Energy-Efficient Monitoring of Fine Particulate Matter with Tiny Aerosol Conditioner

Abstract

:1. Introduction

1.1. Problems with Conventional Devices

- Dryer placed after separator: Because the dryer is located behind the particle separator, particle size can increase due to their hygroscopic growth and, in turn, might be removed from the separator [18]. This is why the traditional system underestimates PM concentrations under high-humidity conditions.

- High energy consumption: A large volume of air is required to aggregate enough PM in the filter. For example, BAM 1020 of Met One Instruments Inc. (Grants Pass, OR, USA) requires a nominal flow rate of 16.7 L/min. A pump model, BX-121, used in BAM 1020, requires 520 W [1]. A heater model, BX-830, used in BAM 1020, consumes 175 W to dehumidify aerosols [1]. Additional power is required to maintain the proper temperature of the shelter enclosing the monitor. A shelter heater, BX-902B, and a shelter air conditioner, BX-904, consume 500 and 1172 W, respectively [1].

- Downward airflow against buoyancy: In winter, air inside the pipe has an upward buoyant force because of the temperature difference between the outside and inside of the shelter. The heat from the dryer further increases this force. The pump makes the air flow downward. The combination of the upward and downward force lowers the air pressure inside the pipe and expands the air volume. This leads to underestimation of PM concentrations by erroneously measuring the air volume.

- Inefficient separator at high temperatures: The temperature dependency of an impactor causes errors when used as a particle separator. High temperature makes its impaction plate unstable, which in turn lowers the impactor performance [19,20]. High temperature increases the re-bounce of the particles that are captured on the plate and decreases the viscosity of the oil on the plate. Additionally, the efficiency of the cyclone separator decreases at high temperatures [21,22]. Hence, during summer, the traditional system overestimates PM concentrations.

- Frequent maintenance: Many parts require frequent cleaning. Separators should be cleaned weekly or bi-weekly. The nozzle requires monthly cleaning.

- Wind-sensitive intake pipe: Wind decreases the air pressure inside the pipe. From Bernoulli’s principle, air pressure inside the pipe depends on the square of the wind velocity v and the height of the pipe h. The air pressure P is defined as:where is the air density. The change in the air pressure, , is:Low air pressure expands the air volume according to Boyle’s law. On that account, strong wind likely affects monitor performance, resulting in underestimation of PM concentrations.

1.2. Contribution

- A small dryer placed before logical separator: The proposed device includes a tiny aerosol conditioner (TAC) that dehumidifies air with low power. The device logically separates the particle size by measuring the size of the dust at the sensor without a physical separator. Both PM measurement and logical separation are performed after dehumidification. Hence, during both separation and measurement steps, hygroscopic growth is not possible.

- Low energy consumption: The proposed monitor, TAM, requires up to 2.9 W of power for dehumidification. Generating airflow requires 0.11 W. All electronic circuits including the airflow fan consume 1.8 W. TAM requires a total of 3.7 W. A traditional system consumes a total of 715 W, which consists of a 175 W heater, a 520 W pump, and a 20 W main device.

- Upward airflow following the direction of buoyant force: In contrast to conventional devices, the proposed device makes air flow upward from the bottom with low air pressure using low electric ventilation power (0.11 W). Since the direction of the airflow is the same as that of buoyant force, this results in the expansion of air volume being negligible and lowers energy requirements.

- Logical separator independent of temperature: The proposed system uses the light scattering method, so particle size separation is unaffected by temperature. This is because the diameter of each particle is electronically measured by the Mie scattering principle.

- Minimal maintenance: Periodic cleaning is not required because dust cannot accumulate on device parts with a perfectly vertical structure.

2. Design and Implementation

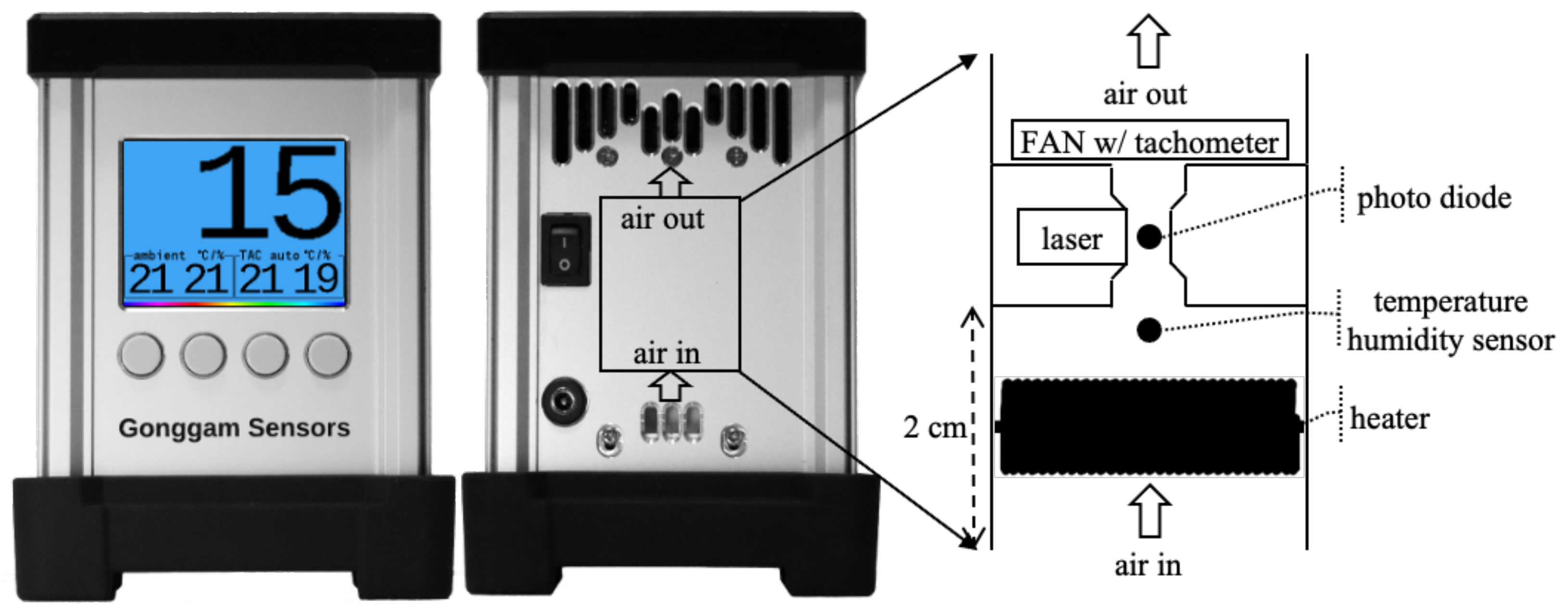

2.1. Dehumidifier with Upward Airflow: TAC

2.2. Upward Airflow and High Reliability

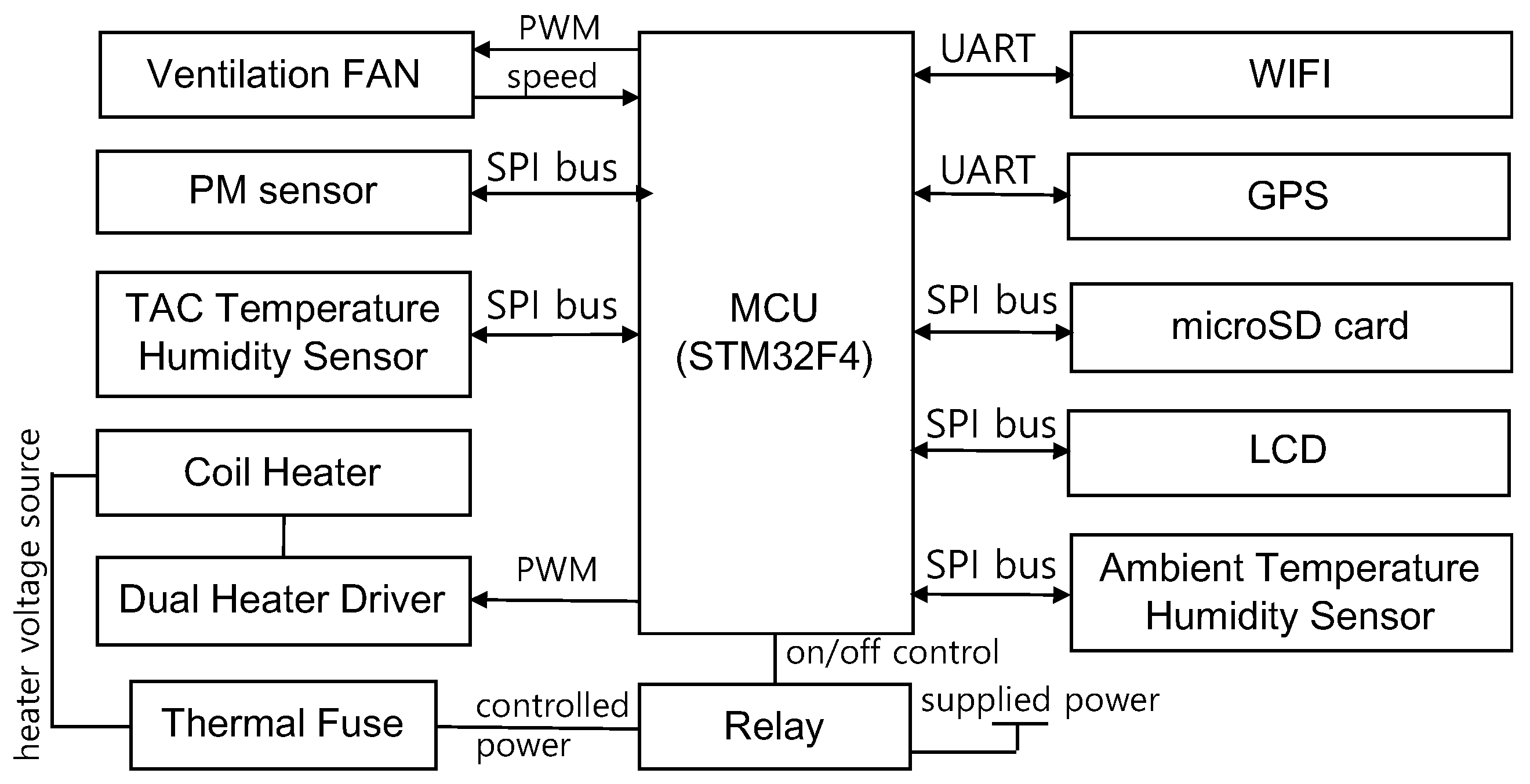

2.3. Block Diagram

3. Experimental Results

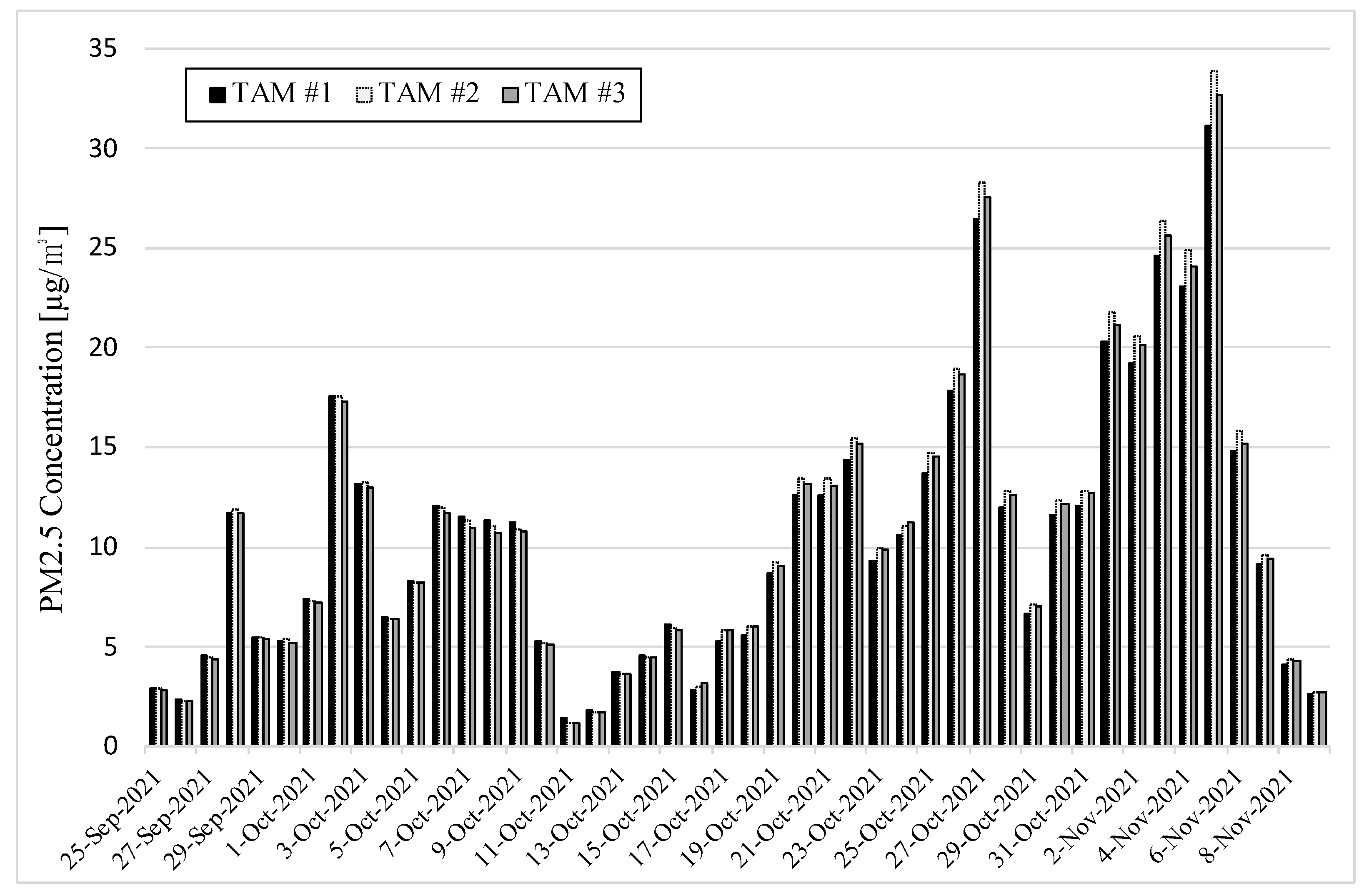

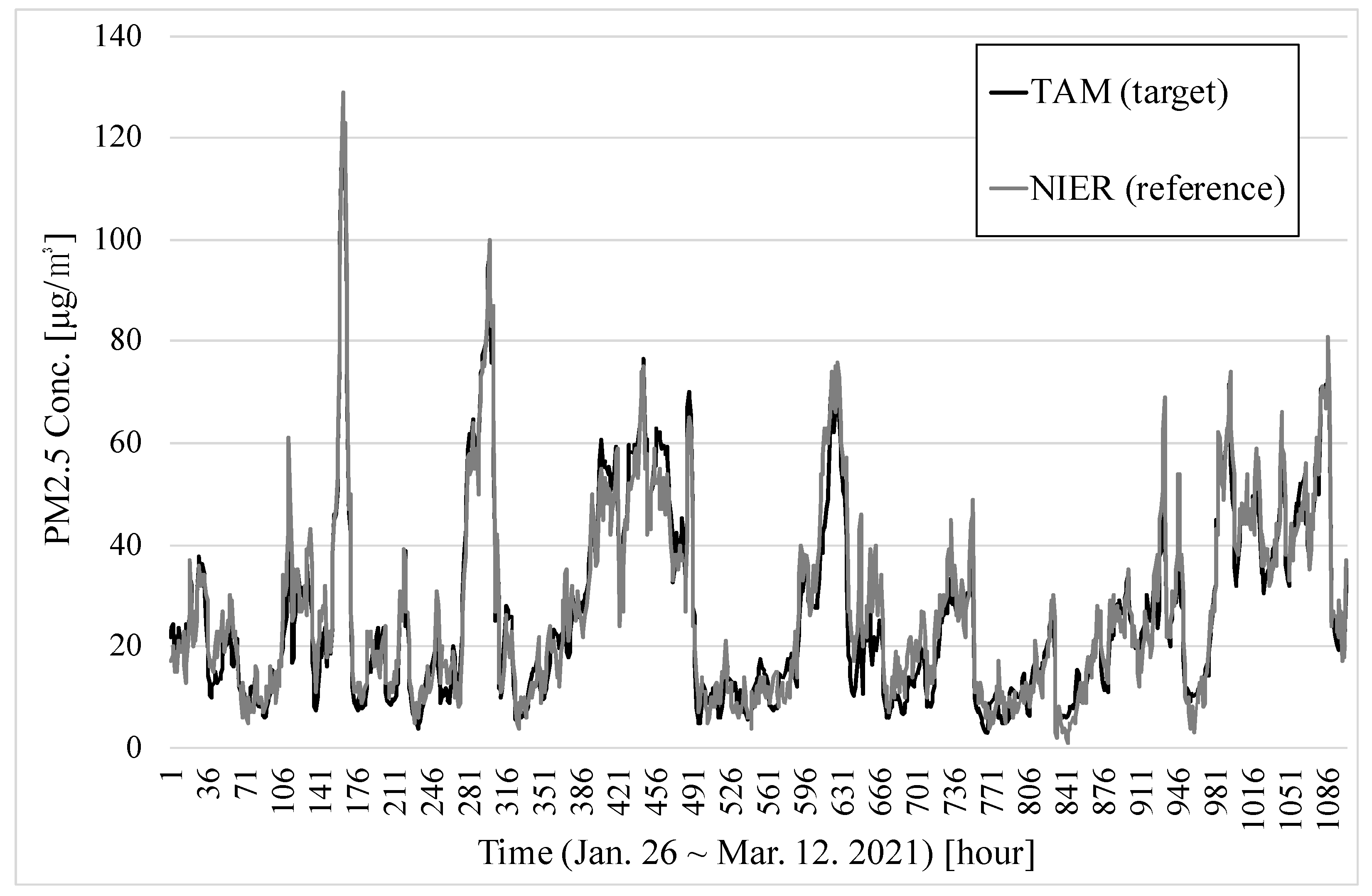

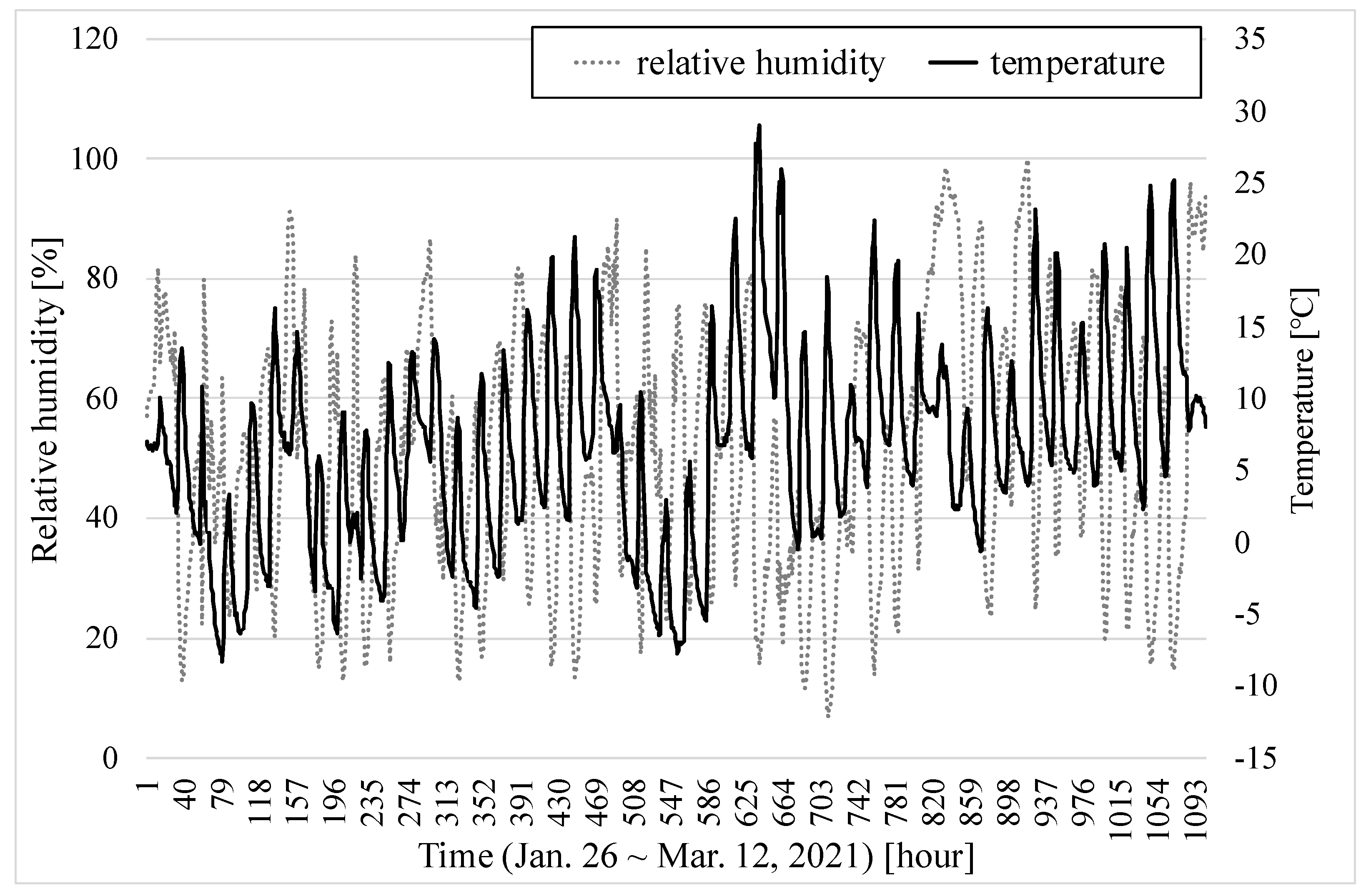

3.1. Relative Precision

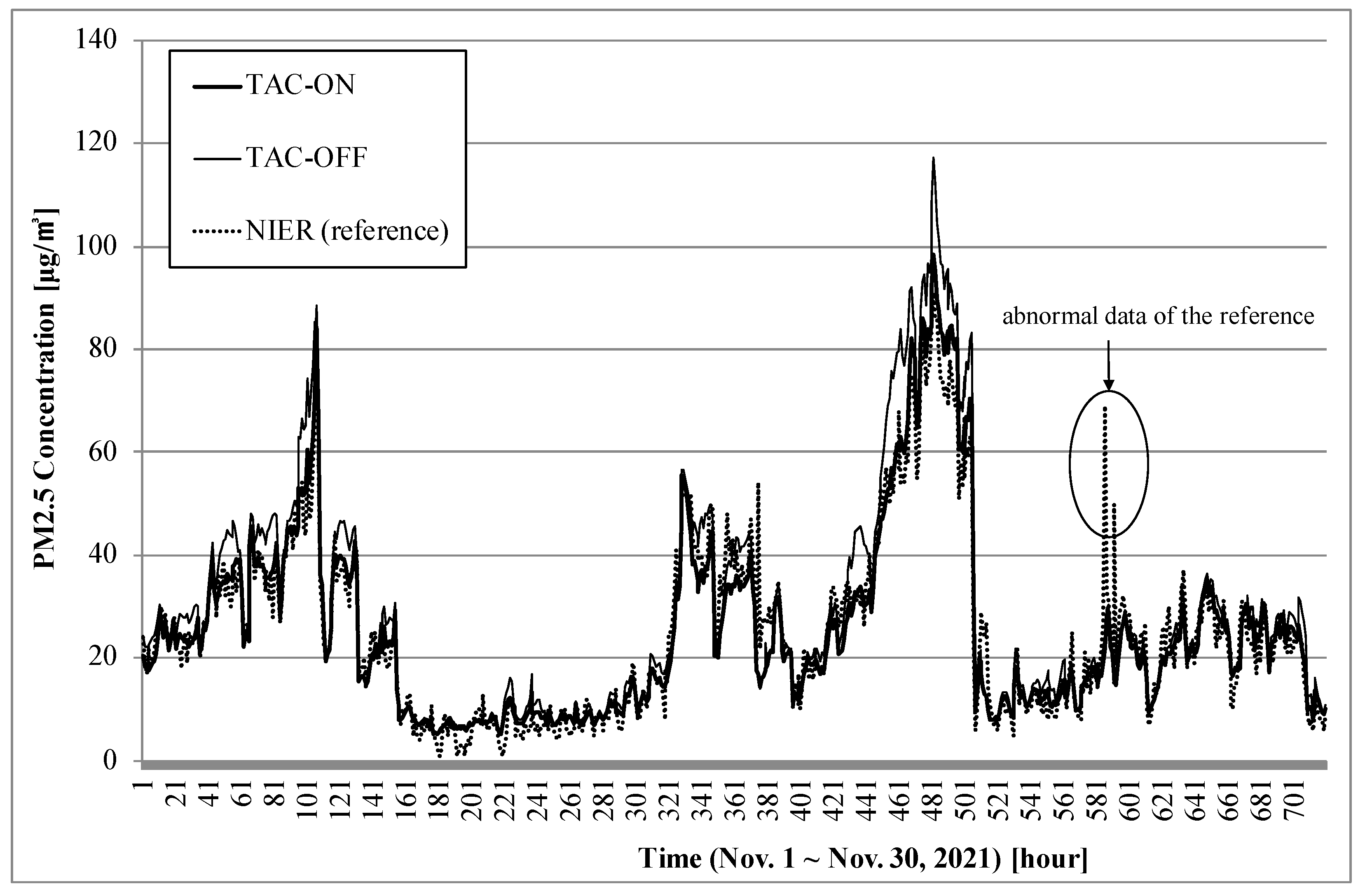

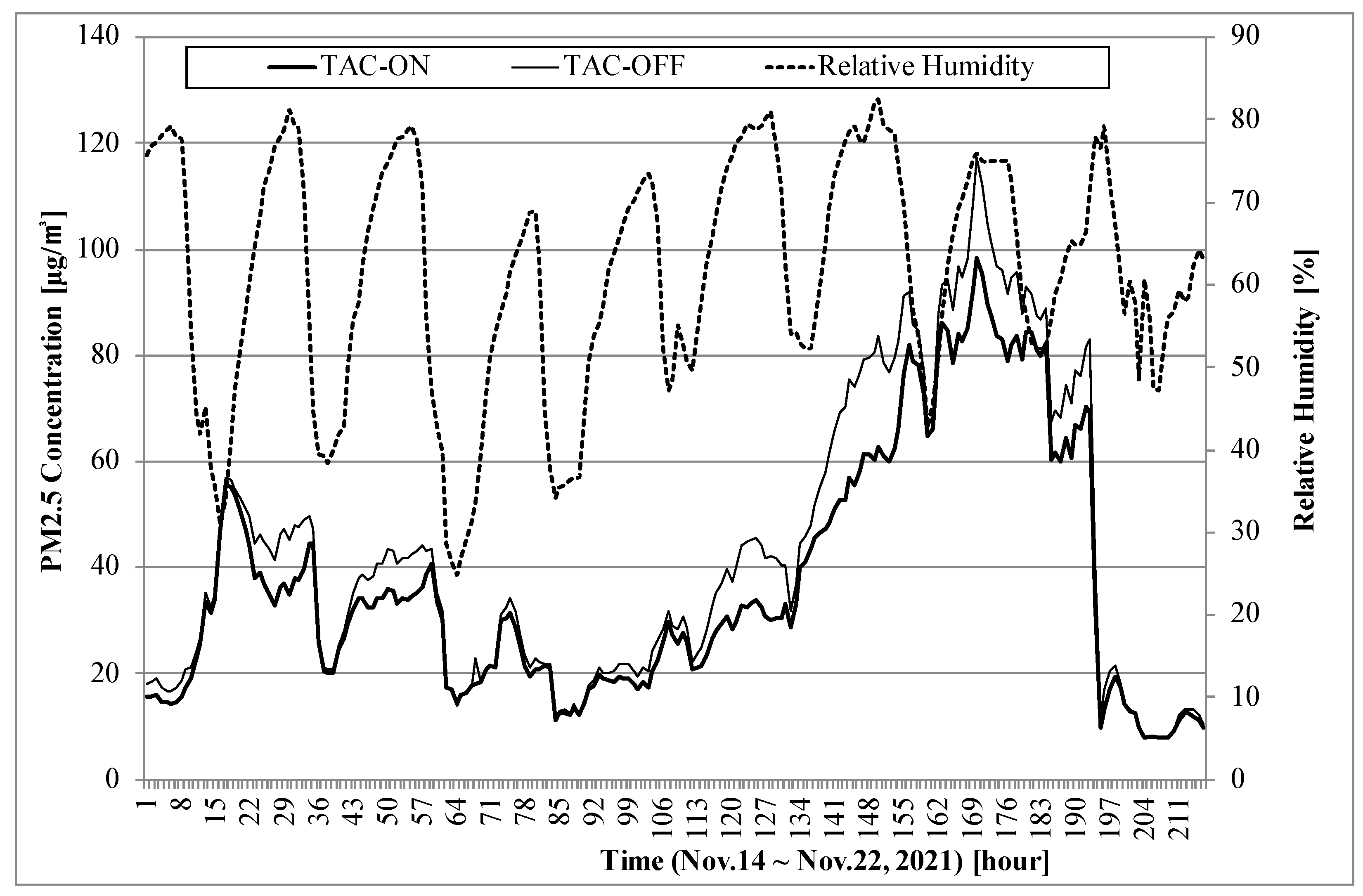

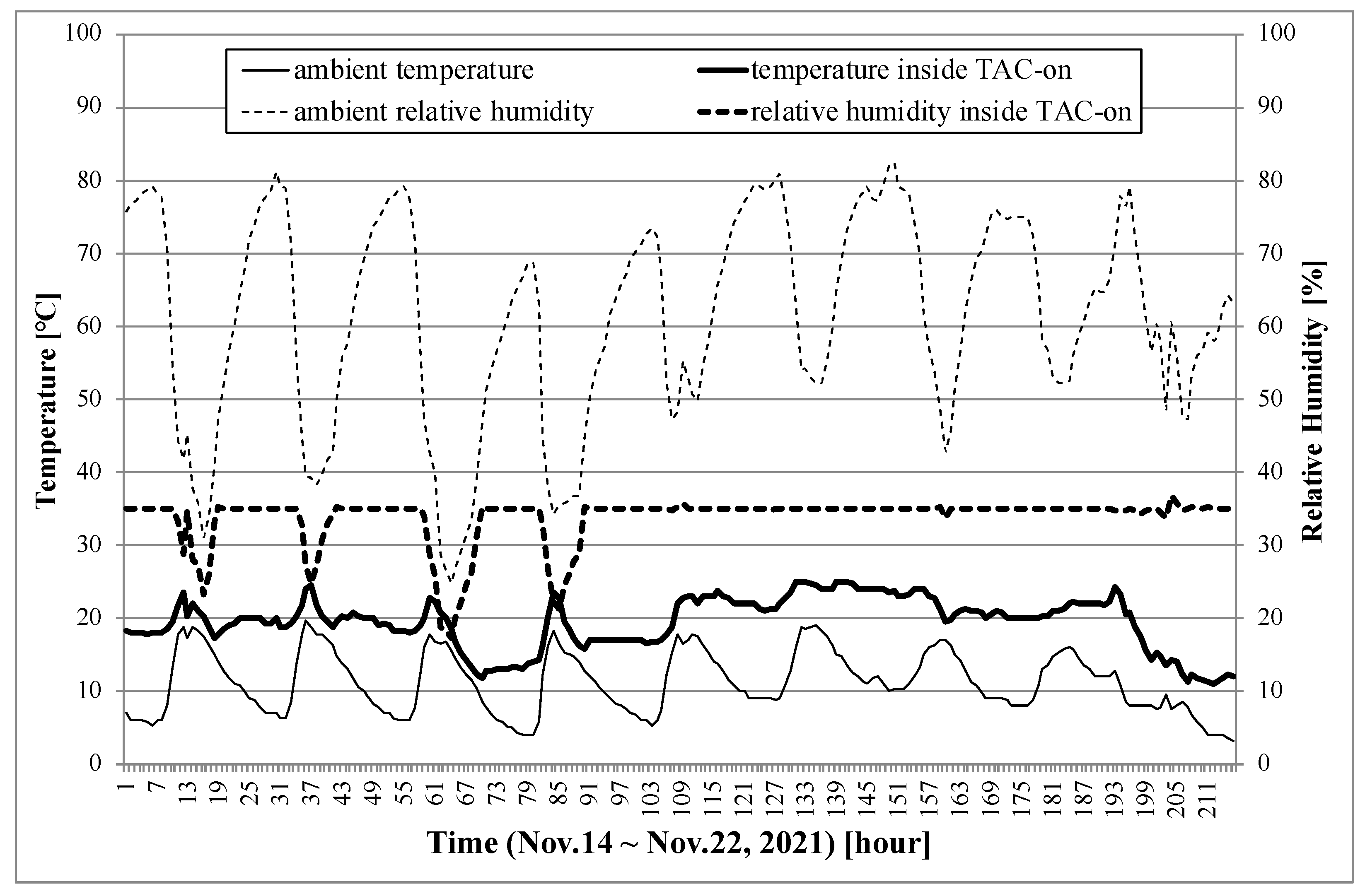

3.2. Assessment of TAC

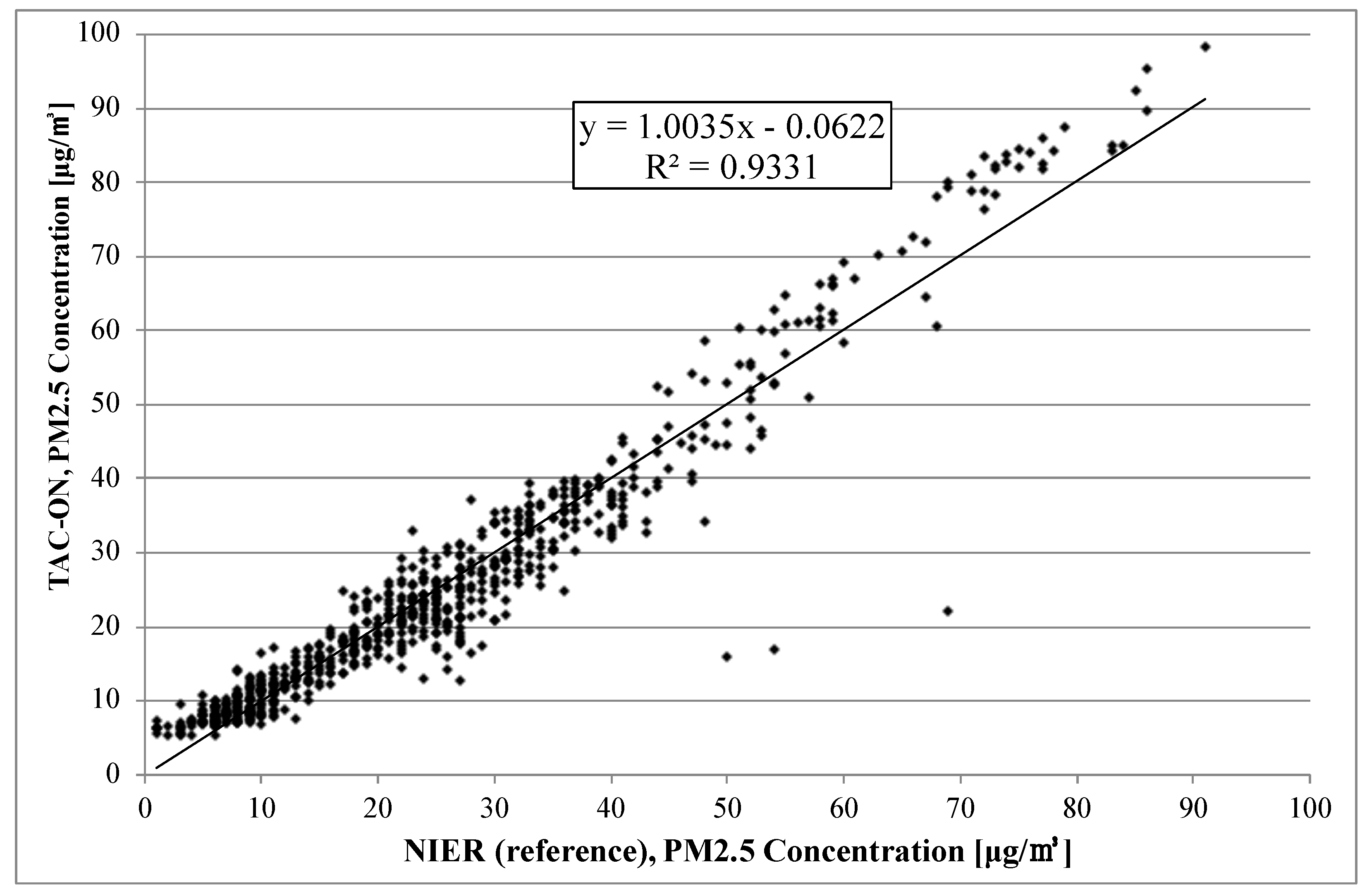

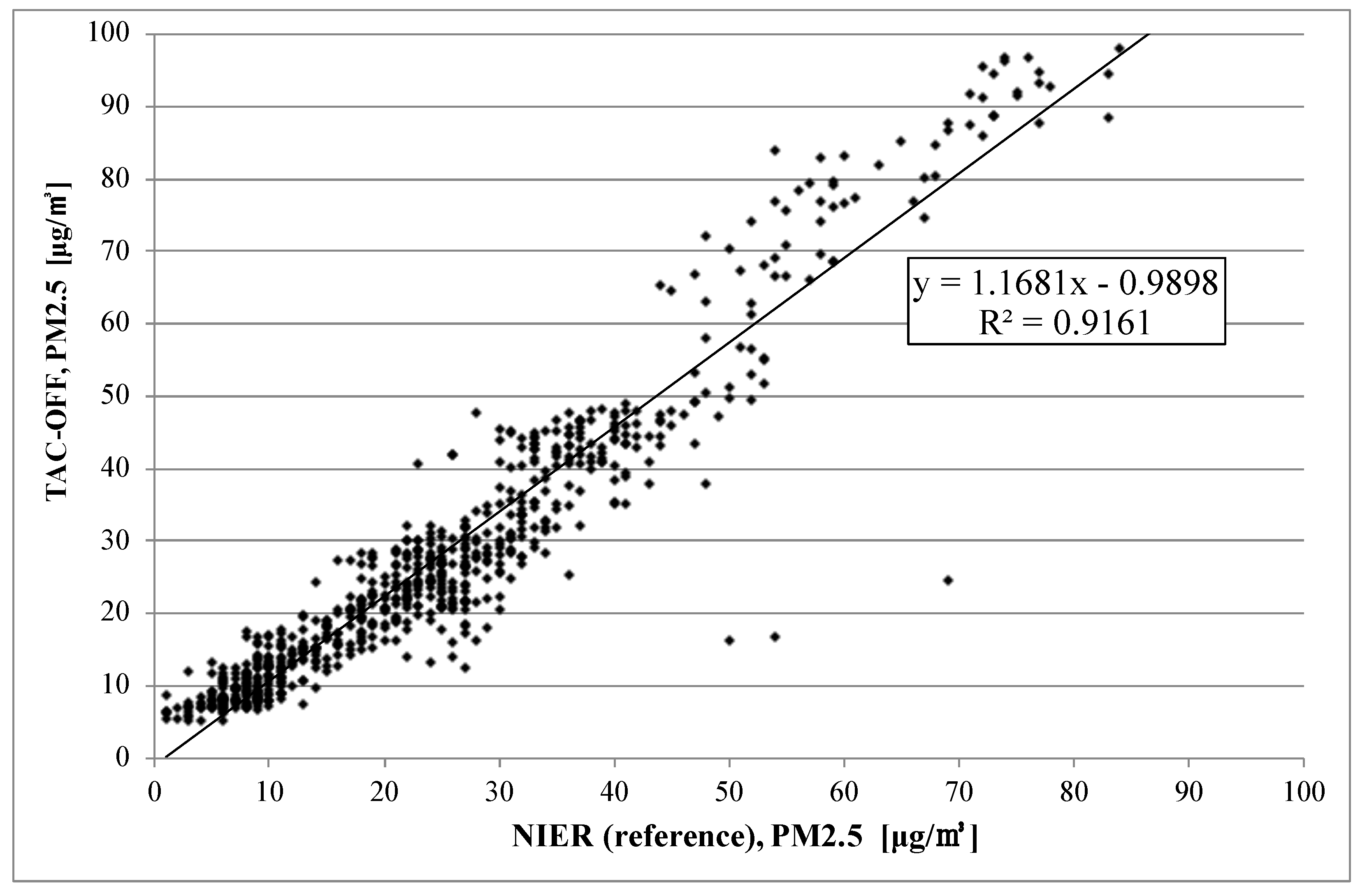

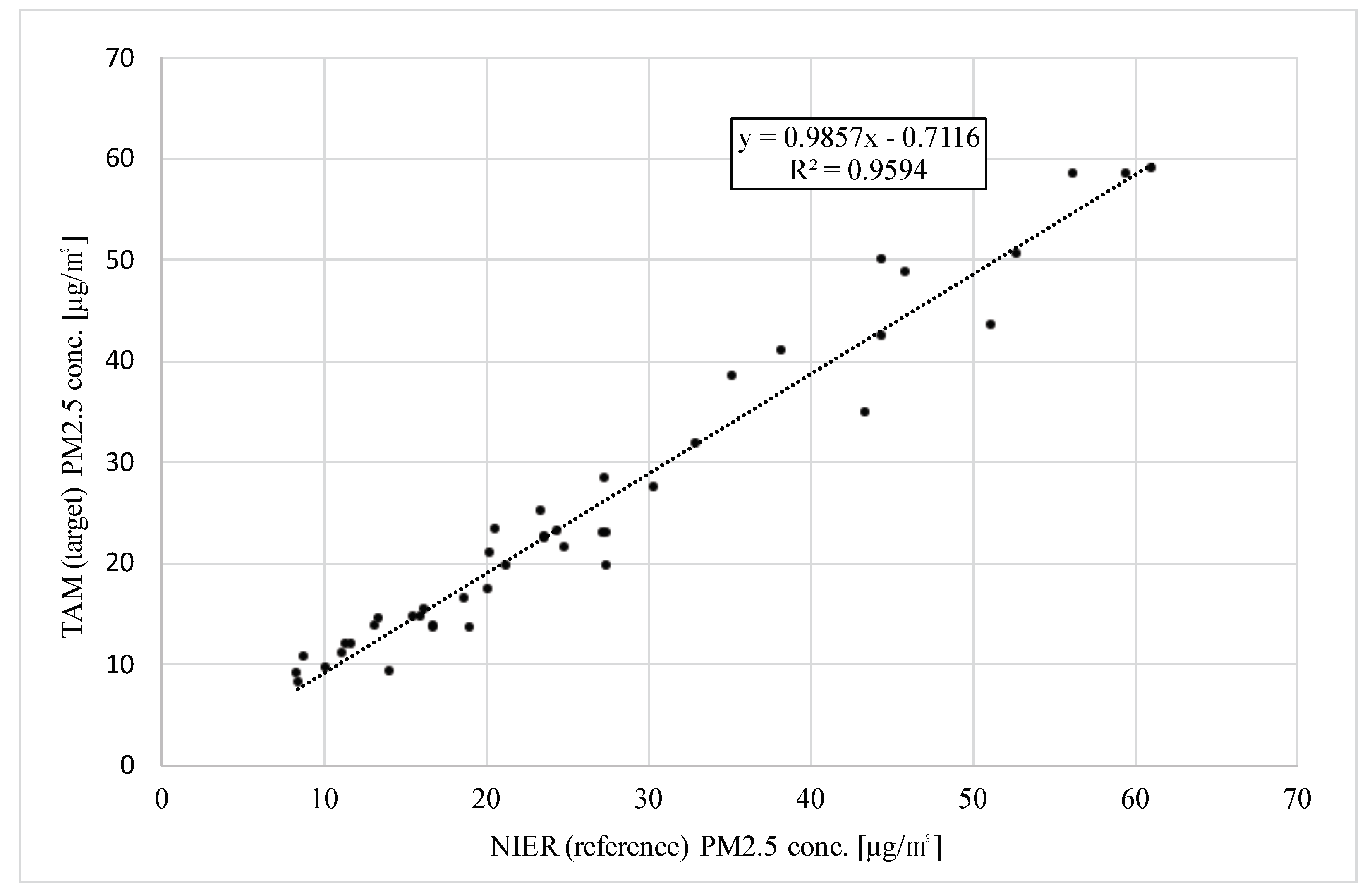

3.3. Slope, Intercept, and Correlation Coefficient

4. Conclusions

Funding

Conflicts of Interest

Abbreviations

| PM | Particulate Matter |

| BAM | Beta-Radiation Attenuation Monitor |

| TEOM | Tapered Element Oscillating Microbalance |

| OPM | Optical Particle Monitor |

| RH | Relative Humidity |

| TAC | Tiny Aerosol Conditioner |

| TAM | TAC Inside Air Monitor |

| U.S. EPA | United Sates Environmental Protection Agency |

| NIER | National Institute of Environmental Research |

References

- Met One Instruments, Inc. BAM 1020 Particulate Monitor Operation Manual; Met One Instruments, Inc.: Grants Pass, OR, USA, 2016. [Google Scholar]

- Met On Instruments, Inc. BAM 1022 Real-Time Portable, Beta Attenuation Mass Monitor; Met One Instruments, Inc.: Grants Pass, OR, USA, 2019. [Google Scholar]

- Patashnick, H.; Rupprecht, E.G. Continuous PM-10 measurements using the tapered element oscillating microbalance. J. Air Waste Manag. Assoc. 1991, 41, 1079–1083. [Google Scholar] [CrossRef]

- Wikipedia Contributors. TOEM Series 1400; Wikipedia: San Francisco, CA, USA, 2021. [Google Scholar]

- Thermo Fisher Scientific Inc. TEOM Series 1400a Ambient Particulate (PM-10) Monitor Operationg Manual; Thermo Fisher Scientific Inc.: Waltham, MA, USA, 2008. [Google Scholar]

- Pangestu, A.; Yusro, M.; Djatmiko, W.; Jaenul, A. The Monitoring System of Indoor Air Quality Based on Internet of Things. Spektra J. Fis. Dan Apl. 2020, 5, 141–152. [Google Scholar] [CrossRef]

- Reisen, F.; Cooper, J.; Powell, J.C.; Roulston, C.; Wheeler, A.J. Performance and Deployment of Low-Cost Particle Sensor Units to Monitor Biomass Burning Events and Their Application in an Educational Initiative. Sensors 2021, 21, 7206. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.; Baek, Y. Practical Particulate Matter Sensing and Accurate Calibration System Using Low-Cost Commercial Sensors. Sensors 2021, 21, 6162. [Google Scholar] [CrossRef]

- Sloane, C.S.; White, W.H. Visibility: An evolving issue. Environ. Sci. Technol. 1986, 20, 760–766. [Google Scholar] [CrossRef] [PubMed]

- Day, D.E.; Malm, W.C.; Kreidenweis, S.M. Aerosol light scattering measurements as a function of relative humidity. J. Air Waste Manag. Assoc. 2000, 50, 710–716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, I.N.; Munkelwitz, H.R. Composition and temperature dependence of the deliquescence properties of hygroscopic aerosols. Atmos. Environ. Part A Gen. Top. 1993, 27, 467–473. [Google Scholar] [CrossRef]

- Steinfeld, J.I. Atmospheric chemistry and physics: From air pollution to climate change. Environ. Sci. Policy Sustain. Dev. 1998, 40, 26. [Google Scholar] [CrossRef]

- Braniš, M. The contribution of ambient sources to particulate pollution in spaces and trains of the Prague underground transport system. Atmos. Environ. 2006, 40, 348–356. [Google Scholar] [CrossRef]

- Chang, C.; Tsai, C. A model for the relative humidity effect on the readings of the PM10 beta-gauge monitor. J. Aerosol Sci. 2003, 34, 1685–1697. [Google Scholar] [CrossRef]

- Chang, C.; Tsai, C.; Lee, C.; Chang, S.; Cheng, M.; Chein, H. Differences in PM10 concentrations measured by β-gauge monitor and hi-vol sampler. Atmos. Environ. 2001, 35, 5741–5748. [Google Scholar] [CrossRef]

- Thermo Fisher Scientific. Model 5014i Bet Instruction Manual; Thermo Fisher Scientific Inc.: Waltham, MA, USA, 2009. [Google Scholar]

- Deuerling, C.F.; Maguhn, J.; Nordsieck, H.O.; Warnecke, R.; Zimmermann, R. Measurement system for characterization of gas and particle phase of high temperature combustion aerosols. Aerosol Sci. Technol. 2010, 44, 1–9. [Google Scholar] [CrossRef]

- Biswas, P.; Jones, C.L.; Flagan, R.C. Distortion of size distributions by condensation and evaporation in aerosol instruments. Aerosol Sci. Technol. 1987, 7, 231–246. [Google Scholar] [CrossRef]

- Lee, B.U.; Kim, S.S. The effect of varying impaction plate temperature on impactor performance: Experimental studies. J. Aerosol Sci. 2002, 33, 451–457. [Google Scholar] [CrossRef]

- Vasiliou, J.G.; Sorensen, D.; McMurry, P.H. Sampling at controlled relative humidity with a cascade impactor. Atmos. Environ. 1999, 33, 1049–1056. [Google Scholar] [CrossRef]

- Gimbun, J.; Choong, T.S.; Fakhruâ, A.; Chuah, T. Prediction of the effect of dimension, particle density, temperature, and inlet velocity on cyclone collection efficiency. J. Teknol. 2004, 40, 37â–50. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Shi, M. Analysis on cyclone collection efficiencies at high temperatures. China Particuol. 2003, 1, 20–26. [Google Scholar] [CrossRef]

- Thermo Fisher Scientific Inc. Thermo Scientific Model 5030 SHARP Synchronized Hybrid Ambient, Real-Time Particulate Monitor; Thermo Fisher Scientific Inc.: Waltham, MA, USA, 2013. [Google Scholar]

- Malm, W.C.; Day, D.E.; Kreidenweis, S.M. Light scattering characteristics of aerosols as a function of relative humidity: Part I—A comparison of measured scattering and aerosol concentrations using the theoretical models. J. Air Waste Manag. Assoc. 2000, 50, 686–700. [Google Scholar] [CrossRef] [Green Version]

- McMurry, P.H.; Stolzenburg, M.R. On the sensitivity of particle size to relative humidity for Los Angeles aerosols. Atmos. Environ. (1967) 1989, 23, 497–507. [Google Scholar] [CrossRef]

- Kang, D.S.; Oh, J.E.; Lee, S.Y.; Shin, H.J.; Bong, H.K.; Choi, J.; Kim, D.S. Development of drying systems for accurate measurement of particulate matter by means of optical particle measuring instruments. Part. Aerosol Res. 2018, 14, 191–203. [Google Scholar]

- Chen, H.C. A multi-issued tag key agreement with time constraint for homeland defense sub-department in nfc environment. J. Netw. Comput. Appl. 2014, 38, 88–98. [Google Scholar] [CrossRef]

- Malcolm, N.; Zhao, W. The timed-token protocol for real-time communications. Computer 1994, 27, 35–41. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Title 40, Chapter I, Subchapter C, Part 53, Subpart C, Section 53.35 Test Procedure for Class II and Class III Methods for PM 2.5; U.S. Government Information; U.S. Environmental Protection Agency: Washington, DC, USA, 2006.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.H. Energy-Efficient Monitoring of Fine Particulate Matter with Tiny Aerosol Conditioner. Sensors 2022, 22, 1950. https://doi.org/10.3390/s22051950

Baek SH. Energy-Efficient Monitoring of Fine Particulate Matter with Tiny Aerosol Conditioner. Sensors. 2022; 22(5):1950. https://doi.org/10.3390/s22051950

Chicago/Turabian StyleBaek, Sung Hoon. 2022. "Energy-Efficient Monitoring of Fine Particulate Matter with Tiny Aerosol Conditioner" Sensors 22, no. 5: 1950. https://doi.org/10.3390/s22051950

APA StyleBaek, S. H. (2022). Energy-Efficient Monitoring of Fine Particulate Matter with Tiny Aerosol Conditioner. Sensors, 22(5), 1950. https://doi.org/10.3390/s22051950