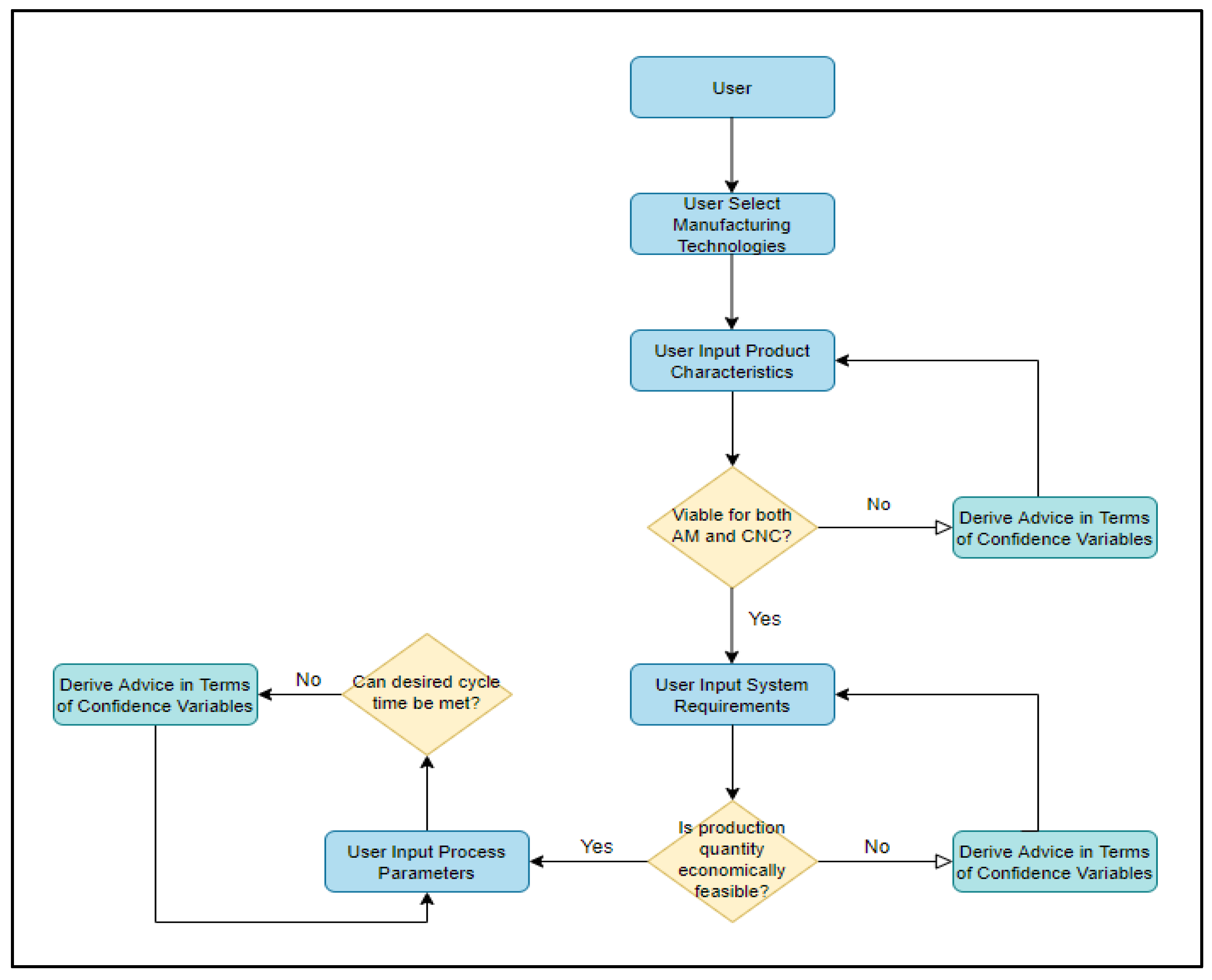

It was considered essential to identify the product parameters (material, geometric complexity, surface quality, hardness, strength, and dimensional accuracy) and system parameters (production quantity considering overall unit cost and cycle time based on process parameters) equally viable for each considered technology. Through extensive literature reviews, it was found that the material types valid for the comparison of these technologies are variants of stainless steel (in the form of solid metal powder and billets).

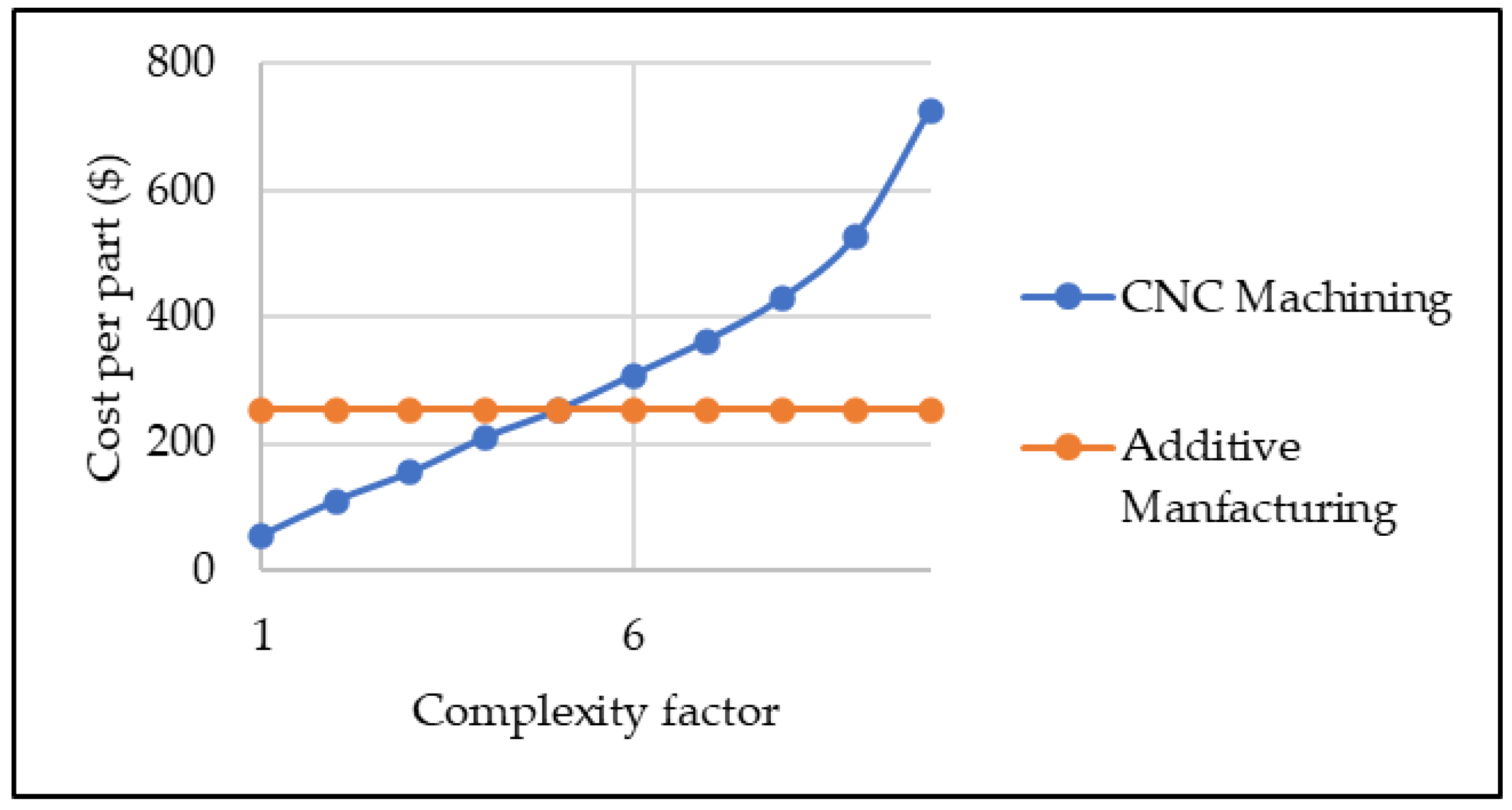

Since geometric complexity has a negligible impact on the resources required for additive manufacturing, the complexity factor is only applicable to products manufactured using CNC machining. As described by Valentan [

11], higher volume-to-facet ratios depict lower geometric complexity, whereas lower ratios illustrate higher complexity. Based on the research of Wedlund et al. [

12] and the analysis of the breakeven point in terms of geometric complexity, the volume-to-facet ratios and the corresponding complexity factors for CNC machining were modified as represented in

Table 1, for the purposes of this research study. The assignment of complexity factors to the volume–facet ratio was based on the estimation of machine time difference due to each complexity level.

It is important to understand that the exact geometric complexity of products viable for both CNC machining and additive manufacturing is challenging to ascertain. However, by using subjective knowledge arising from existing research such as the studies of Varotsis [

13,

14] and the research study of Wedlund et al. [

12], the equally viable geometric complexity factor (considering the overall cost per unit) was approximated to attain the value of 5, as shown in

Figure 3.

The feasible material types were selected based on existing machine capabilities and specifications for BJP, DMLS, and CNC machining. With most stainless steel materials, CNC machining is capable of fabricating components with higher performance (in terms of quality and mechanical properties).

In production setups where either BJP has to be compared to CNC machining or DMLS to CNC machining, the customer expectations of component quality and mechanical properties are important considerations in selecting the most optimal technology. Therefore, the ranges for surface quality, hardness, strength, and tolerance describe the maximum possible component performance levels, which allow for the impartial comparison of BJP, DMLS, and CNC machining. If the required mechanical properties and quality of a component exceed the competency of current additive manufacturing technology, the manufacturing facility should opt for CNC machining.

According to the information provided by Varotsis [

15], CNC machining and BJP are comparable when production quantities of less than 500 parts (of medium complexity) are required, and CNC machining and DMLS are comparable when the customer requirement is for less than 100 parts (of medium complexity.) In scenarios where the production quantity demanded by the customer exceeds the above-mentioned limits, manufacturing technologies such as injection molding should be considered.

In addition to considering production quantities justified by unit cost, it is crucial to verify if the selected process parameters of each technology can achieve the required cycle time. For CNC machining, BJP, and DMLS to be equally viable on a system level, the cycle times of the processes need to be equal to or less than the required cycle time as per the customer demands. The required cycle time (

Tc(required)) is calculated as follows:

where

The processing time calculations for each manufacturing method were adopted from the work of Wedlund et al. [

12] and Meteyer et al. [

16]. However, the CNC machining time calculation was modified in order to account for the impact of the cutting speed, feed rate, and depth of the cut required for each operation (milling, drilling, and turning) on cycle time. For the purposes of this research, machining time was considered a suitable indicator of CNC toolpath for parts with varying geometric features. As an example, the time taken for milling can be calculated as follows:

where

tCNC(milling) = the time taken for the milling operation (h);

Vmilling = the volume removed through the milling process (mm3);

Qmilling = the material removal rate of the milling process (mm3/min);

α = the geometric complexity.

As CNC milling time exponentially increases with complex geometric features, the previously mentioned complexity factor was incorporated into the machining time calculations for milling processes. Furthermore, the cutting speed, feed rate, and depth of the cut were integrated into the material removal rate associated with each operation.

Similarly, the processing time required for BJP and DMLS is calculated as follows:

where

tBJP = the time taken for the binder jetting process (h);

tcuring = the curing time (h);

tsintering = the sintering time (h);

hcomponent = the height of the component as per the build orientation (mm);

hlayer = the height of the print layer (mm);

tlayer = the time taken to print one layer (s);

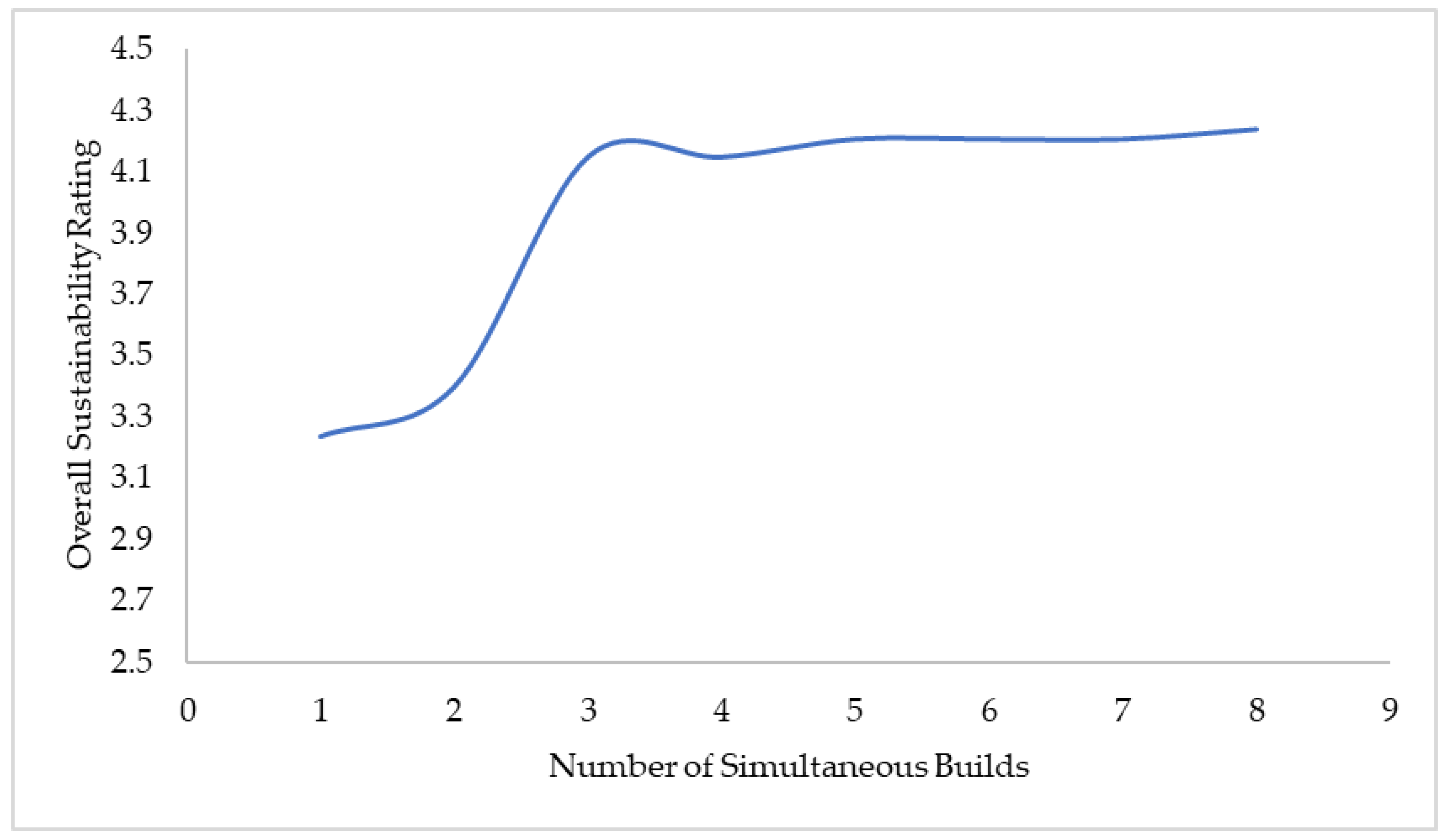

N = the number of simultaneous builds.

tDMLS = the processing time for direct metal laser sintering (h);

V = component volume (mm3);

S = support material as a percentage of component volume;

ν = the build rate of the printer (mm3/min).

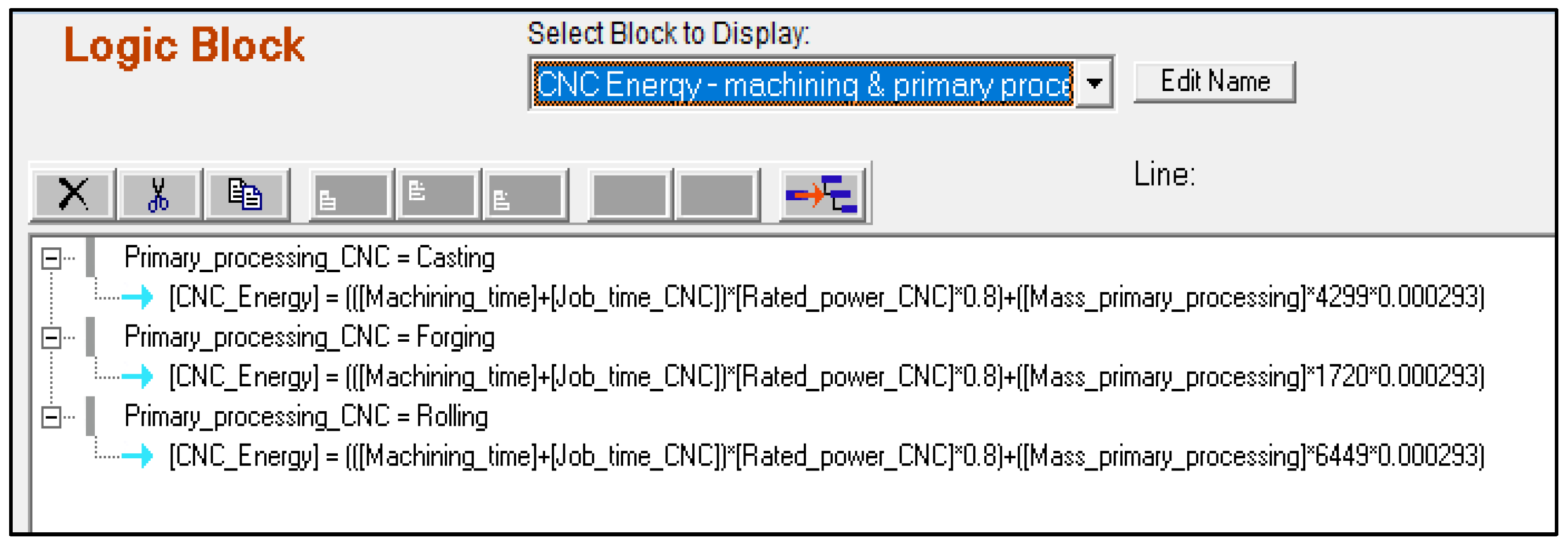

4.1.2. Energy Consumption

Although it is imperative to consider environmental emissions at each individual stage of the manufacturing life cycle, the main focus of this research study was to evaluate the energy consumption resulting from the fabrication and material processing stages of the products. In scenarios where CNC machining and BJP were compared on a sustainability basis, the material types considered were stainless steel 304L, stainless steel 316, stainless steel 316L, stainless steel 420, and stainless steel 17-4. For the cases involving CNC machining and DMLS, stainless steel 316L and stainless steel 17-4 were considered.

The material preparation phases required for CNC machining are the initial mining of raw materials, conversion to primary metal, and the processing required to convert the initial stainless steel material to workpieces. In the case of BJP and DMLS, following the initial mining and conversion to the initial metal material, atomization is required to achieve the required powder metal. The average material embodied energy values (Btu/lb) for stainless steel billets and stainless steel powder were ascertained from the existing research [

7,

17]. The determination of total material processing energy for CNC machining is restricted to casting, rolling, and forging.

Since CNC machining results in a substantial amount of material waste, the impact of recycling metal chips on energy consumption was evaluated in this research study. Due to the fact that BJP and DMLS only utilize the amount of metal powder required by the component being built, material waste is minimal. Therefore, the impact of additive manufacturing waste material on energy consumption was assumed to be negligible.

The calculation procedures for determining the energy consumption of each manufacturing technology are depicted below.

- ▪

Material Processing Energy

Ematerial(CNC) = the material processing energy for CNC machining (kWh);

Eembodied(billet) = the material embodied energy for stainless steel (kWh/lb);

Mbillet = the mass of billet used for CNC machining (lb);

Eprimary = the embodied energy for workpiece fabrication (kWh/lb);

Erecycling = the embodied energy for recycling the resultant waste (kWh/lb);

W = the percentage of waste recovered/recycled at the facility;

Mwaste = the mass of the resultant CNC machining waste (lb).

Ematerial(DMLS) = the material processing energy for DMLS (kWh/lb);

Ematerial(BJP) = the material processing energy for BJP (kWh/lb);

Mcomponent = the mass of the printed component (lb);

Eembodied(powder) = the material embodied energy for stainless steel (kWh/lb).

- ▪

Manufacturing Process Energy

To determine the amount of energy consumption related to the manufacturing process, it was imperative to use minimal empirical data. The energy consumption for DMLS was calculated using the generalized load factor [

18], time for the build [

12], and rated power of the machine.

where

EDMLS = the energy consumption of the DMLS process (kWh);

PDMLS = the rated power of the DMLS machine (kW);

LF = the load factor (%);

V = the component volume (mm3);

S = support material as a percentage of the component volume;

ν = the build rate of the printer (mm3/min);

tjob(DMLS) = the start-up time for the DMLS machine (h).

Miyanaji et al. [

19] state that, at a constant saturation level, operating the infrared heater power of the BJP printer between 55% and 65% yields structures with required dimensional accuracies and appropriate characteristics sufficient for curing. For the purposes of this research, the heater power was considered to have a direct correlation with the input power of the BJP printer. For the energy consumption calculation of BJP printers, a 55% load factor was used as a generalized value.

where

EBJP = the energy consumption of the BJP process (kWh);

tBJP = the time taken for the binder jetting process (h);

tjob(BJP) = the start-up time for the BJP machine (h);

LFBJP = the load factor for the binder jetting printer;

PBJP = the rated power of the binder jetting printer (kW);

Taverage(curing) = the average temperature used in the curing process (°F);

Trated(curing) = the maximum rated temperature of the curing oven (°F);

Prated(curing) = the rated power of the curing oven (kW);

tcuring = the curing time (h);

Taverage(sintering) = the average temperature used in the sintering process (°F);

Trated(sintering) = the maximum rated temperature of the sintering oven (°F);

Prated(sintering) = the rated power of the sintering oven (kW);

tsintering = the sintering time (h);

N = the number of simultaneous builds.

According to the data obtained from numerous manufacturing facilities, the average load factor for metal CNC machining was generalized to be roughly 80%.

where

ECNC(milling) = the energy consumption of the CNC milling process (kWh);

PCNC = the rated power of the CNC machine (kW);

LFCNC = the load factor of the CNC machine (%);

tCNC(milling) = the machining time for the CNC milling process (h).

The energy consumption for CNC turning and drilling can be calculated using the machining time for each process and substituting in the formula above.

For the analysis of energy consumption during the manufacturing processes, secondary finishing processes such as finish machining and painting were considered. The calculation procedure for secondary processing energy (

Esecondary) was adopted from [

17].

* Assumption: the finishing process for CNC machining removes 10% of the initial mass difference.

where

EDMLS(painting) = the energy consumption of painting for DMLS (kWh);

EBJP(painting) = the energy consumption of painting for BJP (kWh);

ECNC(painting) = the energy consumption of painting for CNC (kWh);

Minitial = the mass of the initially printed component for DMLS/BJP (lb);

Mfinal = the mass of the component after secondary processing DMLS/BJP (lb);

Mbillet = the mass of billet used in CNC machining (lb);

Mcomponent = the mass of the component for CNC machining (lb);

E(painting) = the embodied energy value for painting (kWh/lb);

E(finishmachining) = the embodied energy value for finish machining (kWh/lb);

EDMLS(finishmachining) = the energy consumption of finish machining for DMLS (kWh);

EBJP(finishmachining) = the energy consumption of finish machining for BJP (kWh);

ECNC(finishmachining) = the energy consumption of finish machining for CNC (kWh).

In addition to secondary processing, the energy consumption of post-processing (heat treatment) steps was considered in this research. It was assumed that all heat treatment devices were electric. The energy consumption of hot isostatic pressing and annealing can be calculated as follows:

where

Epostprocessing = the energy consumption of the heat treatment process (kWh);

Ppostprocessing = the rated power of the heat treatment equipment (kW);

Tzone(avg) = the average zone temperature in the heat treatment equipment (°F);

Trated = the maximum rated temperature of the heat treatment equipment (°F);

tpostprocessing = the time taken for the heat treatment process (h).

The total energy consumption for CNC machining, binder jetting, and direct metal laser sintering can be summarized as follows:

4.1.3. Economic Impact

In this research study, the economics pertaining to each manufacturing technique comprise equipment cost, material cost, labor cost, and cost due to energy consumption of the processes. For the purposes of this research study, it was considered important to include depreciation of equipment, installation and maintenance costs, and tax rates for equipment in determining the overall hourly cost rate for each machine. In order to account for the reduction in taxable income, the modified accelerated cost recovery system (MACRS) [

20] was adopted in calculating the equipment cost. The overall costs associated with each manufacturing method were calculated as described below.

Operator involvement for a build entails concurrent activity time, independent activity time, and programming time required for the machine. The programming time for CNC and additive manufacturing was estimated as a function of the product’s geometric complexity [

12]. Therefore, the total operator cost for CNC machining, BJP, and DMLS can be calculated as follows:

where

a = the concurrent activity time;

b = the independent operator activity time;

α = the geometric complexity factor;

Lcost = the hourly labor cost at the facility (USD/h);

LCNC = the total labor cost for CNC machining (USD);

LBJP = the total labor cost for BJP (USD);

LDMLS = the total labor cost for DMLS (USD).

Material costs are calculated as follows:

where

MBJP = the total material cost incurred during the BJP build (USD);

MDMLS = the total material cost incurred during the DMLS build (USD);

MCNC = the total material cost incurred during the CNC machining build (USD);

Mcomponent = the mass of BJP/DMLS component (lb);

Mbillet = the mass of billet used in the CNC machining process (lb);

Mcost(powder) = the cost of metal powder (USD/lb);

Mcost(billet) = the cost of metal billet (USD/lb).

Electricity costs for the manufacturing processes are quantified in the following manner:

where

Ecost(BJP) = the electricity cost incurred for the BJP process (USD);

Ecost(DMLS) = the electricity cost incurred for the DMLS process (USD);

Ecost(CNC) = the electricity cost incurred for the CNC machining process (USD);

Etotal(BJP) = the total energy consumption of BJP (kWh);

Etotal(DMLS) = the total energy consumption of DMLS (kWh);

Etotal(CNC) = the total energy consumption of CNC machining (kWh);

Ecost = the blended electricity cost at the facility (USD/kWh).

In order to calculate the equipment depreciation costs, a 10-year class life was assumed for CNC machining, BJP, and DMLS equipment.

where

Ccost = the hourly cost of the machine (USD/h);

Ccapital = the capital cost of equipment (USD);

Cinstallation = the installation cost as a percentage of the capital cost;

Cmaintenance = the maintenance cost as a percentage of the capital cost;

Cincrease = the percentage annual increase in the maintenance cost;

R = the tax rate for manufacturing equipment;

UF = the utilization factor of equipment on an annual basis.

To calculate the machine cost incurred per build, the following equations were used:

where

CCNC = the total CNC machine cost for the build (USD);

CBJP = the total BJP machine cost for the build (USD);

CDMLS = the total DMLS machine cost for the build (USD);

Ccost(CNC) = the cost per hour for the CNC machine (USD/h);

Ccost(BJP) = the cost per hour for the BJP machine (USD/h);

Ccost(DMLS) = the cost per hour for the DMLS machine (USD/h);

tCNC = the processing time for CNC machining (h);

tBJP = the processing time for BJP (h);

tDMLS = the processing time for DMLS (h).

The total economic impact of the manufacturing processes (CNC machining, BJP, and DMLS) was estimated by combining material, labor, electricity, and machine costs relevant to the fabricated component.

4.1.4. Impact of Auxiliary Material on Sustainability

Intuitively, CNC machining consumes a larger proportion of auxiliary material due to the nature of its process. The auxiliary systems with the highest sustainability impact in CNC machining have been considered to be cutting tools and cutting fluids. In this research, the considered cutting tool types for machining stainless steel were carbide and ceramic, due to their significant usage in industry. Ceramic cutting tools have a much higher resource efficiency than carbide tools during the high-speed machining of hard materials in dry conditions [

21].

According to [

22], dry machining is recommended for milling operations with ceramic materials. Due to the absence of cutting fluid, dry machining would result in a reduced burden on the environment and less adverse impact on worker safety due to decreased exposure to harmful chemicals. However, turning processes would require the use of cutting fluid. In cases where dry machining is not viable, minimum lubrication is utilized by the use of ceramic tools. However, ceramic tools require precious resources and higher energy expenditure during production and recycling due to added processing steps such as sintering and other heat treatment methodologies [

21].

In the case of carbide tools, upon reaching tool life, roughly 40 percent of the recycled material is used for the production of new cutting tools, and the remainder is used for mining tools. The use of chemical recycling processes allows for the reuse of almost 100% of disposed carbide-cutting tools for the production of new tools. Therefore, carbide tools undergo either open- or closed-loop recycling during their end-of-life phase. It has been proven that cutting tools manufactured using recycled tool material results in 75% less energy consumption than that of virgin material-based production [

23].

During the binder jetting process, the auxiliary material used consists of binder fluid and cleaning fluid. In this research, only the sustainability impact of binder fluid was considered. Since all binder material is consumed during the printing process, there is no requirement for recycling or disposal. The auxiliary material consumption of DMLS is only due to inert gas utilization and compressed air. Since compressed air is used at low flow rates, its impact on sustainability was neglected. It is important to note that the sustainability impact due to the flow rates of the auxiliary materials used in BJP and DMLS was not taken into consideration as they are highly variable among machines and processes.