Development of KOSEN Weather Station and Provision of Weather Information to Farmers

Abstract

1. Introduction

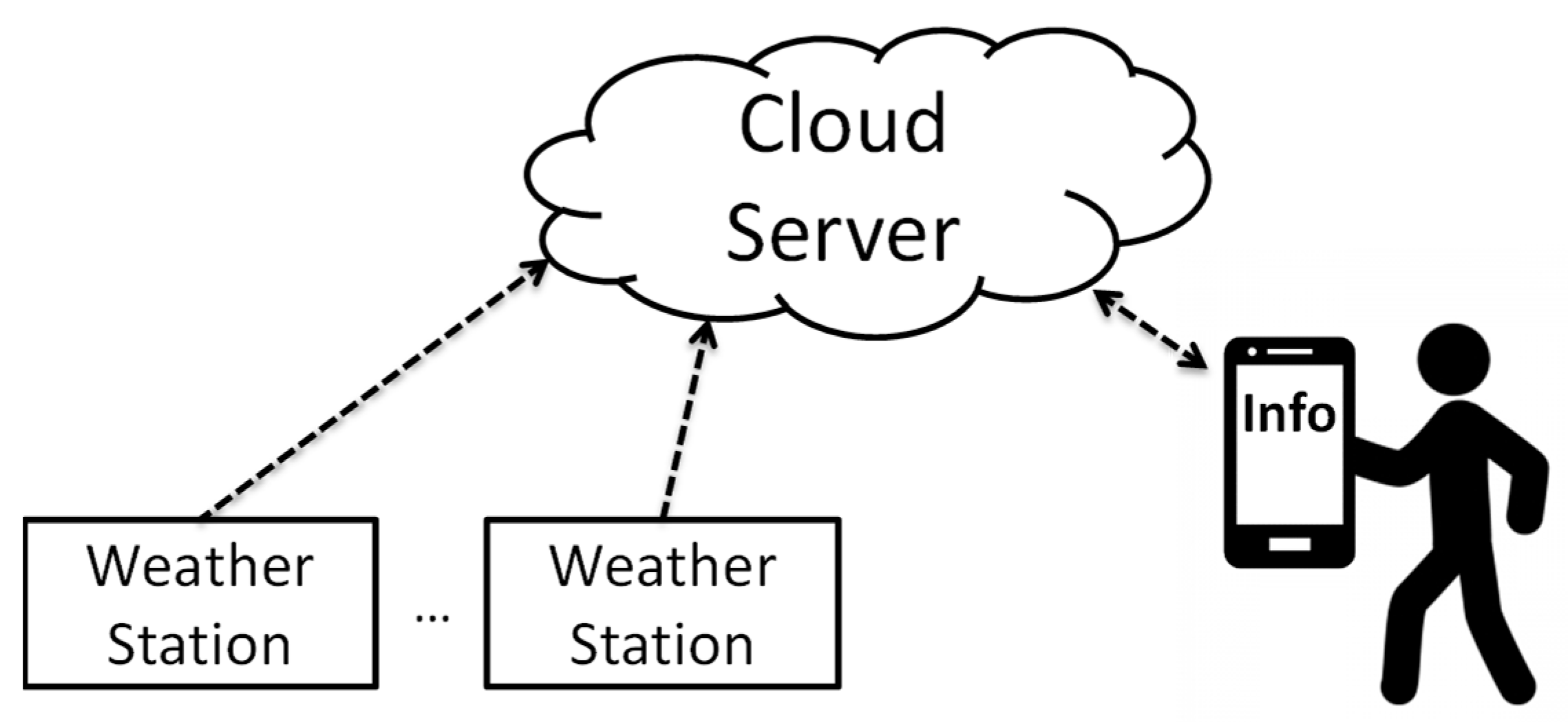

- Development of weather station

- Cloud server construction.

- The server stores weather information.

- Provision of weather information.

2. Related Work and Methodology

2.1. Related Work Methodology

2.2. Methodology

- Problem definition: Meteorological information is applicable to the monitoring of growth, prediction of harvest time, prevention of pests and diseases, dealing with climate change and abnormal weather, and prediction of frost damage. The weather information acquisition, server construction, and provision of weather information to farmers are important elements of work in agricultural fields. Nevertheless, studies of WSs that are inexpensive, precise, and capable of obtaining stable weather information over a long period of time in local areas are lacking. Moreover, studies of the provision of reliable and easy-to-understand weather information needed by farmers are insufficient, as are studies examining alert notifications at high or low temperatures. In particular, no reported study has considered the three elements above simultaneously.

- Opinions that include the approach: To grasp the current situation in agricultural fields, we conducted literature searches and field visits. We also administered a questionnaire survey to farmers and JA staff members about the types of weather information necessary for agricultural work and the weather information that should be provided to users. Questionnaire items for WS include the crop type, the type of weather information required (sensor type), the period of use, the price, the size, and the installation location. Based on questionnaire survey results and the knowledge of the authors, the specifications used to implement the WS were determined. The questionnaire items related to information provision include the crop types, pull-type weather information, push-type weather information, frequently used places, and devices for providing information. After summarizing the WS specifications, server construction method, and information provision method based on the results of the questionnaire survey and the authors’ knowledge, methods and steps to resolve difficulties in the next “instrument” are discussed.

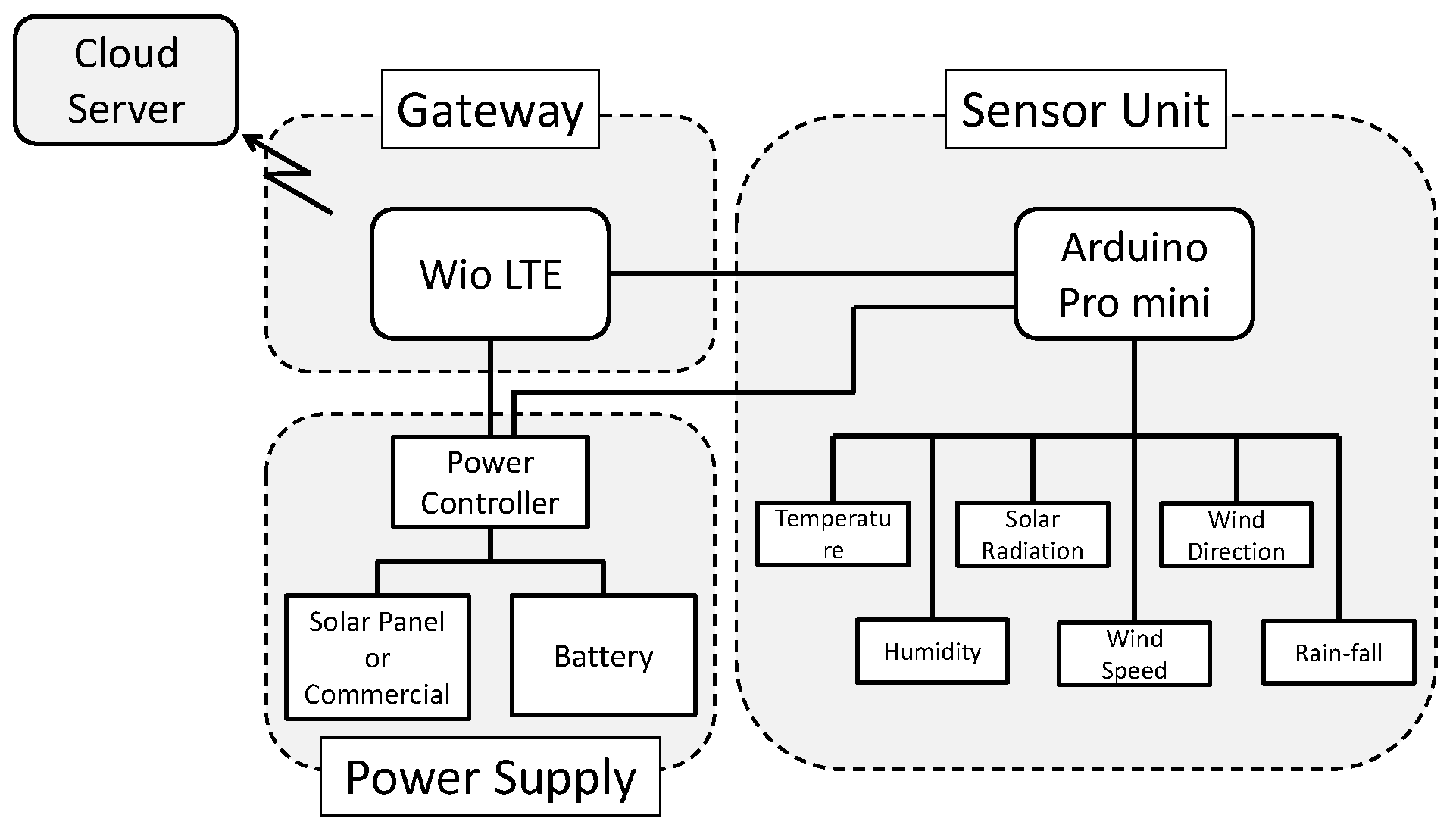

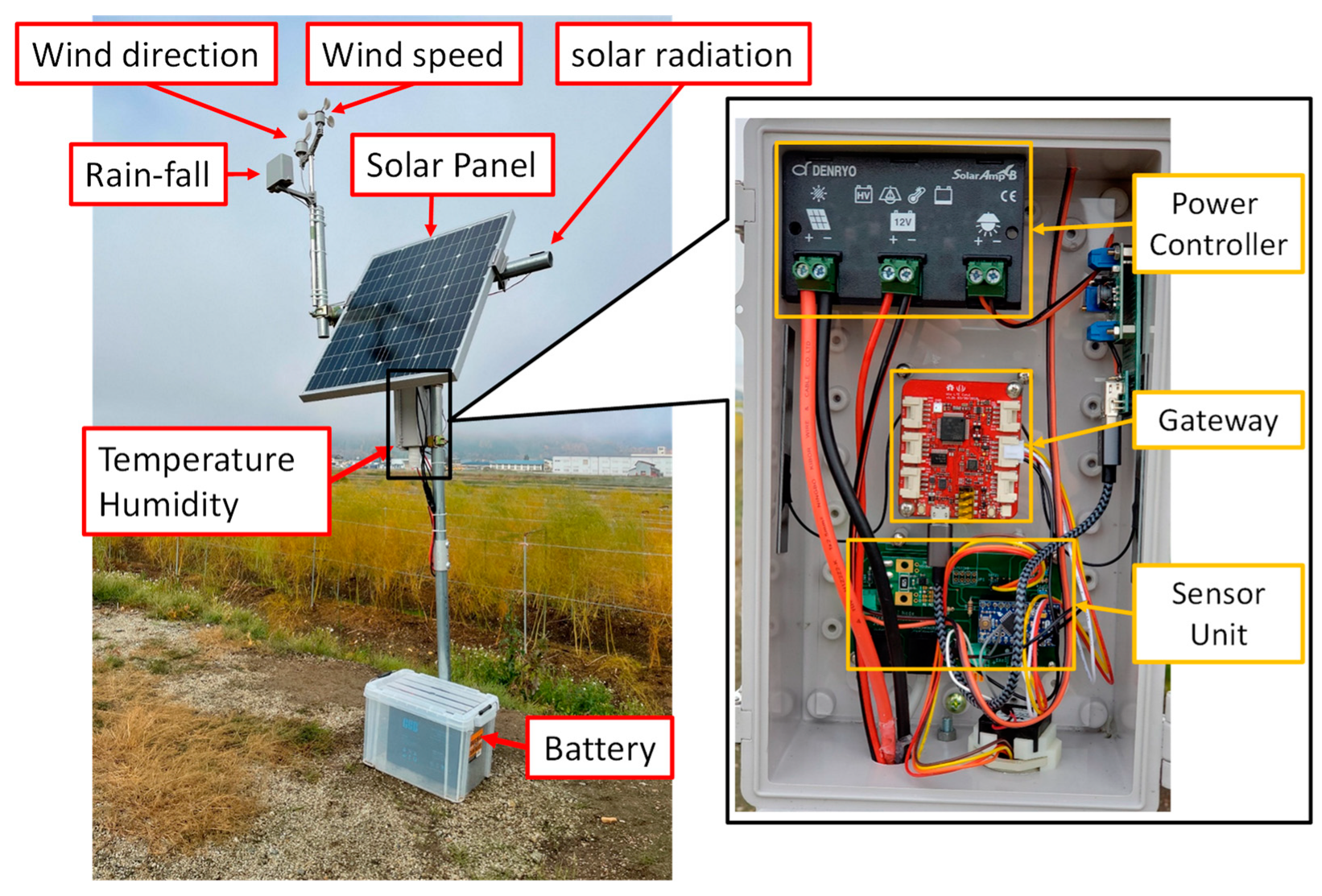

- Instrument: The WS, server, and information provision are described hereinafter in that order. The questionnaire survey results and the authors’ knowledge were summarized to support the development of a WS that can acquire weather information stably over a long period of time. We describe the various components, including sensors, microcomputers, communication devices, circuit boards, and power supplies, in addition to power consumption, WS size, and server construction. Weather information necessary for agricultural work was investigated. Subsequently, we considered the measurement precision, price, and measurement range of sensors for weather information of each type. We examined whether the microcomputer can measure various sensors easily, whether the microcomputer can operate stably for a long time, and so on. To ensure stable transmission of meteorological information to the server at any location, one must consider the communication device and the connection method between the microcomputer and the communication device. We discuss the circuit board design. A durable circuit board that is useful for a long time in indoor and outdoor environments must be designed. We discussed the WS power consumption. One must consider where power is secured and where it is not. In places where power is secured, we can use a USB adapter. However, in places where power is not secured, solar panels and batteries must be considered for use to mitigate some of the power consumption of a WS. Because Japan has a rainy season, securing a power source that is useful during this period is necessary. The WS size must be sufficiently small to be installed easily by farmers. In addition, after WS is installed, the WS should not interfere with farm work after installation. We discuss items to be considered when building a server. Building a server to accumulate weather information uploaded from the WS and to provide weather information to users is necessary. There are servers of two types: on-premises and cloud servers. Moreover, the initial cost and running cost must be considered. Information provision to farmers is described. Results of the questionnaire survey, field visits, and the authors’ knowledge based on literature research are summarized. In particular, devices for providing information, the kinds of pull-type information, and the kinds of push-type information in weather information provision are summarized. After summarization of the points above, we built a prototype of the WS, constructed a server, created a webpage for providing information, and provided alerts.

- Validation: For WS validation, we conducted basic and field experiments. By basic experimentation, we validated whether this prototype is useful in a real environment. The WS and the reference WS were installed at the same place. The precision of the sensors was compared. In case of WS failure, the causes were listed. Countermeasures were taken. We resolved the difficulties that occurred in the basic experiment and conducted the field experiment, which is a hot and humid environment. Using field experiments, we investigated whether the WS can operate stably and continuously for a long time in the real environment. We conducted field experiments in four places (fields and greenhouses with power supply, and fields and greenhouses without power supply) to verify whether the WS can operate for a long time stably and continuously. Then, in cases of WS failure, the causes were listed. Countermeasures were taken. For validation of the information provision, we set up WSs in the fields and validated whether the pull-type and push-type weather information can be provided reliably to farmers and JA staff. The validation method involved a questionnaire survey among agricultural workers and JA staff. For the pull-type information provision, we summarized the readability of the webpage, types of weather information, text size, and graph size. In the case of push-type information provision, we summarized whether alert notifications were sent reliably, whether alert notifications continued to be sent until users confirmed them, how to stop alert notifications, and how to reset alert notifications. We made a list of improvements from the questionnaire survey and solved them by repeating the same process as in “Instruments” again until all the improvements were clarified.

- Synthesis/analysis process: In cases of WS failure, we retrieved them, analyzed the causes of failure from both hardware and software aspects, and resolved the related difficulties. During the basic experiment, we conducted the operation check of the prototype and analyzed hardware and software difficulties. For hardware issues, we analyzed the sensor precision, the soldering of the board, and the solar panel and battery capacity in places where power cannot be secured. Then, we discussed solutions. For software issues, we analyzed the microcontroller program, sensor measurement by the microcontroller, and whether or not the measurement data can be uploaded to a server, and discussed solutions. In the field experiment, we analyzed hardware and software problems to verify that the WS can operate stably and continuously for a long time. Hardware difficulties included failures of each sensor, short-circuit generation because of overcurrent, and corrosion and peeling off of soldered joints in a hot and humid environment. Software difficulties included the occurrence of overflow and microcontroller shutdown because of sensor failure. The solutions to these difficulties were discussed. Considering the questionnaire survey results and the authors’ knowledge, the weather information provision and alert notifications were improved. The problems described above were solved by repeating the same process as in “Instrument” and “Validation”.

3. KOSEN Weather Station and Provision of Weather Information to Farmers

3.1. System Overview

3.2. KOSEN Weather Station

3.3. Cloud Server

4. Basic Experiments

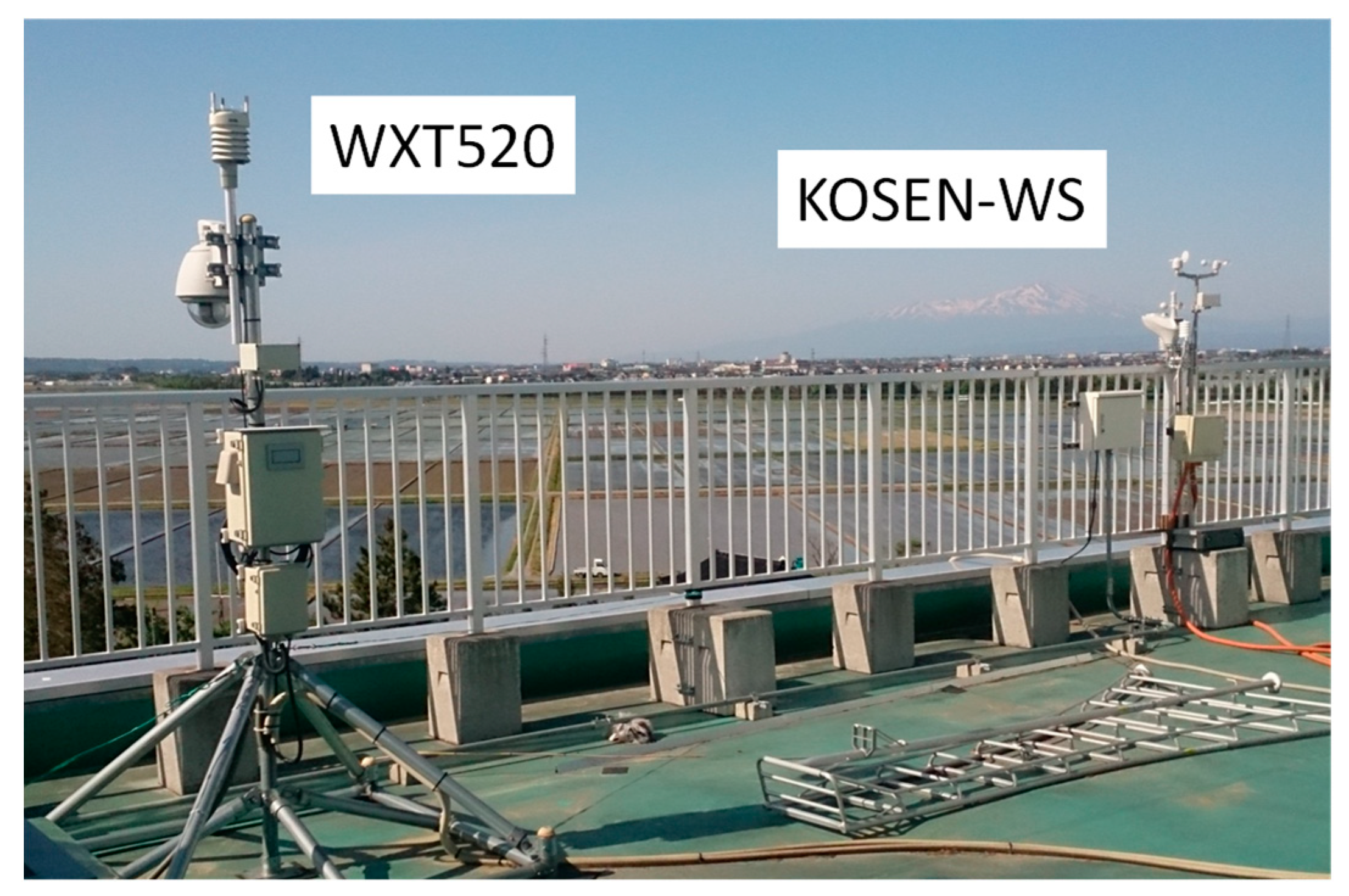

4.1. Experiment Method

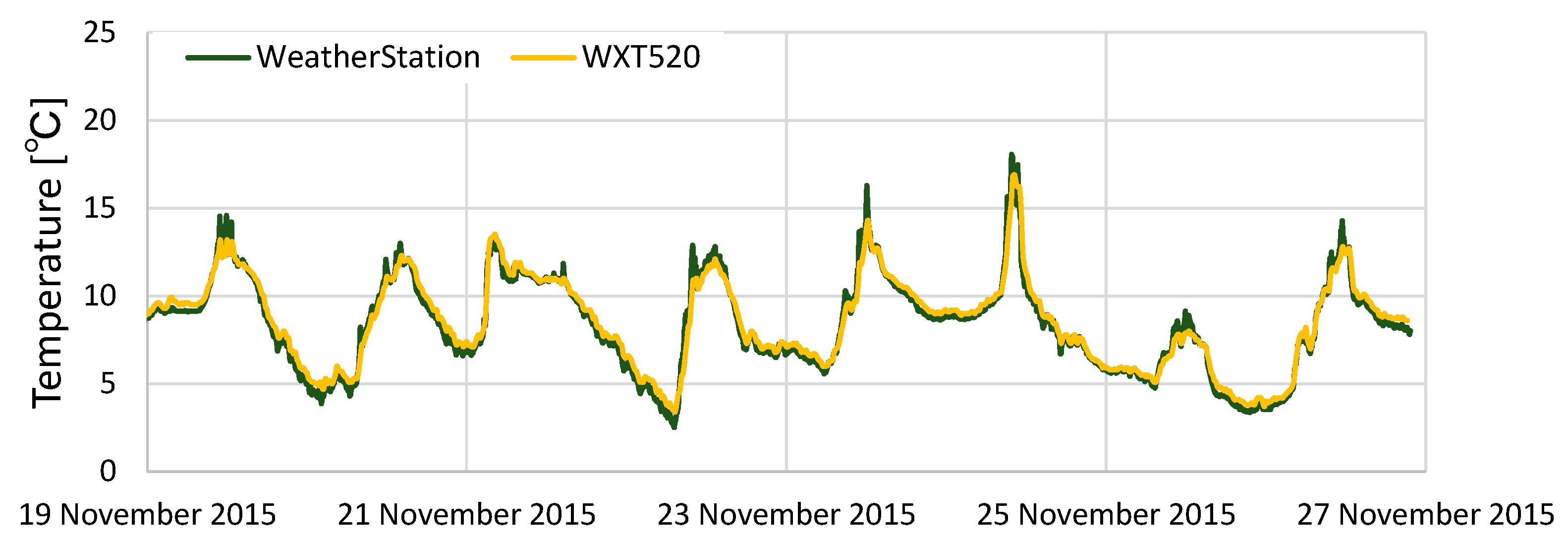

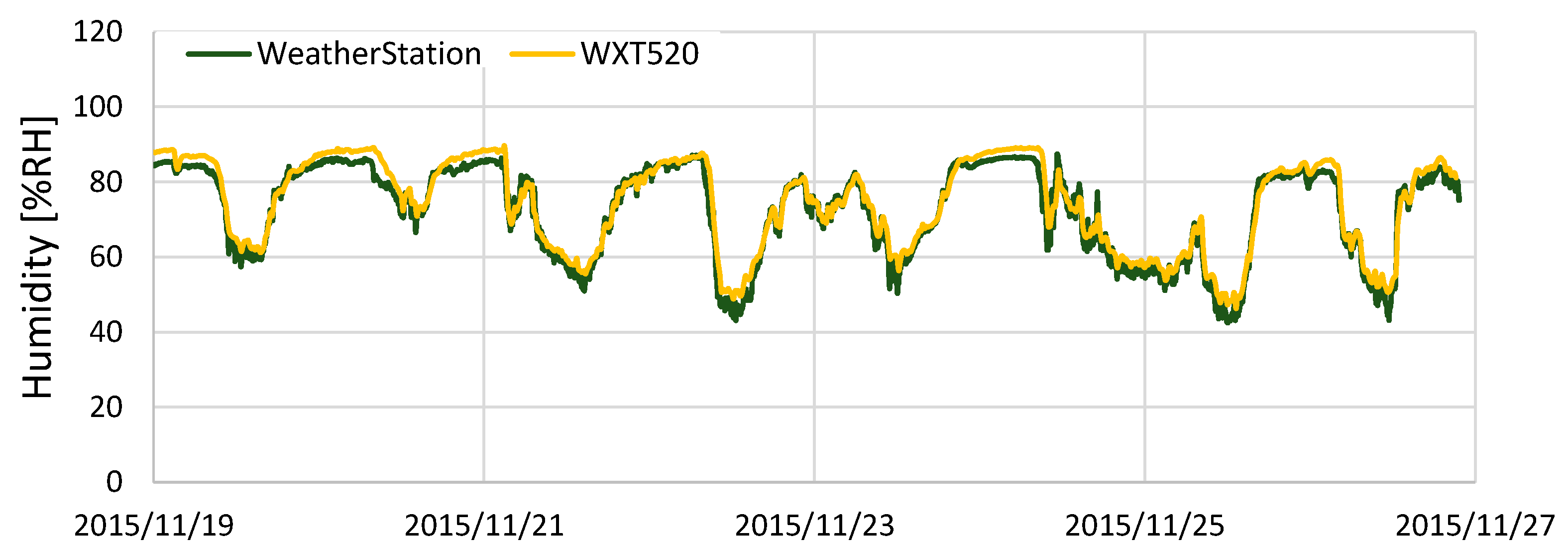

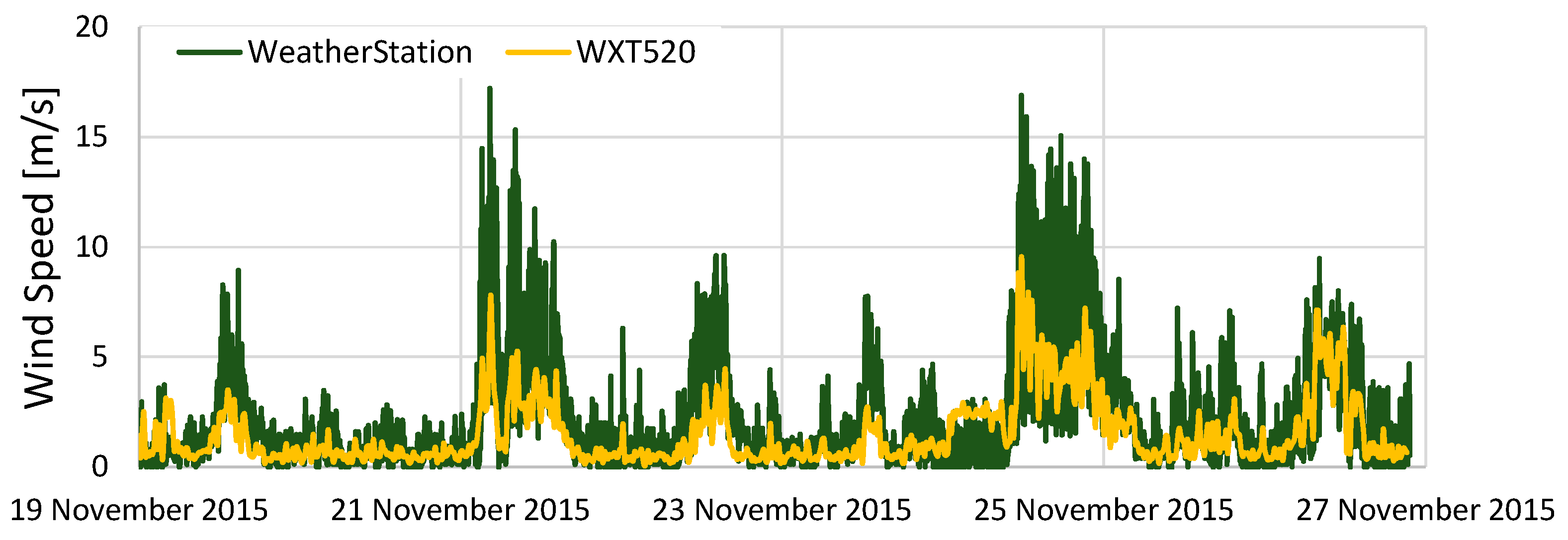

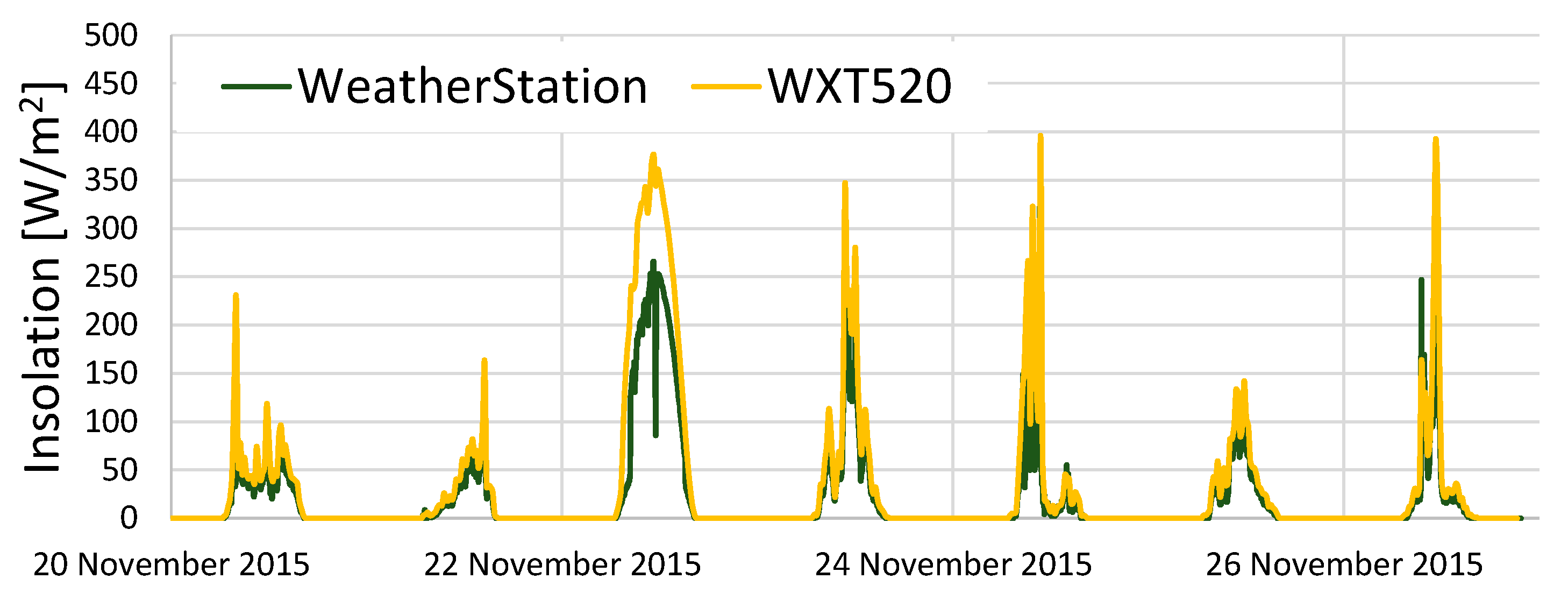

4.2. Experimental Results

5. Field Experiments

5.1. Experiment Method

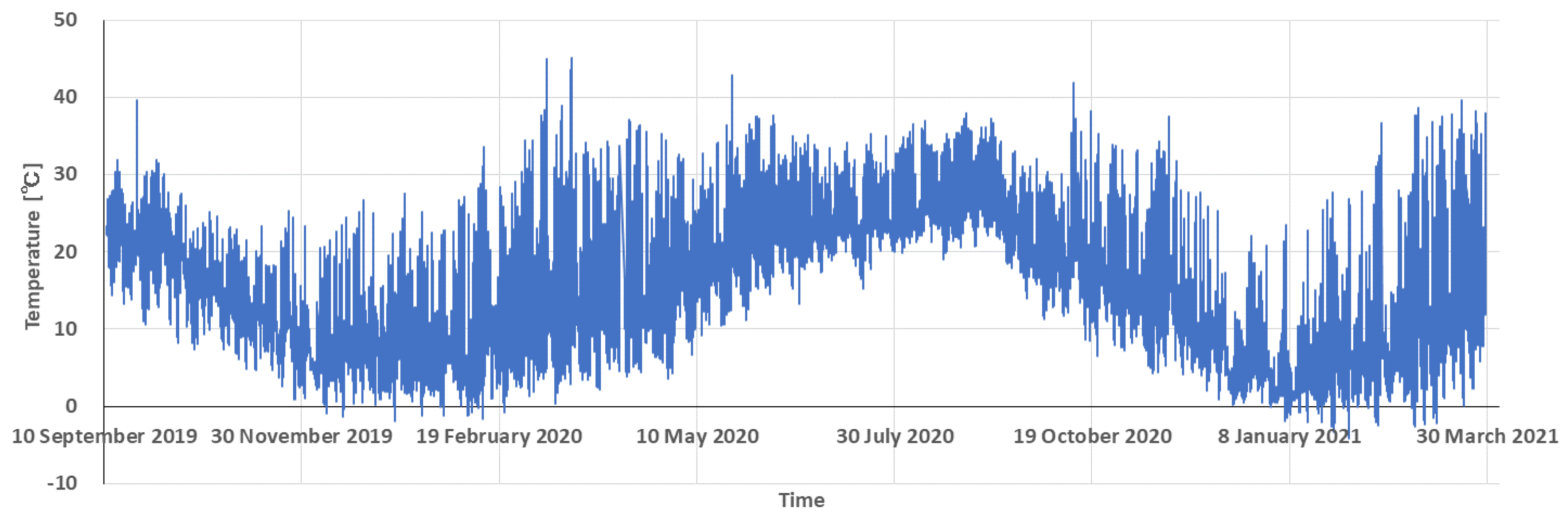

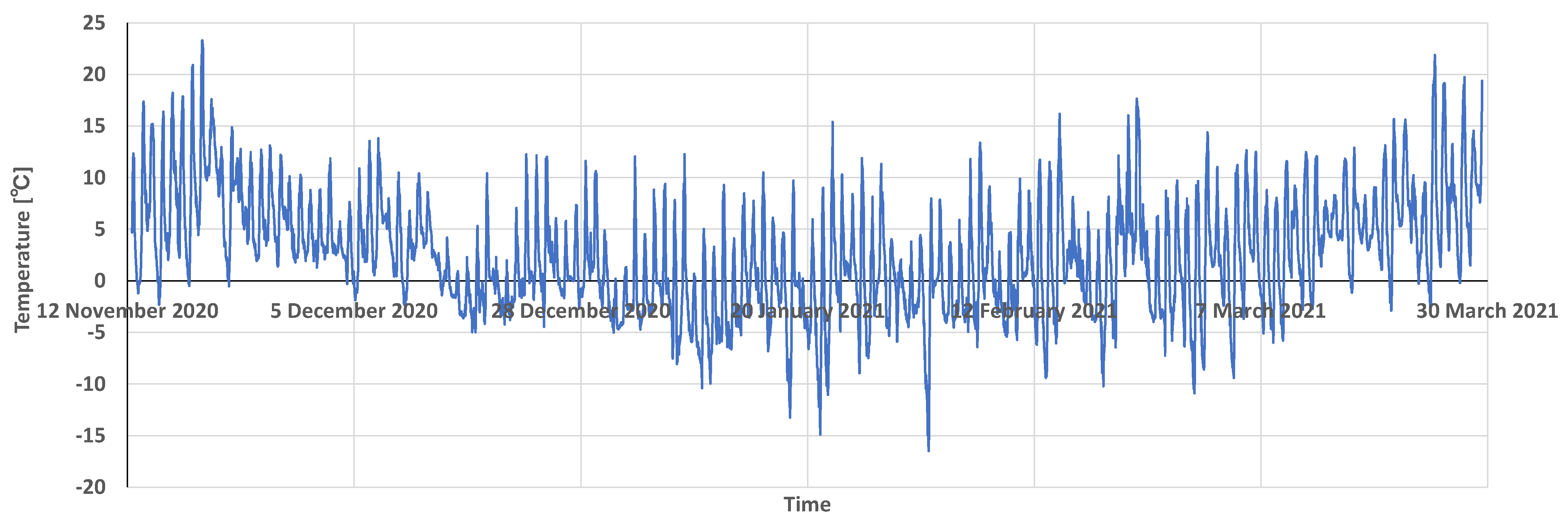

5.2. Experimental Results

5.3. Discussion

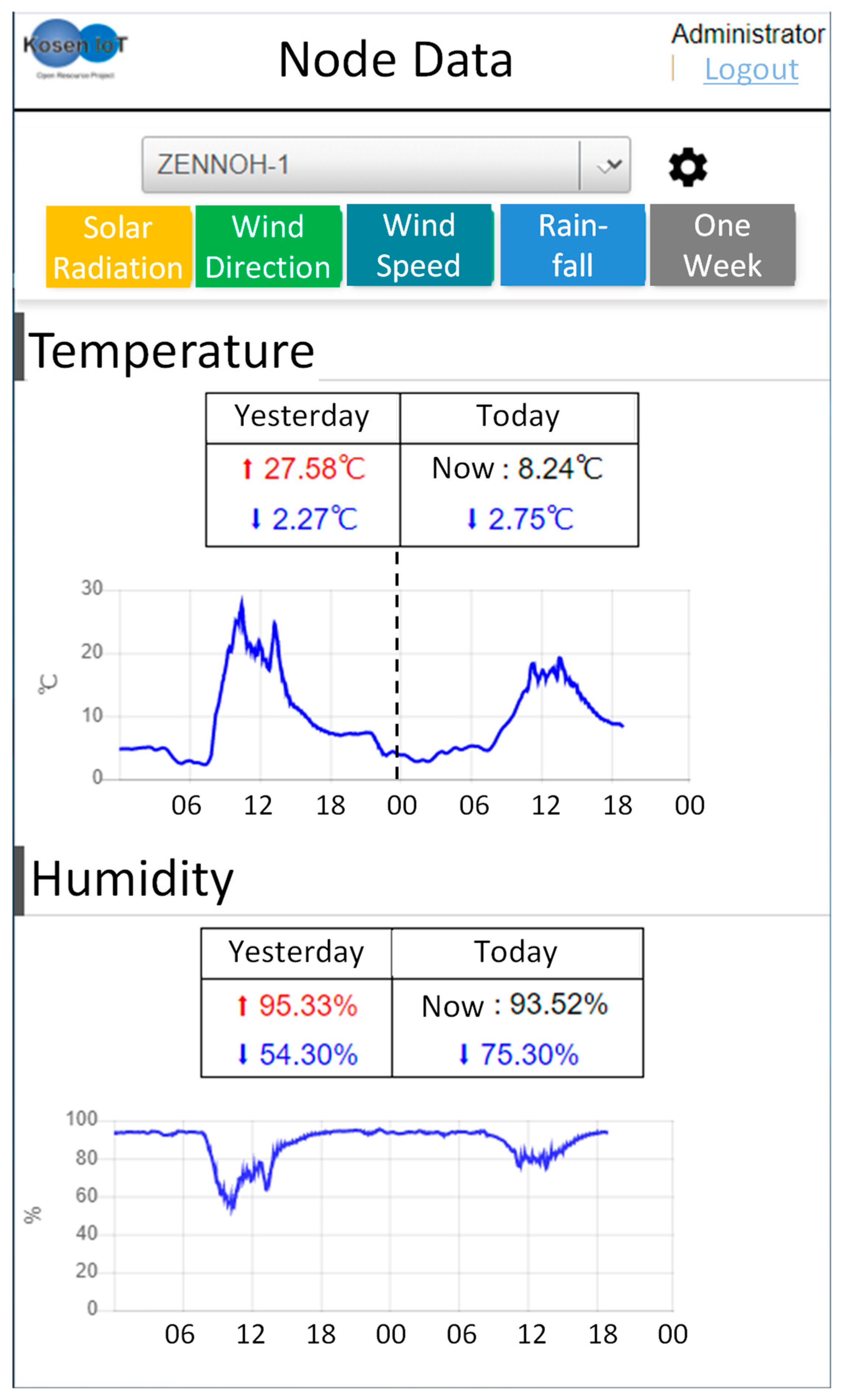

6. Provision of Weather Information to Farmers

- The temperature graph should be placed at the top of the screen, as farmers check the temperature most often.

- Two days of weather information should be presented on a graph.

- If necessary, data for one week should be presented on a graph.

- The maximum and minimum temperatures of the previous day, today’s minimum temperature, and current temperature should be presented in numbers.

- An alert notification interval should be provided.

- The text should be large enough to be read easily on a smartphone.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Agriculture, Forestry and Fisheries (Japanese). Smart Agriculture. Available online: https://www.maff.go.jp/e/policies/tech_res/smaagri/robot.html (accessed on 7 December 2020).

- Ministry of Agriculture, Forestry and Fisheries (Japanese). Deployment of Smart Agriculture. Available online: https://www.affrc.maff.go.jp/docs/smart_agri_pro/attach/pdf/smart_agri_pro-11.pdf (accessed on 7 December 2020).

- Mekala, M.S.; Viswanathan, P. A Survey: Smart Agriculture IoT with Cloud Computing. In Proceedings of the 2017 International Conference on Microelectronic Devices, Circuits and Systems (ICMDCS), Vellore, India, 10–12 August 2017; pp. 1–7. [Google Scholar]

- Totin, E.; Segnon, A.C.; Schut, M.; Affognon, H.; Zougmoré, R.B.; Rosenstock, T.; Thornton, P.K. Institutional perspectives of climate-smart agriculture: A systematic literature review. Sustainability 2018, 10, 1990. [Google Scholar] [CrossRef]

- AMeDAS. Available online: https://www.jma.go.jp/jp/amedas/ (accessed on 7 December 2020).

- The Agro-Meteorological Grid Square Data, NARO. Available online: https://amu.rd.naro.go.jp/ (accessed on 7 December 2020).

- Vaisala. wxt520. 2013. Available online: https://www.vaisala.com/sites/default/files/documents/M210906JA-C.pdf (accessed on 7 December 2020).

- Fukatsu, T.; Hirafuji, M. Development of field server for a field monitoring system. Agric. Inf. Res. 2003, 12, 1–12. [Google Scholar]

- Nakayama, S.; Ohno, M.; Hori, H.; Tanaka, M.; Toda, N.; Hirafuji, M. Research on the requirements for field server, and study of a design and manufacturing method to mass-produce field server. Jpn. Soc. Agric. Inform. 2014, 23, 29–37. [Google Scholar]

- Sekiguchi, O.; Sasaki, J. Remote monitoring system with web cameras for the growth of paddy rice—Outline of system development. Tohoku Agric. Res. 2004, 57, 57–58. [Google Scholar]

- Soft Bank Corp. Available online: https://www.e-kakashi.com/ (accessed on 7 December 2020).

- Dombrowski, O.; Hendricks Franssen, H.-J.; Brogi, C.; Bogena, H.R. Performance of the ATMOS41 All-in-One Weather Station for Weather Monitoring. Sensors 2021, 21, 741. [Google Scholar] [CrossRef]

- Gaurav, J.; Kunal, J.; Kavita, N. Environment monitoring & detecting system using raspberry-pi. Int. Res. J. Eng. Technol. 2016, 3, 1168–1172. [Google Scholar]

- Vujović, V.; Maksimović, M.; Perišić, B.; Milošević, G. A Proposition of Low-Cost Sensor Web Implementation Based on GSM/GPRS Services. In Proceedings of the 2015 IEEE 1st International Workshop on Consumer Electronics (CE WS), Novi Sad, Serbia, 11 March 2015; pp. 52–55. [Google Scholar] [CrossRef]

- Navulur, S.; Sastry, A.S.C.S.; Giri Prasad, M.N. Agricultural management through wireless sensors and internet of things. Int. J. Electr. Comput. Eng. 2017, 7, 3492–3499. [Google Scholar] [CrossRef]

- Caria, M.; Schudrowitz, J.; Jukan, A.; Kemper, N. Smart Farm Computing Systems for Animal Welfare Monitoring. In Proceedings of the 2017 40th International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 22–26 May 2017; pp. 152–157. [Google Scholar] [CrossRef]

- Kamath, R.; Balachandra, M.; Prabhu, S. Raspberry Pi as Visual Sensor Nodes in Precision Agriculture: A Study; IEEE: New York, NY, USA, 2019; Volume 7, pp. 45110–45122. [Google Scholar] [CrossRef]

- Valecce, G.; Strazzella, S.; Radesca, A.; Grieco, L.A. Solarfertigation: Internet of Things Architecture for Smart Agriculture. In Proceedings of the 2019 IEEE International Conference on Communications Workshops (ICC Workshops), Shanghai, China, 20–24 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Kadam, A.A.; Rajashekarappa, D. Internet of things in agriculture. Int. J. Adv. Stud. Sci. Res. 2018, 3. [Google Scholar]

- Mekala, S.; Sarala, S.; Divya, S. Microcontroller based smart irrigation system and weather forecasting using anemometer. Int. J. Pure Appl. Math. 2018, 118, 2931–2936. [Google Scholar]

- Khattab, A.; Habib, S.E.; Ismail, H.; Zayan, S.; Fahmy, Y.; Khairy, M.M. An IoT-based cognitive monitoring system for early plant disease forecast. Comput. Electron. Agric. 2019, 166, 105028. [Google Scholar] [CrossRef]

- Sagheer, A.; Mohammed, M.; Riad, K.; Alhajhoj, M. A cloud-based IoT platform for precision control of soilless greenhouse cultivation. Sensors 2021, 21, 223. [Google Scholar] [CrossRef] [PubMed]

- Shanthini, S.; Deekshath, R.; Dinakaran, G.D.; Dharanya, P.; Kabadia, K.R.D. IoT based environmental monitoring system using arduino UNO and thing speak. Int. J. Sci. Technol. Eng. 2018, 4, 68–75. [Google Scholar]

- Pauzi, A.P.; Hasan, M.Z. Development of IoT Based Weather Reporting System, International Conference on Technology, Engineering and Sciences (ICTES); IOP Publishing: Bristol, UK, 2020; Volume 917. [Google Scholar] [CrossRef]

- Rodríguez-Robles, J.; Martin, Á.; Martin, S.; Ruipérez-Valiente, J.A.; Castro, M. Autonomous sensor network for rural agriculture environments, low cost, and energy self-charge. Sustainability 2020, 12, 5913. [Google Scholar] [CrossRef]

- Sadowski, S.; Spachos, P. Solar-Powered Smart Agricultural Monitoring System Using Internet of Things Devices. In Proceedings of the 2018 IEEE 9th Annual Information Technology, Electronics and Mobile Communication Conference (IEMCON), Vancouver, BC, Canada, 1–3 November 2018; pp. 18–23. [Google Scholar] [CrossRef]

- Georgieva, T.; Paskova, N.; Gaazi, B.; Todorov, G.; Daskalov, P. Design of wireless sensor network for monitoring of soil quality parameters. Agric. Agric. Sci. Proc. 2016, 10, 431–437. [Google Scholar] [CrossRef][Green Version]

- Valente, A.; Silva, S.; Duarte, D.; Cabral Pinto, F.; Soares, S. Low-cost LoRaWAN node for agro-intelligence IoT. Electronics 2020, 9, 987. [Google Scholar] [CrossRef]

- Prakosa, S.W.; Faisal, M.; Adhitya, Y.; Leu, J.-S.; Köppen, M.; Avian, C. Design and implementation of LoRa Based IoT scheme for Indonesian rural area. Electronics 2021, 10, 77. [Google Scholar] [CrossRef]

- Khoa, T.A.; Man, M.M.; Nguyen, T.-Y.; Nguyen, V.; Nam, N.H. Smart agriculture using IoT multi-sensors: A novel watering management system. J. Sens. Actuator Netw. 2019, 8, 45. [Google Scholar] [CrossRef]

- Lalbihari, B. IoT based temperature and humidity controlling using Arduino and raspberry Pi. Int. J. Adv. Comput. Sci. Appl. 2019, 10, 494–502. [Google Scholar]

- Muck, P.Y.; Homam, M.J. Iot based weather station using raspberry Pi 3. Int. J. Eng. Technol. 2018, 7, 145–148. [Google Scholar] [CrossRef]

- Jindarat, S.; Wuttidittachotti, P. Smart Farm Monitoring Using Raspberry Pi and Arduino. In Proceedings of the 2015 International Conference on Computer, Communications, and Control Technology (I4CT), Kuching, Malaysia, 21–23 April 2015; pp. 284–288. [Google Scholar] [CrossRef]

- Jorda, R.; Alcabasa, C.; Buhay, A.; Cruz, E.D.; Mendoza, J.P.; Tolentino, A.; Tolentino, L.K.; Fernandez, E.; Thio-ac, A.; Velasco, J.; et al. Automated smart wick system-based microfarm using internet of things, computer science, engineering. arXiv 2019, arXiv:1911.01279. [Google Scholar]

- Adoghe, A.U.; Popoola, S.I.; Chukwuedo, O.M.; Airoboman, A.E.; Atayero, A.A. Smart Weather Station for Rural Agriculture using Meteorological Sensors and Solar Energy. In Proceedings of the World Congress on Engineering 2017, London, UK, 5–7 July 2017; Volume 1. [Google Scholar]

- Heble, S.; Kumar, A.; Prasad, K.V.V.D.; Samirana, S.; Rajalakshmi, P.; Desai, U.B. A Low Power IoT Network for Smart Agriculture. In Proceedings of the 2018 IEEE 4th World Forum on Internet of Things (WF-IoT), Singapore, 5–8 February 2018; pp. 609–614. [Google Scholar] [CrossRef]

- Sahay, M.R.; Sukumaran, M.K.; Amarnath, S.; Palani, T.N.D. Environmental monitoring system using iot and cloud service at real-time. Eng. Technol. Appl. Sci. Res. 2019, 8. Available online: https://easychair.org/publications/preprint/5Lg1 (accessed on 7 December 2020).

- Pitu, F.; Gaitan, N.C. Surveillance of SigFox Technology Integrated with Environmental Monitoring. In Proceedings of the 2020 International Conference on Development and Application Systems (DAS), Suceava, Romania, 21–23 May 2020; pp. 69–72. [Google Scholar] [CrossRef]

- Kuo, P.-F.; Huang, T.-E.; Putra, I.G.B. Comparing kriging estimators using weather station data and local greenhouse sensors. Sensors 2021, 21, 1853. [Google Scholar] [CrossRef] [PubMed]

- Janssen, T.; BniLam, N.; Aernouts, M.; Berkvens, R.; Weyn, M. LoRa 2.4 GHz Communication link and range. Sensors 2020, 20, 4366. [Google Scholar] [CrossRef] [PubMed]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.-H. Engineering Design—A Systematic Approach, 3rd ed.; Wallace, K., Blessing, L., Eds.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Tomiyama, T.; Gul, P.; Jin, Y.; Lutters, D.; Kind, C.; Kimura, F. Design methodologies: Industrial and educational applications. CIRP Ann. Manuf. Technol. 2009, 58, 543–565. [Google Scholar] [CrossRef]

- Engineering Design Process. Available online: https://www.teachengineering.org/populartopics/designprocess (accessed on 25 February 2022).

- Emeis, S. Aßmann’s development of aspiration psychrometers. Meteorol. Z. 2012, 21, 431–435. [Google Scholar] [CrossRef]

- Wind/Rain Sensor Assembly. Available online: https://www.argentdata.com/catalog/product_info.php?products_id=145 (accessed on 7 December 2020).

- Wio LTE JP Version. Available online: https://soracom.jp/products/module/wio_lte/ (accessed on 7 December 2020).

- SolarAmp B. Available online: https://www.denryo.com/solar_controller/controller/sa_b.html/ (accessed on 20 March 2021).

- Lipo Rider Pro. Available online: https://wiki.seeedstudio.com/Lipo_Rider_Pro/ (accessed on 20 March 2021).

- Azure. Available online: https://azure.microsoft.com/ja-jp/ (accessed on 7 December 2020).

- AWS. Available online: https://aws.amazon.com/jp/ (accessed on 7 December 2020).

- Nginx. Available online: https://www.nginx.com/ (accessed on 7 December 2020).

- Apache Tomcat®—Welcome! Available online: http://tomcat.apache.org/ (accessed on 7 December 2020).

- Burke, B. O’Reilly Media, Inc., RESTful Java with JAX-RS 2.0. Newton, USA. Available online: https://www.oreilly.com/library/view/restful-java-with/9781449361433/ (accessed on 7 December 2020).

- MySQL. Available online: https://www.mysql.com/jp/ (accessed on 7 December 2020).

- Messaging API, LINE. Available online: https://developers.line.biz/ja/ (accessed on 7 December 2020).

| Types of Microcomputer | Overview | Communication | Ref | Measurement Period | Sensors |

|---|---|---|---|---|---|

| Raspberry Pi | The Raspberry Pi plays the role of sensor measurement and gateway; the Raspberry Pi transmits the measured data to the server using 3G/4G, WiFi, Zigbee, LoRa, etc. | 3G/4G | [13] | x | Gas, IR, moisture |

| [14] | x | Temperature, wind, liquid level | |||

| WiFi | [15] | x | Soil moisture, humidity, acoustic, etc. | ||

| [16] | x | Temperature, accelerometer, etc. | |||

| [17] | x | Camera | |||

| Zigbee | [18] | x | Soil moisture | ||

| LoRa | [19] | x | Temperature, humidity, etc. | ||

| Arduino | The Arduino plays the role of sensor measurement and gateway. The Arduino transmits the measured data to the server using 3G/4G, WiFi, Zigbee, LoRa, etc. | 3G/4G | [20] | x | Soil moisture, temperature, humidity |

| [21] | 7 days | Temperature, soil temperature, rain, etc. | |||

| WiFi | [22] | 3 months | Temperature, humidity, pH, soil moisture, etc. | ||

| [23] | x | Temperature, humidity, soil moisture, etc. | |||

| [24] | Less than a day | Temperature, rain, etc. | |||

| Zigbee | [25] | x | Temperature, soil moisture, rain | ||

| [26] | 2 days | Temperature, humidity, soil moisture | |||

| [27] | x | Temperature, humidity, pH | |||

| LoRa | [28] | 7 days | Temperature, soil moisture, etc. | ||

| [27] | x | Temperature, humidity, soil moisture, etc. | |||

| [30] | 1 day | Temperature, humidity, soil moisture, etc. | |||

| Raspberry Pi + Arduino | The Arduino plays the role of sensor measurement and the Raspberry Pi plays the role of gateway. The data measured by the Arduino are transferred to the cloud server via the Raspberry Pi. | 3G/4G | [31] | Less than a day | Temperature, humidity, soil moisture, etc. |

| WiFi | [32] | Less than a day | Temperature, humidity, etc. | ||

| Zigbee | [33] | x | Temperature, soil moisture | ||

| Wire | [34] | Less than a day | Temperature, soil moisture, etc. | ||

| Various micro-computers | Various microcomputers act as measurement sensors and gateways. The microcontrollers will transmit the measured data to the server via 3G/4G, WiFi, SigFox, etc. | 3G/4G | [35] | x | Temperature, anemometer, etc. |

| [36] | x | Soil moisture | |||

| WiFi | [37] | Less than a day | Temperature, humidity | ||

| SigFox | [38] | x | Temperature, humidity, etc. | ||

| Bluetooth | [39] | 1 day | Temperature, humidity, etc. |

| Operating Time * | Temperature [°C] | ||||

|---|---|---|---|---|---|

| Start | Stop | Continuous Operation | Maximum | Minimum | |

| Mikawa (Indoor) | 3 August 2019 | Currently in operation | 19 months | +44.9 | −2.0 |

| Mikawa (Indoor) | 11 September 2019 | Currently in operation | 18 months | +44.8 | −2.4 |

| Mikawa (outdoor) | 2 August 2019 | 26/05/2020 | 9 months | +43.6 | −2.6 |

| Higashine (Indoor) | 27 May 2020 | Currently in operation | 10 months | +38.6 | −10.9 |

| Higashine (Indoor) | 7 December 2019 | Currently in operation | 15 months | +38.0 | −5.4 |

| Operating Time * | Temperature [℃] | ||||

|---|---|---|---|---|---|

| Start | Stop | Continuous Operation | Maximum | Minimum | |

| Tsuruoka (outdoor) | 14 April 2020 | 18 October 2020 | 6 months | +41.3 | −1.9 |

| Tendo (outdoor) | 6 October 2020 | 5 January 2021 | 3 months | +39.8 | +1.1 |

| Nanyo (Outdoor) | 12 November 2020 | currently in operation | 4 months | +27.5 | −16.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Minagawa, D.; Saito, D.; Hoshina, S.; Kanda, K. Development of KOSEN Weather Station and Provision of Weather Information to Farmers. Sensors 2022, 22, 2108. https://doi.org/10.3390/s22062108

Kim J, Minagawa D, Saito D, Hoshina S, Kanda K. Development of KOSEN Weather Station and Provision of Weather Information to Farmers. Sensors. 2022; 22(6):2108. https://doi.org/10.3390/s22062108

Chicago/Turabian StyleKim, Jeyeon, Daichi Minagawa, Daiki Saito, Shinichiro Hoshina, and Kazuya Kanda. 2022. "Development of KOSEN Weather Station and Provision of Weather Information to Farmers" Sensors 22, no. 6: 2108. https://doi.org/10.3390/s22062108

APA StyleKim, J., Minagawa, D., Saito, D., Hoshina, S., & Kanda, K. (2022). Development of KOSEN Weather Station and Provision of Weather Information to Farmers. Sensors, 22(6), 2108. https://doi.org/10.3390/s22062108