Control Method of Cold and Hot Shock Test of Sensors in Medium

Abstract

1. Introduction

2. Test Requirements and Requirements Analysis

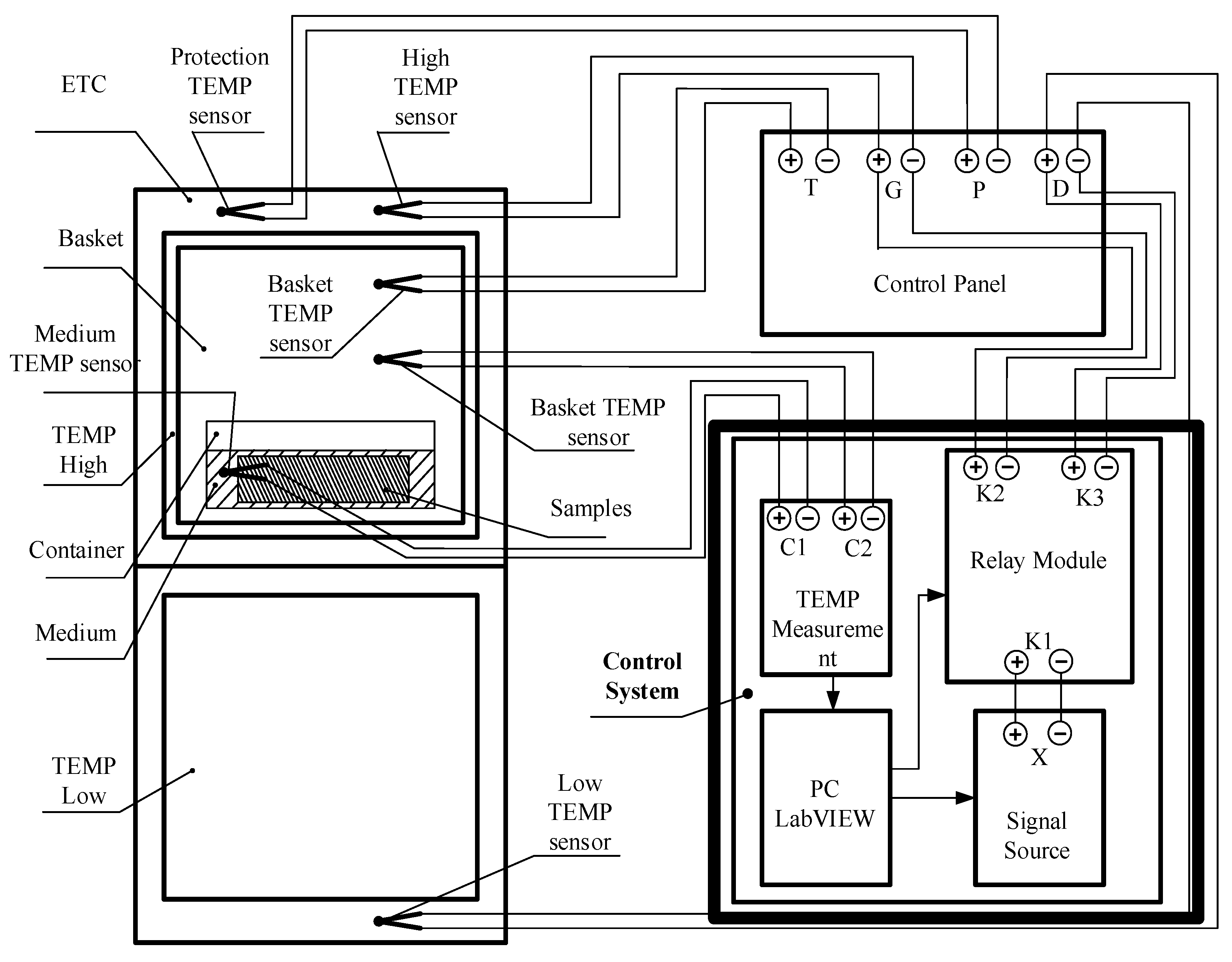

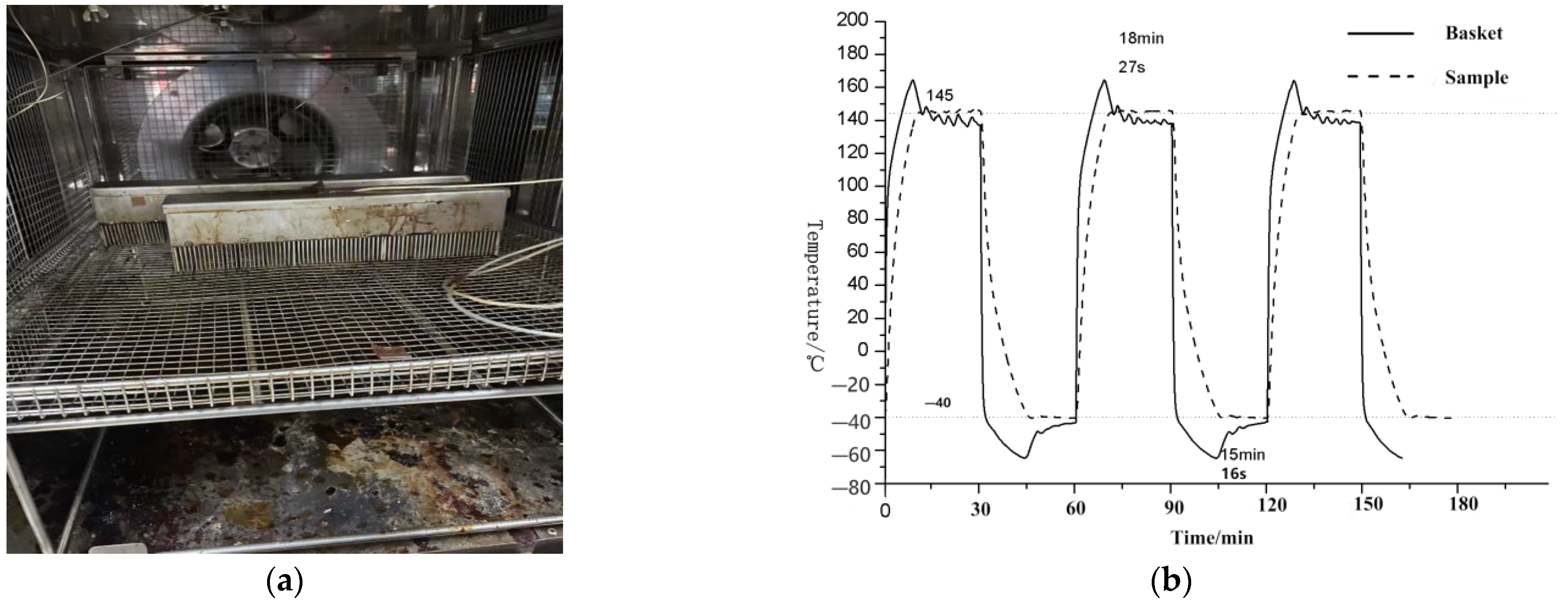

2.1. Test Chamber Structure

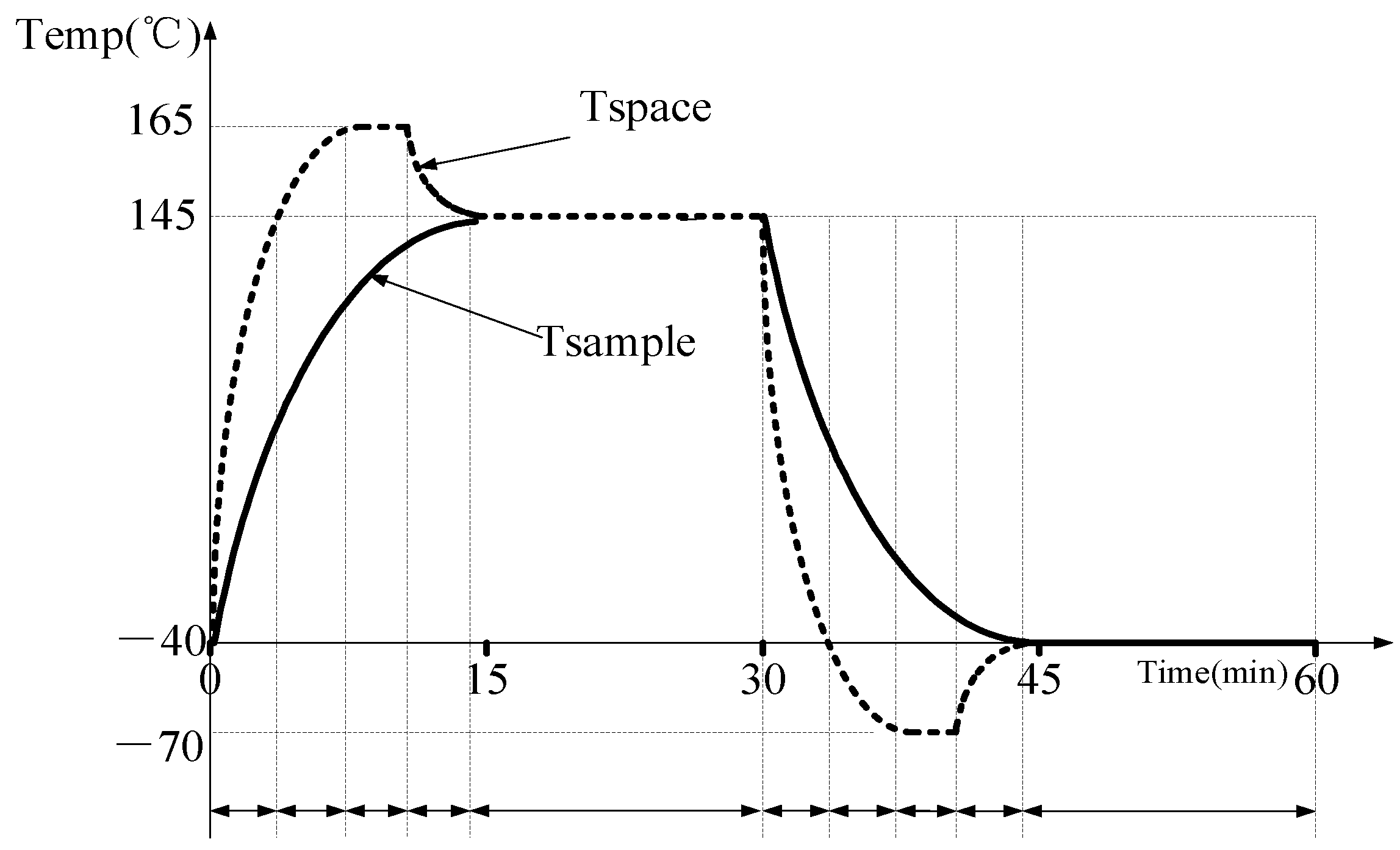

2.2. Principle of Control Process

- (1)

- Space temperature rises rapidly; the sample temperature increases accordingly.

- (2)

- Space temperature reaches the high-temperature limit and maintains; the sample temperature continues to rise.

- (3)

- Space temperature gradually drops to the target temperature, while the sample temperature gradually increases to the target temperature.

- (4)

- Space temperature oscillates around the target temperature, while the sample temperature remains stable at the target temperature.

3. Control Method

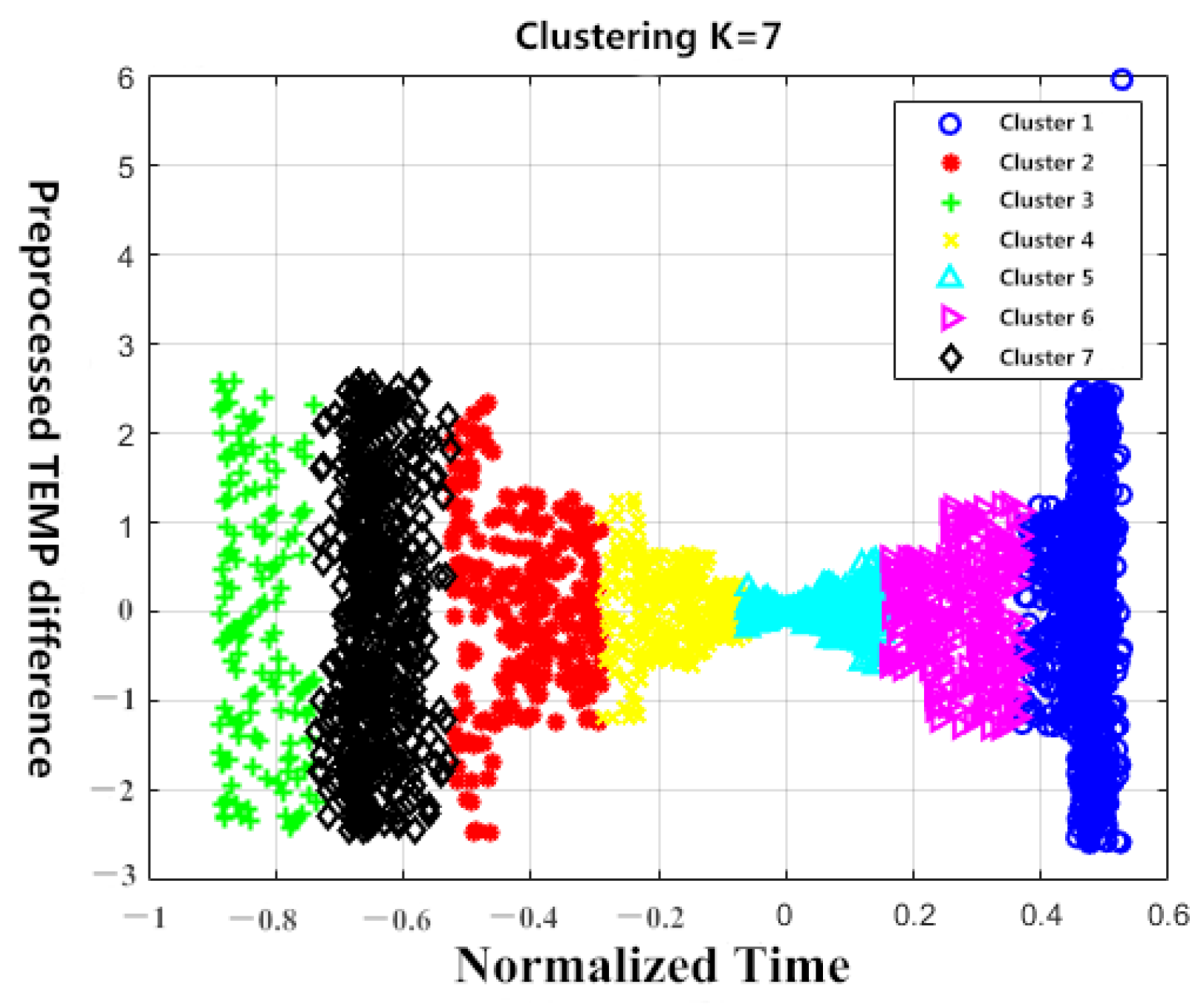

3.1. K-Means Clustering

- (1)

- Calculate the distance between it and the nearest clustering center in the selected cluster center, as shown in Formula (3).

- (2)

- Select a new data point as the new clustering center, and the point with a larger D() value is more likely to be chosen as the clustering center.

- (3)

- Repeat the above steps until K cluster centroids are selected.

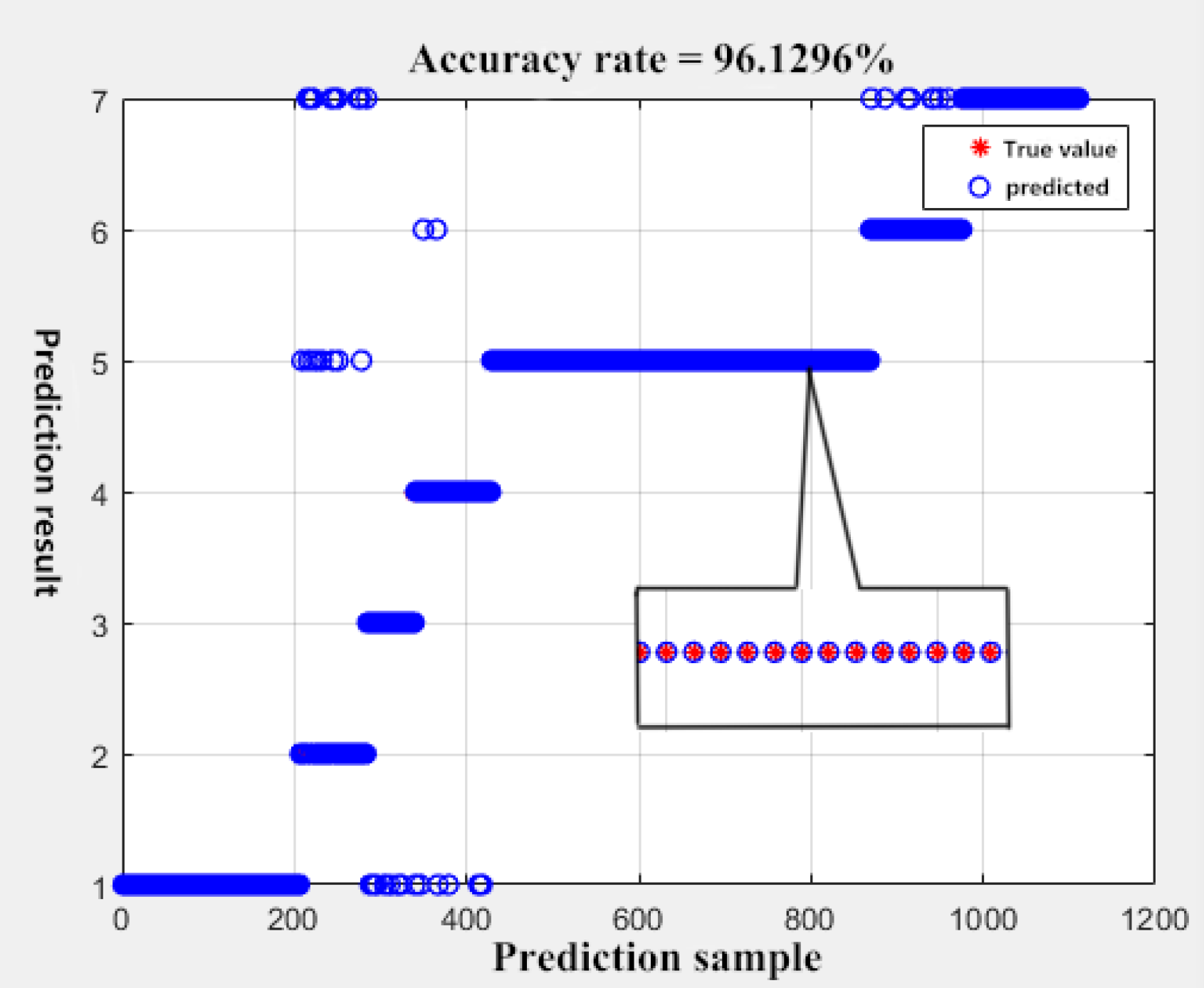

3.2. SVM Control Voltage Classification

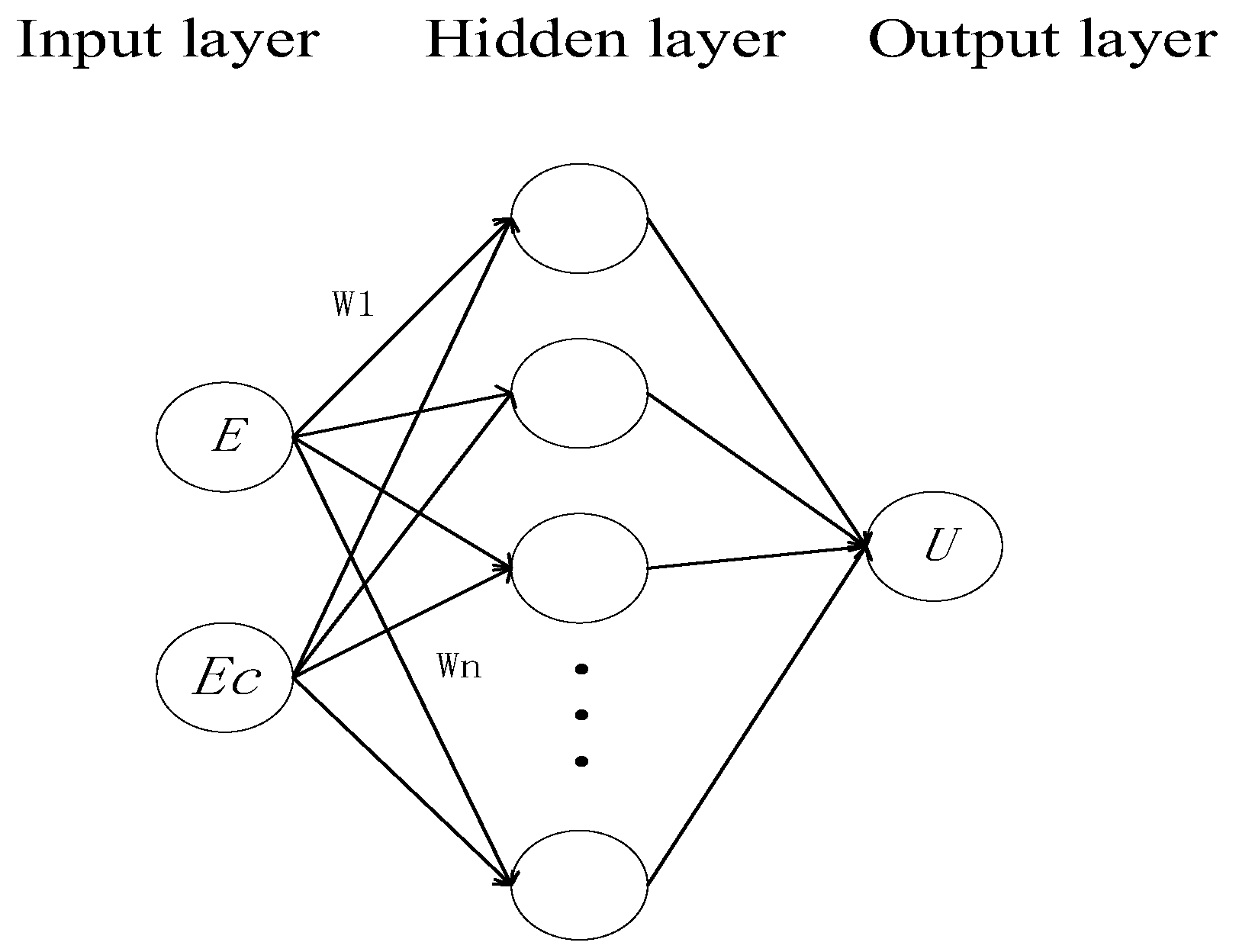

3.3. Back Propagation Neural Network

3.4. Overview of Control Methods

- (1)

- Obtain raw data sets based on experience and experiments.

- (2)

- Use a clustering algorithm to evaluate and obtain the optimal clustering after data preprocessing.

- (3)

- Classify the output voltage using SVM and determine the corresponding voltage value through experimentation.

- (4)

- Accurately adjust the data of temperature holding phase on the basis of existing data. Use this data to train the neural network.

- (5)

- Conduct experiments and set up appropriate nodes to effectively integrate the two methods. Repeat experiments to verify the stability and effectiveness of the method.

3.5. Temperature Compensation

4. Experiments

5. Conclusions

- (1)

- This article proposes a control method that combines K-means and SVM with neural network correction. The method is designed to achieve the efficient control of the cold and hot shock testing of the sensor in the medium. On the whole, the system utilizes K-means clustering analysis of temperature data and the SVM method to distribute the control voltage signal. In detail, the output control voltage is fine-tuned by combining it with neural network control during the temperature holding stage. Timely control the temperature changes in the basket space in order to indirectly regulate the temperature of the sample sensors in the medium. With the combination of overall control and detail control, this method is highly effective in ensuring that the sample’s temperature in the medium meets the industry’s test requirements during the cold and hot shock testing.

- (2)

- Combined with the graphical interface of LabVIEW, the entire system effectively enhances the stability and controllability of the current cold and hot shock test. It realizes the effective control of the sensor’s temperature in the medium, as well as the display and recording of the test data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, L.; Chen, Z.; Jiang, Z.; He, J.; Yang, C.; Gui, W. Optimal temperature rise control for a large-scale vertical quench furnace system. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 4912–4924. [Google Scholar] [CrossRef]

- Castillo-Martínez, D.H.; Rodríguez-Rodríguez, A.J.; Soto, A.; Berrueta, A.; Vargas-Requena, D.T.; Matias, I.R.; Sanchis, P.; Ursúa, A.; Rodríguez-Rodríguez, W.E. Design and On-Field Validation of an Embedded System for Monitoring Second-Life Electric Vehicle Lithium-Ion Batteries. Sensors 2022, 22, 6376. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Yang, R.; Li, H.; Zhang, X.; Xu, T. Active Motor Rotor Temperature Management Based on One-Node hot Network Model Predictive Control. IEEE Trans. Power Electron. 2020, 35, 11213–11221. [Google Scholar] [CrossRef]

- Yang, M.; Hu, K.; Du, Y.; Wei, Z.; Sheng, Z.; Hu, J. Underwater image enhancement based on conditional generative adversarial network. Signal Process. Image Commun. 2020, 81, 115723. [Google Scholar] [CrossRef]

- Qiao, J.; Hao, M.; Guo, M. Design of Meat Product Safety Information Chain Traceability System Based on UHF RFID. Sensors 2023, 23, 3372. [Google Scholar] [CrossRef]

- Duan, Q.; Ping, J.; Xie, H.; Wang, C.; Li, S. Power and Temperature Control of Nuclear Power Plant Based on Transfer Function Matrix Method. IEEE Access 2021, 9, 33922–33928. [Google Scholar] [CrossRef]

- Zhou, C.; Zhuang, L.; Yuan, J.; Gao, C. Optimization and experiment of temperature measuring points for machine tool spindle based on K-means algorithm. Mach. Des. Manuf. 2018, 5, 41–43. [Google Scholar]

- Wang, S.; Zhao, B.; Yi, S.; Zhou, Z.; Zhao, X. GAPSO-Optimized Fuzzy PID Controller for Electric-Driven Seeding. Sensors 2022, 22, 6678. [Google Scholar] [CrossRef]

- Liu, C. Design of an embedded adaptive temperature control system based on ARM. J. Shenyang Univ. Technol. 2020, 42, 448–452. [Google Scholar]

- Xie, J.; Wang, Y. K-means algorithm for optimizing initial clustering centers with minimum variance. Comput. Eng. 2014, 40, 205–211. [Google Scholar]

- Inan, M.; Alam, F.; Hasan, R. Deep integrated pipeline of segmentation guided classification of breast cancer from ultrasound images. Biomed. Signal Process. Control 2022, 75, 103553. [Google Scholar] [CrossRef]

- Chang, C.; Lin, C. LIBSVM: A library for support vector machine. ACM Trans. Intell. Syst. Technol. 2011, 2, 1–27. [Google Scholar] [CrossRef]

- Hong, L.; Wang, J.; Zhang, M.; Dai, H.; Cheng, J. Average convergence rate estimation of clonal selection algorithm. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Zavanella, L. Analysis of Temperature Control Strategy on Energy Consumption in Buildings with Intermittent Occupancy. Energies 2023, 16, 1208. [Google Scholar]

- Yan, H.; Du, B.; Marquez, A.; Buticchi, G. Optimised temperature fluctuation control strategy for lifetime improvement in aircraft electrical power distribution system. IET Electr. Syst. Transp. 2022, 12, 344–357. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, H.; Wu, D.; Li, R. Study on Half-Bridge Voltage Balancing Circuit with Two Driving Methods. J. Electr. Eng. Technol. 2021, 16, 1505–1516. [Google Scholar] [CrossRef]

- Cheng, D.; Huang, J.; Zhang, S.; Xia, S.; Wang, G.; Xie, J. K-Means Clustering with Natural Density Peaks for Discovering Arbitrary-Shaped Clusters. IEEE Trans. Neural Netw. Learn. Syst. 2023. early access. [Google Scholar] [CrossRef]

- Miao, W.; Xu, B. Application of Feedforward Cascade Compound Control Based on Improved Predictive Functional Control in Heat Exchanger Outlet Temperature System. Appl. Sci. 2023, 13, 7132. [Google Scholar] [CrossRef]

- Zhu, C.; Idemudia, C.; Feng, W. Improved logistic regression model for diabetes prediction by integrating PCA and K-means techniques. Inform. Med. Unlocked 2019, 17, 100179. [Google Scholar] [CrossRef]

- Song, C.; Yao, L.; Hua, C.; Ni, Q. A water quality prediction model based on variational mode decomposition and the least squares support vector machine optimized by the sparrow search algorithm (VMD-SSA-LSSVM) of the Yangtze River, China. Environ. Monit. Assessment. 2021, 193, 363. [Google Scholar] [CrossRef]

- Cui, W.; Wang, Y.; Kang, S.; Xie, J.; Wang, Q.; Mikulovich, V. Road lane line detection method based on improved YOLOV3 algorithm. Acta Autom. Sin. 2022, 48, 1560–1568. [Google Scholar]

- Chen, Z.; Cai, R. Updating incomplete framework of target recognition database based on fuzzy gap statistic. Eng. Appl. Artif. Intell. 2022, 107, 104521. [Google Scholar] [CrossRef]

- Chauhan, V.; Dahiya, K.; Sharma, A. Problem formulations and solvers in linear SVM: A review. Artif. Intell. Rev. 2019, 52, 803–855. [Google Scholar] [CrossRef]

- Li, J.; Feng, J.; Wu, W.; Liu, Y. Fault diagnosis of power transformer based on improved firefly algorithm and multi-classification support vector machine. Electr. Meas. Instrum. 2022, 59, 131–135. [Google Scholar]

- Paramasivam, K.; Sindha, M.; Balakrishnan, S. KNN-Based Machine Learning Classifier Used on Deep Learned Spatial Motion Features for Human Action Recognition. Entropy 2023, 25, 844. [Google Scholar] [CrossRef]

- Nurkholis, A.; Alita, D.; Munandar, A. Comparison of Kernel Support Vector Machine Multi-Class in PPKM Sentiment Analysis on Twitter. J. RESTI (Rekayasa Sist. Dan Teknol. Inf.) 2022, 6, 227–233. [Google Scholar] [CrossRef]

- Chen, L.; Jin, P.; Yang, J.; Li, Y.; Song, Y. Robust Kalman filter-based dynamic state estimation of natural gas pipeline networks. Math. Probl. Eng. 2021, 2021, 559057. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, B.; Gao, S.; Zheng, Y.; Zhou, L.; Liu, S. Development of Cotton Picker Fire Monitoring System Based on GA-BP Algorithm. Sensors 2023, 23, 5553. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, H.; Wang, Q.; Zheng, Z.; Wang, H.; Yue, Z.; Yao, M. Investigation on the ignition delay prediction model of multi-component surrogates based on back propagation (BP) neural network. Combust. Flame 2022, 237, 111852. [Google Scholar] [CrossRef]

- Li, T.; Sun, J.; Wang, L. An intelligent optimization method of motion management system based on BP neural network. Neural Comput. Appl. 2021, 33, 707–722. [Google Scholar] [CrossRef]

- Kim, B.; Ryu, K.; Heo, S. Mean squared error criterion for model-based design of experiments with subset selection. Comput. Chem. Eng. 2022, 159, 107667. [Google Scholar] [CrossRef]

- Yang, M.; Yin, G.; Du, Y.; Wei, Z. Pair comparison based progressive subjective quality ranking for underwater images. Signal Process. Image Commun. 2021, 99, 116444. [Google Scholar] [CrossRef]

- Rerkratn, A.; Prombut, S.; Kamsri, T.; Riewruja, V.; Petchmaneelumka, W. A Procedure for Precise Determination and Compensation of Lead-Wire Resistance of a Two-Wire Resistance Temperature Detector. Sensors 2022, 22, 4176. [Google Scholar] [CrossRef] [PubMed]

- Reja, M.; Nguyen, L.; Peng, L.; Ebendorff-Heidepriem, H.; Warren-Smith, S. Temperature-compensated interferometric high-temperature pressure sensor using a pure silica microstructured optical fiber. IEEE Trans. Instrum. Meas. 2022, 71, 1–12. [Google Scholar] [CrossRef]

- Sandesh, R.; Venkatesan, N. Steady state VEP-based BCI to control a five-digit robotic hand using LabVIEW. Int. J. Biomed. Eng. Technol. 2022, 38, 109. [Google Scholar] [CrossRef]

- Wu, D.; Wu, X.; Su, L.; Yuan, X.; Xu, J. A Dual Three-Level Inverter-Based Open-End Winding Induction Motor Drive with Averaged Zero-Sequence Voltage Elimination and Neutral-Point Voltage Balance. IEEE Trans. Ind. Electron. 2016, 63, 4783–4795. [Google Scholar] [CrossRef]

| TEMP difference/°C | 136.631–87.167 | 87.167–53.449 | 53.449–15.902 | 15.902–−4.463 | −4.463–−31.357 | −31.357–−66.852 | −66.852–−140.74 |

| U/v | 0.6 | 1.5 | 4.2 | 6.1 | 5.9 | −0.6 | −2 |

| Neural Network | MSE | Maximum Error/% | MAE |

|---|---|---|---|

| Evaluation value | 0.038 | 4.193 | 0.158 |

| Ts/°C | Tc/°C | E/°C | Ec (°C/s) | U (True)/v | U (Prediction)/v |

|---|---|---|---|---|---|

| 138.844 | 144.976 | −6.132 | 0.08 | 5.72 | 5.56 |

| 139.003 | 144.957 | −5.953 | 0.08 | 5.64 | 5.45 |

| 141.024 | 144.986 | −3.962 | 0.05 | 5.85 | 5.95 |

| 141.074 | 144.996 | −3.922 | 0.04 | 5.86 | 5.97 |

| 141.174 | 145.0168 | −3.842 | 0.05 | 6.12 | 6.29 |

| 141.213 | 145.0367 | −3.822 | 0.02 | 6.12 | 6.33 |

| 141.253 | 145.0397 | −3.785 | 0.03 | 6.15 | 6.3 |

| 141.326 | 145.062 | −3.736 | 0.02 | 6.22 | 6.47 |

| −42.081 | −39.974 | −2.107 | 0.04 | −6.22 | −6.25 |

| −42.031 | −39.984 | −2.047 | 0.03 | −6.19 | −6.31 |

| −41.991 | −40.004 | −1.987 | 0.03 | −6.11 | −6.24 |

| −41.683 | −40.113 | −1.569 | 0.02 | −6.27 | −6.5 |

| −41.593 | −40.153 | −1.440 | 0.01 | −6.31 | −6.37 |

| −41.474 | −40.173 | −1.300 | 0.02 | −6.23 | −6.44 |

| −41.356 | −39.946 | −1.409 | 0.03 | −5.85 | −5.68 |

| −41.322 | −39.923 | −1.398 | 0.01 | −5.82 | −5.59 |

| Number | Overshoot/°C | Steady Time/min | Steady State Value/°C |

|---|---|---|---|

| 1 | 0.37 | 16.33 | 145.11 |

| 2 | 0.3 | 16.25 | 145.24 |

| 3 | 0.22 | 15.87 | 145.13 |

| 4 | 0.41 | 16.08 | 145.31 |

| 5 | 0.38 | 16.22 | 145.22 |

| 6 | 0.23 | 15.61 | 144.91 |

| 7 | 0.27 | 15.74 | 145.15 |

| 8 | 0.36 | 16.06 | 144.85 |

| 9 | 0.26 | 16.21 | 145.09 |

| 10 | 0.25 | 16.15 | 145.14 |

| Number | Overshoot/°C | Steady Time/min | Steady State Value/°C |

|---|---|---|---|

| 1 | 0.28 | 15.12 | −40.25 |

| 2 | 0.41 | 15.08 | −40.31 |

| 3 | 0.27 | 15.19 | −40.11 |

| 4 | 0.51 | 15.22 | −40.23 |

| 5 | 0.36 | 15.11 | −40.18 |

| 6 | 0.32 | 15.42 | −40.25 |

| 7 | 0.64 | 15.03 | −40.39 |

| 8 | 0.25 | 15.25 | −40.14 |

| 9 | 0.19 | 15.06 | −39.94 |

| 10 | 0.35 | 15.33 | −40.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, J.; Zeng, Y.; Ji, L.; Zhu, H.; Guo, Z. Control Method of Cold and Hot Shock Test of Sensors in Medium. Sensors 2023, 23, 6536. https://doi.org/10.3390/s23146536

Tian J, Zeng Y, Ji L, Zhu H, Guo Z. Control Method of Cold and Hot Shock Test of Sensors in Medium. Sensors. 2023; 23(14):6536. https://doi.org/10.3390/s23146536

Chicago/Turabian StyleTian, Jinming, Yue Zeng, Linhai Ji, Huimin Zhu, and Zu Guo. 2023. "Control Method of Cold and Hot Shock Test of Sensors in Medium" Sensors 23, no. 14: 6536. https://doi.org/10.3390/s23146536

APA StyleTian, J., Zeng, Y., Ji, L., Zhu, H., & Guo, Z. (2023). Control Method of Cold and Hot Shock Test of Sensors in Medium. Sensors, 23(14), 6536. https://doi.org/10.3390/s23146536