A New Monitoring Technology for Bearing Fault Detection in High-Speed Trains

Abstract

1. Introduction

2. Sensor Array Design and Impact Point Positioning

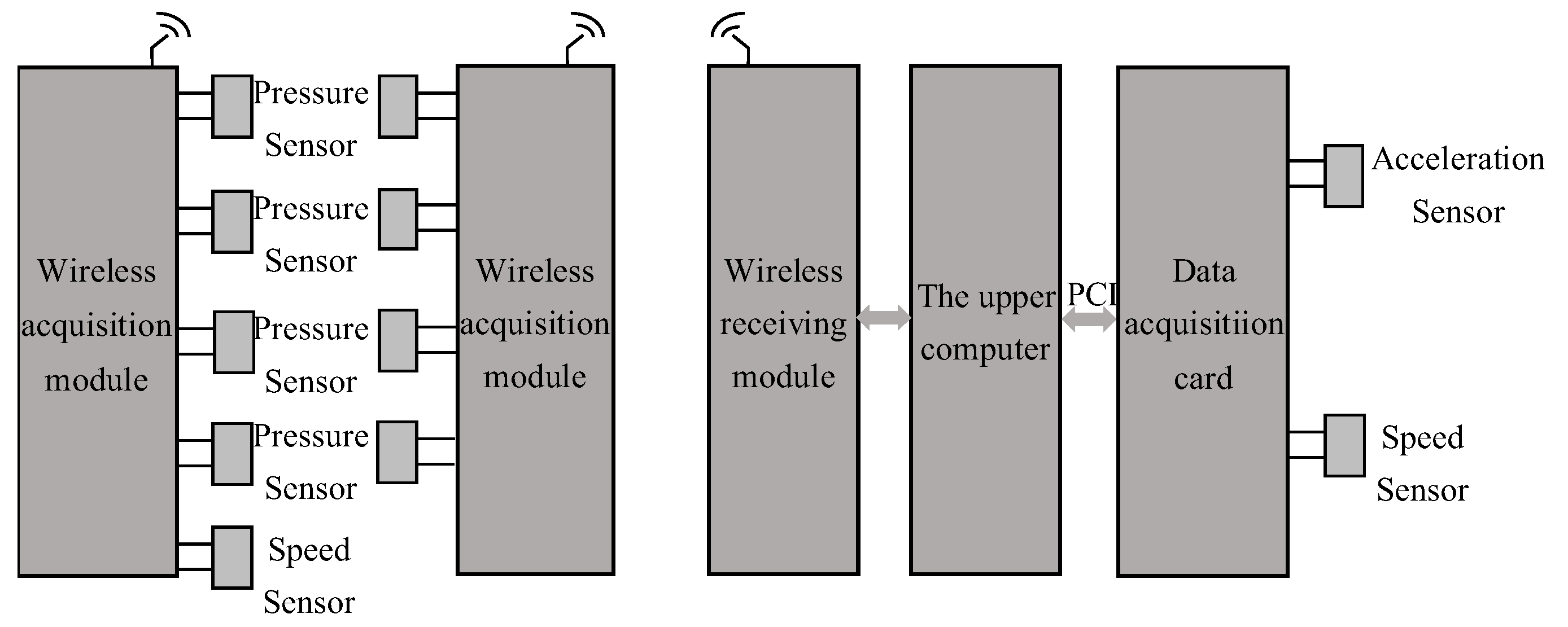

2.1. The Process of Signal Acquisition

Sensor Selection

2.2. Wireless Transmitter Modules

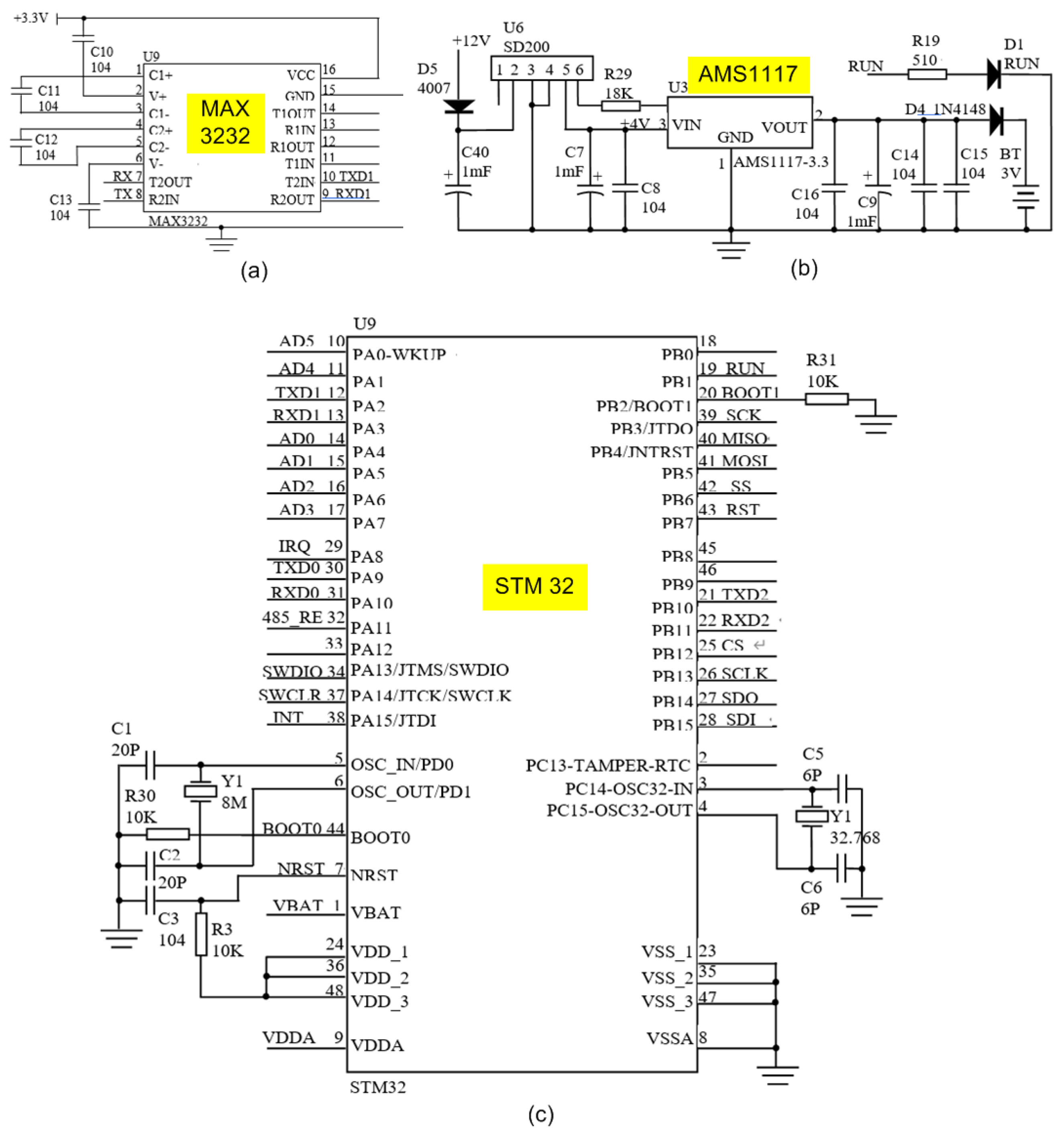

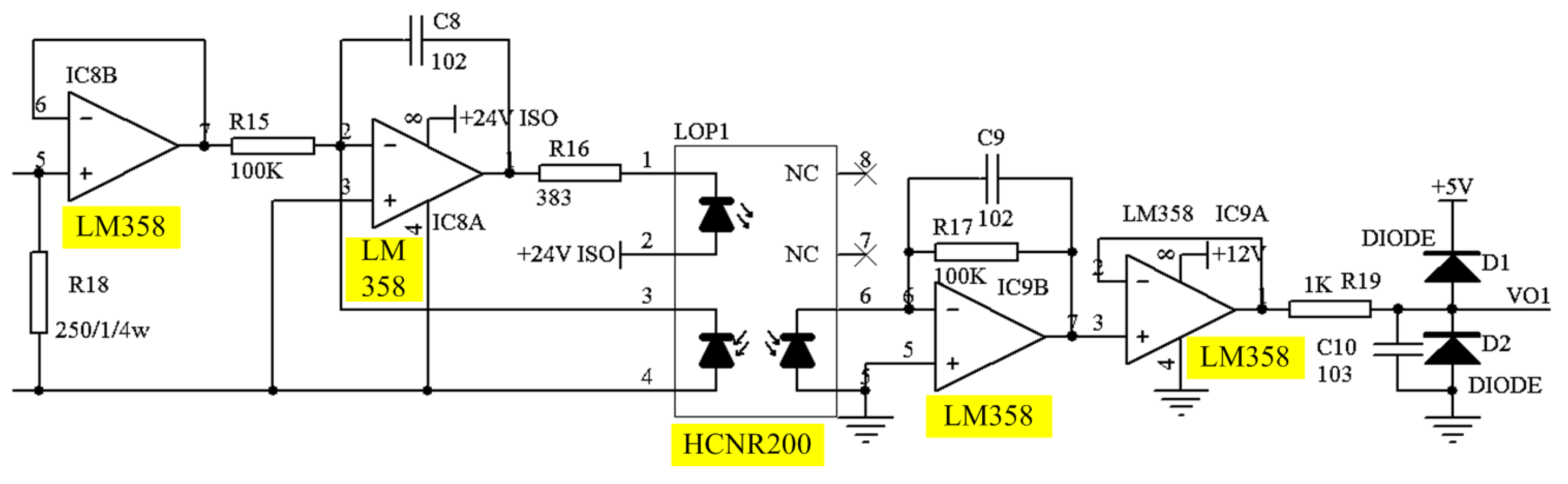

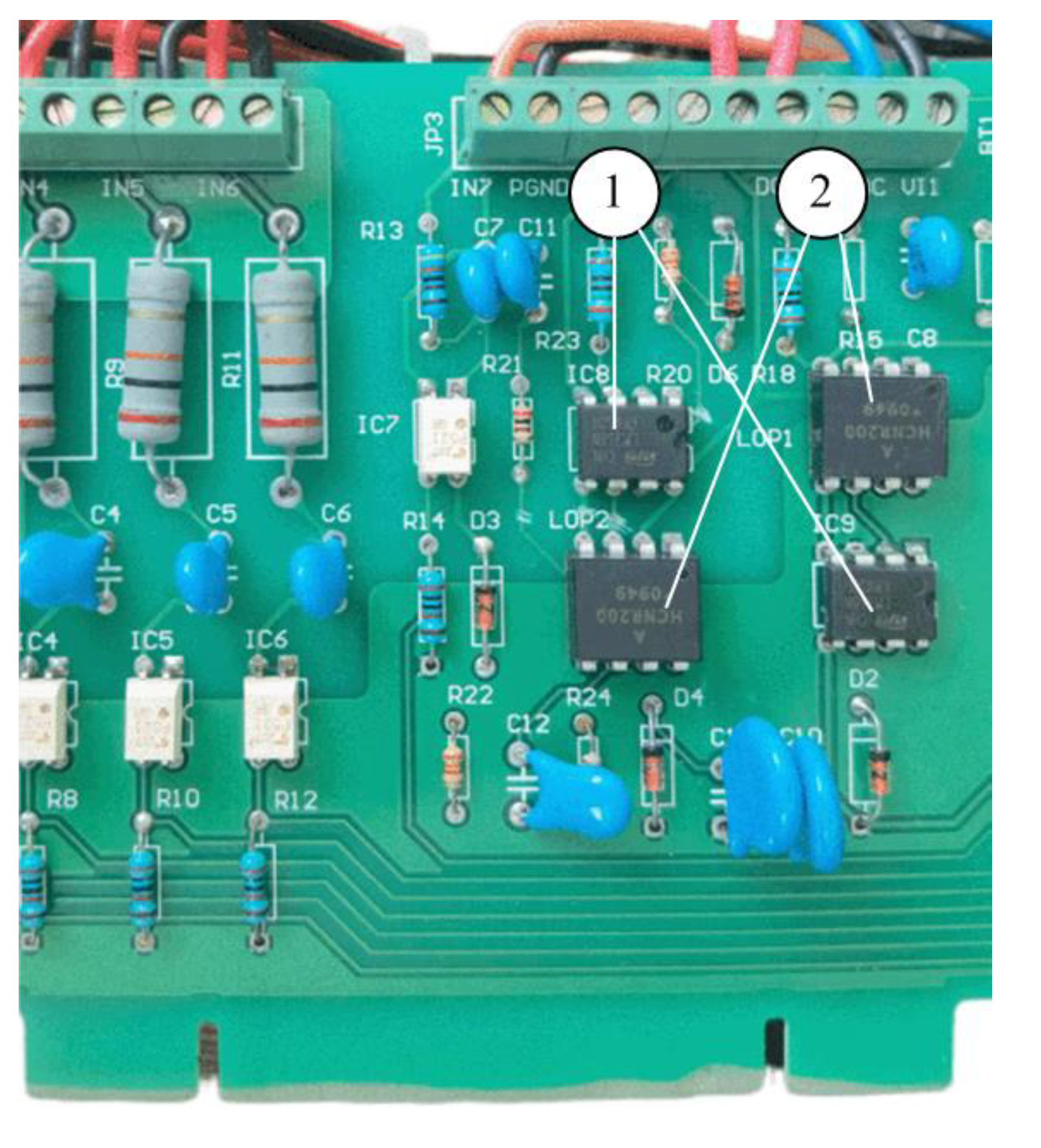

Signal Conditioning Circuit

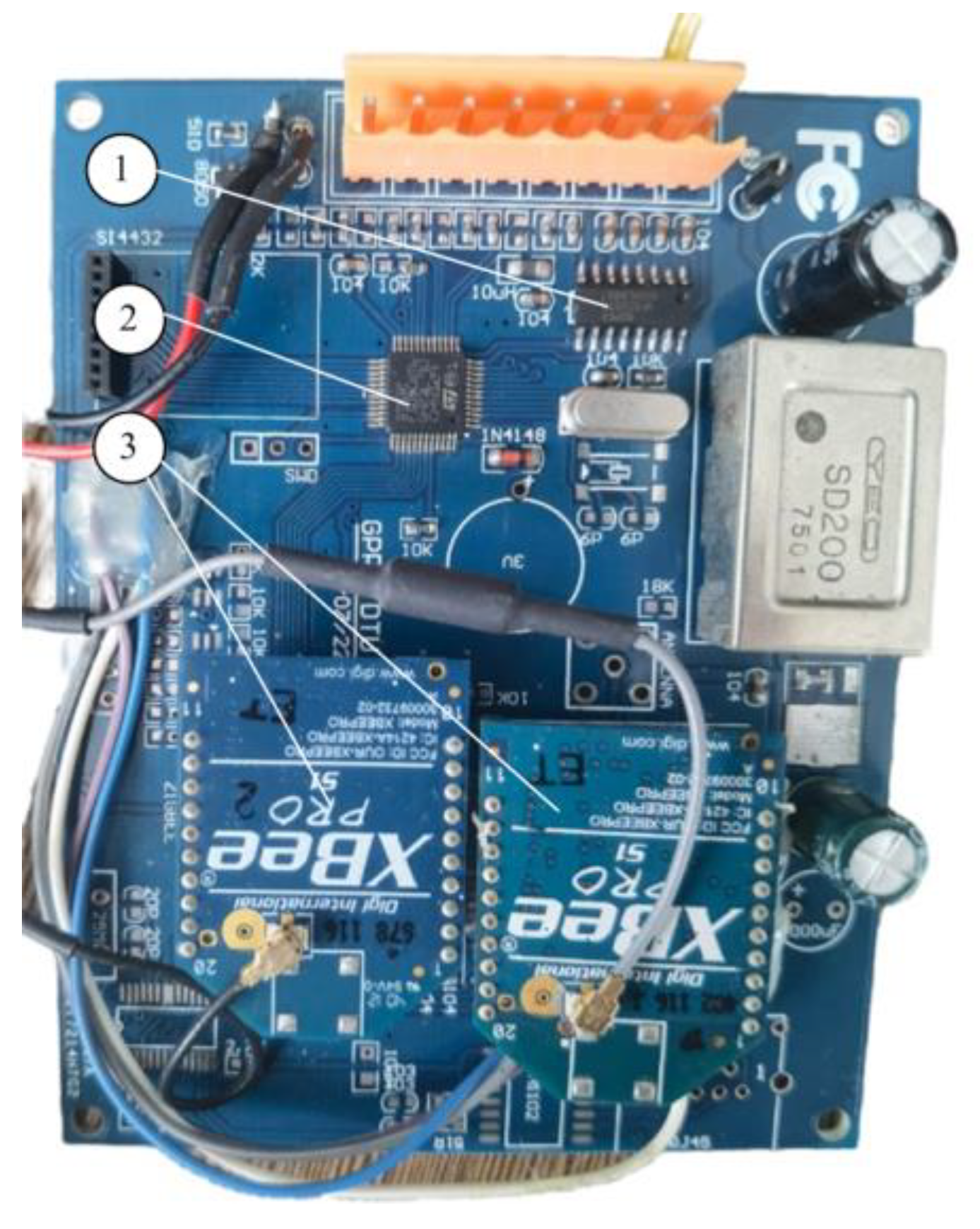

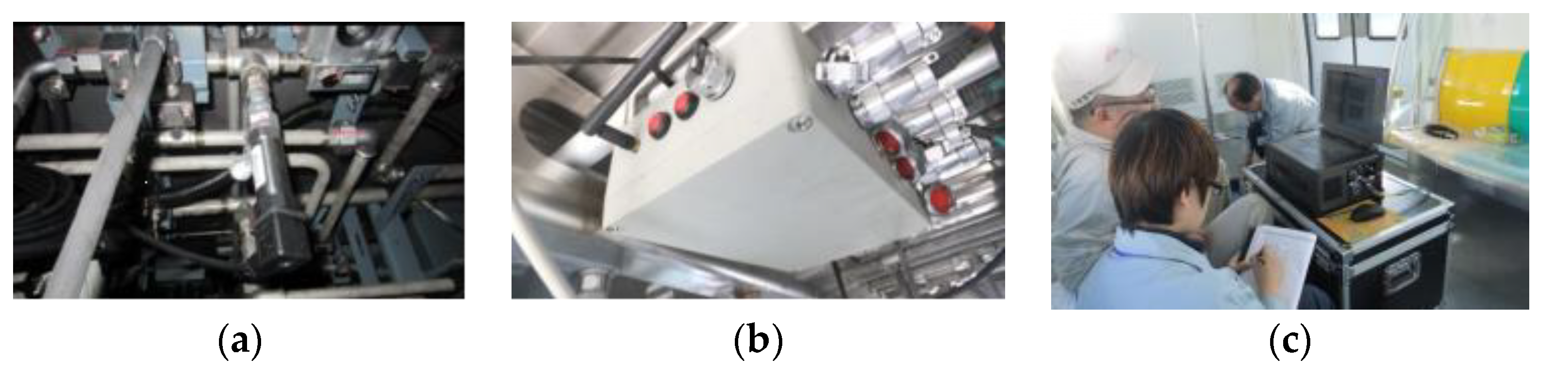

2.3. Implementation and Field Test

3. The Proposed MCA Technique for Bearing Fault Detection

3.1. Overview

- (1)

- Decompose the collected vibration signal into the upper computer conditioning program; and then formulate a group of IMFs by using the VMD.

- (2)

- Compute the normalized correlation measure (NCM), the mutual information analysis (MIA), and the envelope correlation spectrum (ECS) for each IMF.

- (3)

- Calculate the cumulation values and average values of NCM, MIA, and ECS. If the cumulation value is less than the average, the corresponding IMF will be discarded. If the cumulation value is more than the average value, the IMF will be used to formulate an analytical signal.

- (4)

- Conduct spectral analysis of the analytical signal for bearing fault detection.

3.2. Variational Mode Decomposition

- (1)

- Initialize , , , and the maximum number of iterations N, ;

- (2)

- Use Equations (3) and (4) to update and ;

- (3)

- Use Equation (5) to update ;

- (4)

- The criterion of precision convergence is , where is a small positive number over (0, 0.01] (or up to 1%). = 0.001 is used in this work. If or the iteration is completed. Otherwise return to Step (2) and continue until the convergence conditions are satisfied.

3.3. MCA for IMF Selection

- (1)

- The number of local extrema (minima and maxima) and the number of zero crossings must either be equal or differ at most by one in the whole data set;

- (2)

- The mean value of the envelope defined by the local extrema is zero.

3.3.1. Normalized Correlation Measure (NCM)

3.3.2. Mutual Information Analysis (MIA)

3.3.3. Envelope Correlation Spectrum (ECS)

3.4. Signal Reconstruction

4. Performance Evaluation Testing

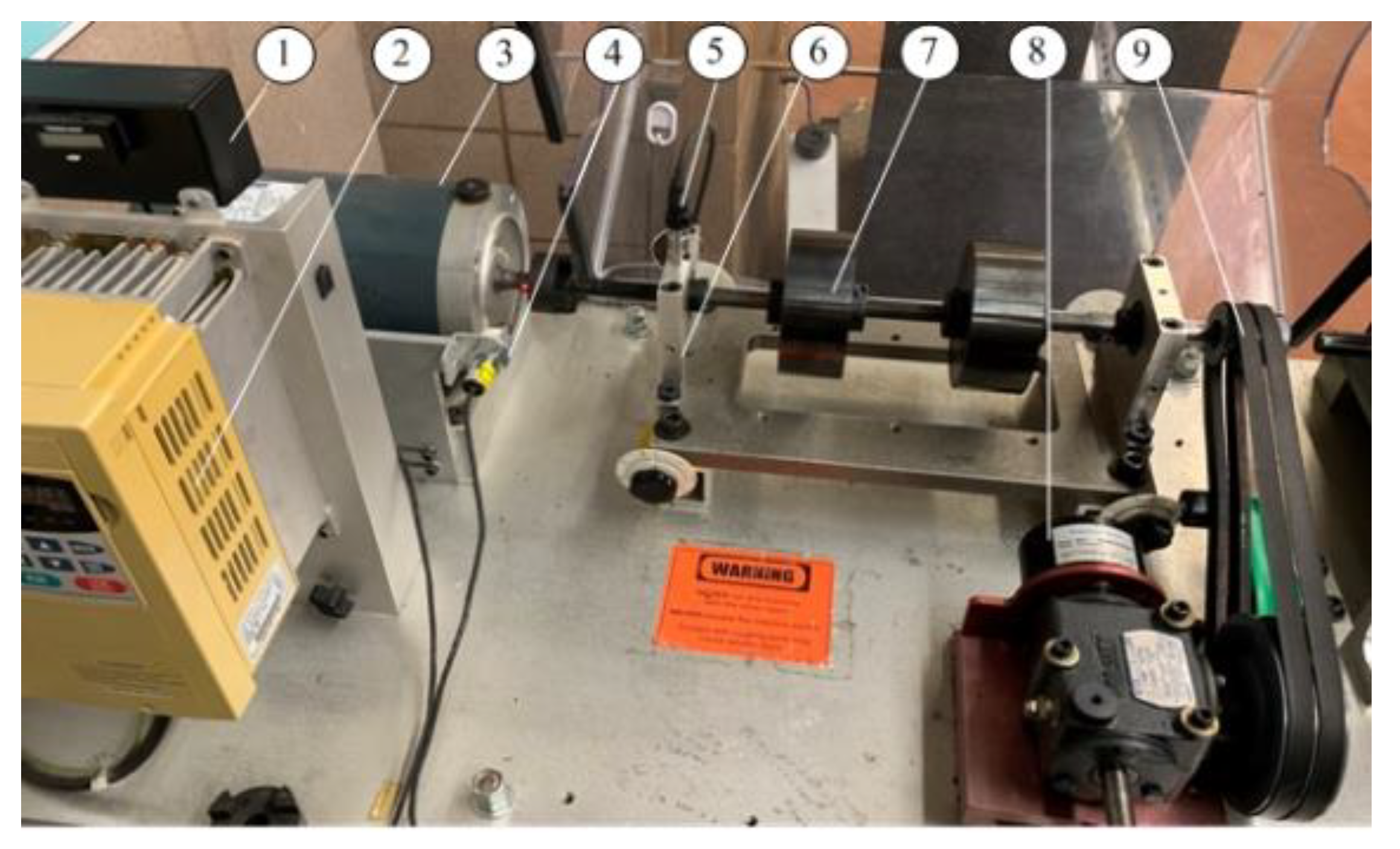

4.1. Experimental Setup

- (1)

- The first technique for comparison is the Synchronous Influence Index (SII) method [23], which can assess the complex impulsive fault component, will be applied for comparison, as specified as SII;

- (2)

- The second method used for comparison is the frequency band entropy (FBE) analysis technique [17]. Its IMF section is based on an optimal algorithm that contains abundant fault information;

- (3)

- The third method for comparison is the general Hilbert–Huang (HH) transform technique. It uses the common IMF selection method or to choose the first two IMFs for analysis, which is designated as HH-C;

- (4)

- The fourth method used for comparison uses the general HH transform technique, but using kurtosis to choose two IMFs (with the highest kurtosis values) for analysis, designated as HH-K;

- (5)

- The fifth method applied for comparison is designated as NME, which uses the highest correlation values of the sum of the NCM, MIA, and ECS values, rather than the comprehensive assessment of these values by using the proposed MCA technique.

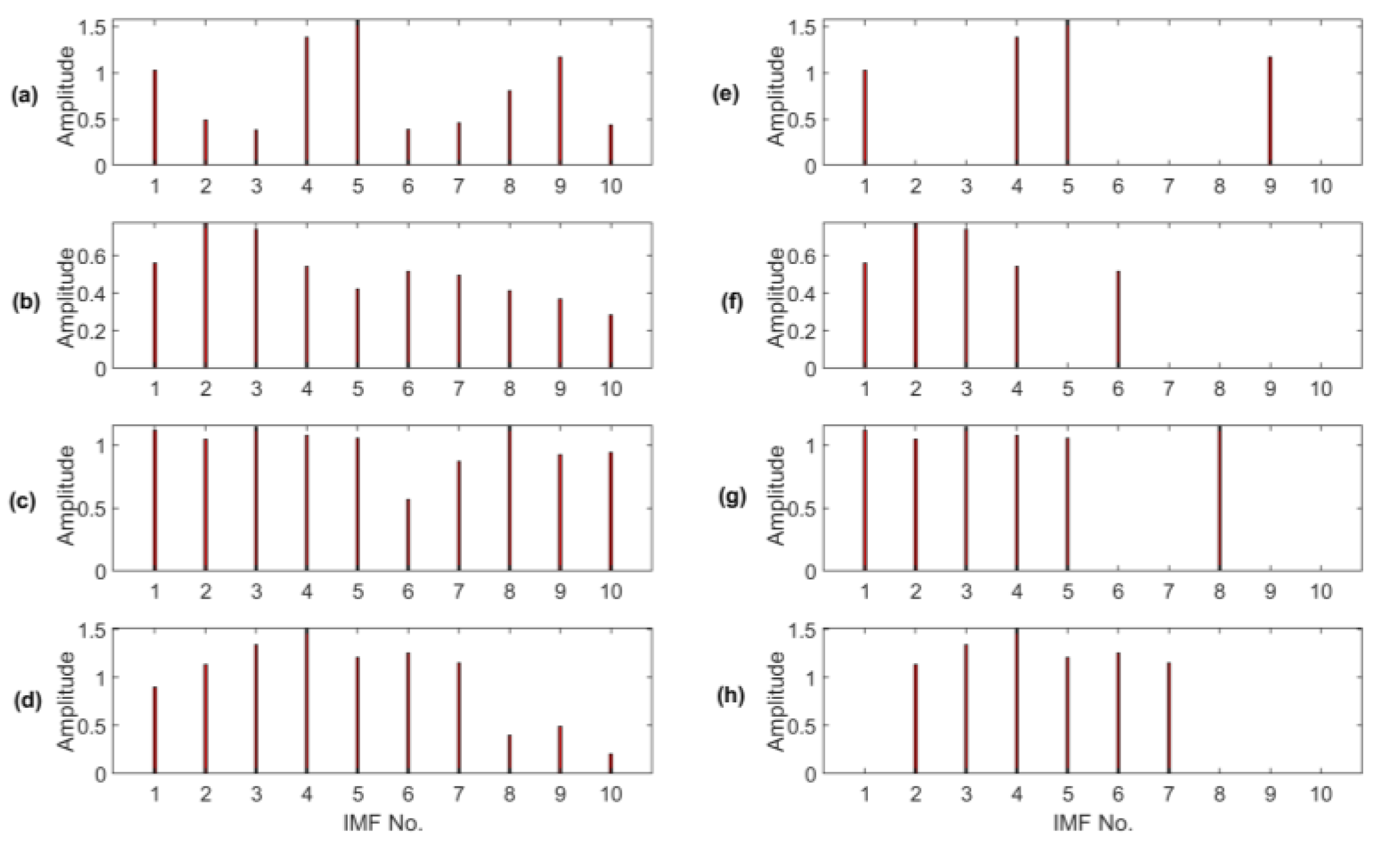

4.2. MCA Technique Implementation

4.3. Experimental Results Discussion

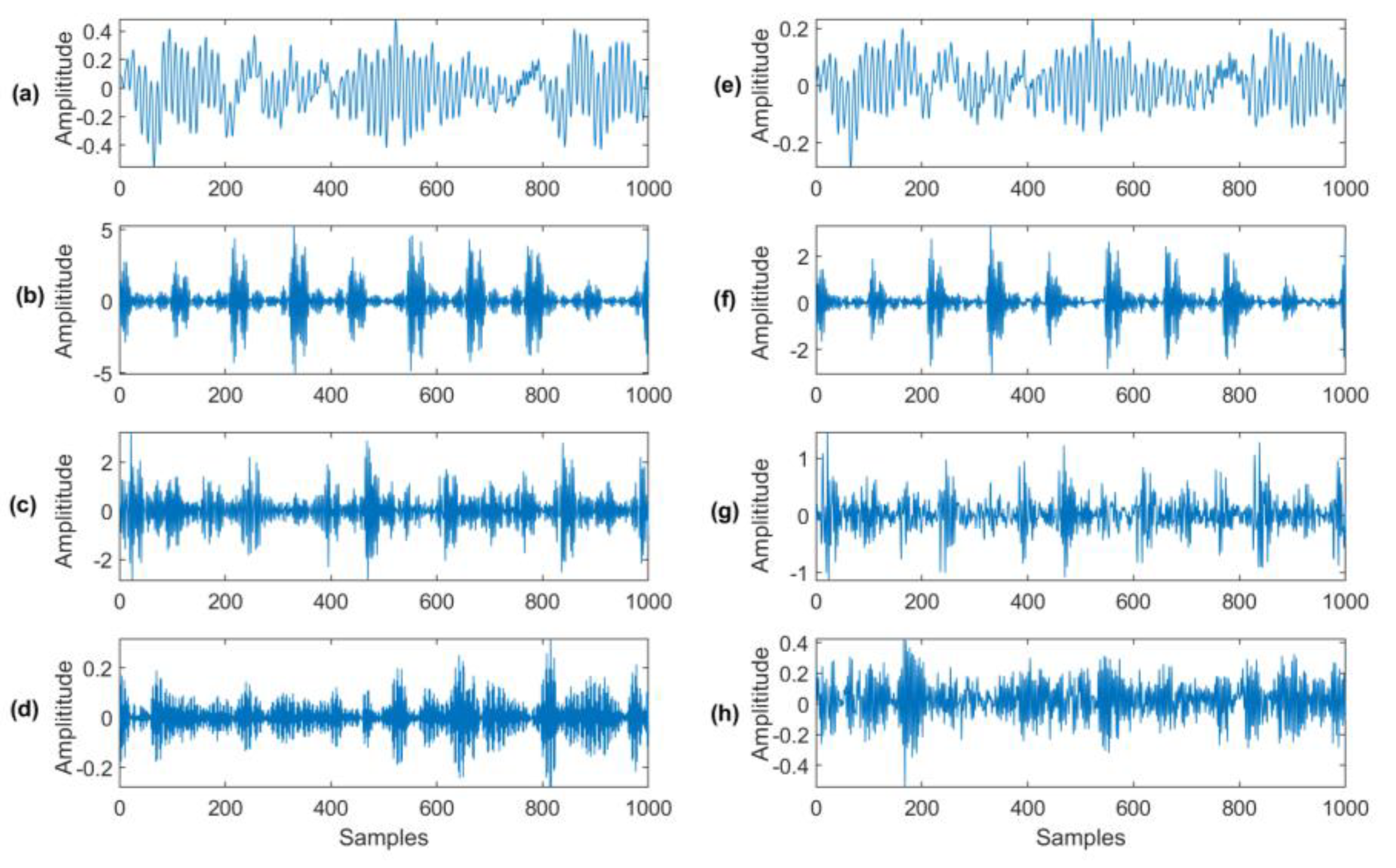

4.3.1. Healthy Bearing Condition Monitoring

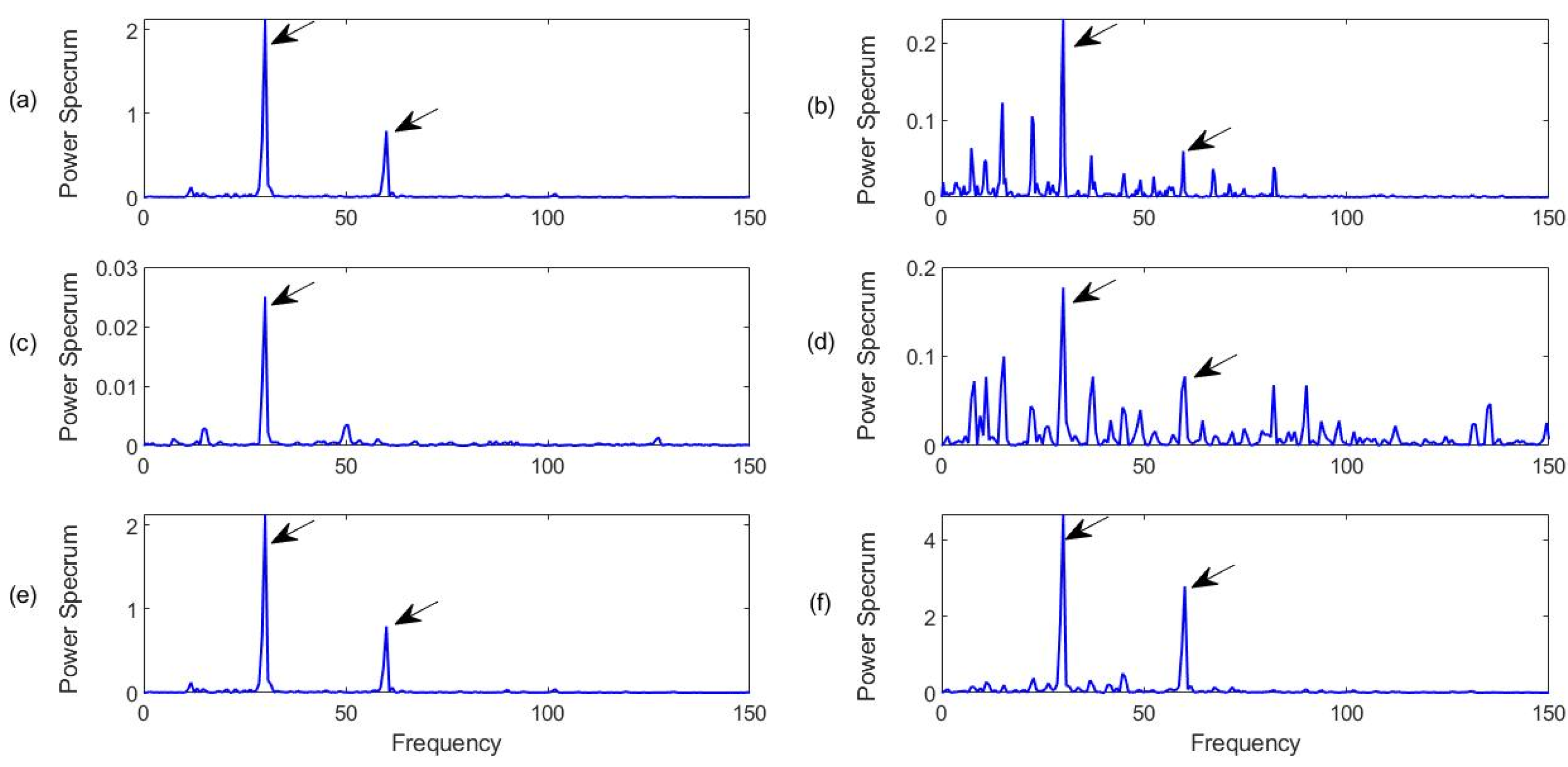

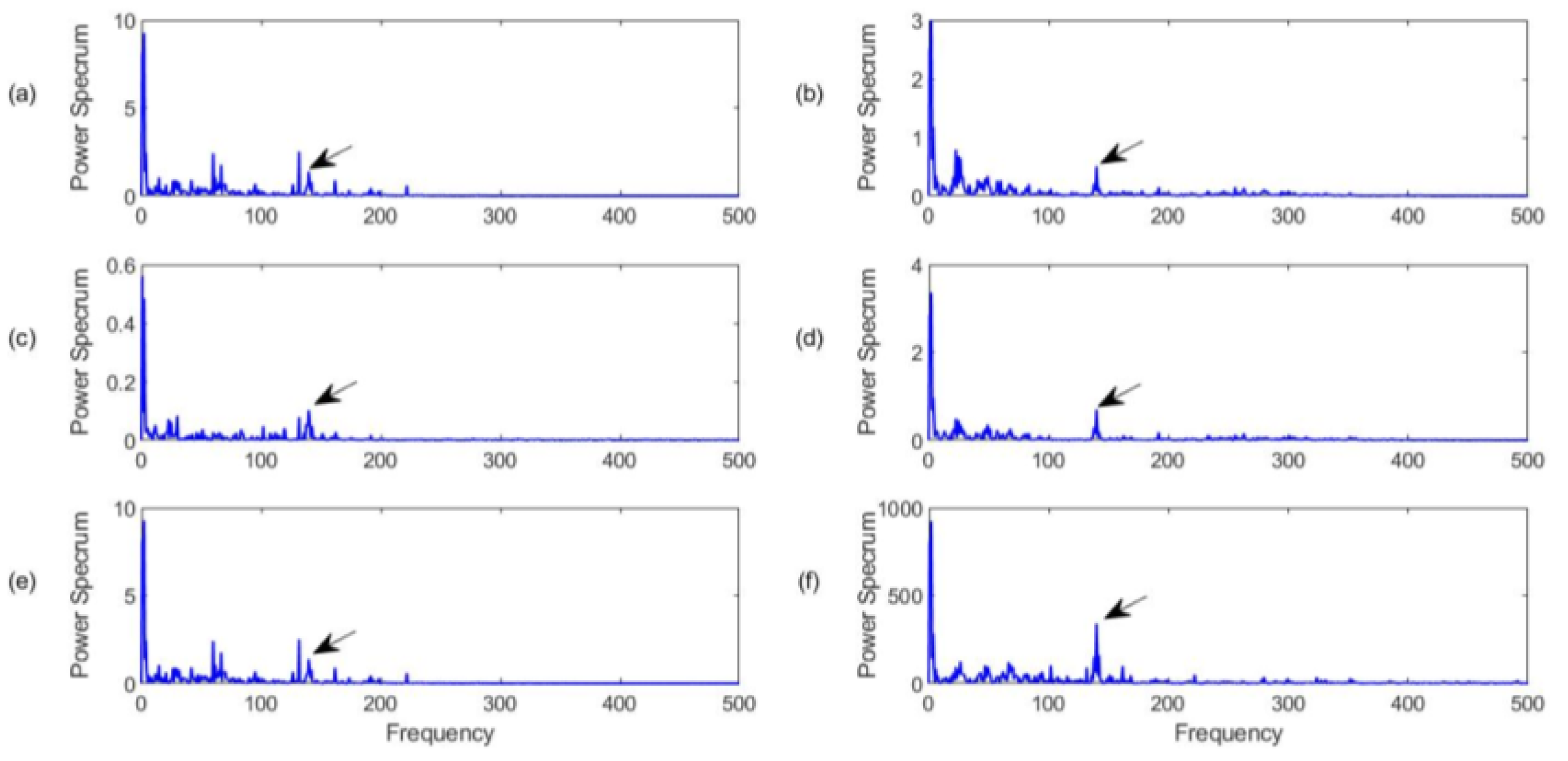

4.3.2. Outer Race Fault Detection

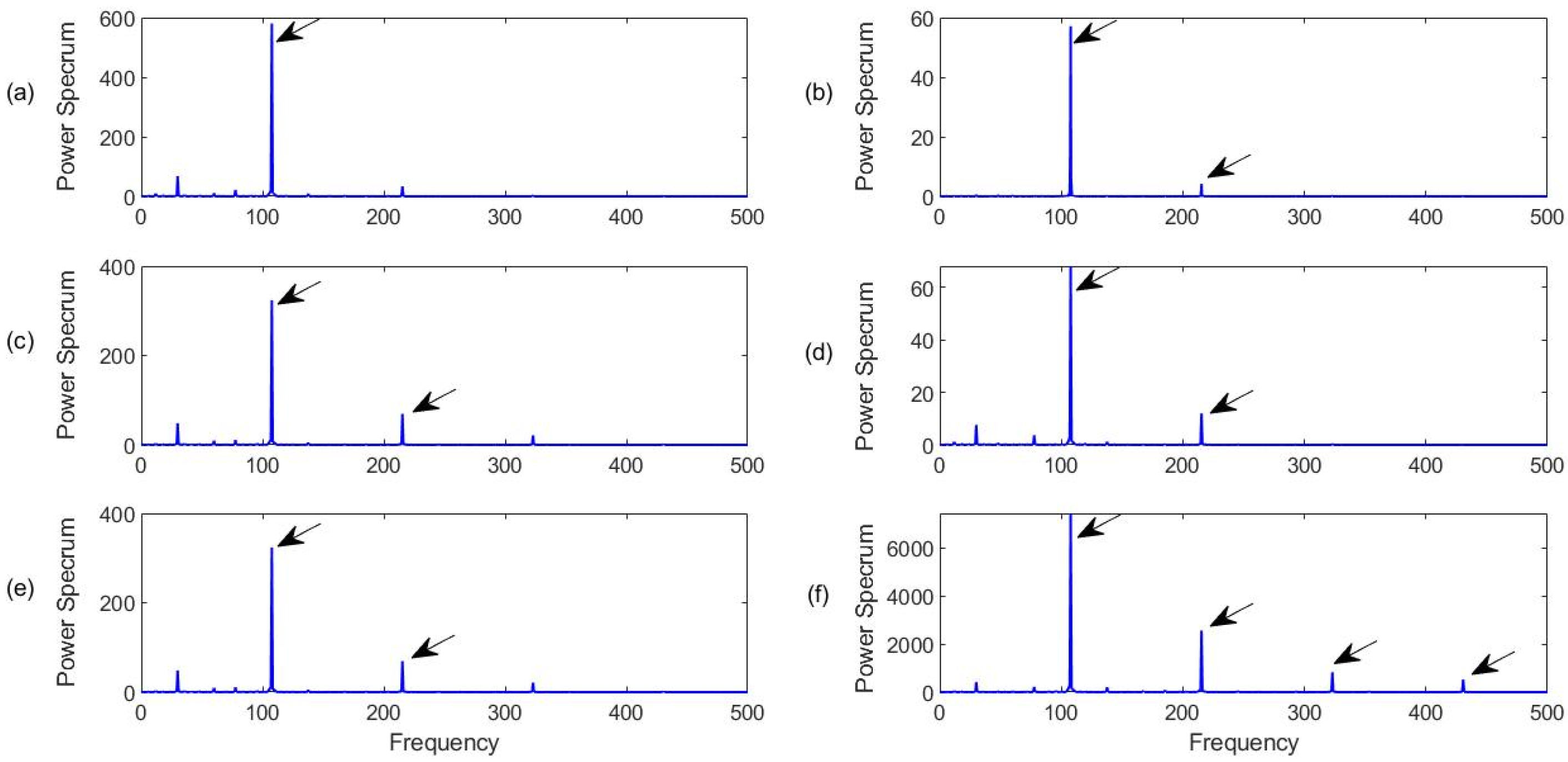

4.3.3. Inner Race Fault Detection

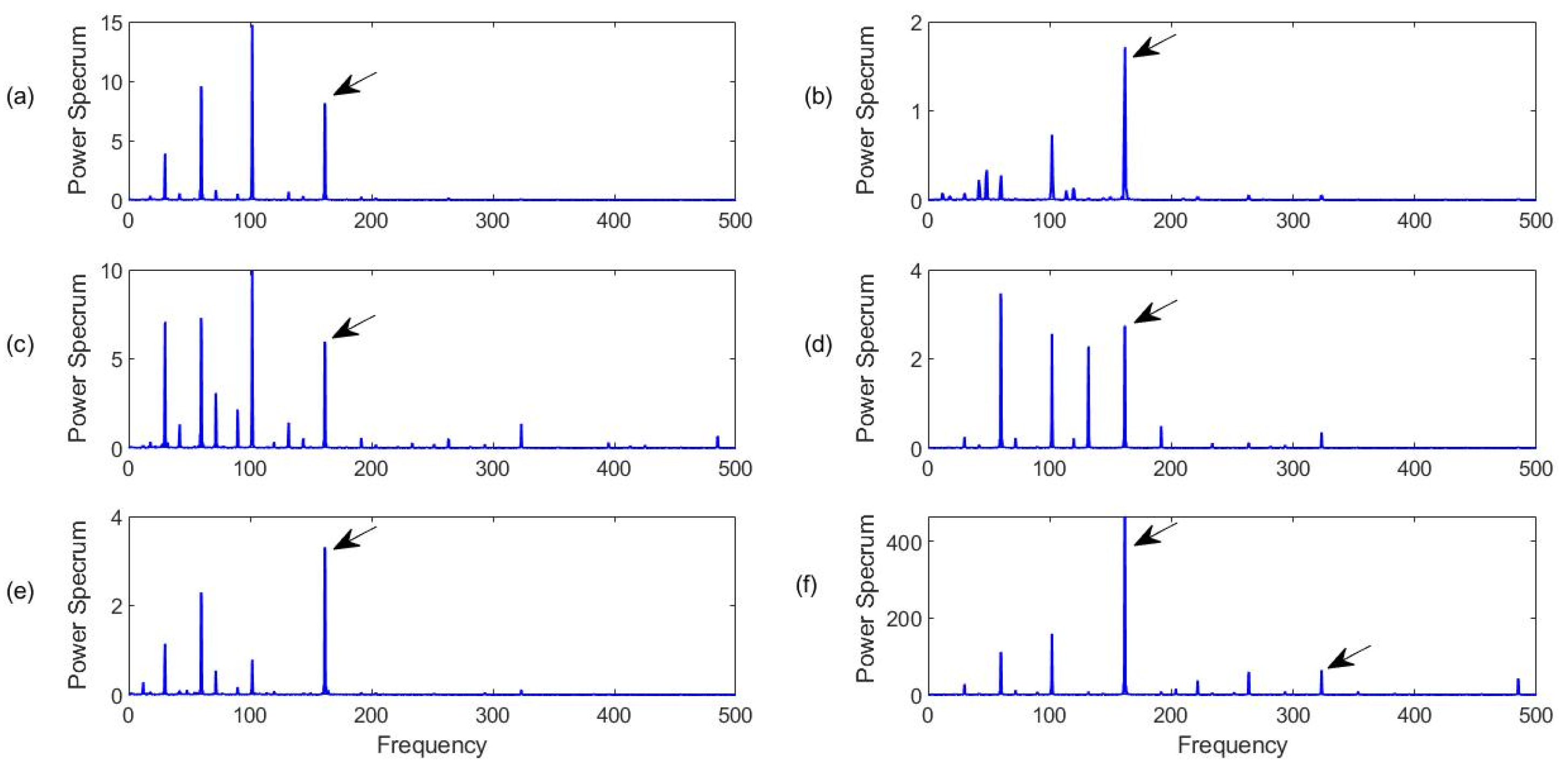

4.3.4. Rolling Element (Ball) Defect Detection

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, H.; Jiang, B. A review of fault detection and diagnosis for the traction system in high-speed trains. IEEE Trans. Intell. Transp. Syst. 2020, 21, 450–465. [Google Scholar] [CrossRef]

- Zhang, C.; Kordestani, H.; Shadabfar, M. A combined review of vibration control strategies for high-speed trains and railway infrastructures: Challenges and solutions. J. Low Freq. Noise Vib. Act. Control 2023, 42, 272–291. [Google Scholar] [CrossRef]

- Chen, H.T.; Jiang, B.; Ding, S.X.; Huang, B.A. Data-driven fault diagnosis for traction systems in high-speed trains: A survey, challenges, and perspectives. IEEE Trans. Intell. Transp. Syst. 2020, 23, 1700–1716. [Google Scholar] [CrossRef]

- Zhen, D.; Guo, J.; Xu, Y.; Zhang, H.; Gu, F. A novel fault detection method for rolling bearings based on non-stationary vibration signature analysis. Sensors 2019, 19, 3994. [Google Scholar] [CrossRef] [PubMed]

- Entezami, E.; Roberts, C.; Weston, P.; Stewart, E.; Amini, A.; Papaelias, M. Perspectives on railway axle bearing condition monitoring. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2020, 234, 17–31. [Google Scholar] [CrossRef]

- Liu, C.; Tan, J.; Huang, Z. Fault Diagnosis of Rolling Element Bearings Based on Adaptive Mode Extraction. Machines 2022, 10, 260. [Google Scholar] [CrossRef]

- Neupane, D.; Seok, J. Bearing fault detection and diagnosis using case western reserve university dataset with deep learning approaches: A review. IEEE Access 2020, 8, 93155–93178. [Google Scholar] [CrossRef]

- Simon, G.D.; Deivanathan, R. Early detection of drilling tool wear by vibration data acquisition and classification. Manuf. Lett. 2019, 21, 60–65. [Google Scholar] [CrossRef]

- Lang, X.; Steven, C.; Paolo, P. Rolling element bearing diagnosis based on singular value decomposition and composite squared envelope spectrum. Mech. Syst. Signal Process. 2021, 148, 107174. [Google Scholar]

- Zhang, S.; Su, L.; Gu, J.; Li, K.; Zhou, L.; Pecht, M. Rotating machinery fault detection and diagnosis based on deep domain adaptation: A survey. Chin. J. Aeronaut. 2023, 36, 45–74. [Google Scholar] [CrossRef]

- Ali, M. Condition monitoring and intelligent diagnosis of rolling element bearings under constant/variable load and speed conditions. Mech. Syst. Signal Process. 2021, 149, 107174. [Google Scholar]

- Deng, F.; Liu, C.; Liu, Y.; Hao, R. A hybrid SVD-based denoising and self-adaptive TMSST for high-speed train axle bearing fault detection. Sensors 2021, 21, 6025. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, X.; Kou, L.; Qin, Y.; Zhao, Y. A simple and fast guideline for generating enhanced/squared envelope spectra from spectral coherence for bearing fault diagnosis. Mech. Syst. Signal Process. 2019, 122, 754–768. [Google Scholar] [CrossRef]

- Zhang, B.; Miao, Y.; Lin, J.; Li, H. Weighted envelope spectrum based on the spectral coherence for bearing diagnosis. ISA Trans. 2021, 123, 398–412. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Wang, X.; Zhu, Y.; Yuan, W.; Hu, Y. Time-frequency transformer with shifted windows for journal bearing-rotor systems fault diagnosis under multiple working conditions. Meas. Sci. Technol. 2023, 34, 085121. [Google Scholar] [CrossRef]

- López-Estrada, F.; Rotondo, D.; Valencia-Palomo, G. A review of convex approaches for control, observation and safety of linear parameter varying and Takagi-Sugeno systems. Processes 2019, 7, 814. [Google Scholar] [CrossRef]

- Li, H.; Liu, T.; Wu, X.; Chen, Q. An optimized VMD method and its applications in bearing fault diagnosis. Measurement 2020, 166, 108185. [Google Scholar] [CrossRef]

- Jin, Z.; He, D.; Wei, Z. Intelligent fault diagnosis of train axle box bearing based on parameter optimization VMD and improved DBN. Eng. Appl. Artif. Intell. 2022, 110, 104713. [Google Scholar] [CrossRef]

- Jin, Z.; He, D.; Ma, R.; Zou, X.; Chen, Y.; Shan, S. Fault diagnosis of train rotating parts based on multi-objective VMD optimization and ensemble learning. Digit. Signal Process. 2022, 121, 103312. [Google Scholar] [CrossRef]

- Wei, D.; Jiang, H.; Shao, H.; Li, X.; Lin, Y. An optimal variational mode decomposition for rolling bearing fault feature extraction. Meas. Sci. Technol. 2019, 30, 055004. [Google Scholar] [CrossRef]

- Fang, C.; Chen, Y.; Deng, X.; Lin, X.; Han, Y.; Zheng, J. Denoising method of machine tool vibration signal based on variational mode decomposition and Whale-Tabu optimization algorithm. Scientific 2023, 13, 1505. [Google Scholar]

- Zhang, C.; Wang, Y.; Deng, W. Fault diagnosis for rolling bearings using optimized variational mode decomposition and resonance demodulation. Entropy 2020, 22, 739. [Google Scholar] [CrossRef]

- He, X.; Zhou, X.; Yu, W.; Hou, Y.; Mechefske, C. Adaptive variational mode decomposition and its application to multi-fault detection using mechanical vibration signals. ISA Trans. 2020, 111, 360–375. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Bao, X.; Tu, X.; Li, F.; Li, K. An adaptive spectral kurtosis method and its application to fault detection of rolling element bearings. IEEE Trans. Instrum. Meas. 2020, 69, 739–750. [Google Scholar] [CrossRef]

- Kumar, A.; Tang, H.; Vashishtha, G.; Xiang, J. Noise subtraction and marginal enhanced square envelope spectrum (MESES) for the identification of bearing defects in centrifugal and axial pump. Mech. Syst. Signal Process. 2022, 165, 108366. [Google Scholar] [CrossRef]

- Bao, W.; Tu, X.; Hu, Y.; Li, F. Envelope spectrum L-kurtosis and its application for fault detection of rolling element bearings. IEEE Trans. Instrum. Meas. 2019, 69, 1993–2002. [Google Scholar] [CrossRef]

- Fan, J.; Qi, Y.; Gao, X.; Li, Y.; Wang, L. Compound fault diagnosis of rolling element bearings using multipoint sparsity–multipoint optimal minimum entropy deconvolution adjustment and adaptive resonance-based signal sparse decomposition. J. Vib. Control 2020, 22, 1212–1230. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, N.; Li, N.; Du, W.; Wang, J. A new fault diagnosis method based on adaptive spectrum mode extraction. Struct. Health Monit. 2021, 20, 3354–3370. [Google Scholar] [CrossRef]

- Liu, H.; Xiang, J. A strategy using variational mode decomposition, L-kurtosis and minimum entropy deconvolution to detect mechanical Faults. IEEE Access 2019, 7, 70564–70573. [Google Scholar] [CrossRef]

- Dibai, A.; Hassannejad, R.; Ettefagh, M.; Ehghaghi, M. Incipient fault diagnosis of bearings based on parameter-optimized VMD and envelope spectrum weighted kurtosis index with a new sensitivity assessment threshold. ISA Trans. 2021, 114, 413–443. [Google Scholar]

- Liu, Y.; Zhan, J.; Wang, Y.; Wang, C.; Zhang, F. An effective procedure for extracting mode shapes of simply-supported bridges using virtual contact-point responses of two-acle vehicles. Structures 2023, 48, 2082–2097. [Google Scholar] [CrossRef]

- Dong, L.; Chen, Z.; Hua, R.; Hu, S.; Fan, C.; Xiao, X. Research on diagnosis method of centrifugal pump rotor faults based on IPSO-VMD and RVM. Nucl. Eng. Technol. 2023, 55, 827–838. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, Q.; Wei, X.; Zhang, J. Variational multi-harmonic mode extraction for characterizing impulse envelope of bearing failures. ISA Trans. 2022, 132, 524–543. [Google Scholar] [CrossRef] [PubMed]

| Bearing Type | MB ER-10K |

|---|---|

| Inside diameter (mm) | 25.001 |

| Outside diameter (mm) | 51.999 |

| Thickness(mm) | 15.001 |

| Pitch diameter (mm) | 39.034 |

| Rolling element diameter (mm) | 7.940 |

| Number of rolling elements | 9 |

| Contact angle (degrees) | 0 |

| Bearing Condition | Characteristic Frequency (Hz) |

|---|---|

| Normal/healthy bearing | fr |

| Outer race defect | 3.58 fr |

| Inner race defect | 5.41 fr |

| Rolling element defect | 4.71 fr |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Zhang, S.; Wang, W. A New Monitoring Technology for Bearing Fault Detection in High-Speed Trains. Sensors 2023, 23, 6392. https://doi.org/10.3390/s23146392

Sun S, Zhang S, Wang W. A New Monitoring Technology for Bearing Fault Detection in High-Speed Trains. Sensors. 2023; 23(14):6392. https://doi.org/10.3390/s23146392

Chicago/Turabian StyleSun, Sitong, Sheng Zhang, and Wilson Wang. 2023. "A New Monitoring Technology for Bearing Fault Detection in High-Speed Trains" Sensors 23, no. 14: 6392. https://doi.org/10.3390/s23146392

APA StyleSun, S., Zhang, S., & Wang, W. (2023). A New Monitoring Technology for Bearing Fault Detection in High-Speed Trains. Sensors, 23(14), 6392. https://doi.org/10.3390/s23146392